Horizontal type small shrimp head bending machine

A shrimp elbow, horizontal technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of affecting the sealing of the joint, the trouble of occlusal work, and reducing the ventilation efficiency of the air duct, so as to increase the forming effect, The effect of quickly fixing and removing workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

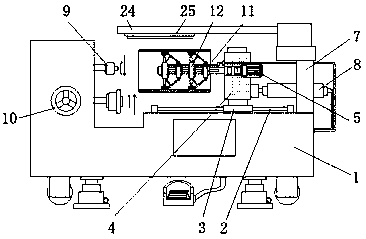

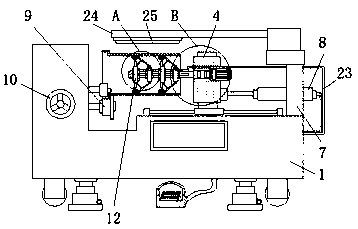

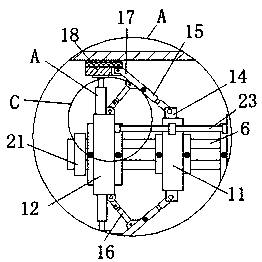

[0027] refer to Figure 1-6 , a horizontal shrimp elbow machine, including a body 1, the body 1 is an "L"-shaped structure, the left side of the body 1 is provided with a nozzle forming assembly; the upper surface of the body 1 is provided with at least two parallel track bars 2, The surface of the track bar 2 is sleeved with a sliding sleeve 3, the upper surface of the sliding sleeve 3 is fixedly connected with a moving seat 4, the right side of the moving seat 4 is embedded with a motor 5, and the output shaft of the motor 5 is fixedly connected with a main shaft 6, The surface of the main shaft 6 is provided with at least two variable-diameter fixing assemblies. The right side of the body 1 is provided with a fixed block 7. The interior of the fixed block 7 is fixedly connected with an electric push rod 8. The nozzle forming assembly includes a Flaring die 9, there are at least two flaring dies 9; the left end front of body 1 is provided with control panel 10, control panel...

Embodiment 2

[0032] refer to Figure 1-2 , different from Embodiment 1, the top of the fixed block 7 is also provided with a flaw detection device. On the lower surface of the horizontal rod 24 and parallel to the main shaft 6 , the flaw detection infrared detection probe 25 can move axially and linearly on the horizontal rod 24 with the horizontal rod 24 as the reference.

[0033] In this embodiment, while performing the flaring of the air duct and processing the rotation of the air duct, the equipment combines the flaw detection infrared detection probe 25 to detect the surface of the air duct to prevent the occurrence of unqualified workpieces caused by large-area missing welding gaps , so that the horizontal shrimp elbow machine has the function of flaw detection.

[0034]When a horizontal shrimp elbow machine proposed by the present invention is used, we first adjust the distance between the first collar 11 and the second collar 12 according to the radius data of the processing air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com