Patents

Literature

37results about How to "Avoid non-conformities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

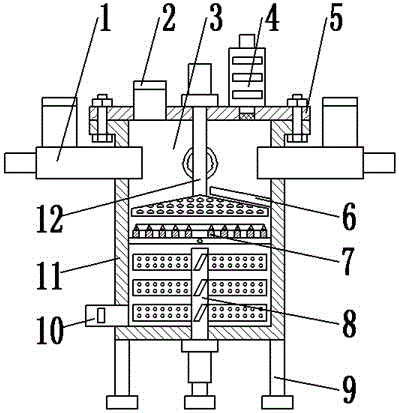

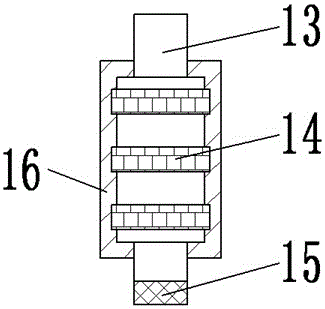

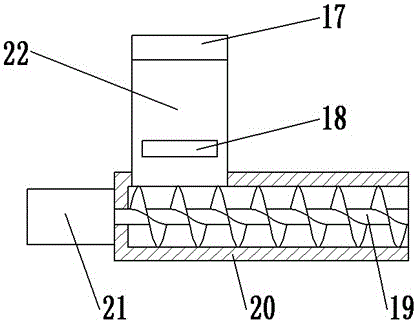

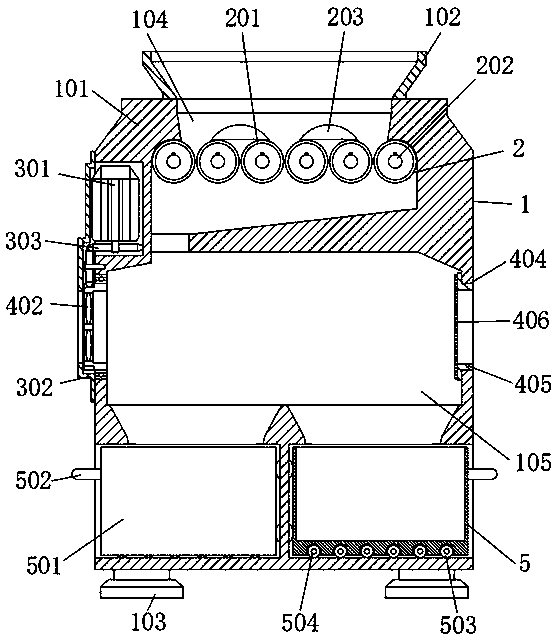

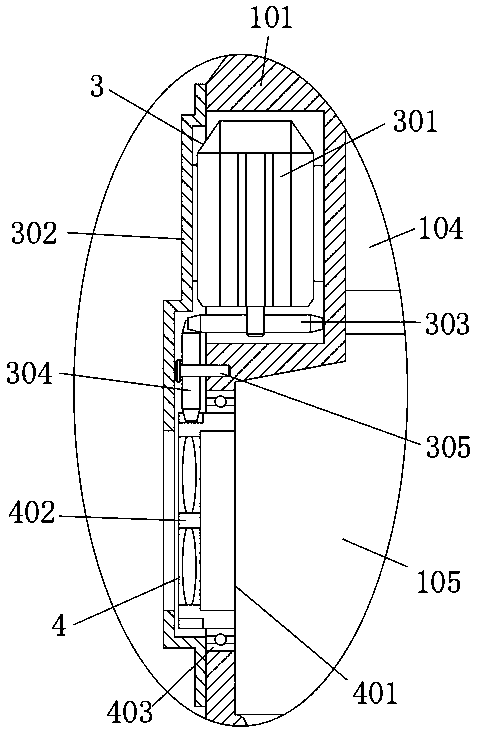

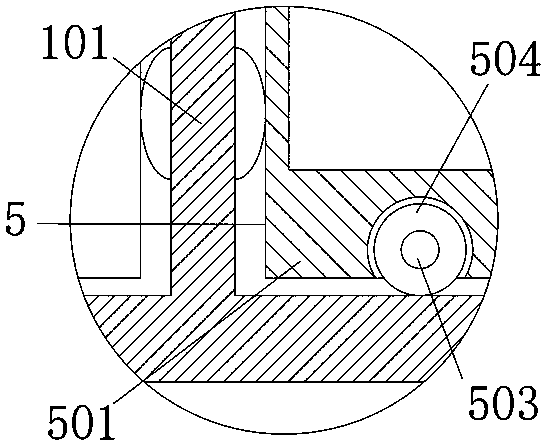

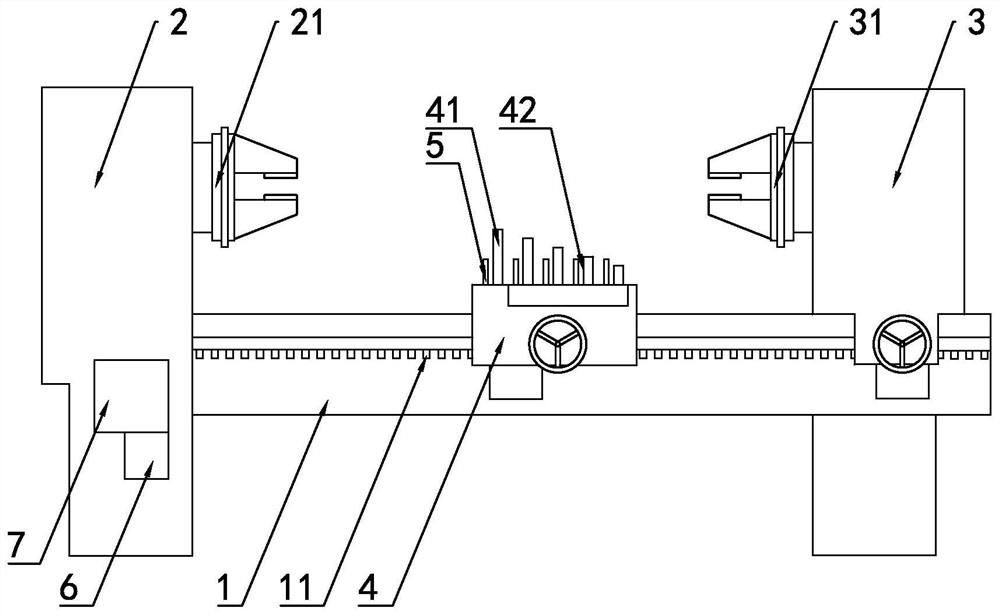

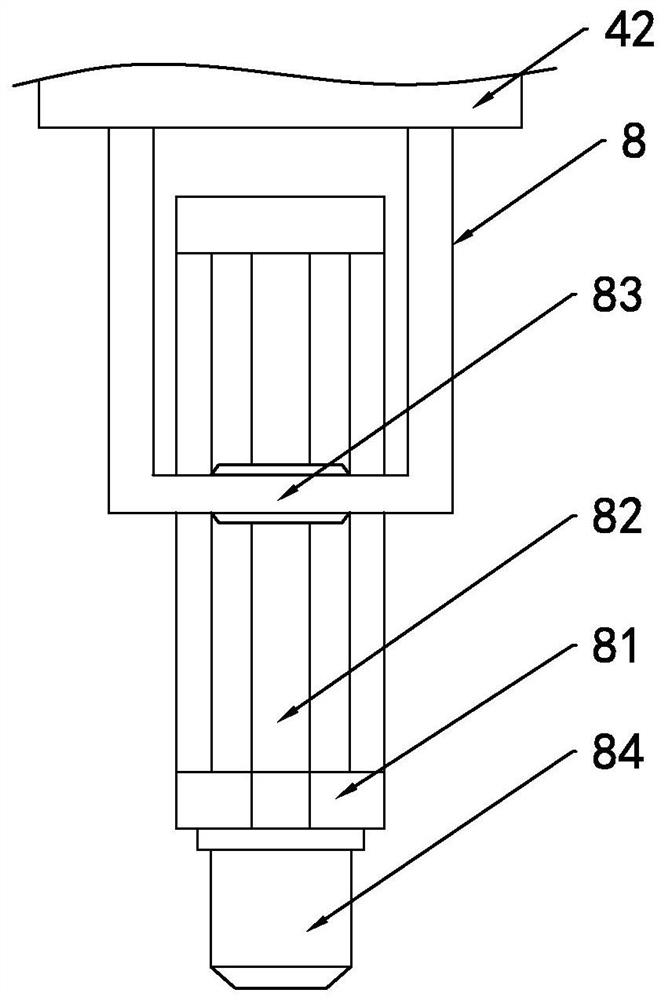

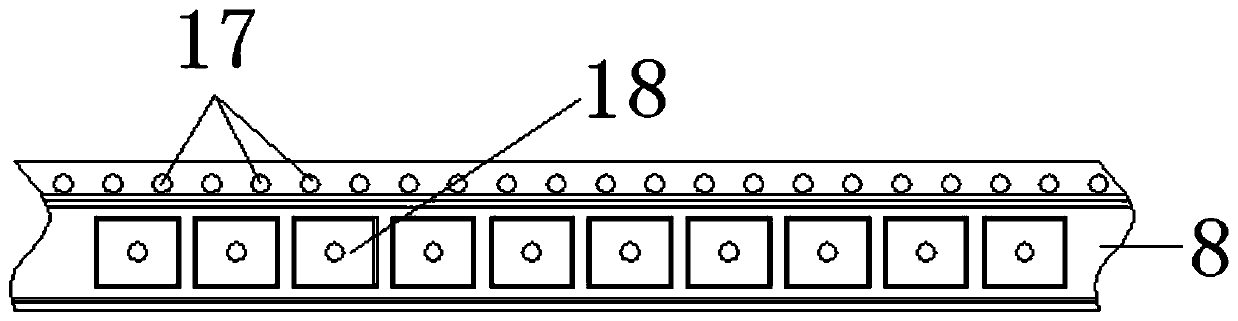

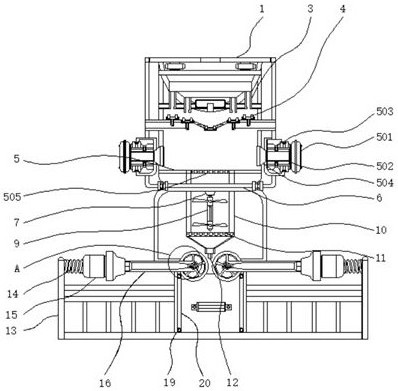

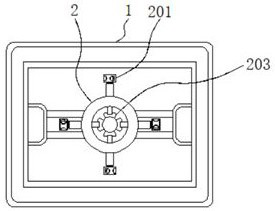

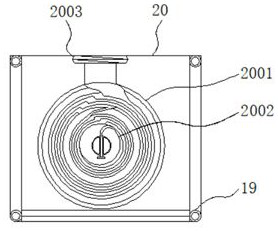

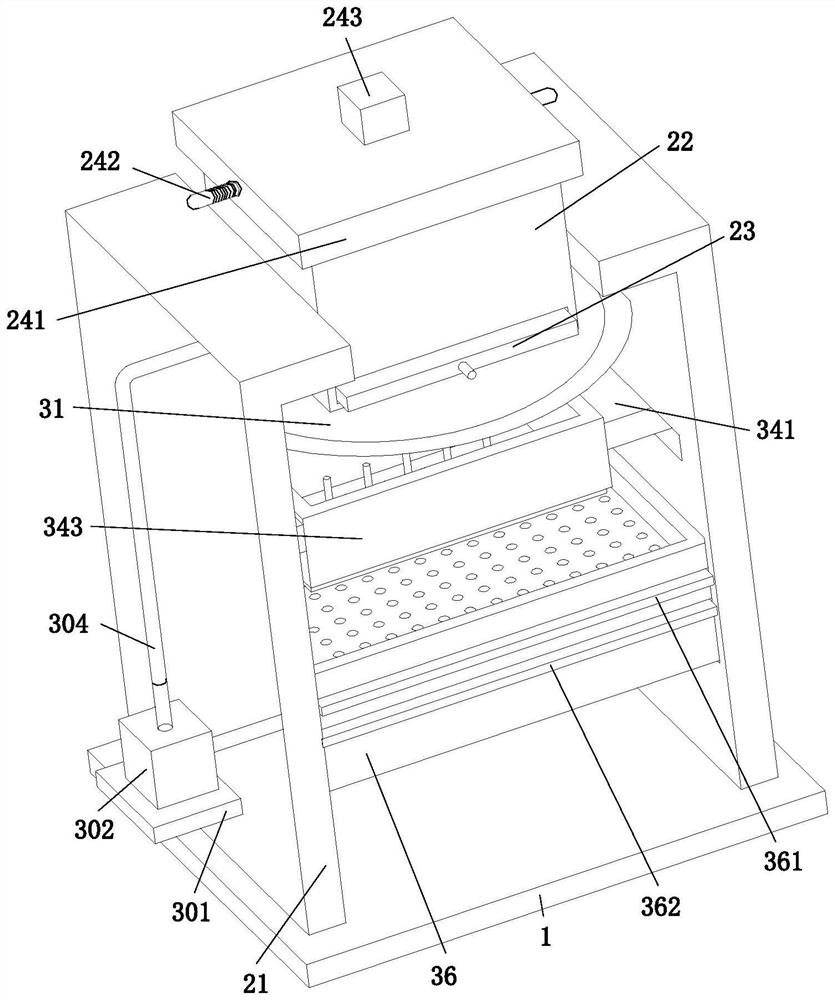

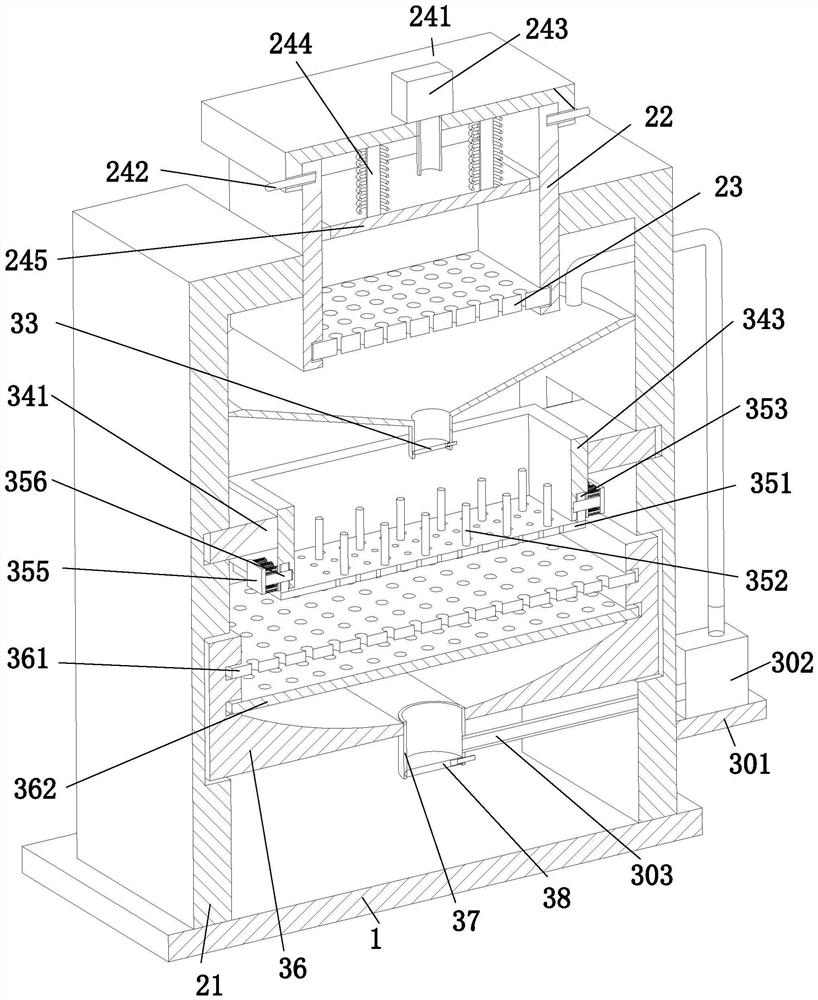

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

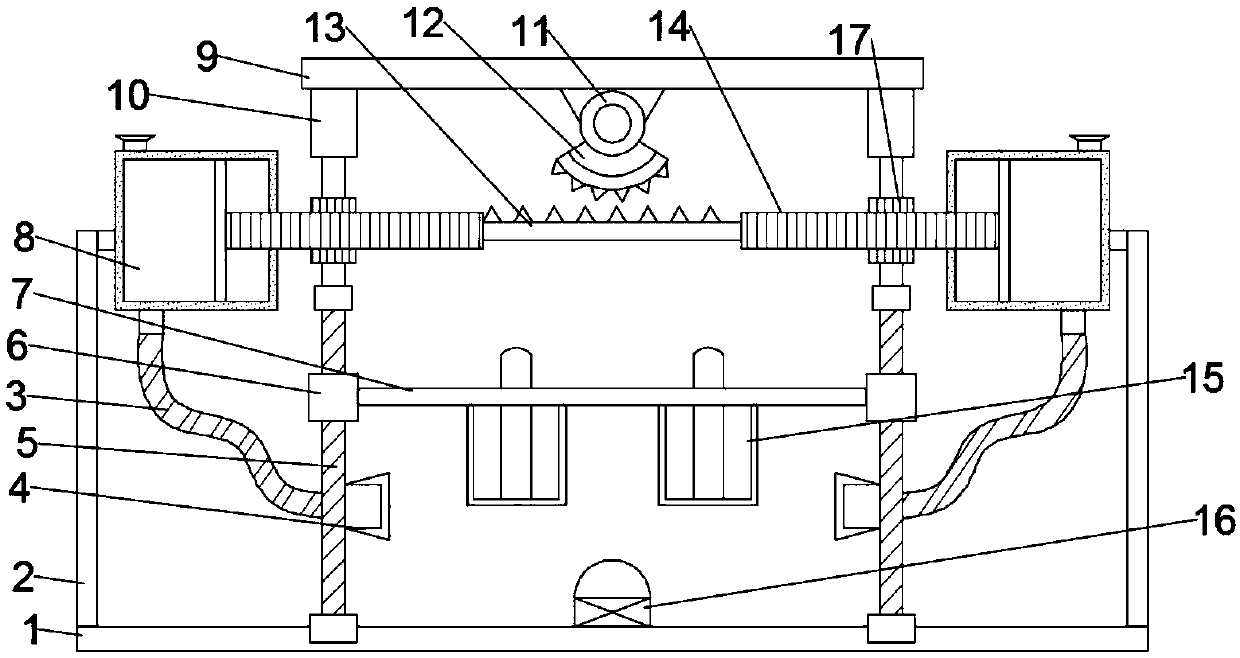

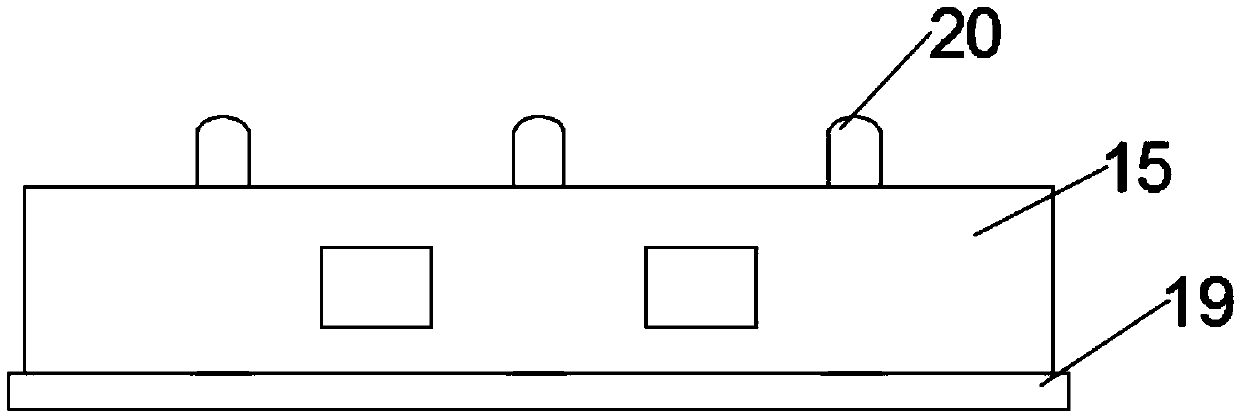

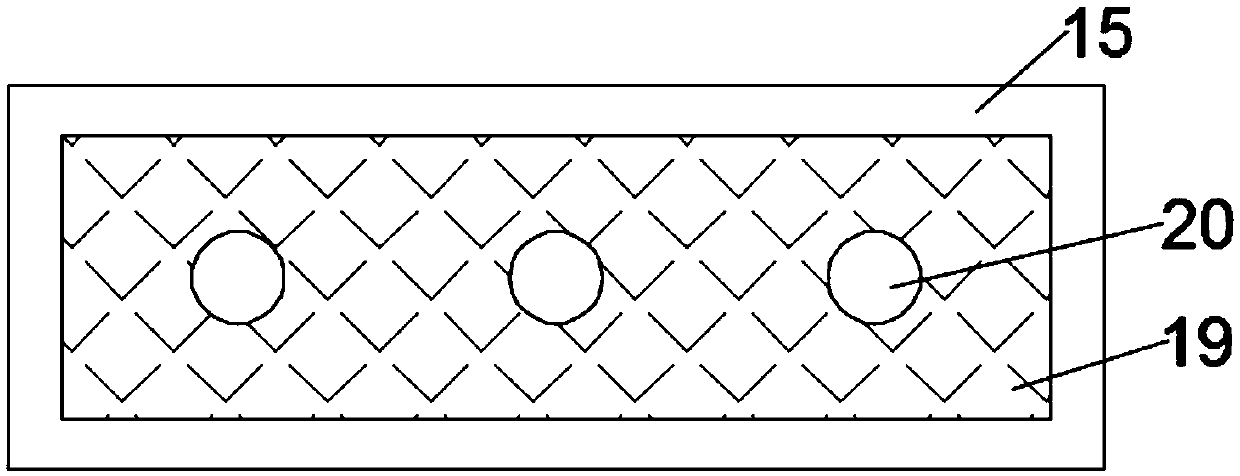

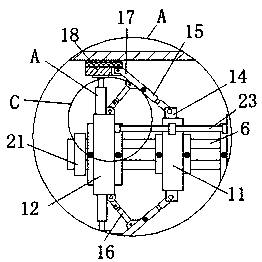

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

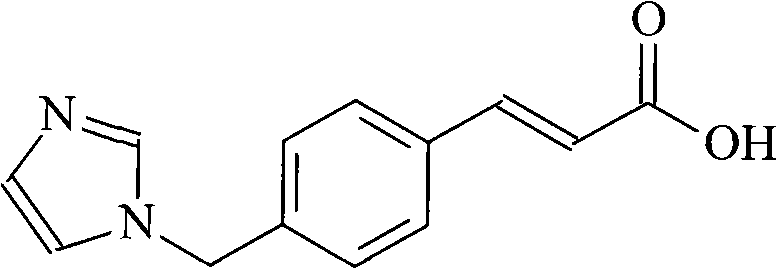

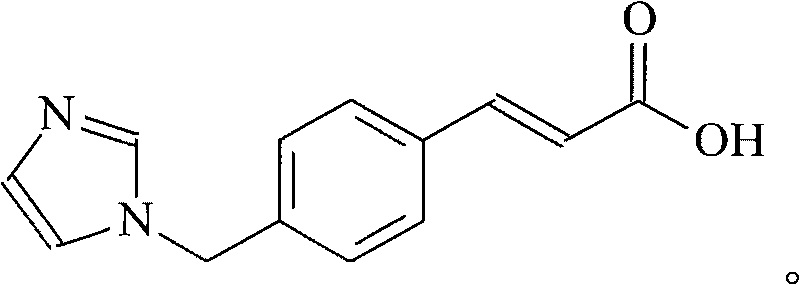

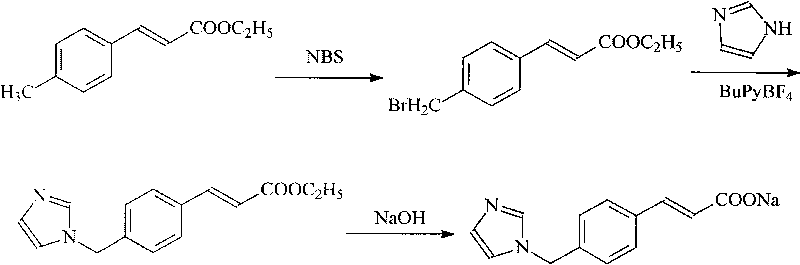

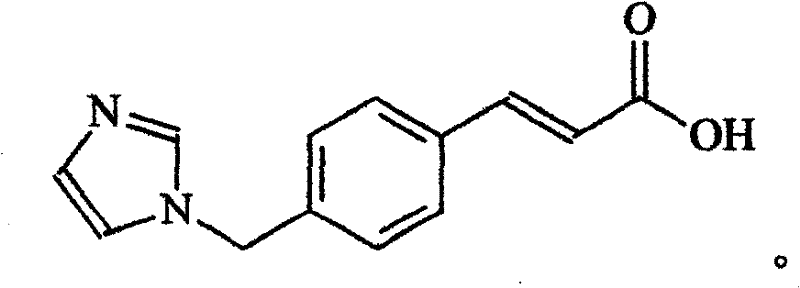

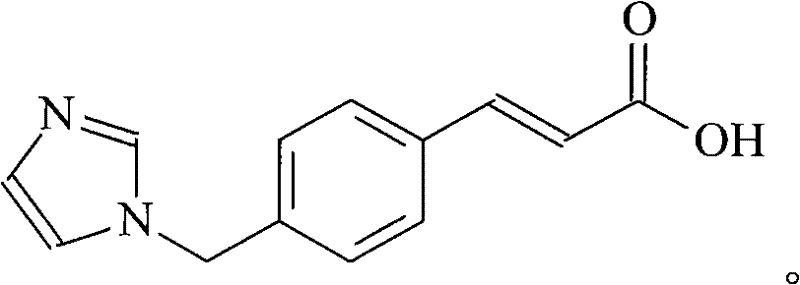

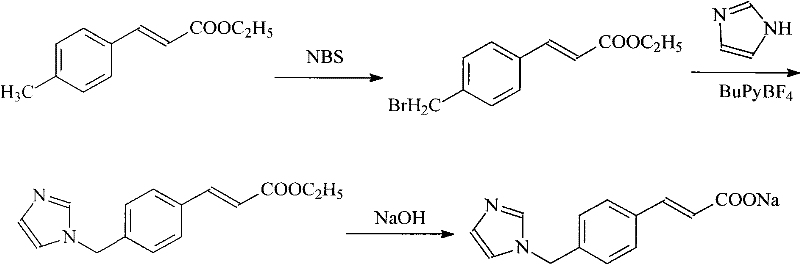

High-purity ozagrel compound

InactiveCN101704786AHigh purityAvoid non-conformitiesOrganic chemistryActivated carbonForeign matter

The invention relates to a high-purity ozagrel compound, and a preparation method of the ozagrel compound guarantees the quality of raw materials, and avoids the phenomenon that visible foreign matters are unqualified in the production process. The preparation method includes the following steps: (1) adding crude ozagrel in water to form aqueous dispersion; (2) then dropwise adding sodium hydroxide solution in the aqueous dispersion until the aqueous dispersion is clear to obtain clear solution; and (3) adding activated carbon in the clear solution for adsorption, conducting filtering and decarburization, adding acid in obtained filtrate to adjust pH value, precipitating solids, filtering, washing, and drying to obtain the high-purity ozagrel.

Owner:HAINAN LINGKANG PHARMA CO LTD

Method for preparing granules for curing infantile lung pathogenic heat and cough and asthma

ActiveCN101780214ASimple and fast operationQuality is easy to controlGranular deliveryRespiratory disorderWater useHouttuynia

The invention discloses a method for preparing granules for curing infantile lung pathogenic heat and cough and asthma. The method comprises the following steps: weighing the following Chinese medicinal materials in part by weight: 30 parts of ephedra, 60 parts of bitter almond kernel, 240 parts of raw gypsum, 30 parts of liquorice root, 100 parts of honeysuckle, 100 parts of weeping forsythiae capsule, 100 parts of anemarrhena root, 100 parts of baikal skullcap root, 100 parts of indigowoad root, 100 parts of dwarf lilyturf tuber and 100 parts of cordate houttuynia; dividing the eleven Chinese medicinal materials into two groups; after performing water extraction on the two groups of Chinese medicinal materials, combining filtrates; mixing an extract prepared by concentrating the filtrate with a proper amount of dextrine and sodium cyclamate; preparing the mixture into granules; and drying the granules to obtain the granules for curing the infantile lung pathogenic heat and cough and asthma. In the method, water use amount in the process of performing water extraction on the Chinese medicinal materials is strictly controlled and extraction in different groups is carried out according to characteristics of different medicinal materials, so compared with a traditional water extraction method, the method has a better effect. The prepared granules for curing the infantile lung pathogenic heat and cough and asthma have stable and controllable quality, and stable baicalin distinguish project which meets requirements of standard. The method greatly improves qualification rate of the product, and has simple operation and is suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

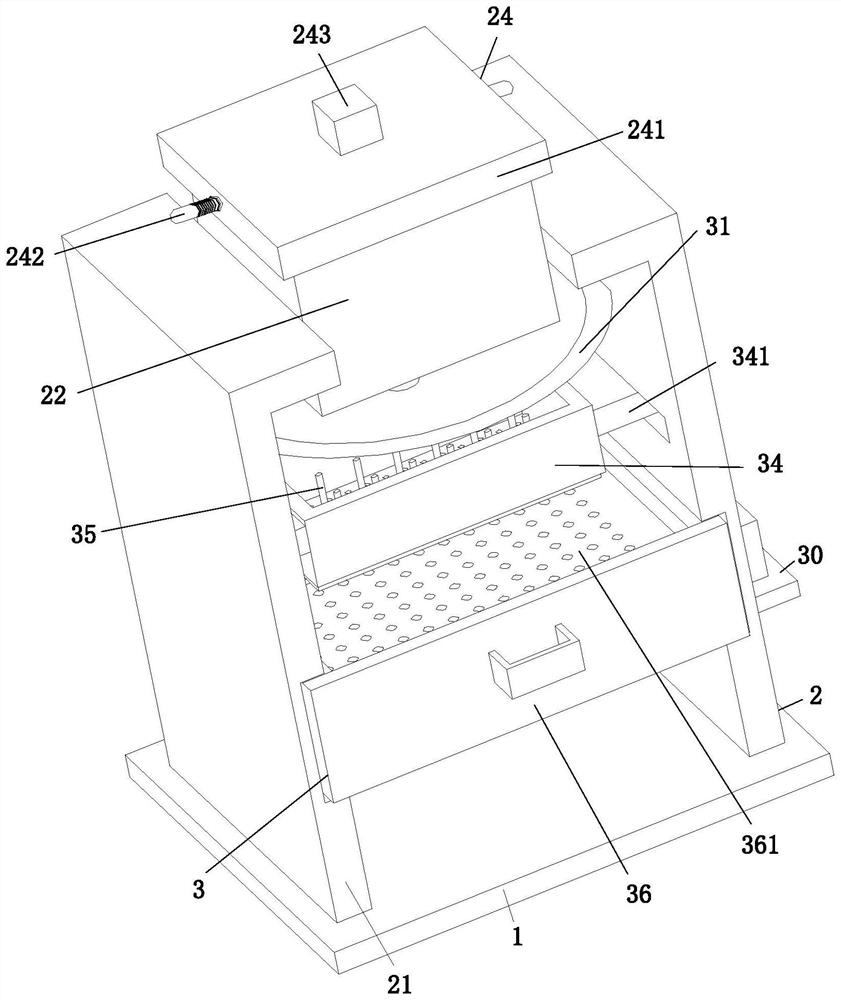

Crushing and screening device for processing nitride metal composite material

InactiveCN110339900AAvoid product failureAvoid non-conformitiesGas current separationGrain treatmentsWind forceEngineering

The invention discloses a crushing and screening device for processing nitride metal composite material. The crushing and screening device comprises a body, wherein a crushing mechanism is arranged atthe top end of the body, the position, on the left side and close to the upper part, of the body is provided with a power mechanism, the left side and the right side of the middle position of the body are provided with winnowing mechanisms, and the bottom end of the body is provided with a collecting device. According to the crushing and screening device for the processing of the nitride metal composite material, crushing of the raw materials in the crushing chamber is realized through the cooperation of a grinding barrel, and a rotating rod and a material guiding block, power is provided forthe winnowing mechanisms through the cooperation of a motor, a first gear and a second gear; and wind force is generated when a fan rotates, so that the falling track of the crushed raw materials ischanged due to wind power, the crushed raw materials are different in gravity due to the size of the crushed raw materials, so that the deflection generated when the raw materials are affected by windforce is distinguished, thus the separation is realized, the qualified particles are directly used, and the oversize particles are uniformly collected for secondary crushing.

Owner:FUJIAN XINHANGKAI MATERIAL TECH

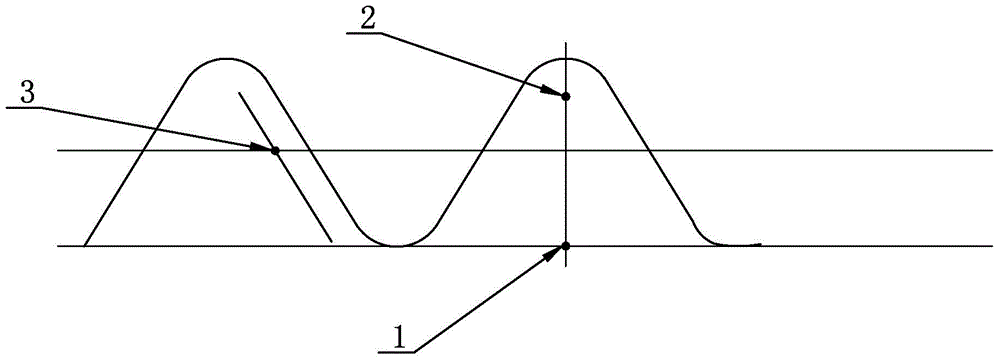

Quartz glass rod flame polishing and annealing device and method thereof

ActiveCN111825321AAvoid bendingAchieve the effect of annealingGlass productionThermodynamicsAuxiliary heating

The invention relates to a quartz glass rod flame polishing and annealing method which is characterized by comprising the following steps: S1, mobile terminal feeding: firstly, clamping a quartz glassrod and rotating the quartz glass rod at a constant speed; S2, preheating: turning on a main combustor, controlling the required temperature, controlling a flame operation table to transversely reciprocate, and preheating the quartz glass rod; S3, polishing and annealing: the height and the angle of the auxiliary flame nozzle and the hydrogen and oxygen supply amount of the auxiliary heating areaare adjusted in advance; each auxiliary flame nozzle is opened; and at the moment, the displacement speed controller is adjusted, the flame operation table drives the flame spray gun fixed to the flame gun frame to heat and polish the quartz glass rod at a constant speed, meanwhile, the distance between the auxiliary combustors and the hydrogen and oxygen amount of each combustor control the temperature to form a temperature gradient, the quartz glass rod can be slowly cooled, and the annealing effect is achieved. The method has the advantages of being good in production quality and high in production efficiency.

Owner:中建材衢州金格兰石英有限公司

Method for testing reliability after welding of battery metal electrode and welding strip

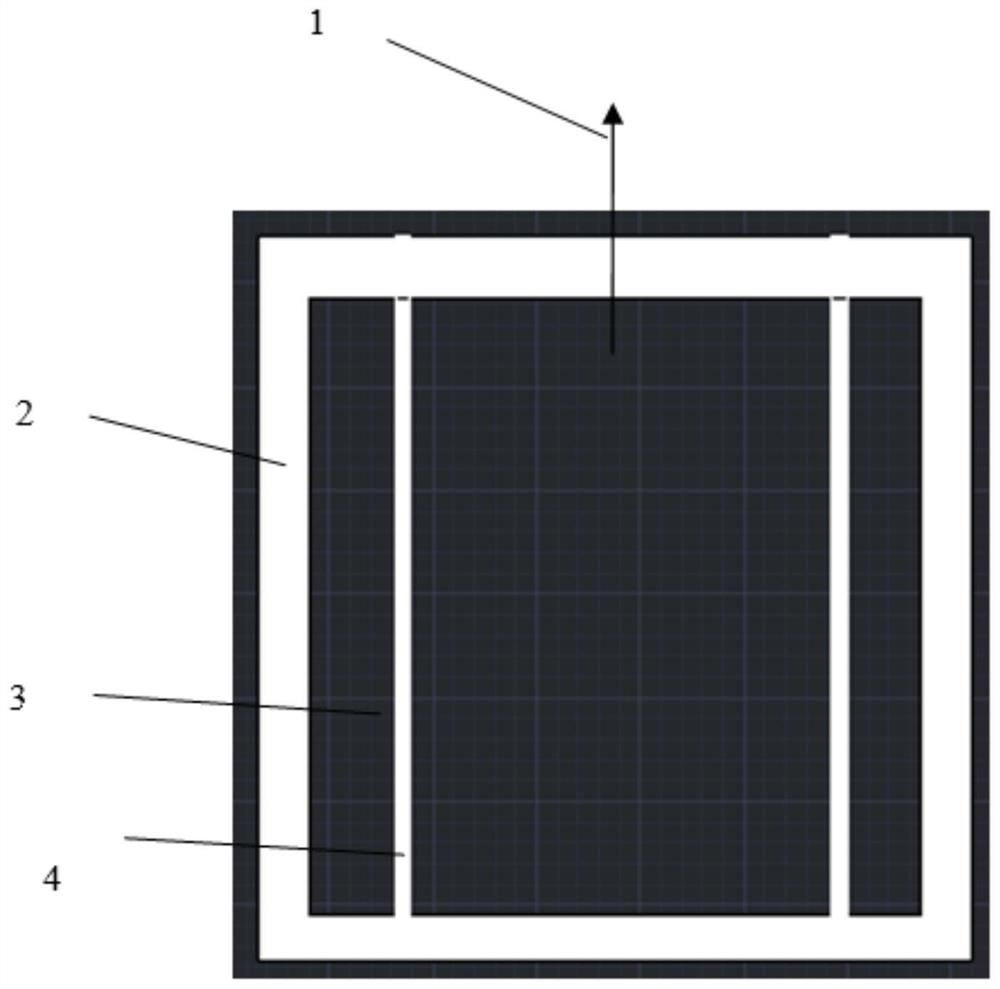

ActiveCN109671639AImprove quality assuranceGuaranteed reliabilitySemiconductor/solid-state device testing/measurementEngineeringMetal electrodes

The invention provides a testing method for the reliability after welding of a battery metal electrode and a welding strip. A test for a pulling-out force between the electrode and the welding strip is increased after a heat cycle, so as to effectively ensure that a battery piece still can have good performance after the heat cycle of the battery piece; a condition that a peeling phenomenon between the welding strip and the battery piece occurs in a post-period utilization process, resulting in an EL failure is avoided. By adopting the method provided by the invention, whether a welding forcebetween the battery electrode and the welding strip is qualified or not can be found; defective products are prevented from flowing into the downstream at a battery end in advance; the problem that low-quality products are used so that the service life of the products is reduced is avoided and the risks and cost are reduced from the source.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

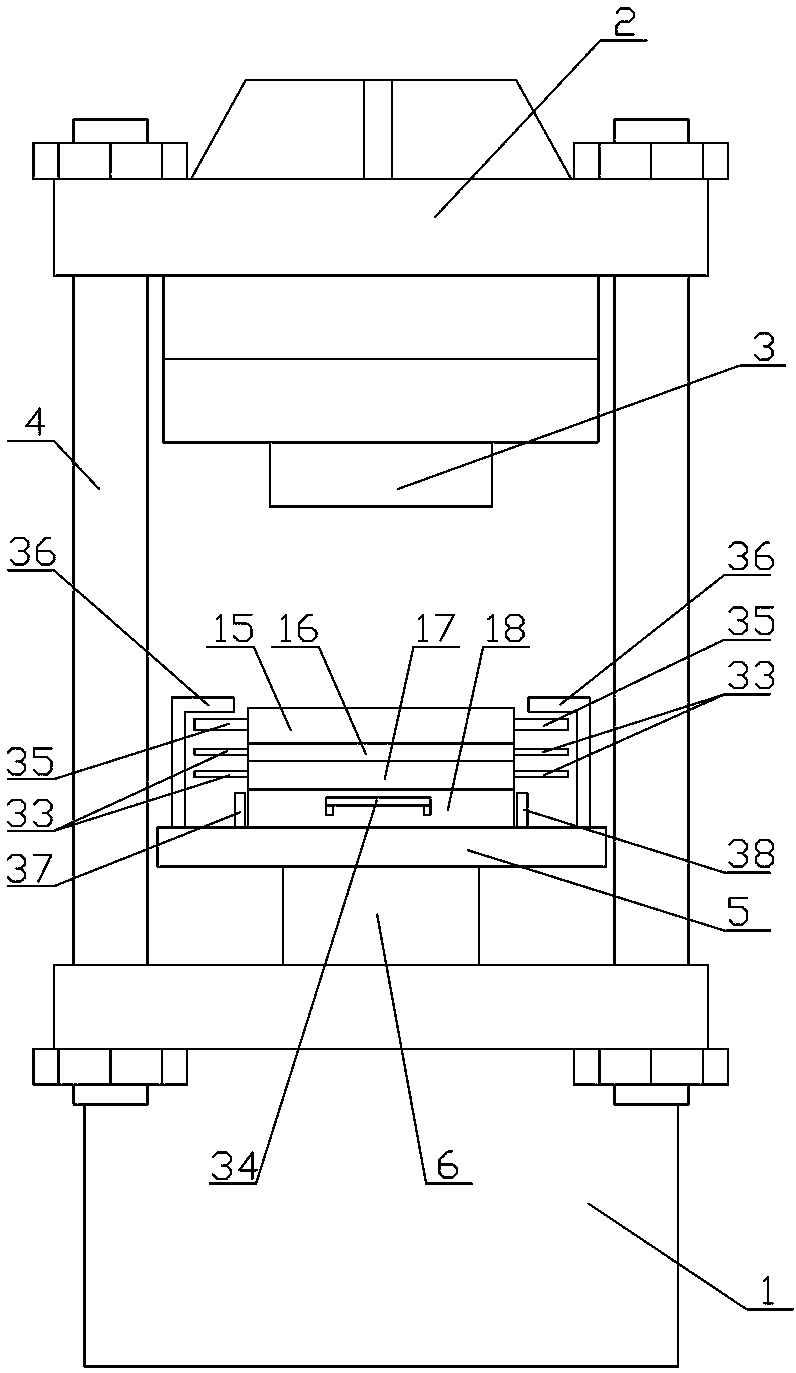

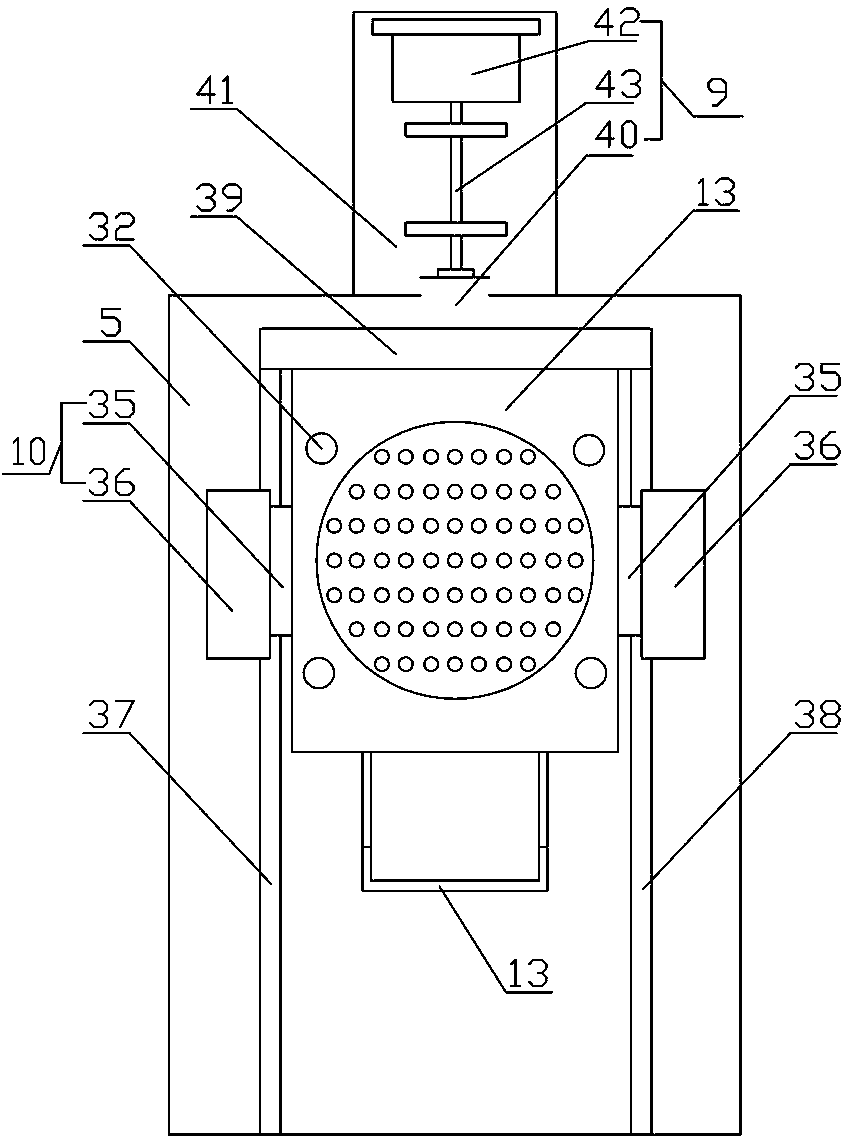

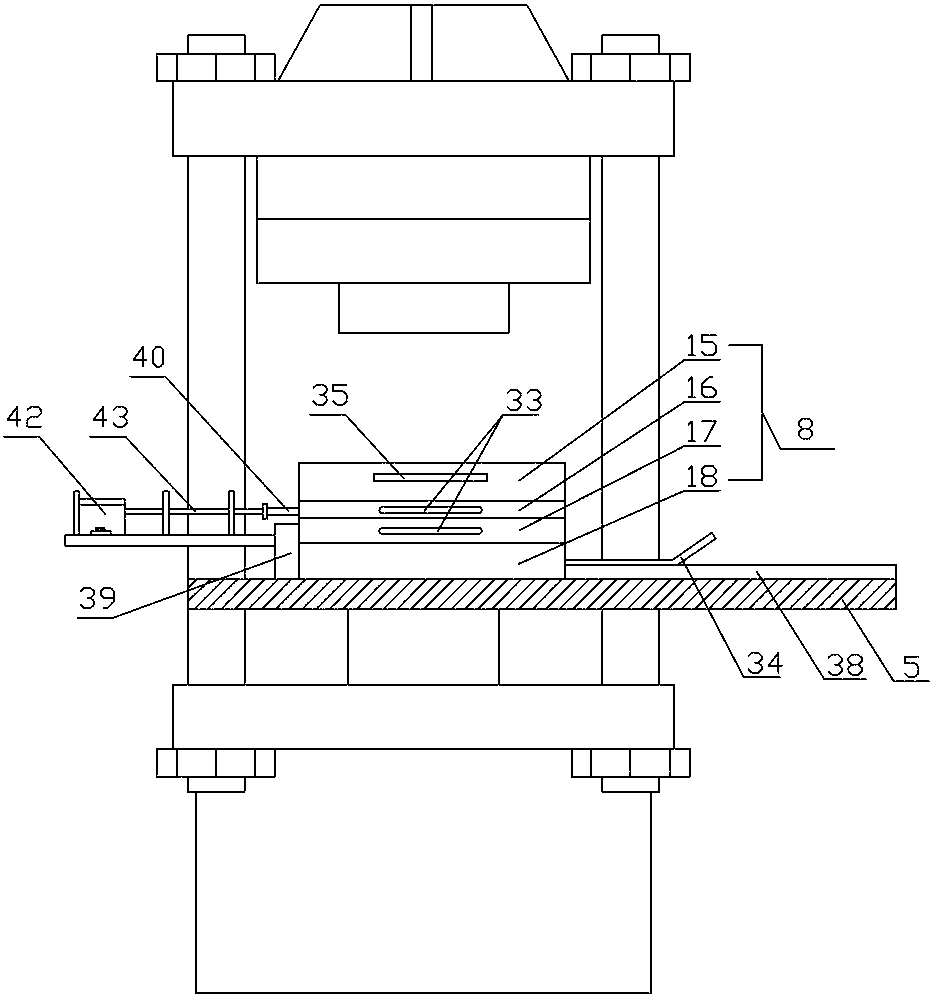

Vulcanizing machine for forming rubber damping seat

The invention relates to the field of vulcanizing machines, specifically to a vulcanizing machine for forming a rubber damping seat. The machine comprises a base which is movably sleeved with a lifting platform through a guide column, wherein a die assembly for preventing the rubber damping seat from bubble is movably mounted on the surface of the lifting platform in a drawer form; the die assembly comprises a material groove die, an upper die plate, an intermediate plate die and a bottom plate die which are overlapped and combined from top to bottom in sequence; a drawer type lower movable stopping point part, positioned to the die assembly, of the lifting platform is equipped with a switch device with the automatic position detecting function; stopping devices for preventing the materialgroove die and a pouring plug from adhering are mounted at two sides of the lifting platform. With the adoption of the machine, bubble and flash which are easily found in the forming process of the rubber damping seat can be effectively solved, and meanwhile, the problems of mistake positioning and missing of the die assembly and the adhering of the die assembly and the pouring plug can be effectively avoided; the machine has extremely good application prospect.

Owner:黄石市东兴橡胶制品有限公司

Process for rapidly realizing short-cut nitrification and denitrification of leather wastewater

InactiveCN110683646AAchieve normal startupAdapt quicklyWater treatment compoundsWater contaminantsActivated sludgeInorganic salts

The invention relates to the technical field of sewage treatment, and particularly provides a process for rapidly realizing short-cut nitrification and denitrification of leather wastewater. The process comprises: (1) carrying out enriching culture on tannery aerobic tank active sludge used as a bacterial source by using a special inorganic salt culture medium for short-cut nitrifying bacteria toprepare a short-cut nitrifying bacterial agent; (2) inoculating the short-cut nitrifying bacterial agent into a tannery aerobic tank according to a certain ratio, and carrying out field process regulation; and (3) after short-cut nitrification is formed in the aerobic tank, realizing short-cut nitrification-denitrification process denitrification through nitrification liquid reflux and feeding ofa carbon source into an anoxic tank. According to the invention, by combining the short-cut nitrifying bacterial culture outside the biochemical system and the biochemical system process regulation, the short-cut nitrification and denitrification process can be rapidly started, the method has advantages of short starting time, low operation cost, simplicity and convenience in operation and high total nitrogen removal rate, and the long-term stable operation of the short-cut nitrification and denitrification process of the biochemical system can be achieved.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Continuous punching die for automobile supporting frame

InactiveCN105537378AGuaranteed identityReduce the failure ratePerforating toolsMaterial resourcesEngineering

The invention provides a continuous punching die for an automobile supporting frame. The continuous punching die for the automobile supporting frame comprises an upper die body and a lower die body. The lower die body comprises a lower die seat and a lower pressing plate arranged in the lower die seat. A conveying mechanism is arranged at one end of the lower die seat. The lower pressing plate is provided with positioning holes, irregular-shaped grooves, conveying positioning blocks and a lower convex block, the multiple positioning holes are arranged at equal intervals in the conveying direction, and the multiple irregular-shaped grooves are distributed in the two sides of the positioning holes. The upper die body comprises an upper die seat and an upper pressing plate. The upper pressing plate is provided with positioning pillars corresponding to the positioning holes and an upper convex block matched with the lower convex block. The upper die seat is provided with positioning punches corresponding to the positioning holes and punches corresponding to the irregular-shaped grooves, and the positioning punches and the punches can penetrate through the upper pressing plate. The continuous punching die for the automobile supporting frame can complete punching work on the automobile supporting frame, is high in punching accuracy, reduces manpower and material resources, lowers the reject ratio and effectively improves the quality of products and production efficiency.

Owner:天津博昊科技发展有限公司

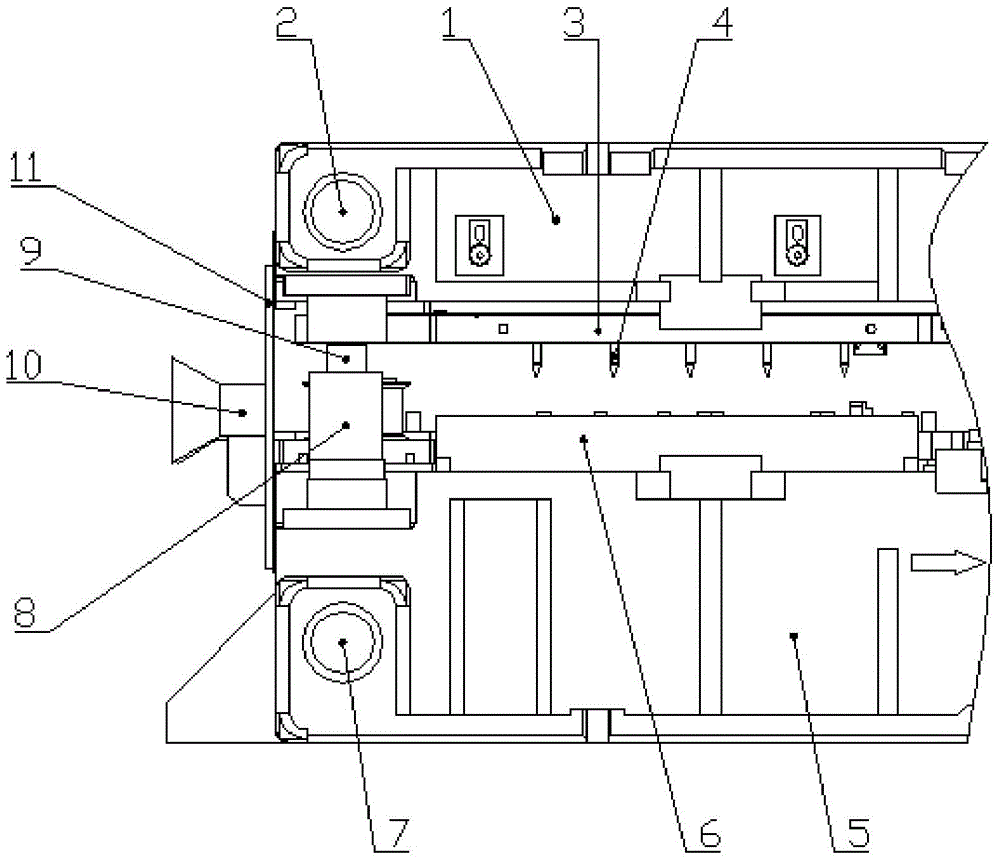

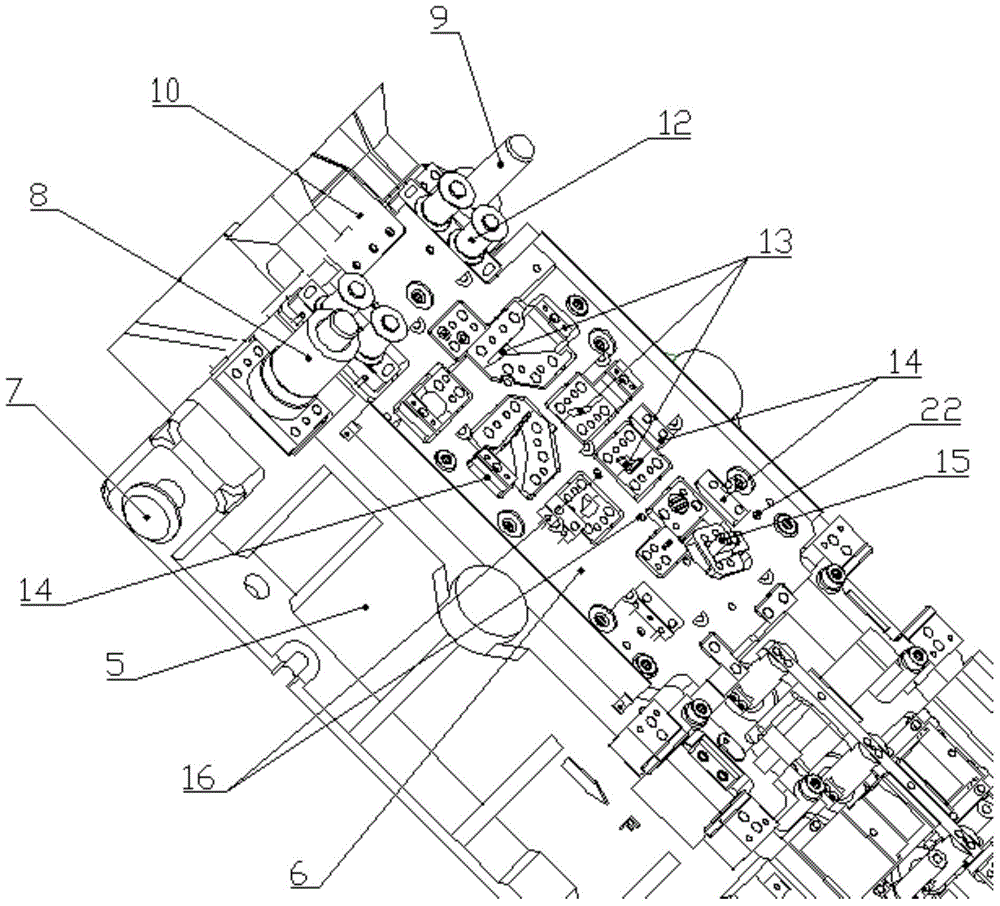

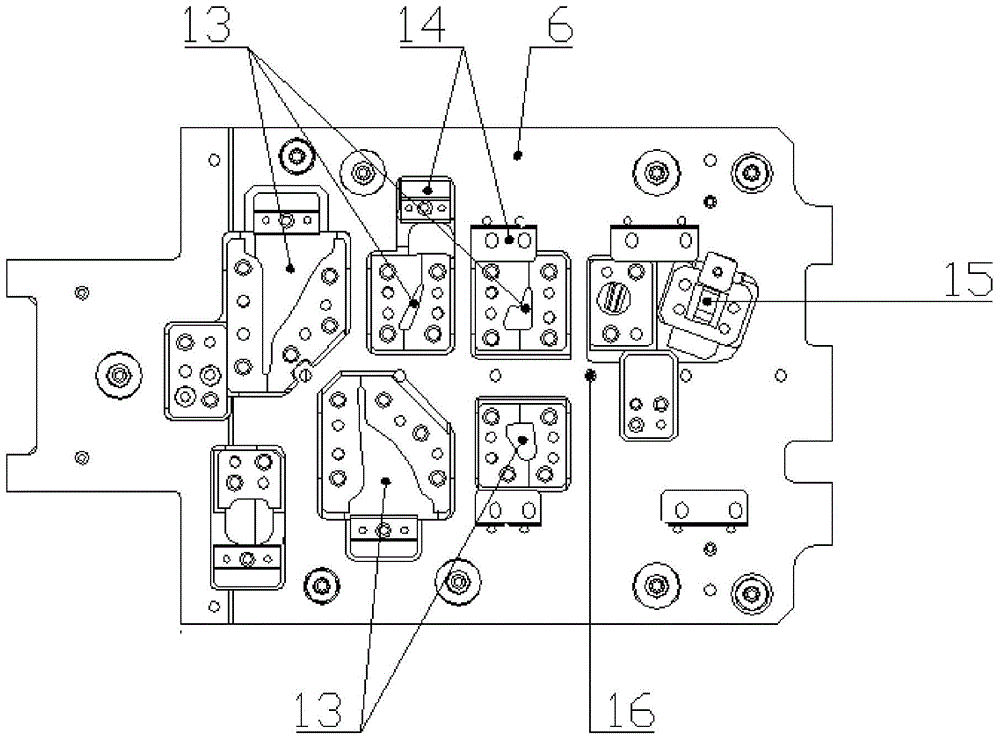

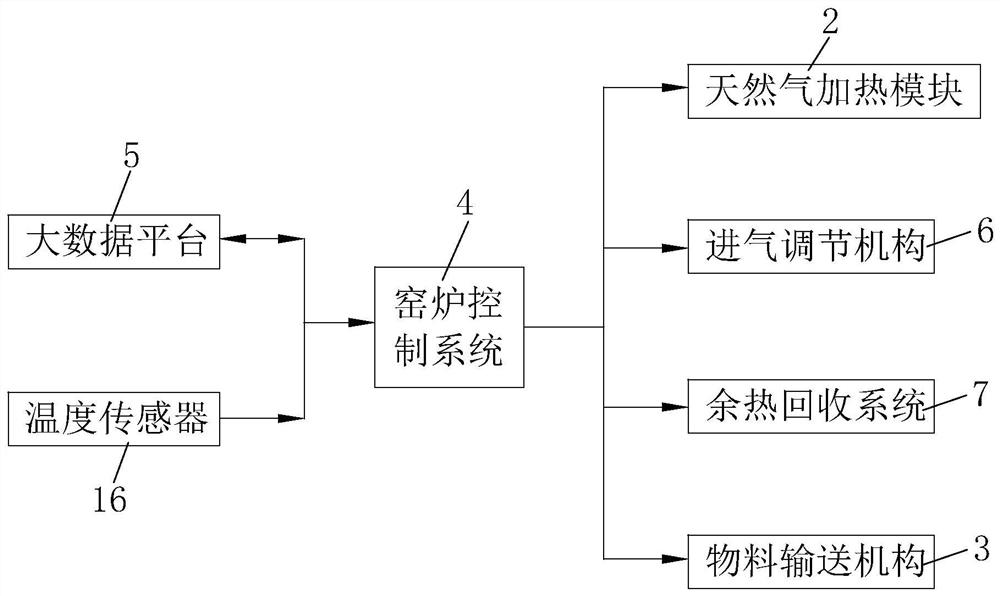

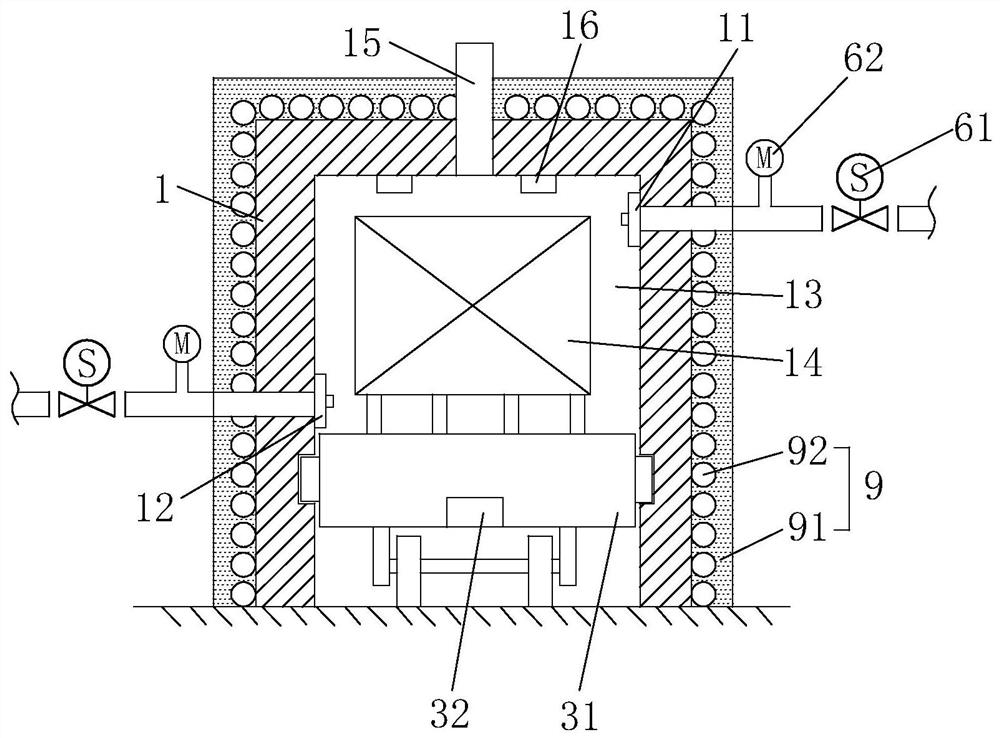

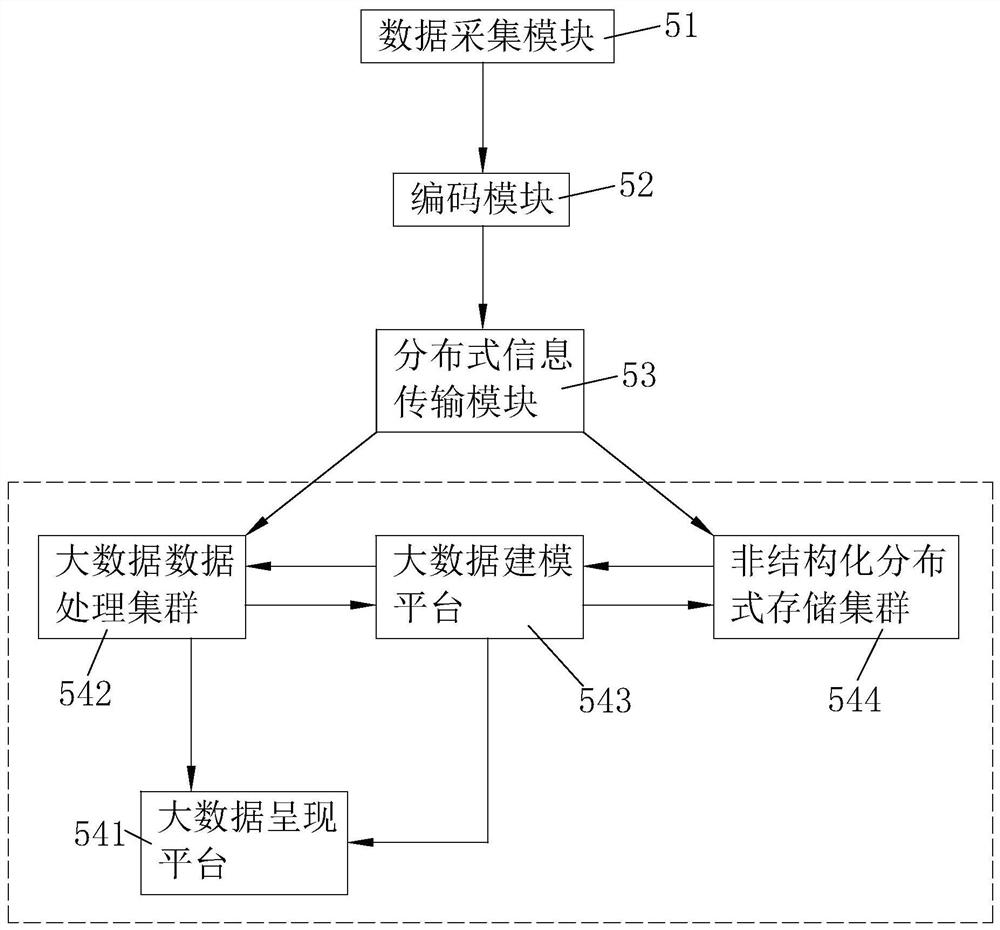

Building material kiln roasting system based on big data and process thereof

InactiveCN113390255AAvoid non-conformitiesImprove quality and efficiencyFurnace typesIncreasing energy efficiencyHeat conservationTime data

The invention relates to a building material kiln roasting system based on big data and a process thereof. The roasting system comprises a kiln body, a natural gas heating module, a material conveying mechanism and a kiln control system. The roasting system further comprises a big data platform, a gas inlet adjusting mechanism and a waste heat recovery system; and a plurality of temperature sensors are installed at the top in the kiln body. After the name of a produced building material is input into the kiln control system, the kiln control system automatically calls corresponding production parameters in the big data platform to control kiln equipment to perform producing and displays the standard temperature and heat preservation time of each section of kiln body on a display screen. Each temperature sensor is used for detecting the temperature in the kiln body and transmitting real-time data of the temperature to the kiln control system, and the kiln control system controls the air inlet adjusting mechanism, the waste heat recovery system and the material conveying mechanism to enable the kiln temperature to reach the preset standard temperature and heat preservation time after comparing and analyzing the real-time data and the standard temperature.

Owner:赣州科帕机电自动化有限公司

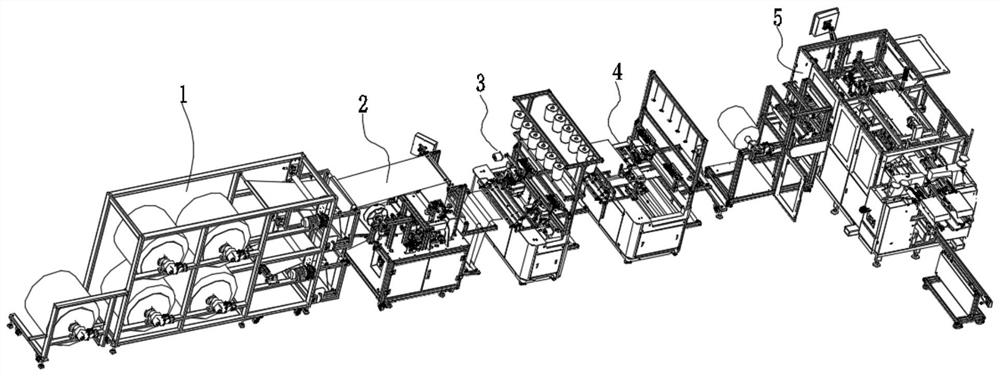

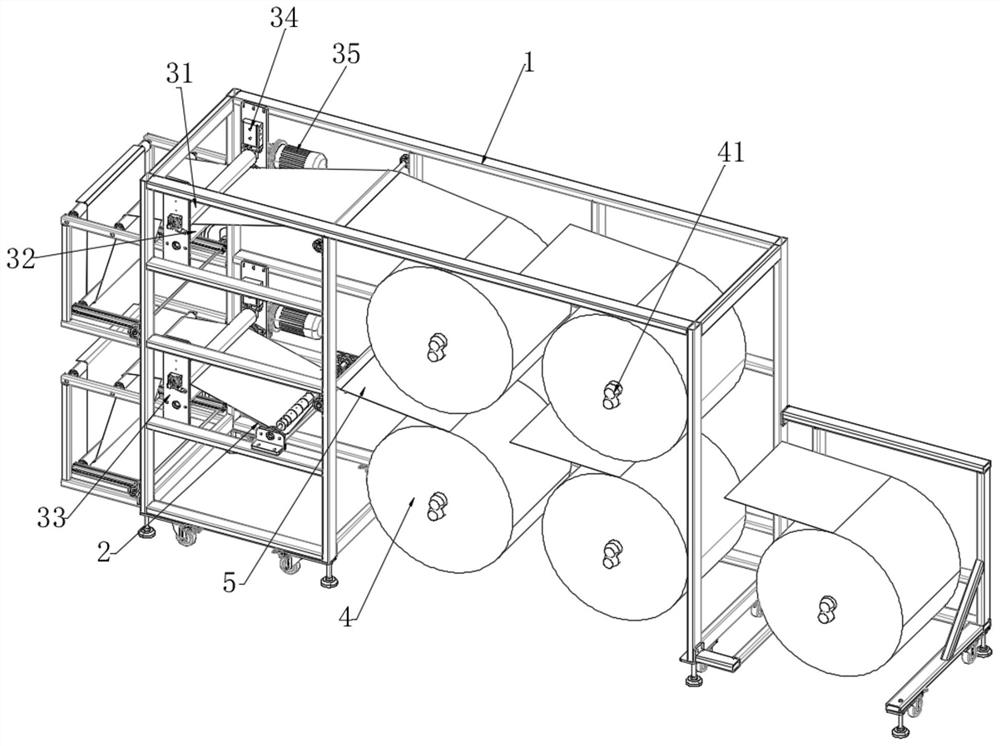

Abdominal pad processing system

PendingCN114108191AImprove efficiencyImprove yieldWorkpiece carriersWork-feeding meansTransfer mechanismEngineering

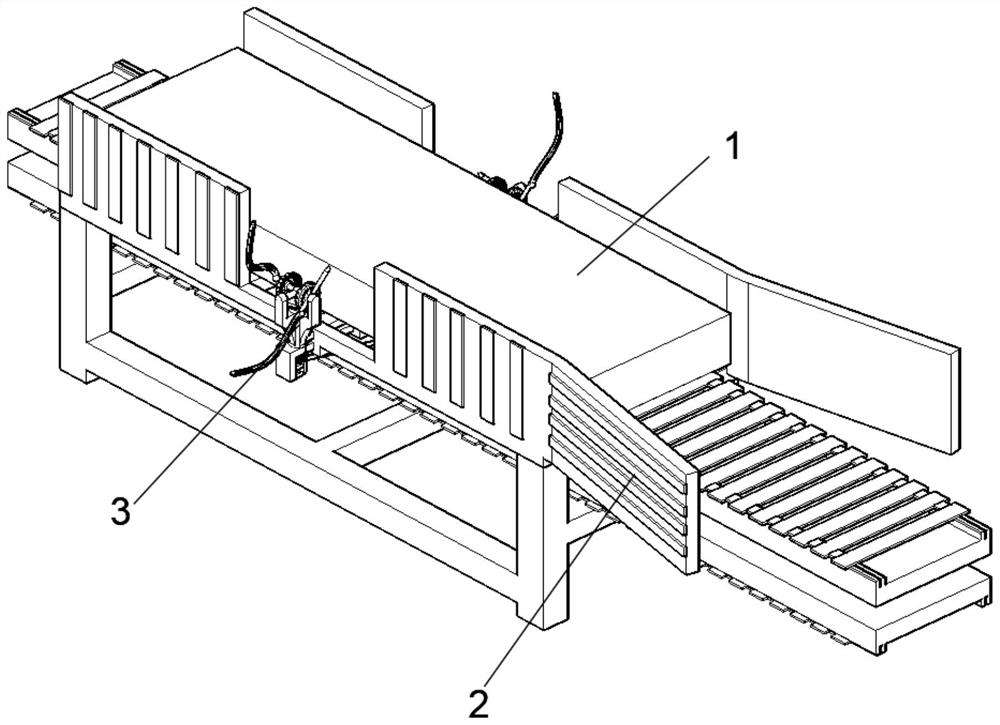

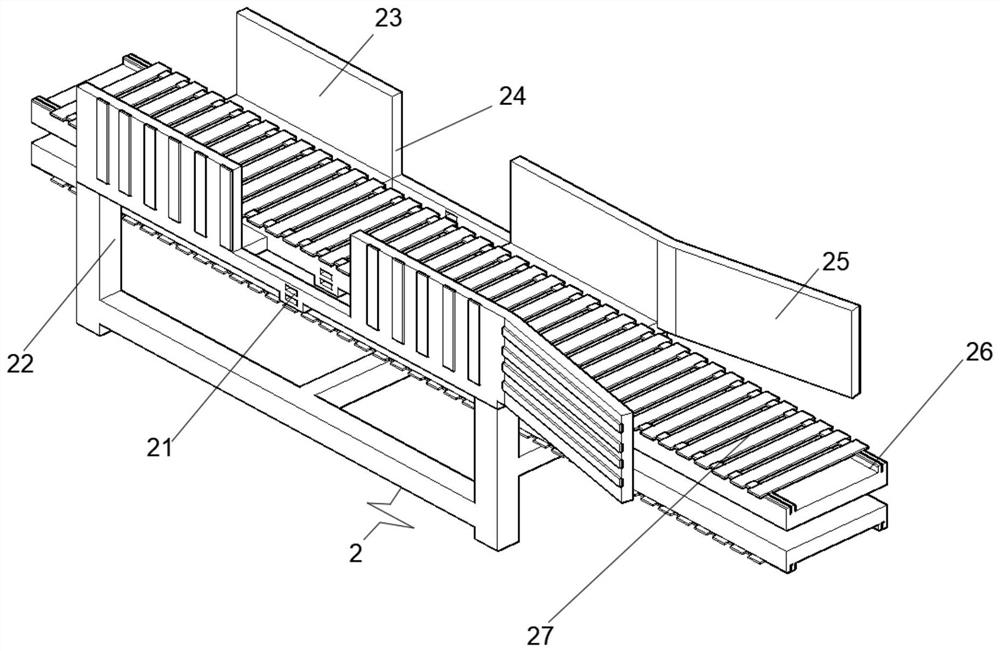

The invention provides an abdominal pad processing system. The abdominal pad processing system comprises a conveying device, a shell piece placing device, a vertical edge sewing device, a middle line sewing device and a transverse edge sewing device. The conveying equipment comprises an edge folding assembly, a plurality of discharging rollers and a plurality of conveying rollers, the shell piece placing equipment comprises a cutting mechanism, a label body transferring mechanism, a spot welding mechanism and a laying mechanism, and the vertical edge sewing equipment comprises a first machine table, a first adjusting assembly and two sets of first sewing machines. The middle line sewing equipment comprises a second machine table, a second adjusting assembly and a plurality of sets of second sewing machines, the transverse sewing machine frame comprises a cotton label feeding area and a folding sewing area, and the cotton label feeding area comprises a feeding platform, a pulling mechanism, a cotton label feeding mechanism, a cutting mechanism and a pressing and conveying mechanism, and the pulling mechanism, the cotton label feeding mechanism, the cutting mechanism and the pressing and conveying mechanism are located on the feeding platform. The folding sewing area comprises a folding platform, and two groups of edge folding mechanisms and two groups of sewing mechanisms which are positioned on the folding platform; the method has the advantages that high production efficiency and high yield can be realized.

Owner:苏州琼派瑞特科技股份有限公司

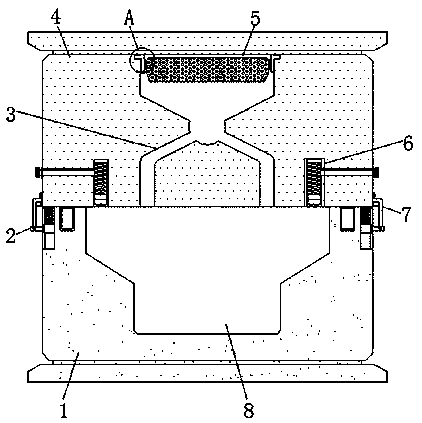

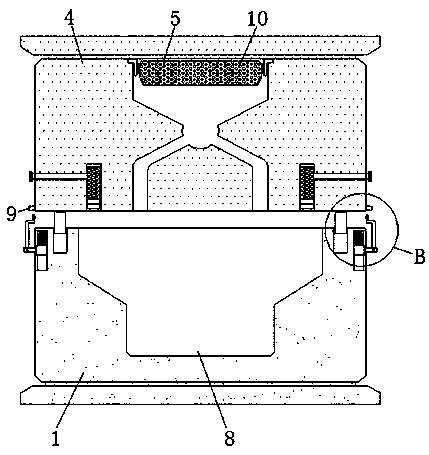

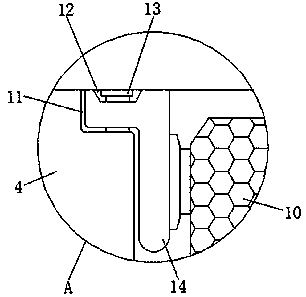

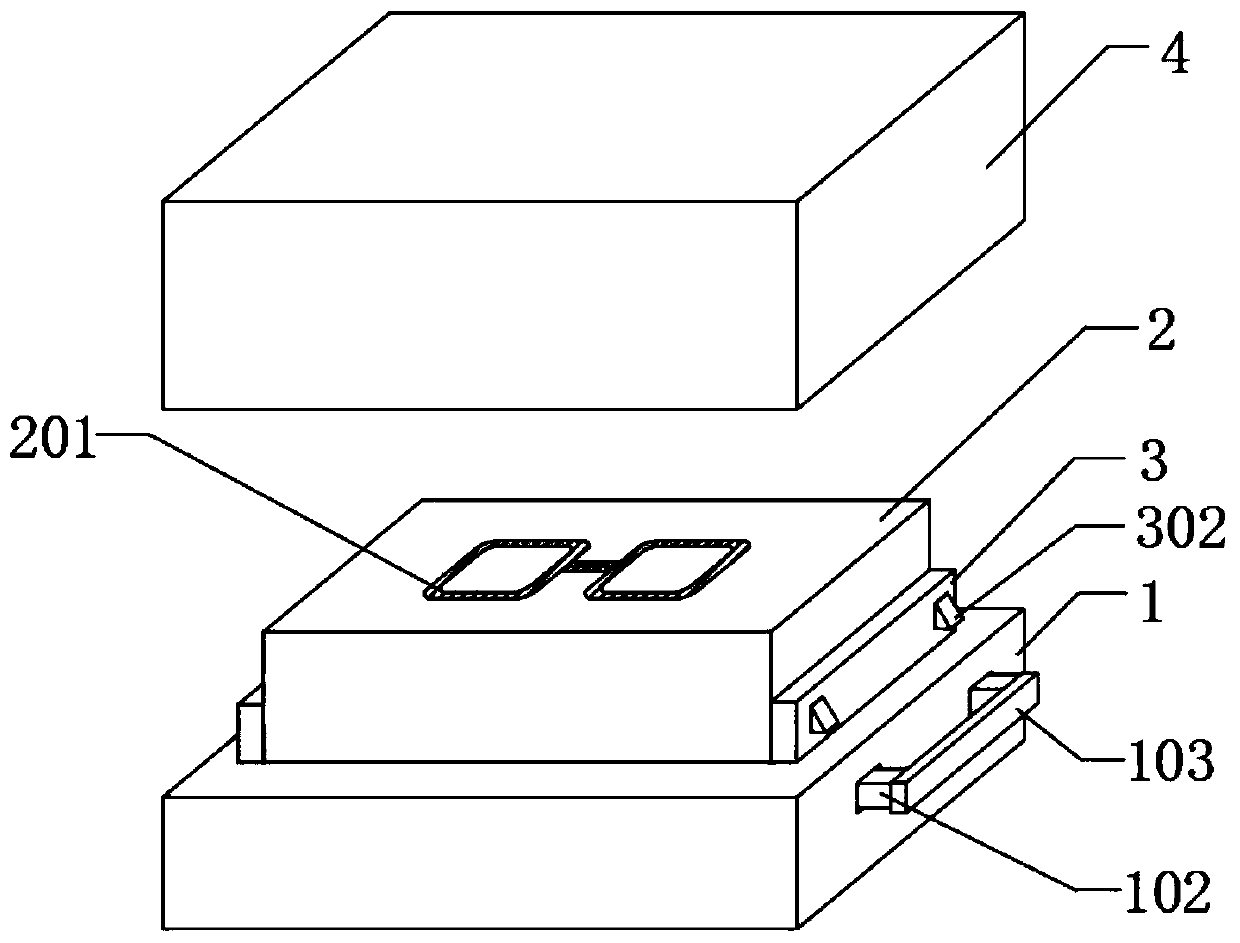

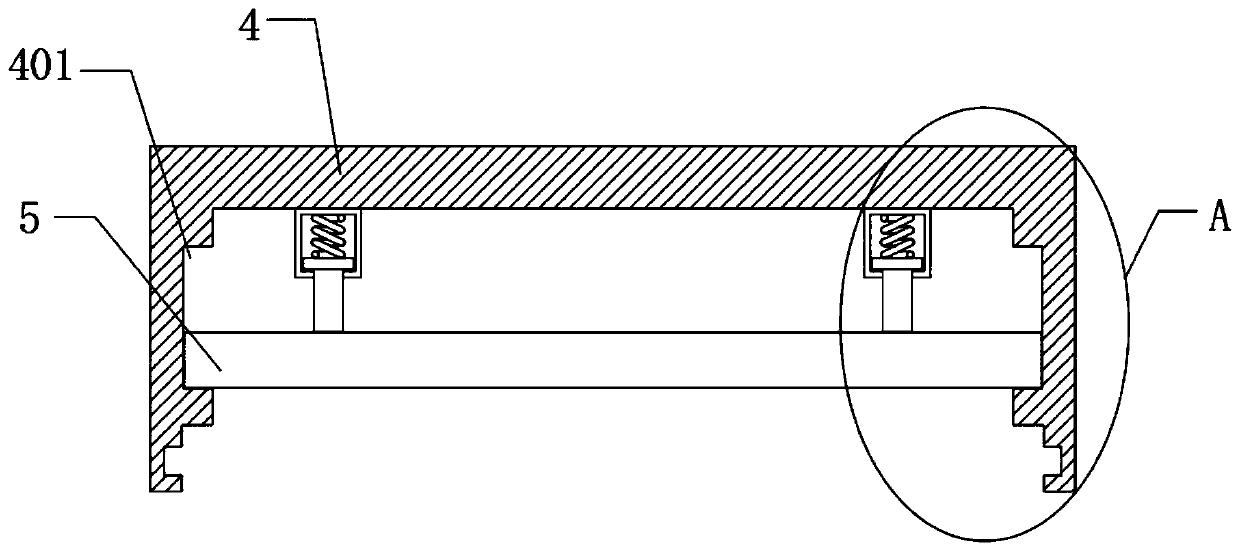

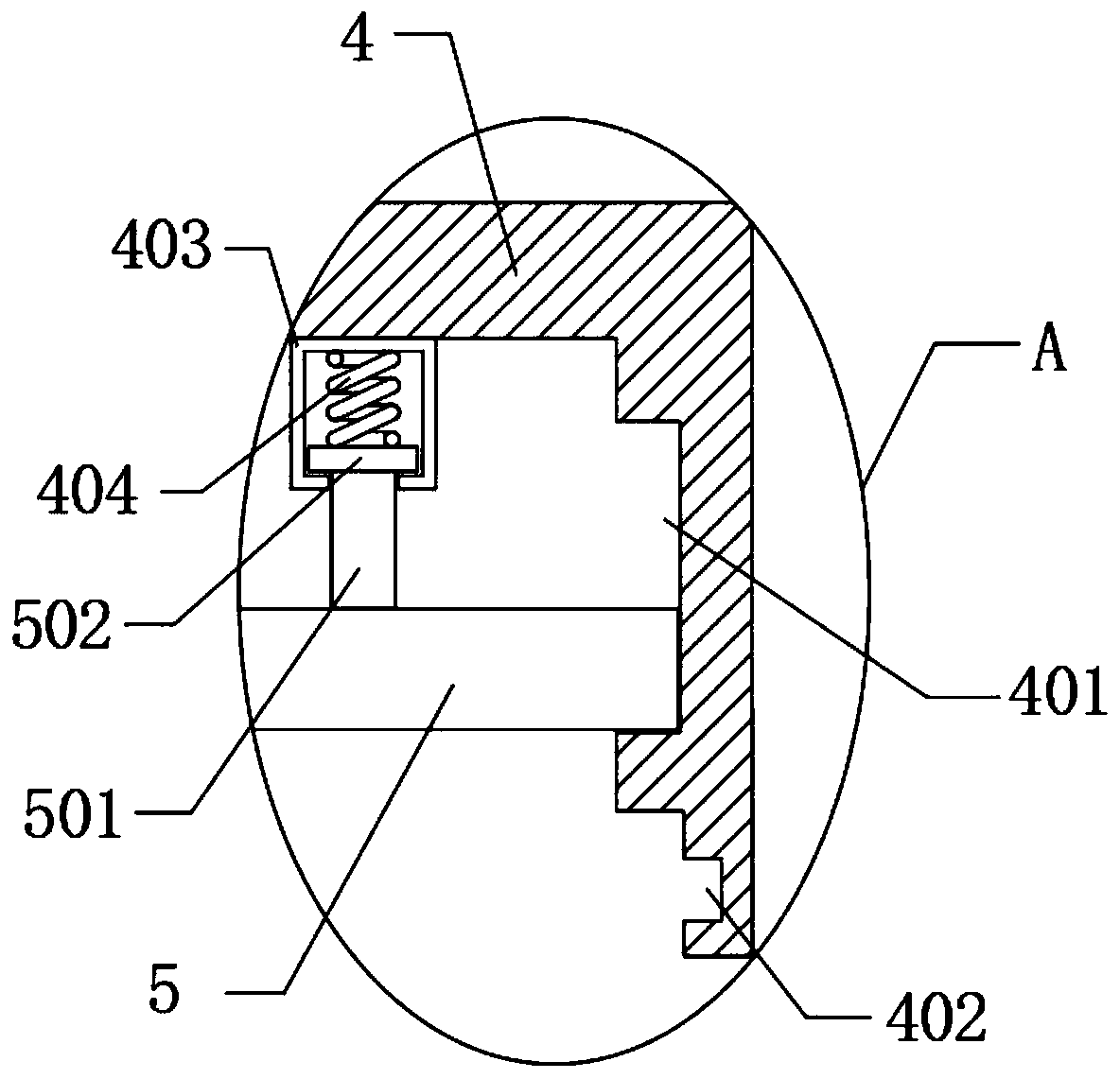

Mold with exhaust filter structure

PendingCN111545704AAvoid mold failureRealize the snap-in positioning functionFoundry mouldsFoundry coresFlue gasMechanical engineering

The invention discloses a mold with an exhaust filter structure. The mold includes a lower mold body, a moving plate, feed channels, a casting mold cavity, and a positioning groove. The lower mold body is internally provided with the casting mold cavity. An upper mold body is arranged above the lower mold body, fixed grooves at equal intervals are formed in the inner side of a feed inlet in the circumferential direction, and a placing groove is formed in the surface of one side of an L-shaped clamping plate. The feed channels are formed in the two sides of the inner part of the upper mold body, exhaust mechanisms are arranged on the two sides, above the casting mold cavity, of the inner part of the upper mold body, limiting baffles are fixed to the two sides of the bottom of the upper moldbody, adjusting grooves are formed in the two sides of the top of the lower mold body, and the side, away from the surfaces of the adjusting grooves, of a compression spring is fixedly connected witha fixing block. The clamping and positioning function at the time of installing the mold is realized, the function of filtering casting mold liquid by the mold is realized, and the function of discharging flue gas inside the mold is realized.

Owner:合肥丰华汽车零部件有限公司

Drying and disinfecting device for production of cosmetic bottles

The invention discloses a drying and disinfecting device for production of cosmetic bottles, belongs to the technical field of the cosmetic bottles, and solves the problem that in the prior art, the interior of the device is poor in air fluidity, so that the cosmetic bottles are not evenly heated, and deformation of the cosmetic bottles is further caused. The drying and disinfecting device is technically characterized by comprising a base, vertical plates, screw rods and placement racks, wherein the vertical plates are symmetrically arranged on the upper surface of the base; steam release chambers are welded at the upper ends of the vertical plates; the screw rods are arranged at the sides, close to each other, of the vertical plates; the lower ends of the screw rods are rotatably connected with the upper surface of the base; the upper ends of the screw rods are connected with bearing seats; the bearing seats are arranged on a supporting horizontal plate; threaded blocks sleeve the screw rods by means of threads; the threaded blocks are connected with each other through a connecting rod; and the connecting rod is used for connecting the placement racks. The drying and disinfectingdevice disclosed by the invention can be used for rapidly drying and disinfecting the cosmetic bottles, and meanwhile, accelerates the flow velocity of steam and changes the direction of the steam soas to realize uniform distribution of the steam, thus avoiding the phenomenon that the cosmetic bottles are not qualified due to uneven heating.

Owner:王钰莹

SMT surface mounting process for PCBA mainboard processing

InactiveCN113163620AGuaranteed eligibilityAvoid non-conformitiesPrinted circuit assemblingSurface mountingSolder paste

The invention discloses an SMT surface mounting process for PCBA mainboard processing. The SMT surface mounting process specifically comprises the steps of solder paste printing, element mounting, inspection after element mounting, reflow soldering, inspection after reflow soldering, cleaning, performance testing and packaging. According to the SMT surface mounting process for PCBA main board processing, the qualification of the PCBA main board is guaranteed by inspecting, cleaning and testing the surface mounting process, the problem can be found out through inspecting and detecting once the problem occurs in the part, the problem can be solved in time, the phenomenon that a large number of PCBA main board patches are unqualified is prevented, and the process is suitable for application and popularization.

Owner:深圳市科美通科技有限公司

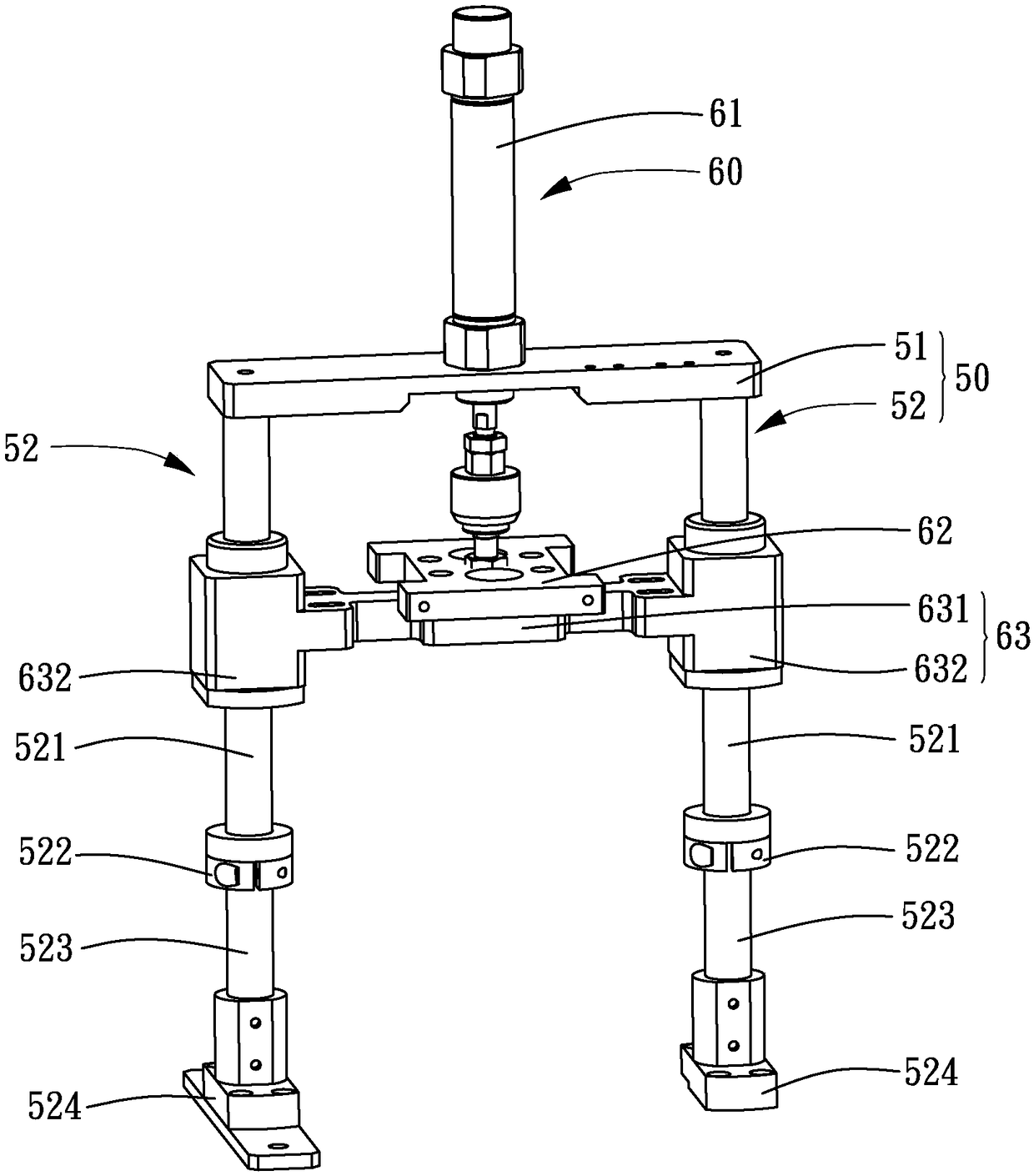

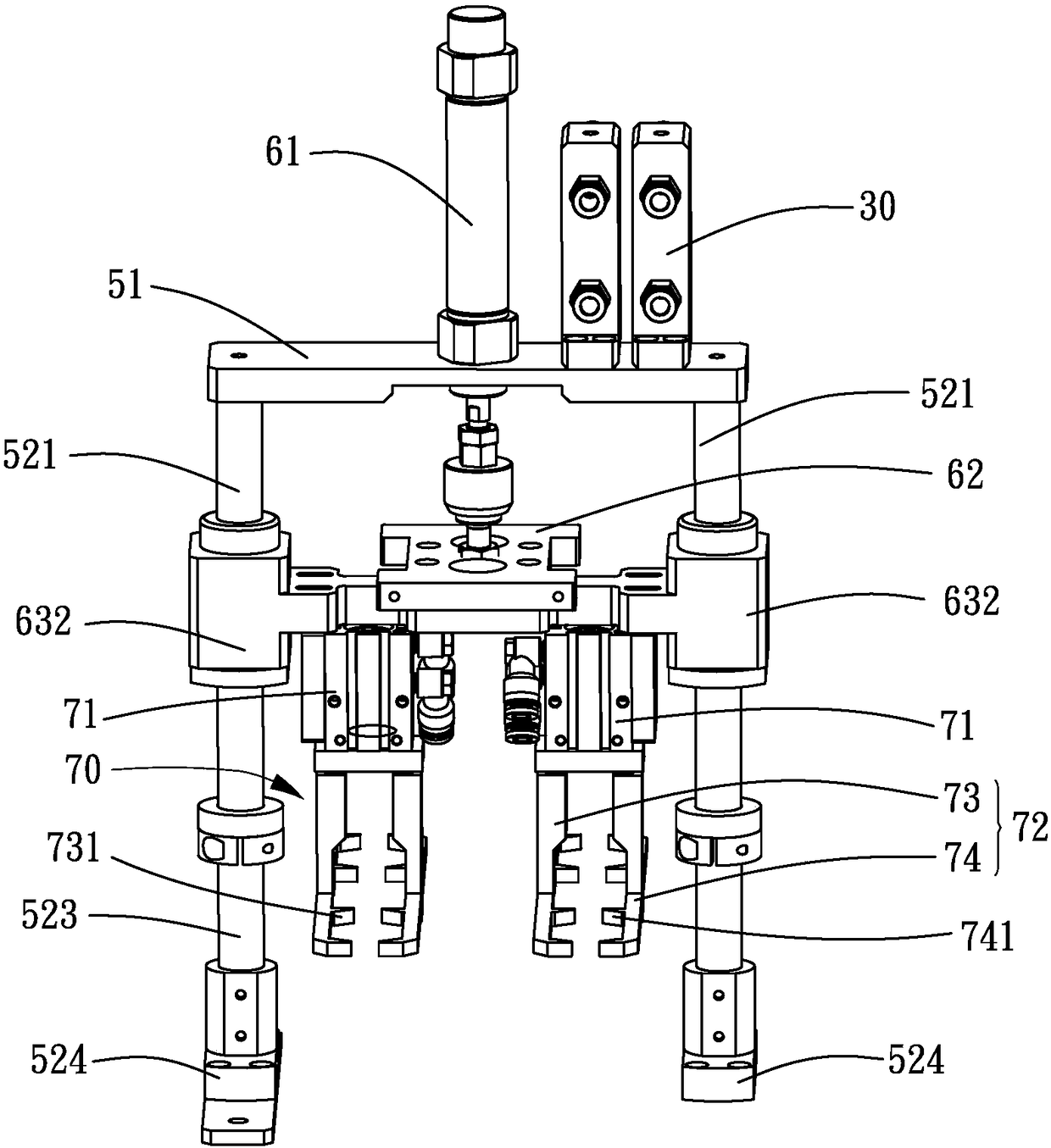

Shaping detection device

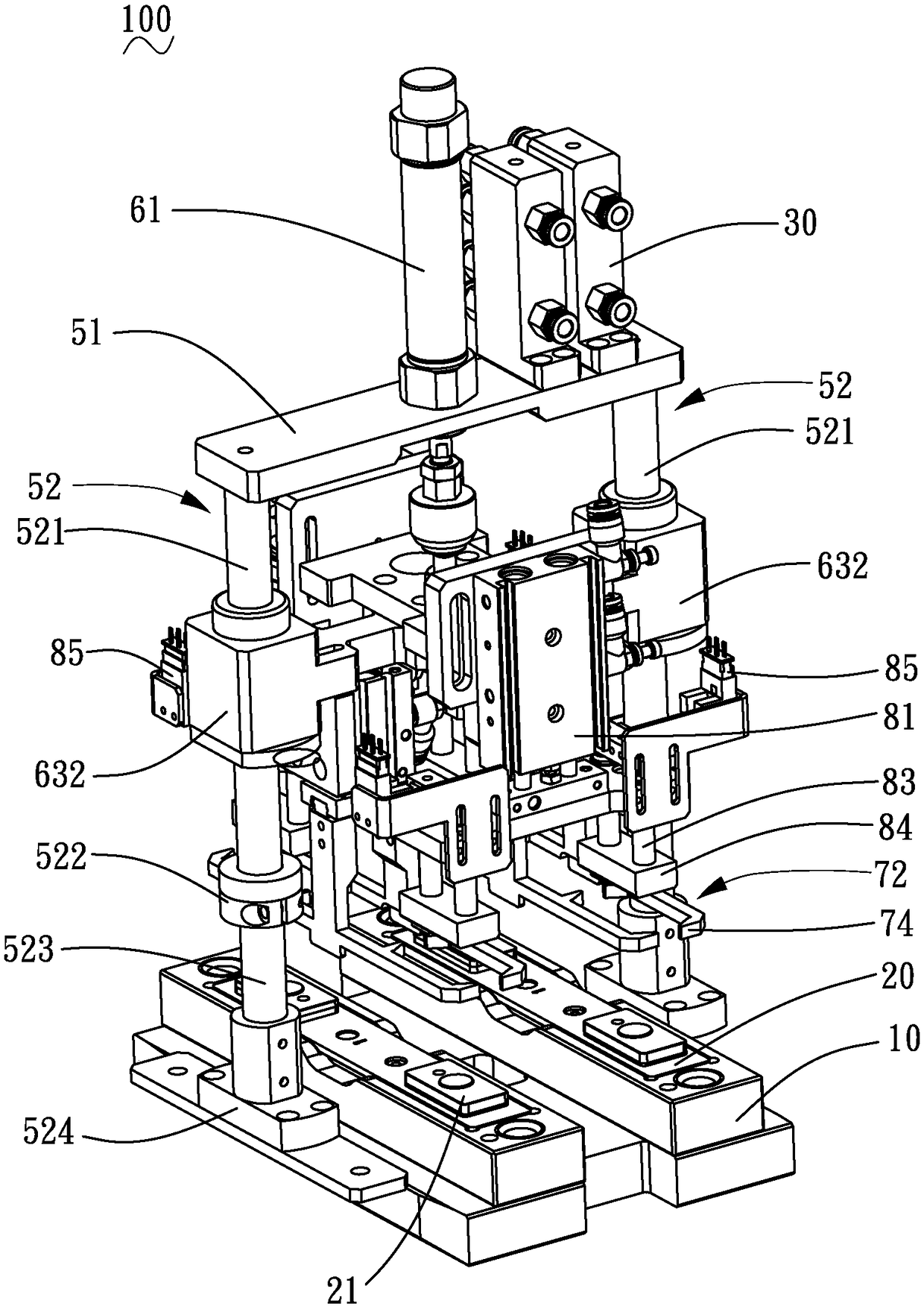

PendingCN108380696AImplement shaping detection processingAvoid non-conformitiesMetal working apparatusElectrical and Electronics engineering

The invention relates to a shaping detection device. The device is used for adjusting and detecting the position of a workpiece. The shaping detection device comprises a supporting assembly, the transmission assembly connected with the supporting assembly, a shaping assembly connected with the transmission assembly, and the detection assembly connected with the transmission assembly; the shaping assembly comprises a second air cylinder connected with the transmission assembly and a shaping hand claw connected with the second air cylinder, and the shaping hand claw is used for shaping the workpiece; the detection assembly comprises a third air cylinder connected with the transmission assembly, an elastic piece connected with the third air cylinder and a pressing block connected with the elastic piece, and an induction device corresponding to the elastic part; and the induction device is used for detecting the deformation degree of the elastic part. The shaping detection device can be used for shaping and detecting the workpiece on a jig, so that the riveting pressure effect is effectively improved, and the phenomenon that the riveting pressure product is unqualified is avoided.

Owner:SHENZHEN XUANSHUO INTELLIGENT MANUFACTURING TECHNOLOGY CO LTD

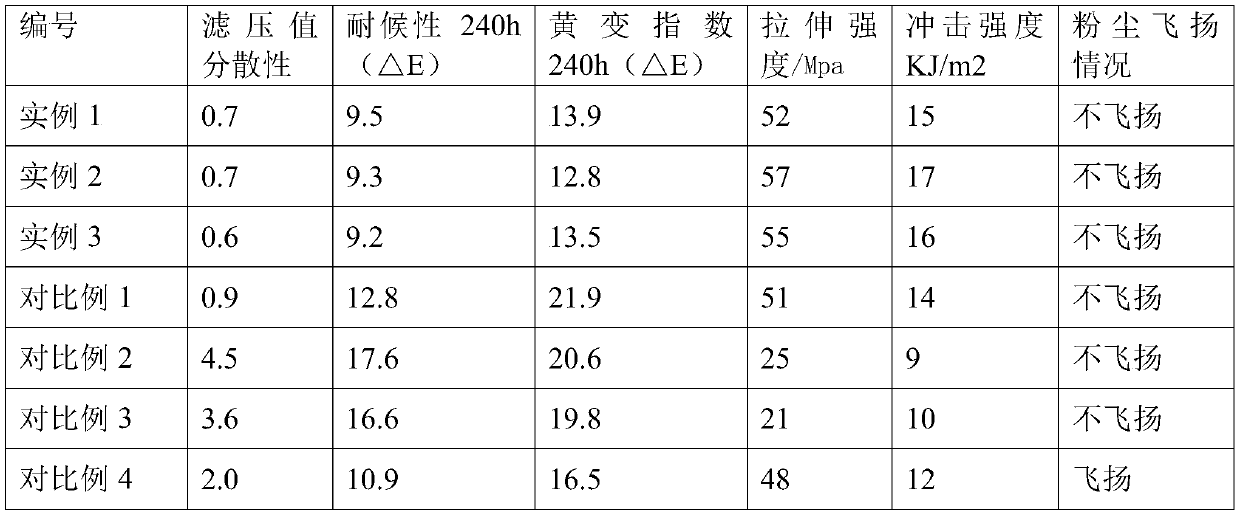

Preparation method of high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment

PendingCN111073351AClose to spherical high proportionSmall particle sizePigment flushingPigment treatment with macromolecular organic compoundsAluminatePolyolefin

The invention relates to a preparation method of a high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment, and the method comprises the following steps: producing a titanium dioxide primary product by a chlorination process, pulping in desalted water to prepare a slurry, regulating the pH value with an inorganic acid or alkali, dispersing, and grinding; heating the slurry, adding an alkaline aluminate compound, and simultaneously maintaining the pH value constant by using inorganic acid or an acidic aluminum compound to form an inorganic aluminum film coating layer on the surface of titanium dioxide particles; adjusting the pH value by adopting an inorganic alkali solution, and adding a polysiloxane liquid containing an active group to form an organic silicon film coating layer; filtering with deionized water, washing, and drying; adding a citrate ester organic treating agent in the steam-pulverizing process, and performing steam-pulverizing treatment to obtain a titanium dioxide finished product. The advantages are that: the titanium dioxide pigment prepared by the method has high weather resistance, high whiteness, high covering power andexcellent dispersion processability, has low dust flying in the production and use processes, is environment-friendly, and is suitable for the application fields of high-end color master batches suchas polyolefin, engineering plastics and the like

Owner:中信钛业股份有限公司

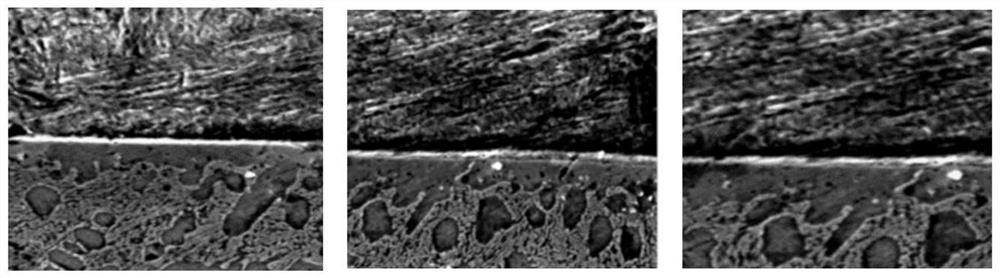

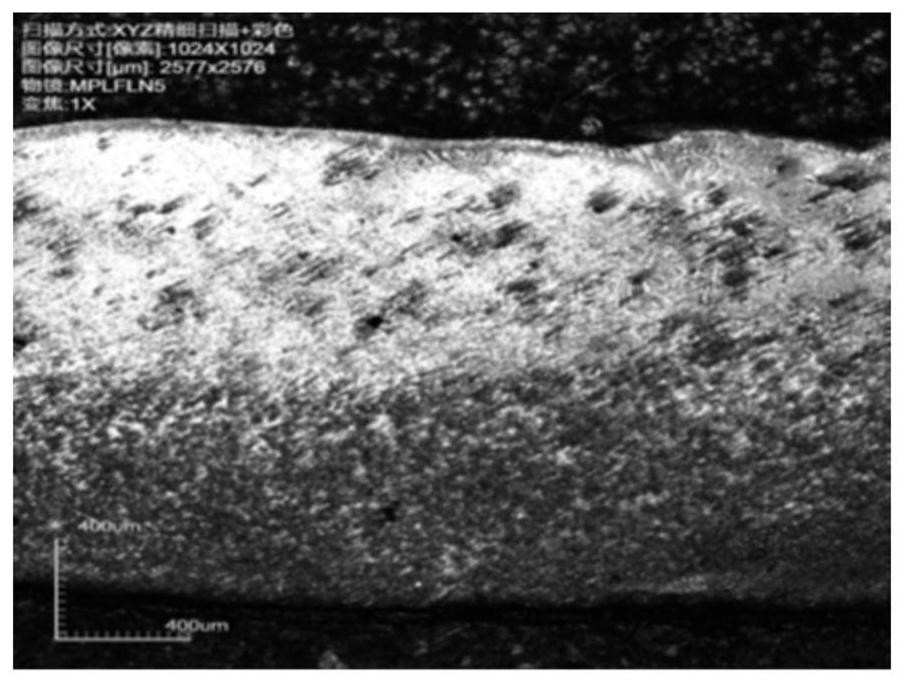

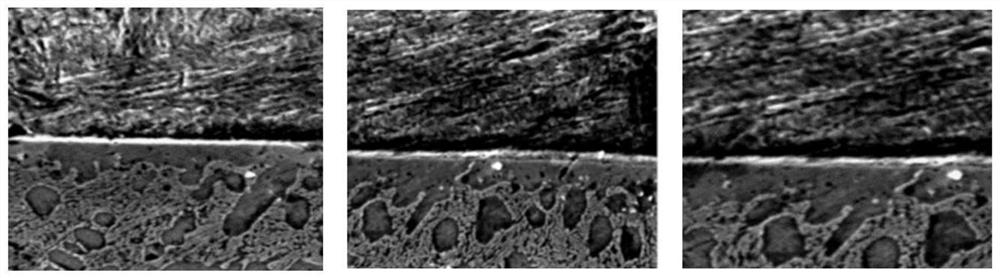

Inspection method of roller surface laser cladding repair layer

PendingCN113960162AQuality improvementAvoid defectsAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansStructural engineeringComputational physics

The invention discloses an inspection method for a laser cladding repair layer on the surface of a roller. The method comprises the following steps of: by using ultrasonic flaw detection, performing flaw detection on a whole repairing layer area, and performing flaw detection on a repairing layer and an original roller surface fusion line; carrying out unevenness measurement on the repair layer and the original roll surface fusion area; carrying out metallographic inspection on the repair layer and the original roll surface fusion area, wherein a metallographic sampling mode is parallel to a fusion line or a tangent line of the fusion line; and carrying out hardness test on the repair layer and the original roll surface fusion region, adopting a Rockwell hardness detection method, sampling in a manner of being vertical to a fusion line, and carrying out multi-point measurement on each sample. The method is used for inspecting the laser cladding repair layer prepared on the surface of the roller, so that the quality of the laser cladding repair layer on the surface of the roller can be effectively judged, and normal operation and use of the repaired roller can be guaranteed.

Owner:NANJING IRON & STEEL CO LTD

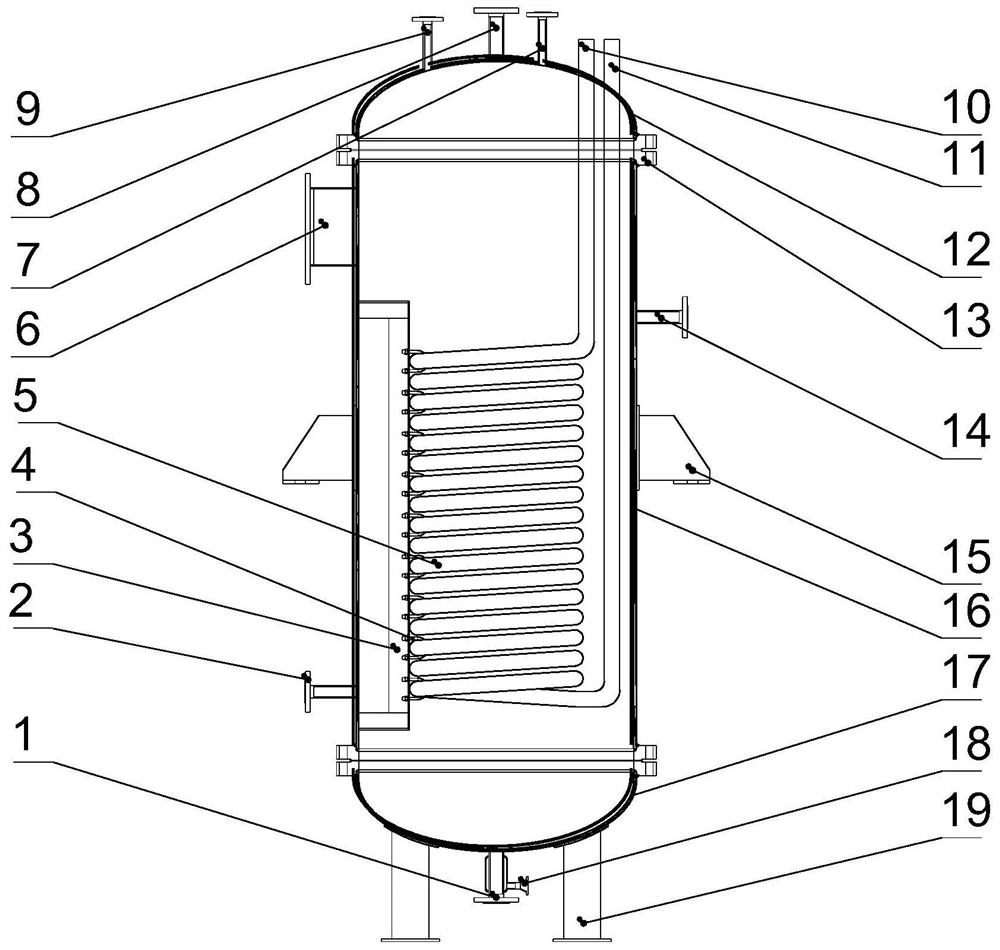

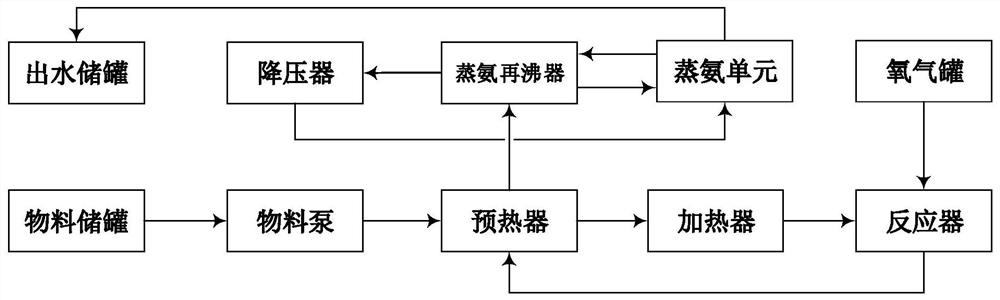

Ammonia distillation reboiler for supercritical water oxidation system and its processing method and use method

ActiveCN109305709BAvoid destructionImprove work efficiencyWater/sewage treatment by heatingWater/sewage treatment apparatusChemical industryInorganic salts

The invention discloses an ammonia distilling reboiler for a supercritical water oxidation system as well as a processing method and an application method thereof, which belongs to the field of chemical industry and environmental protection heat exchangers. The ammonia distilling reboiler comprises a barrel, an upper end enclosure, a lower end enclosure, a sewage inlet, a side surface sewage discharging opening, a heating coiled pipe, a steam outlet and a bottom sewage discharging opening. When in work, hot fluid enters the heating coiled pipe, the sewage is continuously heated and evaporatedto form vapor to enter an ammonia distilling tower, the sewage is discharged from the side surface sewage discharging opening according to the concentration of inner inorganic salt, and when the ammonia distilling reboiler is in normal work, the sewage can be normally discharged. The crystallization of inorganic salt caused by the continuous gathering and concentration of the sewage in the ammoniadistilling reboiler can be prevented from damaging a part, the working efficiency and safety of the equipment can be improved, and the equipment maintenance cost and the component replacement cost can be reduced.

Owner:XI AN JIAOTONG UNIV

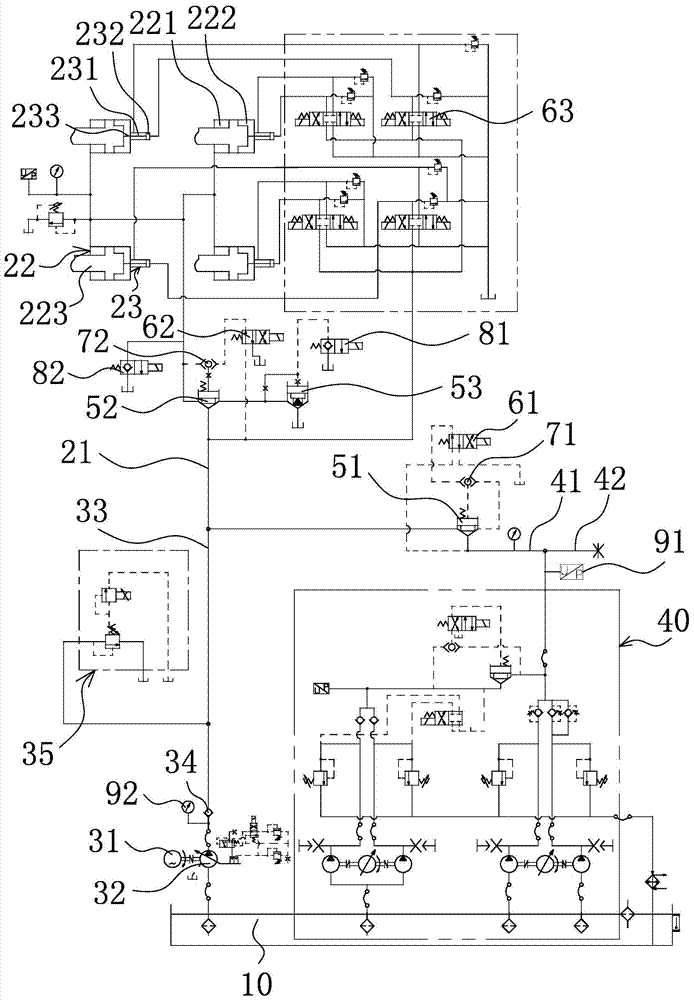

Synchronous system of injection molding machine and oil circuit control method thereof

The invention provides an injection molding machine synchronizing system and belongs to the technical field of hydraulic transmission, aiming at solving the problem of low working efficiency of existing injection molding machine structures. The injection molding machine synchronizing system comprises an oil tank used for storing oil, a working unit provided with a working oil way used for conveying the oil, a main unit provided with a first oil way and a second oil way which communicate with each other and are used for conveying oil, and an auxiliary unit provided with an auxiliary oil way used for conveying oil, wherein the first oil way is connected with the working oil way, and the auxiliary oil way communicates with the working oil way. The system has the advantages of being reasonable in design, capable of realizing synchronization and high in working efficiency.

Owner:HAITIAN PLASTICS MACHINERY GRP

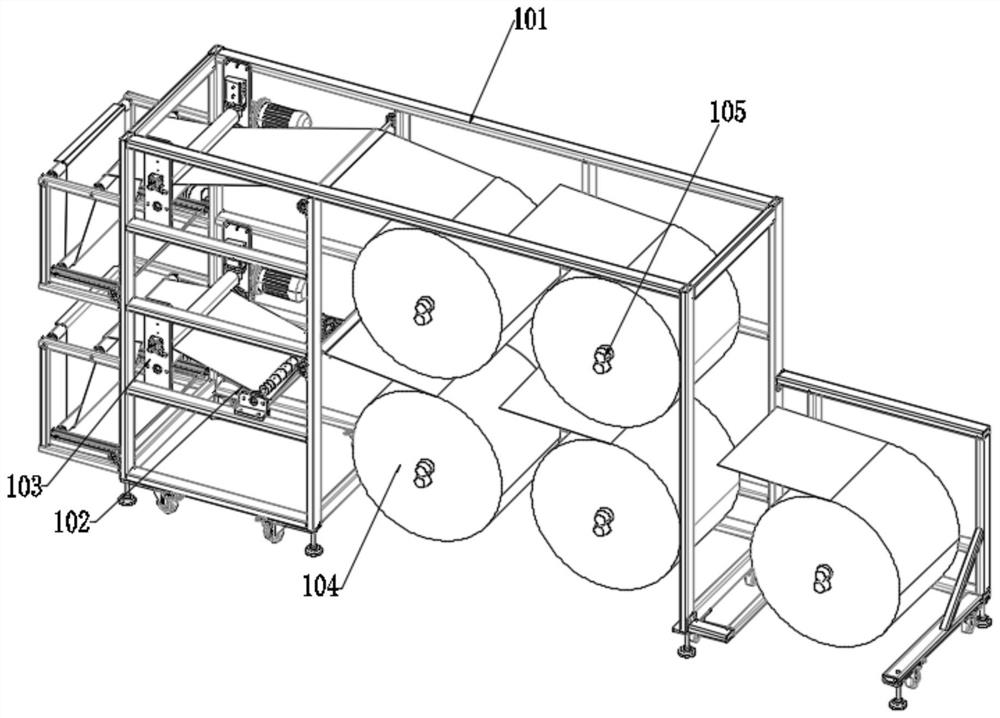

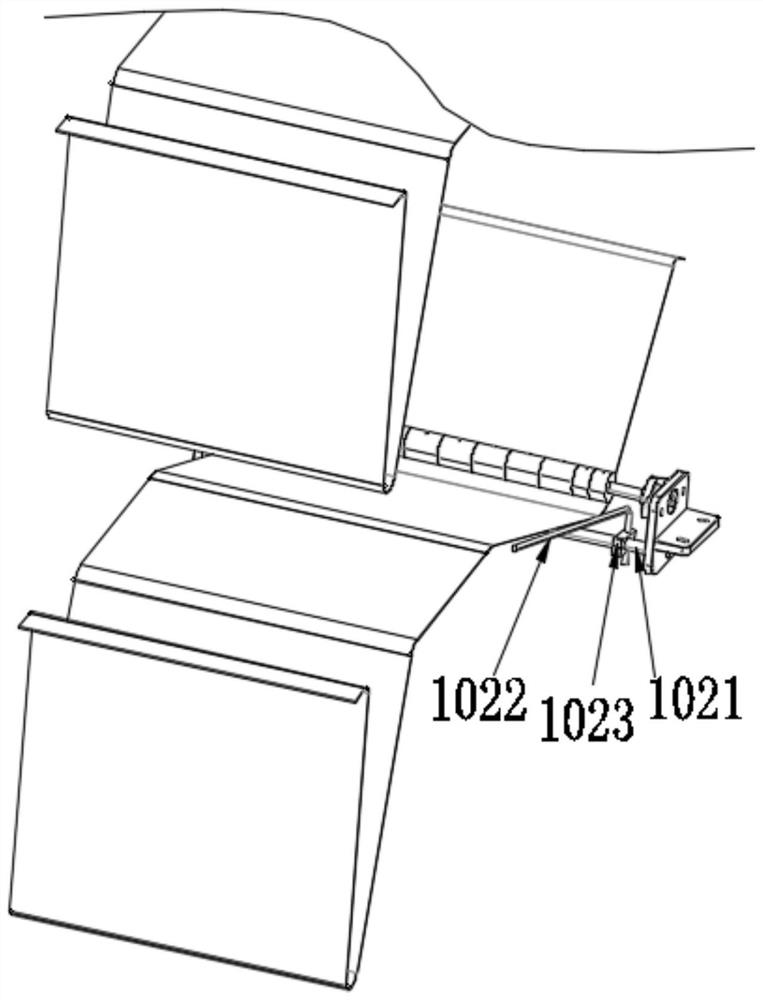

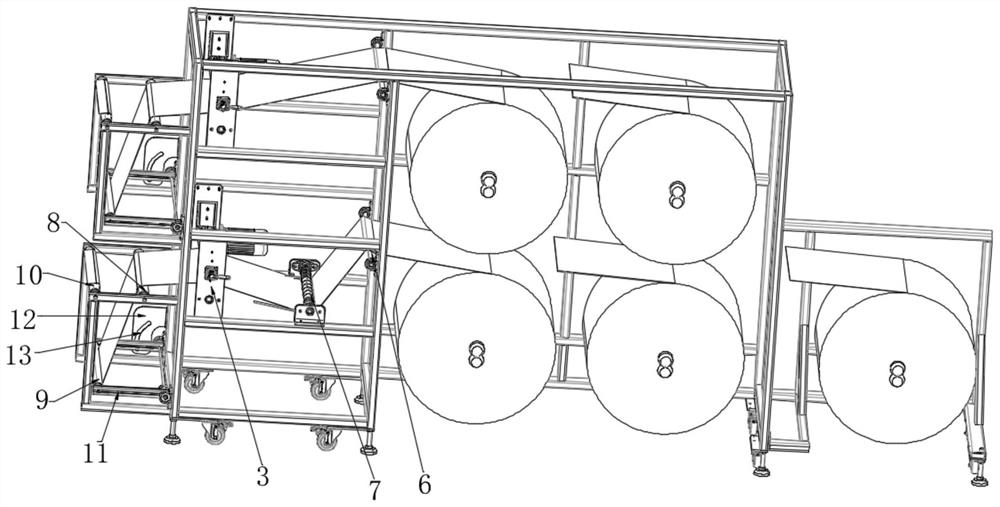

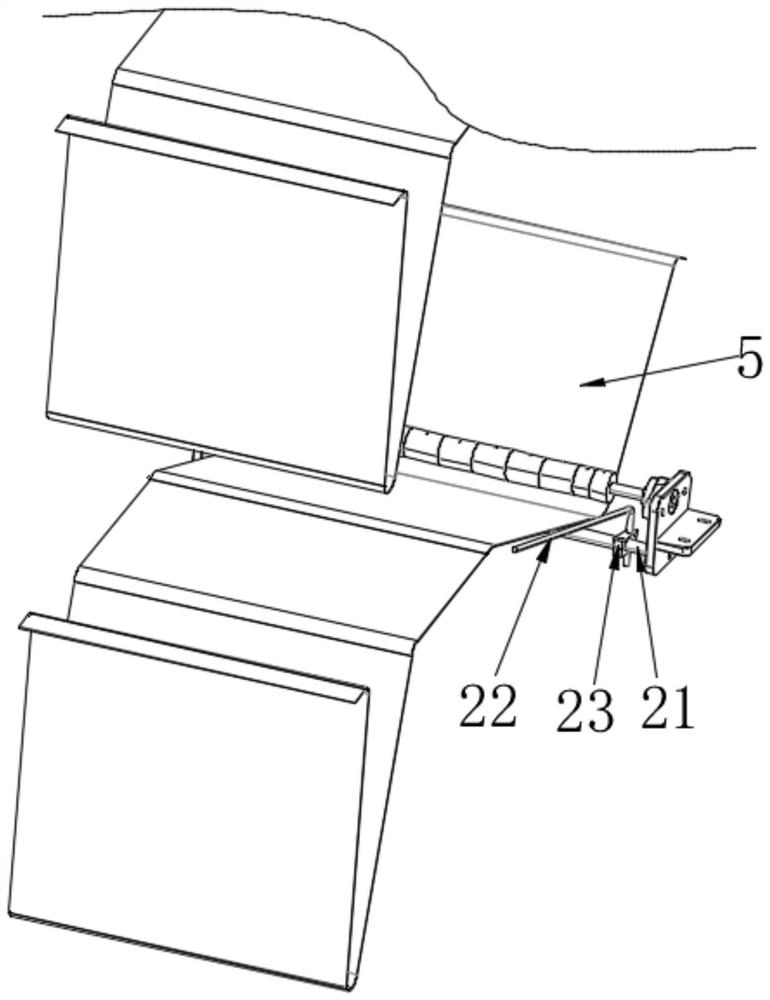

Feeding frame for abdominal pad processing

PendingCN114104814AAvoid non-conformitiesFolding thin materialsWebs handlingStructural engineeringAbdominal pad

The invention innovatively provides a feeding frame for processing an abdominal pad, the feeding frame comprises a rack, the rack comprises a plurality of groups of conveying mechanisms, each group of conveying mechanisms comprises a discharging roller, an edge folding assembly, an edge pressing assembly and a plurality of groups of conveying rollers, and the output fabric of an abdominal pad fabric roll sequentially passes through the plurality of groups of conveying rollers; the edge folding assembly comprises a cross rod, two sets of pressing rods and two sets of adjusting seats, the cross rod is located below the output fabric, the two sets of pressing rods are rotationally connected to the cross rod on the two sides of the output fabric through the adjusting seats correspondingly, the two sets of pressing rods are opposite and extend to the lower bottom face of the output fabric, and the outer surfaces of the two sets of pressing rods abut against the two sides of the lower bottom face of the output fabric correspondingly; the edge pressing assembly comprises an upper pressing roller and a lower pressing roller, the upper pressing roller is located above the output fabric subjected to edge folding through the edge folding assembly, and the lower pressing roller is located below the output fabric subjected to edge folding through the edge folding assembly; the edge folding and pressing device has the advantages that stacking, edge folding and edge pressing can be conducted in the conveying process, and edge deviation is avoided.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Optical frame PU foaming mould

Owner:江苏森宝节能材料有限公司

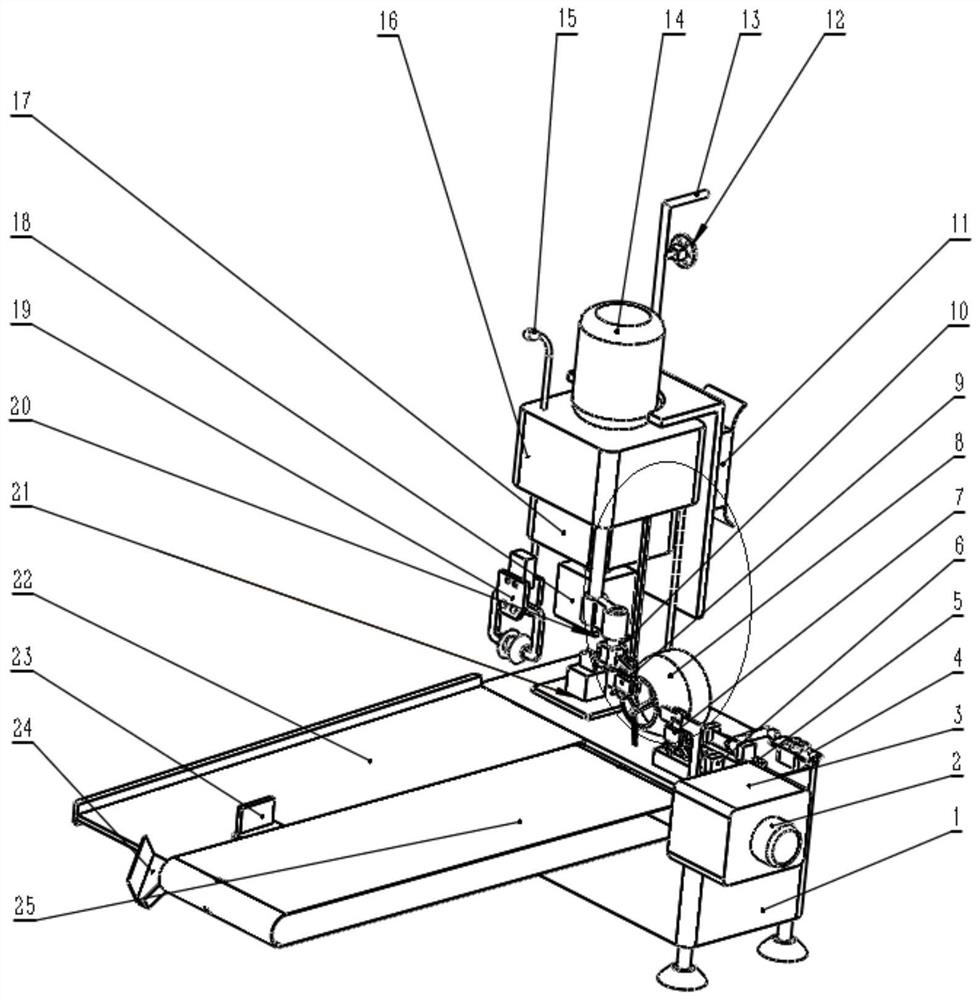

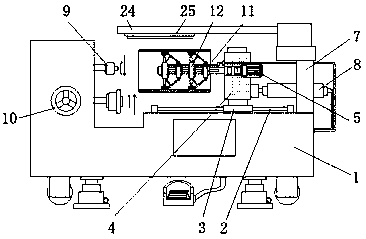

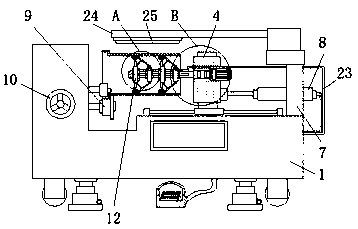

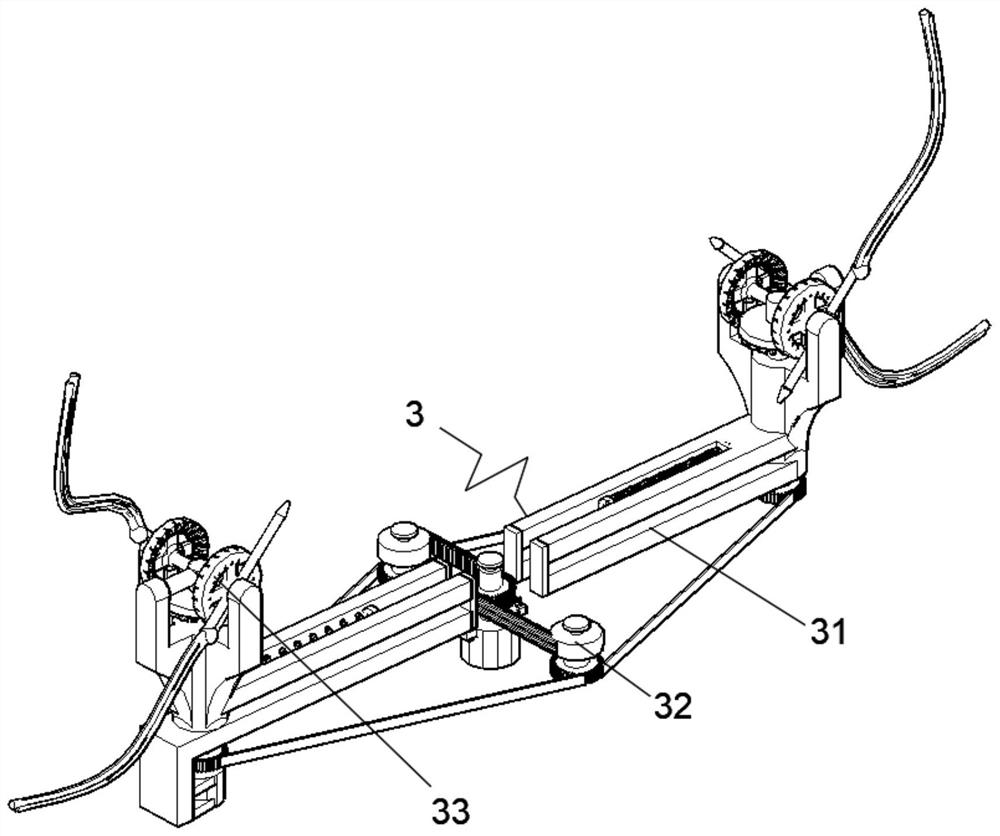

Three-in-one machine for cutting, stringing, plugging and end pressing

PendingCN114374130AImprove efficiencyReduce riskConnection formation by deformationProduction lineWire cutting

The invention discloses a wire cutting, stringing and end pressing three-in-one machine, which comprises a main box body, a machine body, an end pressing part, a stringing device, a wire stroking device and a wire cutting and stripping part, a power supply is turned on, a wire harness enters through a wire inlet device, an automatic propelling device is arranged in the wire inlet device to realize stable wire inlet operation of the wire harness, a small motor provides power, and the machine body is driven by the small motor to rotate. The two blades of the wire cutter and the wire stripper are used for cutting and stripping wire skins at two ends of a required wire harness; the wire harness needing to be serially connected with the sealing plug is clamped by the wire clamping device b to reach the plug stringing device to be serially connected with the sealing plug; the technical problems that in the prior art, wire cutting, sealing plug stringing and end pressing are all independent procedures, wire feeding is conducted back and forth in three stations according to drawing requirements, time and labor are wasted, and efficiency is reduced are solved, the complexity of a production line is reduced, wire harness rolling can be obviously reduced, efficiency is improved, and end pressing failures are effectively avoided.

Owner:QINGDAO UNIV OF SCI & TECH

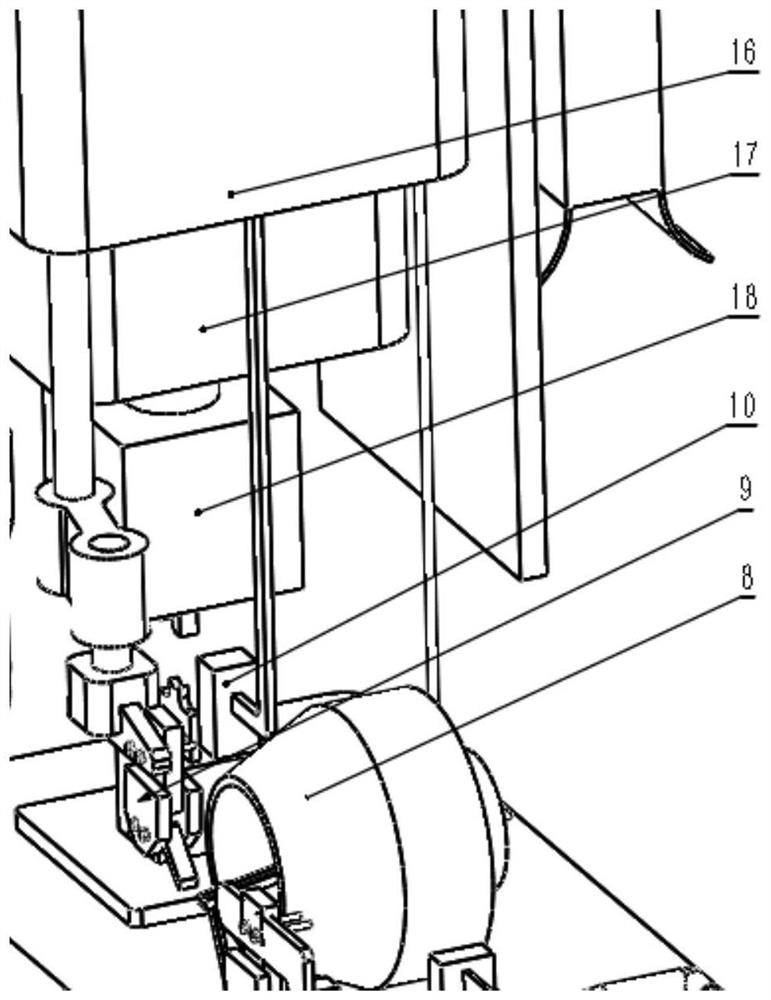

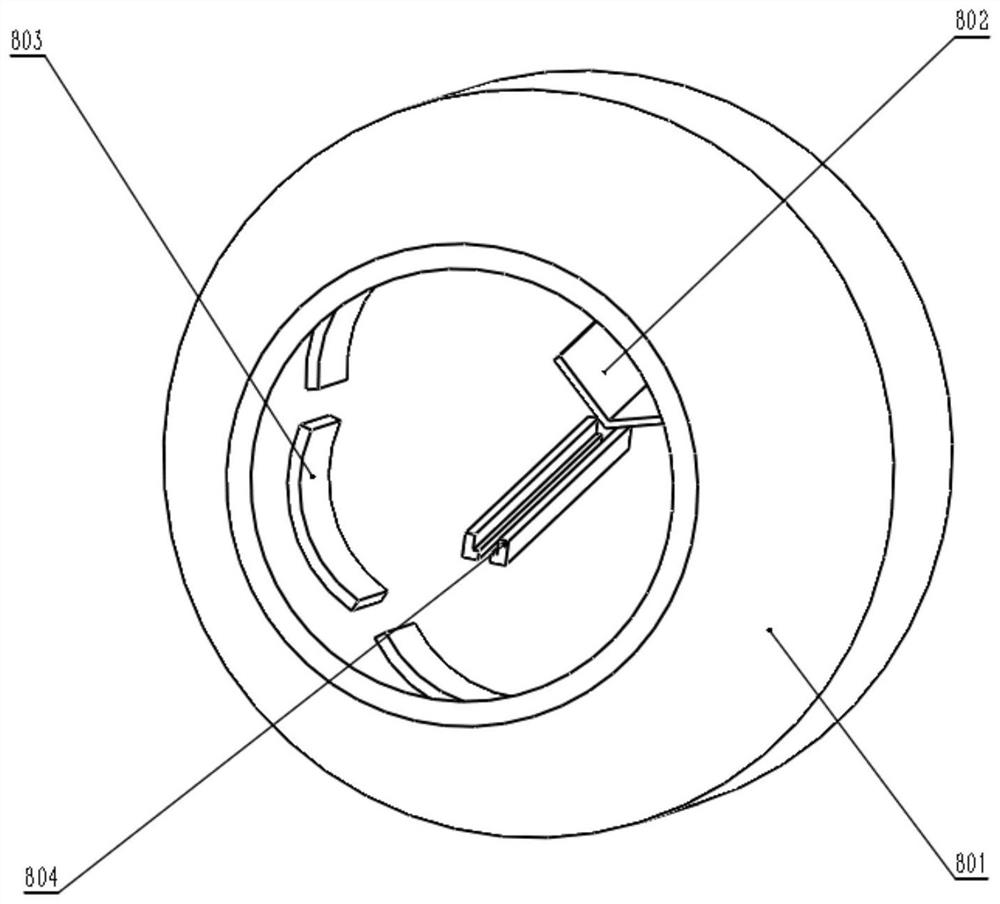

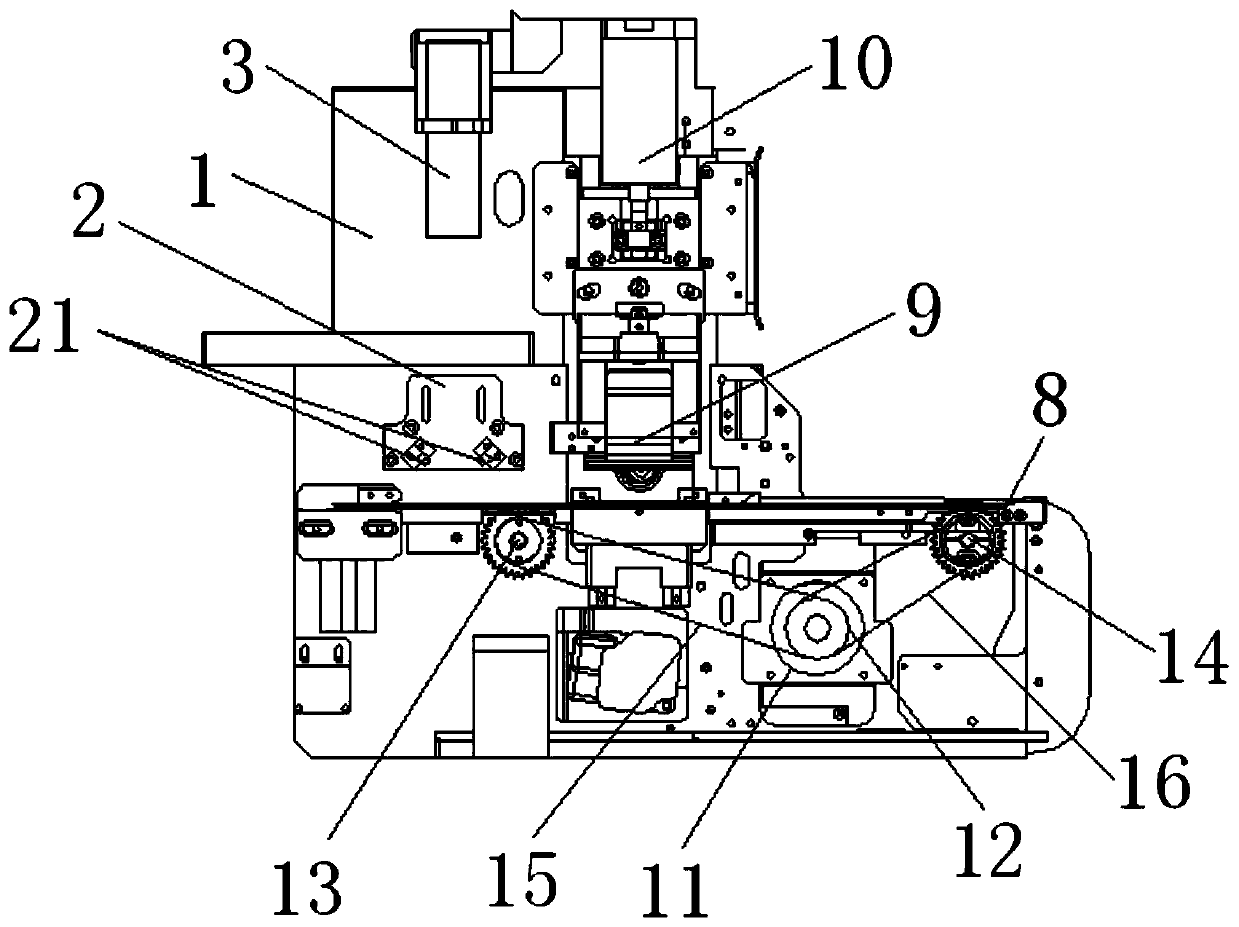

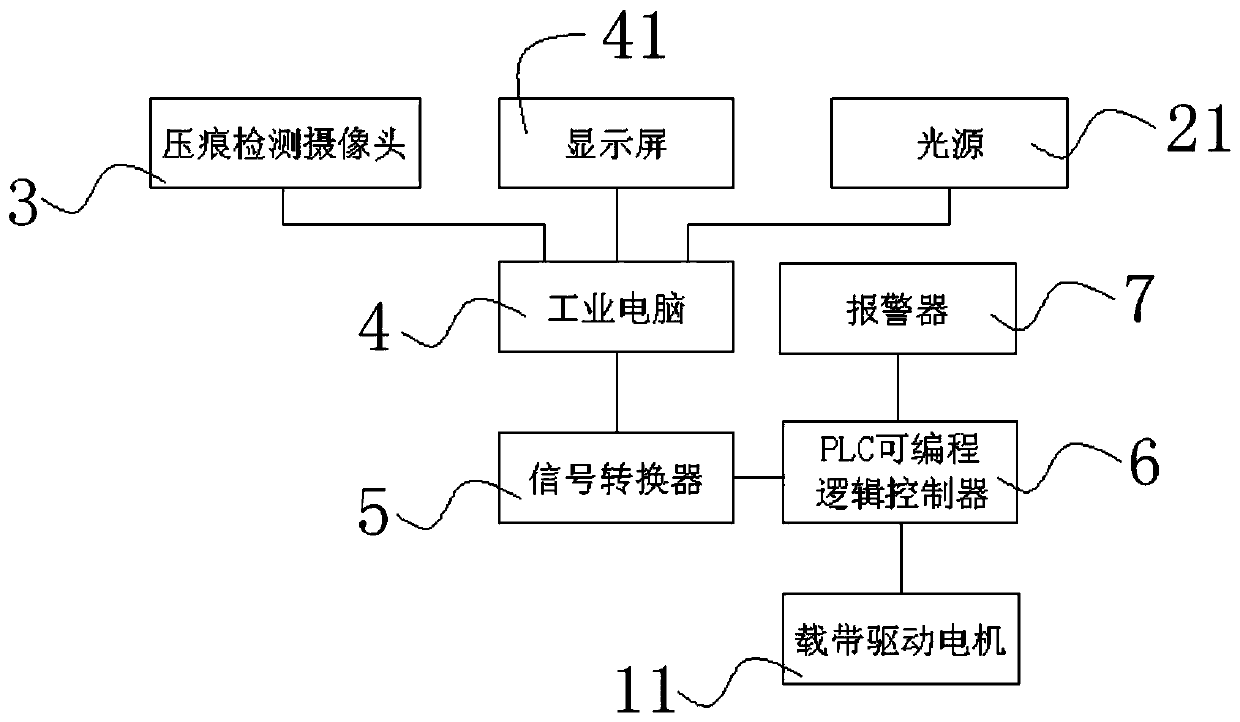

Tape indentation detecting machine

InactiveCN110261400AEasy to review and checkEasy to findOptically investigating flaws/contaminationProgrammable logic controllerEngineering

The invention discloses a tape indentation detecting machine. The detecting machine includes a carrier tape transmission mechanism, a frame, a light source support, light sources, an indentation detection camera, an industrial computer, a signal converter, a PLC (programmable logic controller), a carrier tape, a tape heat-sealing soldering iron block, a tape heat-sealing air cylinder, etc. Through the detecting machine, automatic detection on a tape and the carrier tape accomplishing hot melt indentation can be realized, the detecting machine can control the carrier tape transmission mechanism to stop running according to detection results, operators can conveniently and timely check and inspect unqualified tapes and carrier tapes, so that the operators can conveniently find problems and rapidly find the sources of the problems, and therefore, faults can be effectively eliminated, parameters operated by each part can be re-adjusted and controlled, the phenomenon of the follow-up appearance of unqualified hot melt indentation can be effectively avoided, the rate of finished products of hot melted tapes and carrier tapes can be increased, detection efficiency can be enhanced, thus, the detecting machine is high in detection precision, good in detection effect, and more convenient and faster in usage.

Owner:东莞市华越半导体技术股份有限公司

Decarburization and recarburization determination method for bolt under quenched state

InactiveCN105203371AAvoid non-conformitiesPrevent deviationPreparing sample for investigationInvestigating material hardnessEngineeringHardness

The invention relates to a decarburization and recarburization determination method for a bolt under a quenched state. The decarburization and recarburization determination method comprises the following steps: (1) cutting out a cross section sample from a part, corresponding to a thread, on the bolt under the quenched state; grinding the cut off sample; selecting three points on the sample, wherein the first point is a root of thread, the second point is a point shifting perpendicular to the axial direction of the bolt for 0.15 to 0.25mm from a top of thread to the root of thread, and the third point is a point intersected with the pitch line of the thread after transversely shifting for 0.10 to 0.20mm from the side of a thread tooth to the inner side; if the difference obtained by subtracting the hardness value of the second point from the hardness value of the first point is greater than or equal to 50HV, showing that the bolt is in decarburization; if the difference obtained by subtracting the hardness value of the first point from the hardness value of the third point is greater than or equal to 50HV, showing that the bolt is in recarburization. The decarburization and recarburization determination method disclosed by the invention is capable of performing decarburization and recarburization determination on the quenched bolt, therefore the phenomenon that batch products are unqualified is avoided; moreover, the generation time is shortened, and the production cost is reduced.

Owner:浙江迪特高强度螺栓有限公司

Horizontal type small shrimp head bending machine

PendingCN110369623AEasy to removeQuick releaseMetal-working feeding devicesMetal working apparatusShrimpEngineering

The invention discloses a horizontal type shrimp head bending machine. The horizontal type shrimp head bending machine comprises a machine body, wherein the machine body is of a L-shaped structure, and a pipe opening forming assembly is arranged on the left side of the machine body; at least two parallel rail strips are arranged on the upper surface of the machine body, sliding sleeve pipes are sleeved on the surfaces of the rail strips, and a moving base is fixedly connected to the upper surfaces of the sliding sleeve pipes, a motor is embedded on the right side of the movable base, and an output shaft of the motor is are fixedly connected with a main shaft. The horizontal type shrimp head bending machine comprises first lantern rings, second lantern rings and reducing assemblies, whereinthe first lantern rings and the second lantern rings are arranged on the main shaft and the reducing assemblies are connected with the first lantern rings, the second lantern rings and movable blocks, By adjusting the distance between the first lantern rings and the second lantern rings, the distance between the two movable blocks at the same straight line position can be adjusted, and thereforethe diameter of equipment fixing device can be flexibly adjusted according to the diameter of air pipes, so that the machining requirements of the air pipes with different diameters can be met, and the forming effect of the air pipes can be improved.

Owner:安徽省重望精密机械制造有限公司

On-line automatic correction steel billet continuous chamfering device

InactiveCN114160915AAvoid non-conformitiesImprove work performance and efficiencyGas flame welding apparatusConveyor partsMachiningSupport plane

The invention discloses an on-line automatic correction steel billet continuous chamfering device which comprises a steel plate, a conveying device and a chamfering device, the steel plate is placed on the upper surface of the center of the conveying device, and the chamfering device is fixedly installed in the center of the bottom face of the conveying device. The conveying device internally comprises an inserting groove, a supporting frame, side plates, a groove, a correction guide plate, a limiting sliding rail and a conveying belt, the inserting groove is formed in the centers of the two side faces of the supporting frame, the side plates are symmetrically and fixedly connected to the top edges of the two side faces of the conveying device, and the groove is formed in the centers of the side faces of the side plates; the correction guide plate is fixedly connected to one end face of the side plate, and the limiting sliding rail is fixedly installed in the center of the top face of the supporting frame. According to the steel billet chamfering device, adaptive chamfering machining can be carried out on steel billets with different widths by adjusting the chamfering device, the steel billets can be automatically corrected, meanwhile, chamfering machining can be continuously carried out on the steel billets, and therefore the steel billet chamfering machining efficiency is improved.

Owner:杨再宾

A method for testing the reliability of battery metal electrodes and welding strips after welding

ActiveCN109671639BImprove quality assuranceGuaranteed reliabilitySemiconductor/solid-state device testing/measurementMetallic electrodeProcess engineering

The invention provides a testing method for the reliability after welding of a battery metal electrode and a welding strip. A test for a pulling-out force between the electrode and the welding strip is increased after a heat cycle, so as to effectively ensure that a battery piece still can have good performance after the heat cycle of the battery piece; a condition that a peeling phenomenon between the welding strip and the battery piece occurs in a post-period utilization process, resulting in an EL failure is avoided. By adopting the method provided by the invention, whether a welding forcebetween the battery electrode and the welding strip is qualified or not can be found; defective products are prevented from flowing into the downstream at a battery end in advance; the problem that low-quality products are used so that the service life of the products is reduced is avoided and the risks and cost are reduced from the source.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

High-purity ozagrel compound

InactiveCN101704786BHigh purityAvoid non-conformitiesOrganic chemistryForeign matterActivated carbon

The invention relates to a high-purity ozagrel compound, and a preparation method of the ozagrel compound guarantees the quality of raw materials, and avoids the phenomenon that visible foreign matters are unqualified in the production process. The preparation method includes the following steps: (1) adding crude ozagrel in water to form aqueous dispersion; (2) then dropwise adding sodium hydroxide solution in the aqueous dispersion until the aqueous dispersion is clear to obtain clear solution; and (3) adding activated carbon in the clear solution for adsorption, conducting filtering and decarburization, adding acid in obtained filtrate to adjust pH value, precipitating solids, filtering, washing, and drying to obtain the high-purity ozagrel.

Owner:HAINAN LINGKANG PHARMA CO LTD

A cleaning device capable of recycling waste materials during electrothermal film processing

The invention relates to an electrothermal film processing cleaning device capable of cyclically recycling waste materials. The electrothermal film processing cleaning device comprises an inlet, a melting box, a fixing plate, a fixing base and a collection box. A connecting pipe is arranged inside the inlet in a penetrating manner. The inlet is fixedly connected with a connecting pipe. A threadedpillar is arranged inside the connecting pipe in a penetrating manner. An attachment plate is welded to one end of the threaded pillar. A vertical dropping pipe is arranged at the bottom of the inletin a penetrating manner. An extrusion pipe is arranged below the vertical dropping pipe. The melting box is mounted below the extrusion pipe. The electrothermal film processing cleaning device has thebeneficial effects that the electrothermal film processing cleaning device capable of cyclically recycling the waste materials is provided with extruding wheels; a servo motor is started, and the extruding wheels mounted at the periphery of movable shafts are driven by the servo motor to rotate through rotating shafts, so that the materials dropping out of an extrusion opening are extruded into certain piece shapes through the two extruding wheels to smoothly fall into an assembling device for storage; and the complex process that workers need to pack and store the materials is avoided.

Owner:旌德县展嘉智能科技有限公司

Industrial lubricating oil preparation equipment and preparation method

PendingCN114273081AAvoid non-conformitiesEasy to operateMagnetic separationFiltration circuitsOil canProcess engineering

The invention relates to industrial lubricating oil preparation equipment and a preparation method, the industrial lubricating oil preparation equipment comprises a workbench, a fixing device and a filtering device, the top of the workbench is provided with the fixing device, and the fixing device is provided with the filtering device; the filtering device comprises a funnel, a hollow pipe, a first clamping frame, a moving frame, a mounting frame, a rectangular box, an annular pipe and a second clamping frame, different types of impurities contained in industrial lubricating oil can be filtered, so that the filtering effect is enhanced, the phenomenon that the industrial lubricating oil is unqualified due to traditional filtering is avoided, and the quality of the industrial lubricating oil is improved. After the industrial lubricating oil is filtered, the filtered industrial lubricating oil can be circularly filtered again, so that the problem of tedious operation of workers due to traditional multiple times of filtration is avoided.

Owner:黄永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com