System and method for detecting atmosphere components in rotary hearth furnace in real time and optimally controlling combustion

A real-time detection and combustion optimization technology, which is applied in combustion methods, combustion control, and fuel supply regulation. Combustion efficiency and guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

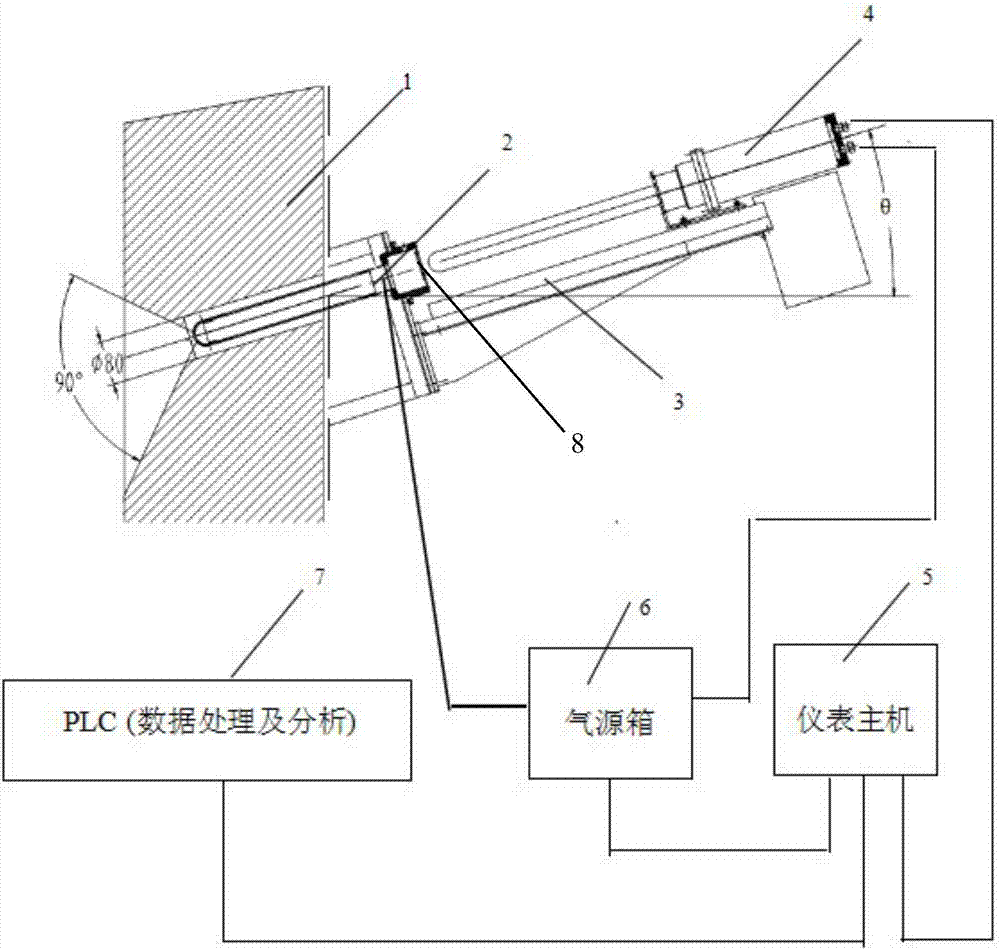

[0051] In this embodiment, the present invention provides a system for real-time detection of atmosphere components in a rotary hearth furnace and combustion optimization control system, the system mainly includes:

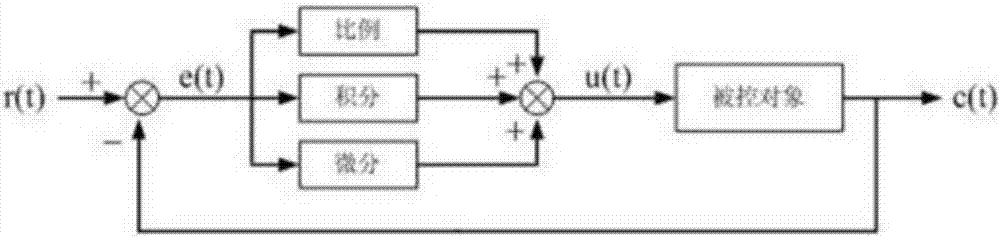

[0052] A combustion controller (such as a PID controller) for controlling the combustion environment in the rotary hearth furnace;

[0053] The pneumatic advancing and retreating device 3 is fixed on the side wall of the rotary hearth furnace 1. The pneumatic advancing and retreating device 3 has a sliding guide rail, a cylinder and a propeller, and the propeller is pushed by the cylinder to reciprocate on the sliding guide rail;

[0054] The composite probe 4 is installed on the sliding guide rail, and the composite probe 4 can move back and forth on the sliding guide rail, and extend into the rotary hearth furnace 1 through the through hole opened on the side wall of the rotary hearth furnace 1 to monitor the atmosphere in the rotary hearth furnace 1 ingredient ...

Embodiment 2

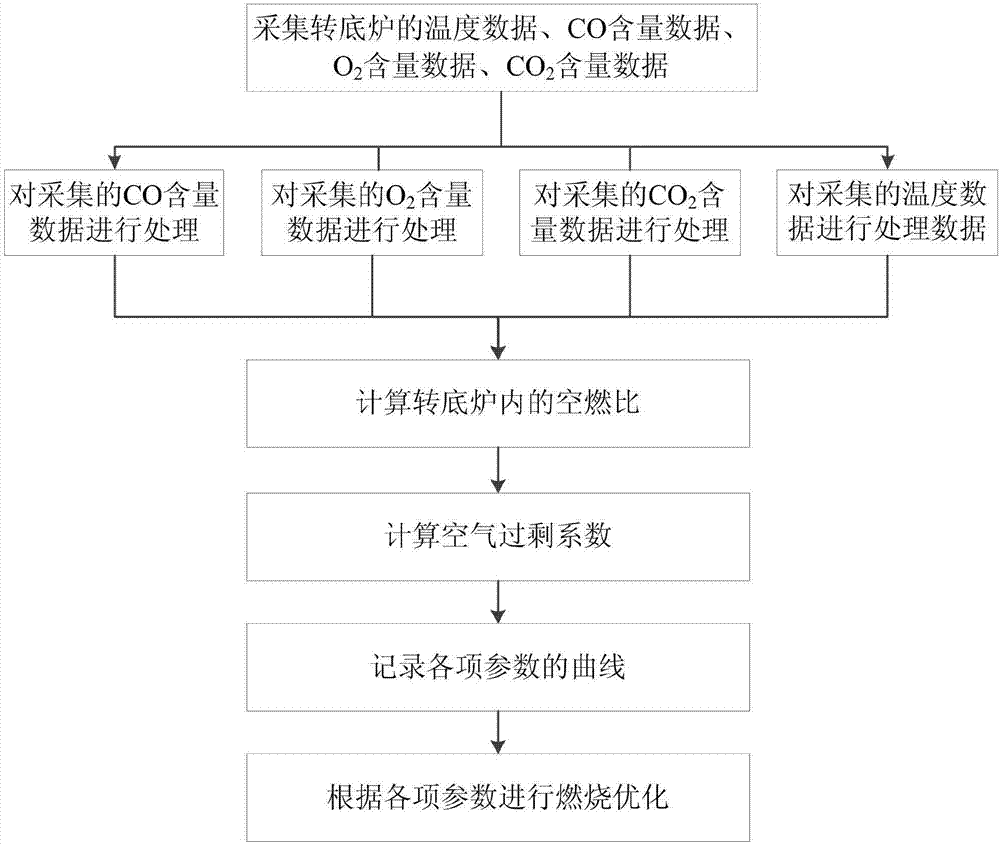

[0075] In this embodiment, the present invention provides a method for real-time detection of atmospheric composition and combustion optimization control in a rotary hearth furnace, such as figure 2 shown, including the following steps:

[0076] Collect temperature data, CO content data, O 2 content data, CO 2 content data;

[0077] Process the collected CO content data, and remove the data below 0 and greater than 70%;

[0078] For the collected O 2 The content data will be processed, and the data lower than 0 and greater than 25% will be eliminated;

[0079] For collected CO 2 The content data will be processed, and the data lower than 0 and greater than 30% will be eliminated;

[0080] Process the collected temperature data, and remove data below 0 and above 1400°C;

[0081] Calculate the air-fuel ratio in the rotary hearth furnace, air-fuel ratio = the amount of air entering the rotary hearth furnace: the amount of gas entering;

[0082] According to the formula t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com