Method and apparatus for improving sludge dehydration

A dehydration and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of complex conditioning process, high equipment requirements, and large consumption of chemicals, so as to increase permeability and improve work efficiency , activity and solubility enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

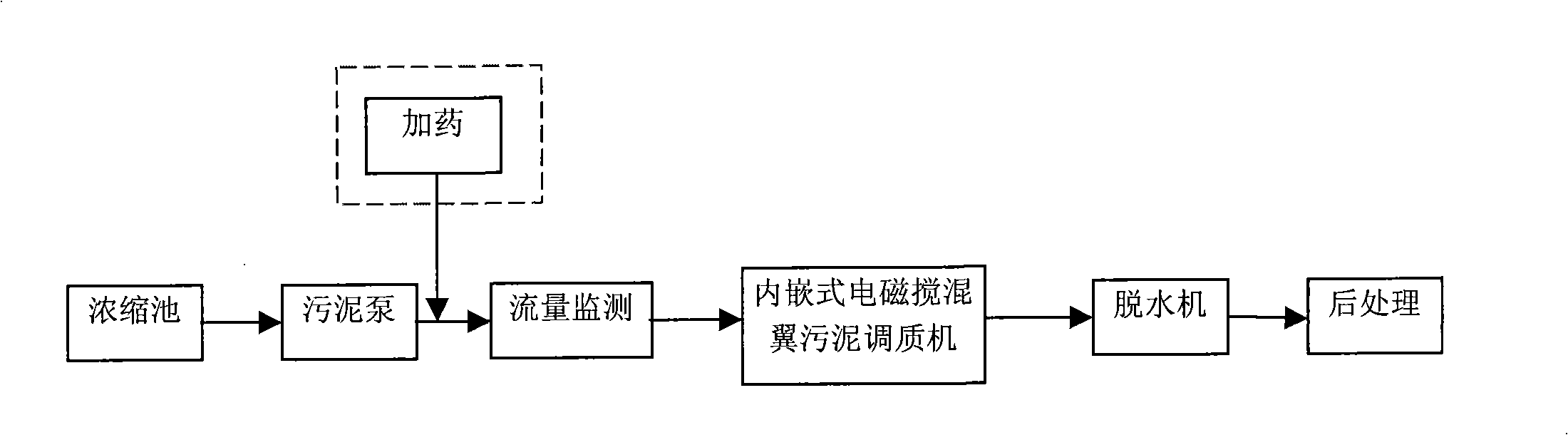

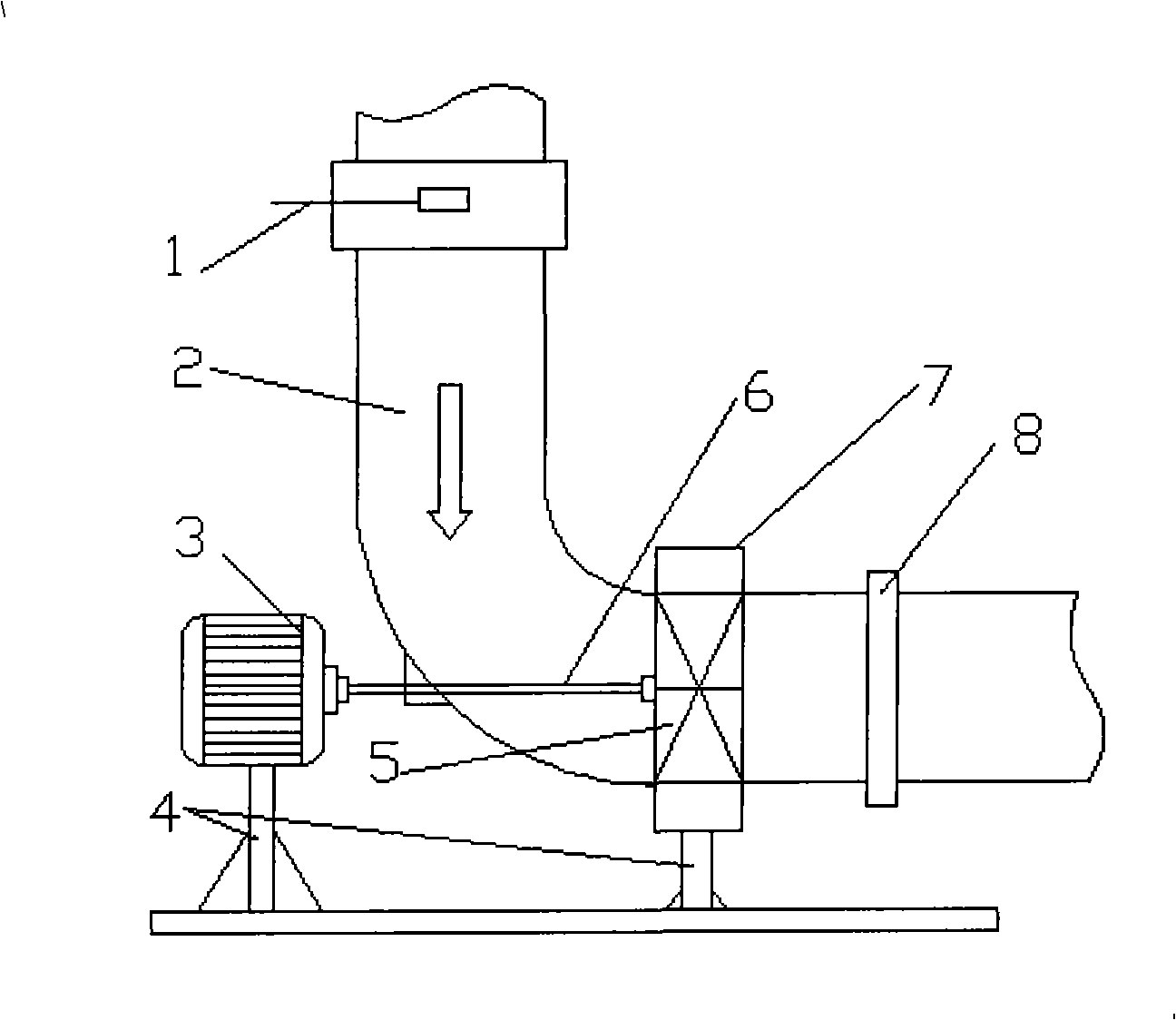

[0038] according to figure 2 The process flow chart shown in the sewage treatment plant sludge, using image 3 and Figure 4 The shown built-in electromagnetic stirring wing sludge conditioning machine performs sludge conditioning. image 3 and Figure 4 Description of the numbers in:

[0039] 1 On-line flowmeter 2 Sludge pipe 3 Motor 4 Bracket

[0040] 5 Electromagnetic mixing wing 6 Drive shaft 7 Embedded electromagnetic mixing wing sludge conditioning machine

[0041] 8 flange 9 fixed magnet 10 mixing wing 11 serrated wing

[0042] The structure of the built-in electromagnetic stirring wing sludge conditioning machine mainly includes two layers inside and outside. The outer layer is equipped with four fixed magnets 9 arranged at intervals of four equal intervals. The diameter of the inner layer is equivalent to that of the sludge pipeline 2. The inner layer is provided with power-driven rotating electromagnetic stirring blades 5, which are at least 16 equally spaced ...

Embodiment 2

[0046] according to figure 2 The process flow chart shown in the sewage treatment plant sludge, using image 3 and Figure 4 The shown built-in electromagnetic stirring wing sludge conditioning machine performs sludge conditioning.

[0047] The control test of the final conditioner: the sludge from the sewage treatment plant has a water content of 98% after being concentrated in the concentration tank for 12 hours, and the volatile solid content accounts for 45% of the solid content. The sludge enters the sludge pump and is pumped out , the flow rate is 240m 3 / h, head H=11.9m, pump outlet flow rate reaches 4.5m / s. The dosing device supplies polyacrylamide, the dosage is 0.1% of the dry basis of the sludge, mixed with the sludge in the pipeline, and then directly enters the plate and frame filter press for dehydration, the working pressure is 15 kg, and the dewatered sludge (mud cake ) has a moisture content of 82%.

[0048] The test of the present invention loaded into ...

Embodiment 3

[0050] according to figure 2 The process flow chart shown in the sewage treatment plant sludge, using image 3 and Figure 4 The shown built-in electromagnetic stirring wing sludge conditioning machine performs sludge conditioning.

[0051] Control test without conditioning machine: The sludge from the sewage treatment plant has a water content of 98% after being concentrated for 1.5 hours in a thickening tank, and the sludge with a volatile solid content of 77% of the solid content enters the sludge pump and pumps it out , the flow rate is 400m 3 / h, head H=8.6m, pump outlet flow rate reaches 3m / s. The dosing device supplies polyaluminum ferric chloride, the dosage is 2% of the dry basis of the sludge, mixed with the sludge in the pipeline, and then directly enters the rolling belt filter press for dehydration, and the grid rotates 2 revolutions per minute , The moisture content of the dewatered sludge (mud cake) is 86%.

[0052] The test of the present invention loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com