Biological-organic fertilizer special for corn and preparation method thereof

A special fertilizer for corn, organic technology, applied in the field of bio-organic special fertilizer for corn and its preparation, can solve the problems of increasing fertilization amount, poor product quality, endangering human health, etc., and achieve the goal of increasing microbial community and reducing ammonia gas Volatilization, the effect of improving the utilization rate of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

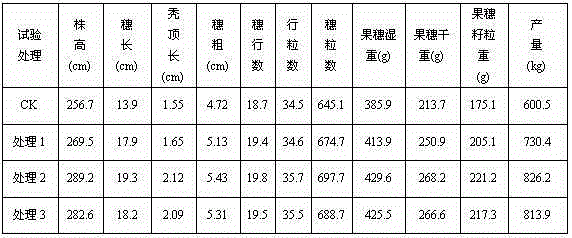

Examples

Embodiment 1

[0067] Mix 35g of straw mixture, 10g of seaweed residue, 20g of waste edible fungus sticks, 12g of amino acid, 8g of trace elements in EDTA chelation, 5g of compound microbial inoculants, etc. to obtain mixed fermentation materials; put the mixed fermentation materials into the fermentation tank. For fermentation, when the temperature of the fermented material rises to 60-70°C, the first turning is performed, and the stack is turned 3-5 times to achieve full fermentation. The fermentation temperature should be controlled at 40-60°C. A fermentation material can be obtained. Finally, the fermentation materials are crushed and screened. Then, add 10g of activated weathered coal humic acid to the primary fermentation material, mix well and pile into a pile with a height of 3-4m. The temperature is controlled at about 60-70℃, and the pile is turned 1-2 times during the period, and the moisture content is controlled. Within 40-50%, organic fertilizer can be obtained within 5-7 days....

Embodiment 2

[0070] Mix 40g of straw mixture, 9g of seaweed residue, 10g of edible fungus sticks, 15g of amino acids, 10g of trace elements in EDTA chelation, 7g of compound microbial agents, etc. to obtain mixed fermentation materials; put the mixed fermentation materials into the fermentation tank For fermentation, when the temperature of the fermented material rises to 60-70°C, the first turning is performed, and the stack is turned 3-5 times to achieve full fermentation. The fermentation temperature should be controlled at 40-60°C. A fermentation material can be obtained. Finally, the fermentation materials are crushed and screened. Then, add 9g of activated weathered coal humic acid to the primary fermentation material, mix well, and pile it into a pile with a height of 3-4m. The temperature is controlled at about 60-70℃, during which the pile is turned 1-2 times, and the moisture content is controlled. Within 40-50%, organic fertilizer can be obtained within 5-7 days.

[0071] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com