A method for testing the reliability of battery metal electrodes and welding strips after welding

A test method and battery electrode technology, which is applied in the field of solar cell technology, can solve problems such as defects, affecting the performance of solar modules, stripping of solder strips and battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 A test method for the reliability of battery metal electrodes and welding strips after welding

[0029] (1) The bare electrode of the battery is welded with ribbon;

[0030] (2) The cell is tested in a thermal cycle box, and the thermal cycle condition is

[0031] time temperature(℃) 0-15min -40℃ 15min-1h -40℃~20℃ 1h-2h 20℃~80℃ 2h-2h15min 80℃ 2h15min-3h 80℃~20℃ 3h-4h 20℃~-40℃

[0032] A total of 5 cycles;

[0033] (3) After the thermal cycle is completed, the tensile force between the battery electrode and the welding strip is tested again, which is 93% of the tensile force of the battery sheet that has not been subjected to the thermal cycle test.

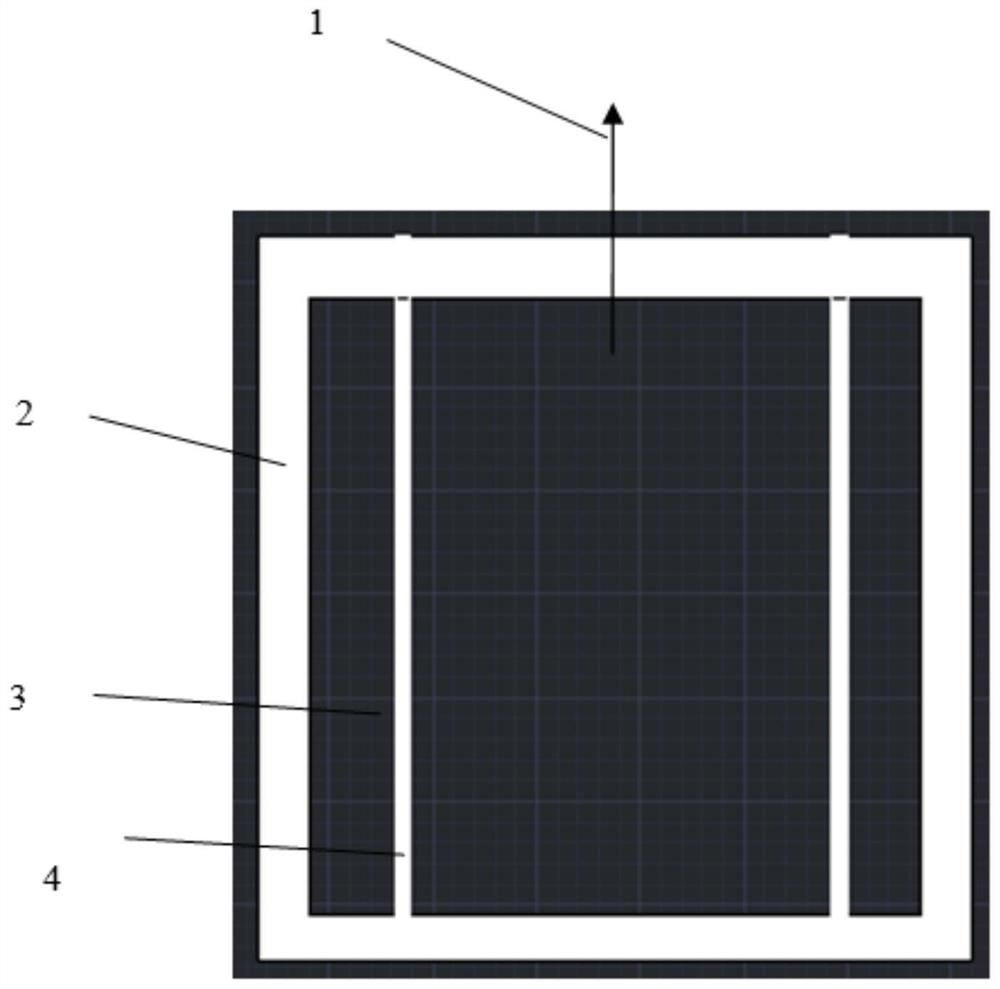

[0034] Among them, in step (1), the electrode of the battery bare chip adopts a hollowed-out through-type busbar, and the hollowed out pattern is linear, see the attached figure 1 .

[0035] When testing the tensile force, fix the battery sheet in the slot 2 ...

Embodiment 2

[0036] Example 2 A test method for the reliability of battery metal electrodes and welding strips after welding

[0037] (1) The bare electrode of the battery is welded with ribbon;

[0038] (2) The cell is tested in a thermal cycle box, and the thermal cycle condition is

[0039] time temperature(℃) 0-0.5h -38℃ 0.5h-1.5h -38℃~22℃ 1.5h-2.5h 22℃~82℃ 2.5h-3min 82℃ 3h-4h 82℃~22℃ 4h-5h 22℃~-38℃

[0040] A total of 10 cycles;

[0041] (3) After the thermal cycle is completed, the tensile force between the battery electrode and the welding strip is tested again, which is 97.9% of the tensile force of the battery sheet without thermal cycle test.

[0042] Wherein, in the step (1), the electrode of the battery bare chip adopts a hollowed-out through-type busbar, and the hollowed out pattern is a rhombus.

[0043] When testing the tensile force, fix the battery sheet in the slot 2 of the tensile tester and press it with the pressure...

Embodiment 3

[0044] Example 3 A test method for the reliability of battery metal electrodes and welding strips after welding

[0045] (1) The bare electrode of the battery is welded with ribbon;

[0046] (2) The cell is tested in a thermal cycle box, and the thermal cycle condition is

[0047] time temperature(℃) 0-10min -42℃ 10min-30min -42℃~-10℃ 30min-1h -10℃~20℃ 1h-2h 20℃~80℃ 2h-2h10min 80℃ 2h10min-2.5h 80℃~50℃ 2.5h-3h 50-10℃ 3h-4h 10℃~-42℃

[0048] A total of 7 cycles;

[0049] (3) After the thermal cycle is completed, the tensile force between the battery electrode and the welding strip is tested again, which is 89.0% of the tensile force of the battery sheet without thermal cycle test.

[0050] Wherein, in step (1), the electrode of the battery bare chip adopts a hollowed-out through-type busbar, and the hollowed out pattern is circular.

[0051] When testing the tensile force, fix the battery sheet in the slot 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com