Preparation method of high-weather-resistance and high-dispersion plastic color master batch titanium dioxide pigment

A titanium dioxide, high-dispersion technology, used in chemical instruments and methods, dyeing polymer organic compounds treatment, inorganic pigment treatment, etc., can solve the adverse effects of personnel safety and environmental safety, yellowing resistance and degradation resistance, dust flying and other problems, to solve the effects of yellowing resistance and degradation resistance, improve anti-discoloration performance, and solve the effect of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

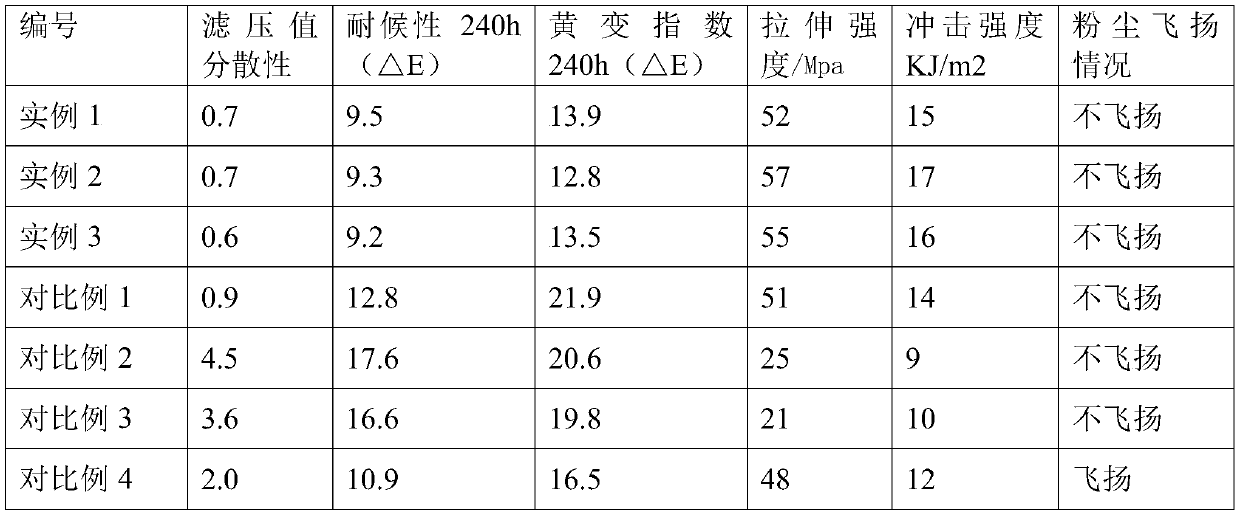

Examples

Embodiment 1

[0031] 1.1. Using the chloride method rutile titanium dioxide preliminary product, add a certain amount of deionized water to prepare a titanium dioxide slurry with a concentration of 300g / L, the rutile content of the titanium dioxide preliminary product is 99.5%, the D50 particle size is 0.20μm; Adjust the pH of the titanium dioxide slurry to 4.5 for 30% sodium hydroxide solution, add 0.1% sodium silicate solution (the amount of sodium silicate solution added is SiO 2 TiO 2 Weight), sodium silicate solution is SiO 2 150g / L, aging for 10min;

[0032] 1.2. Grind the dispersed titanium dioxide slurry, the D50 particle size is 280nm, and the particle size exceeding 500nm is less than 5.0%, and the grinding medium is removed from the water slurry;

[0033] 1.3. Heat the polished slurry to 40°C and maintain this temperature throughout the coating process;

[0034] 1.4. Add 0.5% NaAlO within 30min 2 Solution (addition is calculated based on the weight of aluminum oxide in the weight of tit...

Embodiment 2

[0040] 1.1. Using the chloride method rutile titanium dioxide preliminary product, adding a certain amount of deionized water to prepare a titanium dioxide slurry with a concentration of 500g / L, the rutile content of the titanium dioxide preliminary product is 99.7%, and the D50 particle size is 0.28μm; Adjust the pH of the titanium dioxide slurry to 5.5 for 10% sodium hydroxide solution, and add 0.5% sodium silicate solution (the amount of sodium silicate solution added is SiO 2 TiO 2 Weight), sodium silicate solution is SiO 2 Calculated as 150g / L, aging for 30min;

[0041] 1.2. Grind the dispersed titanium dioxide slurry, the D50 particle size is 287nm, and the particle size exceeding 500nm is less than 5.3%, and the grinding medium is removed from the water slurry;

[0042] 1.3. Heat the grinded slurry to 80°C, and maintain this temperature throughout the coating process;

[0043] 1.4. Add 3.0% NaAlO within 30min 2 Solution (addition is calculated based on the weight of aluminum o...

Embodiment 3

[0049] 1.1. Using the chloride method rutile titanium dioxide preliminary product, adding a certain amount of deionized water to prepare a titanium dioxide slurry with a concentration of 400g / L, the rutile content of the titanium dioxide preliminary product is 99.9%, and the D50 particle size is 0.25μm; Adjust the pH of the titanium dioxide slurry to 5.0 for 20% sodium hydroxide solution, add 0.3% sodium silicate solution (the amount of sodium silicate solution added is SiO 2 TiO 2 Weight), sodium silicate solution is SiO 2 Calculated as 150g / L, aging for 20min;

[0050] 1.2. Grind the dispersed titanium dioxide slurry, the D50 particle size is 285nm, and the particle size exceeding 500nm is less than 5.5%, and the grinding medium is removed from the water slurry;

[0051] 1.3. Heat the grinded slurry to 60°C and maintain this temperature throughout the coating process;

[0052] 1.4. Add 2.0% NaAlO within 120min 2 Solution (addition is calculated based on the weight of aluminum oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com