Nicotine liquid raw material of electronic cigarette and preparation device and method of nicotine liquid raw material

A technology of e-cigarette liquid and raw materials, applied in tobacco, tobacco processing, application, etc., can solve the problems of e-cigarettes without natural aroma characteristics and taste, and achieve the effect of reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

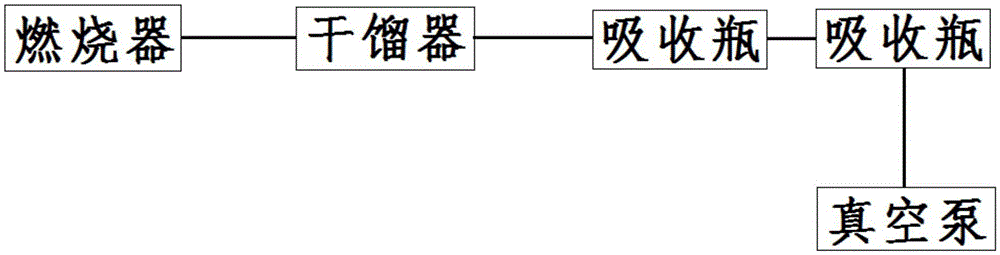

[0032] A kind of preparation of electronic cigarette liquid raw material with traditional cigarette aroma characteristics, the steps are as follows:

[0033] Heat the three-necked round bottle (burner) equipped with a stirrer with an electric heating mantle, and stir with an electric stirrer to heat the temperature inside the bottle to 800°C and keep a constant temperature; slowly add 50 grams of shredded tobacco preheated to 200°C from the bottle mouth (The amount of shredded tobacco is suitable for the stirrer to be able to stir and the shredded tobacco to be able to rotate flexibly, and to maintain a continuous stirring state), and sufficient oxygen to fully burn the shredded tobacco is introduced, and the igniter is activated instantaneously to make the shredded tobacco burn quickly and generate combustion flue gas. Turn on the vacuum pump to force the combustion fumes into the retort.

[0034] At the same time, the temperature of the retort was heated to 320°C; 170 grams ...

Embodiment 2

[0041] A kind of preparation of electronic cigarette liquid raw material with traditional cigarette aroma characteristics, the steps are as follows:

[0042] Heat the three-necked round bottle (burner) equipped with a stirrer with an electric heating mantle, and stir with an electric stirrer to heat the temperature inside the bottle to 900°C and keep a constant temperature; slowly add 50 grams of shredded tobacco preheated to 400°C from the bottle mouth (The amount of shredded tobacco is suitable for the stirrer to be able to stir and the shredded tobacco to be able to rotate flexibly, and to maintain a continuous stirring state), and sufficient oxygen to fully burn the shredded tobacco is introduced, and the igniter is activated instantaneously to make the shredded tobacco burn quickly and generate combustion flue gas. Turn on the vacuum pump to force the combustion fumes into the retort.

[0043] At the same time, the temperature of the retort was heated to 400°C; 200 grams ...

Embodiment 3

[0050] A kind of preparation of electronic cigarette liquid raw material with traditional cigarette aroma characteristics, the steps are as follows:

[0051] Heat the three-necked round bottle (burner) equipped with a stirrer with an electric heating mantle, and stir with an electric stirrer to heat the temperature in the bottle to 850°C and keep a constant temperature; slowly add 50 grams of shredded tobacco preheated to 300°C from the bottle mouth (The amount of shredded tobacco is suitable for the stirrer to be able to stir and the shredded tobacco to be able to rotate flexibly, and to maintain a continuous stirring state), and sufficient oxygen to fully burn the shredded tobacco is introduced, and the igniter is activated instantaneously to make the shredded tobacco burn quickly and generate combustion flue gas. Turn on the vacuum pump to force the combustion fumes into the retort.

[0052] At the same time, the temperature of the retort was heated to 360°C; 150 grams of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com