Patents

Literature

100results about How to "Avoid incomplete combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

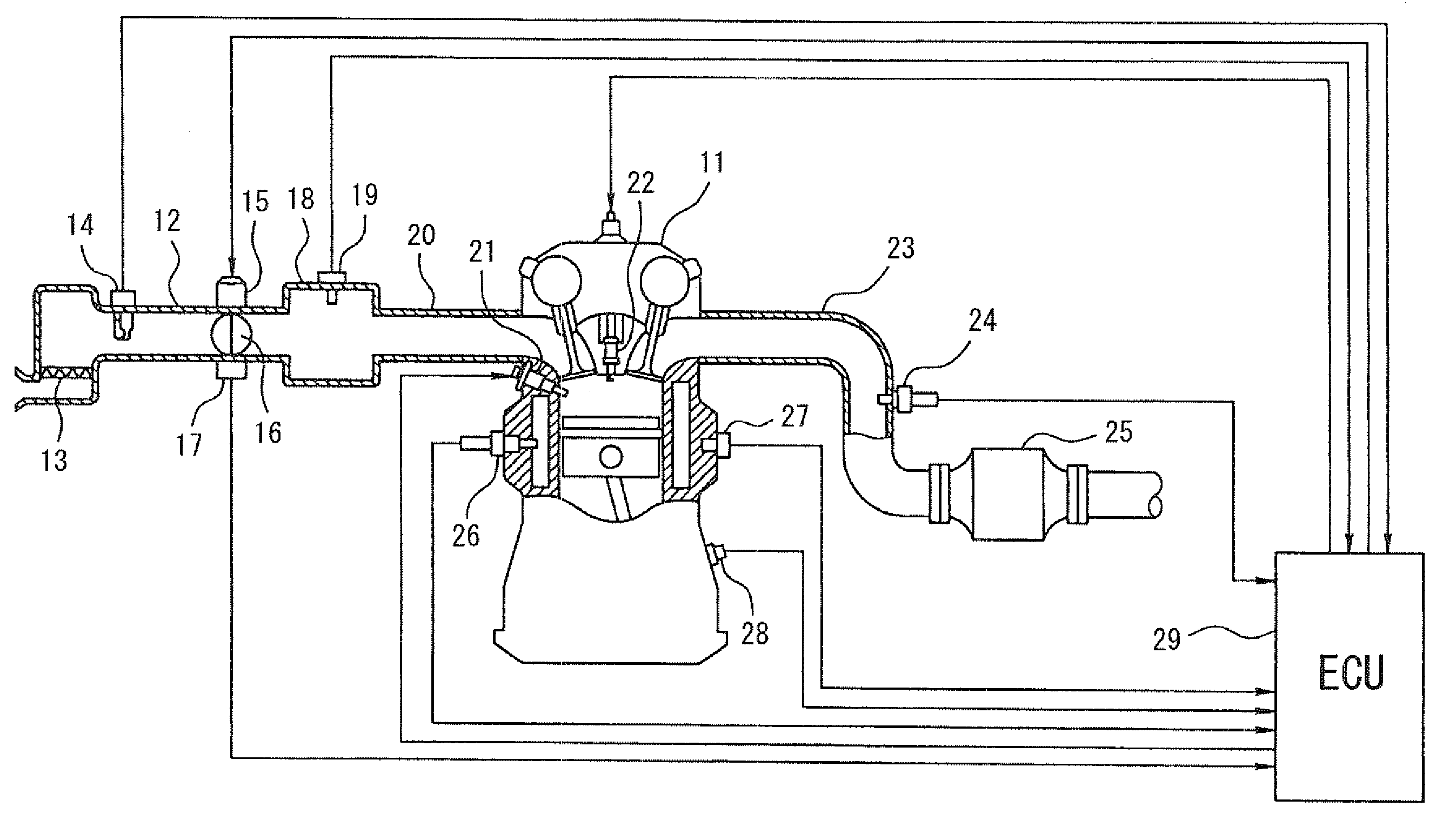

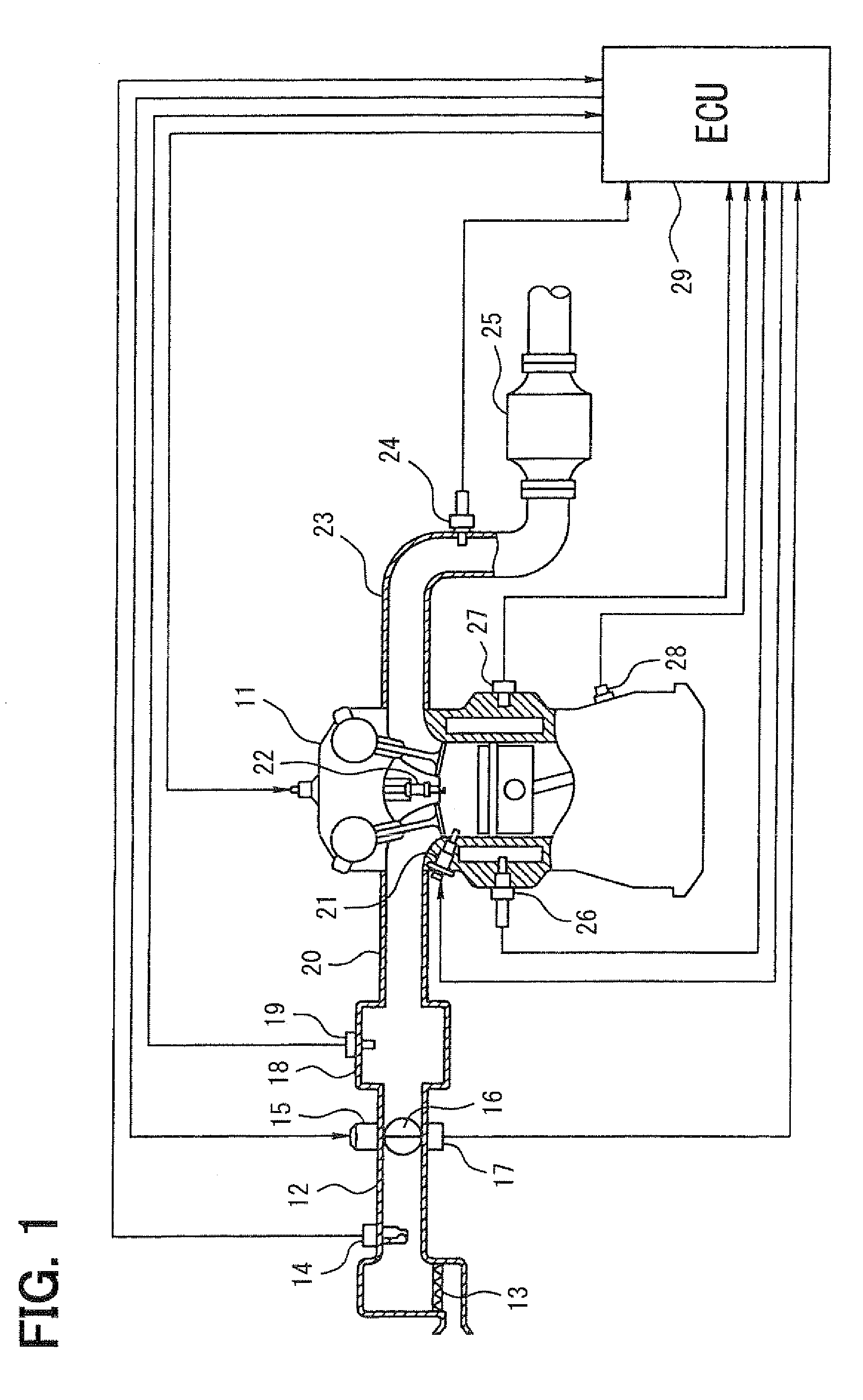

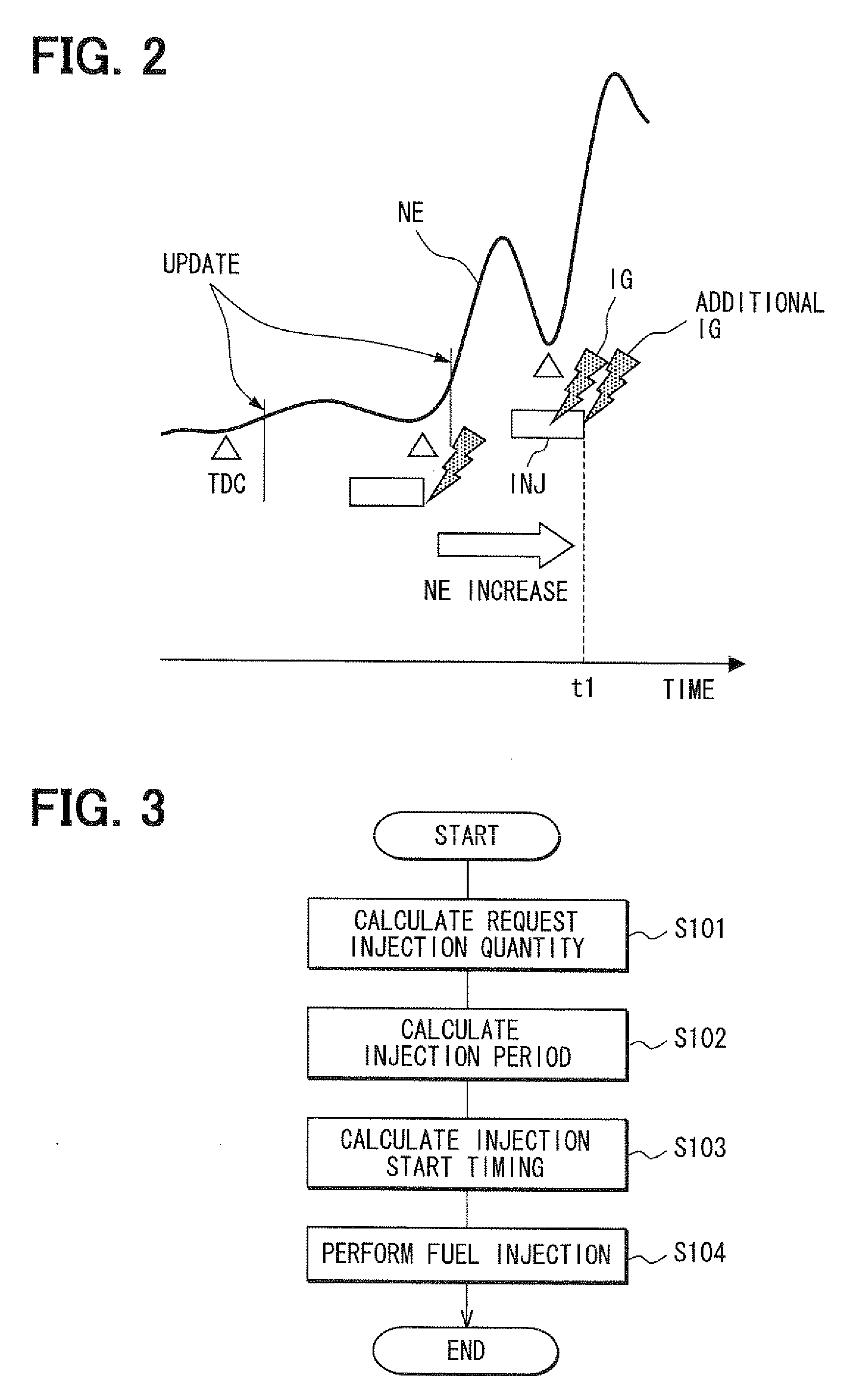

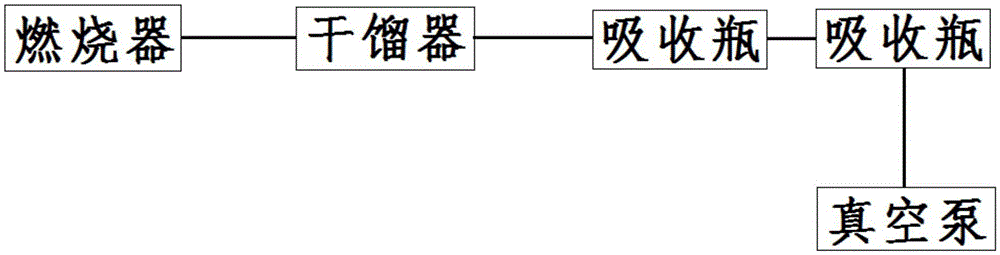

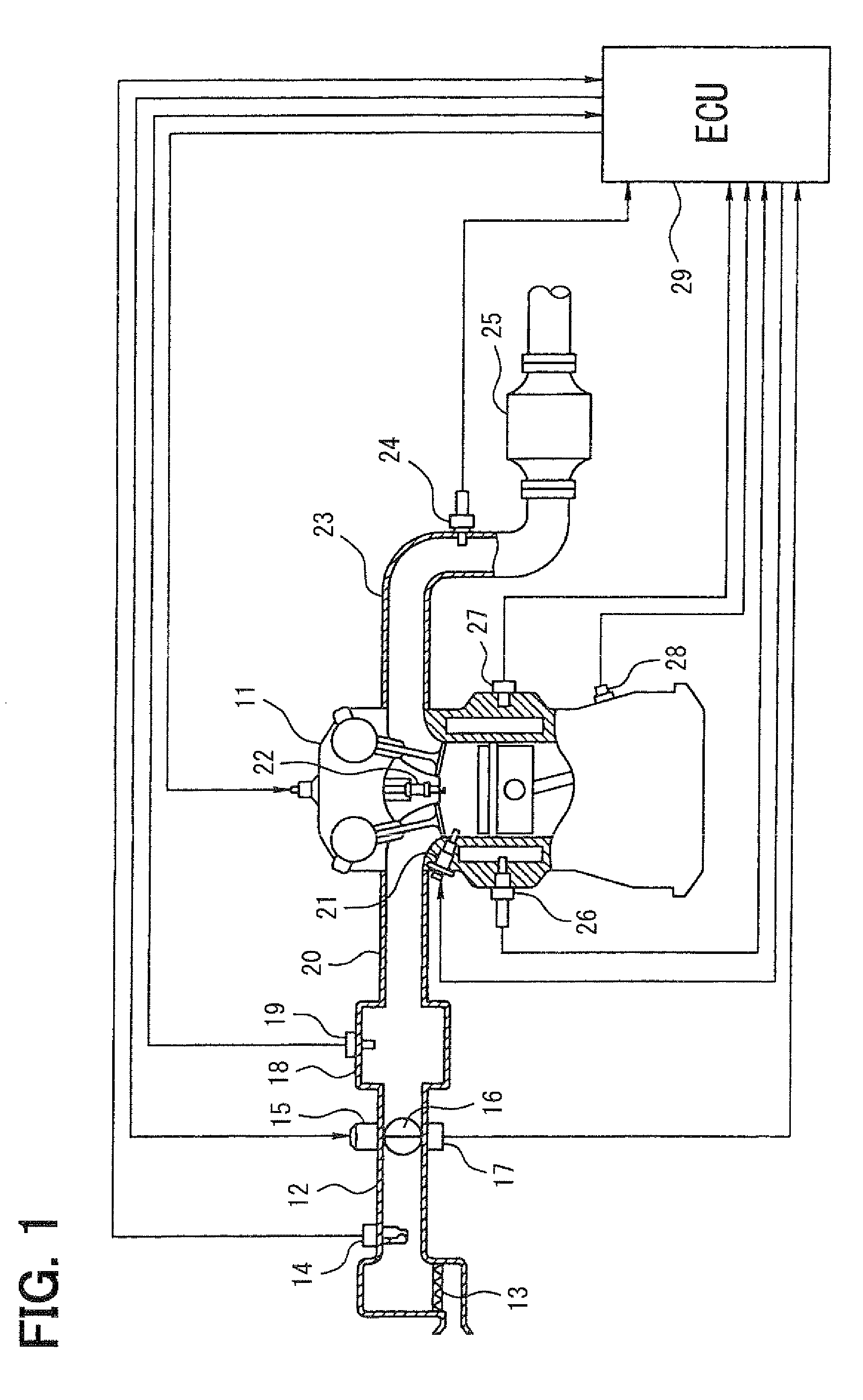

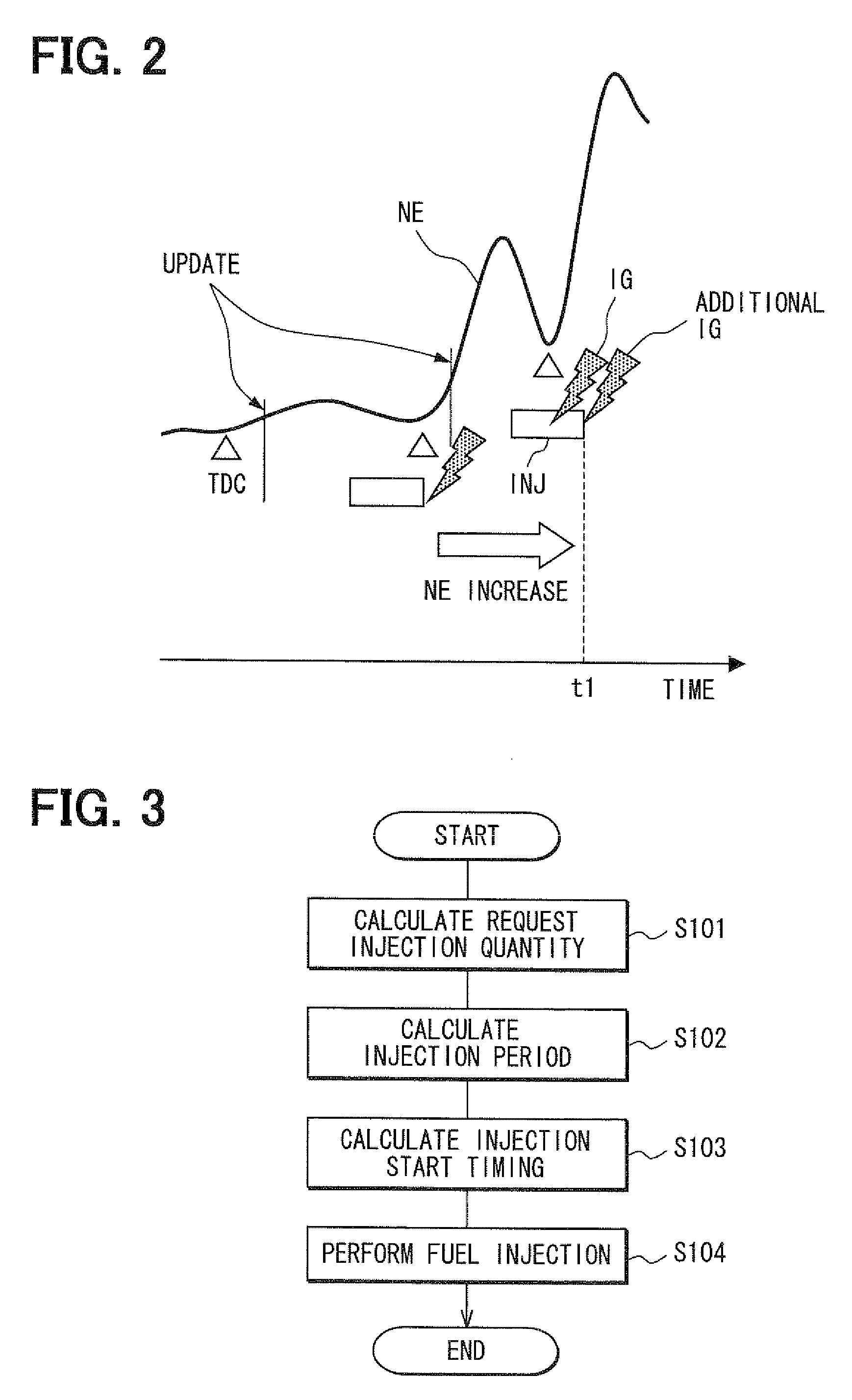

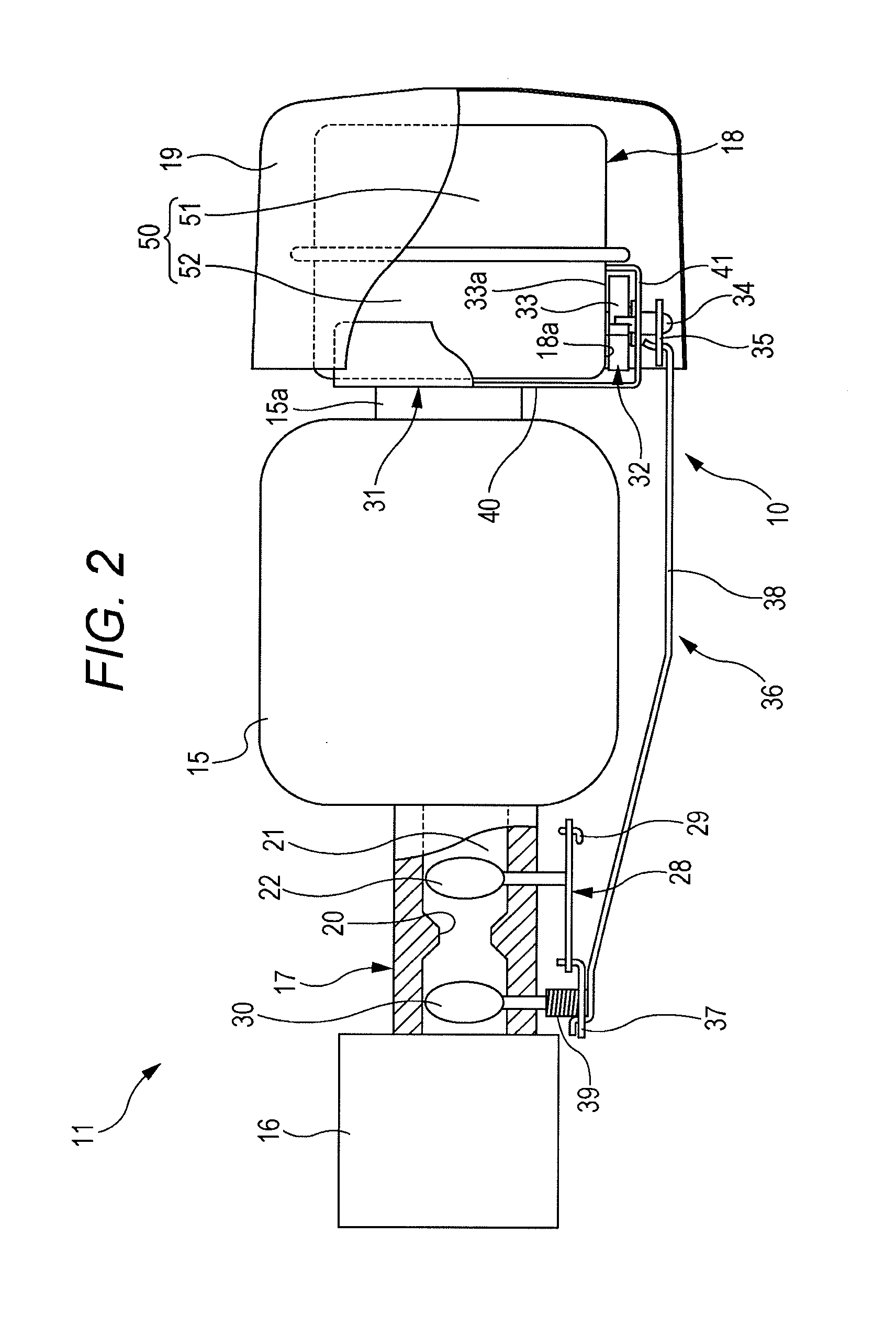

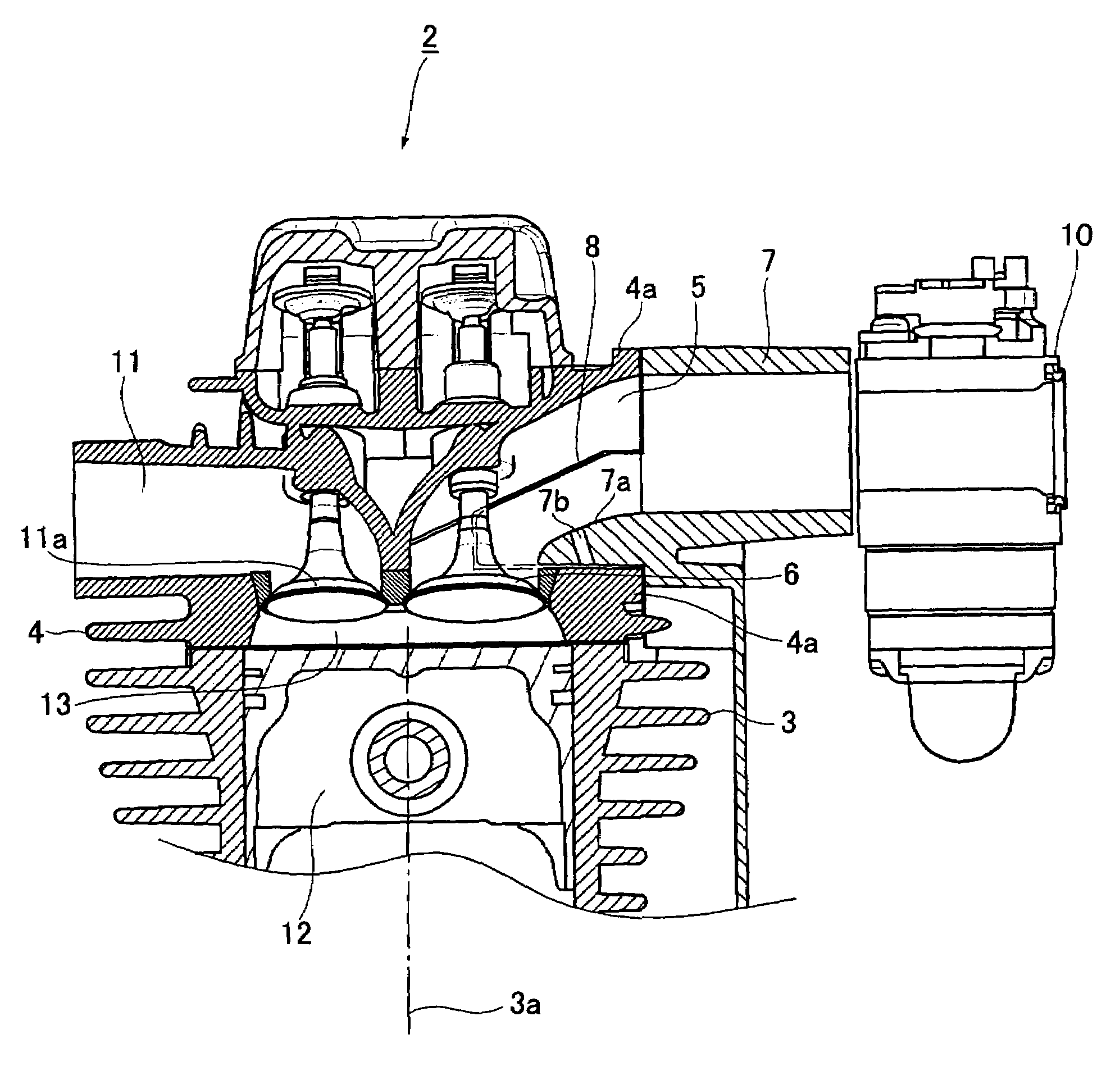

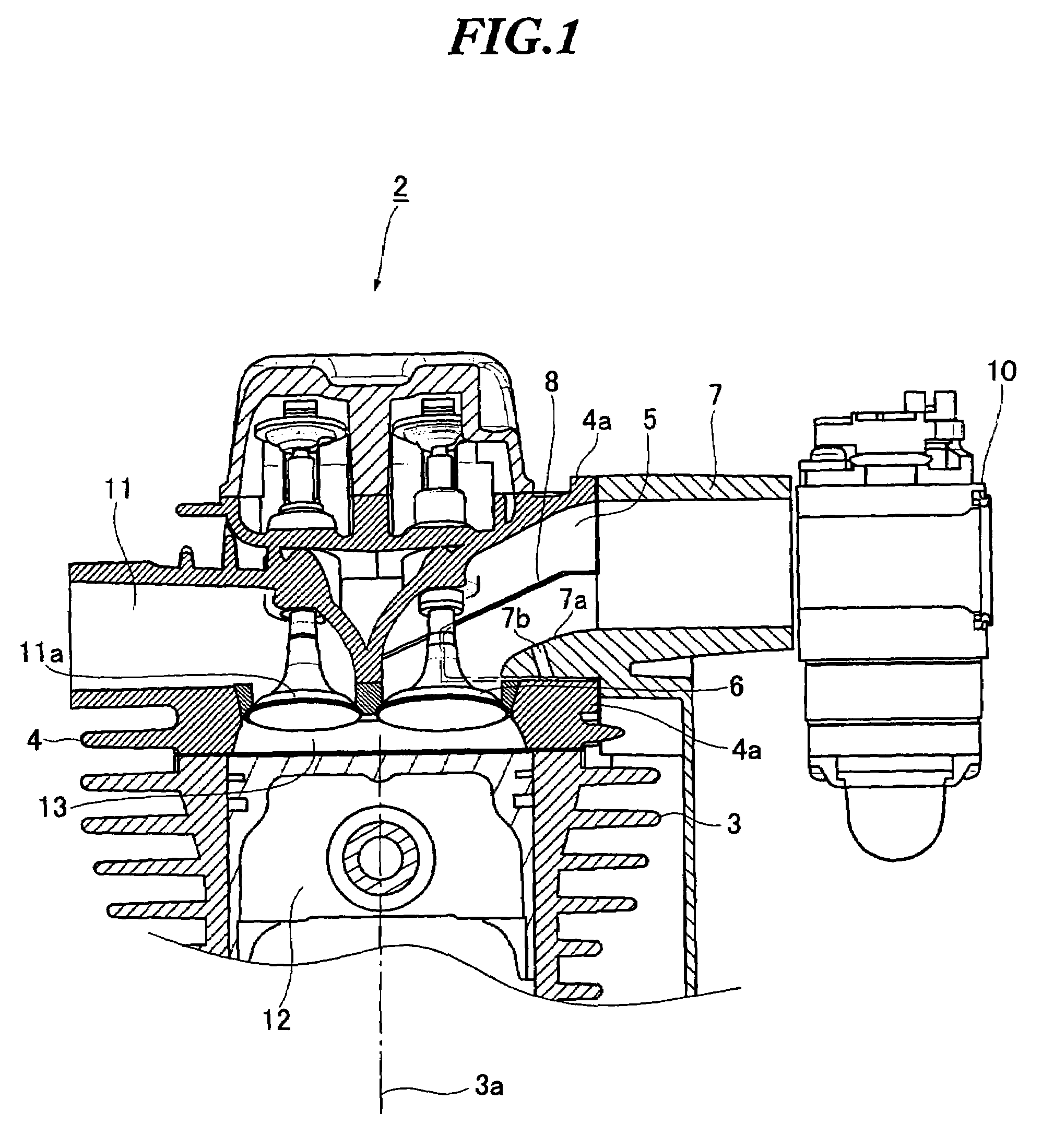

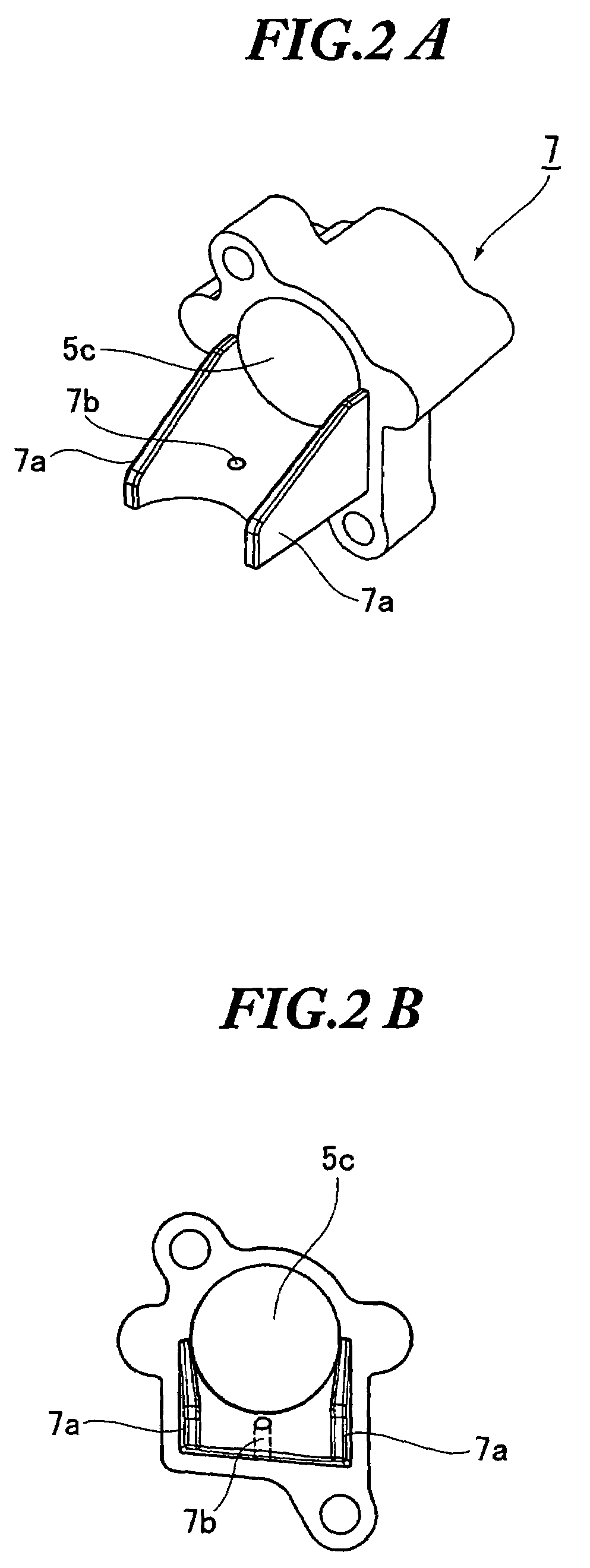

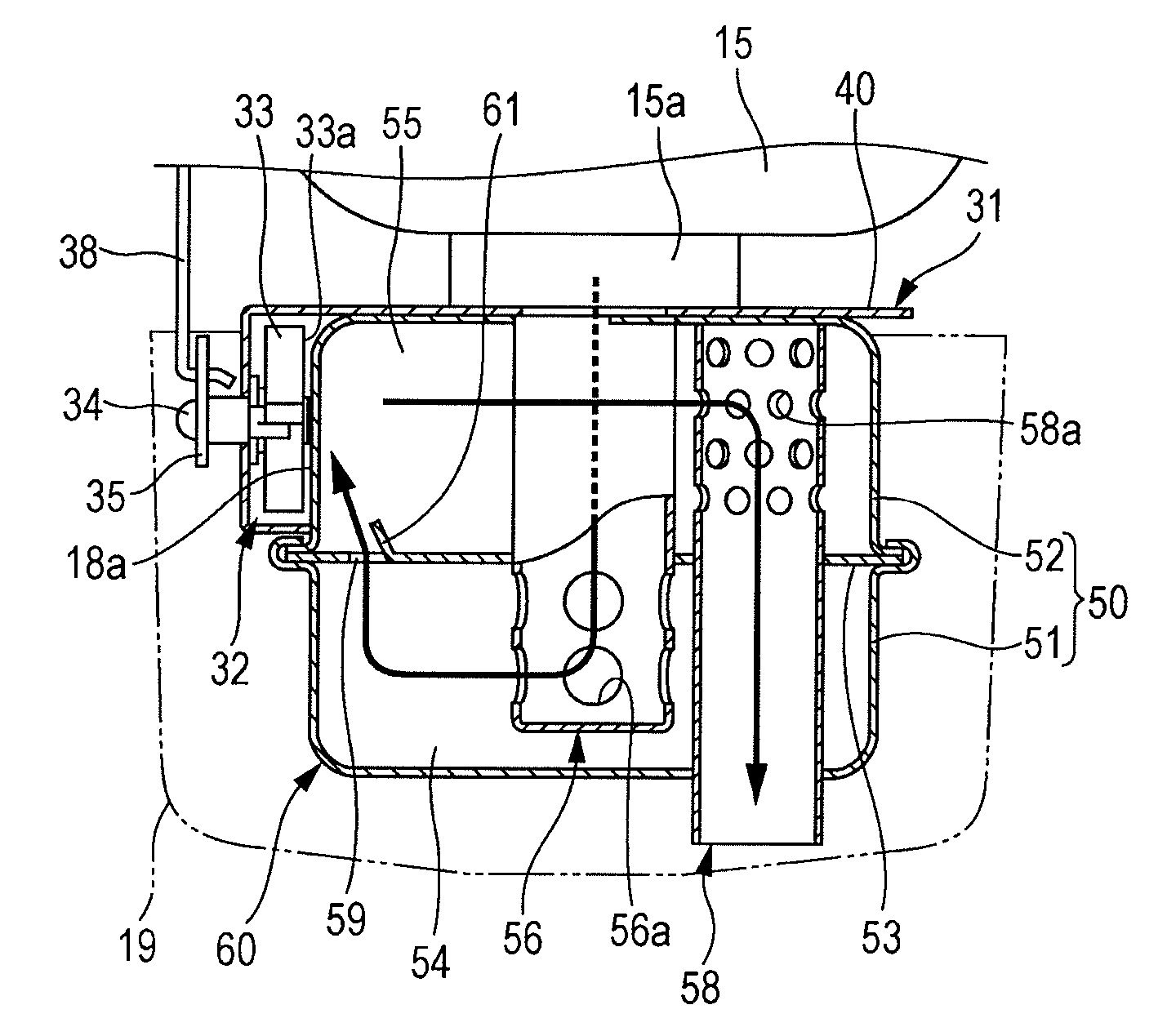

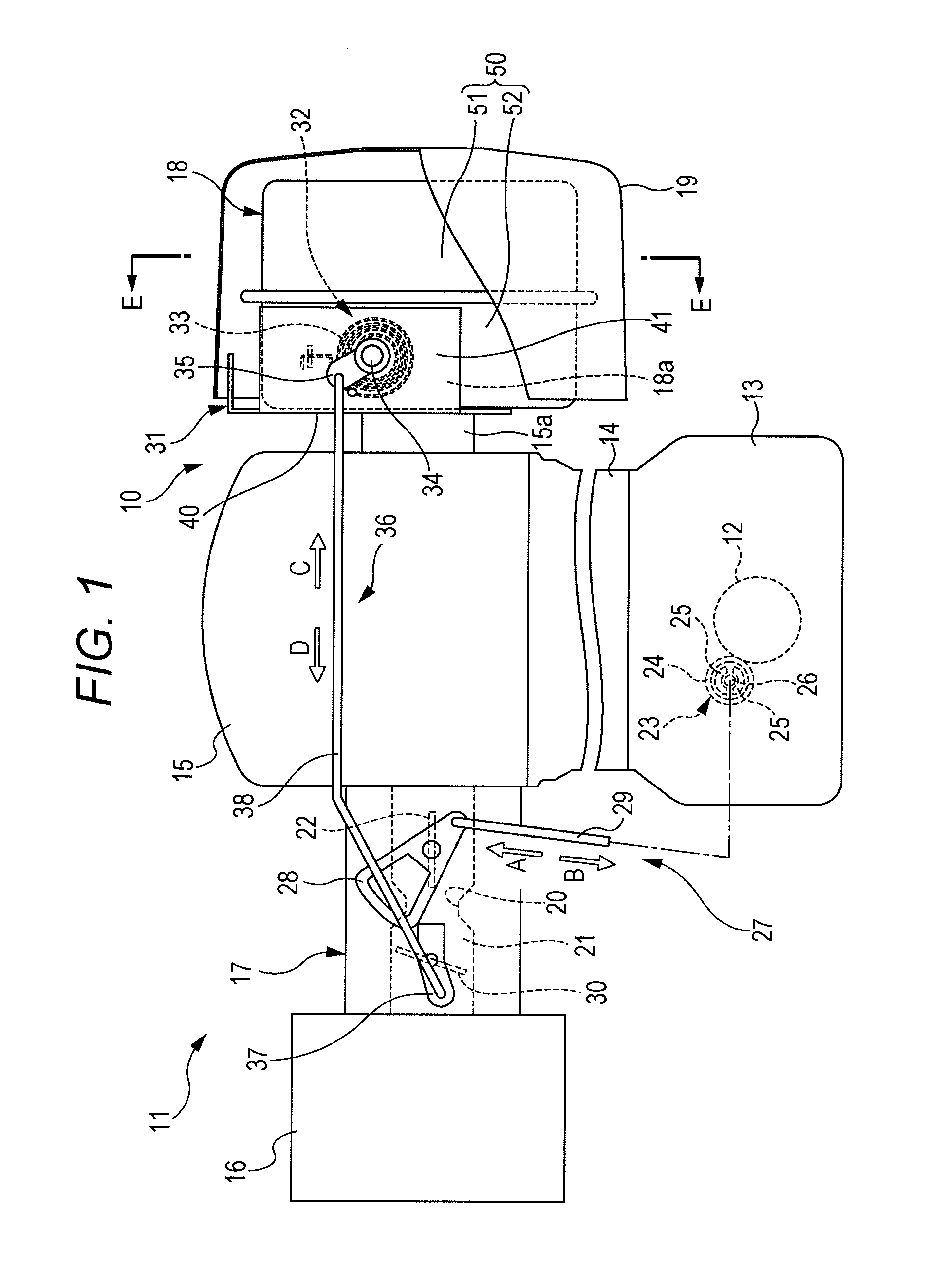

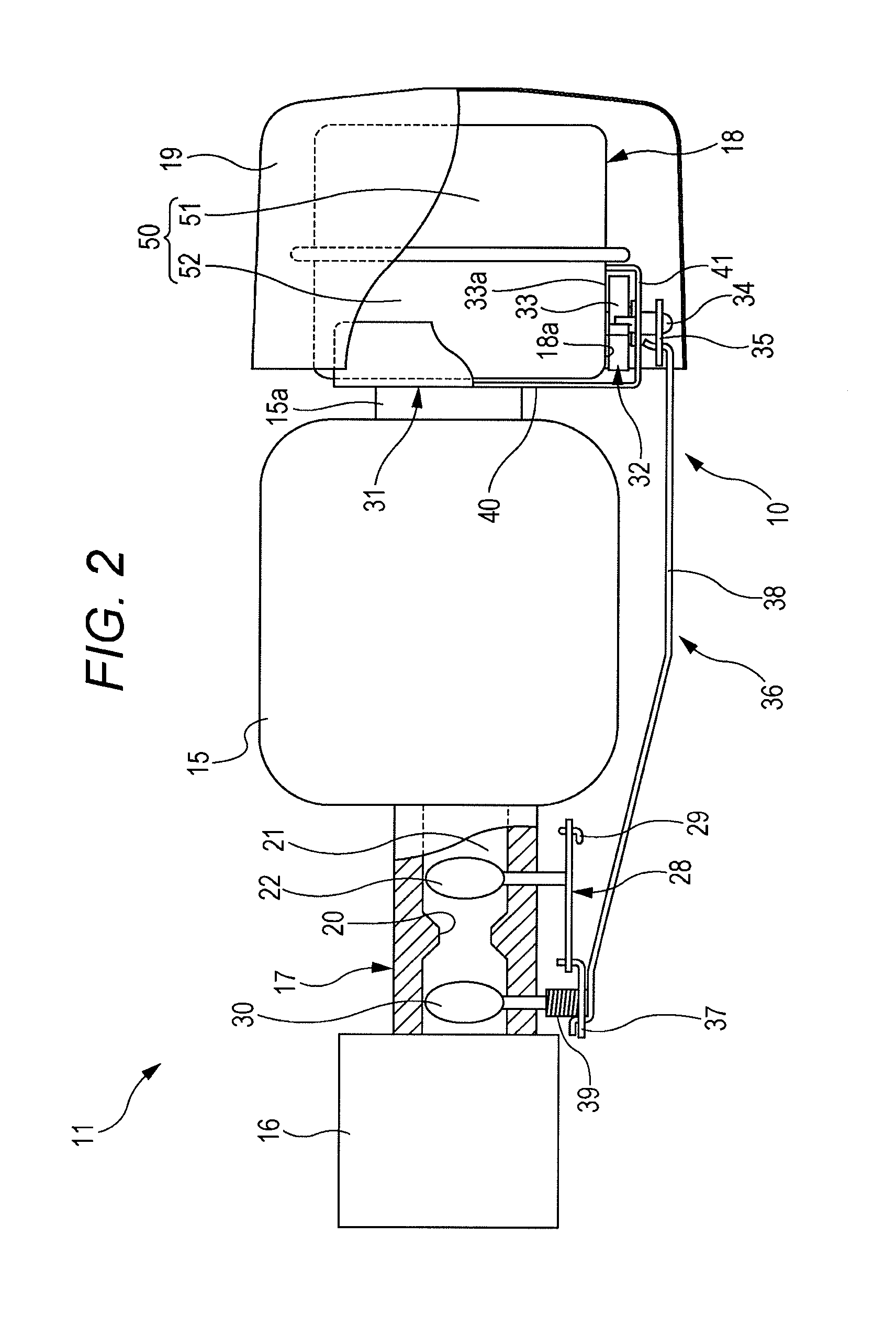

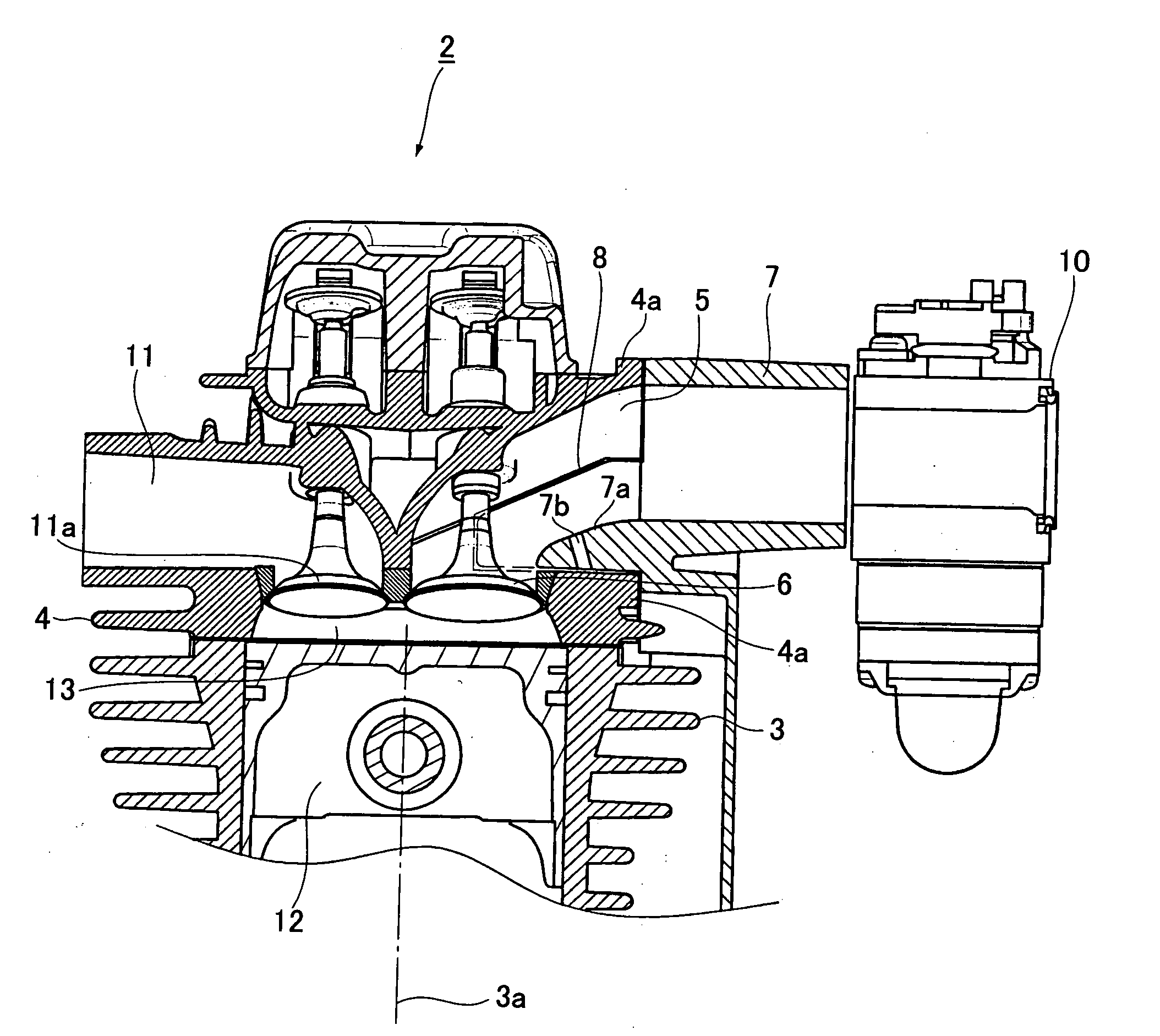

Control device of direct injection internal combustion engine

InactiveUS20090118986A1Increase rotation speedAvoid incomplete combustionElectrical controlDigital data processing detailsEngineeringIgnition timing

When engine rotation speed is increasing in a compression stroke injection mode, a control device determines that a crank angle at injection end timing of an injector deviates toward a delayed crank angle side and performs additional ignition at timing when (or immediately before or after) a crank angle at actual injection end timing of the injector of a present injection cylinder is reached. Thus, even when the crank angle at the injection end timing deviates toward the delayed crank angle side with respect to preset original ignition timing, a combustion state can be stabilized by performing the additional ignition at timing, at which a suitable stratified mixture gas is formed in a cylinder, through the execution of the additional ignition at the timing substantially the same as the actual injection end timing.

Owner:DENSO CORP

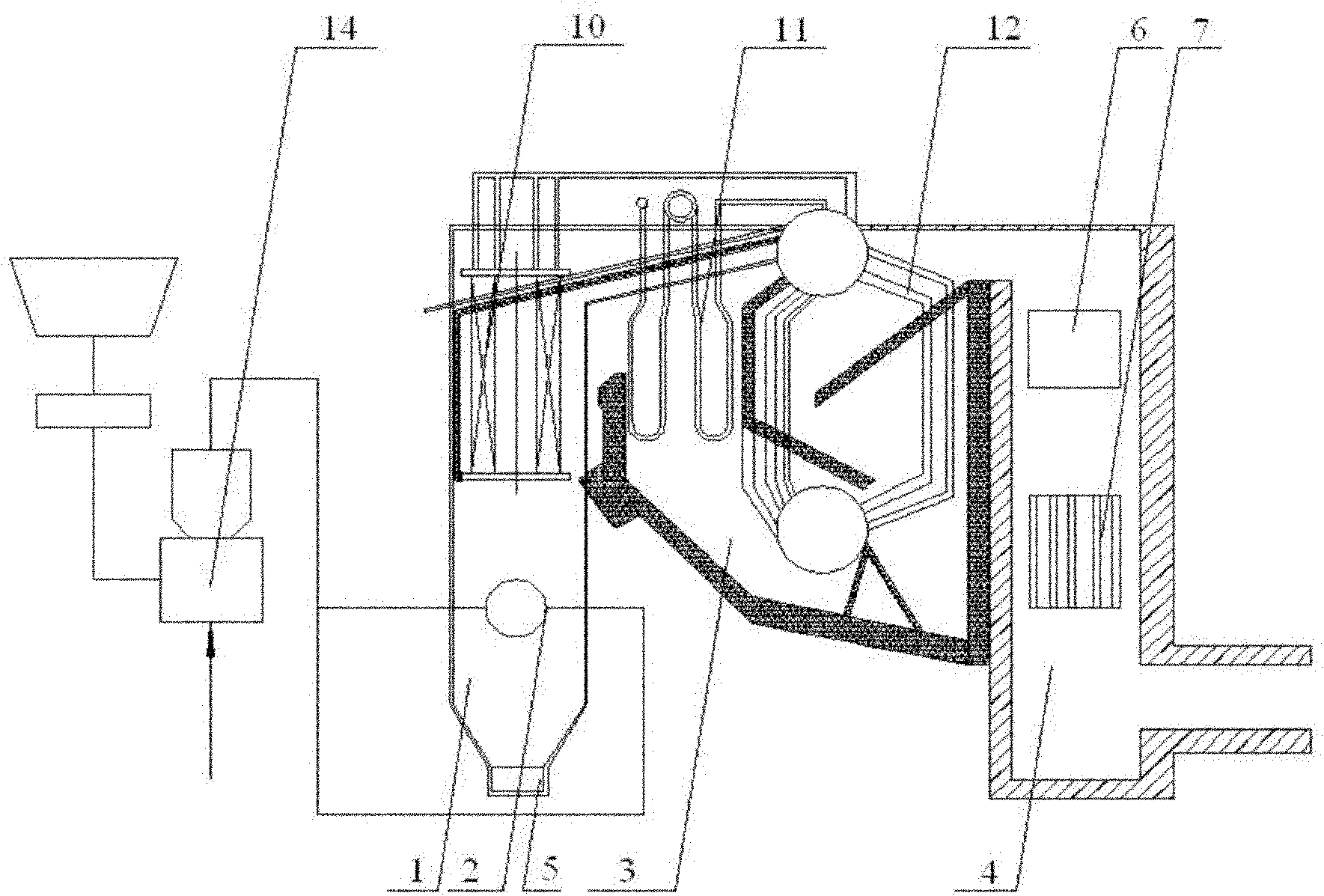

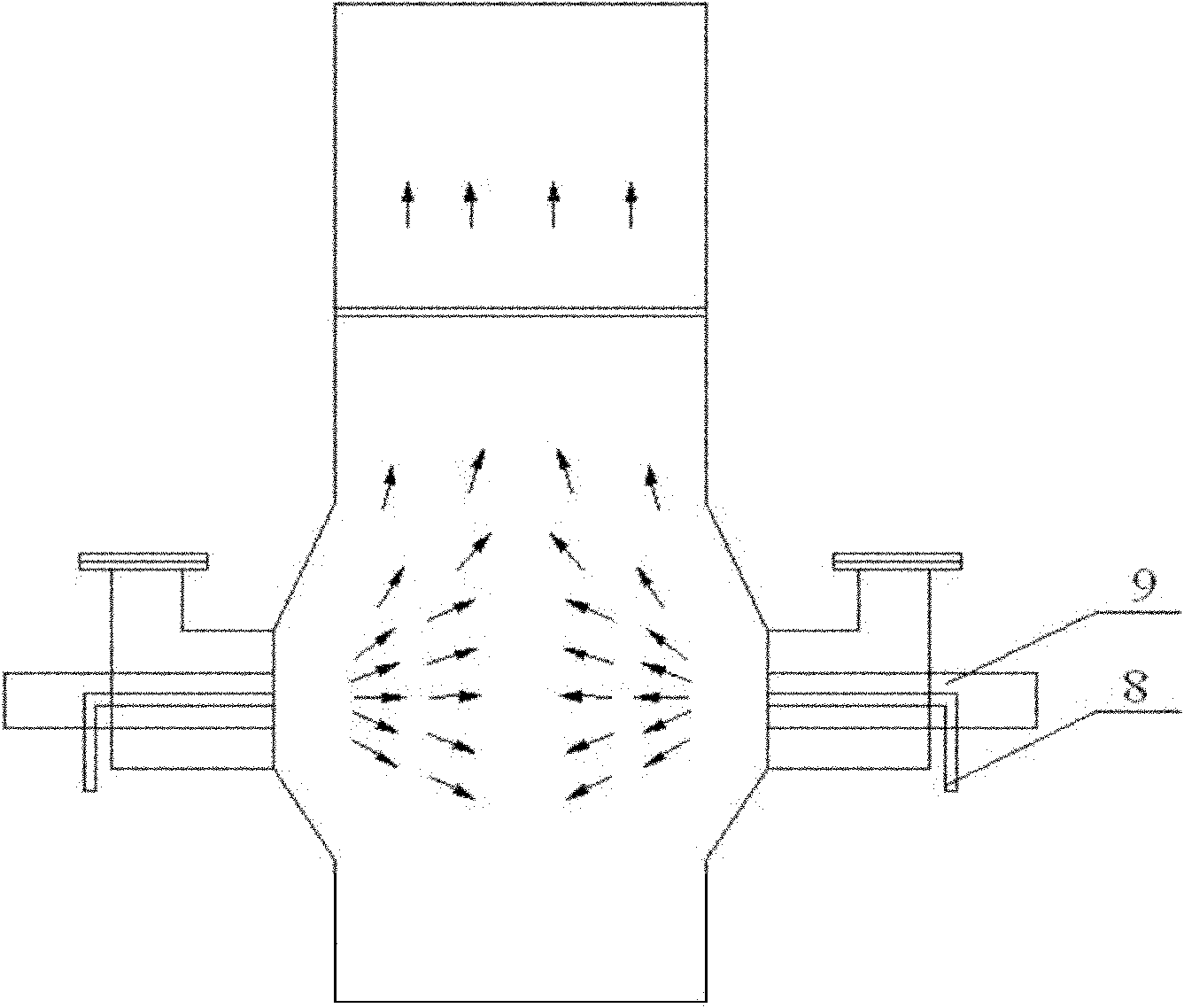

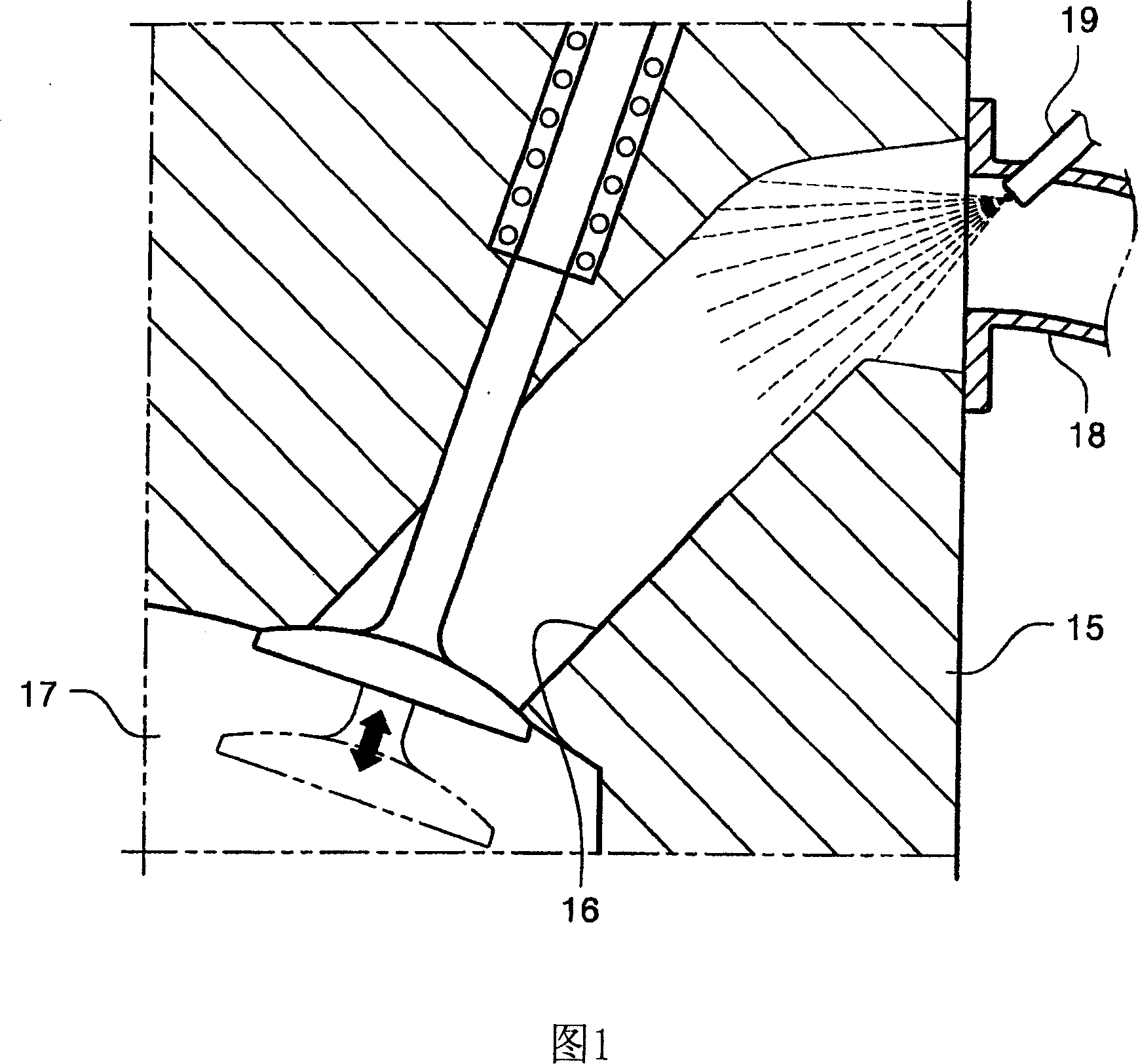

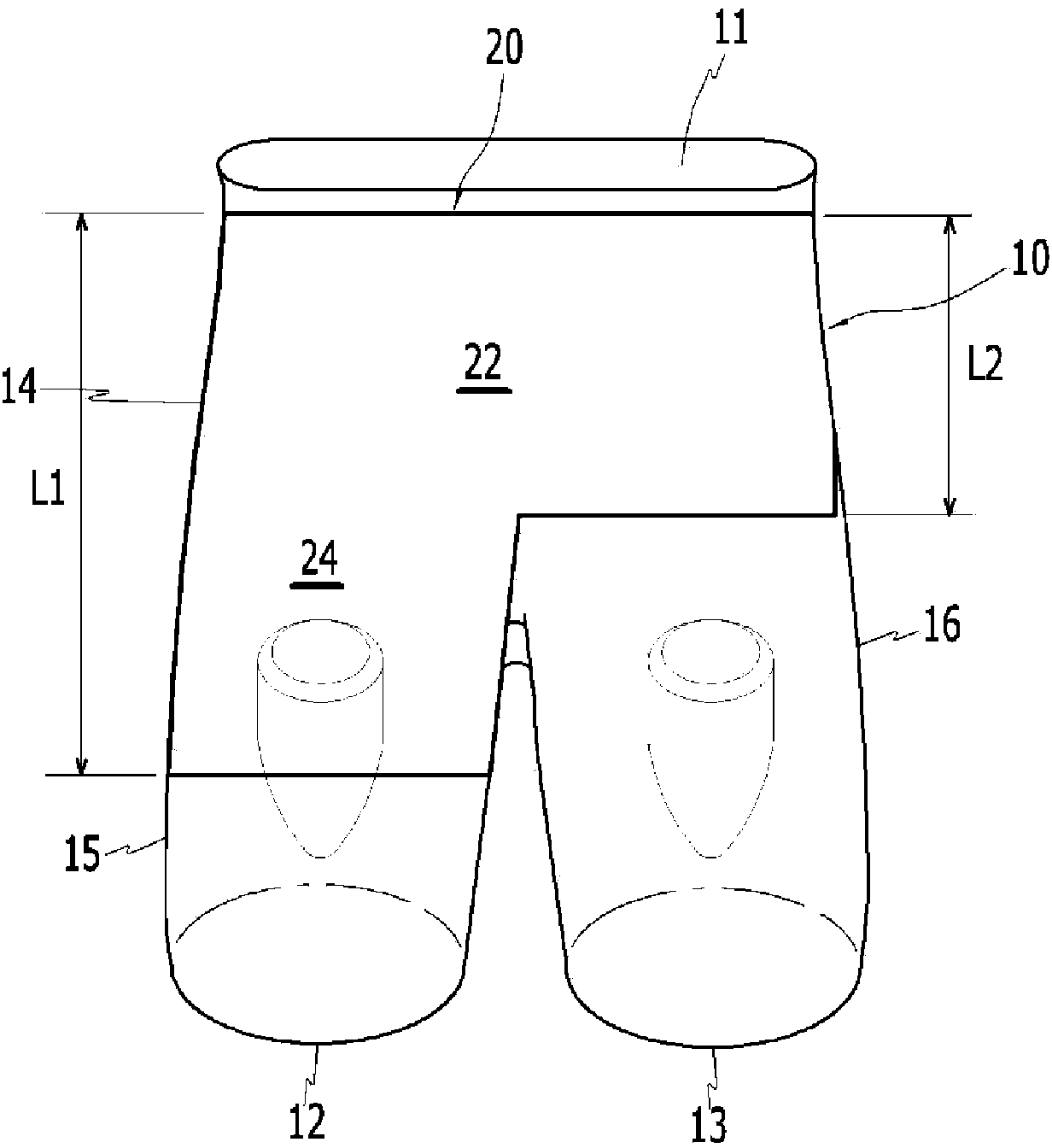

Low NOx rotational flow coal dust combustion device of industrial boiler

InactiveCN101936525AImprove burnout efficiencyDown to fly ash carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterCombustion

The invention discloses a low NOx rotational flow coal dust combustion device of an industrial boiler, belonging to the technical field of industrial boilers. The low NOx rotational flow coal dust combustion device of the industrial boiler comprises a hearth, a rotational flow coal dust burner, a burnout chamber, a tail flue, an ash bucket, an economizer and an air preheater, wherein the hearth is divided into a lower heat-insulation hearth and an upper water cooled hearth; the heat-insulation hearth is positioned on the lower part of the hearth and is in a front-back wall protruded or left-right wall protruded structure; the rotational flow coal dust burner is respectively arranged on the left and right walls or the back and rear walls of the heat-insulation hearth; the ash bucket is positioned in the lower part of the heat-insulation hearth to collect the ash residue of combusted coal dust; the water cooled hearth is internally provided with a water cooled wall used for adsorbing radiant heat and convection heat so as to heat steam water mixture from the economizer; the burnout chamber is positioned on the upper outlet of the heart; the tail flue is positioned on the outlet of the burnout chamber; and the economizer and the air preheater are successively arranged in the tail flue. The invention realizes hedging combustion of the left and right walls or the back and rear walls of the rotational flow burner so as to realize stable and efficient combustion and realize the application of the low NOx combustion technology.

Owner:SHANGHAI JIAO TONG UNIV

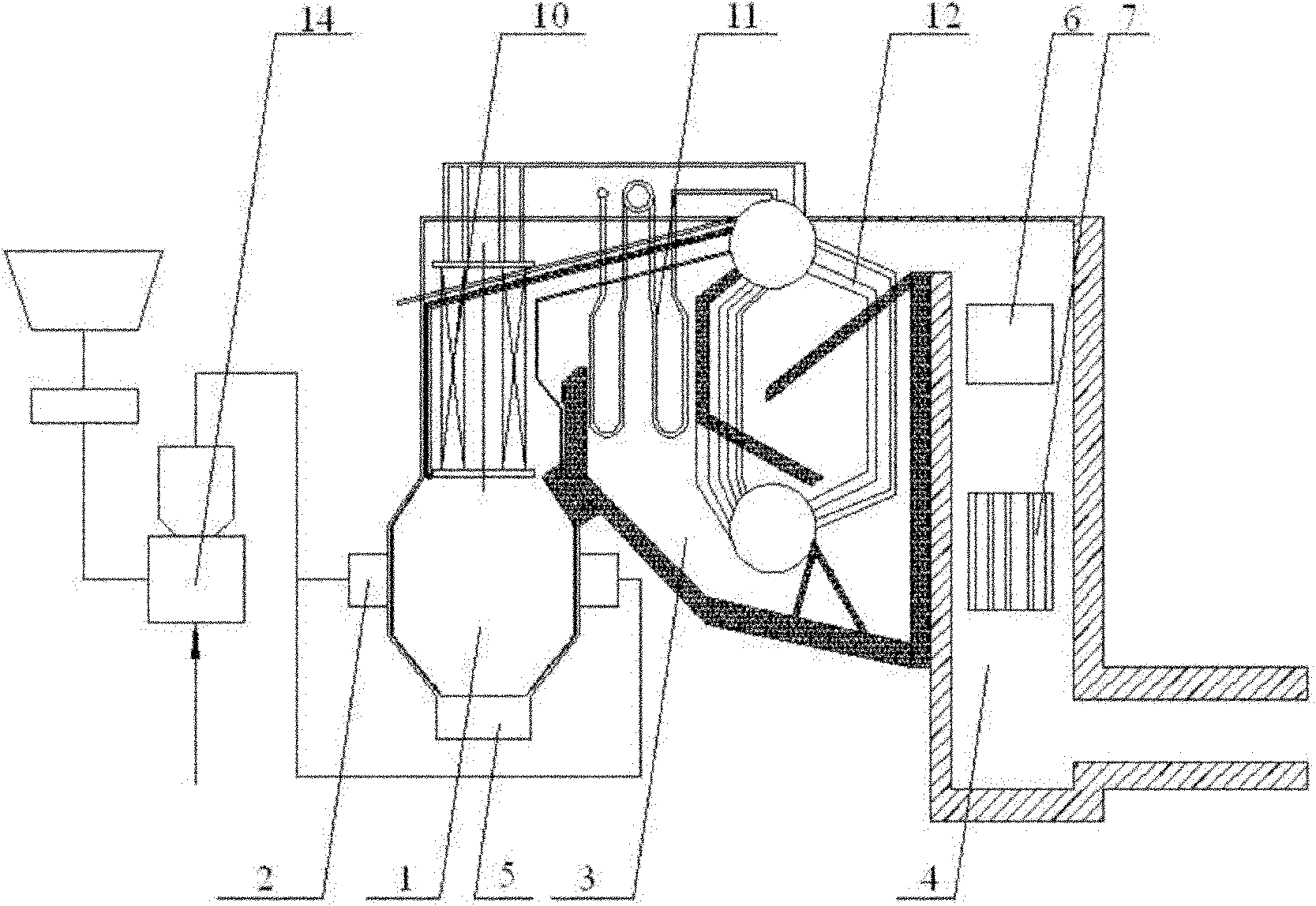

Nicotine liquid raw material of electronic cigarette and preparation device and method of nicotine liquid raw material

The invention relates to nicotine liquid of an electronic cigarette with conventional cigarette fragrance and a preparation method thereof. The preparation method comprises the following steps: combusting cut tobaccos and performing dry distillation: combusting the cut tobaccos under the temperature of 800 to 900 DEG C to obtain fully combusted cut tobaccos, and performing dry distillation on cut tobaccos under the temperature of 300 to 400 DEG C to obtain cut tobaccos subjected to dry distillation; reacting the combusted cut tobaccos and the cut tobaccos subjected to dry distillation under the temperature of 300 to 400 DEG C, and dissolving in an organic solvent such as ethyl acetate; steaming a solvent absorption solution at -0.09 MPa and 27 to 30 DEG C in a rotatable manner to obtain a brown oily extract which is the nicotine liquid raw material with the fragrance of the conventional cured tobacco type cigarette. According to the method, the material can be fully extracted, and the extracted nicotine liquid raw material can be used for preparing electronic cigarettes and low-temperature cigarettes without producing tar oil, so that harm to a human body due to smoking is greatly reduced.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

Control device of direct injection internal combustion engine

InactiveUS7747379B2Increase rotation speedAvoid incomplete combustionDigital data processing detailsAutomatic initiationsEngineeringIgnition timing

When engine rotation speed is increasing in a compression stroke injection mode, a control device determines that a crank angle at injection end timing of an injector deviates toward a delayed crank angle side and performs additional ignition at timing when (or immediately before or after) a crank angle at actual injection end timing of the injector of a present injection cylinder is reached. Thus, even when the crank angle at the injection end timing deviates toward the delayed crank angle side with respect to preset original ignition timing, a combustion state can be stabilized by performing the additional ignition at timing, at which a suitable stratified mixture gas is formed in a cylinder, through the execution of the additional ignition at the timing substantially the same as the actual injection end timing.

Owner:DENSO CORP

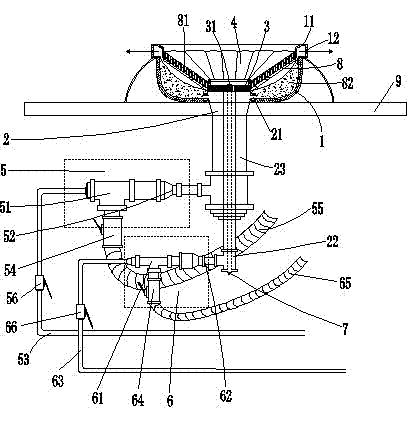

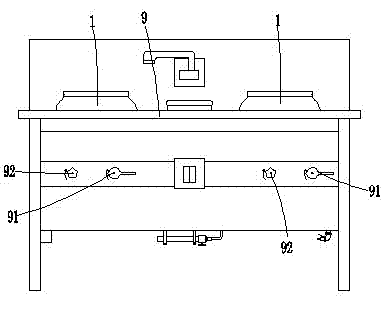

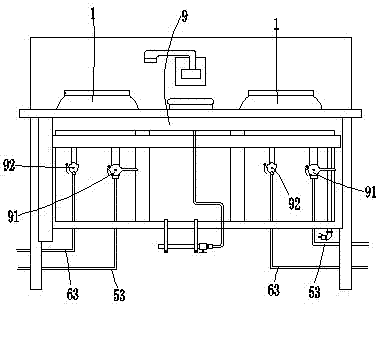

Safe energy-saving gas cooker

InactiveCN102374556AAvoid risk factorsAvoid incomplete combustionDomestic stoves or rangesGaseous fuel burnerProduct gasEngineering

The invention discloses a safe energy-saving gas cooker, which comprises an ejector, a porous plate, a tray and a cooker-pan body, wherein the cooker-pan body is placed on the table surface of a cooker seat, a convex-edge body is manufactured at the outer side at the head of the ejector, and the convex-edge body is fixedly connected with the inner surface of the cooker-pan body; the middle of the ejector is matched with a small-fire passage in a penetrating way, and the space of an inner cavity of the ejector positioned at the outer side of the small-fire passage is arranged into a main-fire passage; one lateral surface at the lower part of the ejector is matched with a main-fire gas-mixing chamber, and the main-fire gas-mixing chamber is communicated with the main-fire passage; the lower part of the small-fire passage extends out of the bottom end of the ejector, and the lower part of the small-fire passage is matched with a small-fire gas-mixing chamber; through gas-pipeline thinning and bending measures, the generation of dangerous factors is avoided, and the thoroughness of burning is realized; the fixation and the fastening for the position of the ejector are the keys for keeping the gas tightness of products; an ignition device is installed at the axle-center position of a gas ejector, so that the burnout by a main fire is avoided, the igniting speed is high, and the safe energy-saving gas cooker is convenient to maintain and install; and a plurality of fire-spraying holes are arranged on a burning plate, so that flames can not be tempered.

Owner:吉林省胜佳环保节能科技有限责任公司

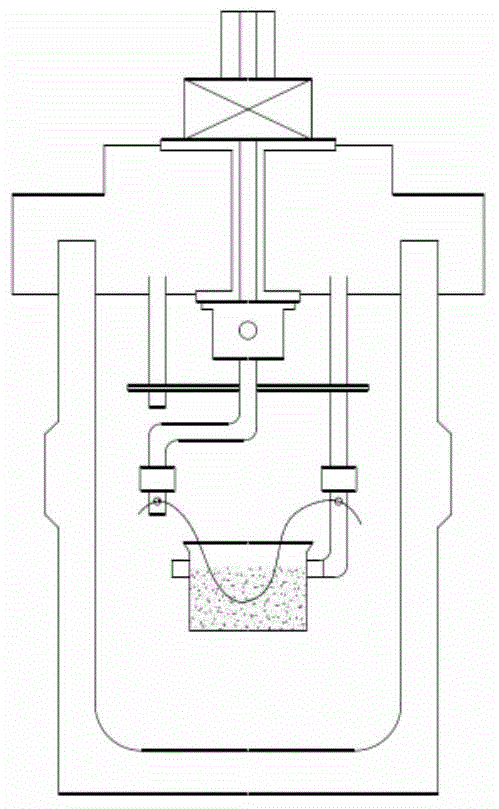

Boron powder combustion heat value testing device

InactiveCN104155341AIncrease volumePlay a role of fixed protectionMaterial heat developmentEngineeringOxygen

The invention discloses a boron powder combustion heat value testing device. The device comprises a bomb body, a bomb head, a crucible, a crucible cover and conducting posts, wherein the crucible is fixed on a crucible frame in the bomb body; the bomb head is arranged on the bomb body; a vent pipe is arranged at the middle part of the bomb head, and is communicated with the interior of the bomb body; a thimble type gas valve is arranged on the vent pipe; the two conducting posts are ignition electrodes; small holes are formed in the conducting posts; conducting ferrules are arranged on the upper parts of the conducting posts; the two ends of an ignition fuse are inserted into the small holes in the conducting posts respectively, and are fixedly connected with the conducting posts through the conducting ferrules; the crucible cover is positioned on the crucible; two step holes embedded with ceramic plates are formed in the crucible cover, and are used for allowing the ignition fuse to be inserted; two rows of guide holes are circumferentially formed in the middle part of the wall of the crucible, so that burning on an oxygen bomb part by boron powder with a high combustion heat value can be prevented; the volume of the crucible is increased, so that sufficient oxygen can be ensured to participate in combustion; the step holes are formed in the crucible cover to balance the internal and external pressure of the crucible. The testing device is particularly applied to the testing of a combustion heat value of a boron fuel, and is also applied to the testing of combustion heating values of a solid propellant, coal and a petroleum substance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Method for preparing smoking fluid through carya illinoinensis shells and application of smoking fluid during preparation of smoked meat

PendingCN107624860AAvoid incomplete combustionRich sourcesMeat/fish preservationChemistryActivated carbon

The invention relates to the field of food processing, in particular to a method for preparing smoking fluid through carya illinoinensis shells. The method comprises the following steps of performingdry distillation and carbonization on carya illinoinensis shells under the condition of 250-290 DEG C, and performing condensation and carbonization on produced flue gas so as to obtain flue gas condensate; performing mixed adsorption on the flue gas condensate and activated carbon of which the mass is 3-10% of that of the flue gas condensate, and performing solid-liquid separation; and finally performing distillation on filtrate obtained through the solid-liquid separation under the condition of 100-120 DEG C so as to obtain condensate namely the smoking fluid. The smoking fluid prepared by the method disclosed by the invention is claret red and has rich natural smoking fragrance and specific fat fragrance of carya illinoensis, the content of total phenol is not less than 160.5mg / mL, thecontent of guajacolum is not less than 8.0mg / mL, the content of carboxyl compounds is 145-155mg / mL, and the smoking fluid does not contain benzo (alpha) pyrene.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

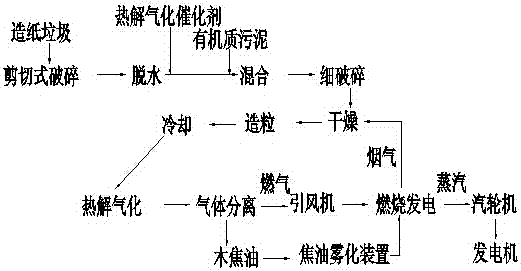

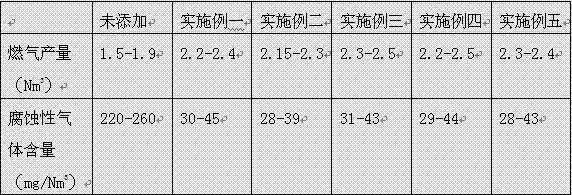

Pyrolysis gasification catalyst and papermaking waste treatment process using pyrolysis gasification catalyst

ActiveCN107497467AGood hygroscopicityImprove pyrolysis gasification efficiencyGasification catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonateEquivalence ratio

The invention discloses a pyrolysis gasification catalyst which comprises the following components: 35 to 50% of calcium oxide, 10 to 20% of zirconium oxide, 15 to 25% of titanium dioxide, 15 to 25% of sodium bicarbonate and 10 to 20 % of citric acid. The components are crushed to form a mixture; the present invention also discloses a papermaking waste treatment process comprising 1) crushing: crushing papermaking waste into flocculent; 2) dehydration: reducing the water of the papermaking waste to 20-40% ; 3) adding: adding the pyrolysis gasification catalyst accounting for 3-5% of the mass of the papermaking waste; 4) mixing: uniformly mixing the papermaking waste and the catalyst; 5) drying: controlling the water of the mixed material to 15-25%; 6) pelletizing: obtaining organic-matter-derived fuel particles; 7) cooling: cooling the particles to room temperature; 8) pyrolyzing and gasifying: pyrolyzing and gasifying the particles at 600-800 DEG C under micro-oxygen conditions of the air equivalence ratio of 0.1-0.28; and 9) gas separation: removing wood tar from mixed fuel gas through purification; and the pyrolysis gasification catalyst can effectively improve the gasification efficiency of the fuel particles and fuel gas production, can neutralize corrosive gases, greatly improves sludge utilization rate, and effectively protects the environment.

Owner:四川雷鸣环保装备有限公司

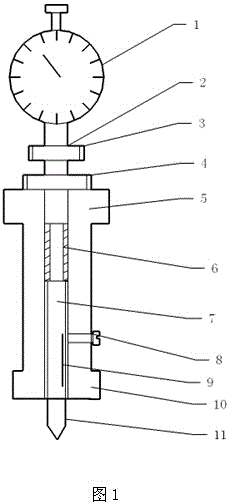

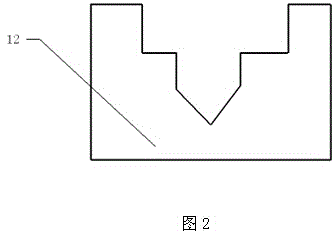

Gauge for detecting protruding volume of cylinder cover oil injector hole

The invention discloses a gauge for detecting the protruding volume of a cylinder cover oil injector hole. The gauge comprises a gauge body, a dial indicator and a correcting block. When the gauge is used for measuring, a gauge oil injector positioning shaft and the cylinder cover oil injector hole are positioned, a gauge body ejector pin is made to extend out of the cylinder cover oil injector hole, and the ejector pin is ejected through the correcting block. The gauge further comprises a plunger bushing, the dial indicator is connected with a plunger shaft, and the plunger shaft comprises a hold-down nut and a tightening nut. The gauge for detecting the protruding volume of the cylinder cover oil injector hole is simple in structure, convenient to use and capable of quickly detecting the protruding volume of the cylinder cover oil injector hole, so that the performance and quality hidden danger of poor atomization, incomplete combustion, high temperatures and the like in the operation process of a motor due to the machining deviation of the protruding volume of the cylinder cover oil injector hole is avoided.

Owner:ANHUI TIANLI ENGINE

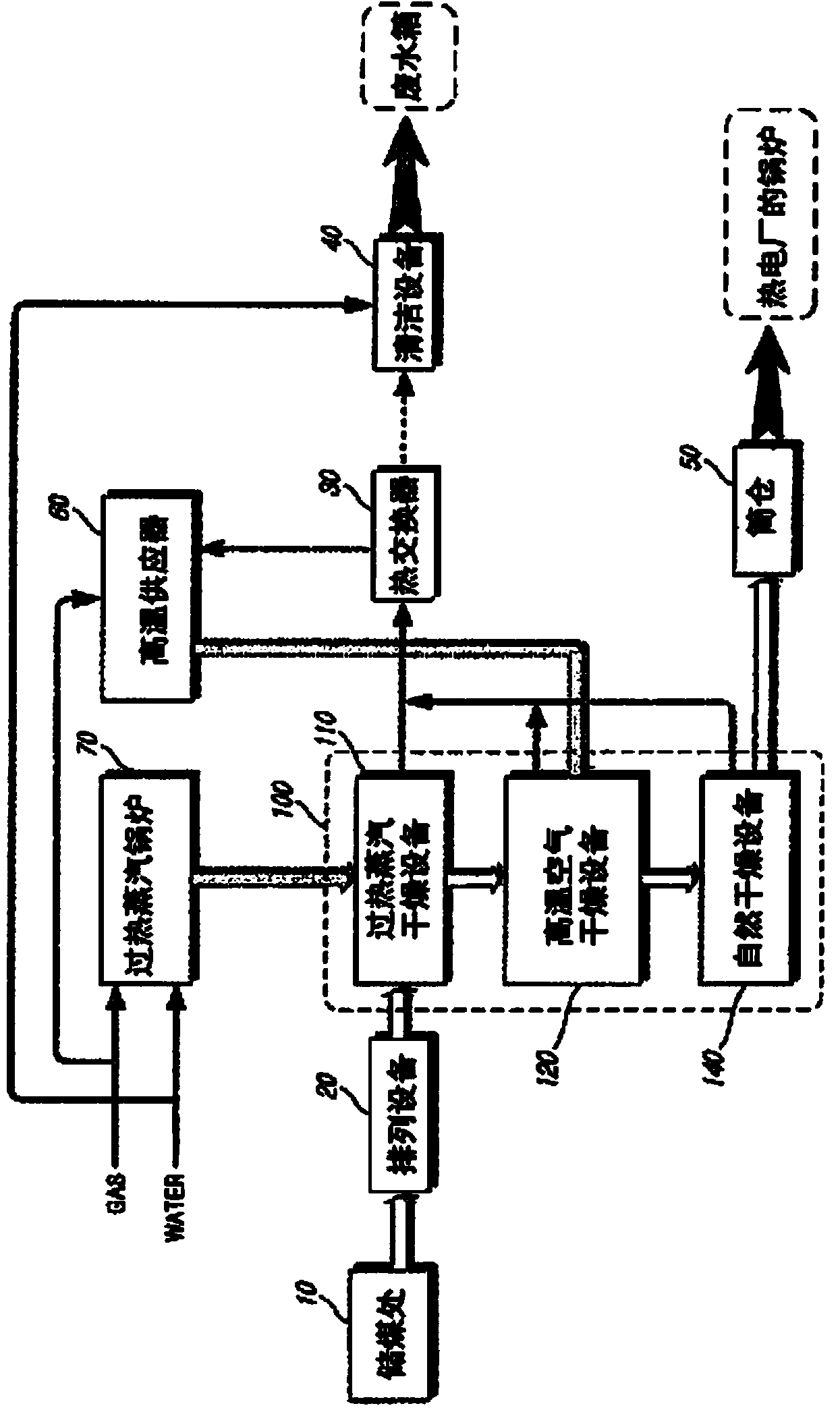

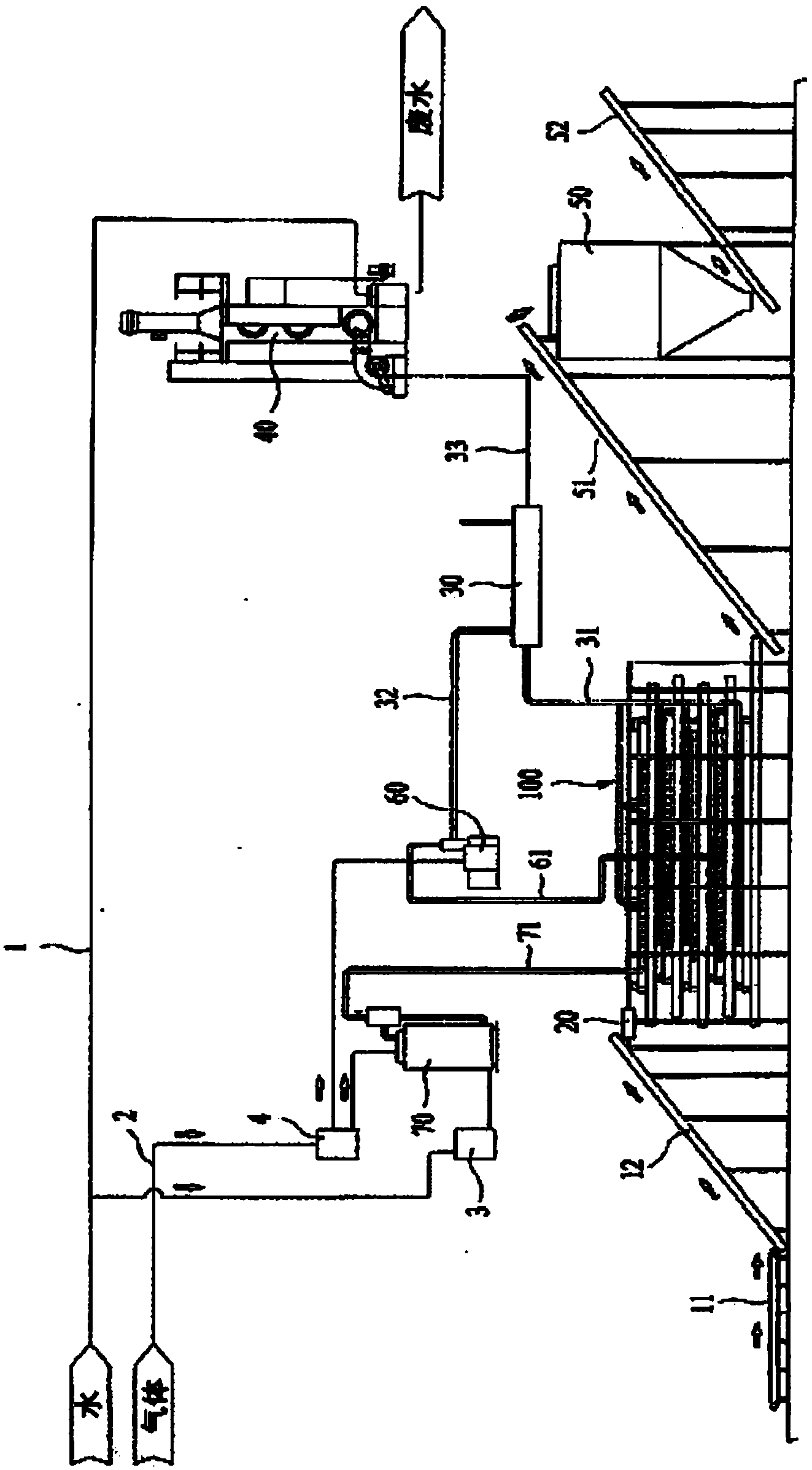

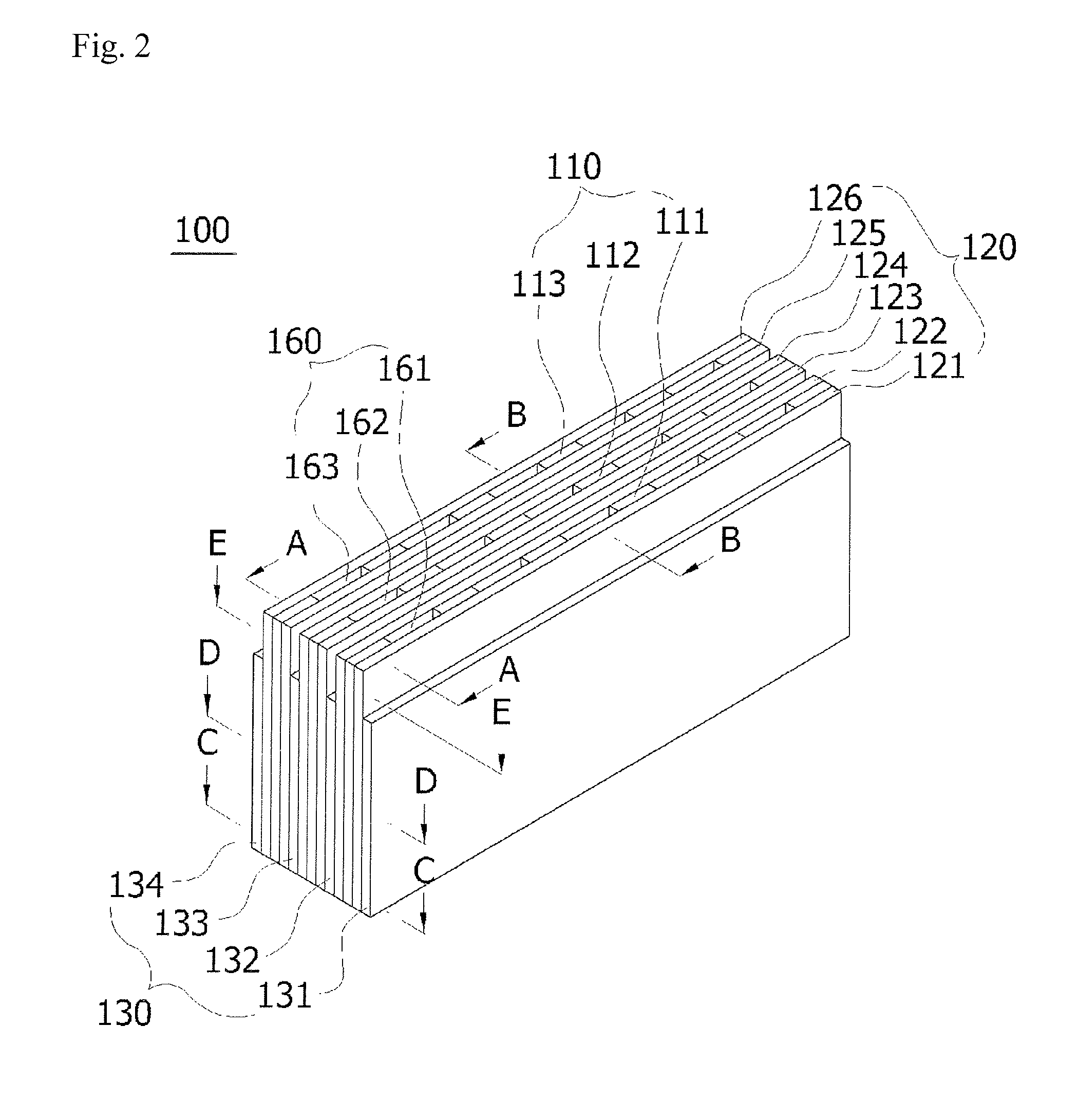

System for drying coal by using superheated steam

InactiveCN104081143AEasy to useAvoid incomplete combustionSteam generation heating methodsDrying solid materials with heatCombustionProcess engineering

The present disclosure relates to a coal drying system for removing water contained in coal used as a fuel of a thermoelectric power plant with superheated steam. The system prevents the incomplete combustion of the coal by removing water existing inside and outside the coal fuel of the thermoelectric power plane, thereby improving a heating value of coal and minimizing the discharge of pollutants, prevents the corrosion of the system and improves the durability, and increases the use of low-quality coal of which the demand is low, thereby improving the stable supply of the coal.

Owner:HANKOOK TECH

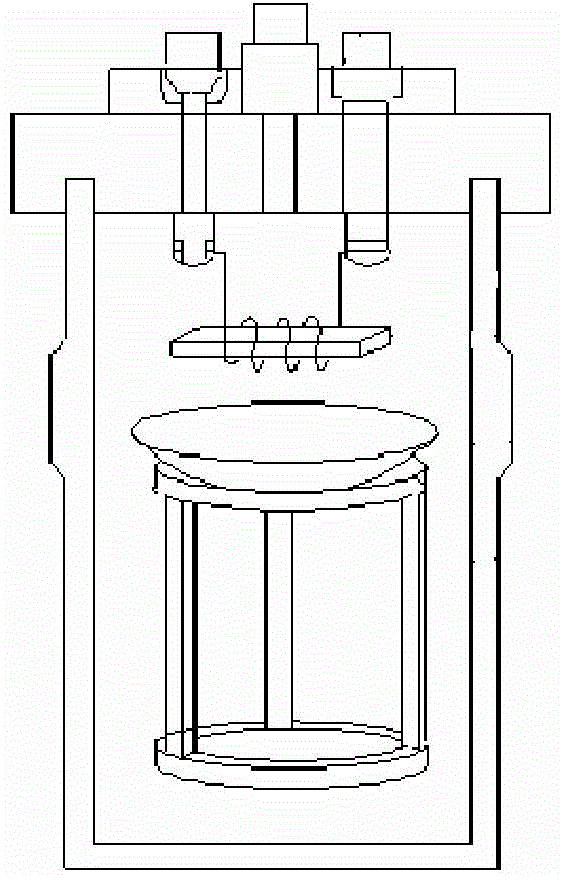

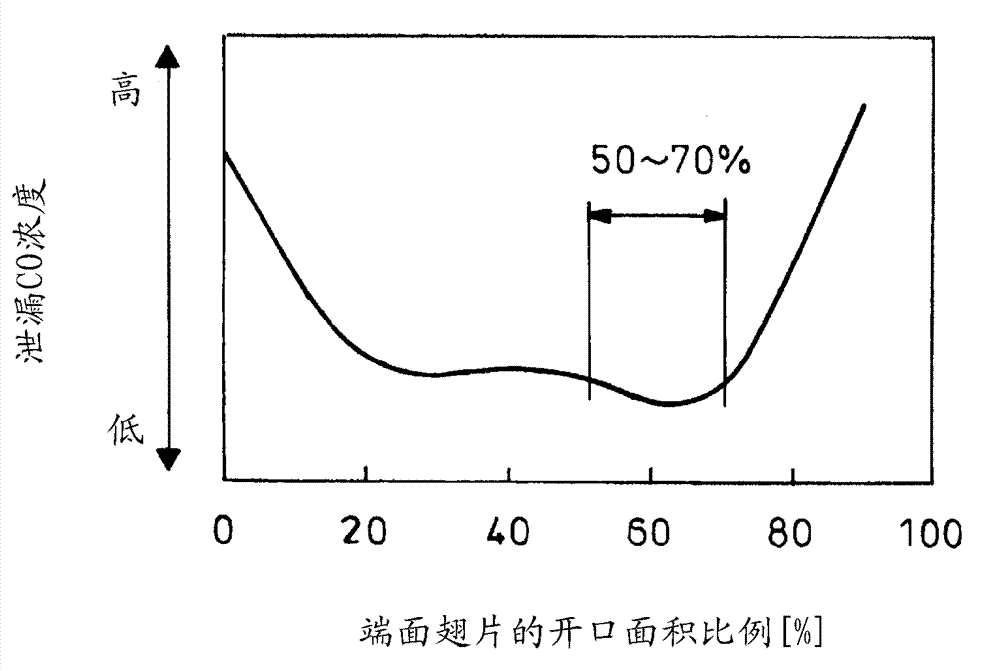

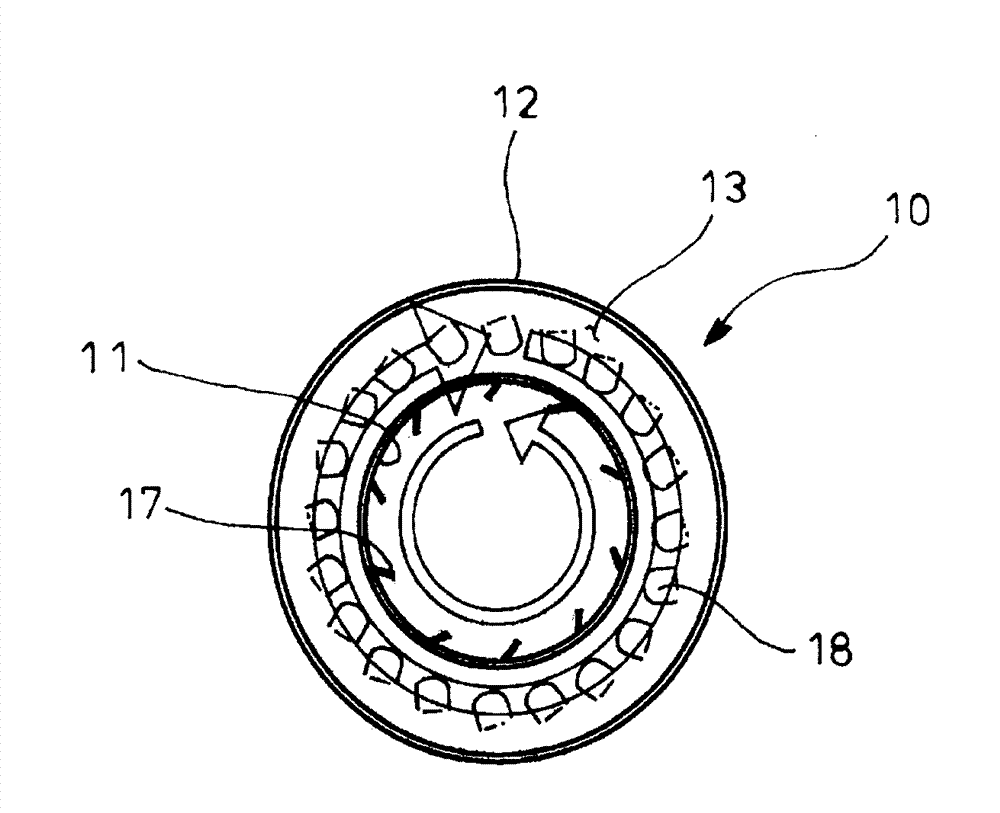

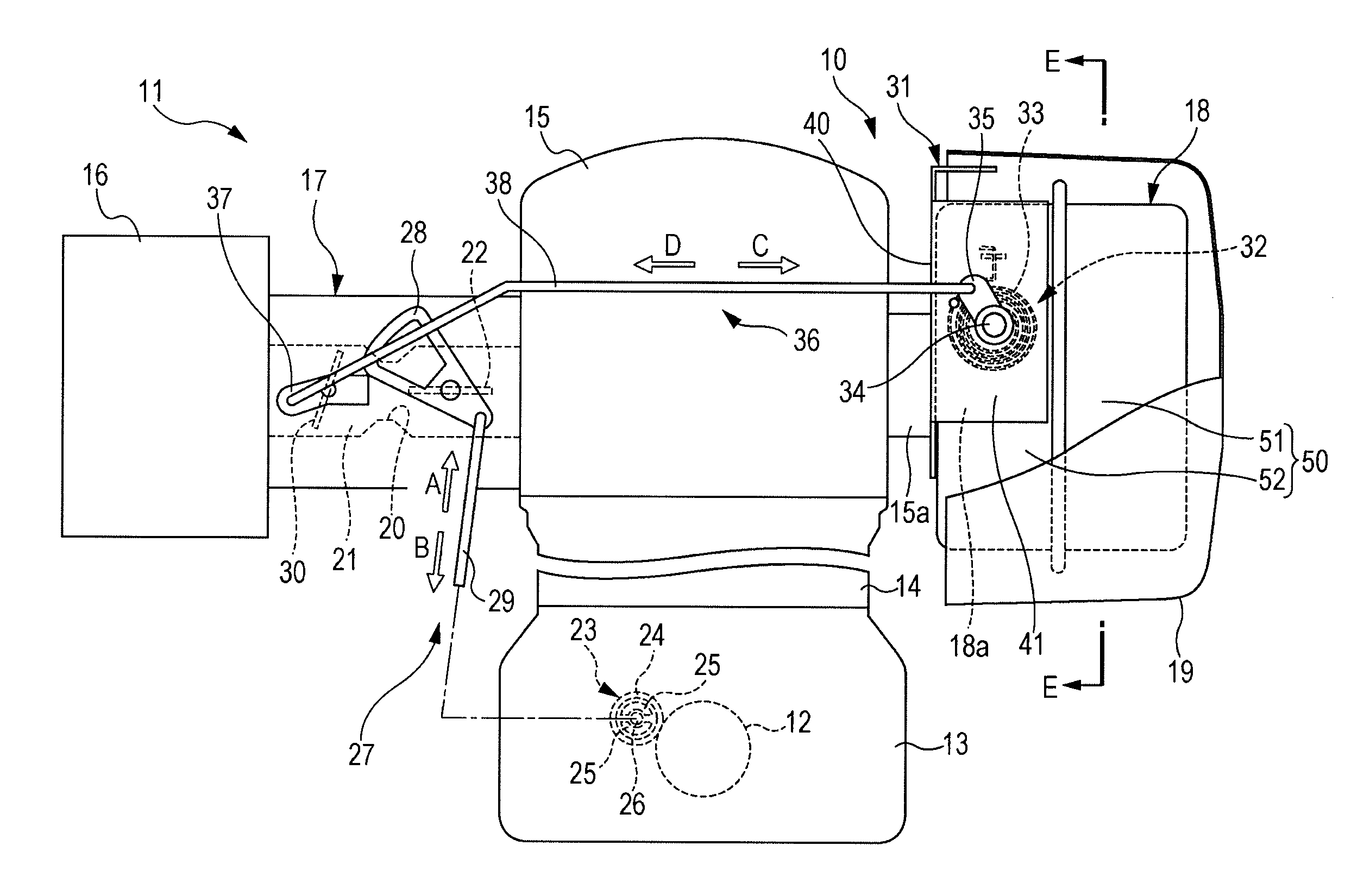

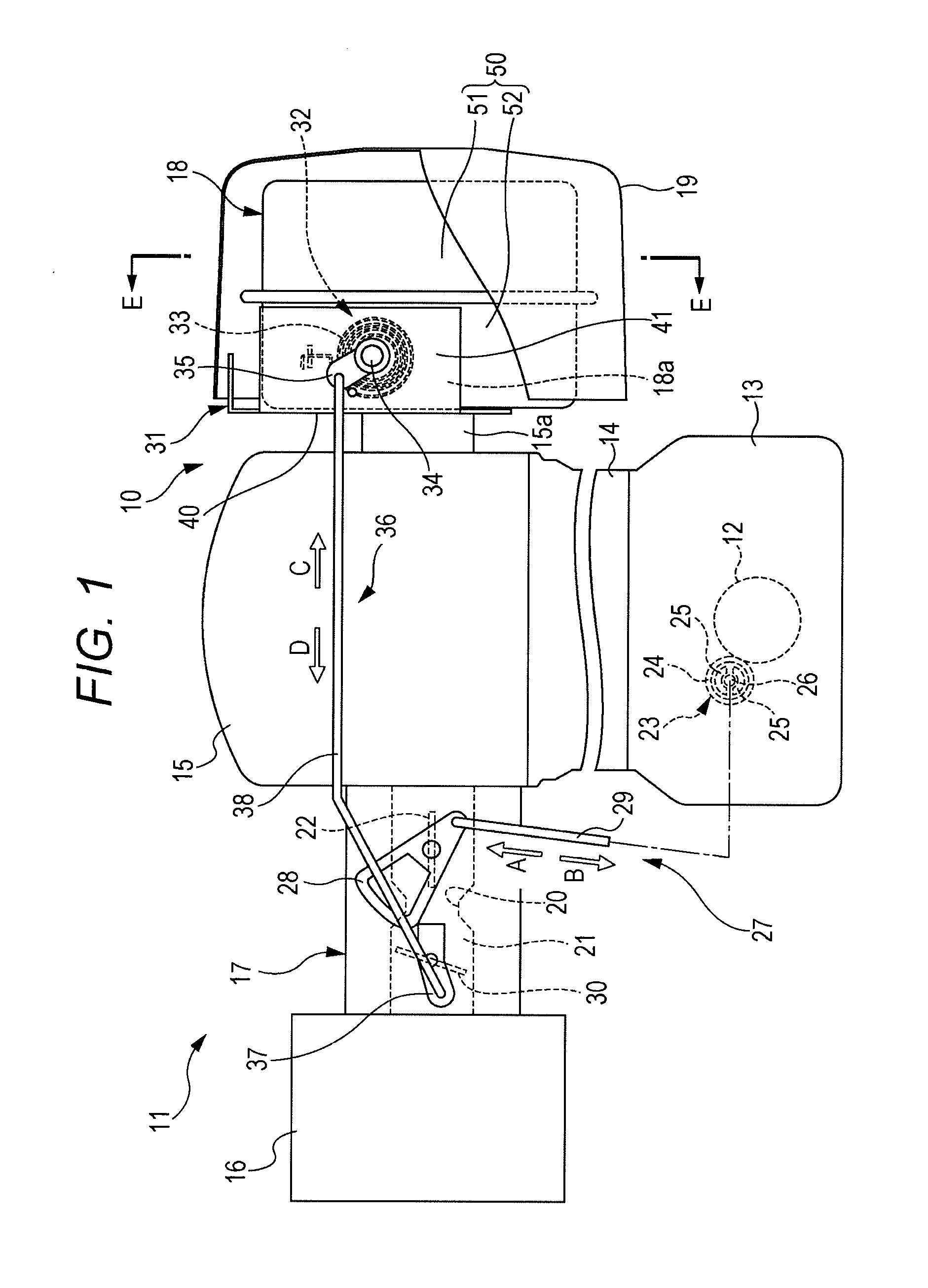

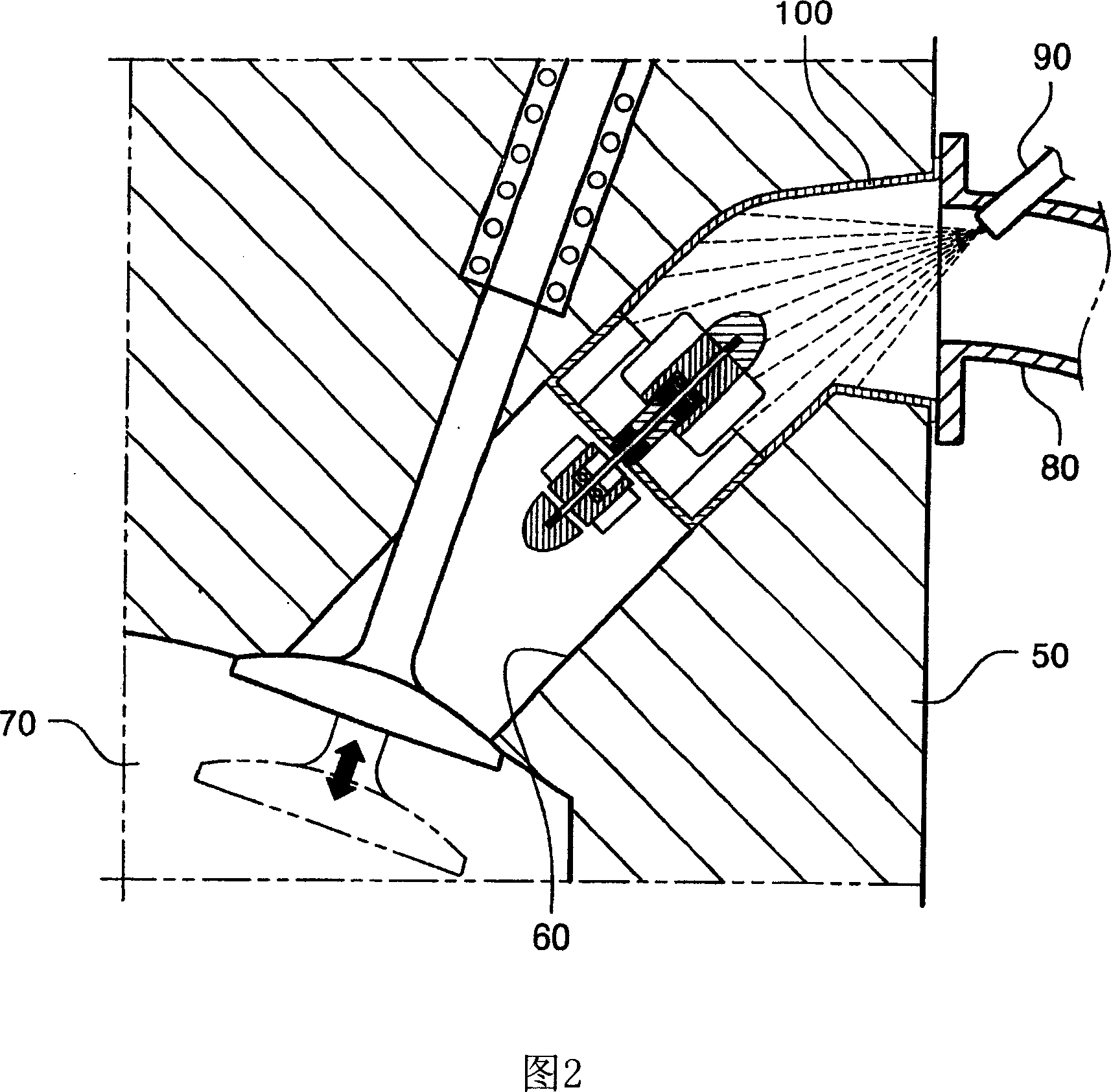

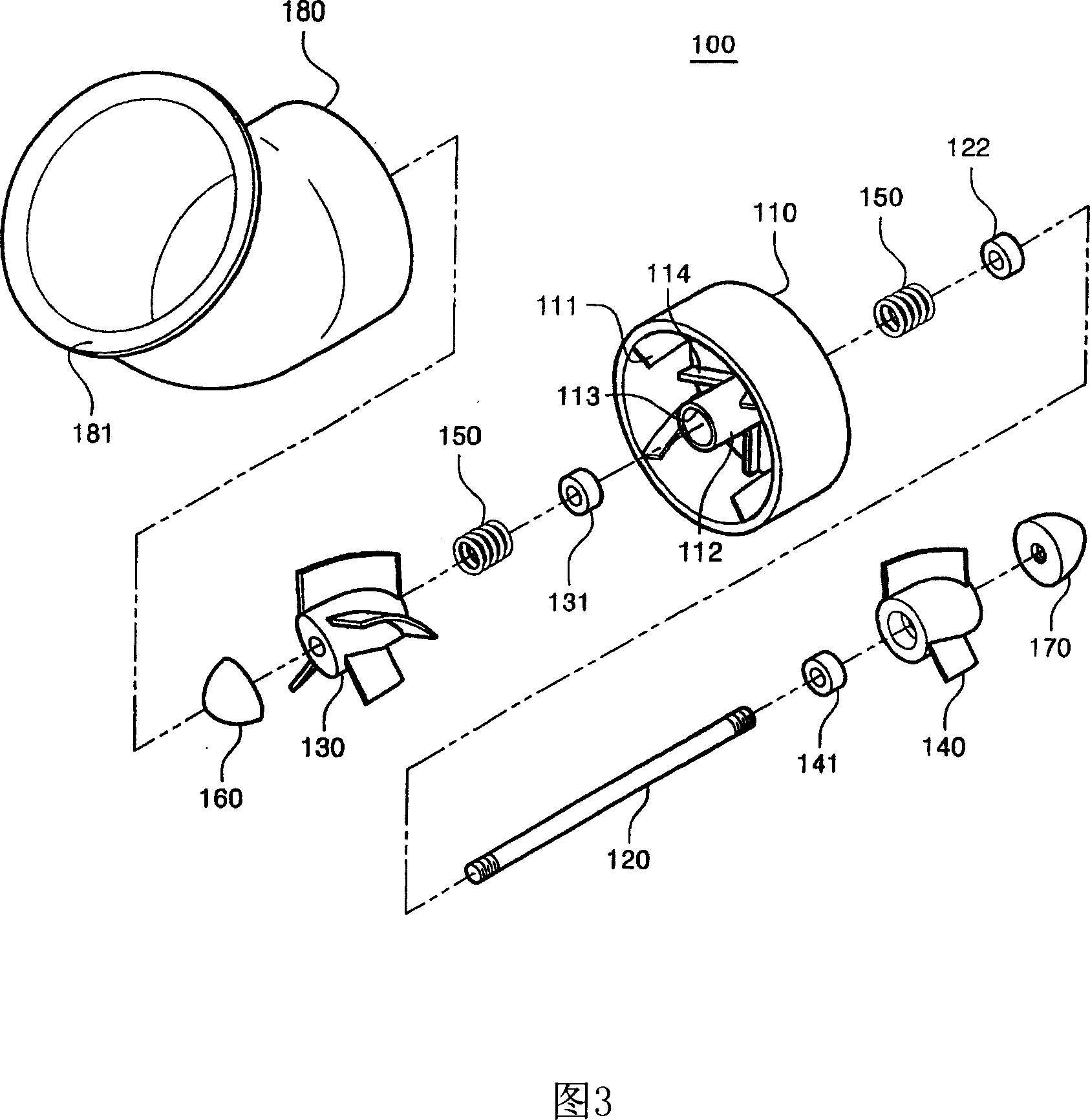

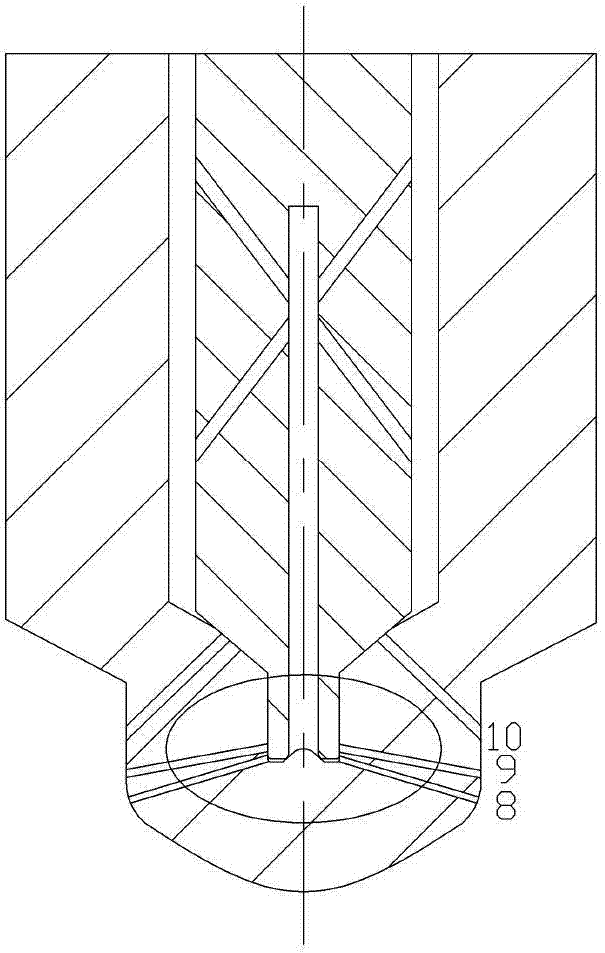

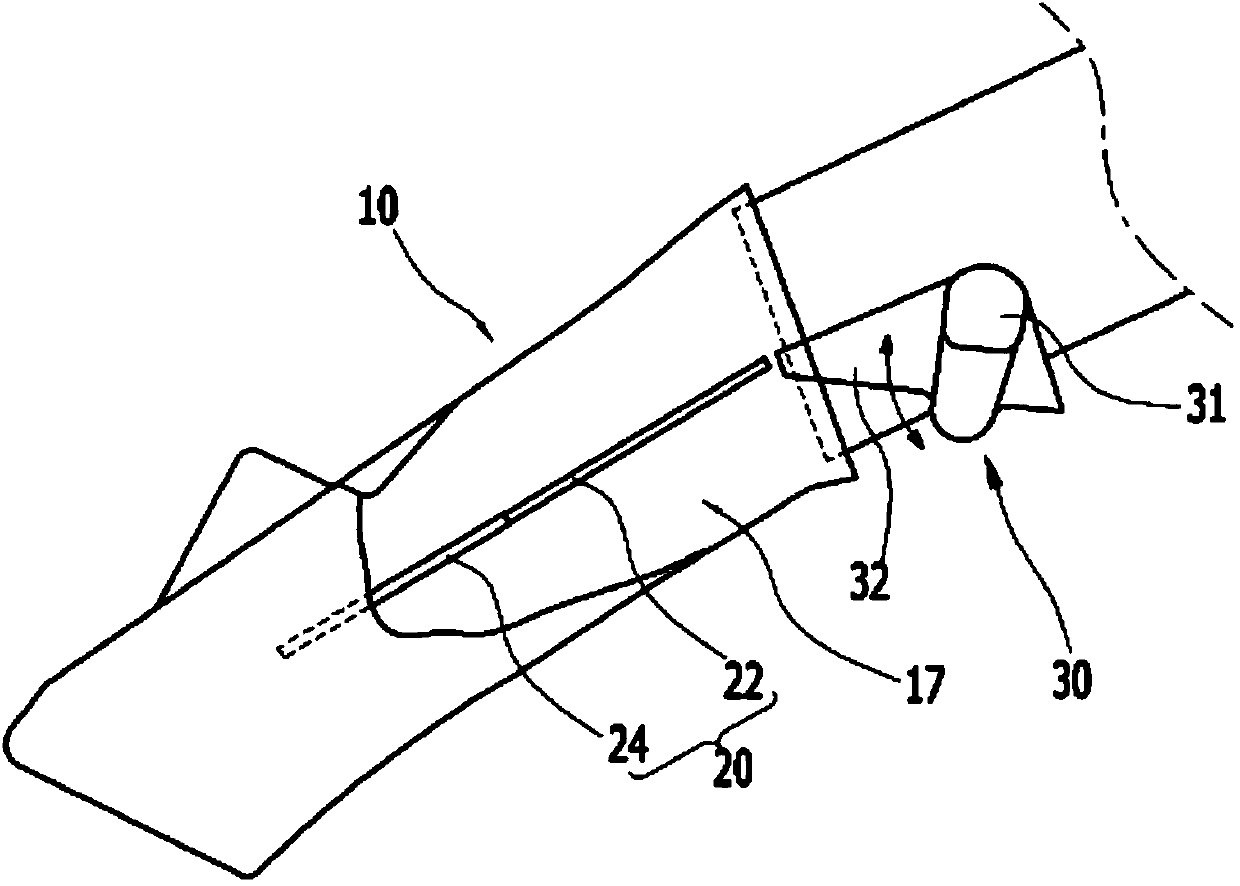

Combustion appliance for raising the temperature of exhaust gas

InactiveCN102782408APromotes early mixingSeeking to heat upBurnersSilencing apparatusCombustorFuel injection

Disclosed is a combustion appliance for raising the temperature of exhaust gas comprised of a fuel injection nozzle (7), electrode rods (ignition devices) (8, 9) and a double cylinder type flame stabiliser (10) disposed so as to encompass the surrounding area thereof; closed on the distal side by a torus-shaped blocking plate (13) disposed between an inner cylinder (11) and an outer cylinder (12) of the flame stabiliser, and connected to one end of a combustion air guide line (15) which guides combustion air (14) between the inner cylinder (11) and outer cylinder (12); with a plurality of combustion air flow holes (16) disposed at the proximal end of the outer cylinder (11), and a plurality of peripheral fins (17) at a different position farther towards the distal end of the circumference of the inner cylinder (11) therefrom which are formed by cutting and raising radially inwards so as to guide the combustion air (14) from a circumferential direction and provide a swirling flow inside the inner cylinder (11); and a plurality of end face fins (18) also formed on the blocking plate (13) by cutting and raising in the direction of fuel injection so as to discharge the combustion air (14) in a circumferential direction and provide a swirling flow around the flame (21).

Owner:HINO MOTORS LTD

Method for prolonging service life of boiler denitration system catalyst

InactiveCN104841269AReduce life lossAvoid incomplete combustionDispersed particle separationFlue gasProcess engineering

The present invention discloses a method for prolonging the service life of a boiler denitration system catalyst. The method comprises a) increasing the denitration system catalyst surface temperature before starting boiler ignition, wherein the denitration system catalyst surface temperature in the step a) is increased to more than or equal to the flue gas dew point temperature, and the step a) comprises a step a1) introduction of an external heat source into the boiler so as improve the denitration system catalyst surface temperature to more than or equal to the flue gas dew point temperature.

Owner:冯伟忠

Automatic choke apparatus for engine

InactiveUS20120247423A1Heating fastAvoid temperature dropInternal combustion piston enginesExhaust apparatusEngineeringExpansion chamber

There is provided an automatic choke apparatus for an engine. A bimetal that is coupled to a choke valve of an intake system is provided in the vicinity of an outer wall face of a muffler. The muffler is divided into a first expansion chamber and a second expansion chamber across a partition plate. An exhaust hole that allows the expansion chambers to be communicated with each other is formed at the lower part of the partition plate. An exhaust gas is guided from the upstream first expansion chamber toward the downstream second expansion chamber through the exhaust hole. A bypass hole is formed at an upper part of the partition plate in such a manner that that the expansion chambers are communicated with each other as bypassing the exhaust hole. The bypass hole is open to the vicinity of the outer wall face opposite to the bimetal.

Owner:SUBARU CORP

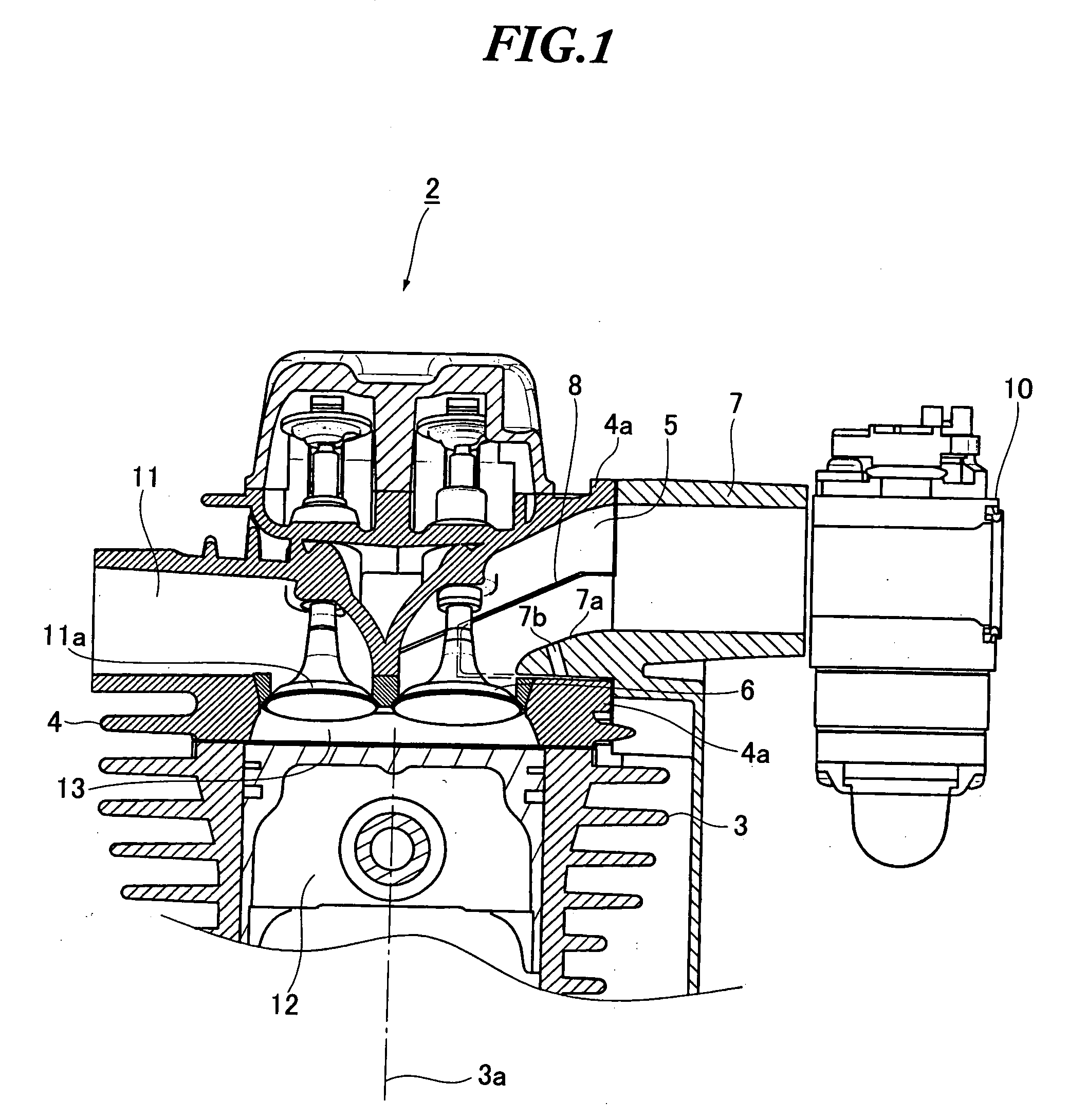

Internal combustion engine having fuel mixing means installed in intake port

InactiveCN1930385AWell mixedImprove performanceDoor/window protective devicesInternal combustion piston enginesExternal combustion engineInternal combustion engine

The present invention relates to an internal combustion engine, and more particularly, to an internal combustion having improved performance by promoting mixing of fuel and air using a fuel mixing means installed at an intake port to improve the flow property of the mixture introduced into a combustion chamber. In an internal combustion engine according to the present invention, a fuel mixing means is installed at an intake port for use in supplying a mixture of fuel and air into a combustion chamber. The fuel mixing means is provided with a stream-disturbing body having a plurality of vanes for disturbing a stream passing through the intake port. The stream-disturbing body is installed rotatably in the intake port to generate a vortex or turbulence so that fuel and air are mixed uniformly and then supplied into the combustion chamber.

Owner:BO KWANG IND

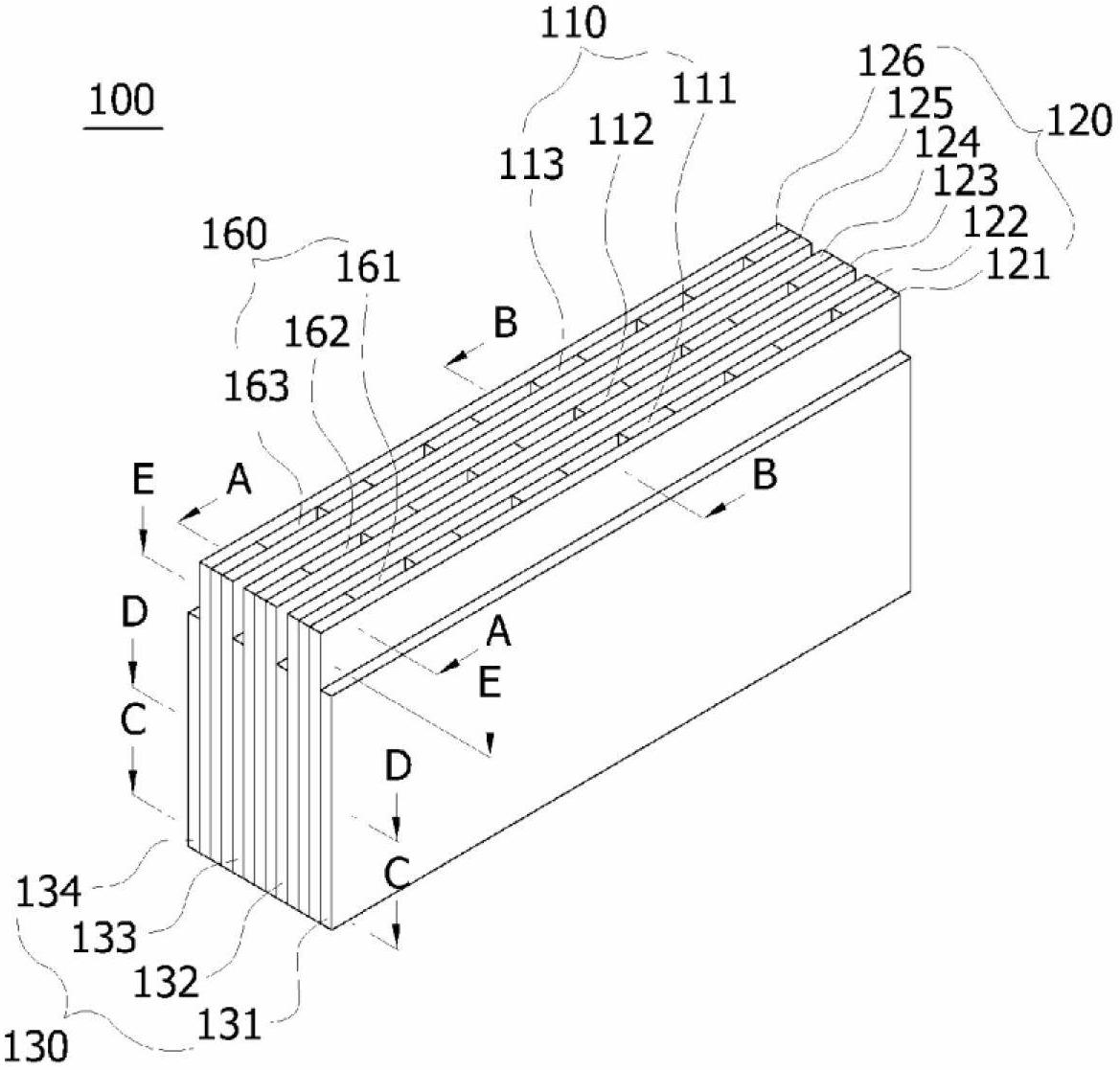

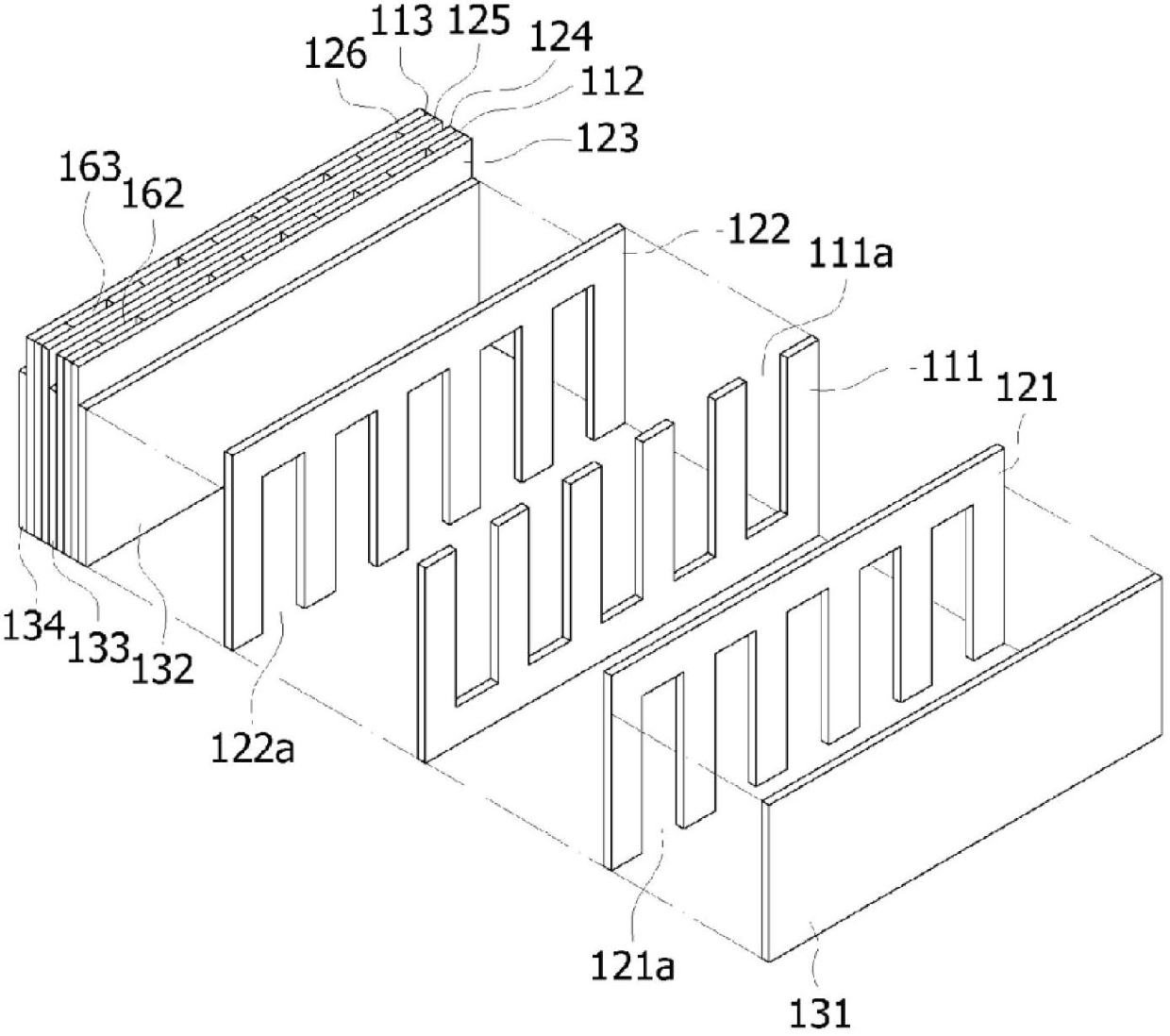

Flame hole unit structure of a gas burner

InactiveUS20120244483A1Easy to manufactureSimple structureBurner manufactureGaseous fuel burnerEngineeringUnit structure

A gas burner for simplifying assembling and manufacturing of a burner flame hole unit by overlapping plates. Portions of the plates are cut so that the cut portions communicate with each other. Flame holes and mixture channels for a mixture of gas and air pass through a gap between the cut portions. The cut portions overlap and communicate with each other between adjacent plates, thereby forming flame holes and channels for flow of the mixture of gas and air through gaps between the cut portions.

Owner:KYUNGDONG NAVIEN

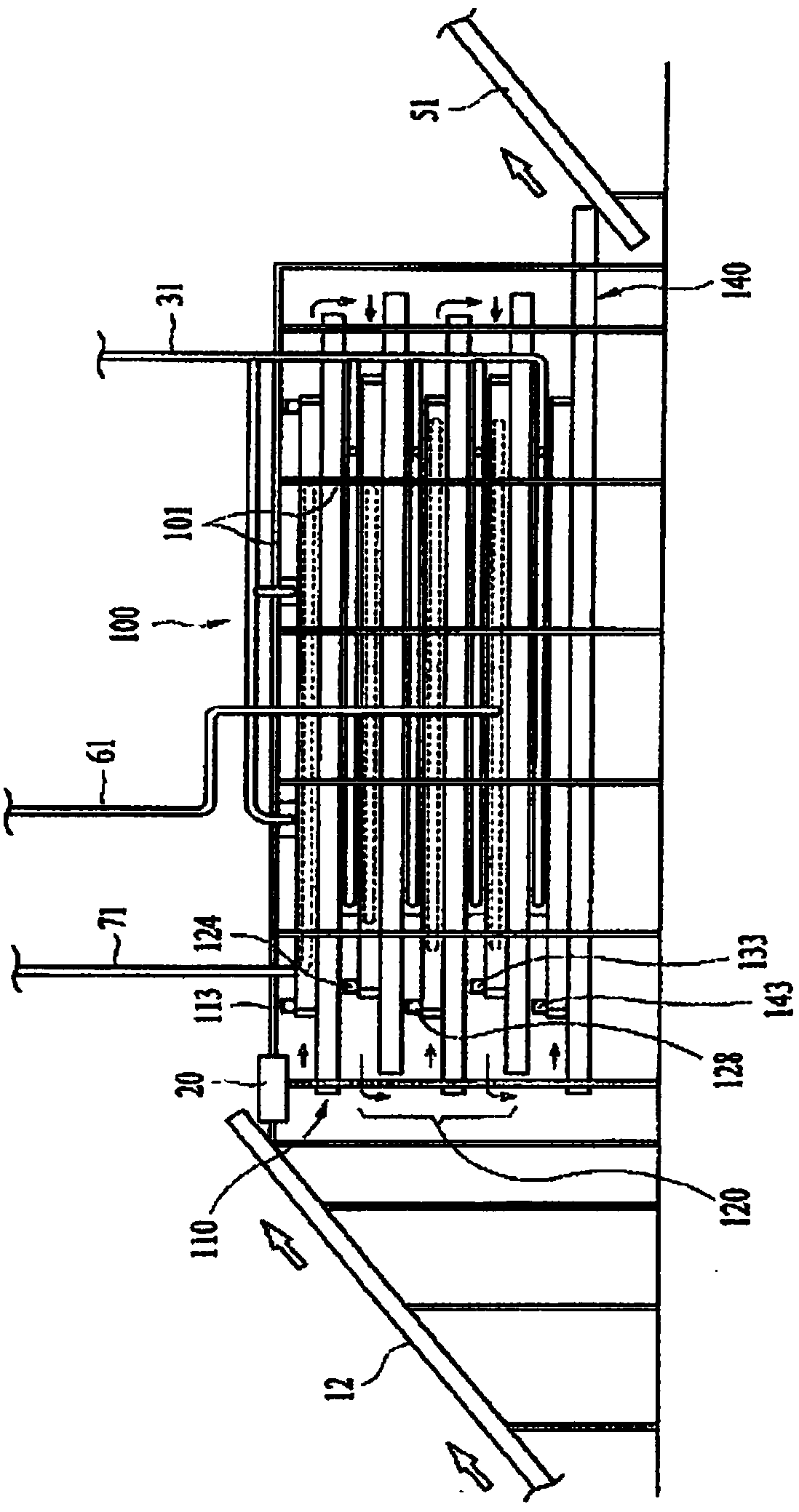

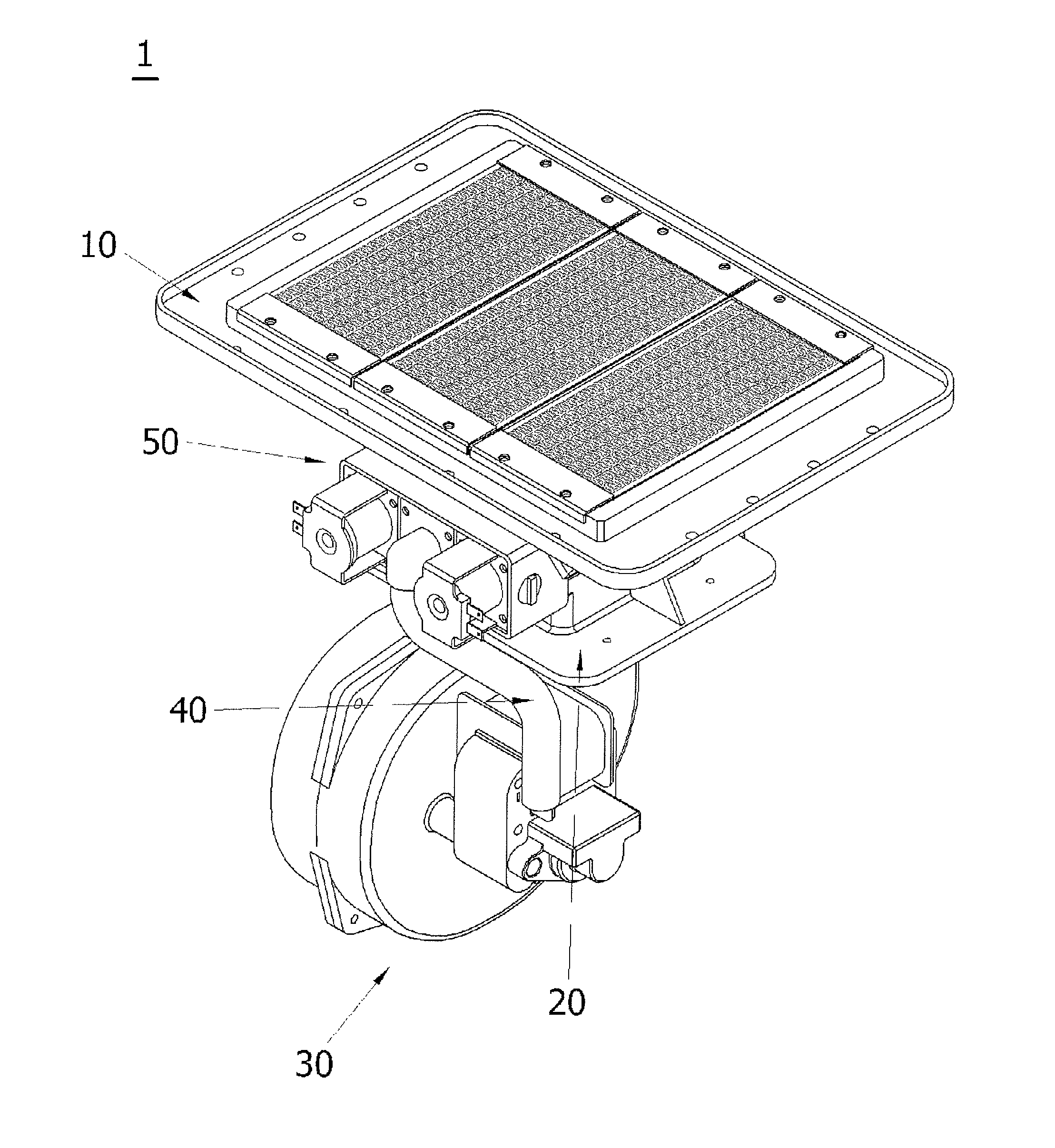

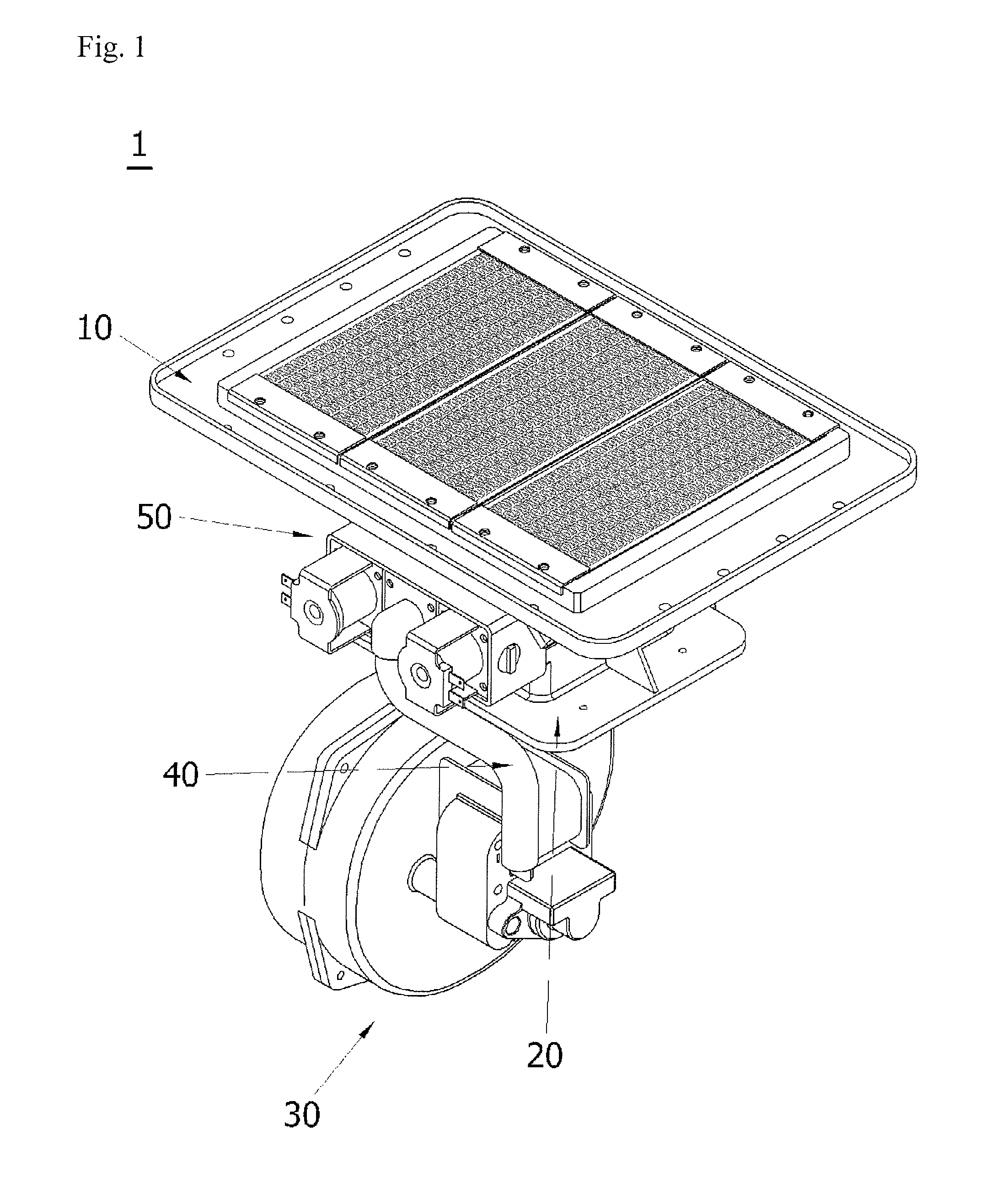

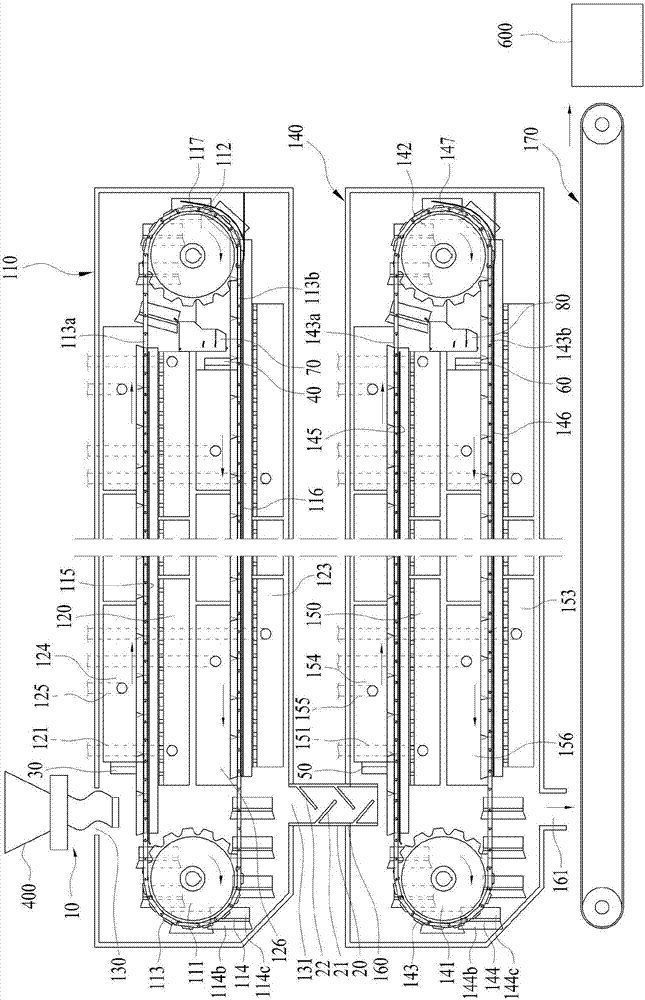

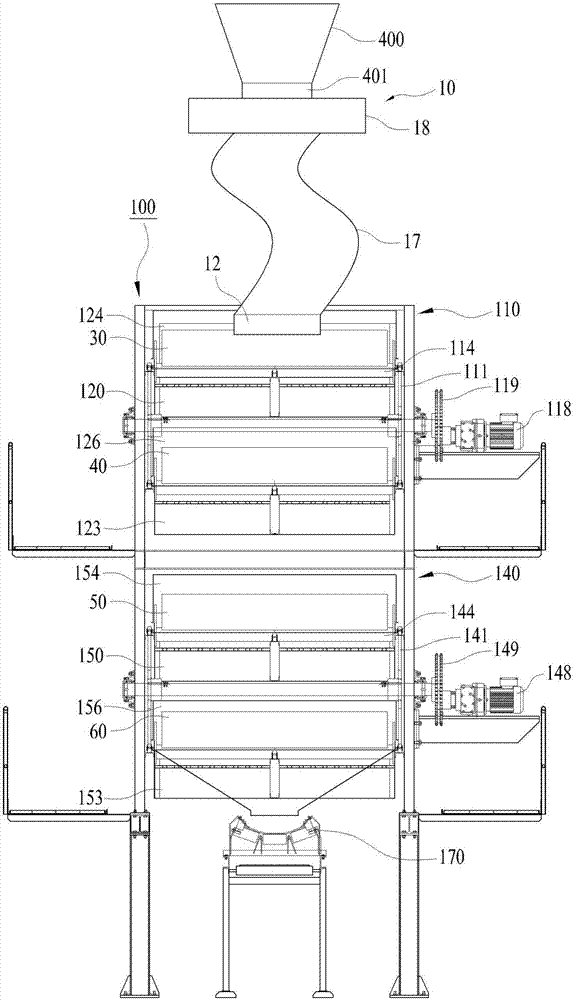

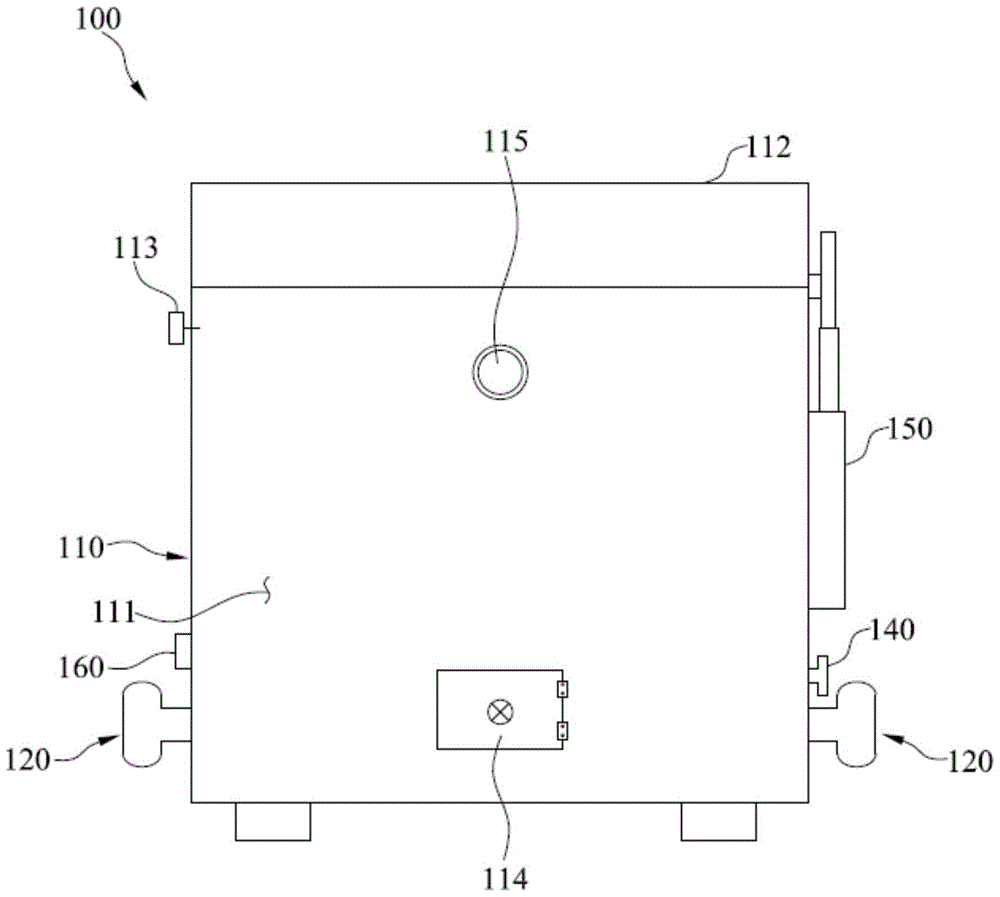

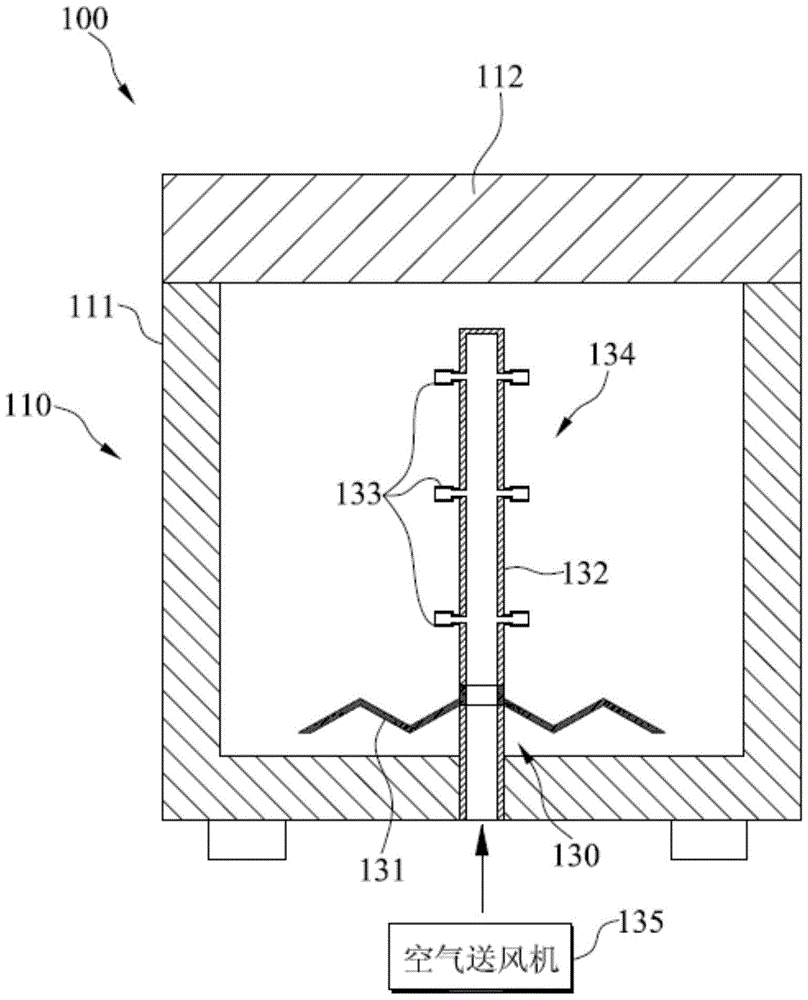

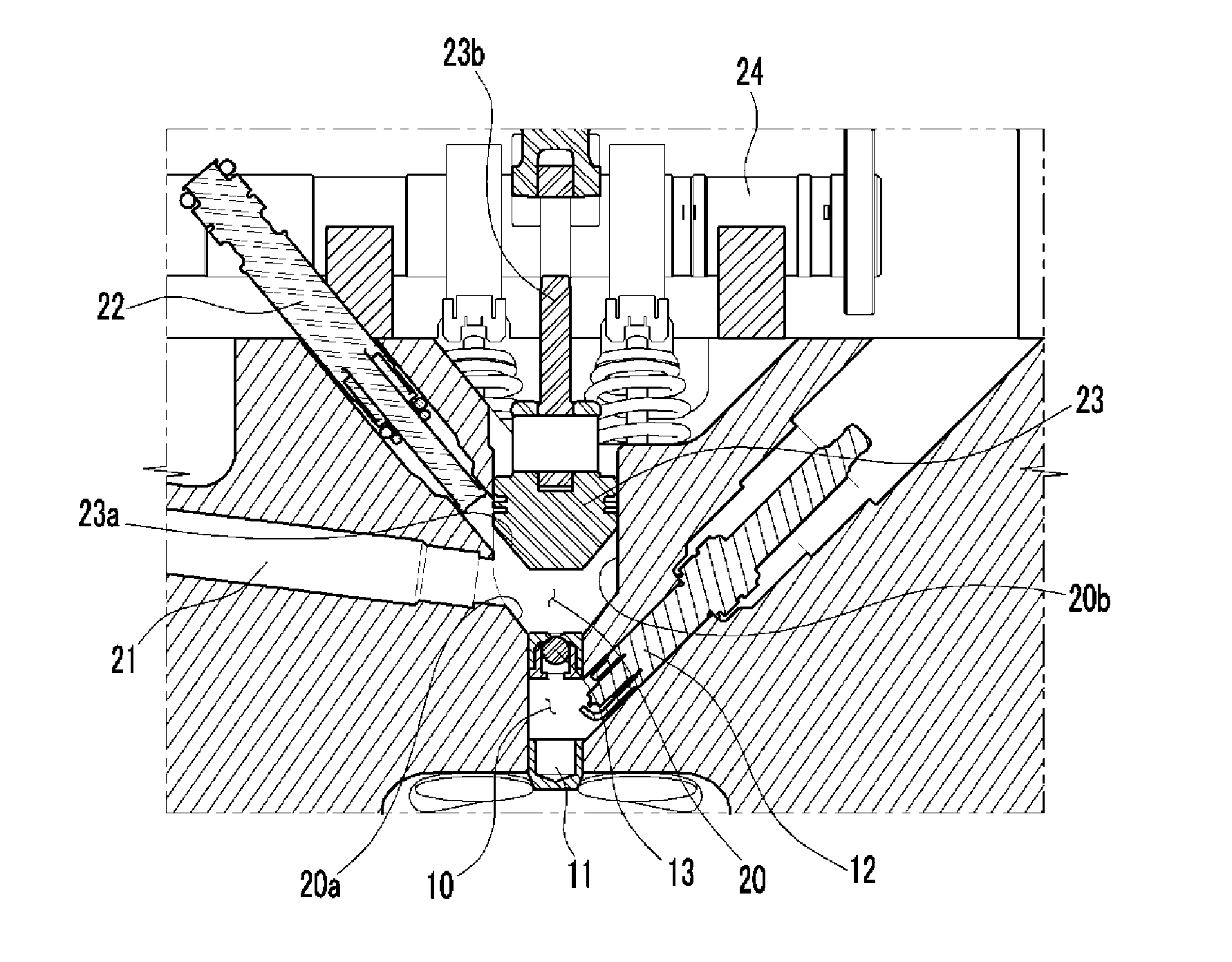

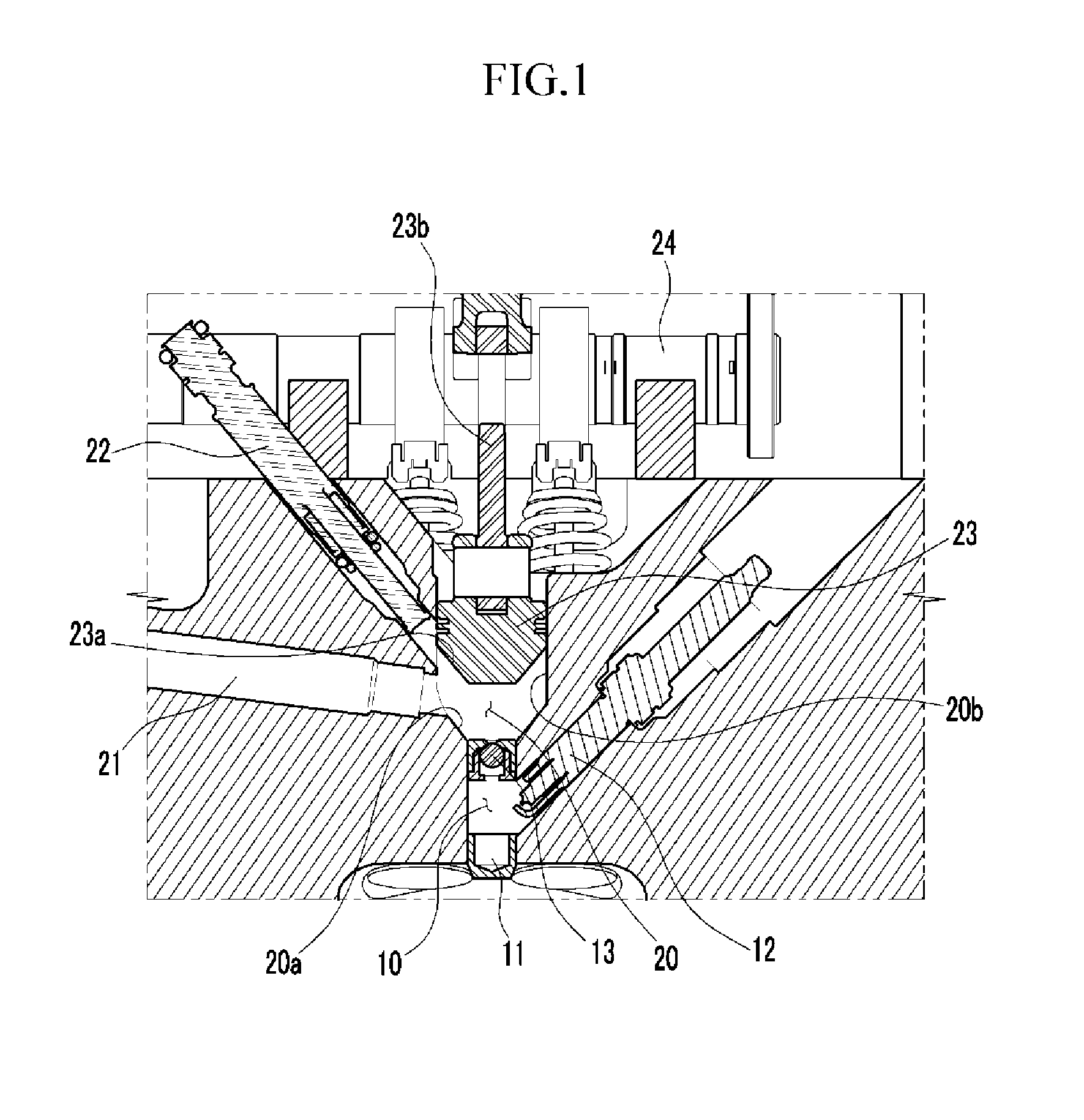

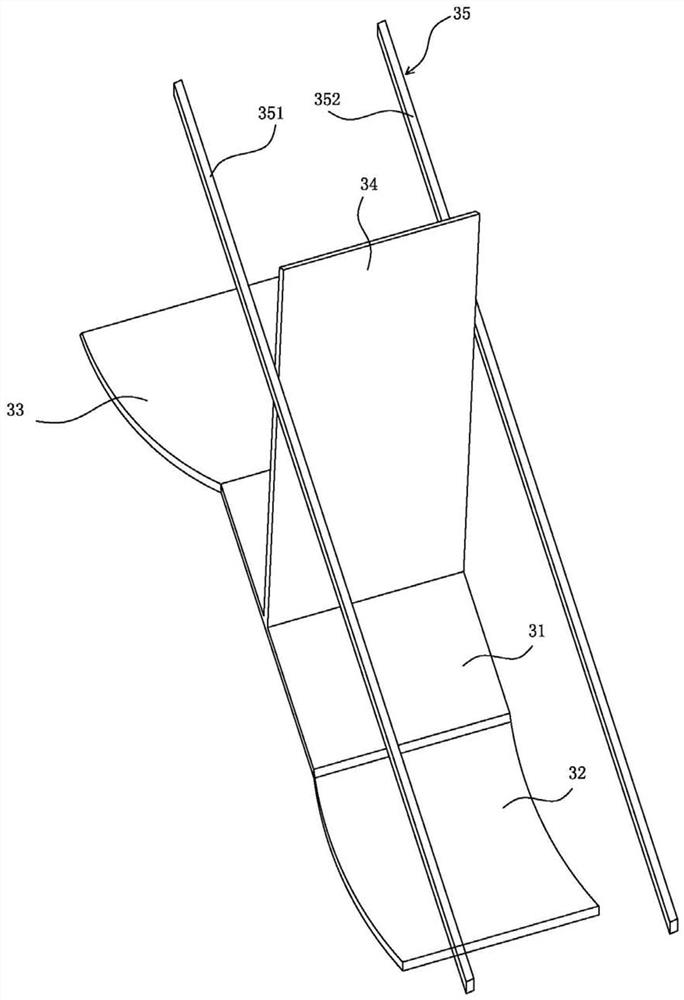

Dust reduction apparatus depending on supply of falling coal in coal drying apparatus using reheat steam

InactiveCN107110600AAvoid incomplete combustionMinimize heatDrying solid materials with heatGranular material dryingEngineeringReducer

The present invention relates to a dust reduction apparatus which minimizes dust generation when coal is dropped and supplied from an upper dryer to a lower dryer in a multi-stage dryer for drying coal using reheat steam. The present invention relates to a coal drying apparatus using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried. The apparatus comprises a fixed quantity coal supplier for supplying a fixed amount of coal onto the surface heading for the top of a first transfer plate, and comprises a dust reducer consisting of: an inlet pipe coupled by a bearing to a discharge port of the fixed quantity coal supplier; a worm wheel coupled to the outer circumferential surface of the inlet pipe; a worm which is coupled by a gear to the worm wheel and which rotates by means of rotational force delivered from a motor; a bent pipe having an upper end coupled to the inlet pipe; and an outlet pipe coupled to one end of the bent pipe. In addition, the apparatus comprises: a first flattening device for uniformly dispersing and flattening a coal pile which is transferred after being dropped and inputted from the dust reducer onto the surface heading for the top of an upper first transfer plate; a first coal receiver which has a plurality of panels fixedly installed therein radially at a certain angle about a rotation axis between a pair of first driven sprockets; a second flattening device for uniformly dispersing and flattening the coal pile which is transferred after being dropped and inputted from the first coal dryer to the surface heading for the top of a lower first transfer plate through rotation of the first driven sprockets; a third flattening device for uniformly dispersing and flattening the coal pile which is transferred after being dropped and inputted from the first coal dryer to the surface heading for the top of an upper second transfer plate of the second coal dryer; a second coal receiver which has a plurality of panels installed therein radially at a certain angle about a rotation axis between a pair of second driven sprockets; and a fourth flattening device for uniformly dispersing and flattening the coal pile which is dropped and inputted from the second coal receiver to the surface heading for the top of a lower second transfer plate through rotation of the second driven sprockets, wherein the first coal receiver receives the coal pile dropped from the surface of the upper first transfer plate, is rotated according to the rotation of the first driven sprockets, and thereafter inputs the coal pile onto the surface of the lower first transfer plate to thereby inhibit dust, and the second coal receiver receives the coal pile dropped from the surface of the upper second transfer plate, is rotated according to the rotation of the second driven sprockets and thereafter inputs the coal pile onto the surface of the lower second transfer plate to thereby inhibit dust.

Owner:HANKOOK TECH

Reciprocating piston six-stroke engine

InactiveCN1412422APlay a cleaning roleSolve the real problemMachines/enginesInlet channelFour-stroke engine

The reciprocating piston fix-stroke engine is a power device used in atomobile, locomotive, ship and engineering machine, and is a new intenral combustion engine, and is expressino of working processof existent four-stroke engine, and is characterized by that after exhaust stroke and before induction stroke two strokes of air admisssino and air discharge and air inlet channel and exhaust line are added so as to possess the actions of cleaning residual waste gas and reducing combustion chamber temperature and can obtain more completely combustion.

Owner:罗庆农

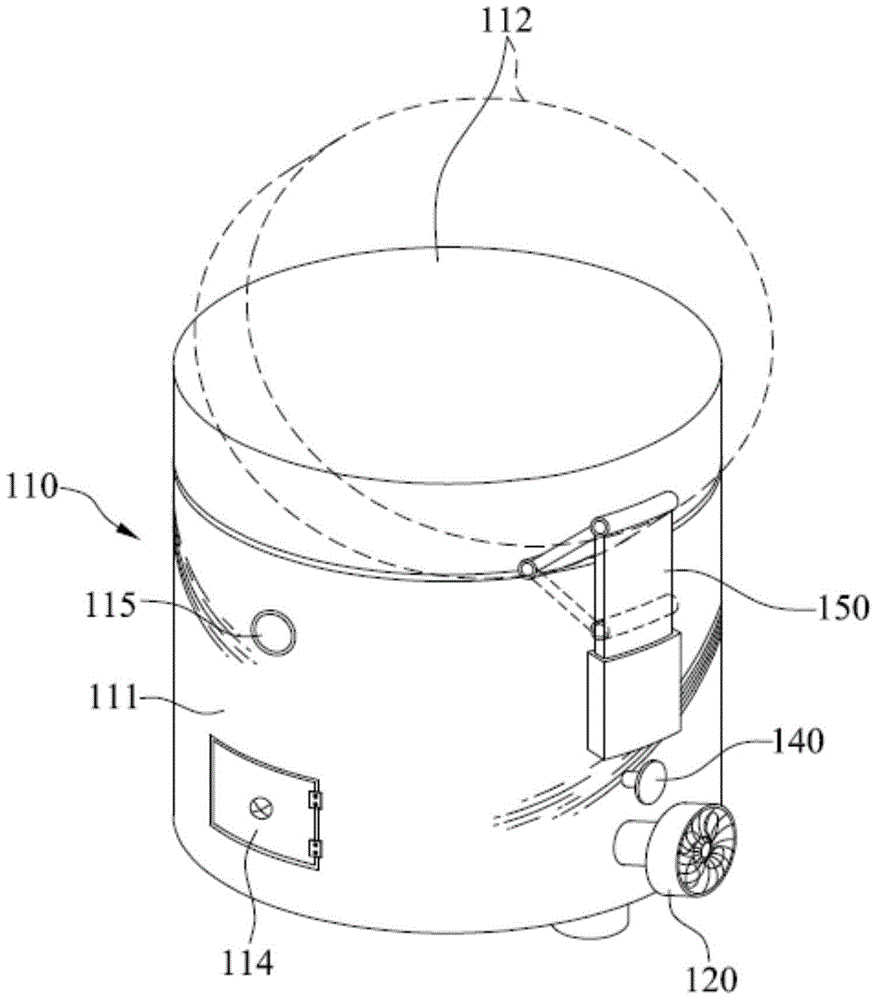

Multi-layer high-temperature pyrolysis incineration apparatus

InactiveCN105745496AProcessing speedLarge processing capacityIncinerator apparatusHazardous substanceEngineering

The multi-layer high-temperature pyrolysis incineration apparatus according to the present invention is proposed in order to solve the problems of conventional methods. The present invention comprises: a plurality of air injection holes which are arranged in multi-stages so as to be vertically spaced apart from each other in a blast pipe installed within a circular incinerator; and a stirring device which is configured in the center of the bottom of the incinerator such that a high water content object to be incinerated, filling the lower part of the incinerator, is stirred by rotation of a stirring blade whereby an object to be treated is completely combusted at a high temperature through multi-layer combustion layers in the incinerator by forcibly blowing outside air into the incinerator, and it is possible to prevent incomplete combustion of the object to be treated, thereby blocking the emission of environmentally hazardous substances and exhaust gases.

Owner:梁福周 +1

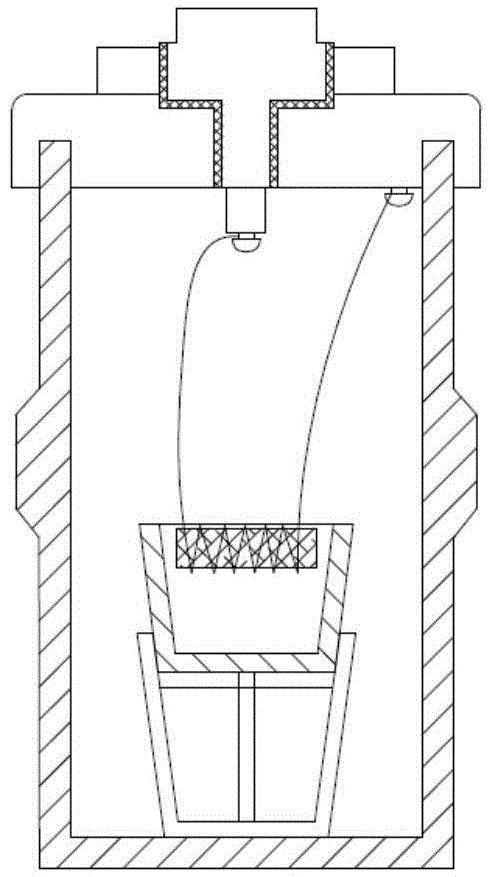

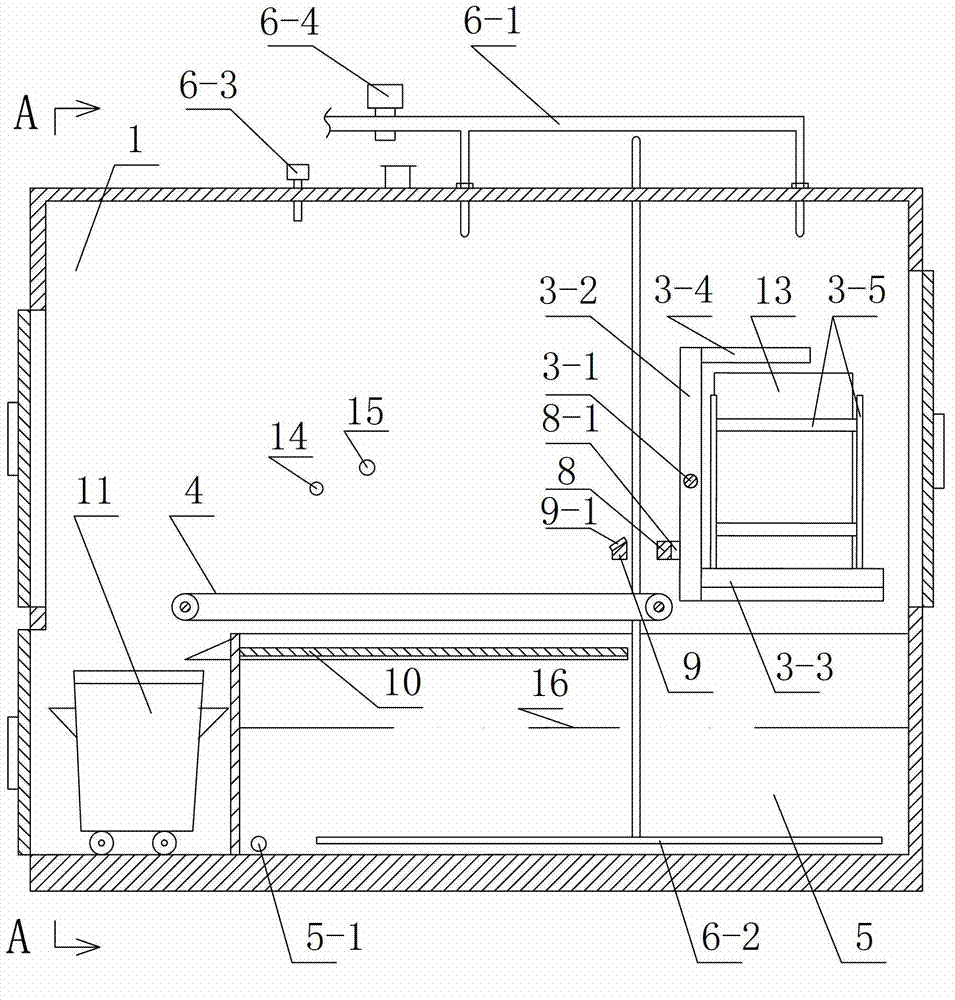

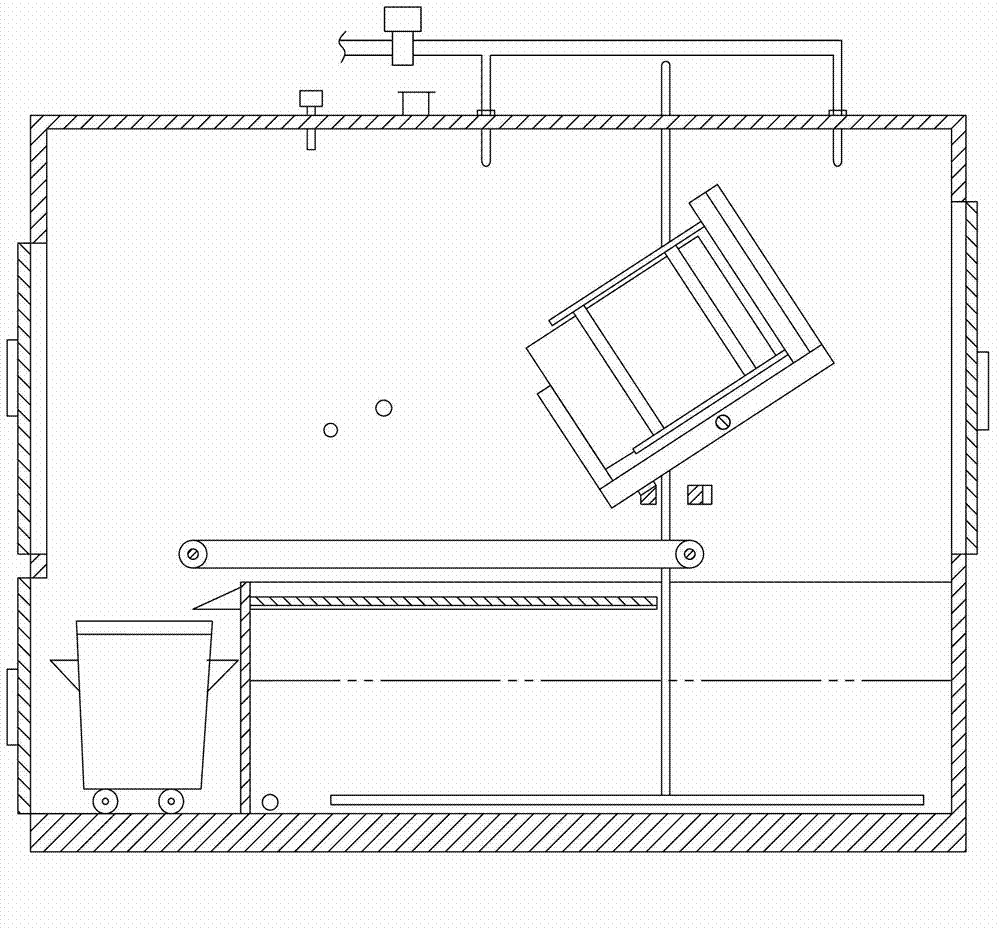

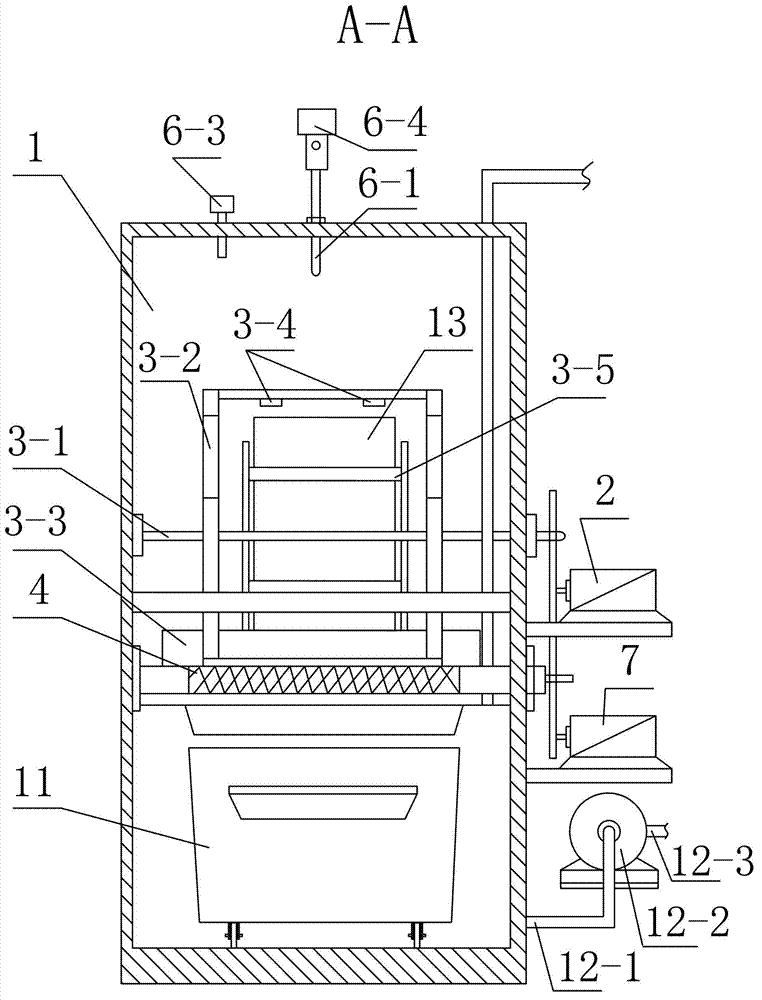

Rectified/distilled residue incineration pretreatment device

ActiveCN102889600AEasy to pourResidue reductionIncinerator apparatusTemperature controlBiochemical engineering

The invention relates to a rectified / distilled residue incineration pretreatment device which is characterized by comprising an openable pretreatment bin, a containing bucket overturning assembly, a filter screen chain, a receiving groove and bin temperature control equipment, wherein the containing bucket overturning assembly is arranged in the pretreatment bin and is driven by turnover driving equipment to be turned over; the filter screen chain is positioned at the rear side of the containing bucket overturning assembly and the feed end of the filter screen chain is positioned below the discharge end of the containing bucket overturning assembly; the receiving groove is positioned below the filter screen chain; the filter screen chain is a circulating screen chain driven by screen chain driving equipment to move; the discharge end of the filter screen chain is positioned outside the receiving groove; and the lower part of the receiving groove is provided with a liquid discharge hole communicated with the outside of the pretreatment bin. The invention aims to provide the rectified / distilled residue incineration pretreatment device which provides convenience to incinerate rectified or distilled residues (rectified / distilled residues in short).

Owner:福建省固体废物处置有限公司

Intake port for 4-cycle engine

InactiveUS7424878B2Reduce in quantityIncrease powerCylinder headsCylindersCombustion chamberCylinder head

An intake port for a 4-cycle engine includes an intake port base integrally formed with a cylinder head, and an intake port forming member that forms an intake port together with the intake port base. The area of the cross section of the intake port orthogonal to a centerline of the intake port is substantially uniform from an open intake side thereof toward a combustion chamber. The angle made by the centerline of the intake port and an intake valve shaft is larger than 90° from a viewpoint of the intake valve. Thereby, the 4-cycle engine can output high power with the intake port shape, as formed with above mentioned configuration, that reduces intake resistance and that uses simple design molds. More specifically, the engine can reliably prevent condensed fuel from remaining in the intake port to avoid incomplete combustion of gas.

Owner:MAKITA NUMAZU CORP

Automatic choke apparatus for engine

InactiveUS8978622B2Heating fastAvoid temperature dropElectrical controlInternal combustion piston enginesEngineeringExpansion chamber

There is provided an automatic choke apparatus for an engine. A bimetal that is coupled to a choke valve of an intake system is provided in the vicinity of an outer wall face of a muffler. The muffler is divided into a first expansion chamber and a second expansion chamber across a partition plate. An exhaust hole that allows the expansion chambers to be communicated with each other is formed at the lower part of the partition plate. An exhaust gas is guided from the upstream first expansion chamber toward the downstream second expansion chamber through the exhaust hole. A bypass hole is formed at an upper part of the partition plate in such a manner that that the expansion chambers are communicated with each other as bypassing the exhaust hole. The bypass hole is open to the vicinity of the outer wall face opposite to the bimetal.

Owner:SUBARU CORP

Pre-chamber structure for piston engine

InactiveUS20140109865A1Effective controlEasy dischargeInternal combustion piston enginesCombustion chamberEngineering

A pre-chamber structure for a piston engine may include: a pre-chamber combustion chamber in which a mixture of fuel and air is combusted and a pre-chamber compression chamber including a sub-chamber communicating with the pre-chamber combustion chamber and having an inclined wall surface, and a main chamber extending from the sub-chamber, thereby preventing the fuel from being adsorbed and remaining in the wall surface of the pre-chamber compression chamber in a droplet state.

Owner:HYUNDAI MOTOR CO LTD

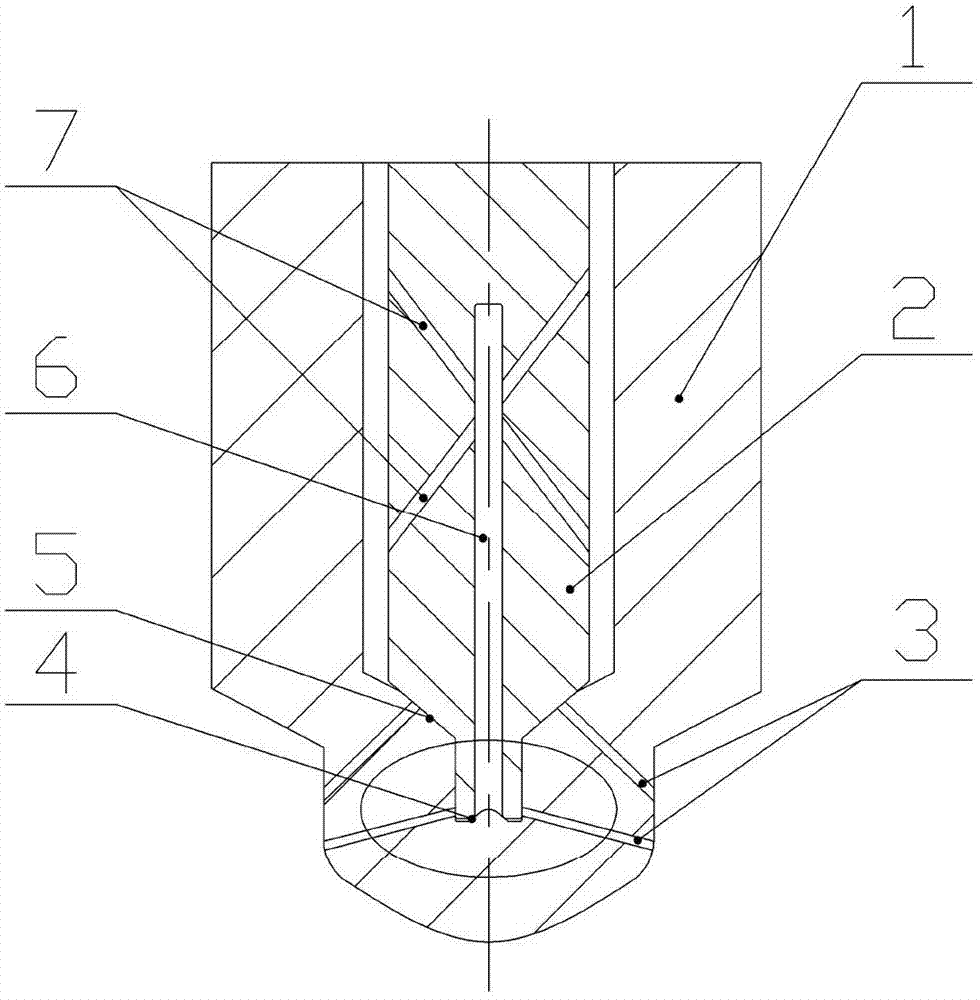

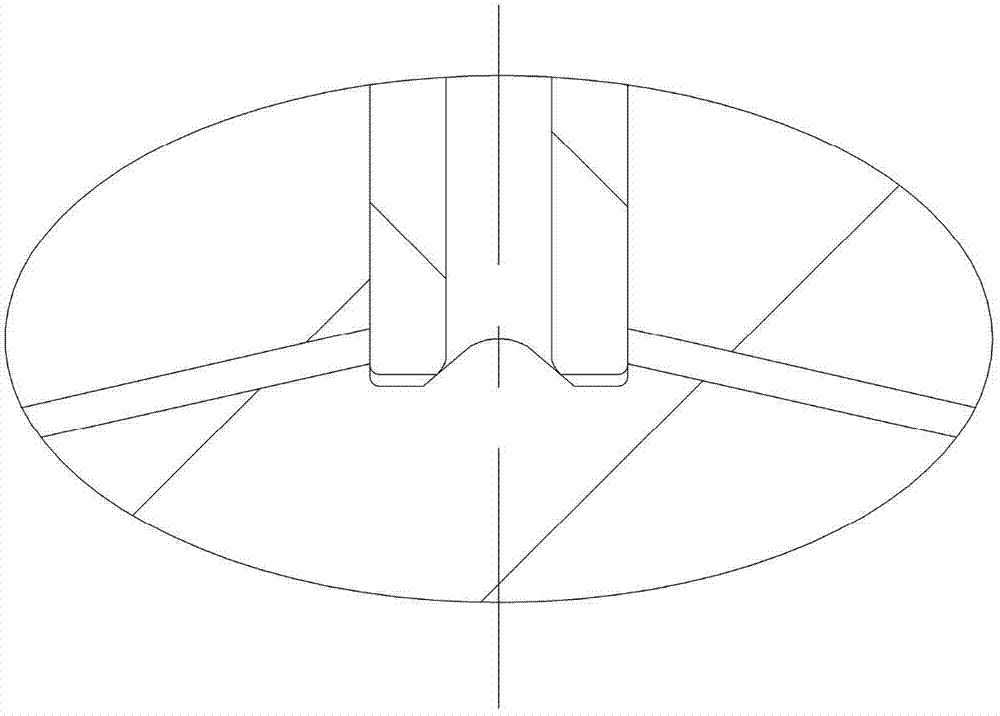

Double-seat multiple-atomizing nozzle

InactiveCN102734026AIncrease the degree of mixingHigh thermal efficiencyFuel injection apparatusMachines/enginesCombustion chamberInternal combustion engine

The invention aims to provide a double-seat multiple-atomizing nozzle which comprises a needle valve body, a needle valve, an oil storage chamber and a spray hole, wherein the needle valve is arranged in the needle valve body; an annular oil chamber is formed by the needle valve and the needle valve body; the middle-lower part of the needle valve is provided with the oil storage chamber; the needle valve is further provided with an oil hole capable of communicating the oil chamber and the oil storage chamber; the lower end part is provided with an upper needle valve seat surface and a lower needle valve seat surface; and the lower end part of the needle valve body is provided with a first spray hole and a second spray hole. When the needle valve is positioned at the lowest end, the first spray hole is sealed by the upper needle valve seat surface, and the second spray hole is sealed by the lower needle valve seat surface; and the first spray hole is communicated with the annular oil chamber when the needle valve moves upwards, and the second spray hole is communicated with the oil storage chamber when the needle valve further moves upwards. The double-seat multiple-atomizing nozzle provided by the invention can realize the atomization twice or multiple times when the same fuel is injected, thereby enhancing the atomizing effects of the fuel and the mixing degree of the mixed gases in a combustion chamber, efficiently enhancing the thermal efficiency of a combustion engine and improving the dynamic property of the combustion engine and the economical efficiency of the fuel.

Owner:HARBIN ENG UNIV

Flame hole unit structure of a gas burner

InactiveCN102639938AShorten the timeLow costBurner manufactureGaseous fuel burnerEngineeringUnit structure

The present invention relates to a flame hole unit structure of a gas burner for simplifying, easily assembling, and manufacturing a structure of a burner flame hole unit by overlapping a plurality of plates of which portions are cut so that the cut portions may be intersected with each other, and by forming flame holes and mixture channels of gas and air through a gap between the cut portions. To realize said purpose, the flame hole unit structure of the gas burner of the present invention has a plurality of flame holes in which a mixture of gas and air is sprayed to form a flame, and the plurality of plates of which the portions are cut are overlapped together, wherein the cut portions are intersected and overlapped with each other between the adjacent plates, thereby forming the flame holes and the mixture channels of gas and air through the gap between the cut portions.

Owner:KYUNGDONG NAVIEN

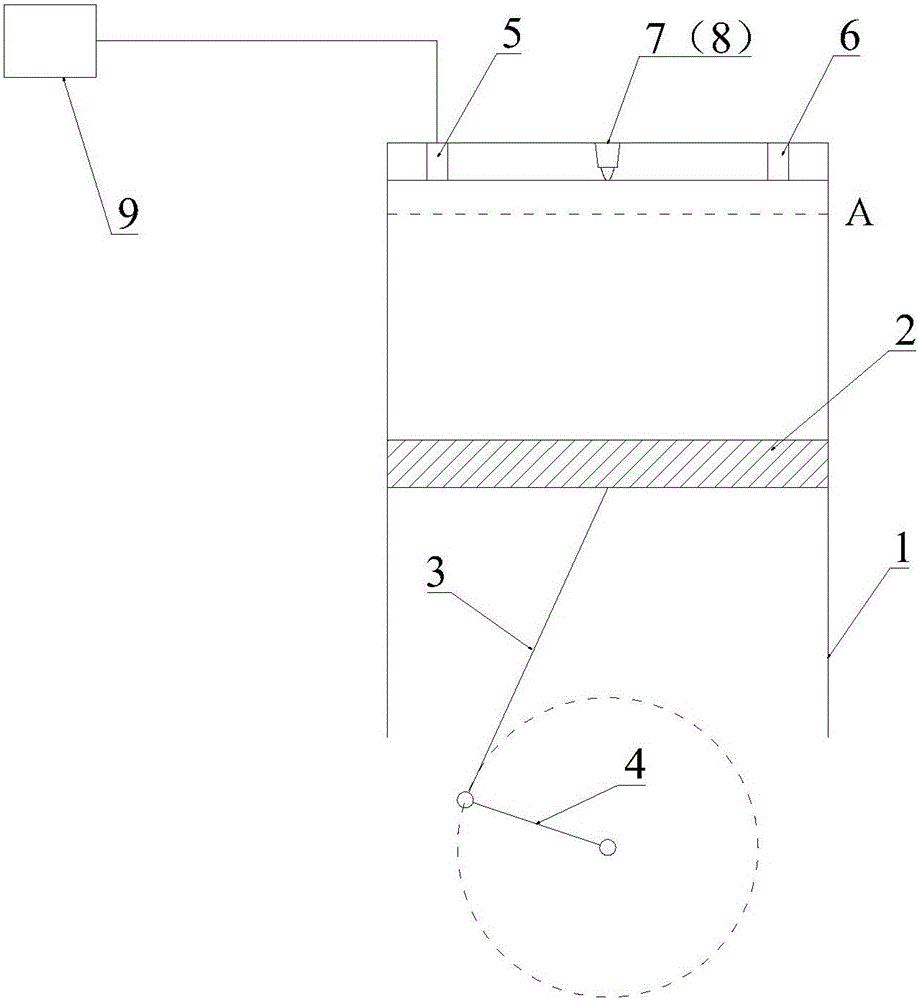

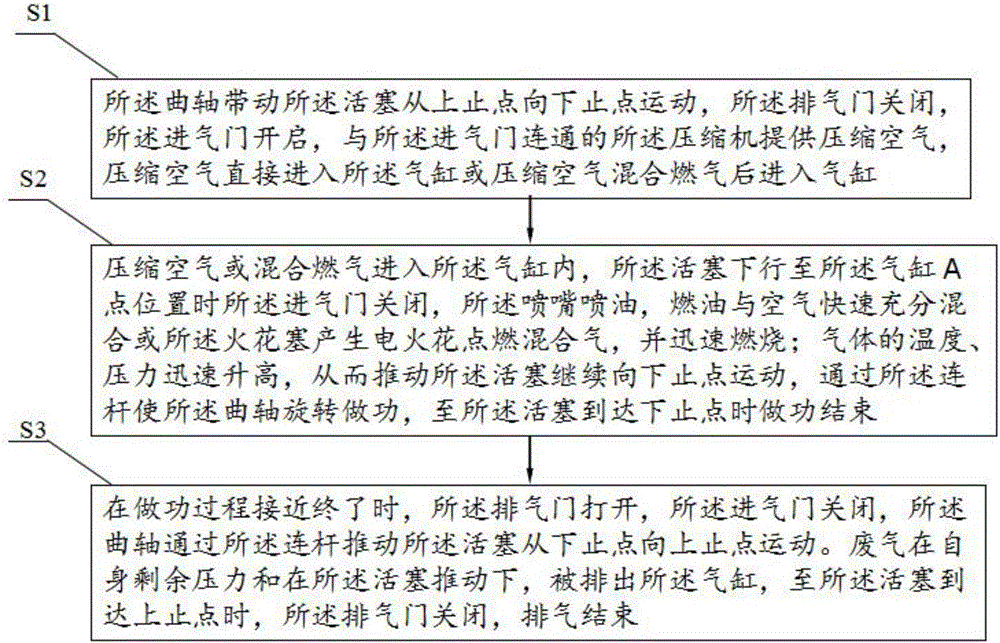

Two-stroke engine transformed from four-stroke engine and working method of two-stroke engine

InactiveCN105927378AImprove powerImprove efficiencyInternal combustion piston enginesCombustionFour-stroke engine

The invention relates to a two-stroke engine transformed from a four-stroke engine. Compared with a traditional multi-stroke engine, the method that the inlet gas is compressed externally is adopted, so that the compression stroke of the engine is omitted, and accordingly the four-stroke engine has the possibility of the two-stroke mode. Compared with the four-stroke engine, two strokes are omitted, so that the power performance is better, the structure is simple, the size is small, and the weight is low; compared with the traditional engine, the compression stroke is omitted, advanced ignition is not needed, and therefore the knocking phenomenon is eliminated; and the independent combustion chamber space is omitted, exhaust is thorough, and the combustion efficiency is substantially improved.

Owner:苏喜清

Variable intake manifold for internal combustion engine and variable air intake device using the same

InactiveCN103867289AIncrease burn rateLow flow resistanceInternal combustion piston enginesCombustion-air/fuel-air treatmentExternal combustion engineEngineering

A variable intake manifold apparatus for an internal combustion engine, may include an inlet drawing in outside air and being connected to a main passage, first and second outlets branched from the main passage and fluid-connected to the inlet through the main passage and releasing the outside air drawn through the main passage through the first and second outlets, and a partition dividing the main passage and one of the first and second intake passages.

Owner:HYUNDAI MOTOR CO LTD +1

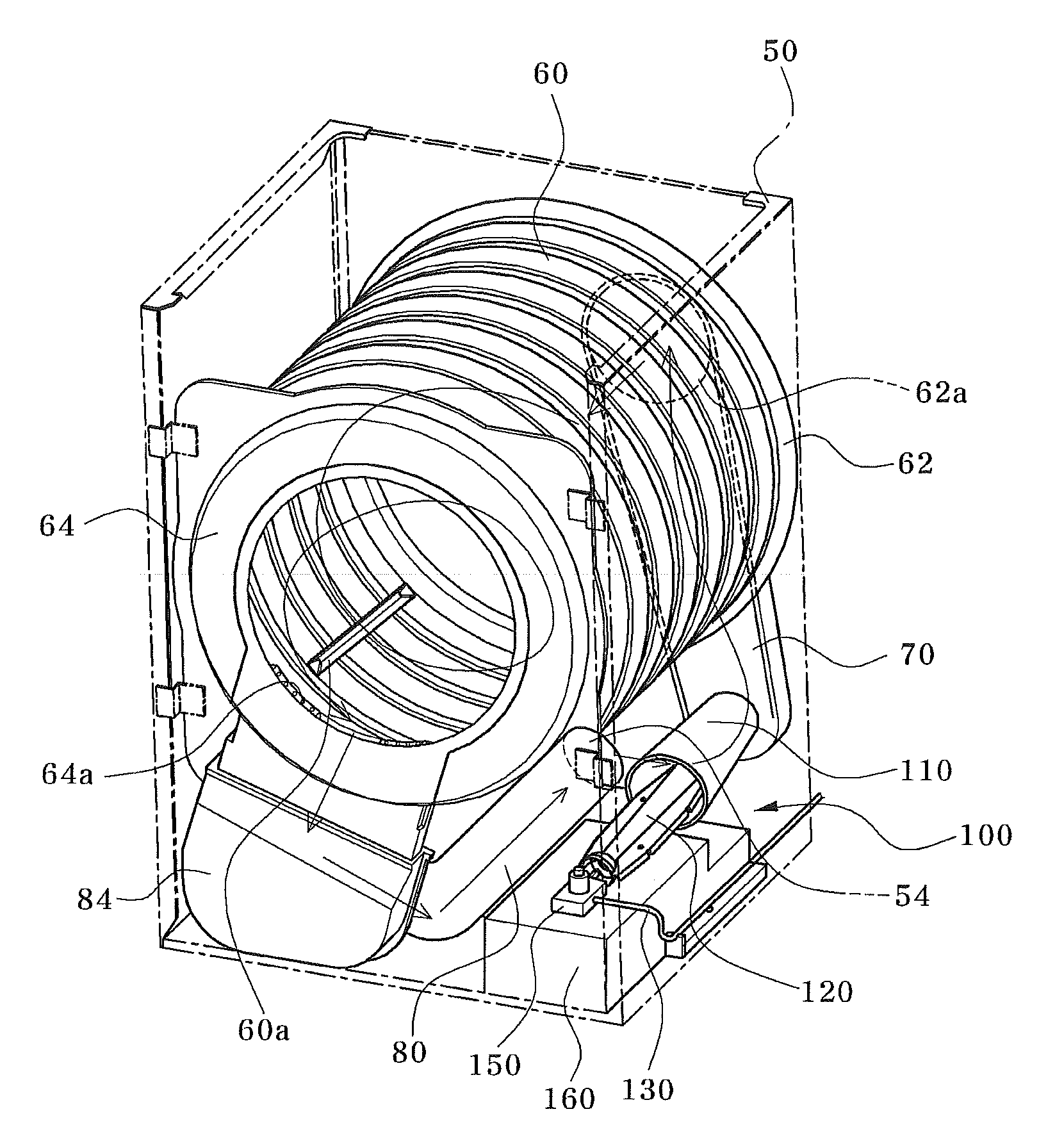

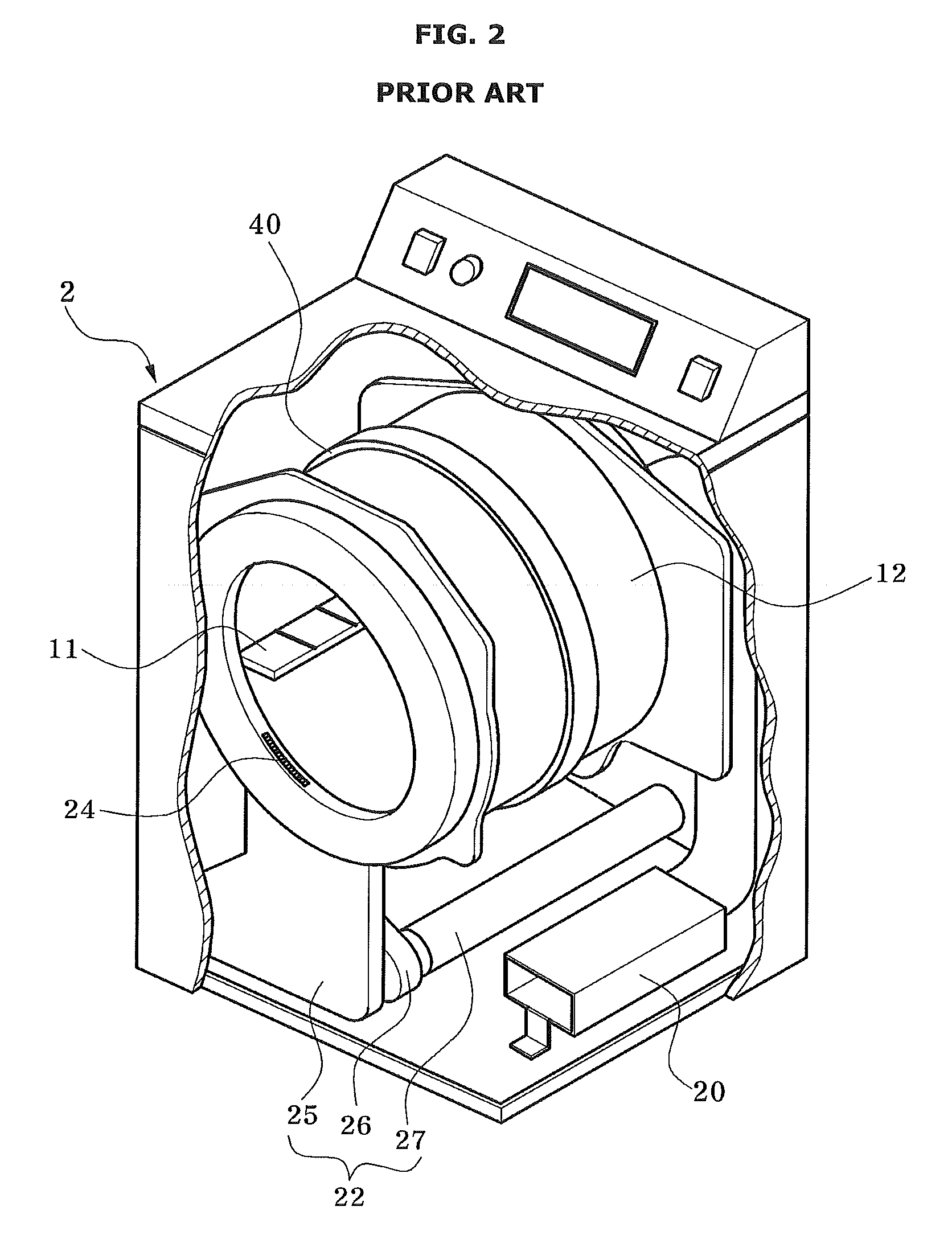

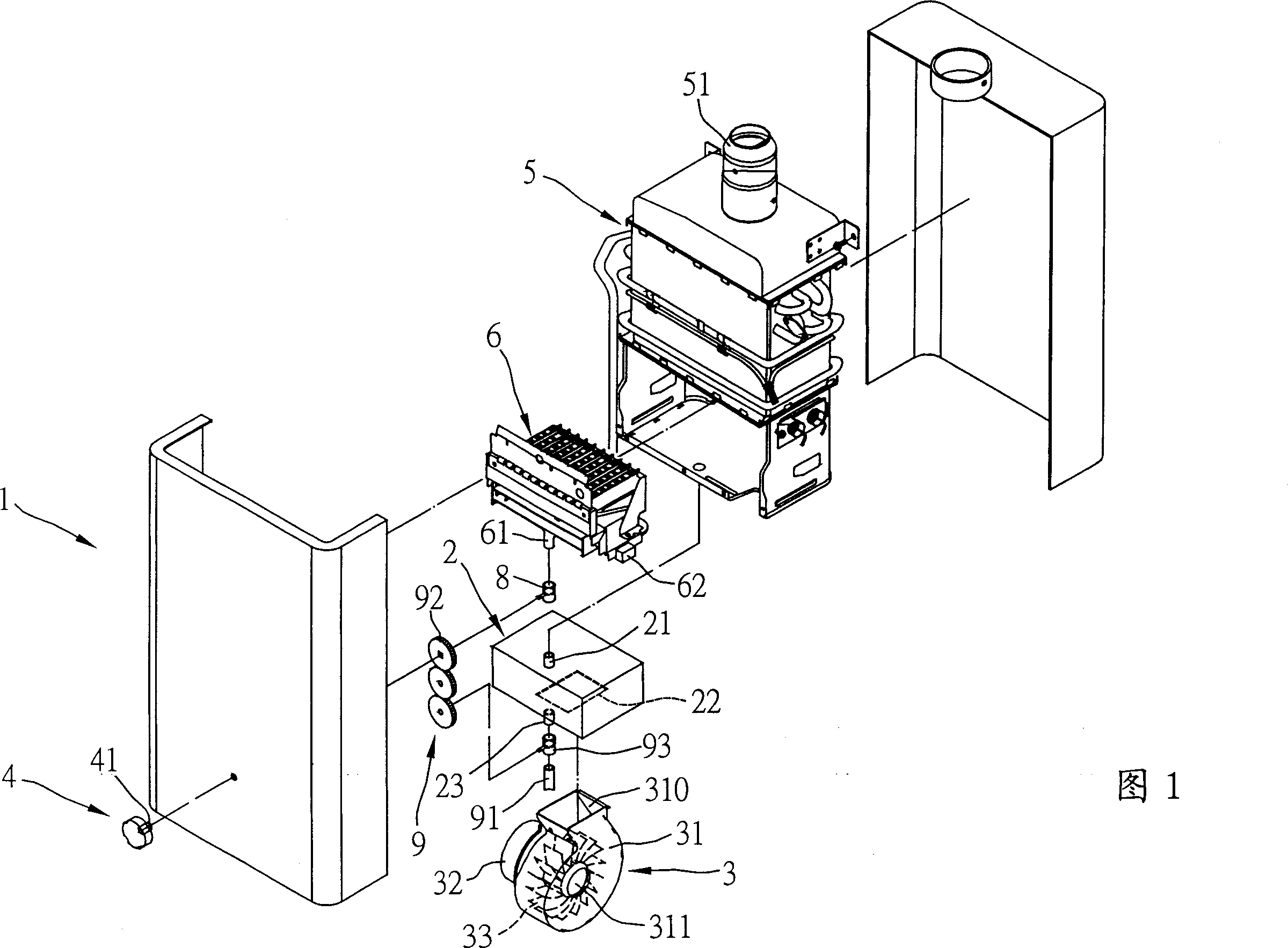

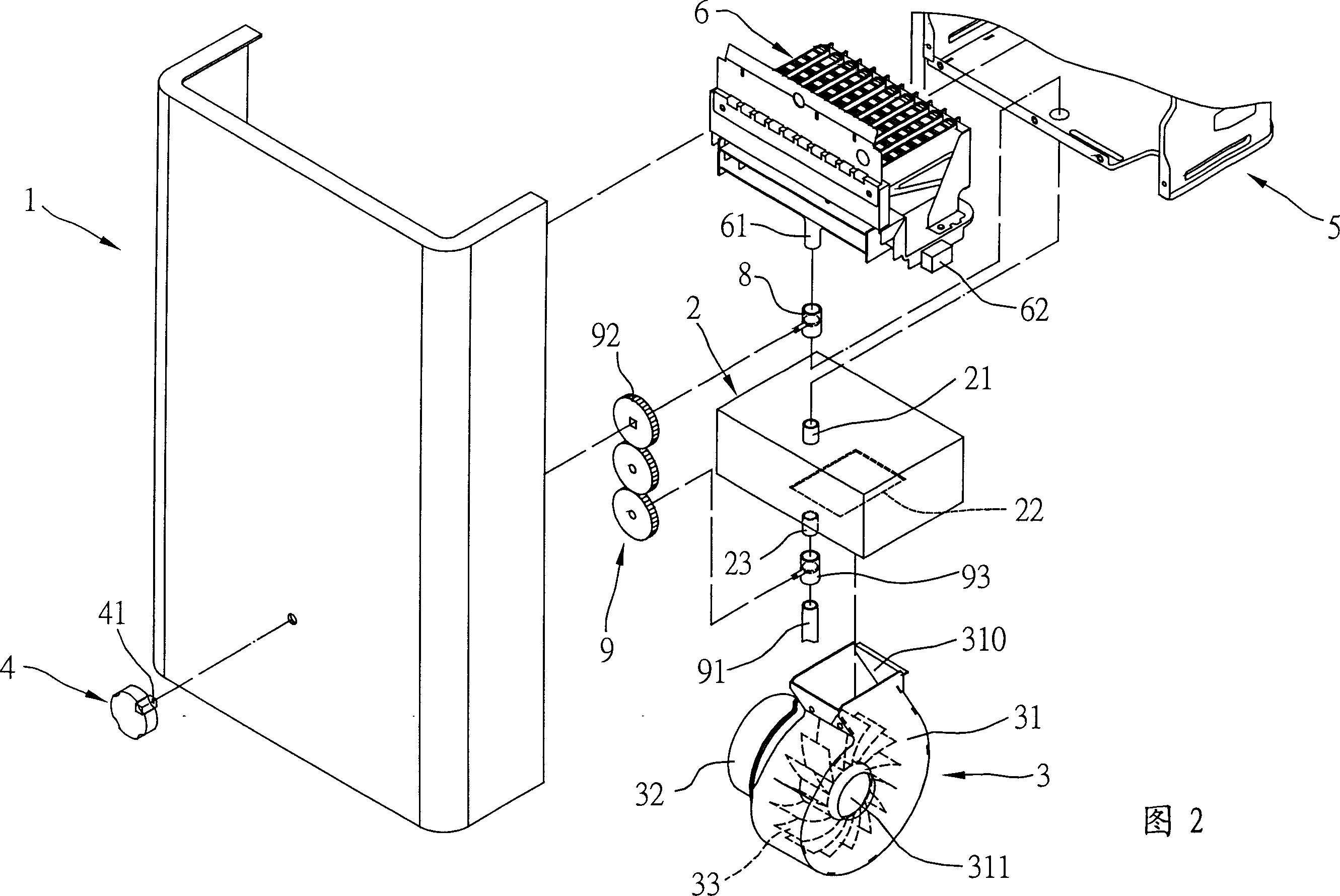

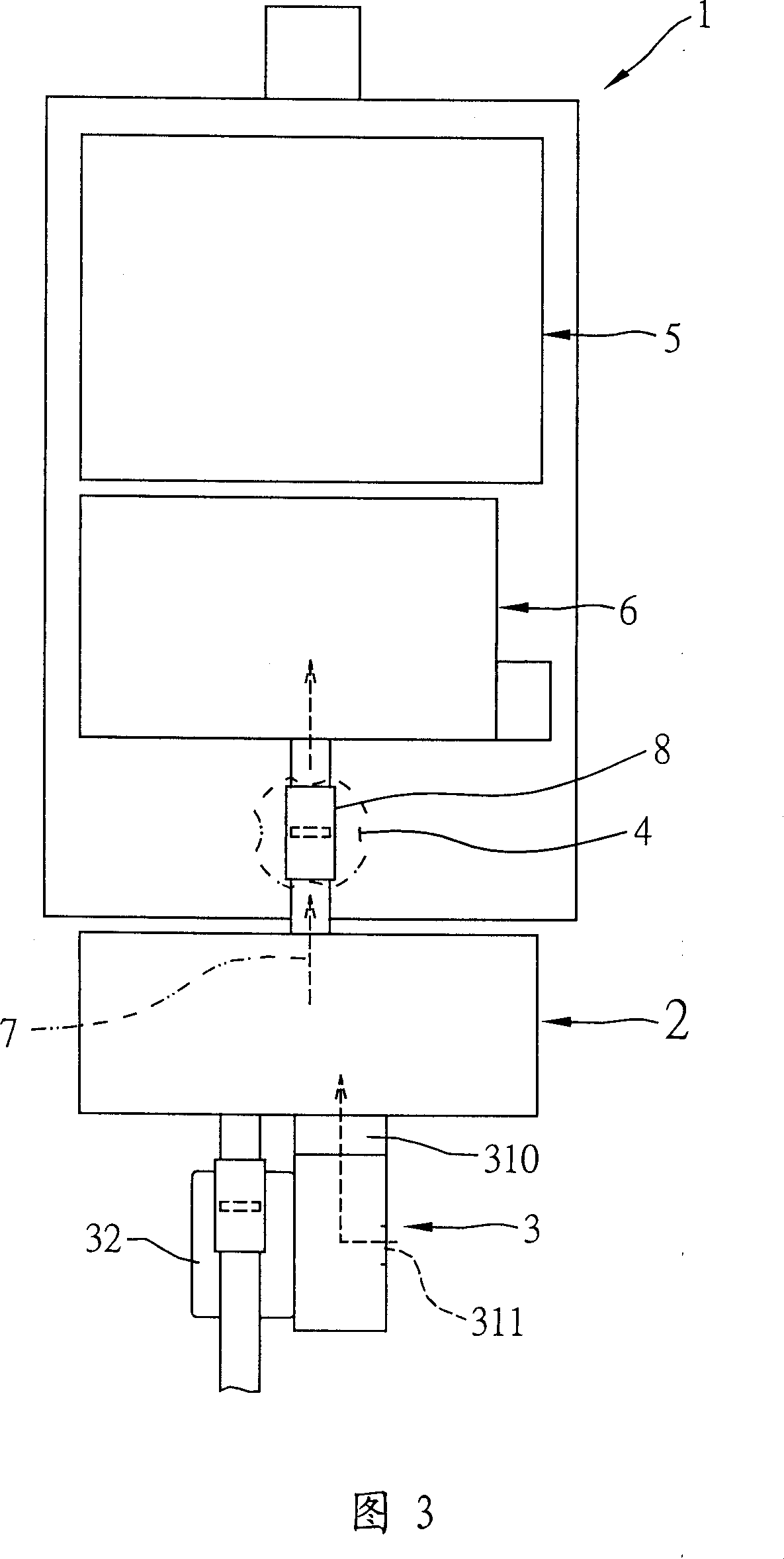

Dryer having gas heater

InactiveUS20090165321A1Narrow widthAvoid incomplete combustionDrying gas arrangementsWater heatersGas heaterEngineering

A dryer having a gas heater includes: a mixing pipe for mixing gas with air; and a flame holder installed on the mixing pipe, wherein the flame holder has a body placed opposite to a discharge port of the mixing pipe and formed with a through hole part, and a support extended from the body to be mounted to the mixing pipe; the support has a mounting part fastened to the mixing pipe and a fixing part connecting the mounting part and the body; and a width of the fixing part is narrower than a width of the mounting part.

Owner:DAEWOO ELECTRONICS CO LTD

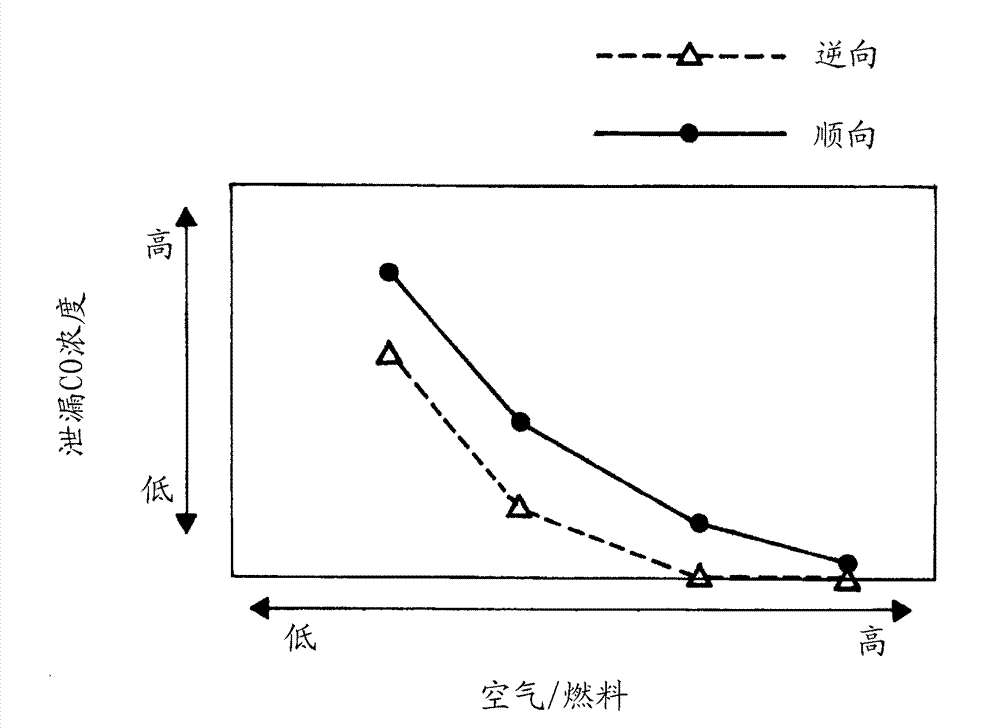

Water heater with interlinked air intake regulator and its operation process

InactiveCN101046291AAvoid incomplete combustionOverall small sizeFuel supply regulationWater heatersFuel supplyCombustion

The present invention provides one kind of water heater with interlinked air intake regulator and its operation process. The water heater includes one water heater body, one pre-mixing tank, one air inlet mechanism and one fuel regulator. The burner inside the water heater body, the pre-mixing tank and the air inlet mechanism constitute one gas flow channel. The fuel regulator has one air inlet shielding mechanism for regulating the flow channel and one fuel shielding mechanism for regulating the fuel supplying pipeline. Rotating the fuel regulator can regulate the fuel shielding mechanism and the air inlet shielding mechanism simultaneously to ensure complete combustion.

Owner:GUARD SOUND IND CO LTD

Intake port for 4-cycle engine

InactiveUS20070169738A1Low intake resistanceEasily makeMuscle operated startersCylinder headsCombustion chamberEngineering

An intake port for a 4-cycle engine includes an intake port base integrally formed with a cylinder head, and an intake port forming member that forms an intake port together with the intake port base. The area of the cross section of the intake port orthogonal to a centerline of the intake port is substantially uniform from an open intake side thereof toward a combustion chamber. The angle made by the centerline of the intake port and an intake valve shaft is larger than 90° from a viewpoint of the intake valve. Thereby, the 4-cycle engine can output high power with the intake port shape, as formed with above mentioned configuration, that reduces intake resistance and that uses simple design molds. More specifically, the engine can reliably prevent condensed fuel from remaining in the intake port to avoid incomplete combustion of gas.

Owner:MAKITA NUMAZU CORP

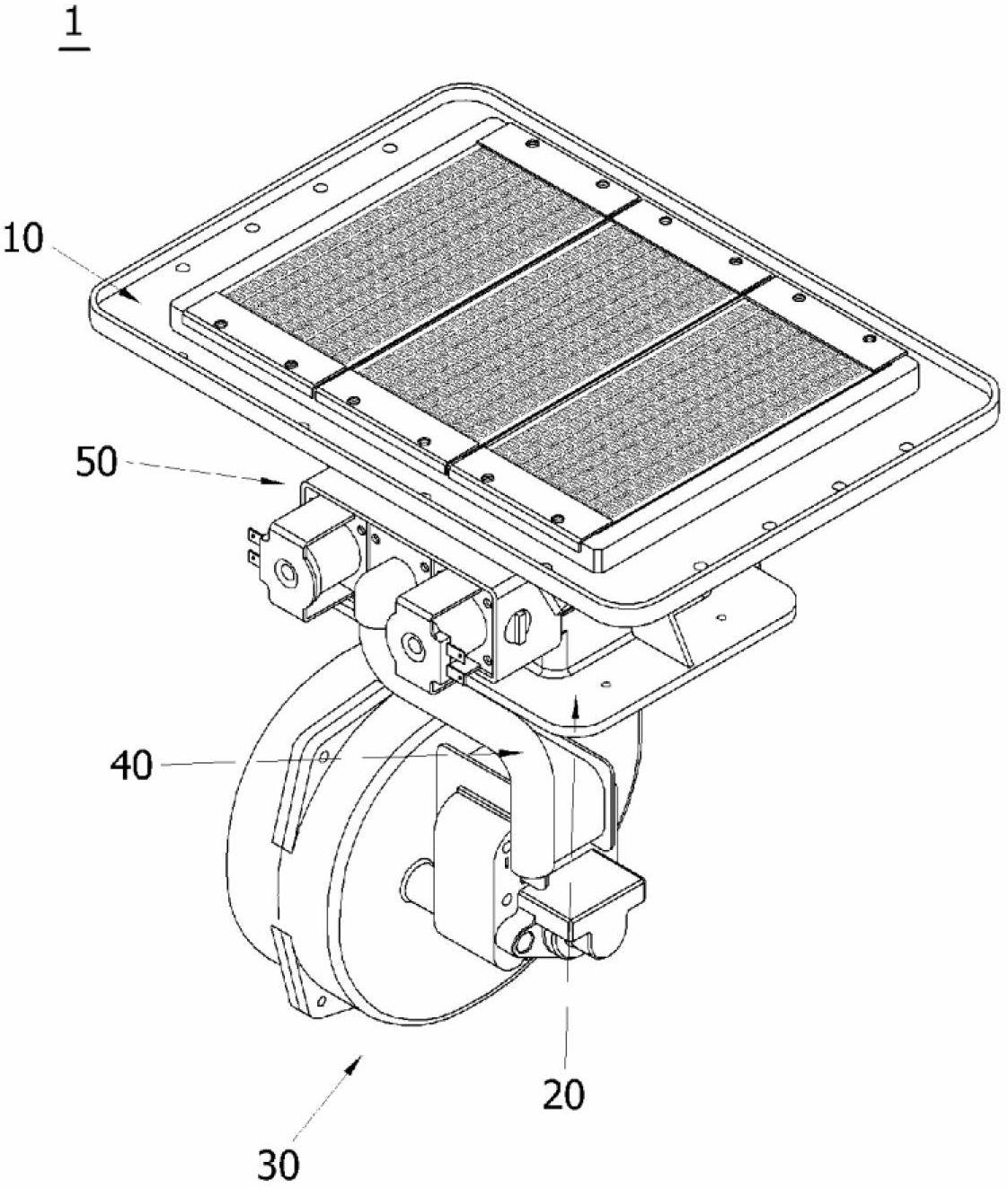

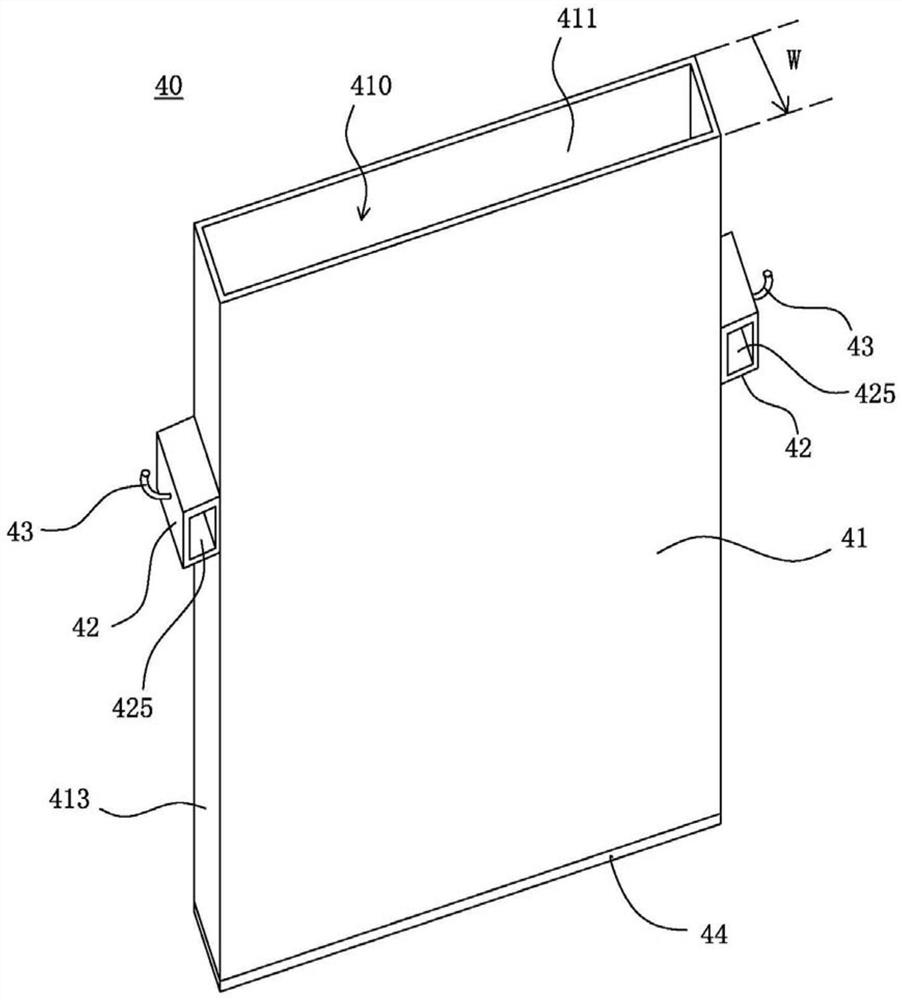

Material collection equipment and material collection method

PendingCN112693642AHigh degree of automationReduce exposureWrapper twisting/gatheringSolid materialBox set

The invention relates to material collecting equipment and a material collecting method. The material collecting device comprises a rail, a sliding device, a supporting device, at least one collecting box set and a driving device. The sliding device is arranged on the rail and can slide back and forth in the first direction. The supporting device is fixedly arranged on the sliding device. Each collecting box set is supported and installed by the supporting device and can move back and forth in the first direction, each collecting box set comprises at least one collecting box, and a box body of each collecting box is provided with a collecting space, a top opening, a bottom opening and a movable bottom plate. Bag bodies are detachably mounted in the collecting spaces. The driving device is in driving connection with each collecting box set, and drives the collecting boxes to sequentially move to a charging position to collect materials to the bag bodies and sequentially move the collecting boxes to a discharging position to discharge after the materials are collected. The bottom plates are located at the opening position when located at the discharging position so that the bag bodies can slide out through the bottom openings.

Owner:诺客环境科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com