Patents

Literature

41results about How to "Improve the combustion environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

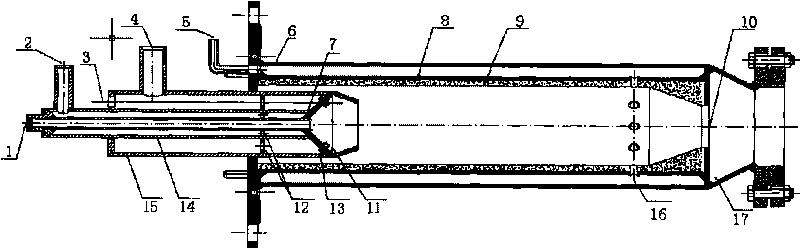

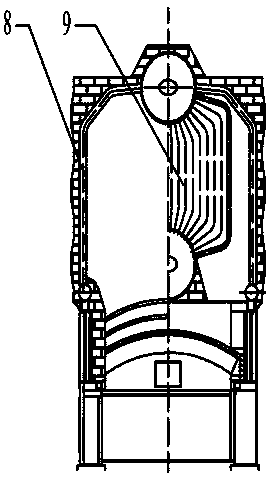

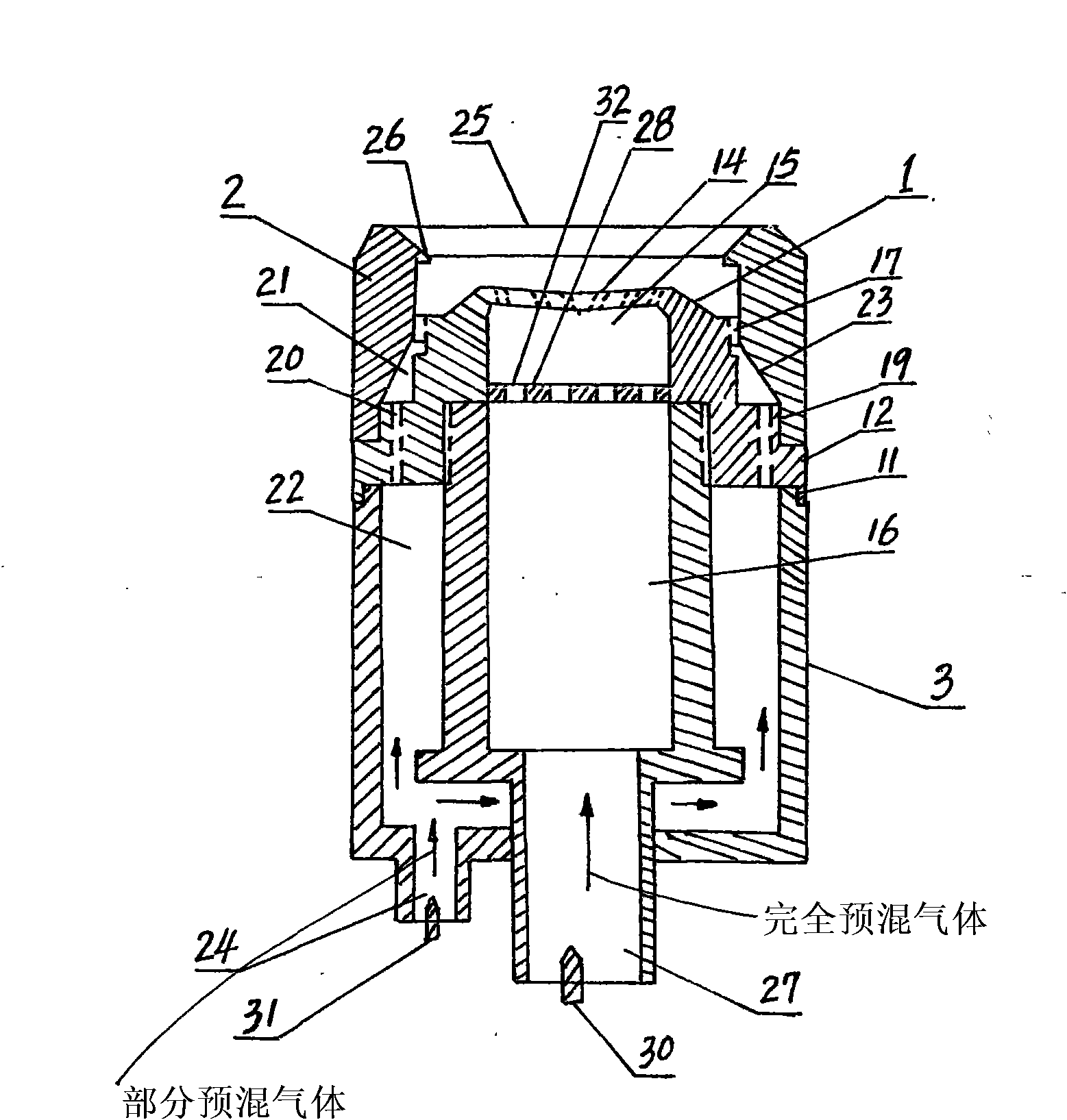

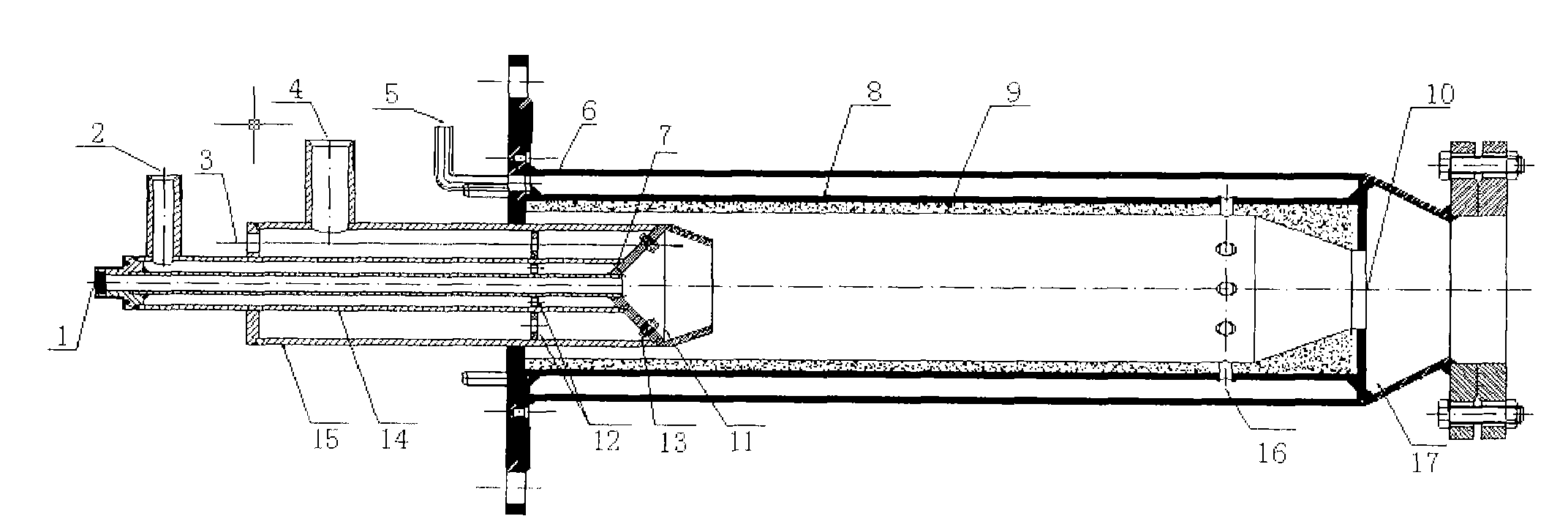

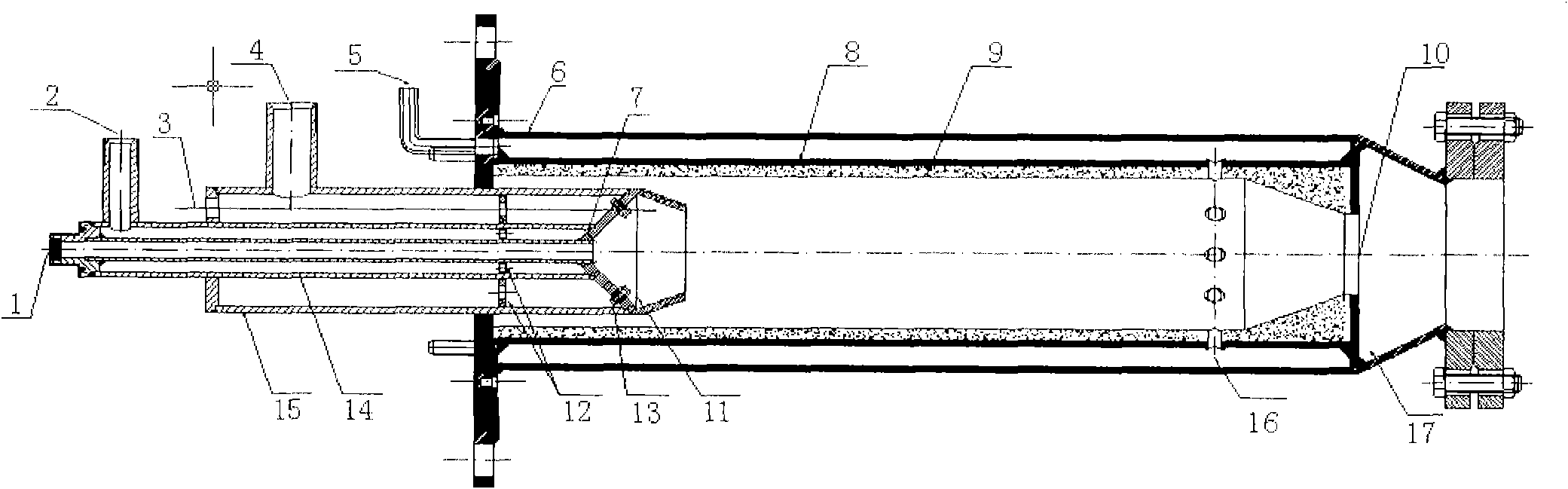

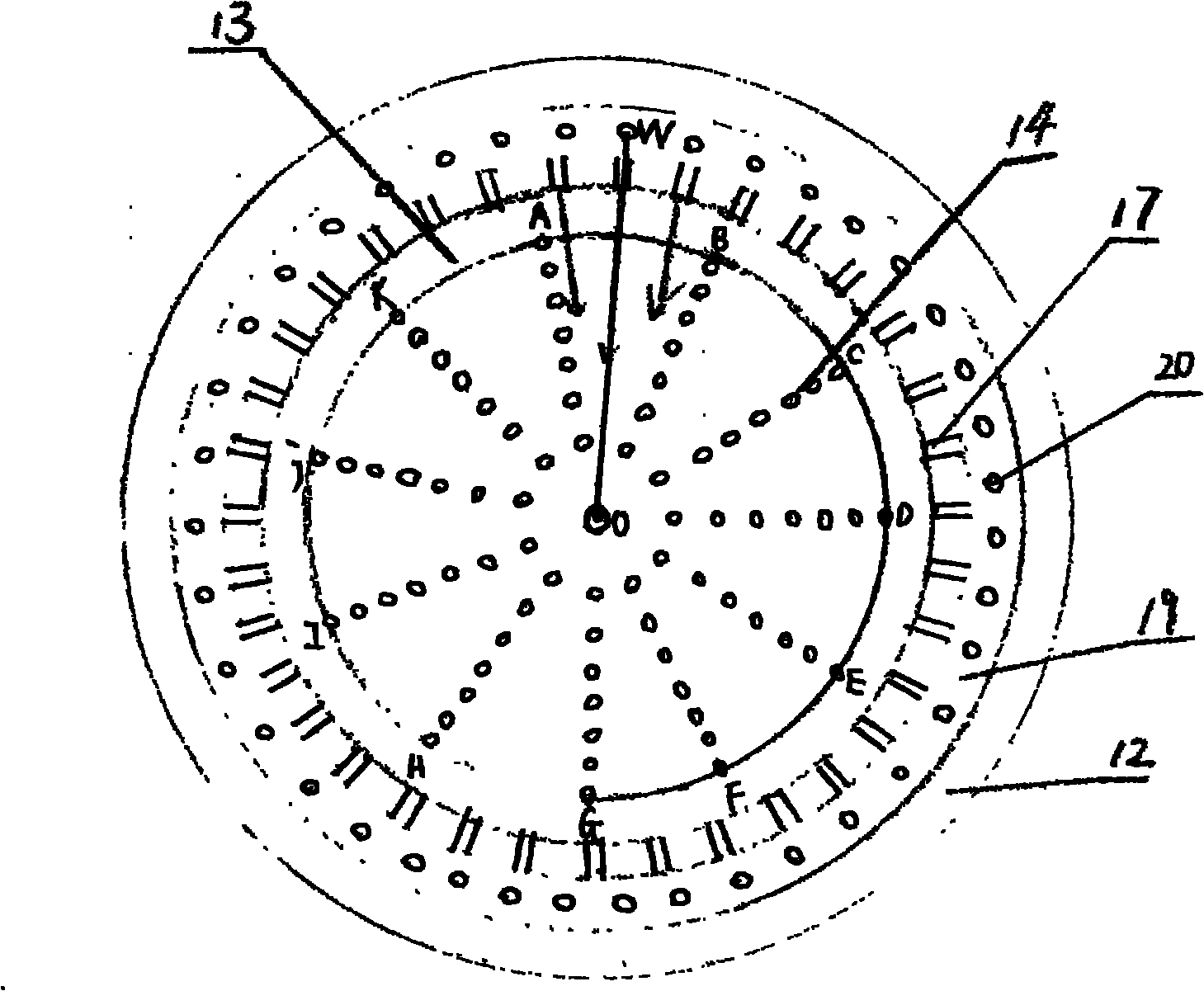

Efficient and energy-saving environment-friendly high-pressure burner

InactiveCN101706103AEnsure safetyStable high pressure combustionGaseous fuel burnerCombustion chamberCombustor

The invention relates to an efficient and energy-saving environment-friendly high-pressure burner, wherein smoke which has high temperature and high pressure as well as low pollution and is generated by the burner can be used in industries of petroleum, chemical engineering and the like. The burner comprises a combustion chamber, the front end of the combustion chamber is provided with a tapered spray nozzle which is provided with a fuel gas spray inlet and a primary air spray inlet, and a fuel air tube and a primary air distribution tube are respectively communicated with the fuel gas spray inlet and the primary air spray inlet. A combustion chamber protective casing is arranged outside the outer wall of the combustion chamber, an annular channel is formed by the surrounding of the outer wall of the combustion chamber and the combustion chamber protective casing, a secondary air inlet is communicated with the annular channel, the tail end of the outer wall of the combustion chamber is provided with a secondary air auxiliary inlet, and secondary air enters the combustion chamber through the secondary air auxiliary inlet. The burner realizes secondary air distribution to the combustion chamber by the secondary air, and secondary air distribution not only plays the role of cooling and heat preservation to the combustion chamber, but also can conduct secondary air distribution combustion supporting by being preheated to certain temperature, thus improving combustion efficiency and saving energy.

Owner:BEIJING UNIV OF TECH

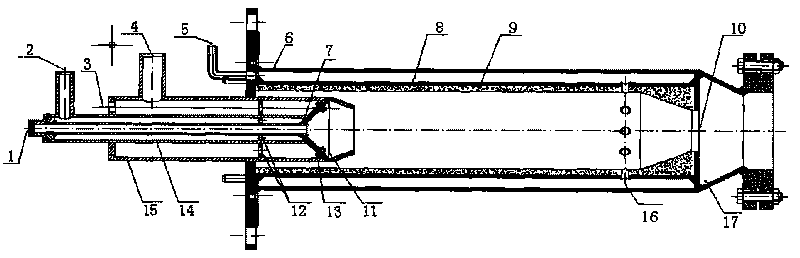

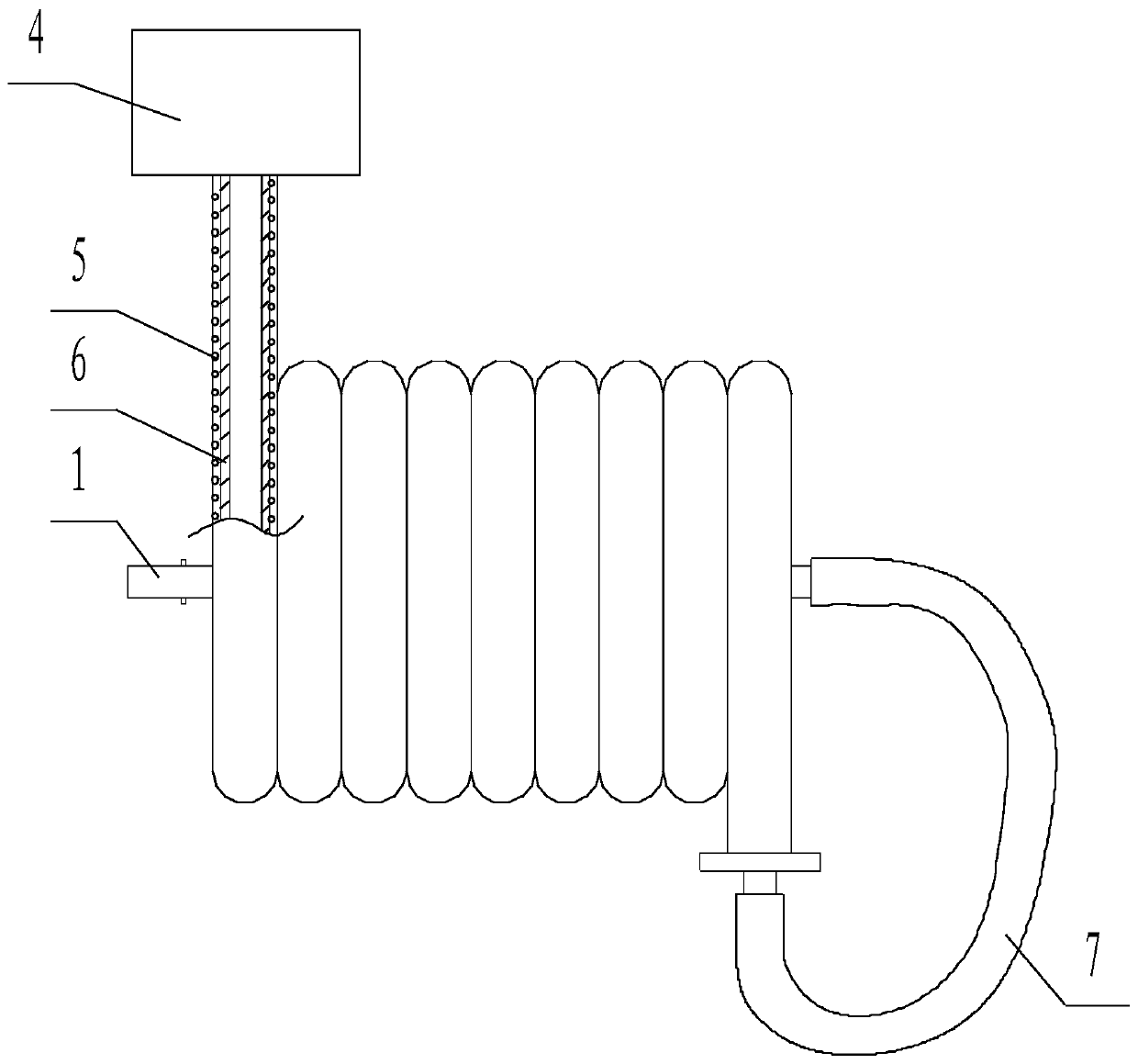

Biomass burning machine

InactiveCN103512024AImprove the combustion environmentLiquidSolid fuel combustionWater heatersCombustion chamberLiquid medium

The invention provides a biomass burning machine. Biomass is used for burning in the biomass burning machine. The biomass burning machine comprises a burning furnace, an air bellow and a feeding device connected to the burning furnace. A combustion chamber and a slag collection chamber are arranged in the burning furnace. The slag collection chamber is arranged below the combustion chamber. A space formed by the combustion chamber, the slag collection chamber and the inner wall of the burning furnace contains liquid mediums which are capable of conducting heat energy in the combustion chamber. Because the specific heat capacity of the liquid mediums is large, the liquid mediums can absorb the heat energy produced through burning of the biomass in the combustion chamber in a heat transmission mode, the burning environment of the biomass is improved, and the biomass burning machine is friendly to environment and reduces manpower and material resources. Moreover, the liquid mediums have fluidity, the liquid mediums absorbing the heat energy can be recycled after being cooled, and therefore the biomass burning machine has an energy-saving effect.

Owner:中山市兴和生物能源科技有限公司

Method for prolonging service life of boiler denitration system catalyst

InactiveCN104841269AReduce life lossAvoid incomplete combustionDispersed particle separationFlue gasProcess engineering

The present invention discloses a method for prolonging the service life of a boiler denitration system catalyst. The method comprises a) increasing the denitration system catalyst surface temperature before starting boiler ignition, wherein the denitration system catalyst surface temperature in the step a) is increased to more than or equal to the flue gas dew point temperature, and the step a) comprises a step a1) introduction of an external heat source into the boiler so as improve the denitration system catalyst surface temperature to more than or equal to the flue gas dew point temperature.

Owner:冯伟忠

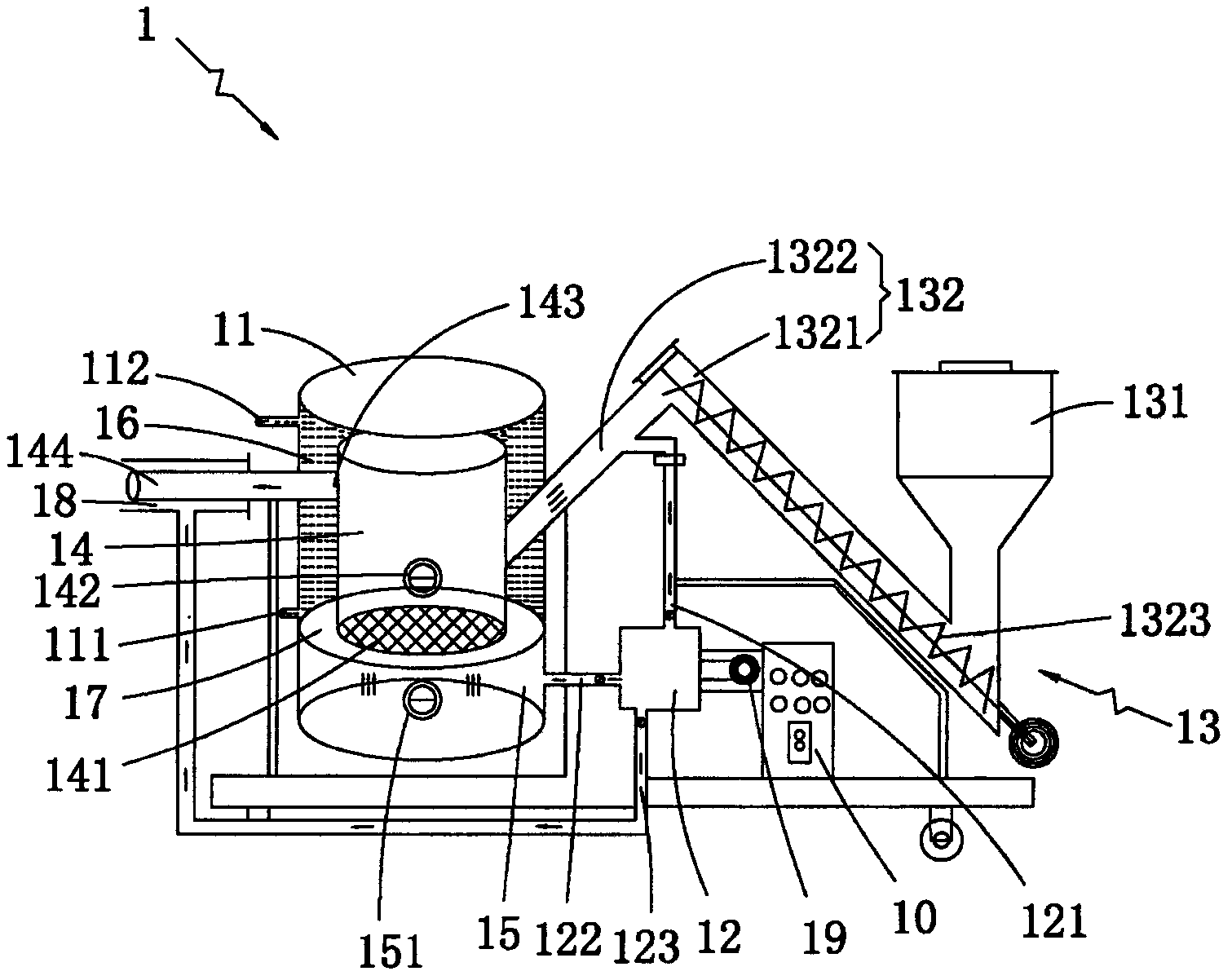

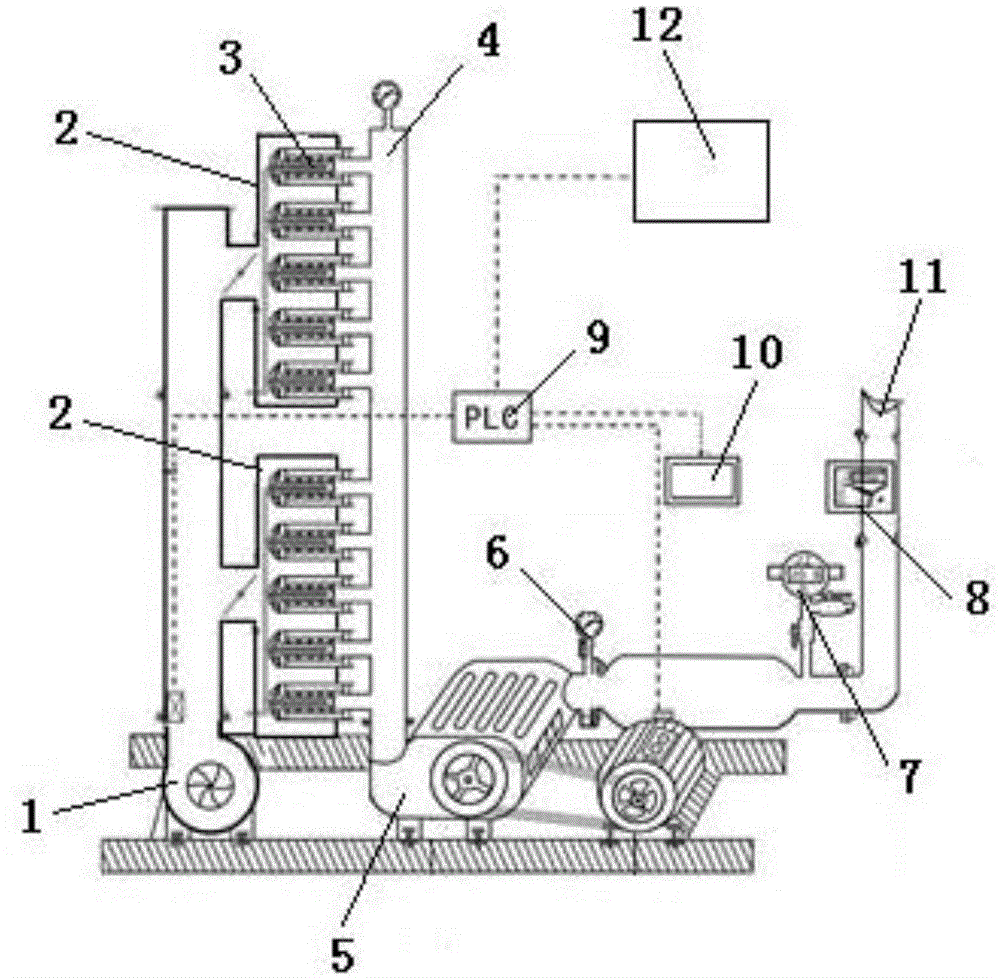

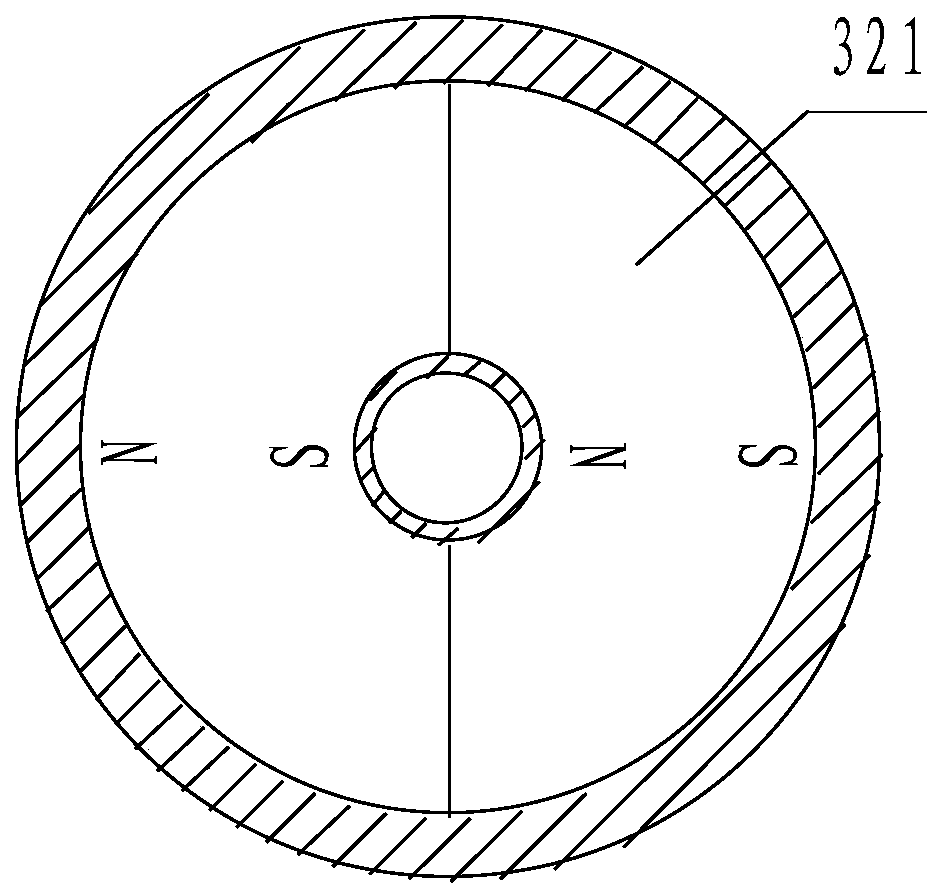

Intelligent linear oxygen-concentrated and thermally-ionized adsorptive-type magnetically-induced airflow combustion-supporting and energy-saving system with magnetic effect

InactiveCN104595923AReduce usageIncrease temperatureAir supply regulationIndirect carbon-dioxide mitigationMagnetizationVacuum pump

The invention relates to an intelligent linear oxygen-concentrated and thermally-ionized adsorptive-type magnetically-induced airflow combustion-supporting and energy-saving system with a magnetic effect. The system comprises a raw material air supply machine, a magnetic effect magnetically-induced airflow pressure-equalizing distribution box and a single stage type roots vacuum pump, wherein an outlet of the raw material air supply machine is connected with the magnetic effect magnetically-induced airflow pressure-equalizing distribution box; a tunnel-type annular linear thermally-ionized magnetization group is arranged in the magnetic effect magnetically-induced airflow pressure-equalizing distribution box and is connected with an adsorption pipeline; the adsorption pipeline is connected with an oxygen-rich magnetized gas output pipeline through the single stage type roots vacuum pump; an oxygen-rich air output pressure gauge, an intelligent online oxygen content analyzer and an intelligent online oxygen-rich output flowmeter are arranged on the oxygen-rich magnetized gas output pipeline; a PLC (Programmable Logic Controller) intelligent industrial control system is connected with a liquid crystal display operation touch screen and an energy-saving variable-frequency control motor. According to the system disclosed by the invention, the combustion speed is accelerated and the complete combustion is facilitated; the combustion environment is optimized, and the life of a stove is prolonged; the product yield and the product quality are improved; the smoke volume after combustion is reduced.

Owner:YANTAI JIUZHOU FUEL OIL & FUEL GAS ENERGY SAVING TECH

Methane gas catalytic combustion agent

InactiveCN102851089ABurn fasterIncreased Flame Correction EfficacyGaseous fuelsWater vaporDissolution

The invention discloses a methane gas catalytic combustion agent. The main component of natural gas is methane gas, the liquefied natural gas has methane content of 99.9% generally, and the general gaseous natural gas belongs to raw gas, and may contain a small amount of ethane, propane or butane resulting from noncomplete purification such as dewatering and desulfurization, and it also contains hydrogen sulfide, carbon dioxide, nitrogen and water vapor, and trace inert gas such as helium and argon. It is characterized in that a liquid catalytic combustion agent is added in the natural gas, wherein when the natural gas weight is 100 kg, the dosage of the liquid catalytic combustion agent is 2.6-3.6 kg. Due to sufficient dissolution of the liquid catalytic combustion agent and the methane gas, high-efficiency catalytic combustion can be carried out, to increase thermal reaction speed of methane molecules, flame temperature and combustion velocity, decrease combustion temperature, improve heat utilization ratio of combustible gas, and enhance safety thereof.

Owner:张国平

Industrial furnace comprehensive energy saving and emission reduction integrated system

InactiveCN103175408AImprove the combustion environmentReduce coal consumptionDispersed particle separationIndirect carbon-dioxide mitigationDust controlSpray atomization

An industrial furnace comprehensive energy saving and emission reduction integrated system is characterized in that the industrial furnace comprehensive energy saving and emission reduction integrated system is a comprehensive integration integrated system which compounds oxygen-enriched combustion-supporting technology, a selective non-catalytic reduction (SNCR) denitrification method and an oxidation neutralization desulfurization and denitrification dedusting method. The industrial furnace comprehensive energy saving and emission reduction integrated system comprises a waste heat boiler, a deduster, a reducing agent spray atomization device, an oxidation neutralization denitrification reaction tower, an ammonium salt pond, an oxygen-enriched generating device, a wind mixing device, an ozone generating device and an ammonium salt liquid-solid separation device, wherein the waste heat boiler, the deduster, the reducing agent spray atomization device, the oxidation neutralization denitrification reaction tower, the ammonium salt pond, the oxygen-enriched generating device, the wind mixing device, the ozone generating device and the ammonium salt liquid-solid separation device are sequentially connected. The industrial furnace comprehensive energy saving and emission reduction integrated system not only is reasonable in process route and high in desulfurization and denitrification efficiency and combustion efficiency; but also is high in use rates of desulfurization and denitrification absorbent, can effectively reduce consumption of fuel such as fire coal, and improves yield of a furnace. Besides, clinker combusted quality of a cement kiln in an industrial furnace can be effectively improved, and intensity of cement end products can be improved by 3 to 28 days.

Owner:DALIAN EAST NEW ENERGY DEV

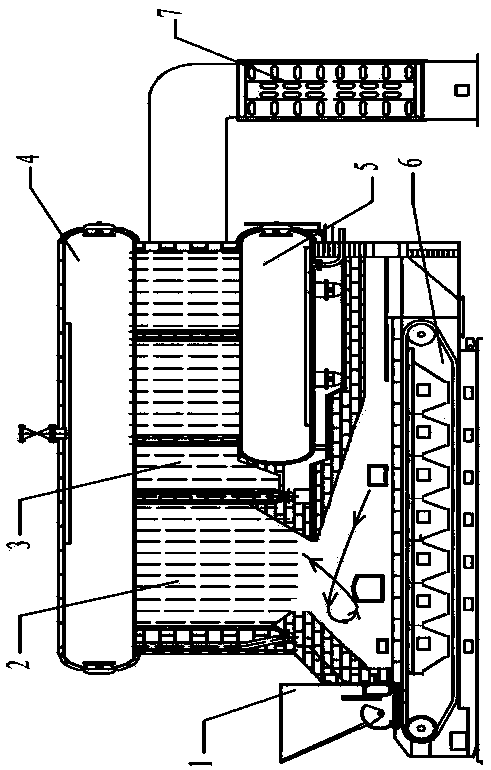

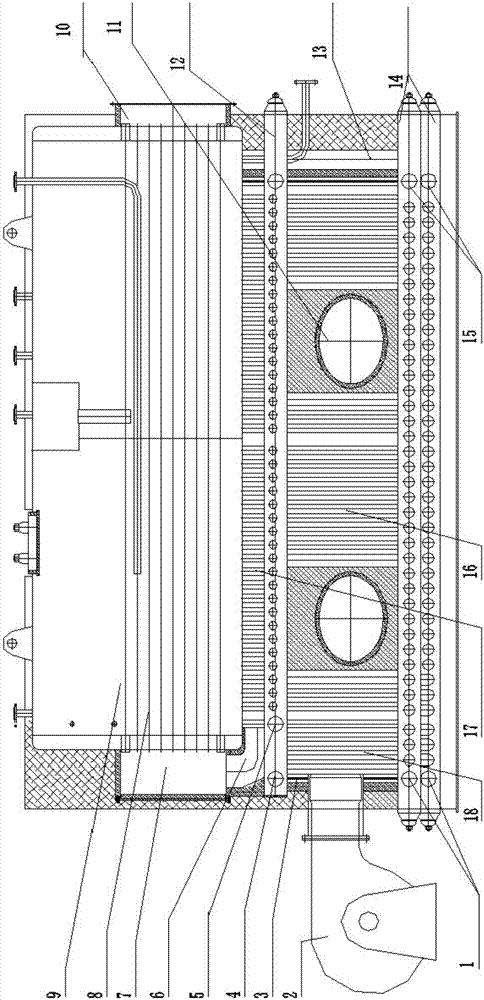

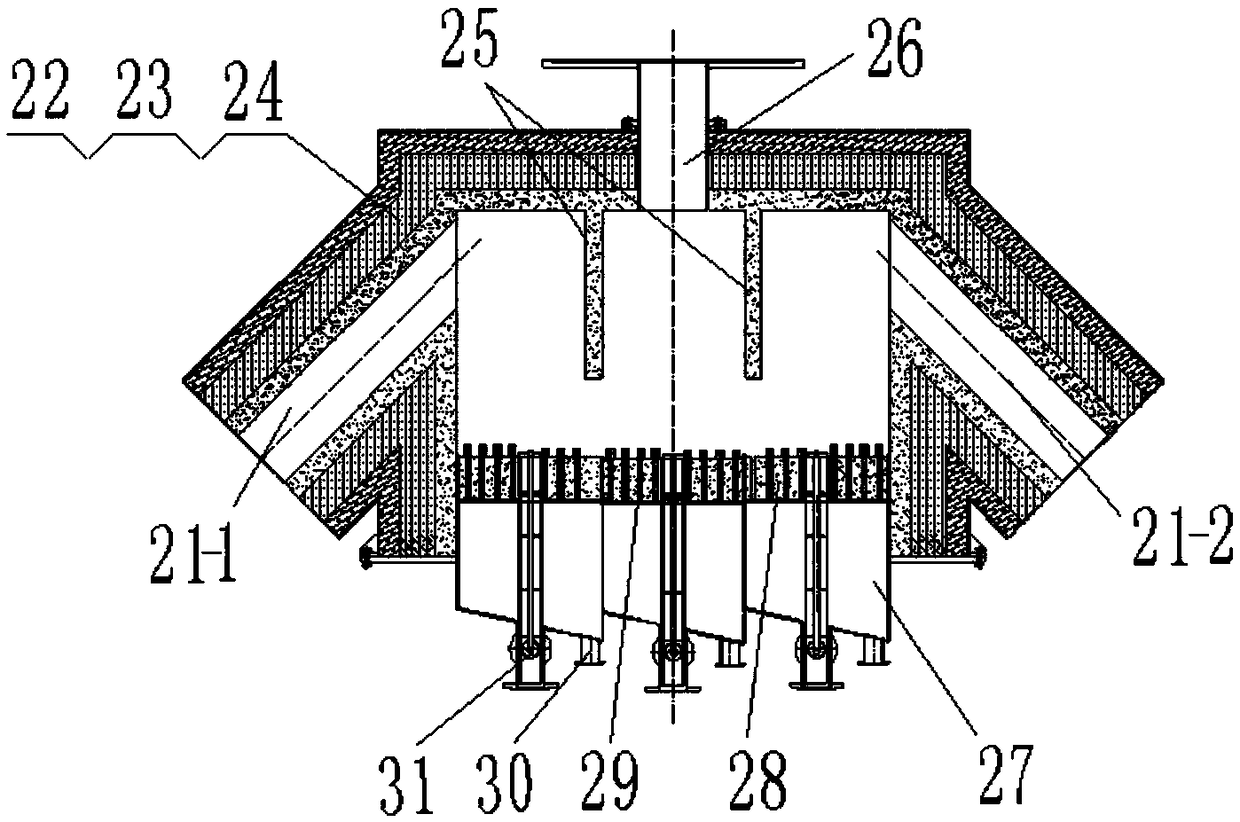

Biomass chain boiler

InactiveCN103925592AImprove combustion conditionsImprove combustion efficiencySolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention discloses a biomass chain boiler. The biomass chain boiler comprises a boiler body provided with a feed port. An upper boiler barrel, a lower boiler barrel, a hearth, a combustion chamber, a front arch, a back arch and a chain grate stoker are arranged in the boiler body. The front end of the upper boiler barrel stretches to the front side of the front end of the lower boiler barrel. The upper boiler barrel and the lower boiler barrel are connected through a convection bank, and the combustion chamber is formed between the upper boiler barrel and the lower boiler barrel. The hearth is located on the lower side of the front of the upper boiler barrel and located on the front side of the combustion chamber and is communication with the combustion chamber. A throat is formed between the front arch and the back arch, and located under the hearth and on the front side of the lower boiler barrel. The chain grate stoker sequentially penetrates through the feed port, the lower portion of the front arch, the lower portion of the back arch and the lower portion of the lower boiler barrel from front to back. The biomass chain boiler can make biomass briquette fully combust and improve combustion efficiency.

Owner:HENAN AGRICULTURAL UNIVERSITY

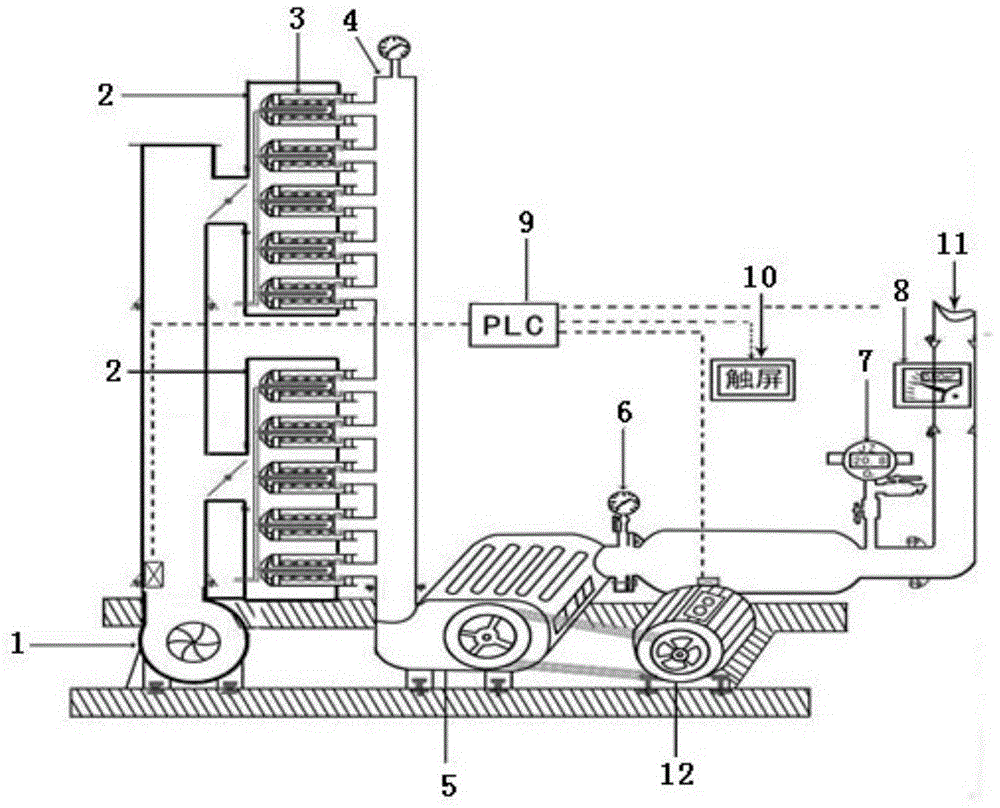

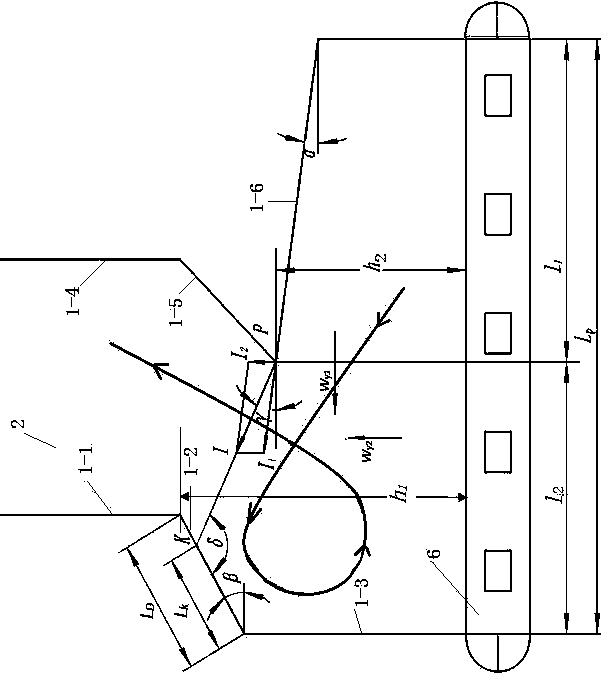

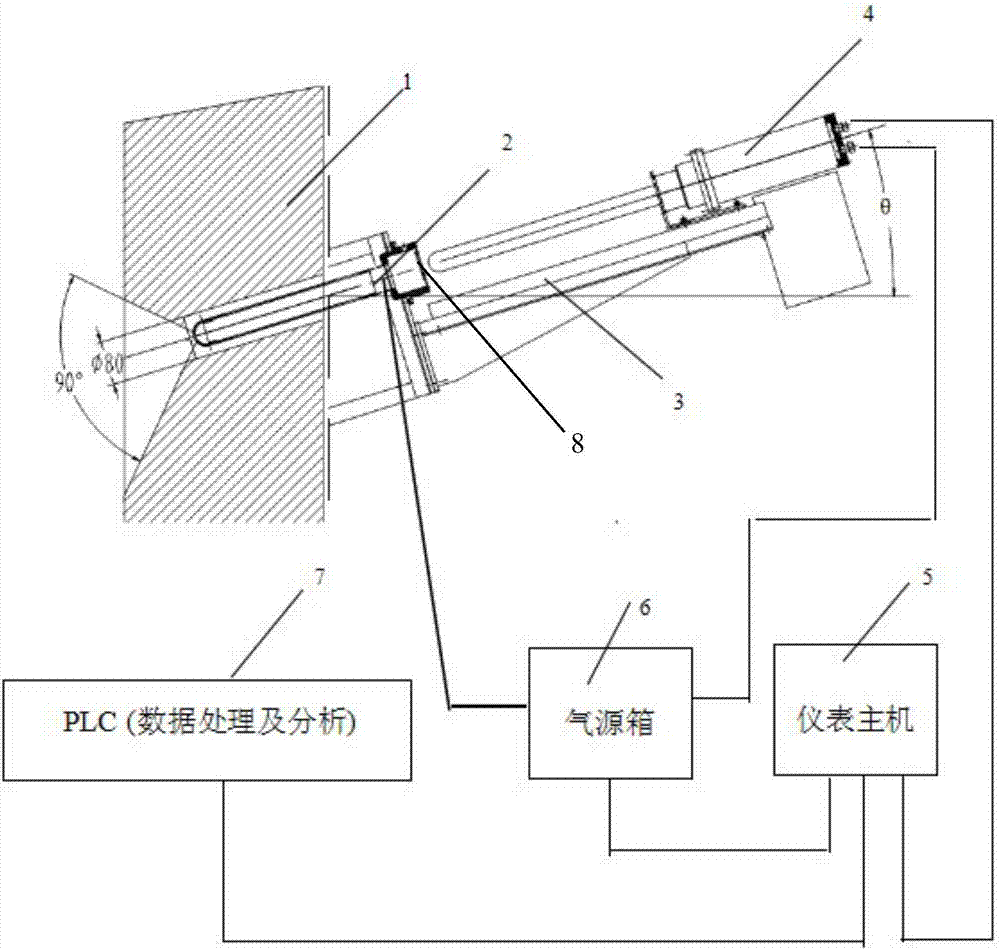

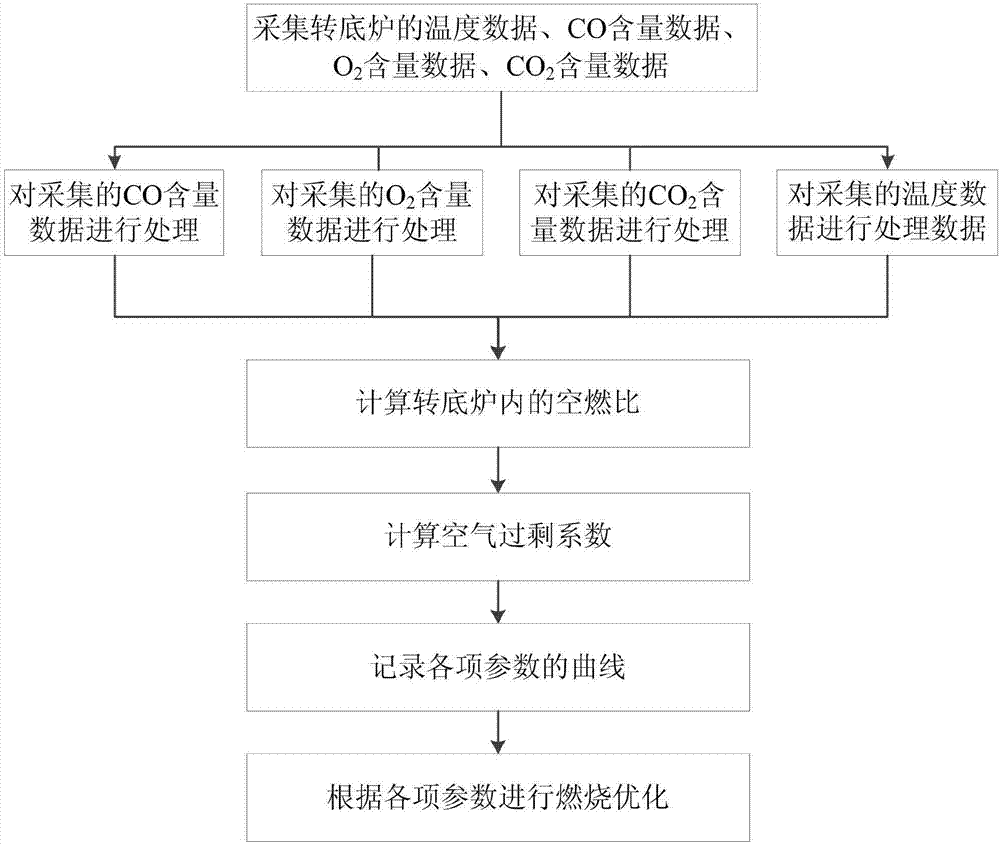

System and method for detecting atmosphere components in rotary hearth furnace in real time and optimally controlling combustion

PendingCN107314671AImprove combustion efficiencyGuaranteed cleanlinessFuel supply regulationMeasurement devicesMonitoring dataEngineering

The invention provides a system and method for detecting atmosphere components in a rotary hearth furnace in real time and optimally controlling combustion. The system comprises a pneumatic advancing and retreating device, a composite probe, an air source box, an instrument host and a PLC (Programmable Logic Controller), wherein the composite probe can do a reciprocating motion on a sliding guide rail and extend into the rotary hearth furnace so as to monitor data of the atmosphere components in the rotary hearth furnace; the air source box is used for controlling an air source of an air cylinder so as to drive the composite probe to move on the sliding rail and for detecting the pressure of the air source of the air cylinder; the instrument host is used for sending a control instruction to the air source box and the composite probe so as to control the composite probe to move on the sliding rail and collecting the monitoring data of the composite probe; and the PLC is used for optimally controlling a combustion model according to the monitoring data collected by the instrument host and sending an instruction to a combustion controller so as to optimize combustion conditions in the rotary hearth furnace. According to the system and the method, all data in the rotary hearth furnace are detected by the composite probe, and the combustion environment in the rotary hearth furnace is adaptively optimized according to all of the data, so that the combustion efficiency is improved.

Owner:宝武集团环境资源科技有限公司

Activation catalyst for energy conservation, automobile economizer containing catalyst and installation method of automobile economizer

PendingCN109261178AIncrease the calorific value of combustionWell mixedInternal combustion piston enginesHeterogenous catalyst chemical elementsCombustionOxygen

The invention relates to the field of energy conservation and emission reduction devices, and provides an activation catalyst for energy conservation, an automobile economizer containing the catalystand an installation method of the automobile economizer. The catalyst comprises a nano composite negative ion far-infrared material and a carrier. By means of the catalyst, the molecular activity of fuel molecules and oxygen molecules can be improved at the same time, the combustion environment is improved, and the combustion heat value of fuel is improved, so that the power of an engine during combustion of equal amount of fuel is higher, therefore the energy-saving effect is achieved, and the safety performance of an automobile and the service life of the engine are not affected. Besides, the power of the engine is improved by the activation catalyst for the automobile economizer, the energy-saving effect is achieved, and harmful gas in tail gas is also reduced. Meanwhile, oxidation is carried out in the exhausted gas, the harmful gas is decomposed, and the catalyst in the tail gas in a silencer is activated. According to the installation method, the energy-saving and emission-reducing effects of the engine at different rotating speeds can be taken into consideration, so that the optimal energy-saving and emission-reducing effects are achieved in general.

Owner:高洁泉 +2

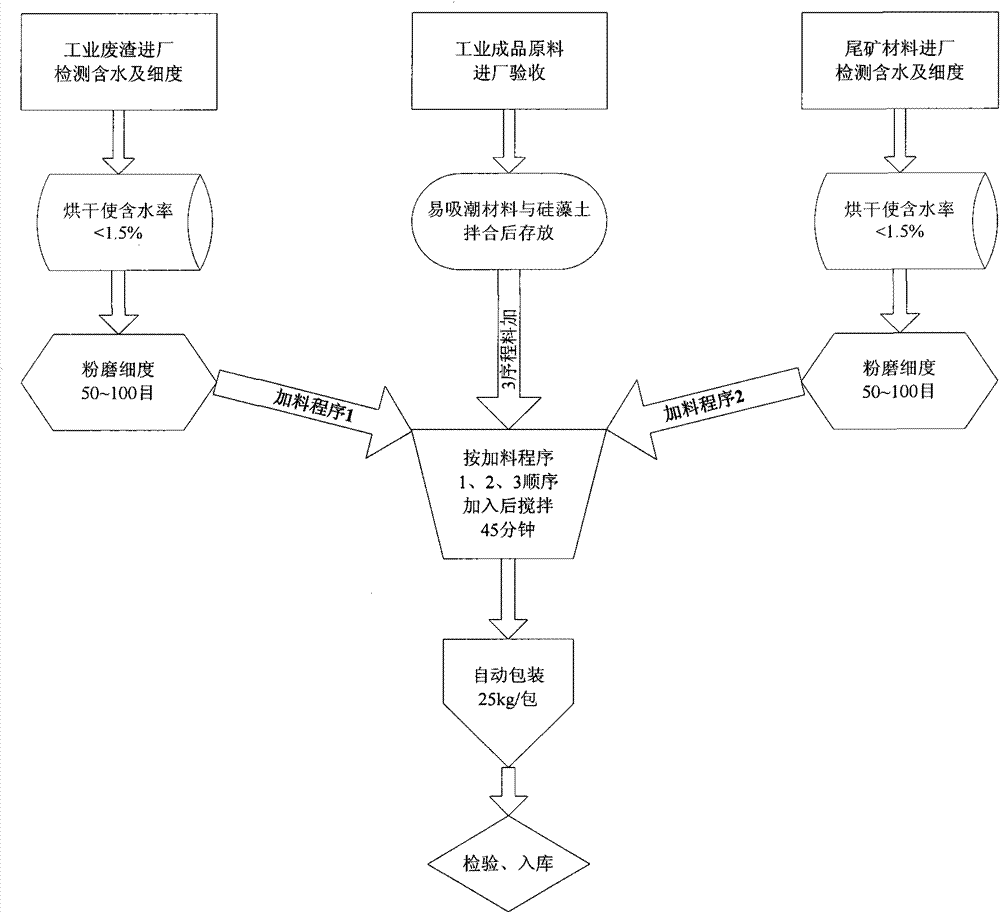

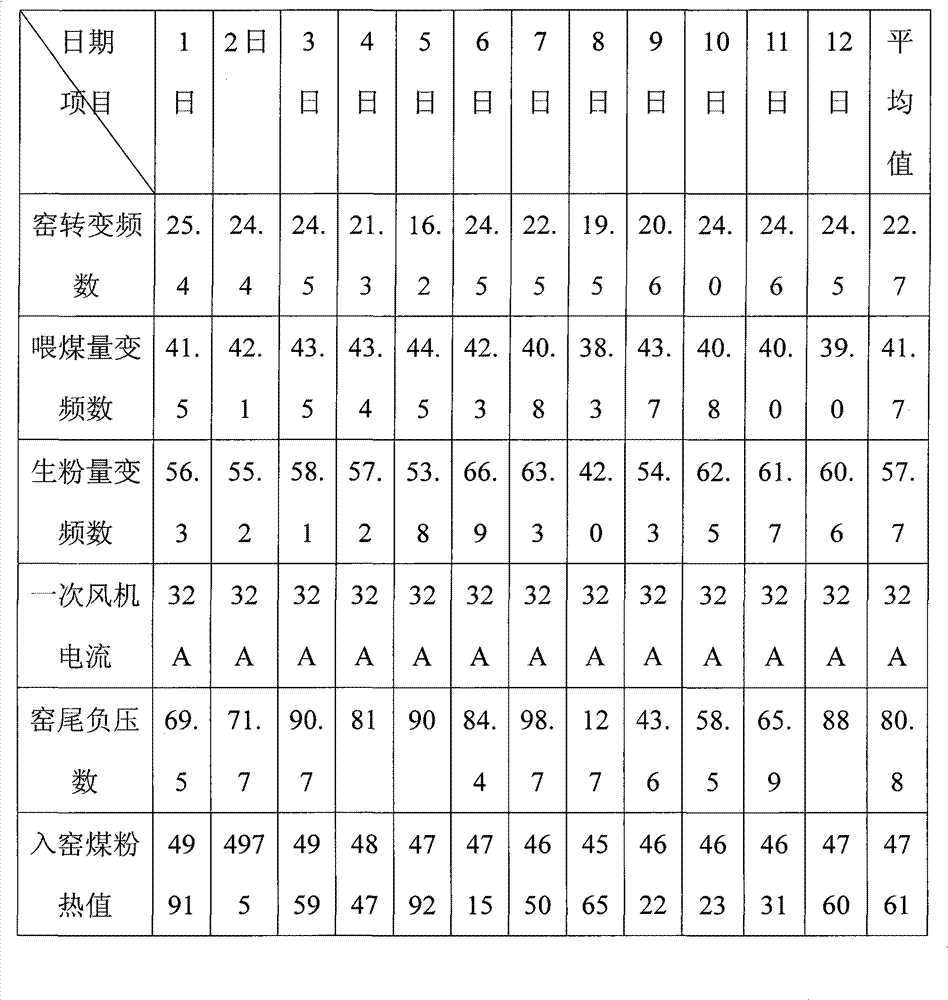

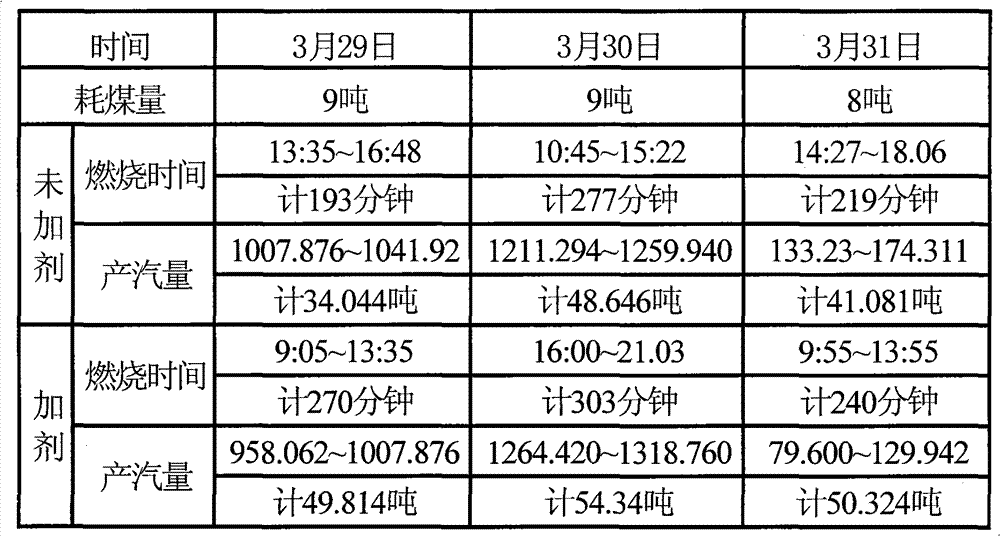

Non-sodium chloride environment-friendly type coal-saving combustion adjuvant special for cement

InactiveCN101475864BReduce contentReduce consumptionSolid fuelsClinker productionChromium CompoundsAdjuvant

The invention discloses a sodium chloride-free environment-friendly coal-saving combustion improver special for cement, which aims to solve the technical problem of eliminating the damage of sodium chloride to furnaces, kiln bodies and the atmosphere. The combustion improver consists of an industrial grade finished product raw material, industrial residue, and a tailing material, and contains a barium compound, boride, carbonate, a chromium compound, fluoride, a magnesium compound, a manganese compound, nitride, a molybdenum compound II, a zirconium compound, industrial residue or tailings of rare earth, oxide and dicyclopentadienyl iron. Compared with the prior art, the combustion improver completely cancels the sodium chloride, furthest reduces the content of Cl<-> in ingredients, eliminates the damage of the sodium chloride to the furnaces, the kiln bodies and the atmosphere, reduces the damage of causing acid rain to the atmosphere, increases a plurality of metal acids, oxygen compounds and rare earth minerals, contains waste residue, ensures that the combustion is controllably performed, improves combustion environment, improves the combustion efficiency of fire coal, reduces energy consumption, prolongs the service life of equipment, and protects the environment.

Owner:深圳市伯益科技有限公司

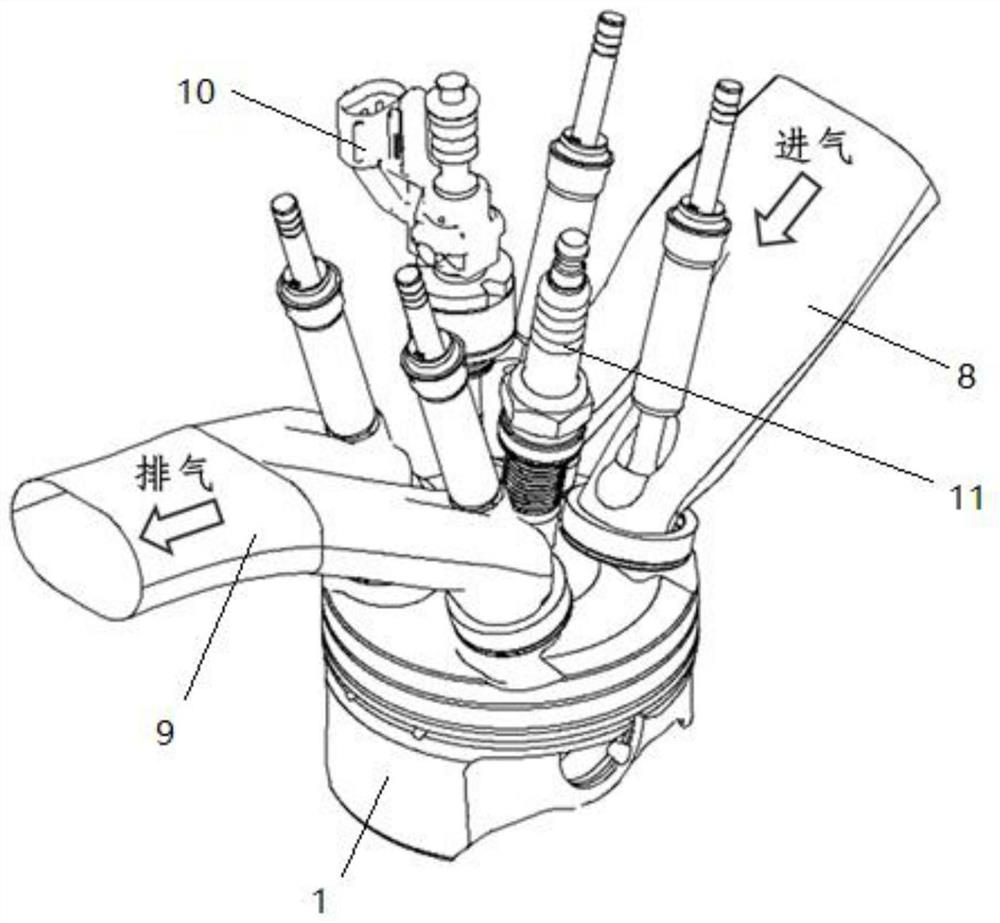

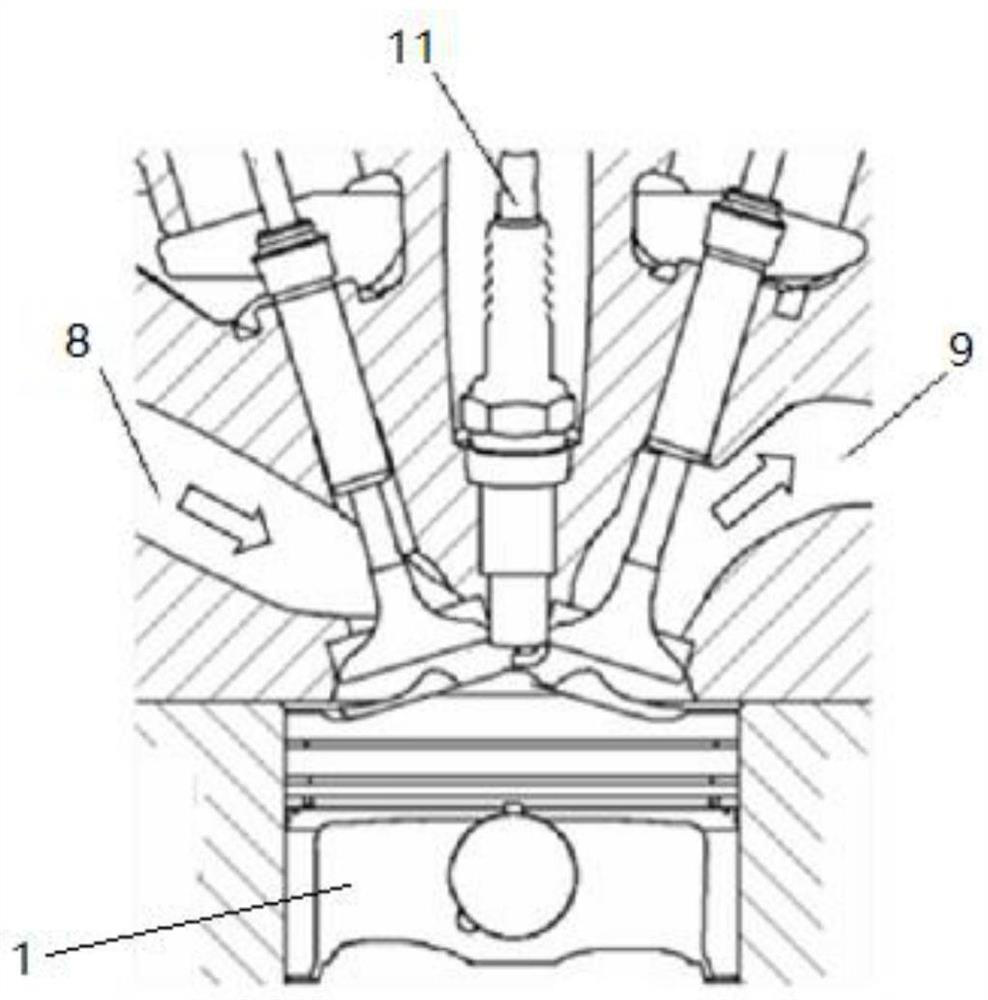

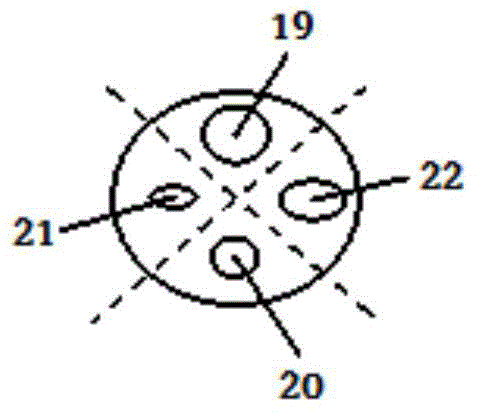

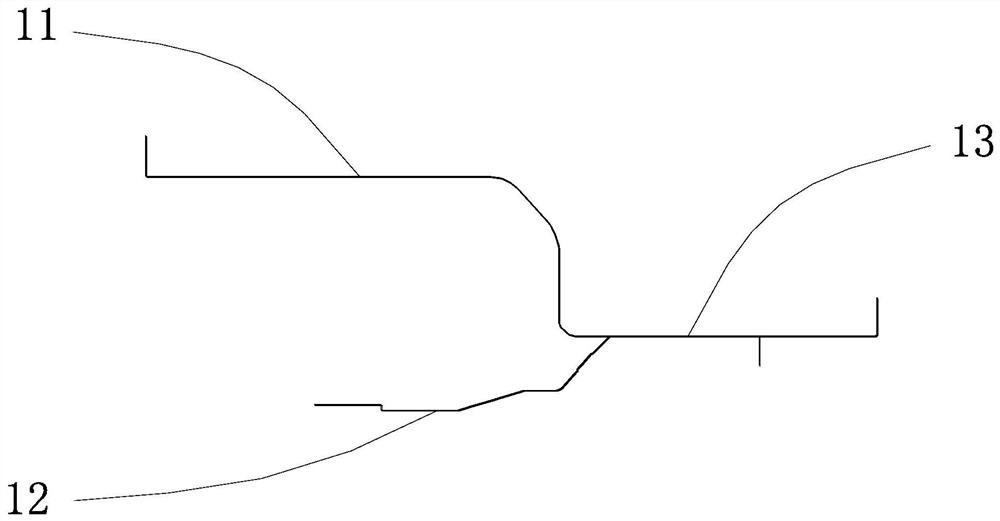

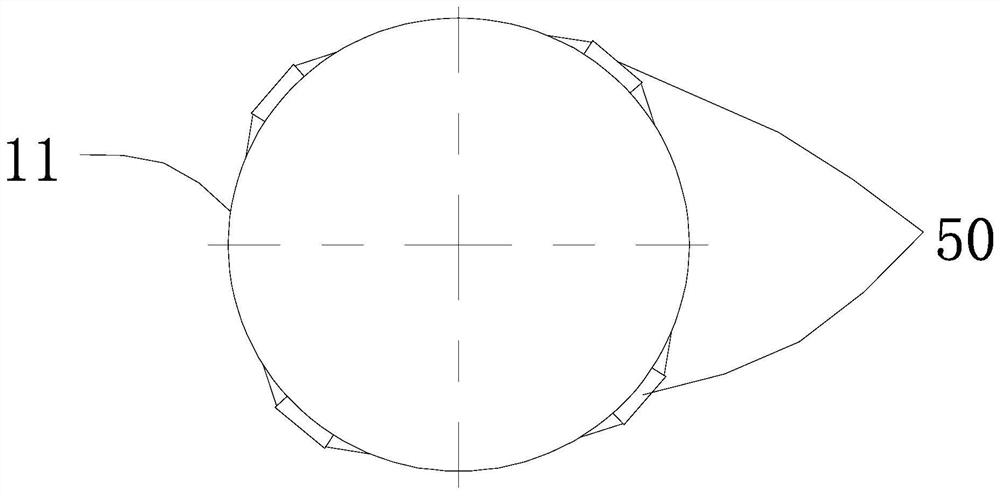

Spark compression ignition type piston, combustion system, power assembly system and control method

ActiveCN112031948AHigh isovolumicity of combustionImprove the combustion environmentCombustion enginesPistonsCombustion systemPressure rise

The embodiment of the invention provides a spark compression ignition type piston, a combustion system, a power assembly system and a control method. The top structure of the piston is symmetrically arranged about the center line in the first direction and the second direction, and the first direction and the second direction are perpendicular to each other; the top structure of the piston comprises a center pit, vortex rings, air inlet pits and air exhaust pits; the central pit is formed in the middle of the piston; the two vortex rings are arranged on the two sides of the center pit in the first direction; the air inlet pits and the air exhaust pits are formed in the two sides of the center pit in the second direction; and the central pit, the air inlet pits and the air exhaust pits arein fluid connection with the same side edges of the vortex rings. By improving the structure of the surface of the piston, time-sharing and partitioning heat release of the combustion system is achieved, short-time constant-volume heat release of unburned mixed gas can be avoided, the pressure rise rate and rough combustion are inhibited, the combustion system can still achieve a high combustion isometric degree under the high load of an ignition compression ignition manner within the wide overall equivalence ratio range, and the thermal efficiency is improved.

Owner:TSINGHUA UNIV +1

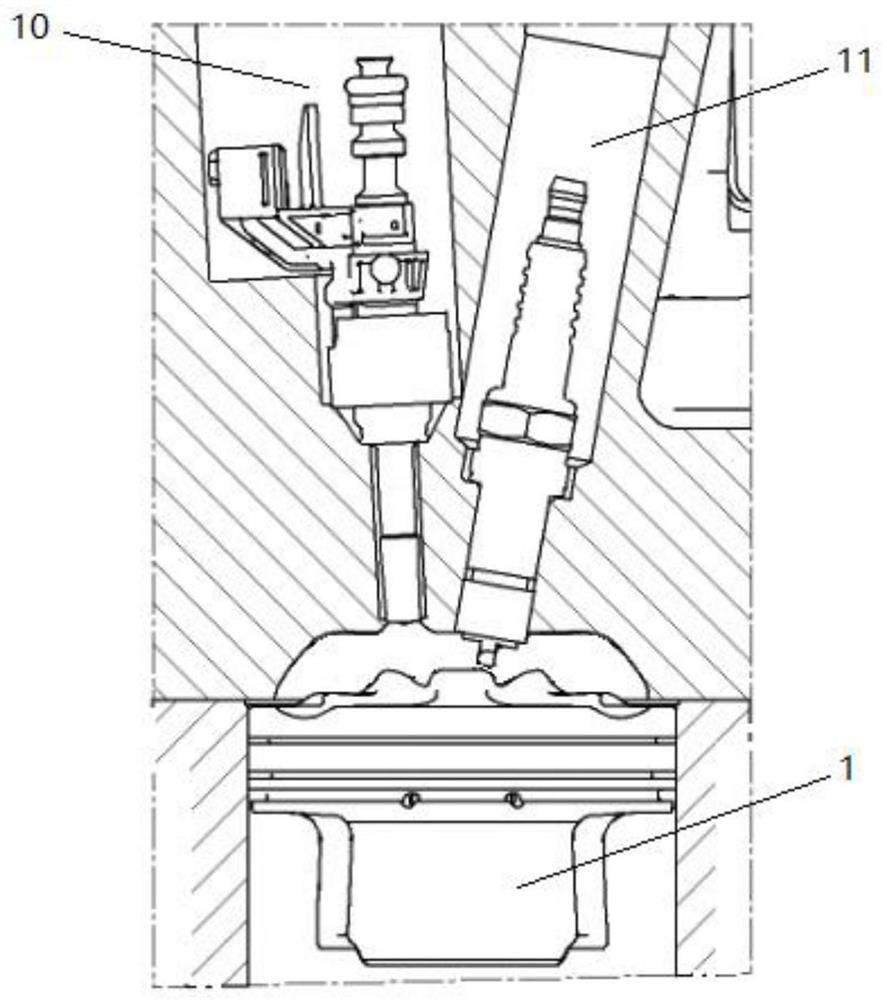

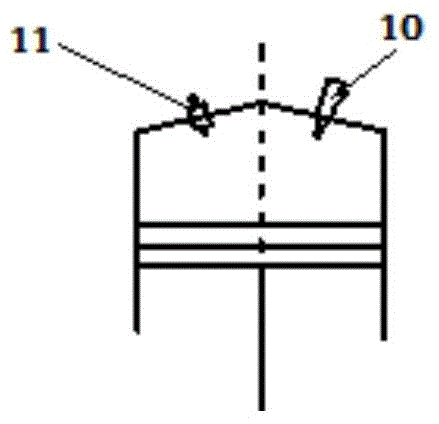

Ignition-mode-variable diesel/natural gas dual-fuel engine and control method thereof

InactiveCN104791075AImprove the combustion environmentImprove efficiencyCombustion enginesElectronic control unitThrottle

The invention discloses an ignition-mode-variable diesel / natural gas dual-fuel engine. The engine is provided with an air inlet valve and an exhaust valve. An original diesel injecting system is not changed, a spark plug igniting system is newly added, and a spark plug installing hole is reserved in a cylinder cover. A spark plug is in threaded connection with a cylinder, and the spark plug and a diesel injector are oppositely arranged relative to the center of the cylinder. An engine electronic control unit judges the work condition of the engine according to the opening degree of a throttle valve; when it is judged that the work condition of the engine is in a low-load state, the electronic control unit transmits a signal to an ignition controller, the spark plug is controlled to perform ignition, and natural gas mixtures in the cylinder are ignited; when it is judged that the work condition of the engine is in the high-load state, the electronic control unit performs calculation, controls the diesel injector to inject diesel and controls the injection amount, the diesel is compressed so that multi-point ignition can be achieved, and the natural gas mixtures in the cylinder are ignited.

Owner:JILIN UNIV

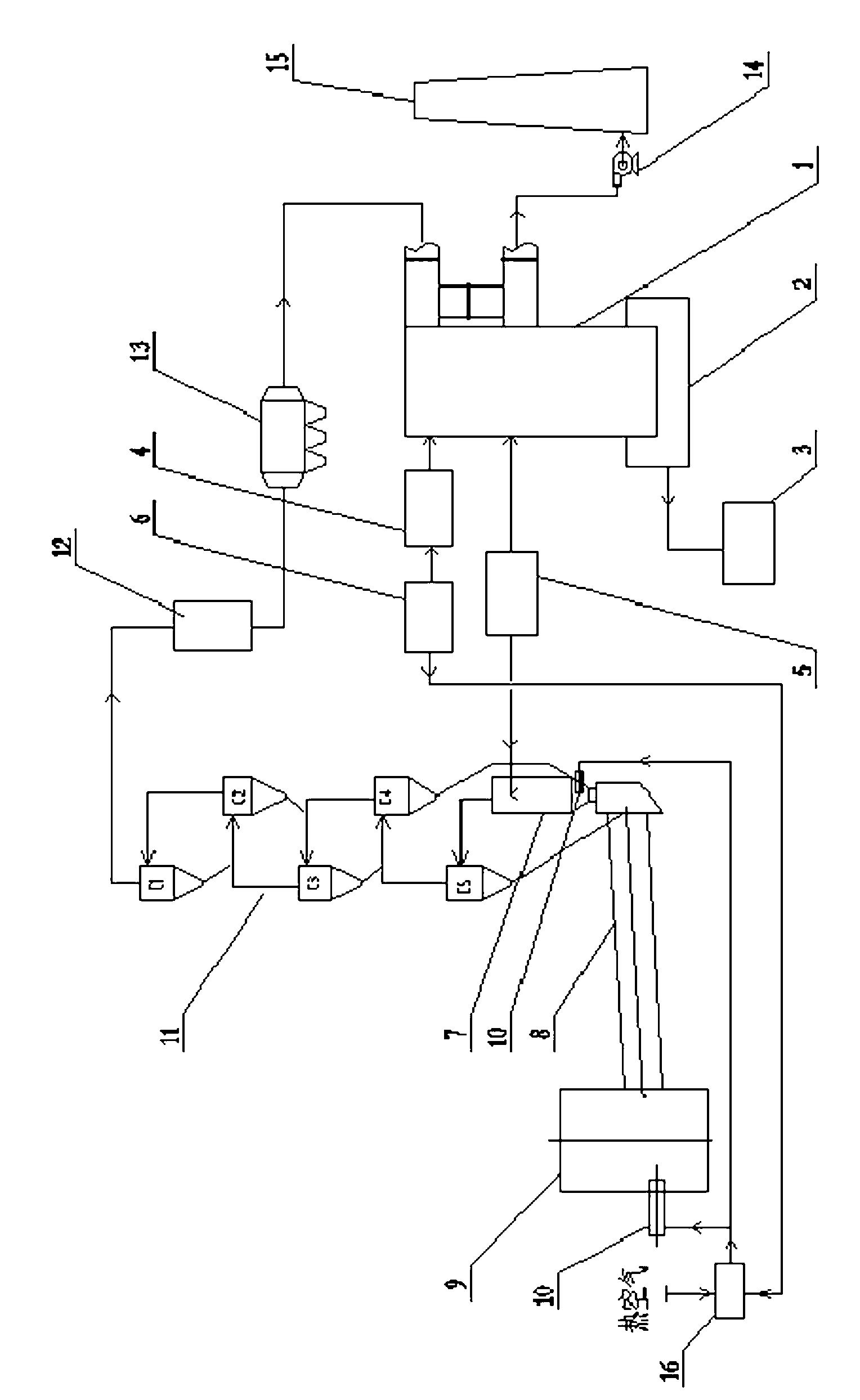

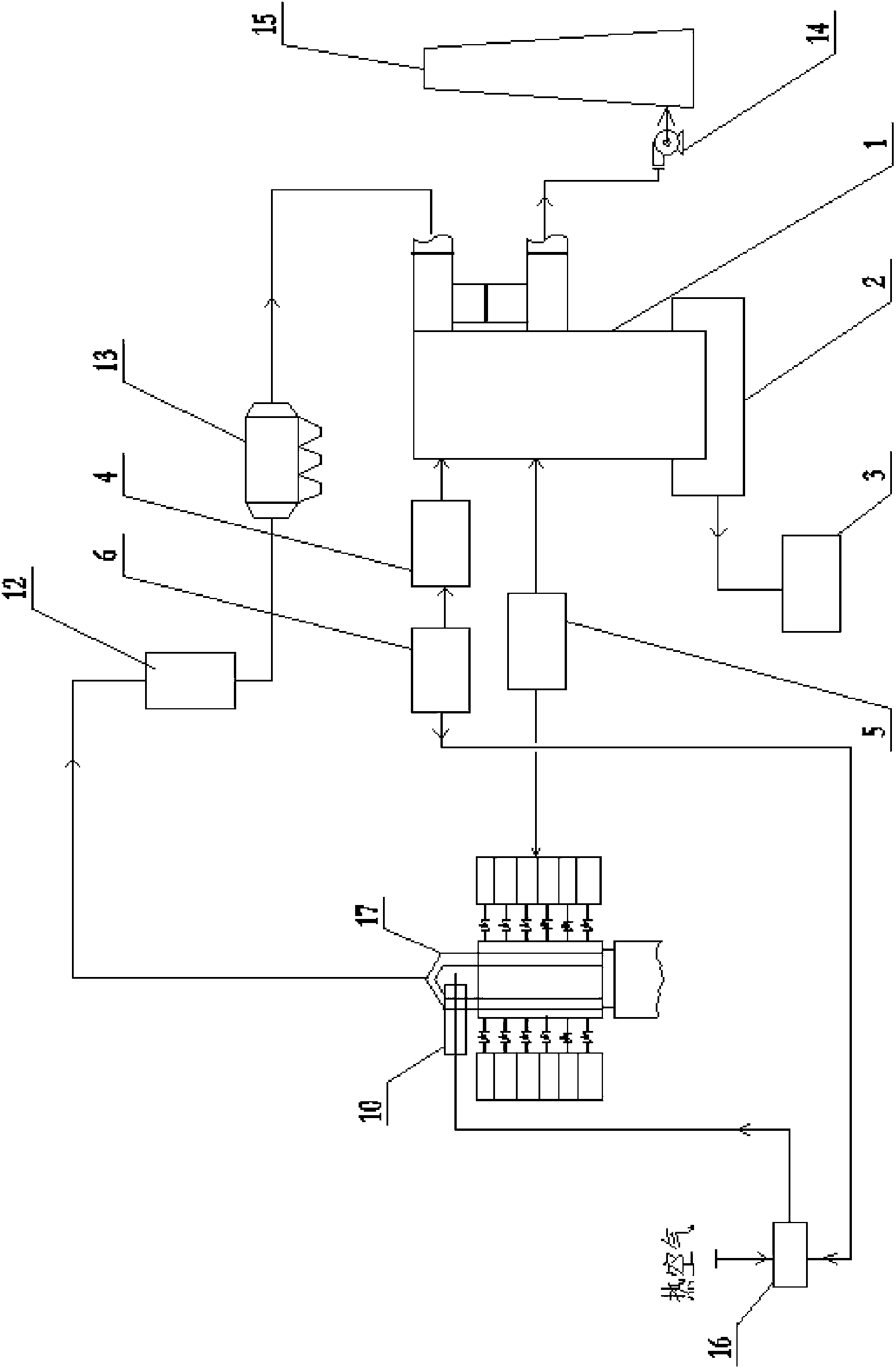

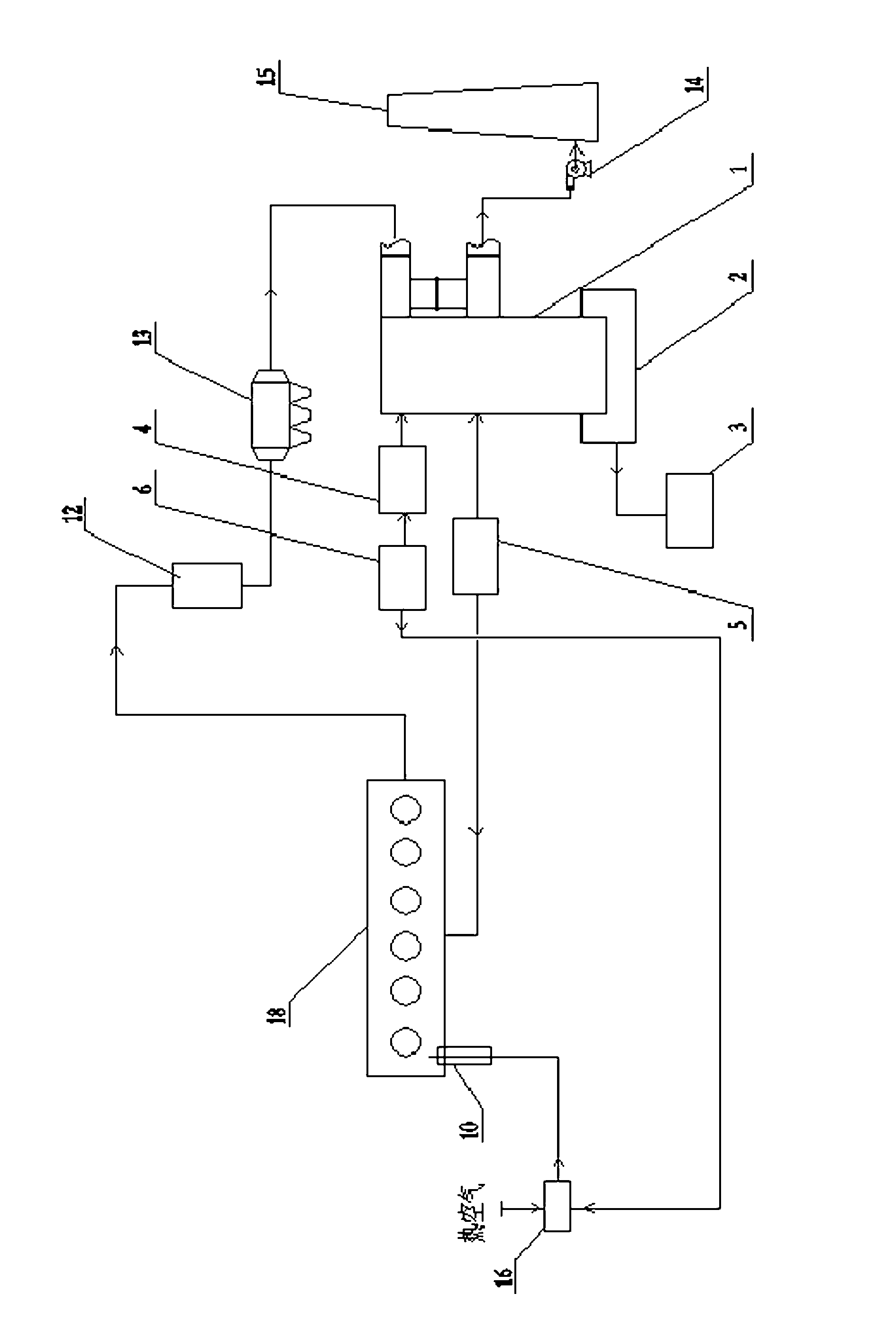

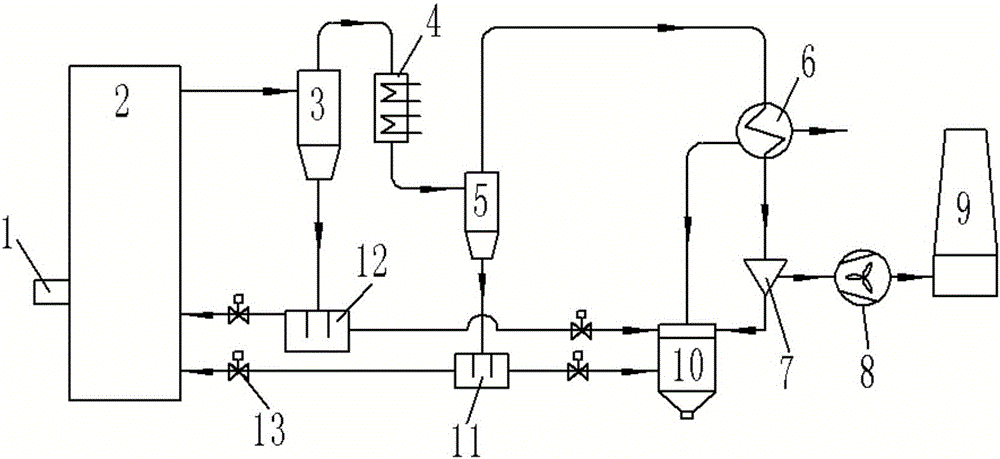

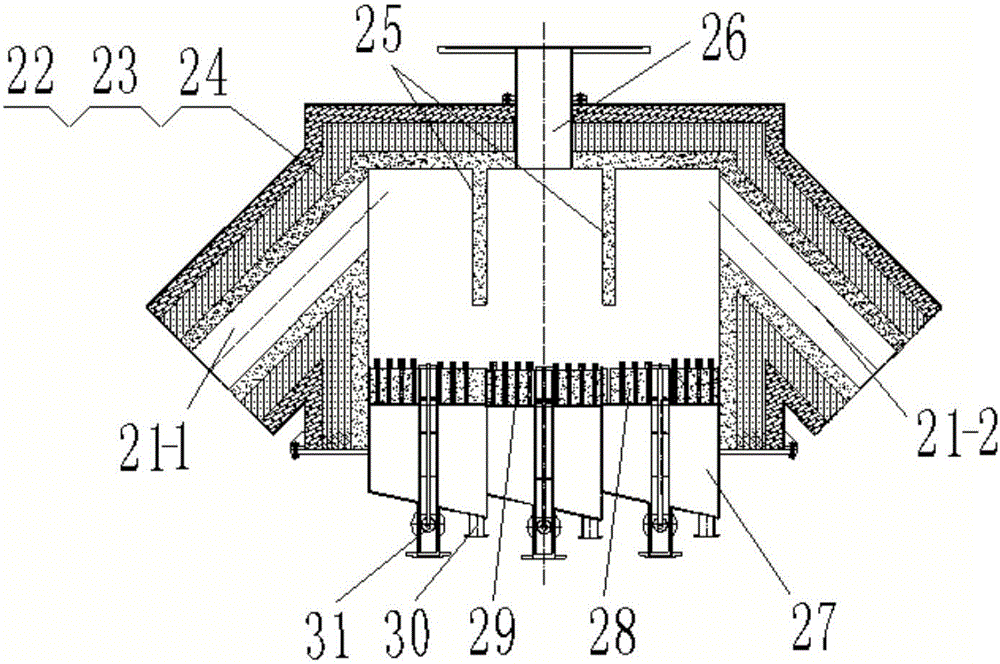

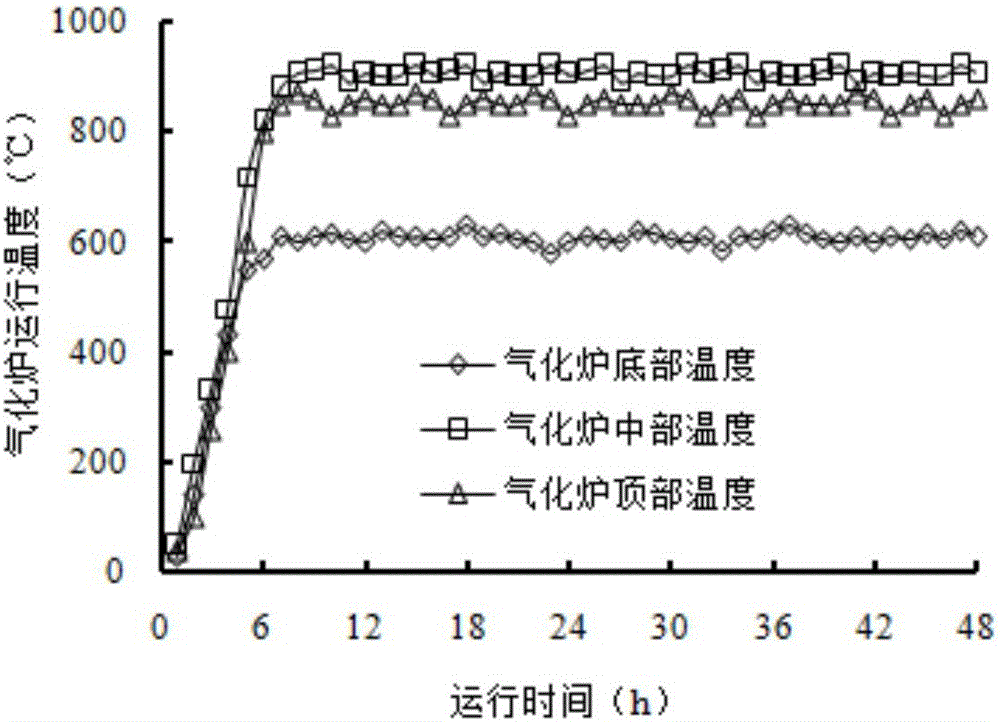

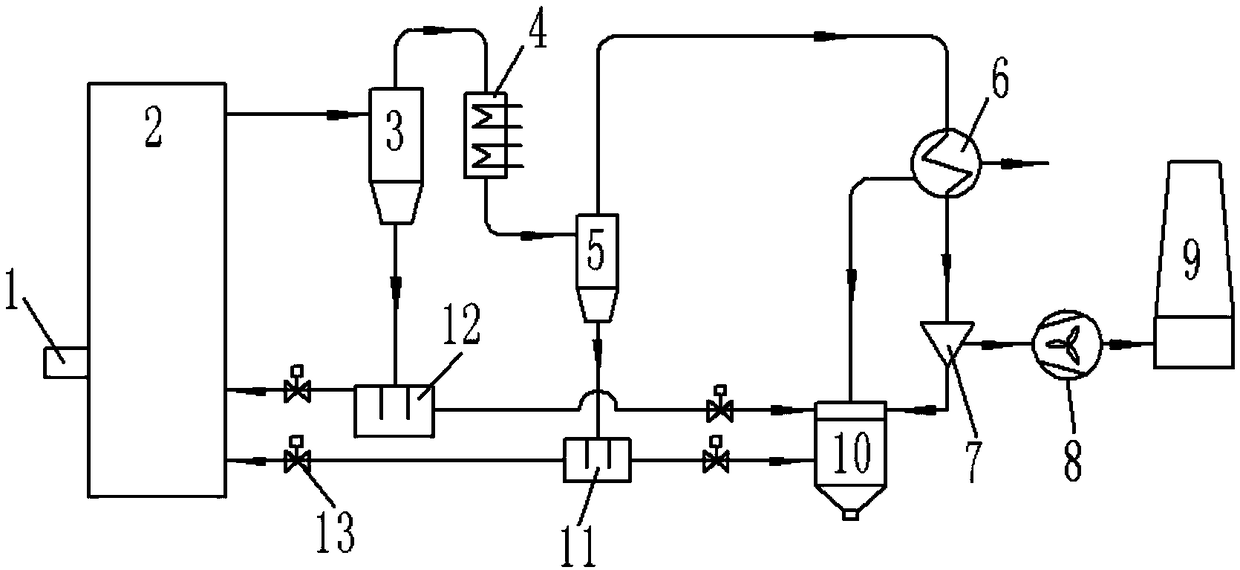

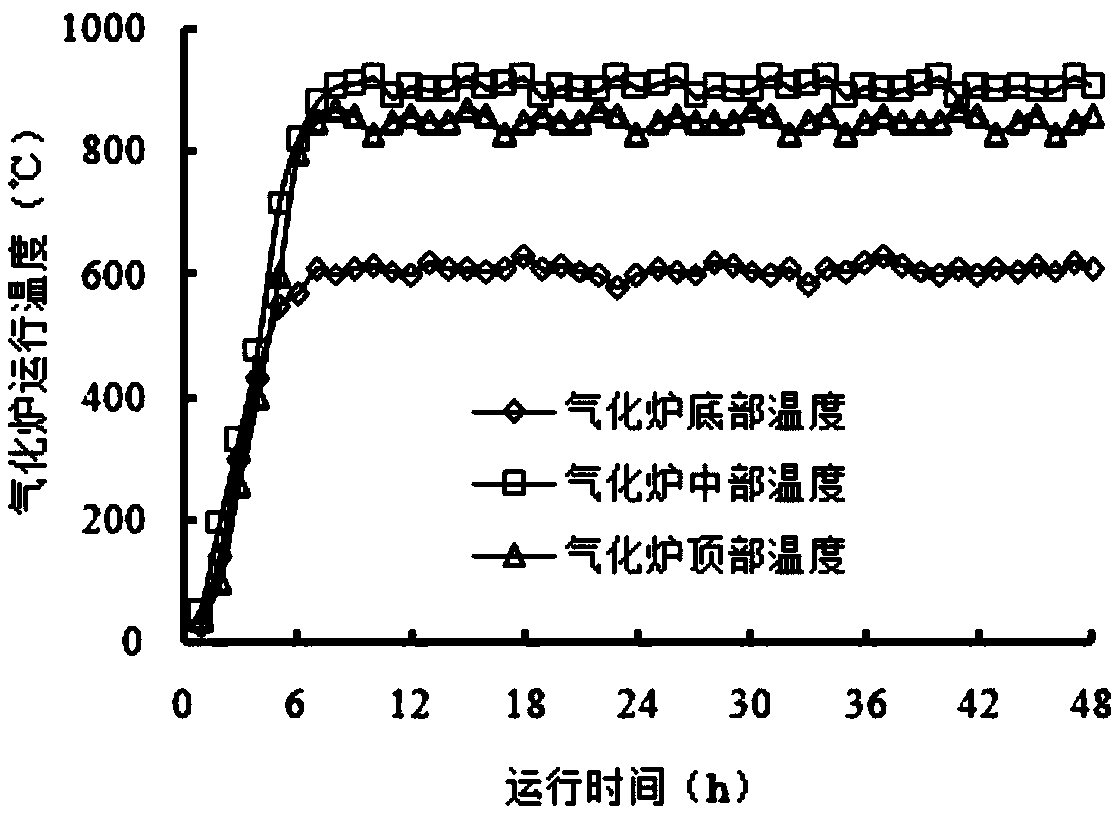

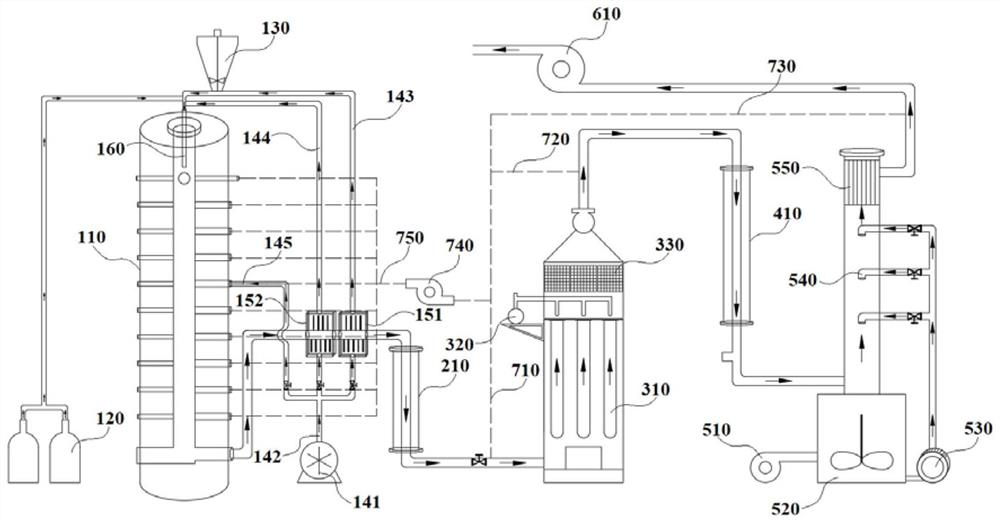

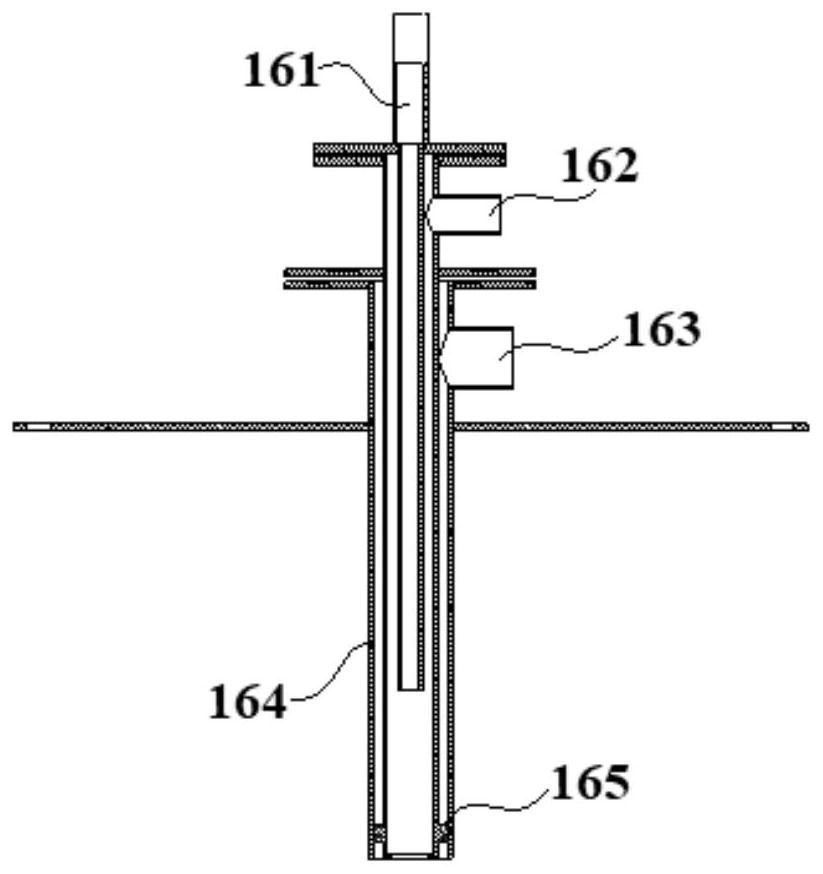

Double-circuit gasification and combustion system based on circulating fluidized bed and method and application thereof

ActiveCN106402911AGuaranteed pressure balanceAvoid running unstableLighting and heating apparatusGasification processes detailsCombustion systemFluidized bed

The invention discloses a double-circuit gasification and combustion system based on a circulating fluidized bed and a method and application thereof. The double-circuit gasification and combustion system comprises a gasifier, a primary separator, a heat exchanger, a secondary separator, a boiler and an ash bin, wherein the inlet of the primary separator communicates with the outlet of the gasifier; the gas outlet of the primary separator communicates with the heat medium inlet of the heat exchanger; the heat medium outlet of the heat exchanger communicates with the inlet of the secondary separator; gas subjected to primary separation is subjected to heat exchange for cooling in the heat exchanger; the gas outlet of the secondary separator communicates with the boiler; the solid outlet of the primary separator communicates with the inlet of a first material return valve; one side outlet of the first material return valve communicates with a first material return opening of the gasifier, and the other side outlet of the first material return valve communicates with the ash bin; the solid outlet of the secondary separator communicates with the inlet of a second material return valve; and one side outlet of the second material return valve communicates with a second material return opening of the gasifier, and the other side outlet of the second material return valve communicates with the ash bin.

Owner:山东百川同创能源有限公司

Horizontal type single boiler barrel multipurpose fuel boiler

PendingCN107327826AEasy to prepareEmission reductionStorage heatersWater heatersThermodynamicsCombustion chamber

A horizontal type single boiler barrel multipurpose fuel boiler comprises a boiler barrel and a combustion chamber. A combustor connector is arranged on the front surface of the combustion chamber. A maintenance opening is formed in the side wall of the combustion chamber. A front smoke box is arranged on the front portion of the boiler barrel. A back smoke outlet is formed in the back portion of the boiler barrel. The boiler barrel is internally provided with a plurality of boiler barrel inner smoke pipes communicating with the front smoke box and the back smoke outlet. The inner smoke pipes form a third return stroke flue. The combustion chamber is a first return stroke flue. A second return stroke flue is arranged between the combustion chamber and the lower portion of the boiler barrel. The front end of the second return stroke flue is sealed and communicates with the front smoke box through a left connecting bent pipe and a right connecting bent pipe. The boiler barrel, the second return stroke flue and the combustion chamber can be manufactured separately, form three components and then are assembled. The combustion chamber and the flues are optimally arranged, and a pipe wall is formed by connecting fins between water passing pipe bundles and pipes. During manufacturing, the space and the length of the combustion chamber can be arbitrarily sized, so that the combustion environment is fully improved, the smoke speed is moderate, fuel combustion is sufficient, emission of harmful substances is low, and the environmental protection requirement is met.

Owner:仲伟军

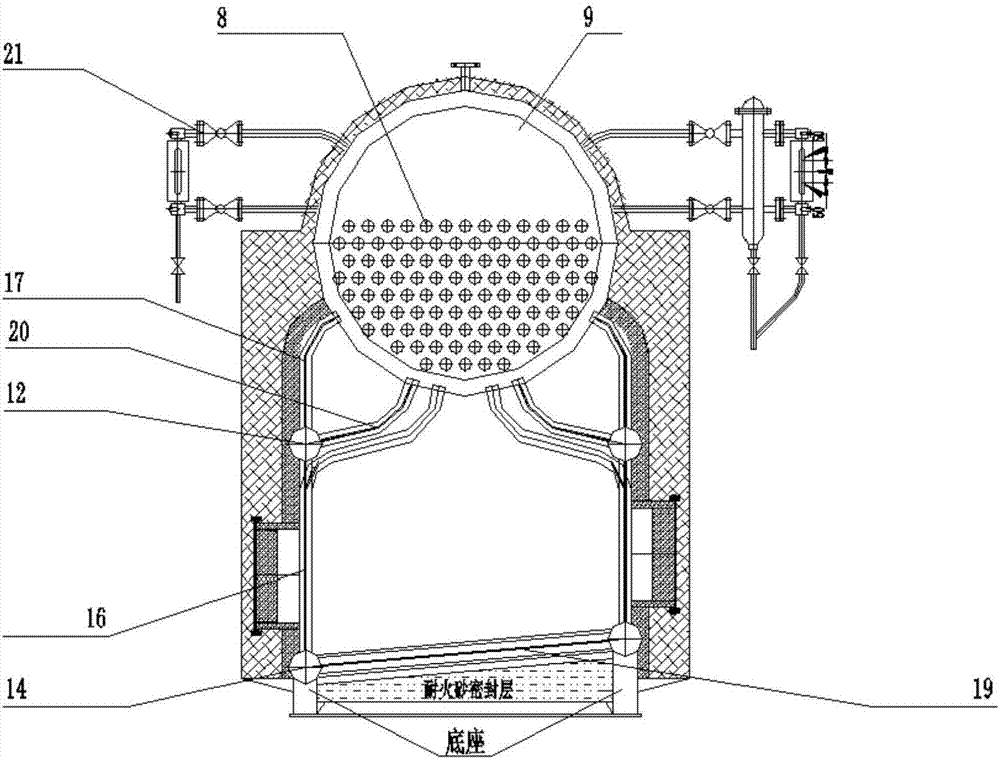

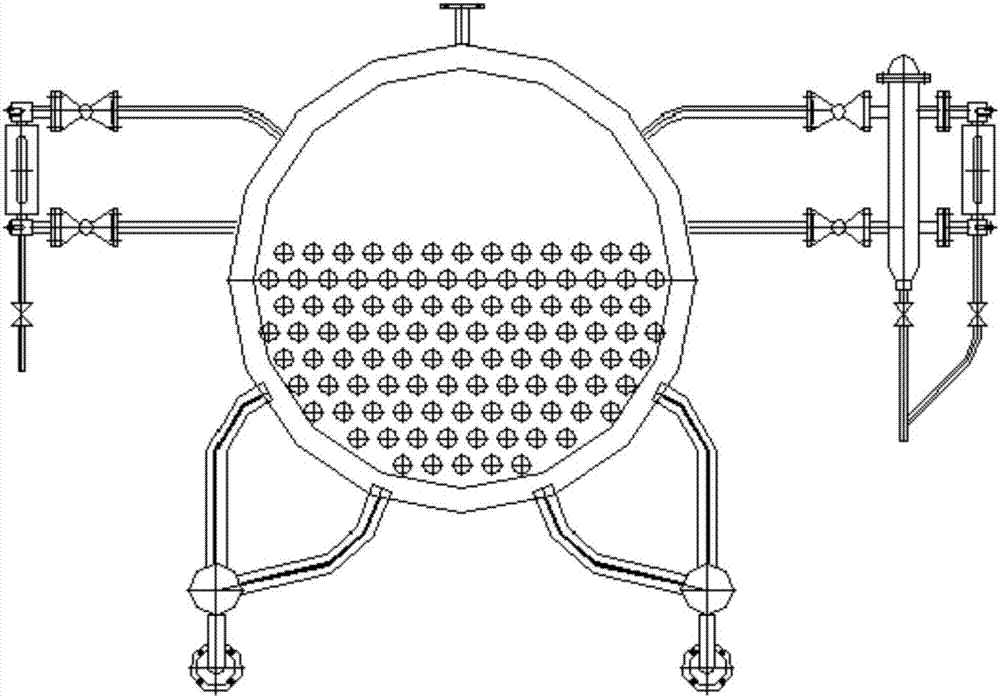

Magnetization oxygen-enriched energy conservation and emission reduction system of gaseous suspension roaster

The invention relates to a magnetization oxygen-enriched energy conservation and emission reduction system of a gaseous suspension roaster. The magnetization oxygen-enriched energy conservation and emission reduction system comprises a raw air supply fan, two multi-duct pressure equalization distribution tanks, a double-stage booster roots pump set, an intelligent PLC (programmable logic control) system and an oxygen-enriched gas output pipeline. The raw air supply fan is connected with the two multi-duct pressure equalization distribution tanks, cyclone concave-convex thermal separation magnetic groups are arranged in the two multi-duct pressure equalization distribution tanks and are connected with an inlet of the double-stage booster roots pump set by vacuum absorption pipelines, the double-stage booster roots pump set is connected with an oxygen-enriched injection point of the gaseous suspension roaster by the oxygen-enriched gas output pipeline, the raw air supply fan, an intelligent oxygen analyzer and an intelligent gas flow meter are connected with the intelligent PLC system, and the intelligent PLC system is connected with a remote computer. The magnetization oxygen-enriched energy conservation and emission reduction system has the advantages that the combustion speeds can be increased, and complete combustion can be promoted; ignition temperatures of fuel can be lowered, combustion environments can be optimized, and the service life of the roaster can be prolonged; the yield of products can be increased, the quality of the products can be improved, and the post-combustion smoke quantity can be reduced.

Owner:YANTAI JIUZHOU ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH

Process for improving combustion efficiency of cement kiln by utilizing high-oxygen content air

InactiveCN105864815AHigh flame temperatureBurn fasterIndirect carbon-dioxide mitigationAir/fuel supply for combustionMembrane methodDecomposition

The invention provides a process for improving combustion efficiency of a cement kiln by utilizing high-oxygen content air. The process comprises the following steps: manufacturing high-oxygen content air with an oxygen content of 28% through a membrane method oxygen enrichment technology, and feeding 10-15% of the high-oxygen content air into a coal injection duct at the head part of the kiln through a blast pipe to combust pulverized coal in the kiln; sending 20-25% of the high-oxygen content air into delivery air of a coal injection duct at the tail part of the kiln through a blast pipe to combust pulverized coal in a decomposition furnace; sending 60-70% of the high-oxygen content air to an air outlet of a cooling fan at a high-temperature section of a grate cooler through a blast pipe, so that the high-oxygen content air and the cooling water are together sent into the grate cooler, and through heat exchange, the generated high-temperature secondary air with relatively high oxygen content is supplied to combust pulverized coal at the head part of the kiln. The process provided by the invention has the advantages of rapidly improving the temperature of the cement kiln, reducing the ignition temperature of the pulverized coal, improving the combustion speed of the pulverized coal, promoting the pulverized coal to be sufficiently combusted, improving the burn-off rate of the pulverized coal, reducing the smoke exhaust rate and saving the fuel. According to the process, the pulverized coal combustion environment of the kiln is improved, the cement quality is improved, and favorable economic benefit and social environment-friendly benefit are provided.

Owner:枣庄中联水泥有限公司

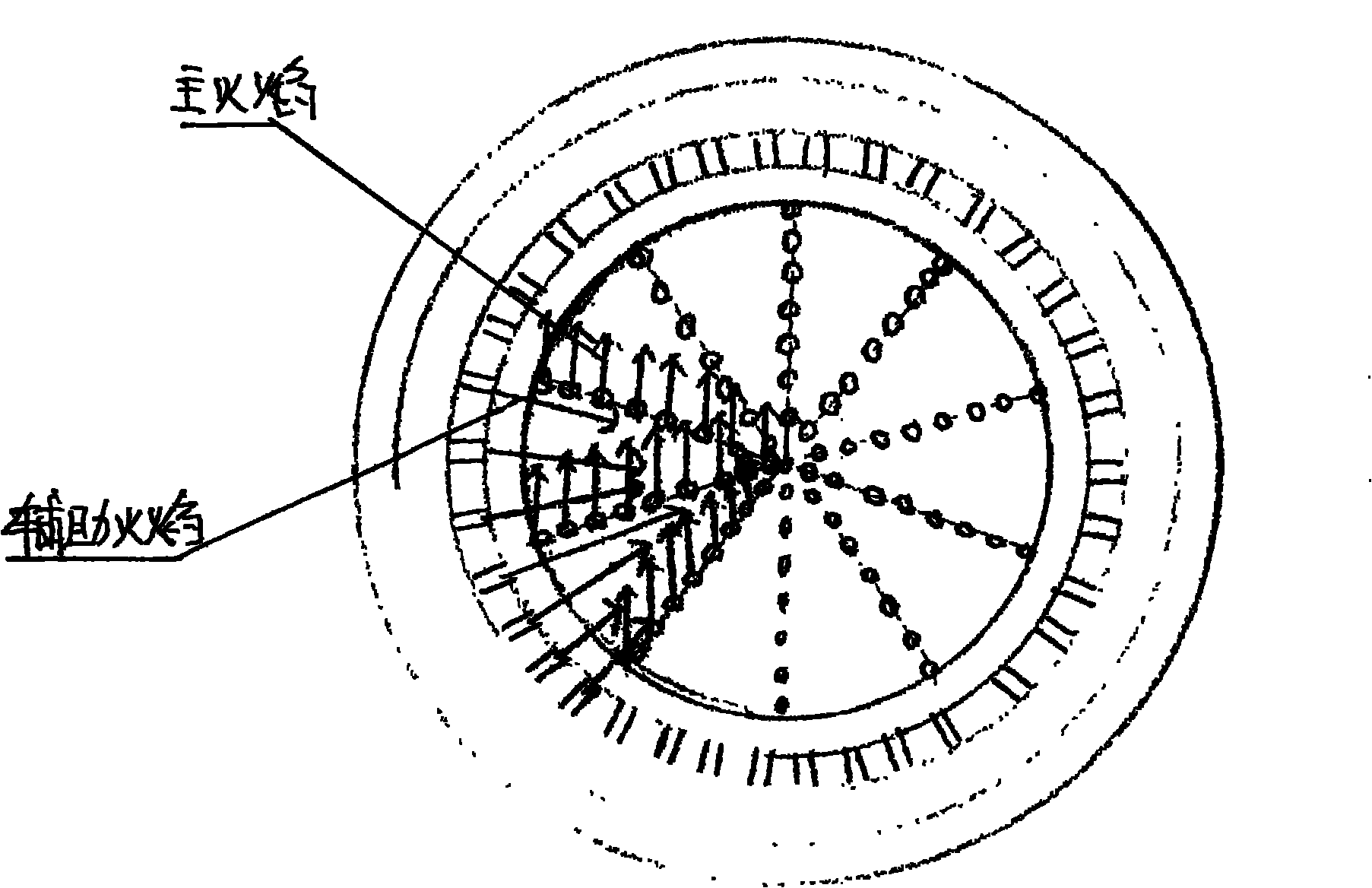

Ignition method for compound burner

The invention relates to an ignition method for a compound burner. The invention is characterized in that the compound burner is combined by a main burner and an auxiliary burner; mixed gas flowing out from the auxiliary burner is partially-premixed burning gas; mixed gas flowing out from the main burner is fully-premixed burning gas; and heat generated by firstly burning the atmospheric partially-premixed gas flowing out from the auxiliary burner is provided for the burning of the fully-premixed burning gas of the main burner, thus a continuously flowing high-temperature environment and a fluid flame-type flame-stabilizing carrier are created for the fully-premixed burning gas of the main burner so that the rapid, full and sufficient burning reaction of the fully-premixed burning gas of the main burner can be realized without the arrangement of a real flame-stabilizing carrier or under the conditions of crash and revolution, back turning and heat storage, and the fully-premixed burning of the main burner can be realized.

Owner:周佳强

Method for preparing emulsified fuel oil

InactiveCN101698804AHigh transparencyImprove stabilityRefining by water treatmentFuel oilPetrochemical

The invention relates to a method for preparing emulsified fuel oil, which comprises the following steps: 1) adding methanol or ethanol into oleic acid or fatty acid, and stirring for forming an acid phase; 2) adding the methanol or the ethanol into ammonia, and stirring for forming a base phase; 3) adding the base phase into the acid phase while stirring for preparing an emulsifier; and 4) adding clean water into petrochemical finished oil, firstly stirring till milk white, then adding the emulsifier, stirring till that liquid is transparent and clear, standing and then filtering, thereby preparing the emulsified fuel oil. The method can also add a diluent, a modifier, a protective agent and the like according to needs. The emulsified fuel oil has the advantages of simple production technology, extensive resources of raw materials, cheap price, high product stability and good intersolubility with the petrochemical finished oil.

Owner:陈映波

Turboprop recirculation combustion chamber and turboprop

ActiveCN113137639BReduce vibrationMeet the needs of single-plane installationContinuous combustion chamberGas turbine plantsThermodynamicsCombustion chamber

The invention discloses a return combustion chamber of a turboprop engine and a turboprop engine, comprising a combustion chamber casing, a diffuser, a flame tube, an exhaust elbow and an installation assembly. The combustion chamber casing comprises an interconnected combustion outdoor casing section, gas turbine casing section and power turbine casing section, the diffuser is located upstream of the return combustion chamber and is used to provide high pressure air for the flame tube, the exhaust elbow is at the airflow outlet of the flame tube and is used to dissipate the high temperature generated in the flame tube. The gas is folded and discharged. The casing section outside the combustion chamber, the casing section of the gas turbine and the casing section of the power turbine are connected to form an integral structure. The installation components are arranged on the outer circumferential wall of the casing of the combustion chamber, and the installation components are attached to the casing surface of the combustion chamber. The mid-section of the mounting assembly coincides with the section where the center of gravity of the engine is located. The turboprop engine returns to the combustion chamber of the invention, which satisfies the requirement of single-plane installation of the engine and realizes the installation requirement of the whole machine.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Semicoke combustion desulfurization and denitrification additive as well as preparation method and application thereof

InactiveCN111732989AFully contactedIncrease contact areaSolid fuelsFuel additivesEnvironmental engineeringSulfur oxide

The invention relates to a semicoke combustion desulfurization and denitrification additive. The additive comprises the following components in parts by weight: 10-50 parts of ammonium chloride; 10-30parts of magnesium hydroxide; and 1-10 parts of sodium tetraborate. Compared with the prior art, the semi-coke combustion efficiency can be improved, sulfur oxides and nitrogen oxides in combustion products are reduced, the pollution of semi-coke combustion to the environment is reduced, and the semi-coke combustion device has the advantages of fuel saving, emission reduction, low production cost, good economic benefits, convenience in storage and transportation and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

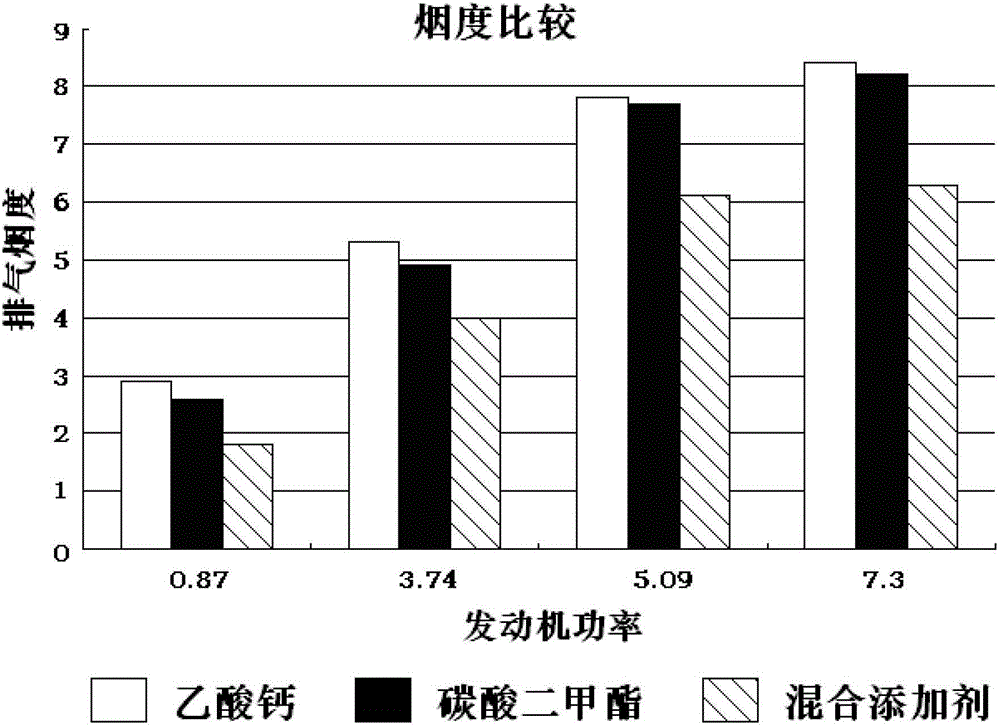

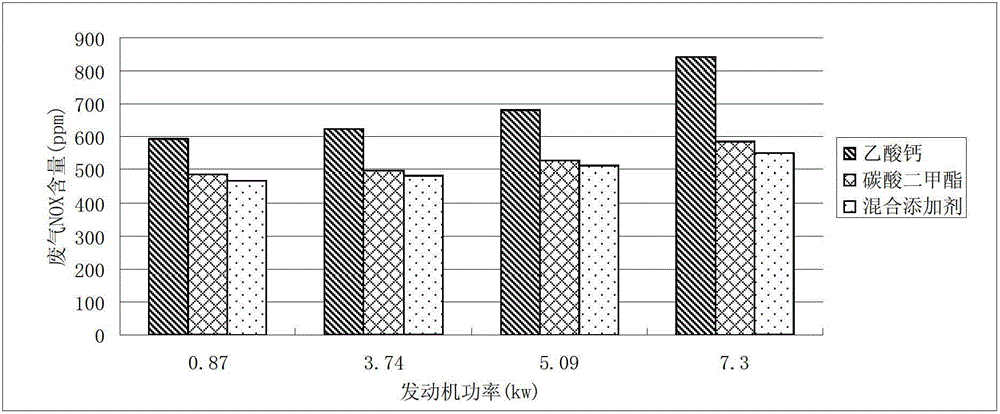

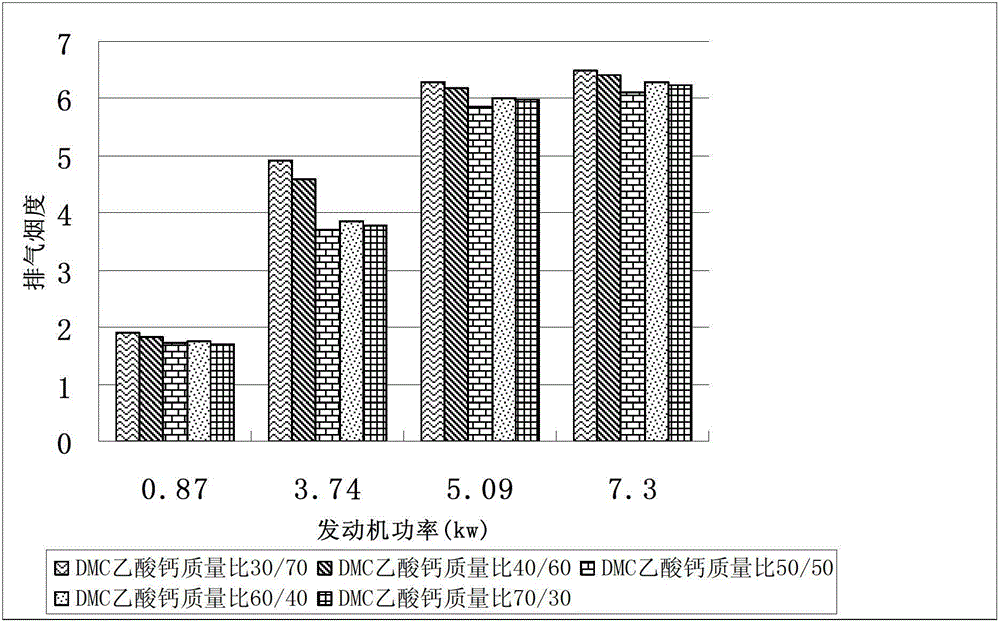

Additive for reducing emission of charcoal smoke and harmful gas of diesel engine and preparation method thereof

InactiveCN103113942BSignificant emission reductionEmission reduction effect is obviousLiquid carbonaceous fuelsFuel additivesEngineeringSolvent

The invention discloses an additive for reducing the emission of the charcoal smoke and harmful gas of a diesel engine and a preparation method thereof. The additive comprises a solute and a solvent, wherein the solute comprises the mixture of dimethyl carbonate and calcium acetate, and the solvent is ethanol or a mixture containing ethanol. With the adoption of the additive capable of reducing the emission of the waste gas harmful ingredients and charcoal smoke of a diesel engine and the preparation method for the same provided by the invention, the burning environment of burning diesel oil is improved from different aspects relative to the prior art, the limitation of the traditional single improvement means is broken, and cost can be reduced while combustion-supporting efficiency is ensured; simultaneously, a certain effect can be generated on the emission reduction of harmful ingredients in tail gas.

Owner:SOUTHEAST UNIV

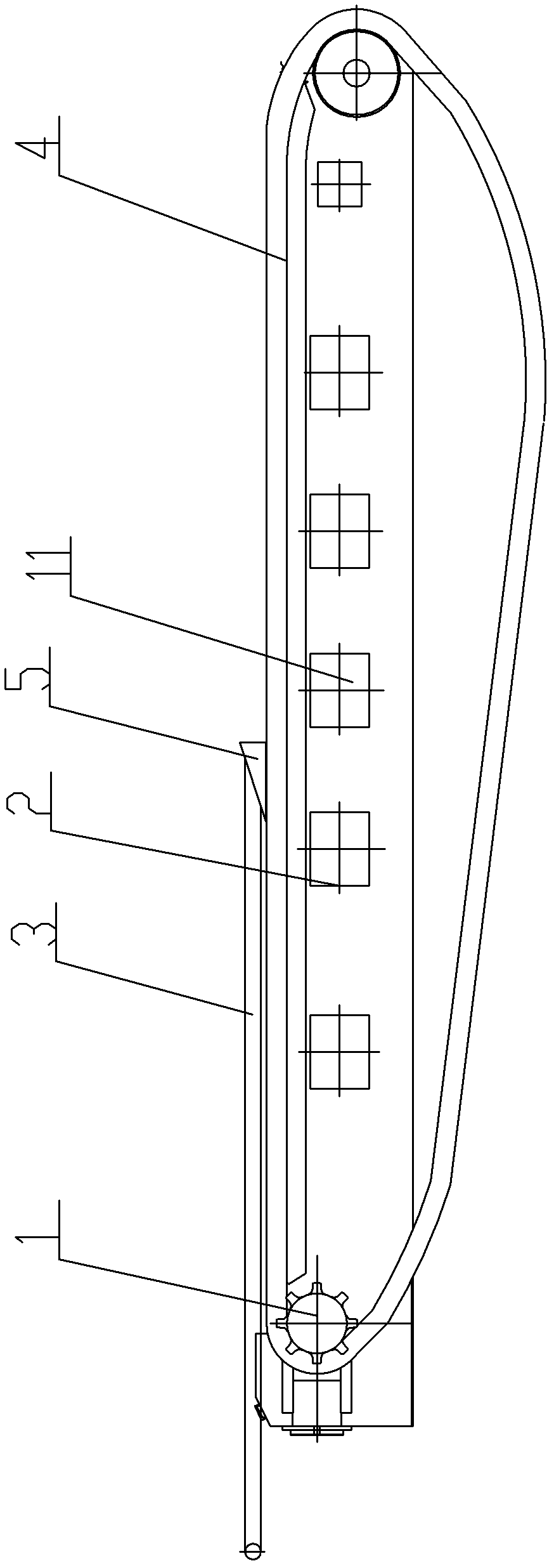

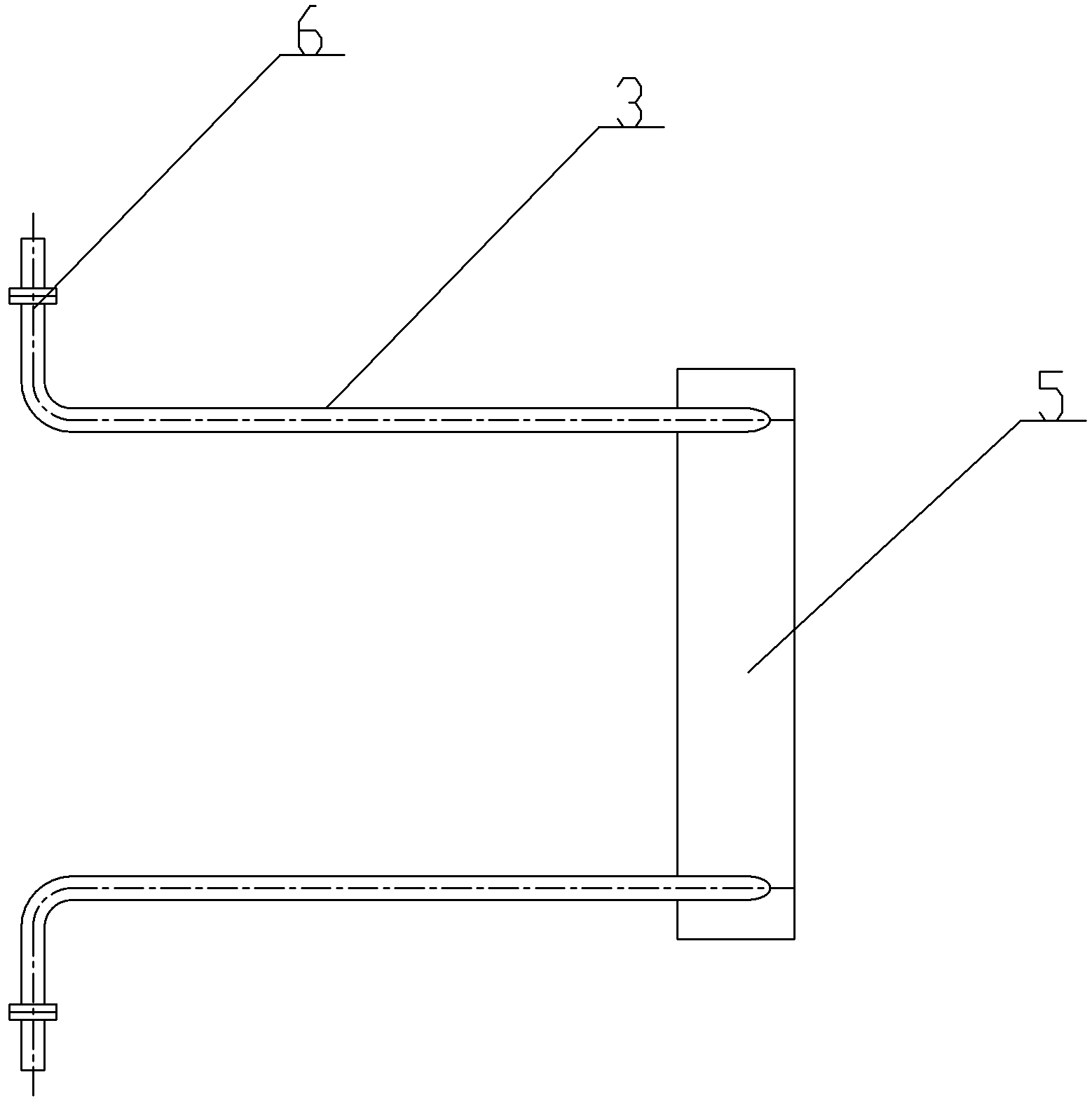

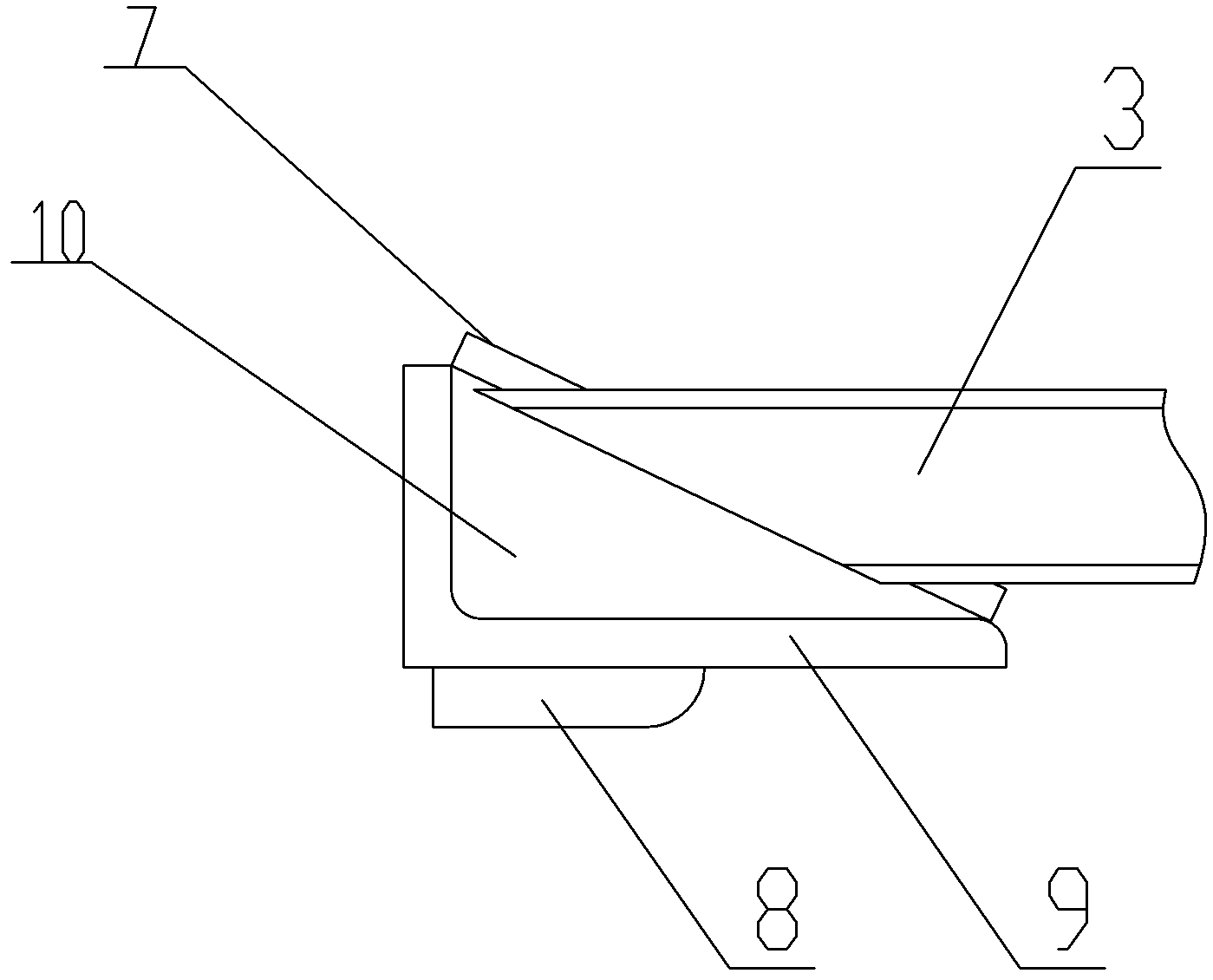

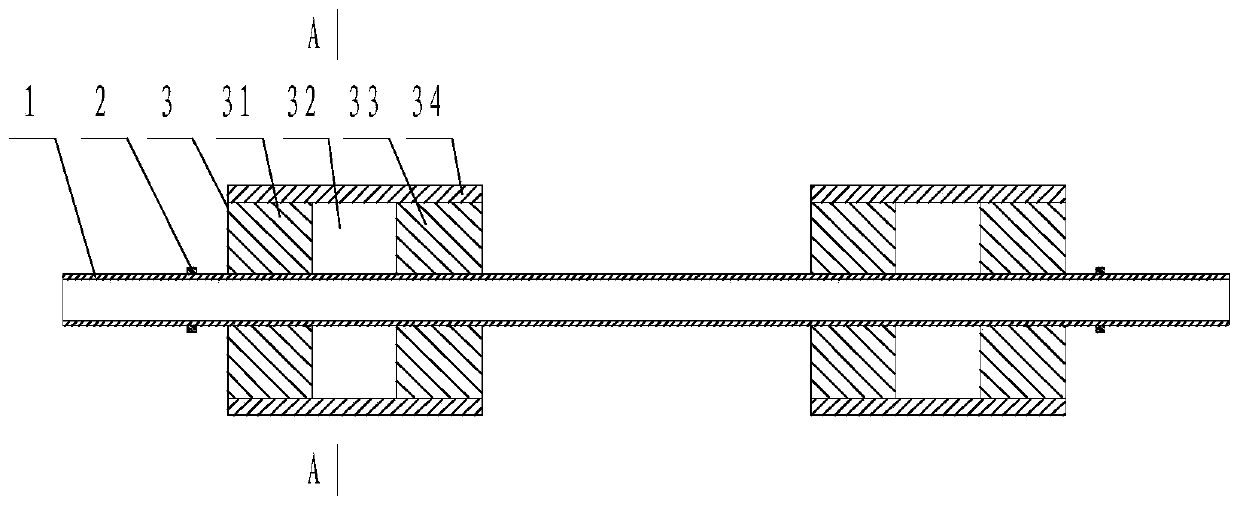

Coal loosening device for traveling grate stoker

The invention relates to a coal loosening mechanism for a traveling grate stoker, in particular to a coal loosening device for a traveling grate stoker, which belongs to the technical field of traveling grate stokers of boilers. The coal loosening device is used for loosening a coal seam when coal passes through the traveling grate stoker, improving a ventilating environment of the coal seam and leading the coal to be combusted more sufficiently, and mainly comprises a coal loosening support and a cooling water pipe, and the coal loosening support is placed on a grate surface and mounted between a third air supply bin and a fourth air supply bin. The cooling water pipe is connected onto the coal loosening support, and a pipe body of the cooling water pipe is fixed onto a coal hopper or a front screen door of the chain grate stoker by a omega-shaped hoop. The coal loosening device is simple, compact and reasonable in structure, the hardened coal seam can be loosened, coal can be combusted more sufficiently, applicability to different types of coal is enhanced, the coal seam and loose and adhered ash generated after the coal is combusted are loosened, a combustion environment of the coal seam is enhanced, and the purpose of durable and stable combustion is achieved.

Owner:WUXI HUAGUANG IND BOILER

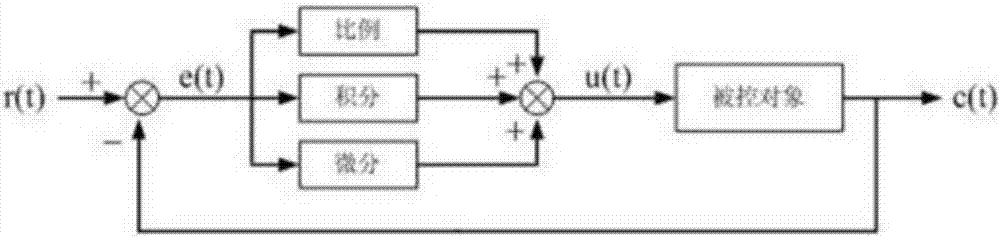

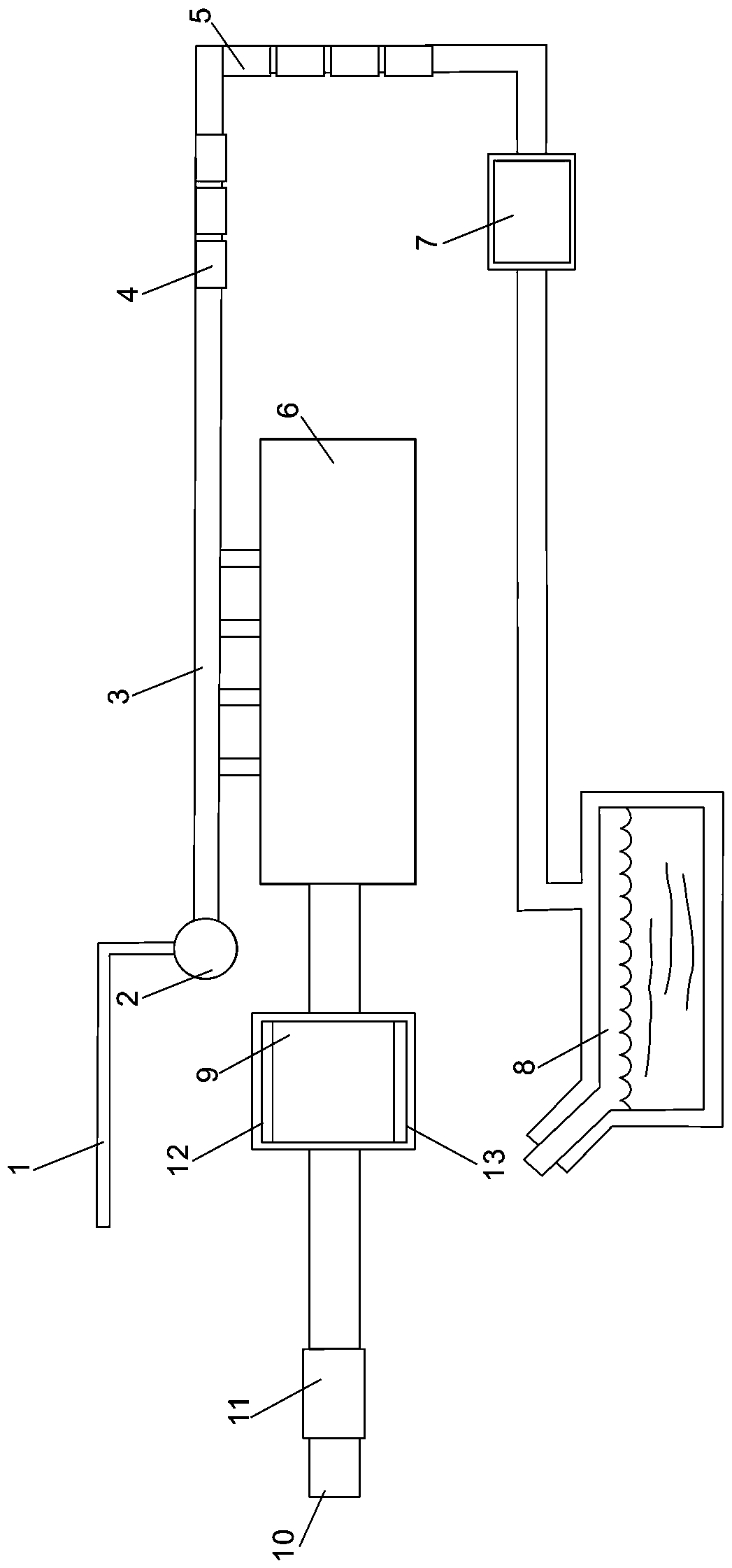

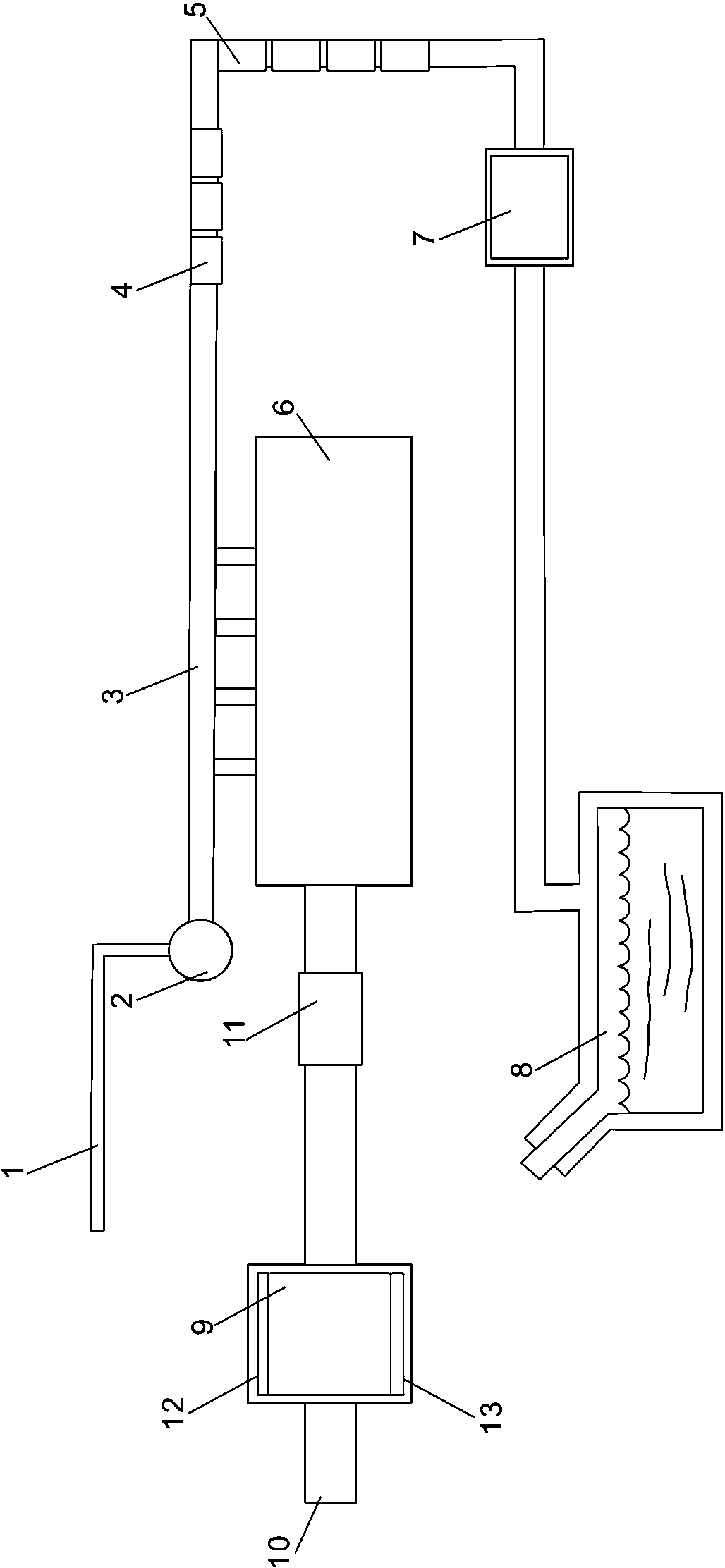

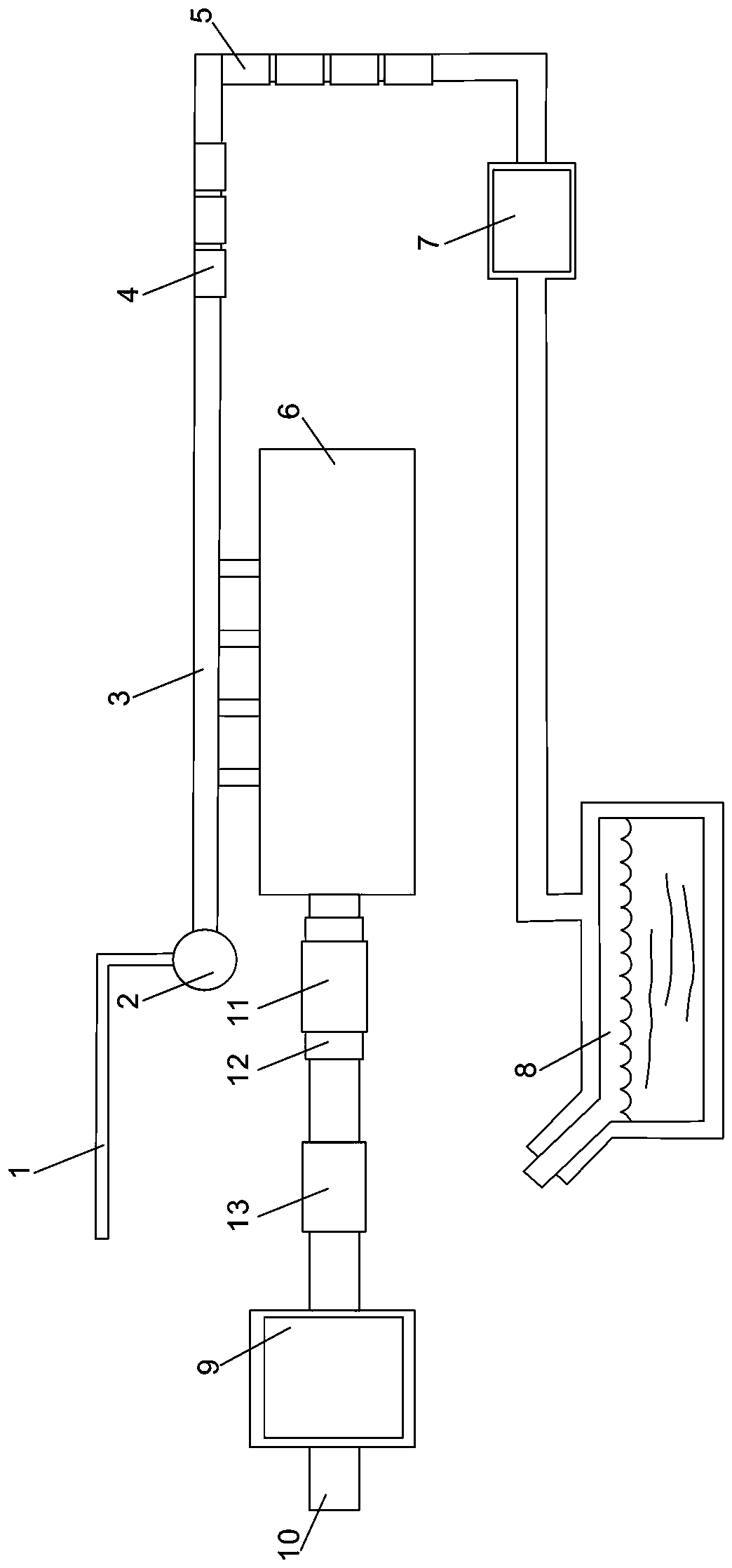

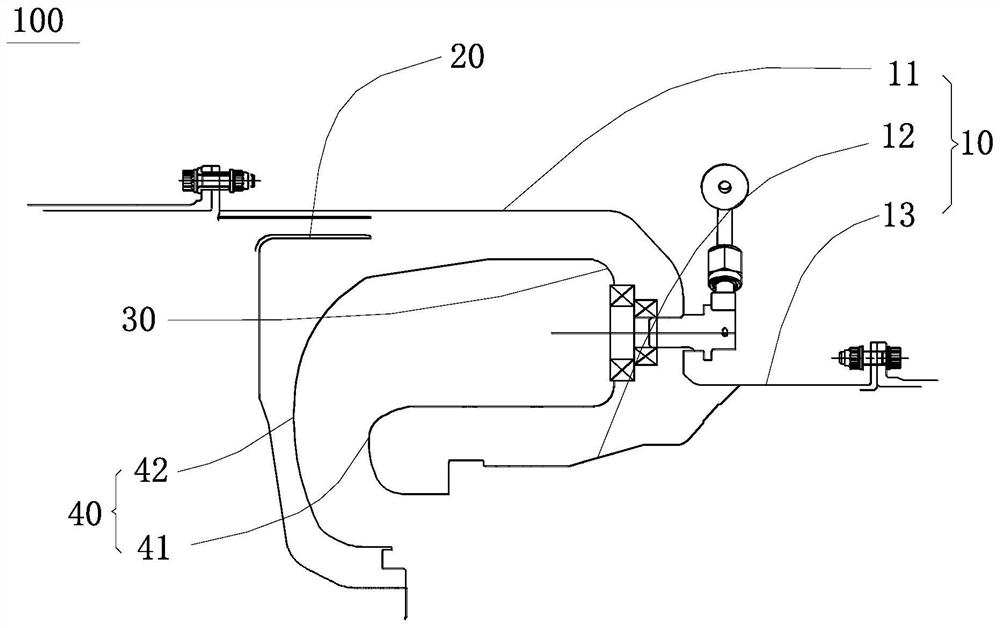

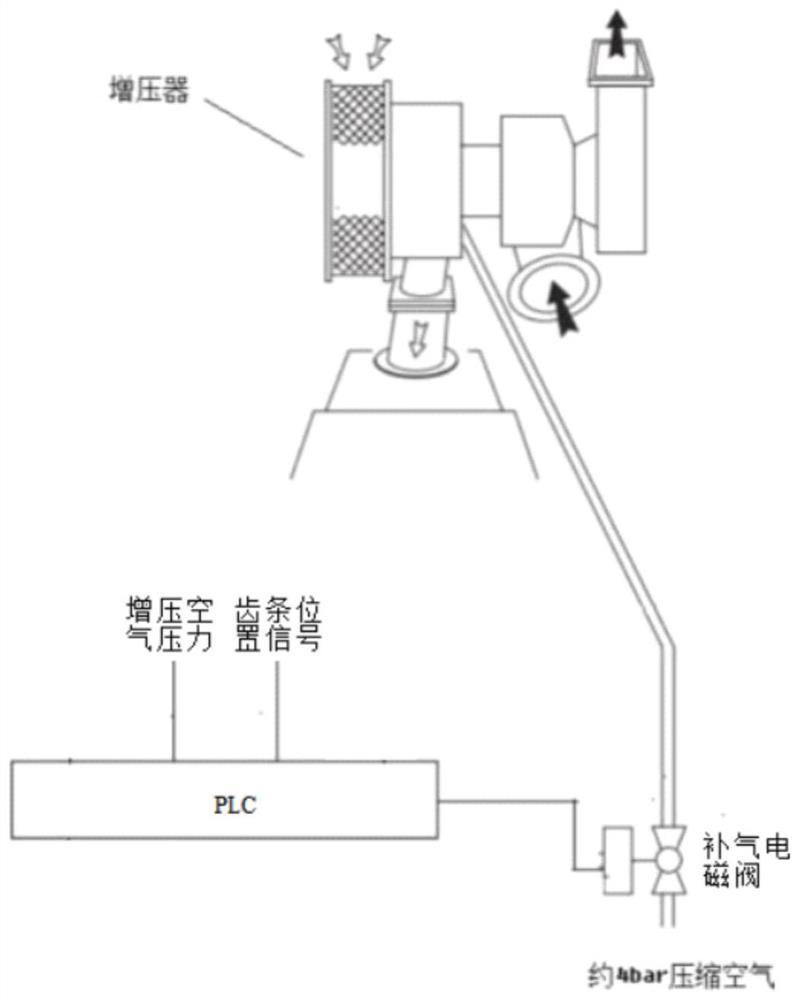

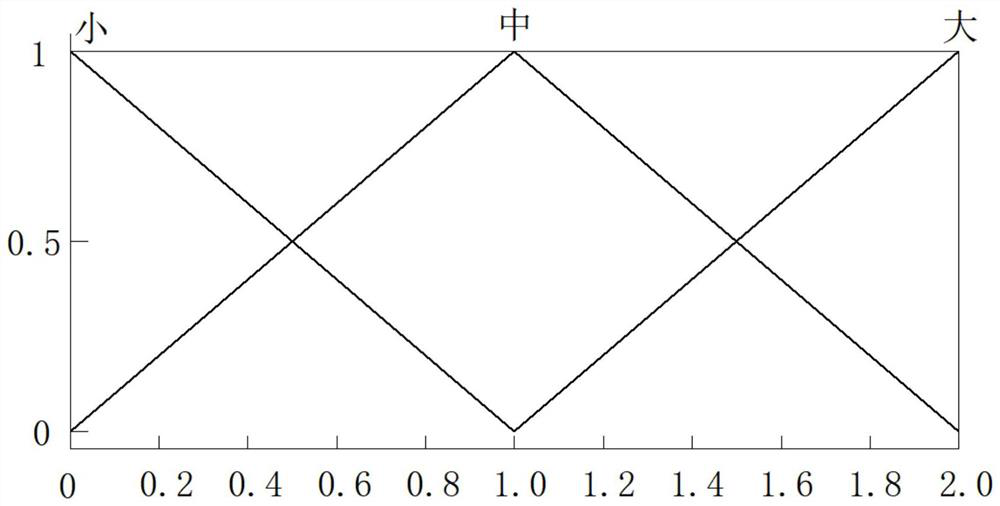

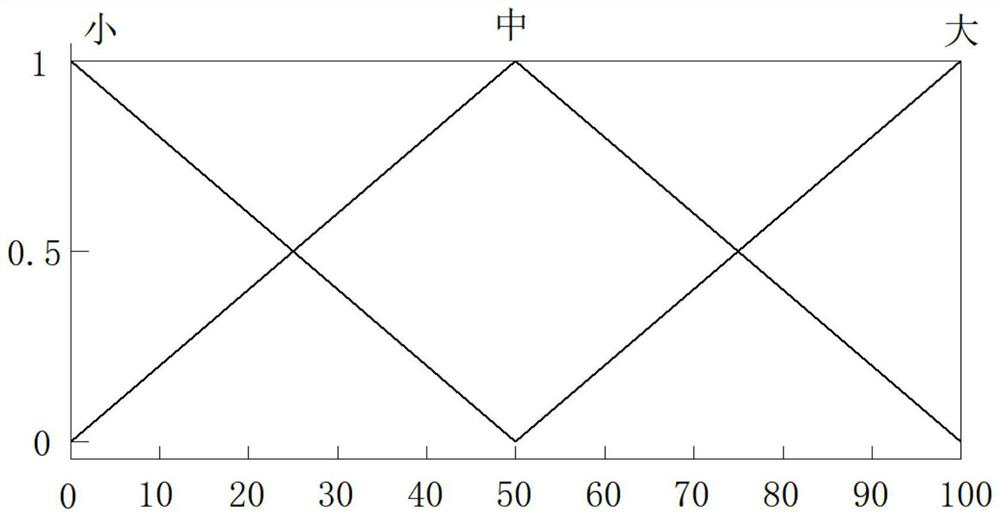

Diesel engine air supply system based on fuzzy algorithm optimization and air supply method thereof

PendingCN114483289AImprove the combustion environmentReduce black smokeCombustion enginesElectromagnetic valveAlgorithm

The invention discloses a diesel engine air supply system based on fuzzy algorithm optimization. The diesel engine air supply system comprises a pressurized air pressure collector, a rack position signal collector and a control processor. The pressurized air pressure collector is in circuit connection with the control processor and is used for collecting a pressurized air pressure value; the rack position signal collector is in circuit connection with the control processor and is used for collecting the rack position of a diesel engine fuel rack; the control processor is in circuit connection with the air supply electromagnetic valve, and the control processor forms a control signal for controlling the on-off of the air supply electromagnetic valve through a fuzzy algorithm based on the pressurized air pressure value and the position of the rack. The invention can increase the rotating speed of the supercharger at the moment of sudden loading of the diesel engine, accelerate the increase of air pressure entering the cylinder, improve the combustion environment in the cylinder, reduce black smoke generated by the diesel engine, improve the working performance of the diesel engine and realize the purpose of environmental protection.

Owner:CSSC MARINE POWER

methane gas catalytic combustor

InactiveCN102851089BBurn fasterIncreased Flame Correction EfficacyGaseous fuelsWater vaporDissolution

The invention discloses a methane gas catalytic combustion agent. The main component of natural gas is methane gas, the liquefied natural gas has methane content of 99.9% generally, and the general gaseous natural gas belongs to raw gas, and may contain a small amount of ethane, propane or butane resulting from noncomplete purification such as dewatering and desulfurization, and it also contains hydrogen sulfide, carbon dioxide, nitrogen and water vapor, and trace inert gas such as helium and argon. It is characterized in that a liquid catalytic combustion agent is added in the natural gas, wherein when the natural gas weight is 100 kg, the dosage of the liquid catalytic combustion agent is 2.6-3.6 kg. Due to sufficient dissolution of the liquid catalytic combustion agent and the methane gas, high-efficiency catalytic combustion can be carried out, to increase thermal reaction speed of methane molecules, flame temperature and combustion velocity, decrease combustion temperature, improve heat utilization ratio of combustible gas, and enhance safety thereof.

Owner:张国平

Method for preparing emulsified fuel oil

InactiveCN101698804BHigh transparencyImprove stabilityRefining by water treatmentFuel oilPetrochemical

The invention relates to a method for preparing emulsified fuel oil, which comprises the following steps: 1) adding methanol or ethanol into oleic acid or fatty acid, and stirring for forming an acid phase; 2) adding the methanol or the ethanol into ammonia, and stirring for forming a base phase; 3) adding the base phase into the acid phase while stirring for preparing an emulsifier; and 4) adding clean water into petrochemical finished oil, firstly stirring till milk white, then adding the emulsifier, stirring till that liquid is transparent and clear, standing and then filtering, thereby preparing the emulsified fuel oil. The method can also add a diluent, a modifier, a protective agent and the like according to needs. The emulsified fuel oil has the advantages of simple production technology, extensive resources of raw materials, cheap price, high product stability and good intersolubility with the petrochemical finished oil.

Owner:陈映波

A dual-loop gasification combustion system, method and application based on circulating fluidized bed

ActiveCN106402911BEasy to adjust controlEasy to prepareLighting and heating apparatusGasification processes detailsCombustion systemFluidized bed

The invention discloses a double-circuit gasification and combustion system based on a circulating fluidized bed and a method and application thereof. The double-circuit gasification and combustion system comprises a gasifier, a primary separator, a heat exchanger, a secondary separator, a boiler and an ash bin, wherein the inlet of the primary separator communicates with the outlet of the gasifier; the gas outlet of the primary separator communicates with the heat medium inlet of the heat exchanger; the heat medium outlet of the heat exchanger communicates with the inlet of the secondary separator; gas subjected to primary separation is subjected to heat exchange for cooling in the heat exchanger; the gas outlet of the secondary separator communicates with the boiler; the solid outlet of the primary separator communicates with the inlet of a first material return valve; one side outlet of the first material return valve communicates with a first material return opening of the gasifier, and the other side outlet of the first material return valve communicates with the ash bin; the solid outlet of the secondary separator communicates with the inlet of a second material return valve; and one side outlet of the second material return valve communicates with a second material return opening of the gasifier, and the other side outlet of the second material return valve communicates with the ash bin.

Owner:山东百川同创能源有限公司

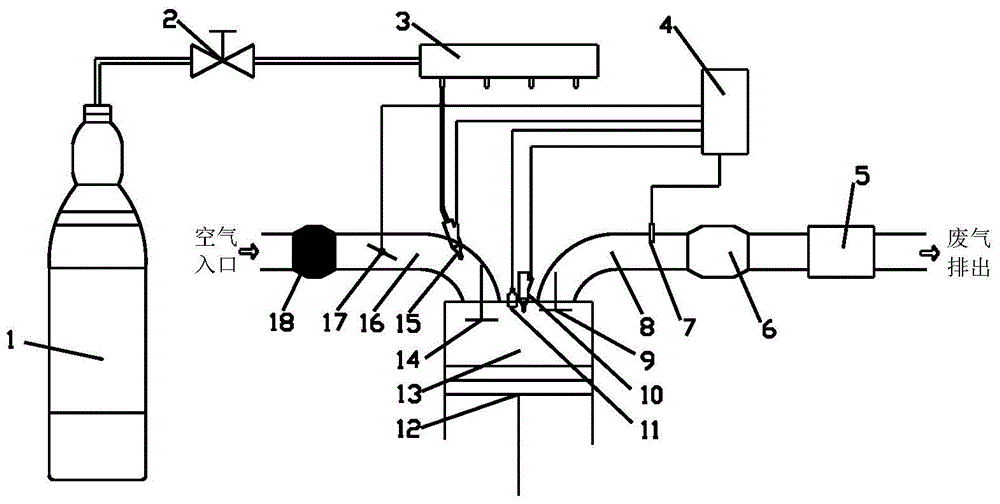

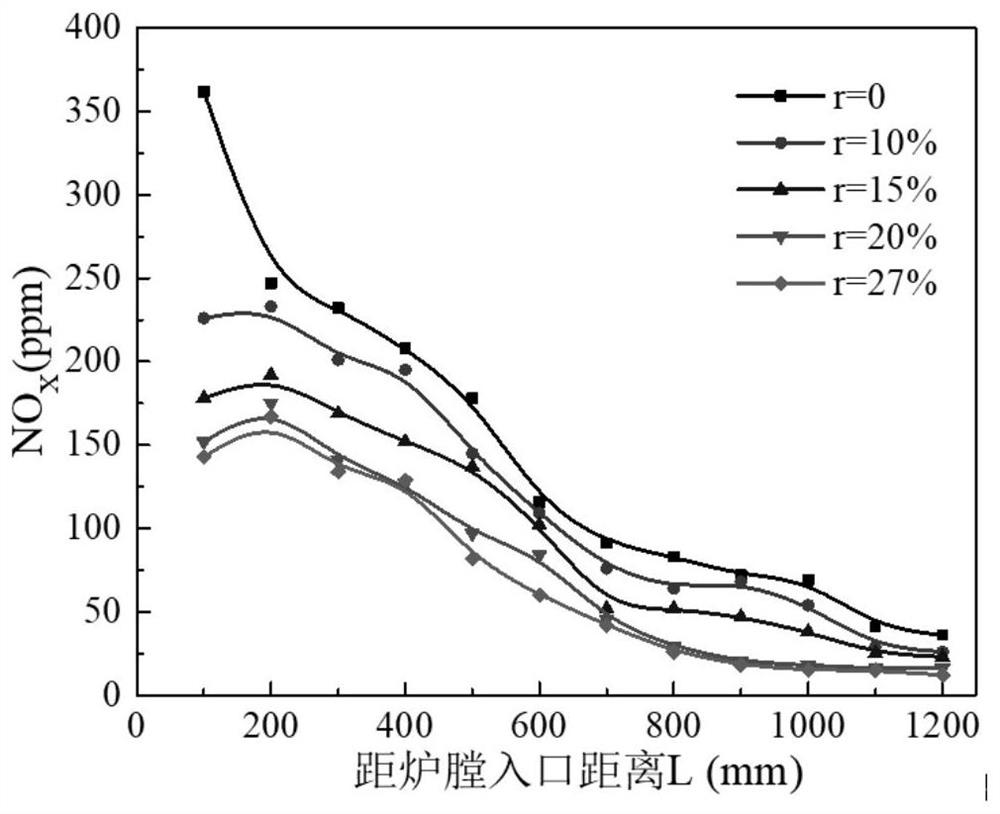

Experimental process used for ultralow emission of pulverized coal combustion

PendingCN113048470AAchieve self-stabilized combustionFully burnt outCombustion using gaseous and pulverulent fuelBurnersThermodynamicsCombustion

The invention discloses an experimental process used for ultralow emission of pulverized coal combustion, and belongs to the technical field of pulverized coal combustion emission. In the experimental process, a combustion unit adopts pulverized coal as a combustion raw material, air required by combustion is introduced into a furnace body through a primary air pipe, a secondary air pipe and an over-fire air pipe, meanwhile, part of flue gas generated by combustion of the combustion unit is conveyed into the furnace body through a flue gas circulation unit, and therefore the combustion environment of the pulverized coal is improved, self-stabilization combustion of the pulverized coal is achieved, and it is guaranteed that the pulverized coal can be fully burnt out; and flue gas generated by the combustion unit is subjected to dust removal and denitration through a dust removal and denitration unit and then enters a desulfurization unit to be desulfurized, and the content of pollutants in the flue gas is effectively reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Efficient and energy-saving environment-friendly high-pressure burner

InactiveCN101706103BWell mixedImprove combustion efficiencyGaseous fuel burnerCombustorCombustion chamber

Owner:BEIJING UNIV OF TECH

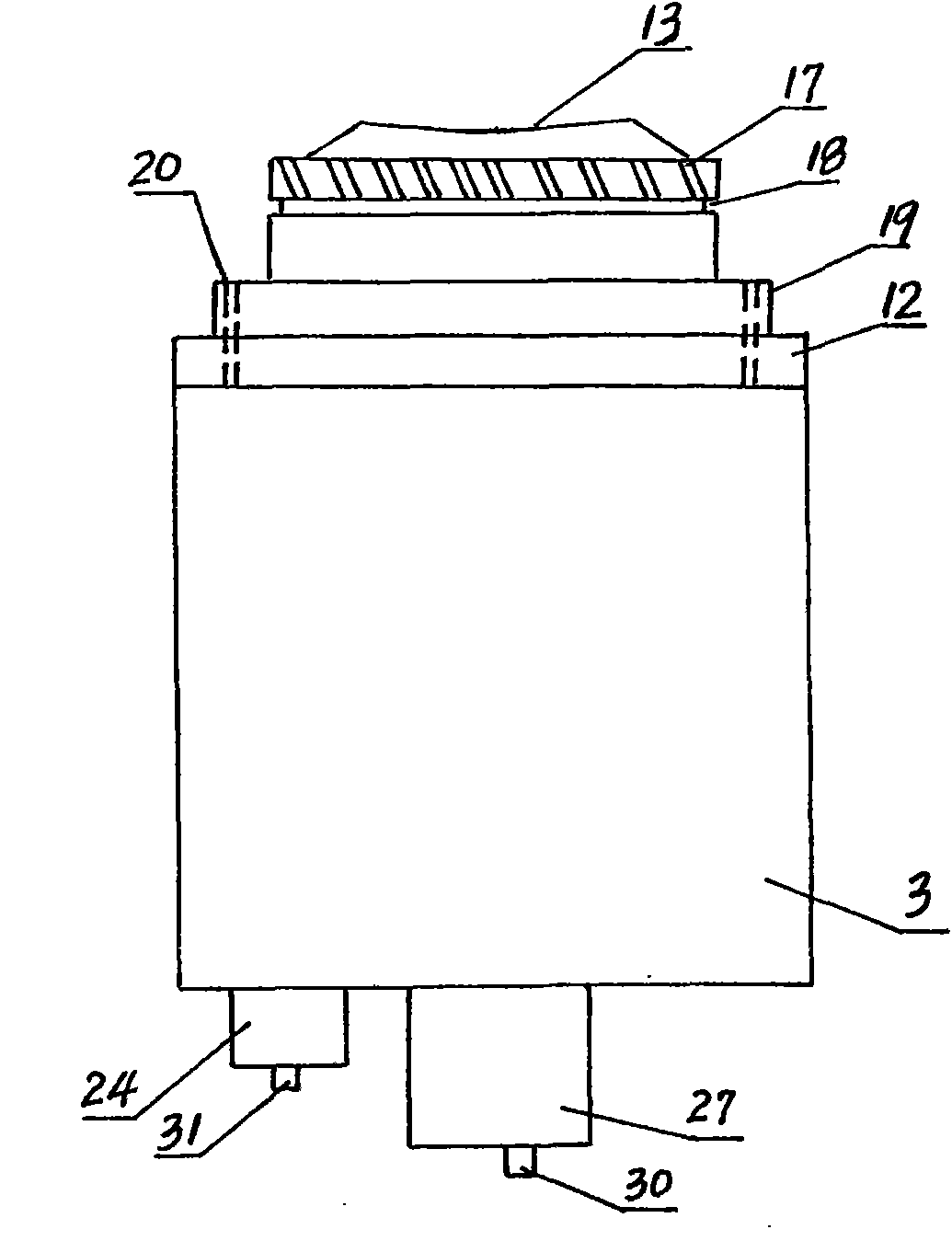

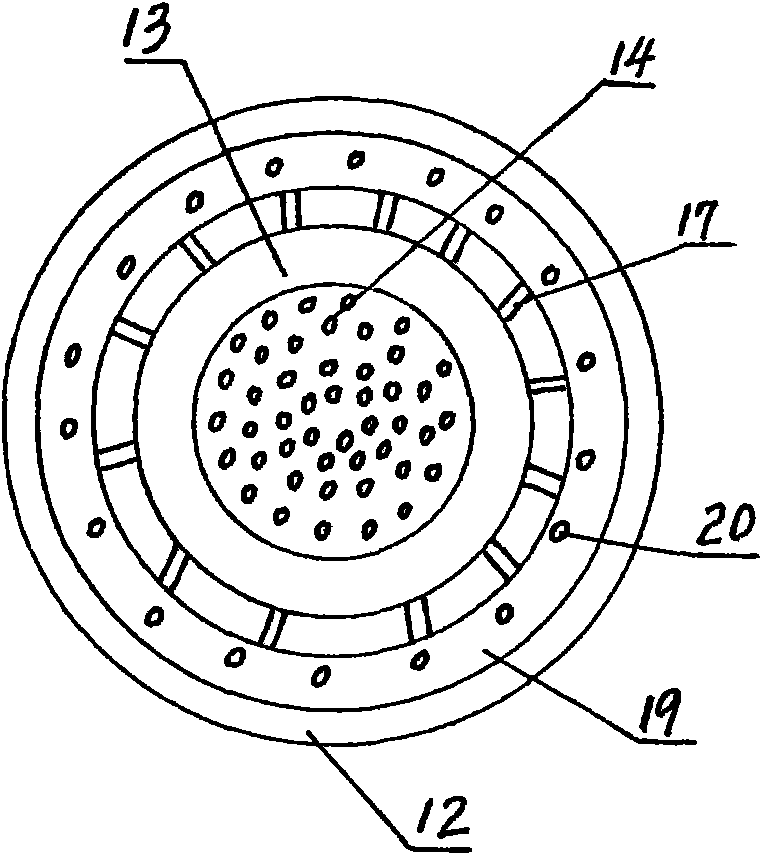

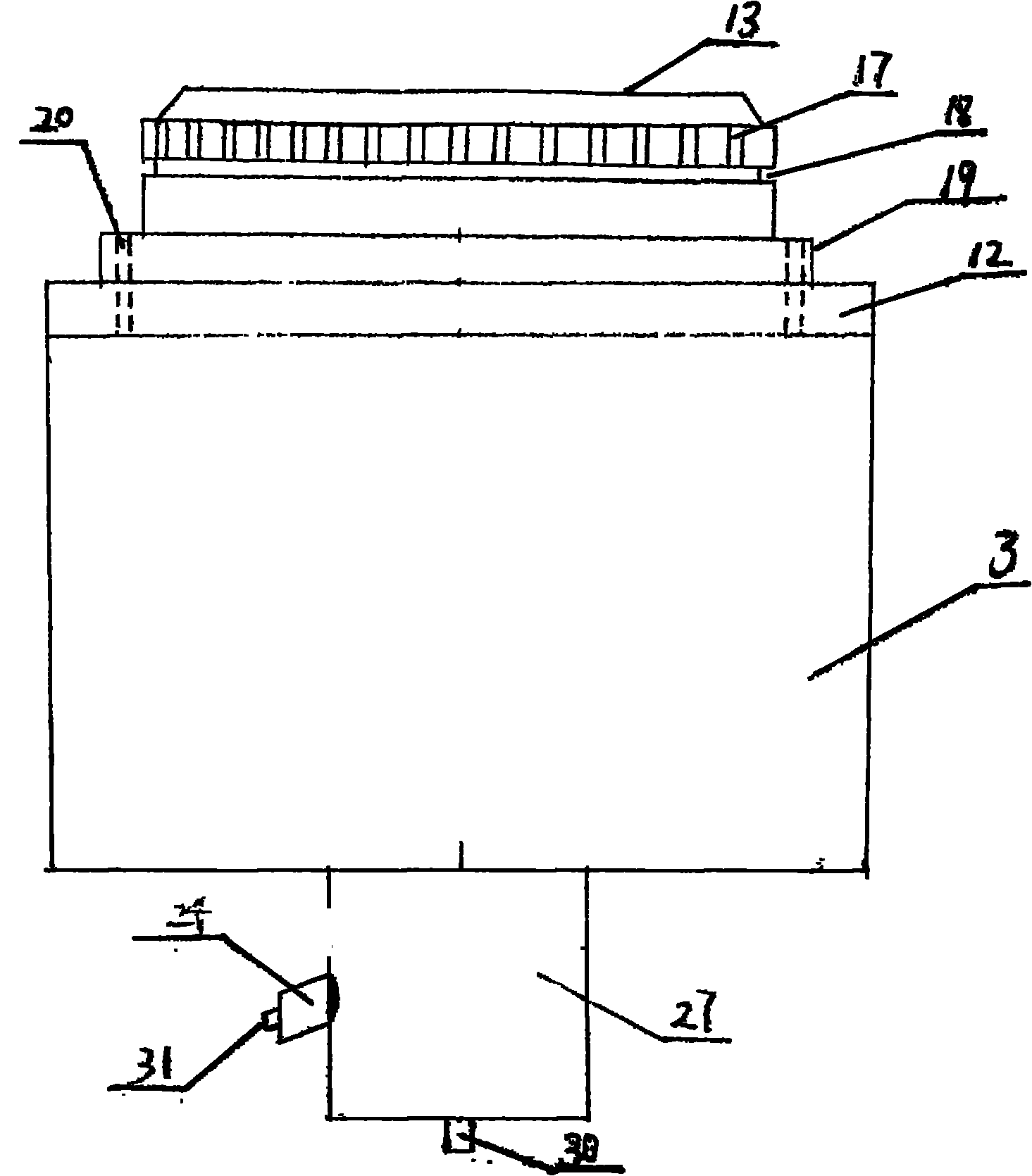

Compound burner

InactiveCN102042593AEfficient deliveryImprove the combustion environmentGaseous fuel burnerCombustorEngineering

The invention relates to a compound burner characterized by comprising a main burner and an auxiliary burner and being mainly composed of an inner core, an upper cover cap and a base, wherein an upper end cover of the inner core is provided with penetrated main burning nozzle holes which are communicated with an upper and a lower main gas chambers to form the main burner; auxiliary burning nozzle holes are arranged in a circle on the outer wall of the inner core below the upper end cover of the inner core, a circular groove is arranged at the lower ends of the auxiliary burning nozzle holes on the outer wall of the inner core, a circular auxiliary gas premixing spacer is arranged at the lower ends of the inner core and the upper end of a convex ring on the outer wall of the inner core, penetrated auxiliary burning channels are arranged in a circle in the auxiliary gas premixing spacer, the upper cover cap is covered on the inner core and provided with an inwards-inclined surface on the inner wall, an upper auxiliary gas chamber is formed among the inclined surface of the inner wall of the upper cover cap, the outer wall of the inner core part and the groove in the outer wall of the inner core, and the auxiliary burning nozzle holes, the upper auxiliary gas chamber, the auxiliary burning channels and a lower auxiliary gas chamber are communicated to form the auxiliary burner; and a mixed gas input pipeline of the auxiliary burner is sheathed outside a mixed gas input pipeline of the main burner. As shown in figure 4, the main burning nozzle holes are reasonably arranged, so that flame of the auxiliary burner can smoothly flow to the center of main flame from the outer circle in the horizontal direction. The auxiliary flame can uniformly heat the main flame, thereby being a stable fluid flame type diffusing carrier for the main flame. Thus, the main and the auxiliary burning systems have the advantages of high efficiency, energy saving and environment protection.

Owner:周佳强

Gasoline engine protection device

PendingCN110863930AHigh calorific valueEmission reductionInternal combustion piston enginesThermal treatment of fuelGasolineProcess engineering

The invention discloses a gasoline engine protection device which comprises a first oil pipe and a second oil pipe. Two or more groups of magnetizers are arranged outside the first oil pipe, and the distance between the opposite end faces of the two adjacent groups of magnetizers is 3-8 cm, a heater is arranged on the outer wall of the second oil pipe, the second oil pipe is arranged to be of a spiral tubular structure, and the magnetizers are arranged in the spiral pipe; and each magnetizer comprises an outer cylinder, wherein an annular magnetic block is arranged at the middle position in the outer cylinder, the left end and the right end of the outer cylinder are connected with a left end cover and a right end cover through threads correspondingly, the annular magnetic block is evenly divided into N equal parts of arc-shaped magnetic blocks, and N is an odd multiple of 2. The gasoline engine protection device is capable of recombining the molecular structure of gasoline, increasingthe temperature and the pressure of a cylinder of a gasoline engine, remarkably improving the power, enabling the combustion environment in the cylinder to be better, effectively fully combusting actual gum and wax in an oil product, effectively removing carbon deposition of the engine and reducing the noise and emission of the engine.

Owner:高梦阳 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com