Double-seat multiple-atomizing nozzle

A technology of atomizing nozzles and seat surfaces, which is applied in fuel injection devices, engine components, machines/engines, etc., can solve problems such as poor atomization of nozzles, improve power and fuel economy, improve atomization effects, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

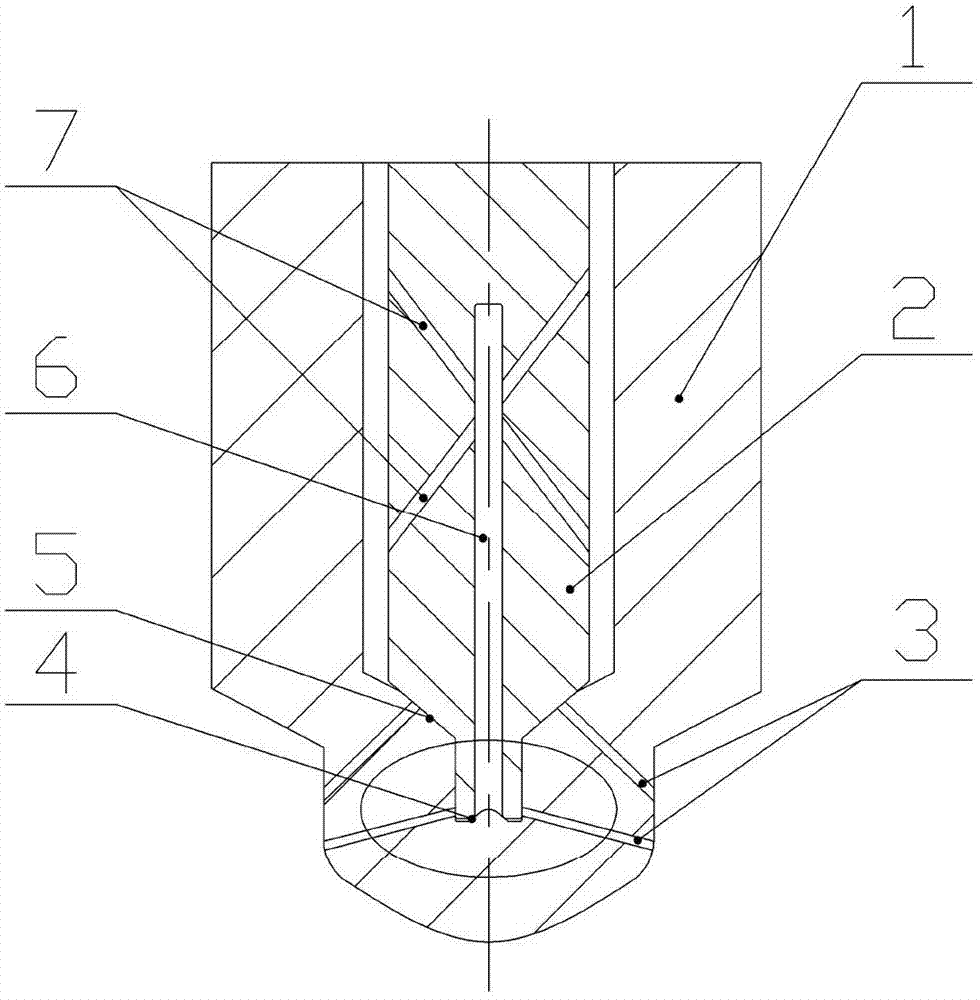

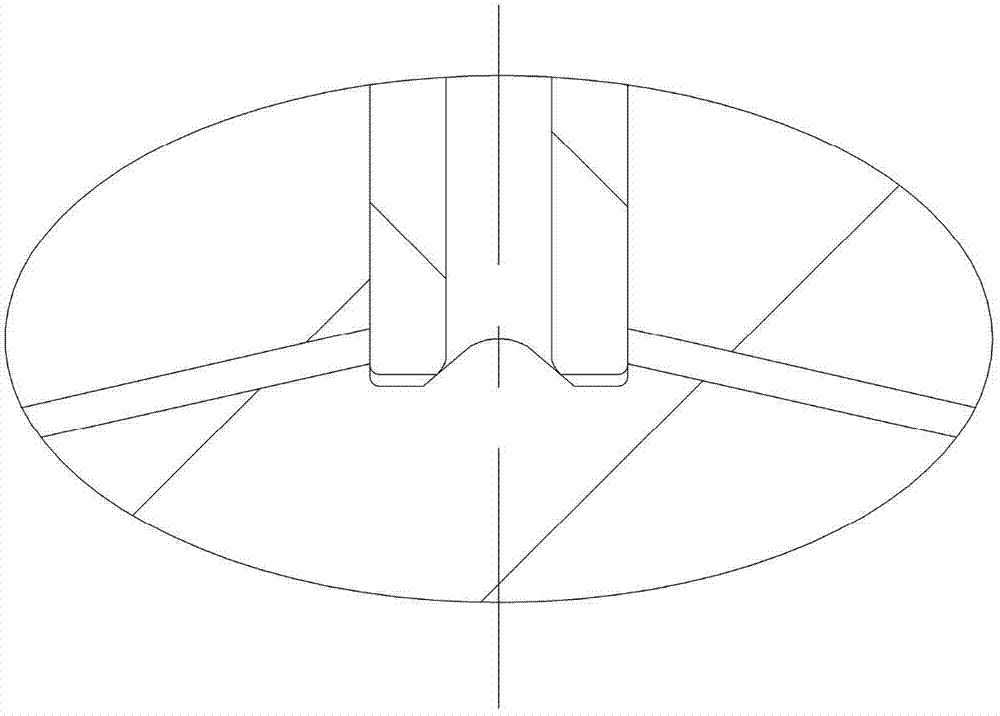

[0018] combine Figure 1~2 , figure 1 It is a schematic diagram of the overall structure of the double-seat surface secondary atomization nozzle of the present invention, including a needle valve body 1, a needle valve 2, an injection hole 3, a needle valve lower seat surface 4, a needle valve upper seat surface 5, an oil storage chamber 6, an oil passage Hole 7. The fuel that enters the injector from the high-pressure fuel pipe enters the annular oil chamber between the nozzle needle valve body 1 and the needle valve 2 through the oil tank, and the high-pressure fuel in the annular oil chamber enters through the cross-arranged oil passage holes 7 on the needle valve 2 There is an oil storage cavity 6 in the lower part of the needle valve 2, and the entire oil storage cavity 6 is filled. The needle valve lower seat surface 4 and the needle valve upper seat surface 5 on the needle valve body 1 form two sealing belts with the needle valve 2. When the needle valve 2 is controll...

Embodiment approach 2

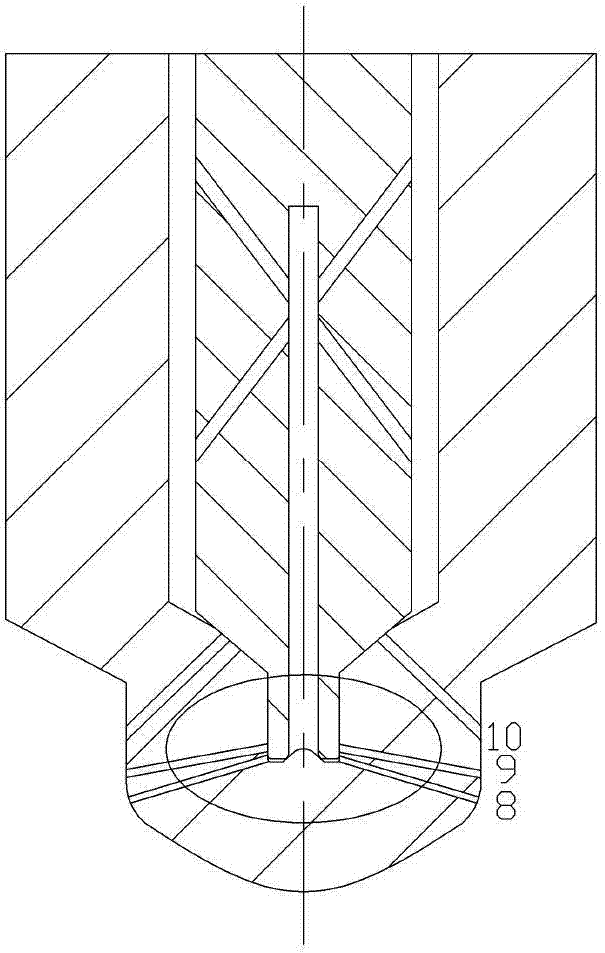

[0020] combine Figure 3-4 , image 3 It is a schematic diagram of the overall structure of the double-seat three-time atomization nozzle of the present invention. On the basis of Embodiment 1, a group of injection holes is added. As described in Embodiment 1, when the needle valve 2 is raised, the injection hole 10 starts to inject oil first, and then the injection holes 8 and 9 inject oil in sequence. , when the nozzle hole 8 is opened, the fuel sprayed from the nozzle hole 10 collides with the fuel sprayed from the nozzle hole 8, and the fuel is atomized for the second time. The fuel is firstly impacted by the fuel sprayed from the injection hole 9, and the fuel is atomized for the second time, and then the fuel sprayed by the second atomization collides with the fuel oil beam sprayed from the injection hole 8. Due to the impact between the oil beams, the fuel oil is again Atomization realizes multiple atomization of fuel. The oil passage holes 7 connecting the oil stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com