Patents

Literature

141results about How to "Improves tarnish resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold-bearing imitation-gold copper alloy and preparation method thereof

The invention relates to gold-bearing imitation-gold copper alloy and a preparation method thereof, belongs to the technical field of alloy materials and solves the technical problem that copper alloy in the prior art is poor in discoloration resistance and poor in gold imitation effect. The gold-bearing imitation-gold copper alloy comprises, by weight percent, 0.5%-10% of Au, 0.5%-40% of Zn, not more than 1% of Si, not more than 1% of RE, 0.4%-5.0% of coloring, and the balance of Cu. The invention further provides the preparation method of the alloy. The preparation method includes: smelting the materials at 1200 DEG C to 1300 DEG C, annealing at 500 DEG C to 600 DEG C, and forging and hot-rolling to obtain the gold-bearing imitation-gold copper alloy. The gold-bearing imitation-gold copper alloy has the advantages that discoloration resistance is high, gold imitation is effective, the alloy has the same appearance color as 14K-18K gold, process is simple, processibility is high, and the gold-bearing imitation-gold copper alloy is easy to process.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

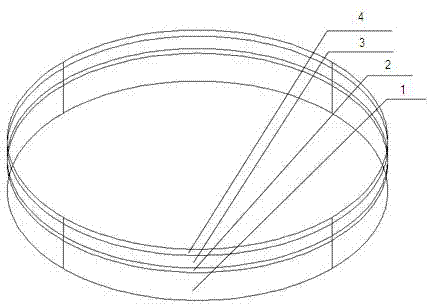

Multi-layer-color denture and base integrated carving block as well as manufacturing and use methods thereof

The invention relates to a multi-layer-color denture and base integrated carving block as well as manufacturing and use methods thereof. The carving block comprises two resin layers with a lower base layer and an upper denture layer. The manufacturing method comprises the following steps: performing color matching on the base layer and the denture layer, performing injection molding, and trimming and forming. According to the method, a user can be freed from a heavy and harmful conventional denture base manufacturing process, and a layer-rich denture and base integrated product conforming to a natural tooth form can be manufactured at the same time in a one-time manufacturing process through a CAD / CAM (computer-aided design / computer-aided manufacturing) technology in the existing dental industry.

Owner:SHANGHAI MEDICAL INSTR

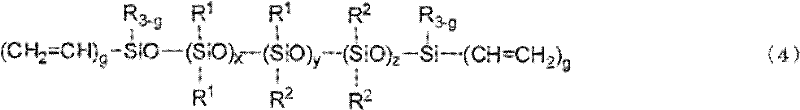

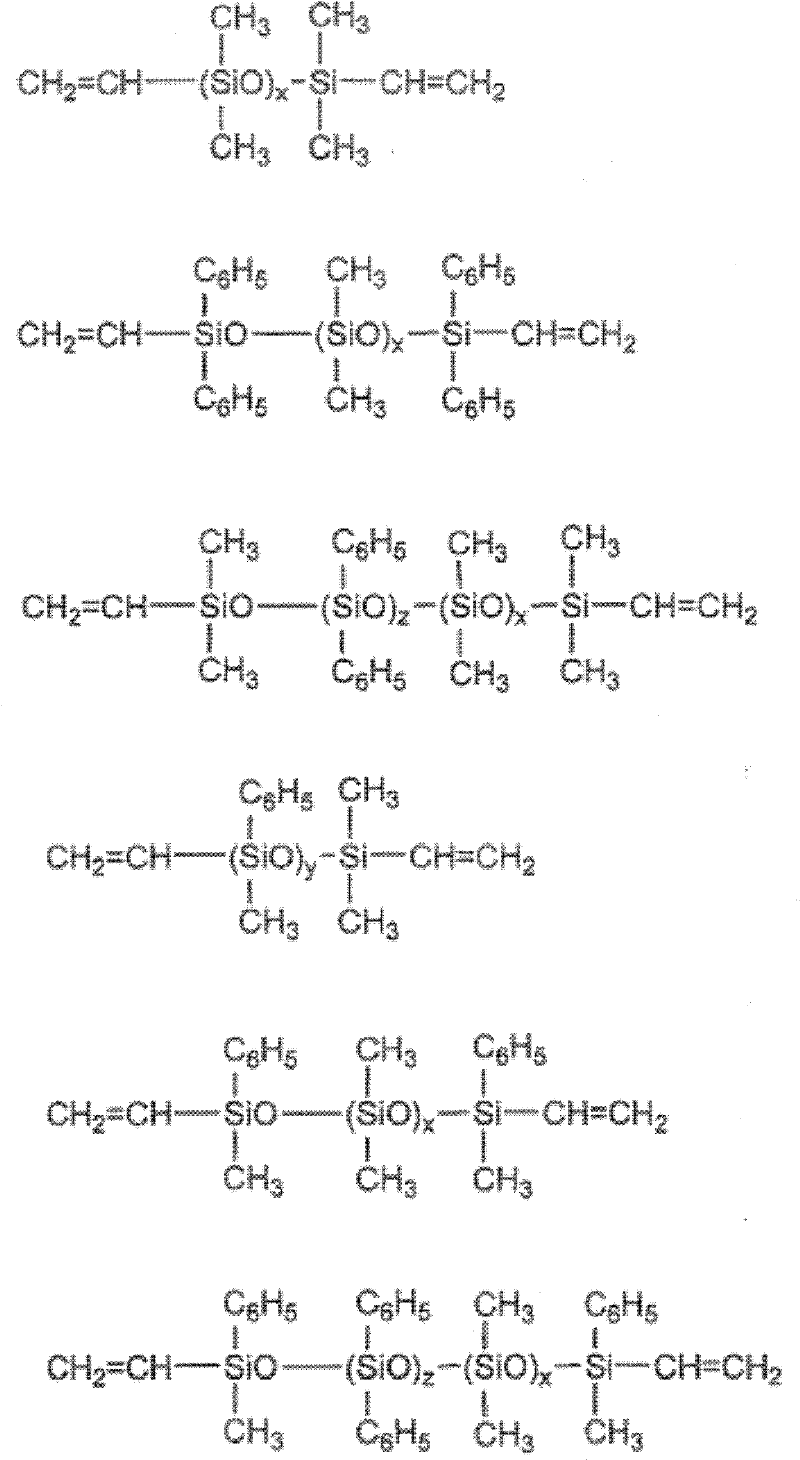

High adhesiveness silicone resin composition and an optical semiconductor device provided with a cured product thereof

The object of the present invention is to provide a silicone resin composition for encapsulating an optical semiconductor element which has strong adhesiveness to a substrate and provide an optical semiconductor element which has high reliability. The present invention provides a silicone resin composition comprising an organopolysiloxane (A) having at least two alkenyl groups per molecule, a liner organohydrogenpolysiloxane (B-1) which has hydrogen atoms each bonded to a silicon atom at the both terminals and a liner organohydrogenpolysiloxane (B-2) which has a hydrogen atom bonded to a silicon atom at one terminal and a hydroxyl or alkoxy group bonded to a silicon atom at the other terminal, a branched organohydrogenpolysiloxane (C) having at least three hydrosilyl groups per molecule, a catalytic (D), and a condensation catalyst (E).

Owner:SHIN ETSU CHEM IND CO LTD

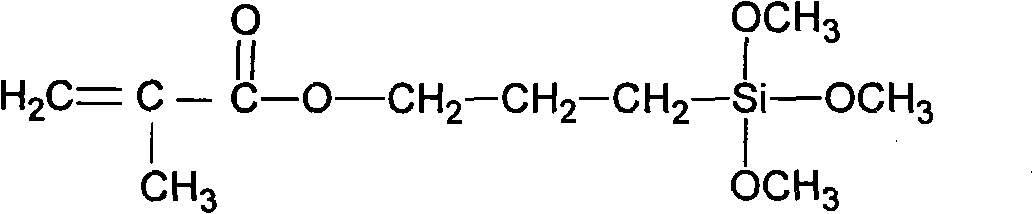

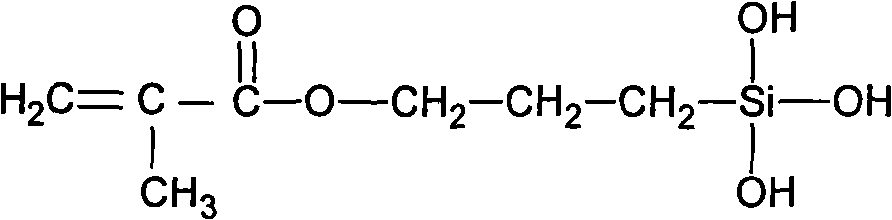

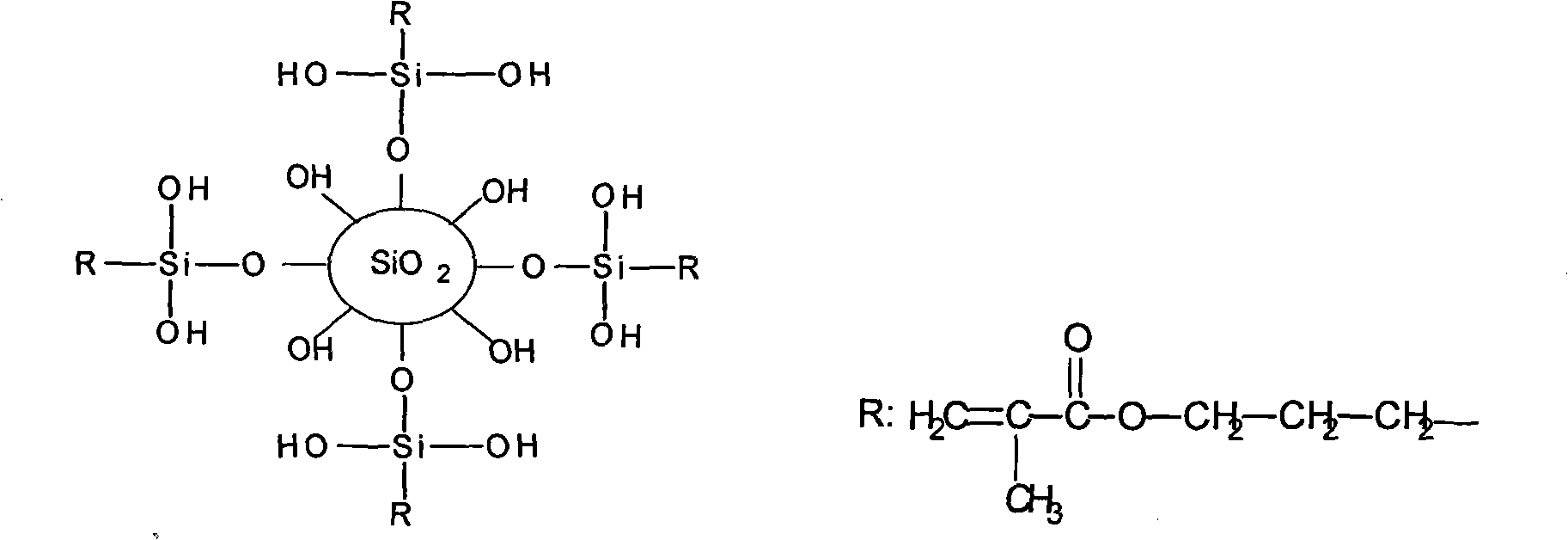

Nano-SiO2 modified aluminium section bar superior atmospheric corrosion resisting polyester powder paint and preparation method thereof

ActiveCN101314696AImprove dispersion stabilityImprove mechanical propertiesPowdery paintsPolyester coatingsWeather resistanceChemistry

The invention discloses nano-SiO2-modified aluminum profile polyester powder coating with high weathering resistance and the preparation method thereof. The nano-SiO2-modified aluminum profile polyester powder coating is characterized in that nano-SiO2 is reacted with hydrolyzed silicane coupling agent; an acrylic acid monomer is subjected to in-situ polymerization with the coupling agent grafted with the nano-SiO2 surface, thus achieving in-situ polymer grafted modification on the nano-SiO2 surface and greatly improving the dispersion stability and the resin compatibility of the nano-SiO2; and the modified nano-SiO2 powder is added into polyester powder coating. The polyester powder coating can be used for electrostatic spraying aluminum profile surface to solve the aging problem of the organic coating of aluminum profile exposed to outdoor UV rays, thus greatly improving the anti-aging performance, tarnish resistance, etc. The weathering resistance of the polyester powder coating is improved by 100 to 250 percent as compared with unmodified polyester powder coating, thus improving the use performance and the use service life of aluminum profile coating.

Owner:GUANGDONG XINGFA ALUMINUM JIANGXI

Argentiferous gold-simulating copper alloy and preparation method thereof

The invention relates to argentiferous gold-simulating copper alloy and a preparation method thereof and belongs to the technical field of alloy materials. The argentiferous gold-simulating copper alloy aims to solve the technical problems of poor color change resistance and gold-simulating effect of copper alloy in the prior art, and mainly comprises, by weight, 1%-20% of Ag, 0.5%-40% of Zn, not more than 1% of Si, not more than 1% of RE, 0.4-5.0% of color matching agents and the balance Cu. The preparation method includes: melting the raw materials at the temperature of 1200-1300 DEG C, performing annealing treatment at the temperature of 500-600 DEG C, forging and performing hot rolling so that the argentiferous gold-simulating copper alloy is obtained. The argentiferous gold-simulating copper alloy is high in color change resistance and good in gold-simulating effect and has the advantages of capability of achieving apparent color and luster of 14K-18K gold, simple technical process, good processability and easiness in processing.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

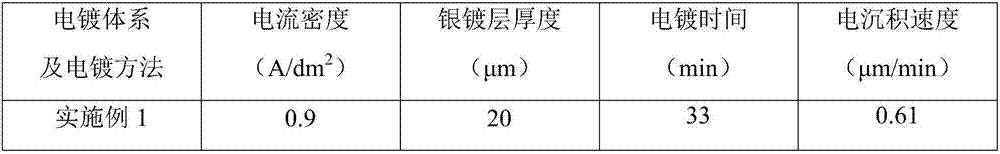

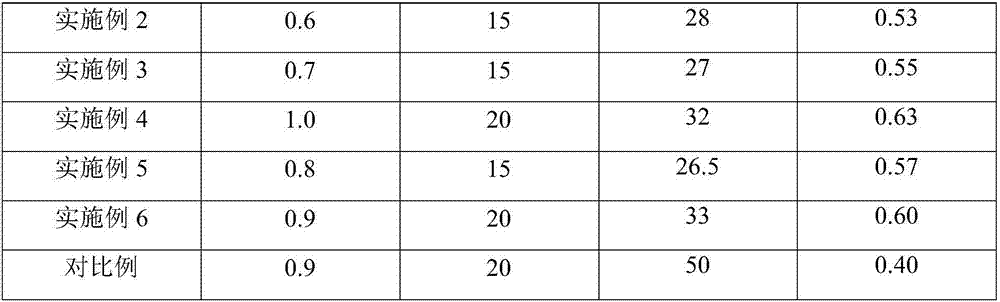

Plating solution and plating method of cyanide-free plating silver

The invention discloses a plating solution and a plating method of cyanide-free plating silver. 20-60g silver nitrate, 70-90g ammonium acetate, 70-110g nicotinic acid, 60-90g potassium carbonate, 40-70g potassium hydroxide, 0.2-1.2g o-benzoyl sulfimide sodium and 0.16-0.64g polyethylene glycol are contained in 1L of the plating solution with a pH value of 9-10. According to the plating solution and the plating method of the cyanide-free plating silver, the plating solution does not contain cyanide ions; the pollution of wastewater treatment is reduced; the injury to a human body due to precious metal plating is reduced; a formula of the plating solution is simple, and easy to control; compared with other cyanide-free plating, the current density is higher; and the deposition efficiency of a silver coating can be improved. With the adoption of pulse plating, a coating that is small in coating stress and good in compactness and brightness, and combines with a matrix well can be obtained.

Owner:XI AN JIAOTONG UNIV +1

Silver-colored alloy with low percentages of copper and zinc

Owner:STERILITE

Nontarnishing multi-element nickel, tin and brass alloy and preparation method thereof

InactiveCN106566944AGood corrosion resistanceGood hot and cold processing propertiesWater pipeCorrosion

The invention provides a nontarnishing multi-element nickel, tin and brass alloy and a preparation method thereof. The alloy comprises the following components in percentage by mass: 70.0-75.0% of Cu, 0.1-0.6% of Al, 0.5-1.3% of Ni, 0.7-1.5% of Sn, 0.02-0.2% of Si, and 0.05-0.20% of Mn. The alloy also comprises 0.003-0.01% of Cr, 0.003-0.01% of B, 0.005-0.015% of RE, and the balance Zn, wherein Cr, B and Re account for 0.015-0.03% of the total content. The preparation method comprises the steps of smelting, casting, hot rolling, primary rolling, first intermediate annealing, acid pickling, finish rolling low-temperature annealing, and other processing to obtain the material. The nontarnishing multi-element nickel, tin and brass alloy is high in strength, abrasion and corrosion resistance, and can be widely applied to copper-based decorating materials, water pipes and other copper-based spare parts.

Owner:NINGBO XINGYE SHENGTAI GROUP

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

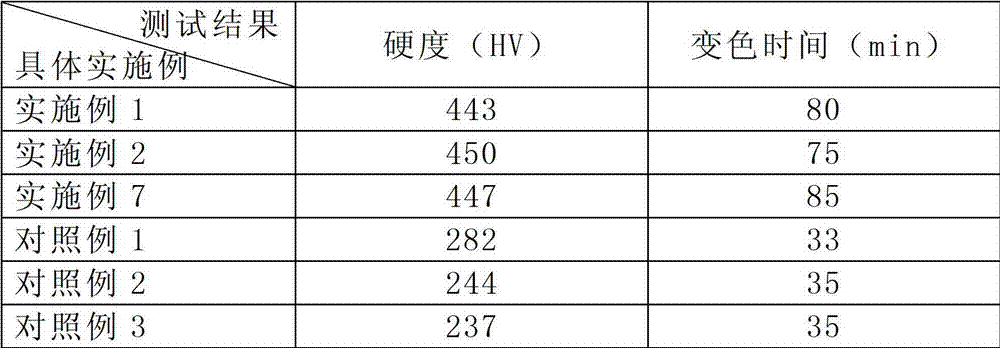

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

Silver-zinc zirconium phosphate composite germicide for paper money and preparation method thereof

ActiveCN102220730AHigh resistance to discolorationSimple processPaper/cardboardInorganic compound additionAqueous solutionBy-product

The invention discloses a silver-zinc zirconium phosphate composite germicide for paper money and a preparation method thereof; the germicide takes laminar zirconium phosphate as a carrier, and is loaded with mono-valence silver ions and zinc ions; the grain size of the germicide is uniform and is smaller than 9 microns; the whiteness and the discoloration durability are high and the antiseptic performance is good; and the germicide is suitable for the field of paper money printing. The manufacturing steps of the germicide are as follows: adding zirconium phosphate powder and soluble zinc salt into a prepared silver ion solution, filtering, washing, drying, burning and crushing the solution after reaction. The method has a simple process and is easy to perform industrial production is free from by-products and has no pollution to the environment.

Owner:CHENGDU BANKNOTE PRINTING

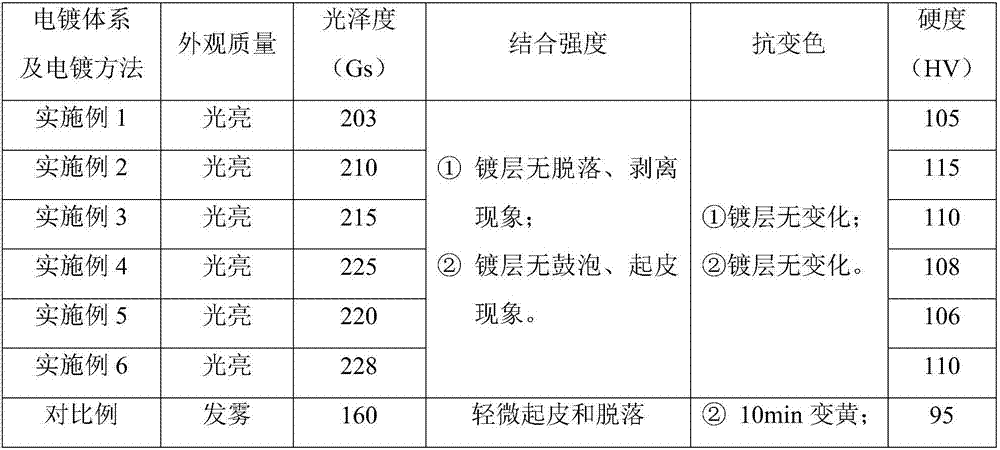

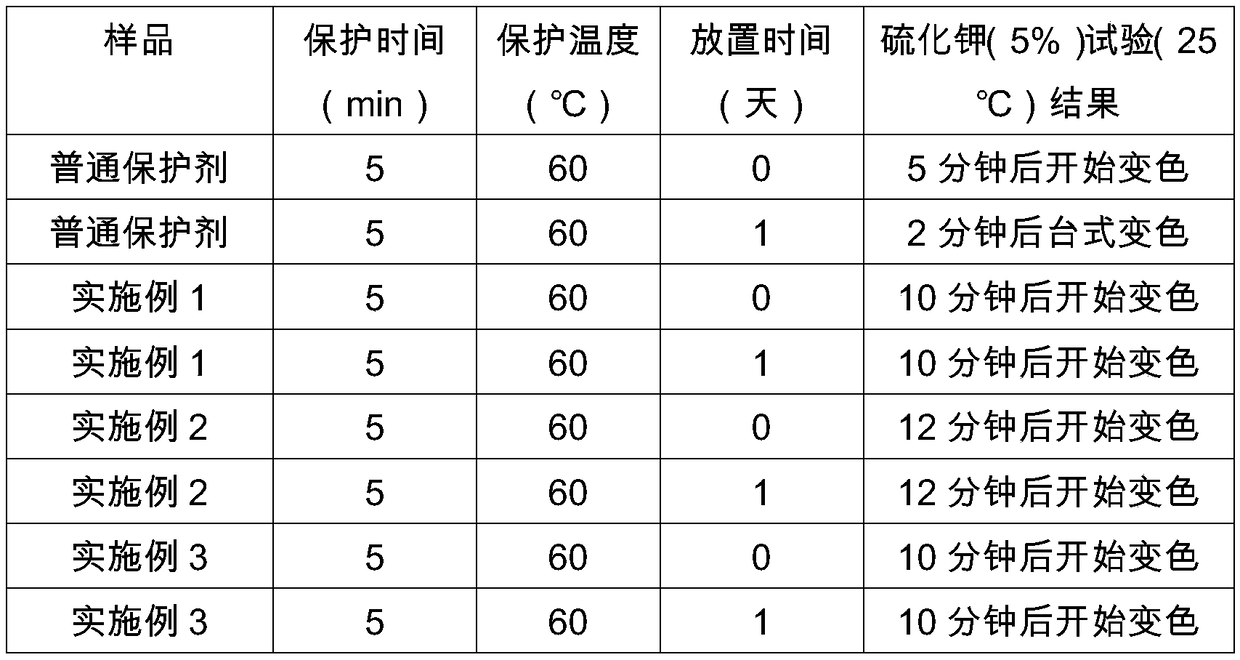

High-stability water-base silver-plating protective agent and preparation method thereof

The invention provides a high-stability water-based silver-plating protective agent. Every liter of the high-stability water-based silver-plating protective agent comprises 40-100 g of octadecanethiol, 4-10 g of trimethyl mercapto phosphate, 100 mg of reduced graphene oxide, 40-100 g of an emulsifier, 10 g of a stabilizer and the balance deionized water. The high-stability water-based silver-plating protective agent adopts the stabilizer and graphene, so that the service life of the protective agent is prolonged, and the corrosion resistance and color change resistance of protected metal are improved; and the surface appearance and performance of the silver-plating layer protected by the protective agent are not affected, a potassium sulfide resistance test of electronic products can be maintained for more than 12 minutes, and the protection time is greatly prolonged.

Owner:SUZHOU HIYIE CHEM CO LTD

Silver-colored alloy with low percentages of copper and zinc

A silver-colored, tarnish-resistant, corrosion-resistant alloy is provided. The alloy includes 92.5-95% silver, combined with a master alloy of 24-34% zinc; 60-74% copper; 0.5-1.8% silicon; 0.0-8.0% tin, or 0.0-1.5% indium, wherein percentages are in terms of weight. The alloy can be used for jewelry items, tableware items, dental items or other items that should resist tarnishing or corrosion and which require a non-brittle alloy.

Owner:STERILITE

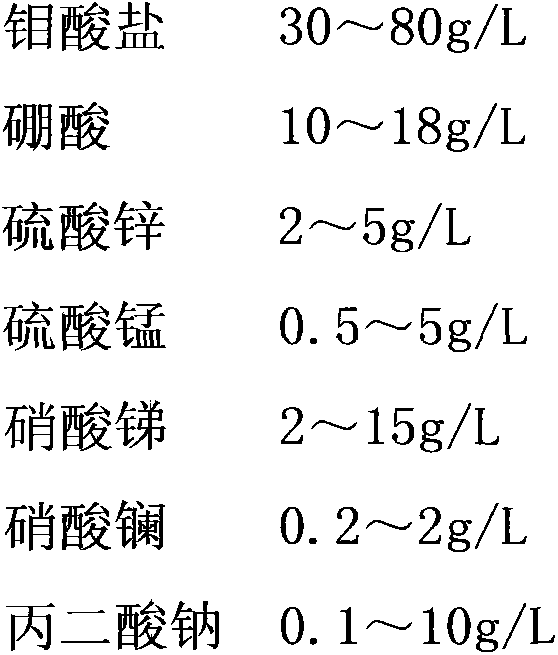

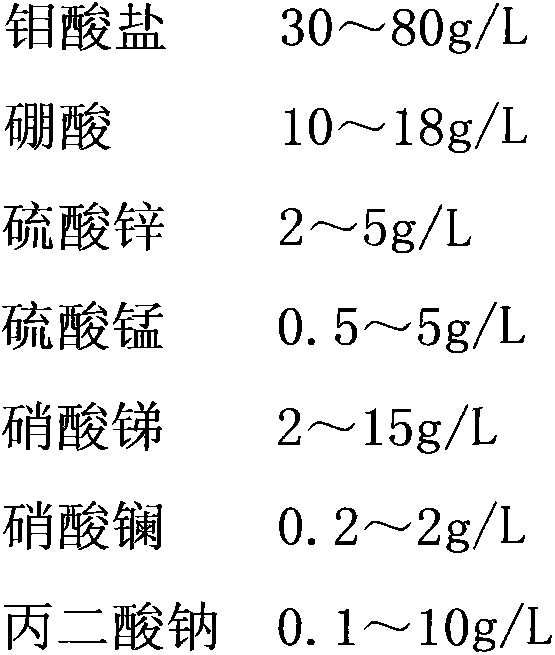

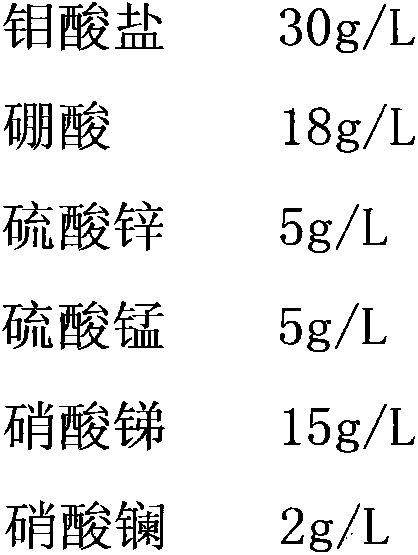

Colouring solution used for stainless steel electrochemical colouring and stainless steel electrochemical colouring method

ActiveCN103114320AChange the polarization processImprove performanceAnodisationToxic materialMalonate

The invention relates to a stainless steel surface treatment reagent, in particular to a stainless steel surface colouring method. According to the invention, with water as a solvent, each litre of solution contains 30-80g of molybdate, 10-18g of boric acid, 2-5g of zinc sulphate, 0.5-5g of manganese sulphate, 2-15g of antimony nitrite, 0.2-2g of lanthanum nitrite and 0.1-10g of sodium malonate. The stainless steel surface colouring method comprises the following basic flow: oil removing, electrolytic polishing, cleaning, colouring, cleaning and drying and obtaining the finished product, wherein an anode is a workpiece to be coloured, a cathode is a lead plate, a colouring current is controlled to be 0.1-5A / dm<2>, voltage is 1.5-2.5V, a colouring temperature is room temperature, colouring time is 0.1-30 minutes, cleaning and drying are carried out after colouring, and the surface of the obtained sample is uniform and bright. The stainless steel electrochemical colouring process provided by the invention needs simple equipment, is easy to operate, contains no toxic substance and is beneficial to environmental protection; and colouring is stable, and a high-quality colour stainless steel product can be produced by adopting the stainless steel electrochemical colouring process.

Owner:湖南中皖骏环保科技有限公司

Wood densification method by impregnating resin

InactiveCN1490136AImprove anti-corrosionImproves tarnish resistanceWood impregnation detailsPhosphoric acidUltimate tensile strength

A method for compacting wood by impregnating resin includes such steps as preparing resin from urea, guanidino contained compound, formaldehyde, phosphoric acid, ammonia water and organic polydrdroxy compound, impregnating wood in it, drying, and hot pressing at 140-160 deg.C under 10-30 MPa for 3-60 min while solidifying. The resultant wood features high strength and high flame-retarding performance.

Owner:陈万利 +3

Highly-color-change-resistant golden brass alloy and preparation method

The invention discloses a highly-color-change-resistant golden brass alloy and preparation method. The highly-color-change-resistant golden brass alloy comprises the following components of Mn, Sn, Ni, Zn, Sr, Ce, B, Si and the balance Cu and inevitable impurities. The preparation process comprises the following steps of casting, hot rolling, cold rolling, intermediate annealing, cold finish roughrolling, cold finish rolling and finished product annealing. The alloy produced by the method is high in golden degree, good in color-change resistance, excellent in hot and cold machining performance, small in deformation resistance, free of precious metal elements and relatively low in cost; the alloy produced by the method is reasonable in component, the golden degree of the alloy is improvedthrough reasonable matching of cheap manganese, nickel, zinc and tin, the zinc content is lower than 20% so that dezincification corrosion can be avoided, through the reasonable combination strontium,cerium, boron and silicon, the process performance can be improved, and the color-change resistance can be improved; according to the alloy, the production process is simple, the production cost is low, the machining performance is good, the golden degree is high, the color-change resistance is excellent in the environment of salt mist, high humidity, synthetic perspiration and the like, and thealloy is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

High discoloration resistance and low-cost gold bronze alloy and preparation method thereof

The invention provides a high discoloration resistance and low-cost gold bronze alloy and a preparation method thereof. The high discoloration resistance and low-cost gold bronze alloy comprises the following components of Mn, Al, Ni, Si, Ce, Sr, P and B, and the balance Cu and inevitable impurities. The preparation method comprises the steps of smelting, semi-continuous casting, hot rolling, surface milling, cold rolling, intermediate annealing, cold finish rough rolling, cold finish rolling and finished product annealing. The alloy produced by the method has high gold color, good discoloration resistance performance, excellent hot and cold working properties and small deformation resistance, and does not contain noble metal elements, so that the alloy is relatively low in cost. The alloyhas reasonable components, and the gold degree of the alloy is improved through reasonable matching of cheap manganese, aluminum, nickel and silicon. The reasonable collocation of strontium, cerium,phosphorus and silicon can improve the technological performance and the discoloration resistance. The alloy is low in price of raw materials, simple in production process, environment-friendly, low in production cost, good in processing performance, high in the gold degree, excellent in discoloration resistance performance in environments such as salt mist, high-humidity and artificial sweat, andsuitable for industrial production.

Owner:CENT SOUTH UNIV

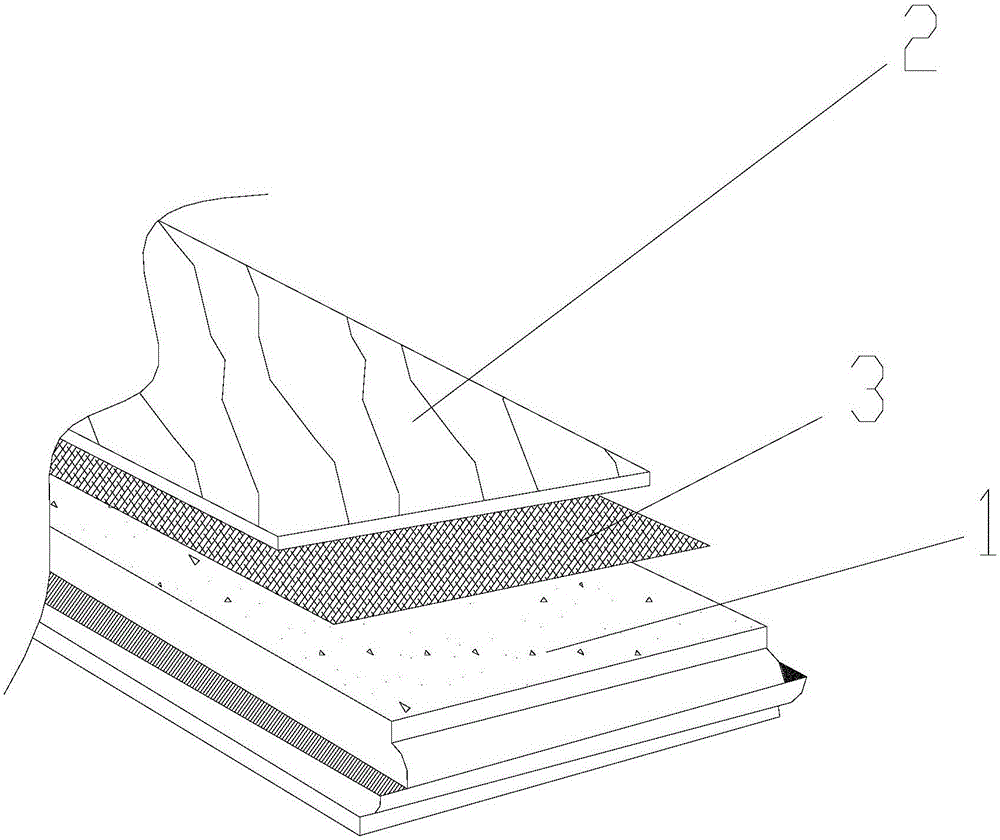

UV transfer printing wood floor and manufacturing method thereof

InactiveCN106592918ATake advantage ofSave resourcesDecorative surface effectsPattern printingSolid woodSurface layer

The invention discloses a UV transfer printing wood floor which is mainly composed of a basic wood floor body and an abrasion-resistant surface layer attached to the basic wood floor body. A transfer printing layer is arranged between the basic wood floor body and the abrasion-resistant surface layer. The basic wood floor body is made of one or more layers of solid wood. The surface of the basic wood floor body is provided with wood natural grains or has a pure color. The transfer printing layer is attached to the surface of the basic wood floor body. The abrasion-resistant surface layer is transparent or semitransparent and is attached to the surface of the transfer printing layer. According to the UV transfer printing wood floor adopting the technical scheme, various wood natural grains, stone grains, wood parquet grains, images arousing the art aesthetic feeling and the like are printed to the surface of the wood floor through a UV transfer printing mode, and low-grade quick-growing wood is decorated with decorative materials with a high-grade effect. Accordingly, fast-growing and high-yield plantation is sufficiently utilized, the valuable wood resource is saved, and the requirements for personalized, diversified and hierarchical home decoration are met. The invention further discloses a manufacturing method of the UV transfer printing wood floor.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

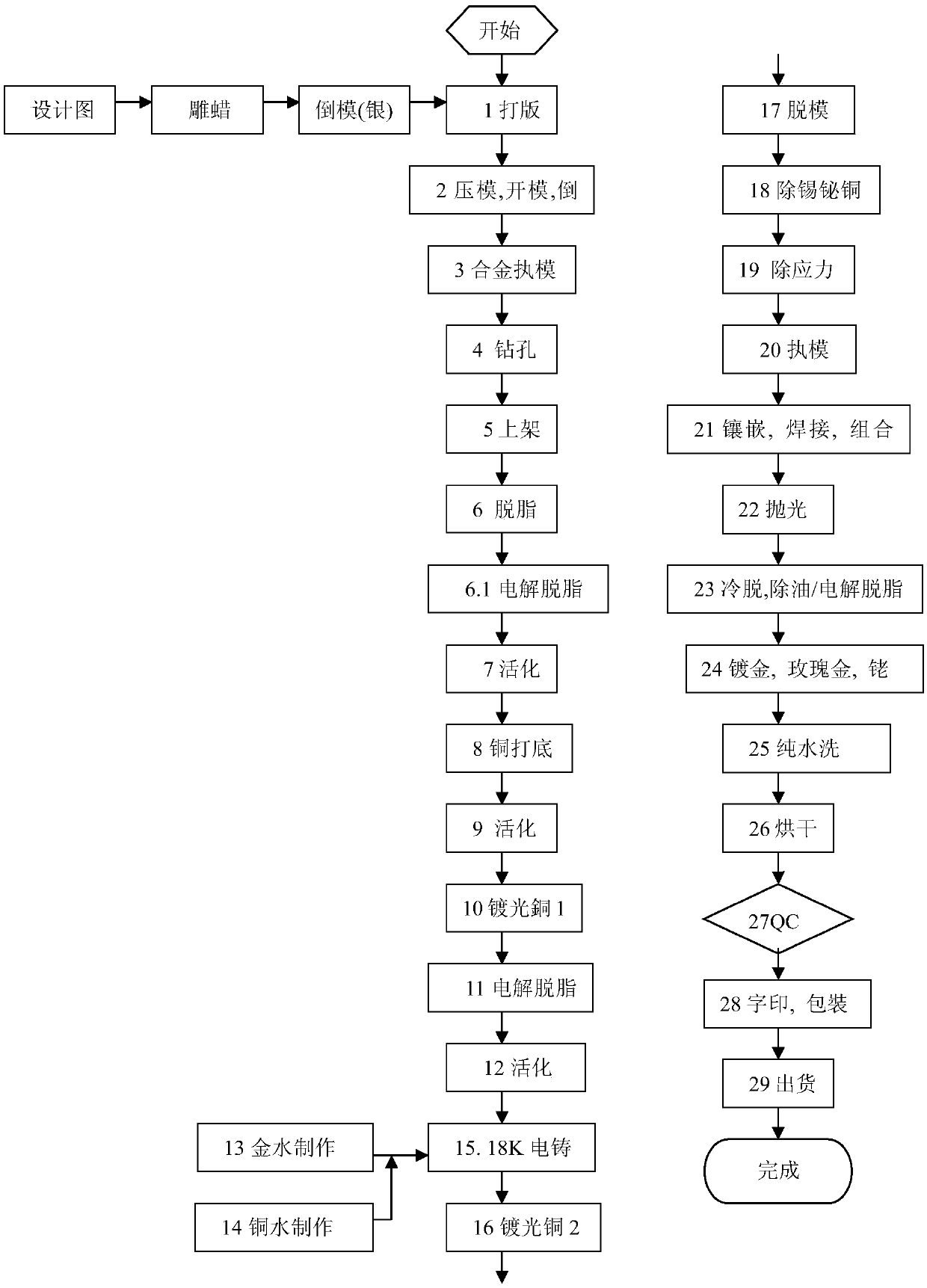

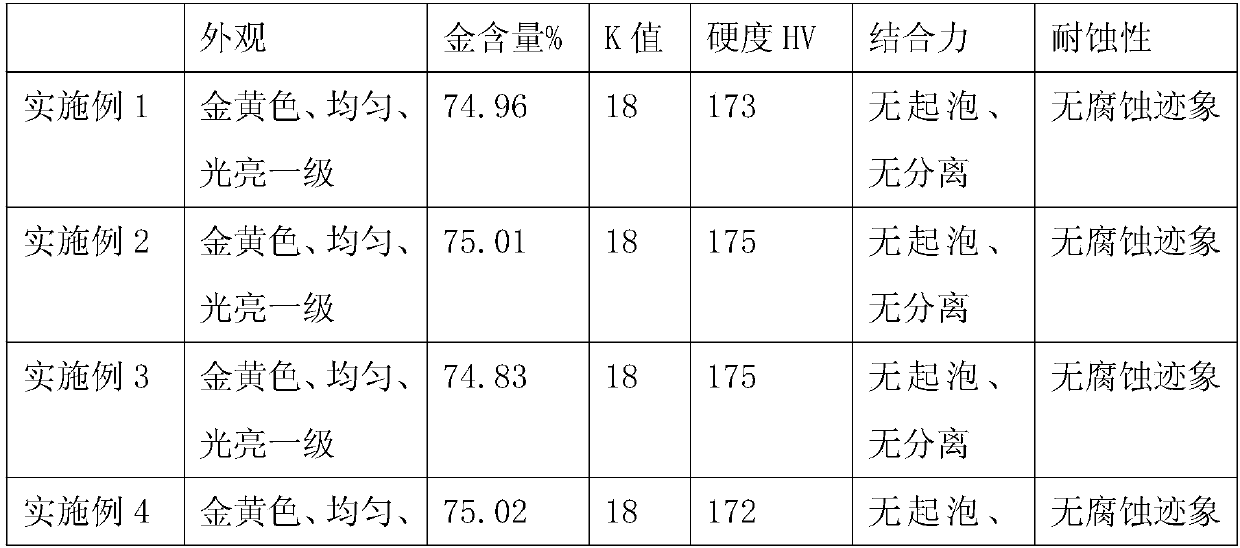

Preparation method for cyanide-free 18 k gold jewelries

The invention discloses a preparation method for cyanide-free 18 k gold jewelries. The preparation method comprises the steps of plate making, mold pressing, opening and reversing, alloy mold carrying, drilling, loading, degreasing, primary activation, copper bottoming, secondary activation, gloss copper 1 plating, electrolytic degreasing, ternary activation, gold water preparation, molten copperpreparation, 18 k electroforming, gloss copper 2 plating, demolding, tin bismuth copper removal, distressing, mold carrying, embedding, welding, combination, polishing, cooling, deoiling, electrolyticdegreasing, gold plating, pure water washing, drying, quality inspection, character printing, packing and delivery in sequence; and then, the cyanide-free 18 k gold jewelries are obtained. The preparation method is simple in process and easy to operate, obviously improves the jewelry quality, reduces the gold loss, and contains no cyanide-contained poisonous substance in the preparation process to achieve environmental protection and safety; the hardness and the toughness of the 18 k gold jewelries are prominently improved to preferably guarantee the stability of the jewelries in the wearingprocess; and further, electroforming liquid is excellent in stability, dispersibility and deep plating capacity, can be prepared beforehand for future use, and improves the production efficiency.

Owner:NANJING INST OF PROD QUALITY INSPECTION

Artificial brushed nickel appearance and anti-tarnish surface treatment method for metal base material

ActiveCN104593726APrevent rustProtection brushed effectVacuum evaporation coatingSputtering coatingTectorial membraneHydrocarbon solvents

The invention provides an artificial brushed nickel appearance and anti-tarnish surface treatment method for a metal base material and a metal decorative assembly obtained by the method. The method provided by the invention comprises the following steps: polishing and drawing the metal base material by virtue of an abrasive tape, adhering a layer of protective film to effectively prevent the drawn metal base material surface from rusting; removing the protective film, removing glue and oil by a vacuum ultrasonic hydrocarbon solvent; carrying out vacuum microwave drying, so that the metal base material is not injured, and no three wastes are discharged; sequentially applying a physical gas-phase deposition layer, an ion glow activation layer, a non-reacting deposition layer and a reacting deposition layer, effectively improving the adhesive force and the appearance chromatism between the coating and the metal base material; and finally, spraying transparent powder. The appearance of the sprayed metal decorative assembly does not change color due to high-temperature baking, so that the antiseptic property, the anti-tarnish property and other properties of the metal base material can be effectively improved.

Owner:NINGBO RUNNER INDAL CORP

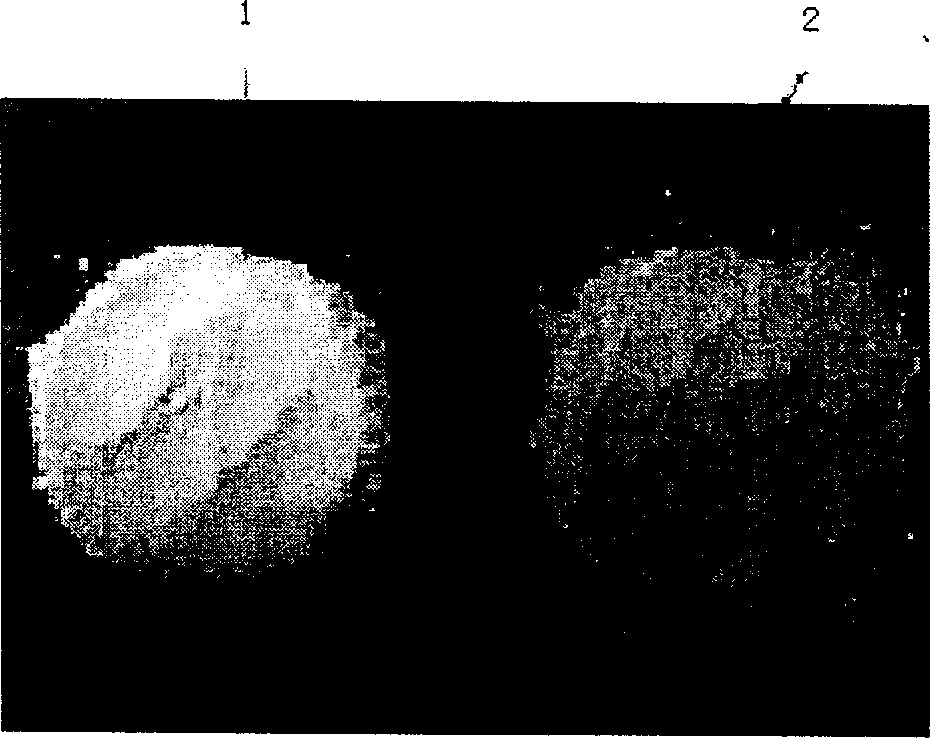

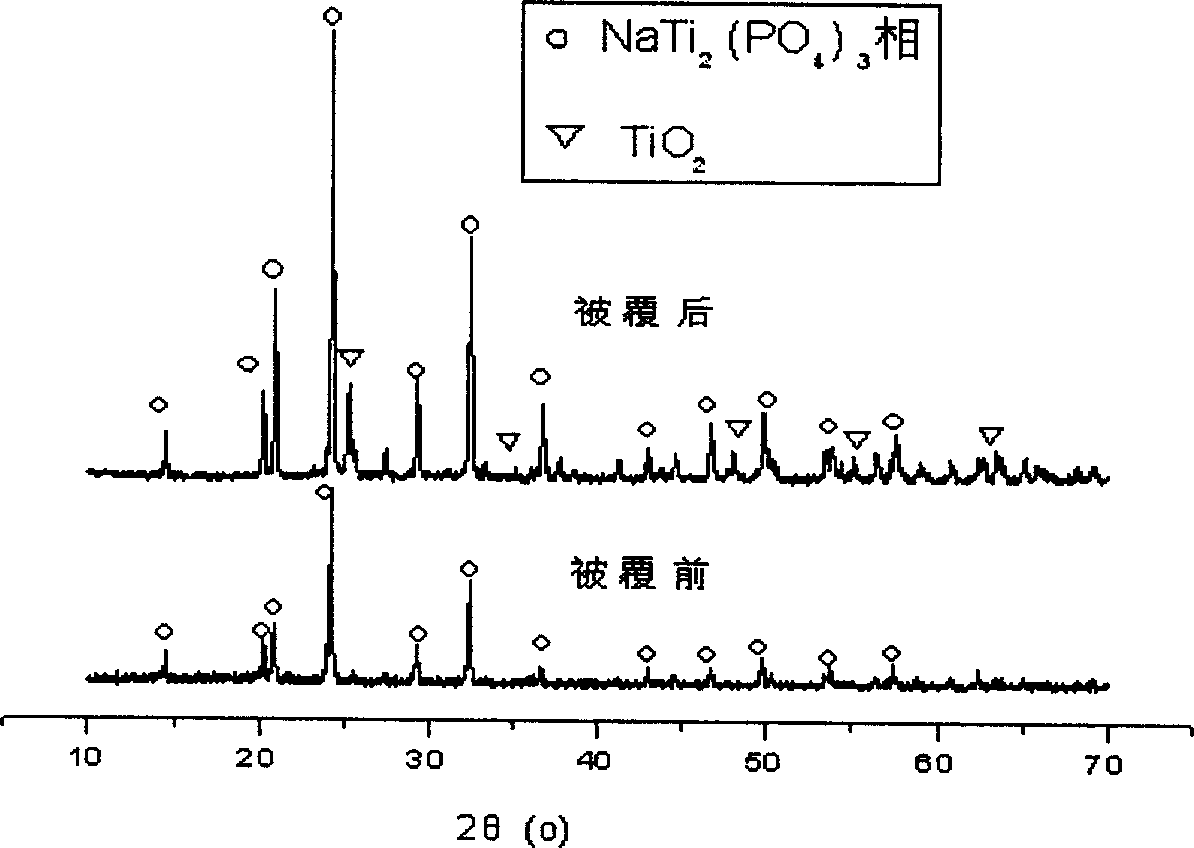

Preparation method for discoloration tolerant antibacterial material of silver-loaded titanium phosphate

InactiveCN1702194AImproves tarnish resistanceRaise the gradeLiquid/solution decomposition chemical coatingWater bathsAdjuvant

The invention belongs to the field of antimicrobial material. It aims at improving the liable color change of silver-carried phosphoric titanate. It contains the following steps: using titanic sulfate or titanoxy sulfate as raw material, and mixing urea as adjuvant to prepare solution, the mass ratio of titanic sulfate to urea being 40: 1- 40: 5, titanoxy sulfate to urea being 30: 1- 30: 5; adding block or powder of phosphoric titanate into the solution, heating by water-bath of temperature of 50-90 Deg. C and stirring for 3-6 hours to deposit titanium-contained substance film on the surface of phosphoric titanate; annealing in the air and the temperature of 500-700 Deg. C by 1-4 hours; exchanging silver ion in silver nitrate water solution of a mass ratio concentration of 1-20% in 20-50 Deg. C by 0.5-4 hours to prepare silver-carried phosphoric titanate material, carrying silver mass being 1-10% by mass, annealing the silver-carried phosphoric titanate complex in 600-1000 Deg. C by 0.5-6 hours. The whiteness can amount to over 89%, antibiosis ratio to 99%, it keeping the fine exterior of material, applying extensively to preparing antimicrobial material in plastic, coating, timber and so on.

Owner:BEIJING UNIV OF TECH

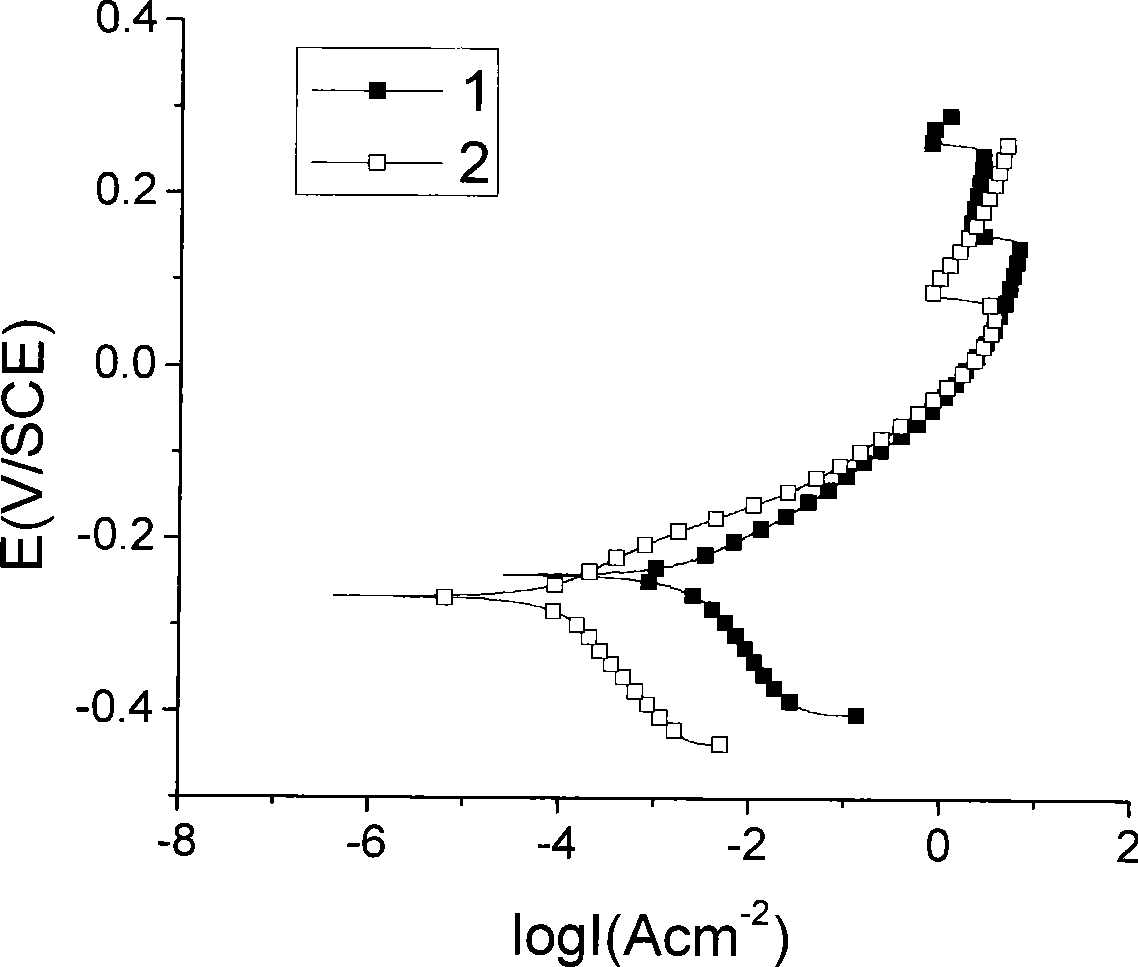

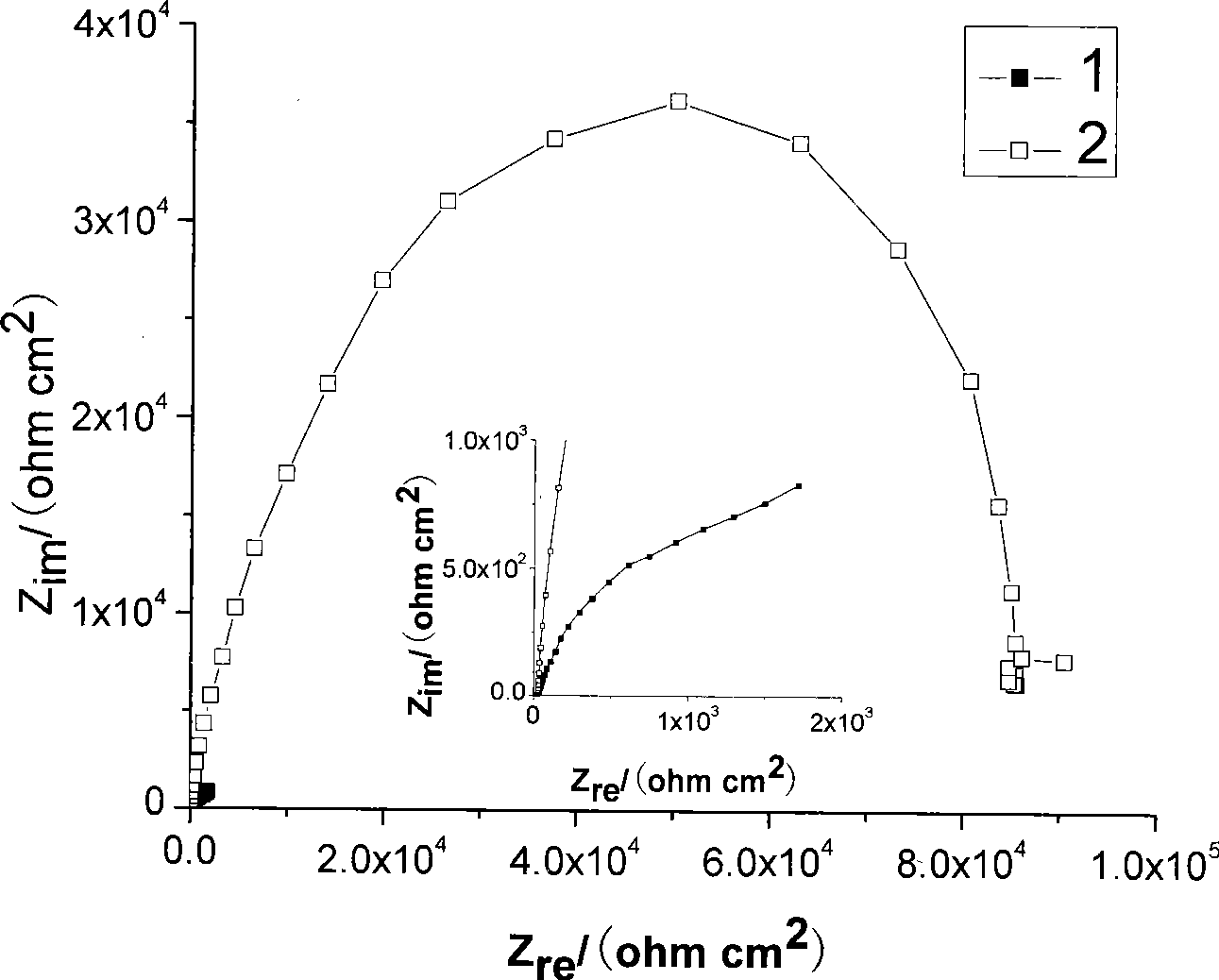

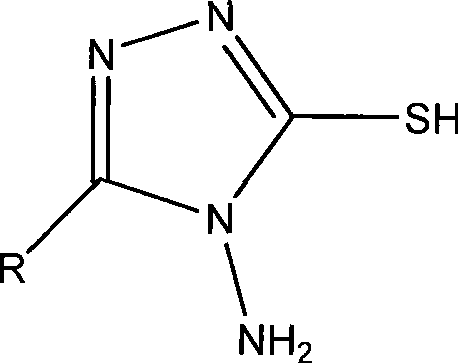

Metal anti-color changing method using self-assembling monomolecular film

InactiveCN101386979AReduce usageEasy to operateMetallic material coating processesTriazole derivativesBiological activation

The invention relates to a process for metal surface treatment, in particular to a metal discoloration resisting method by using a self-assembled monomolecular film. The method aims to the corrosion and discoloration problems of metal like copper, copper alloy, sliver and sliver alloy, gold and gold alloy and so on or other metal or non-metal surface coatings consisting of the metals during the course of storage in the atmosphere, and adopts active environment-friendly material triazole derivatives to form the self-assembled monomolecular film on the metal surface to solve the problems of high toxicity and change of the prior metal color after treatment and so on in the prior discoloration resisting process. The method comprises the steps of degreasing, polishing, activation, surface treatment, cleaning and drying, and avoids the use of poisonous chemicals, is easy to operate and is not affected by the shapes of the surfaces of metal pieces. The treated metal obviously improves discoloration resistance, and the metal gloss and appearance of the surface have no visible change, therefore the process has wider application compared with the prior process.

Owner:DALIAN MARITIME UNIVERSITY

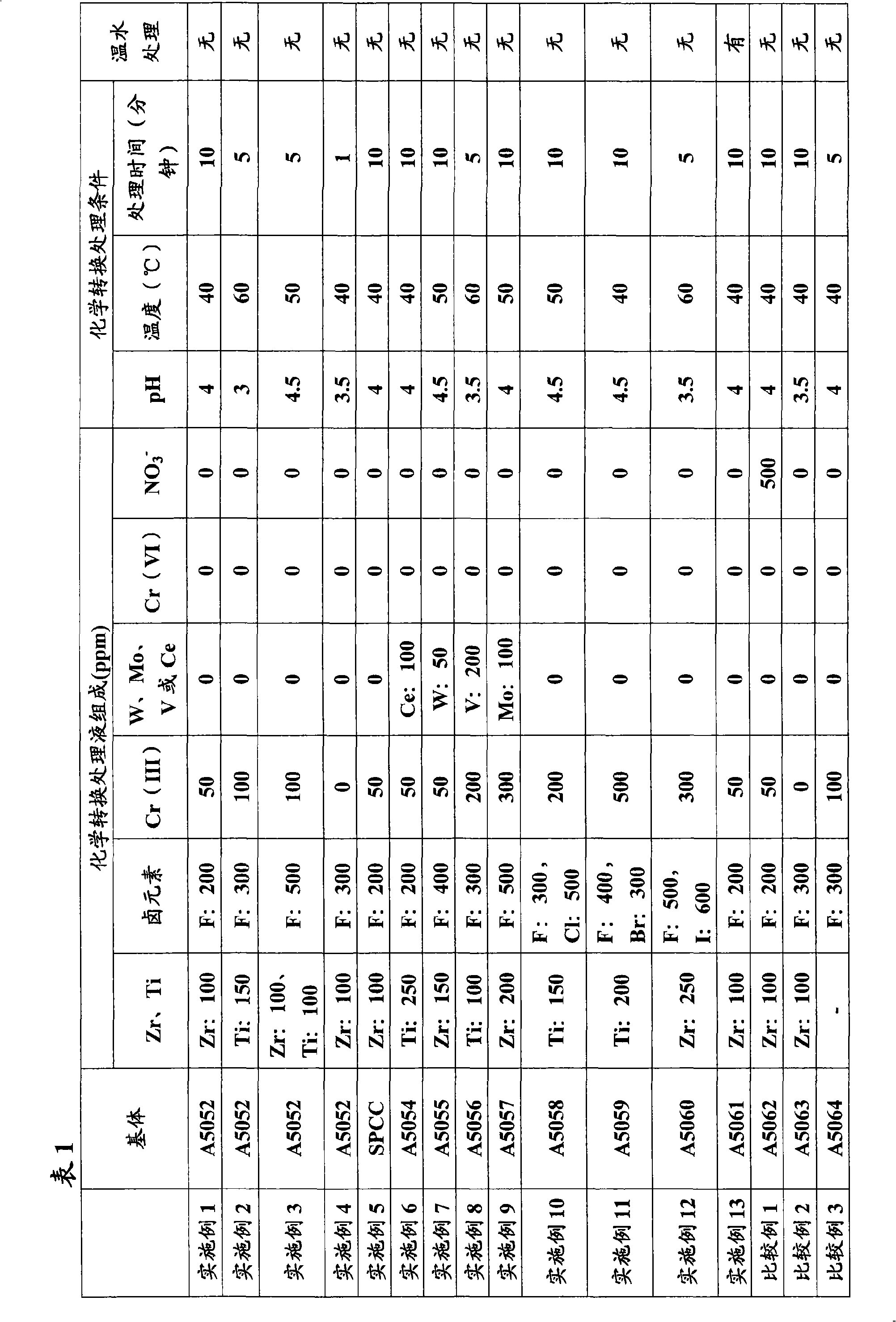

Composite material and preparation thereof

InactiveCN101285184ALess coloringEasy and efficient to manufactureLiquid/solution decomposition chemical coatingSuperimposed coating processHalogenChemical transformation

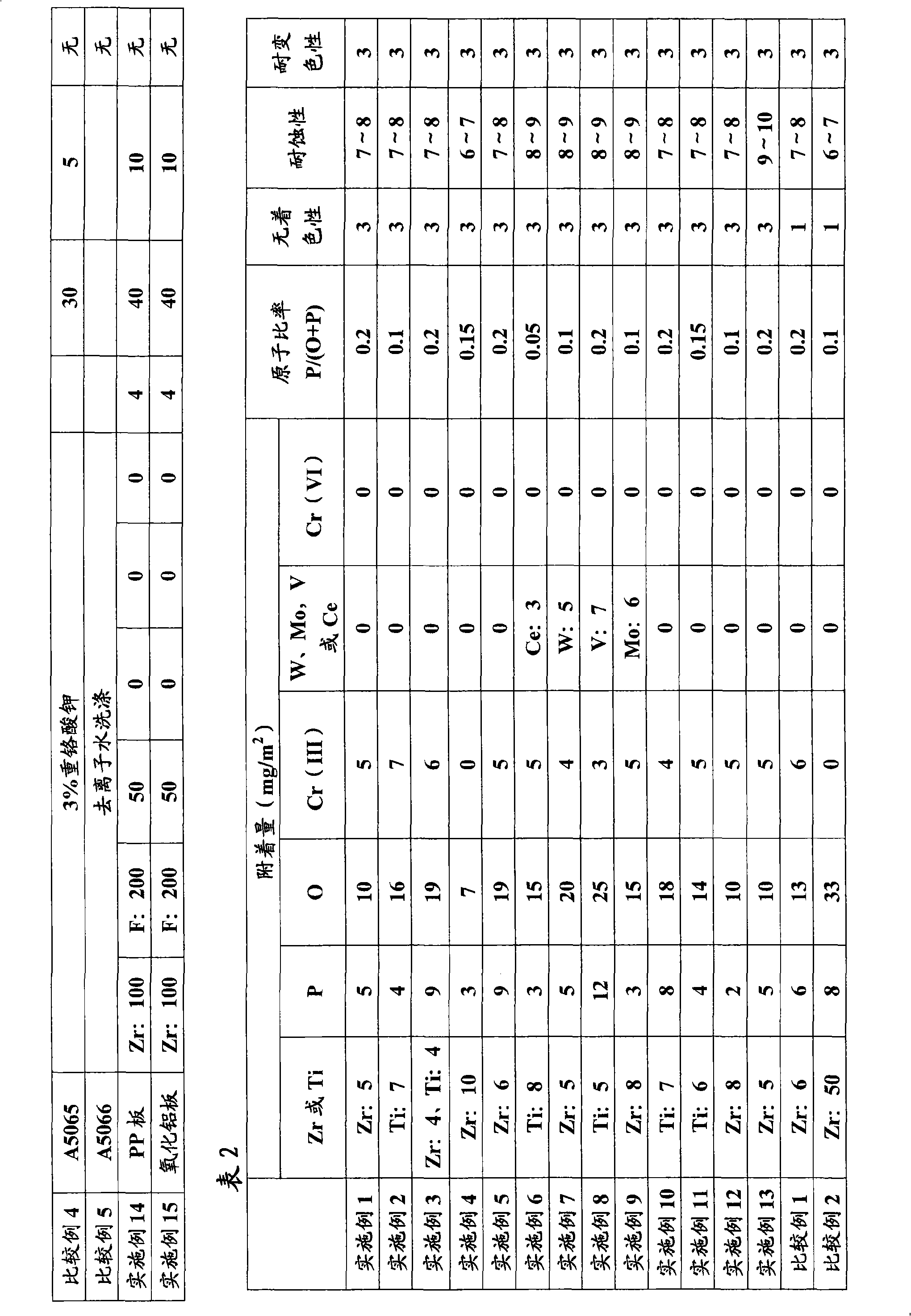

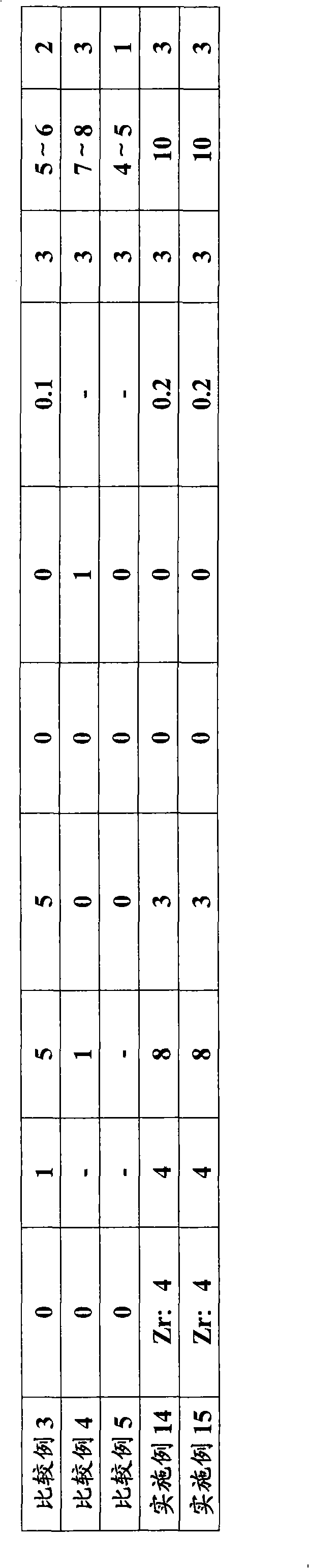

The invention provides a composite material. The composite material is formed by implementing a chemical transformation treatment for a solid material which is provided with a Ni-P alloy coating, doesn't have coloring caused by the chemical transformation treatment or has less coloring, and has excellent corrosion resistance and discoloring resistance. The chemical transformation treatment is implemented for the Ni-P alloy coating on a substrate via adopting following chemical transformation treatment solution to form a chemical transformation capsula layer. The chemical transformation capsula layer is processed water washing so as to obtain the composite material. The chemical transformation treatment solution comprises main metal elements which comprise Zr and / or Ti and halogen, and pH is in the range of 2.0 to 6.0; the chemical transformation capsula layer comprises the main metal elements in the range of 1mg / m<2> to 30mg / m<2>, phosphorus element and oxygen element respectively in the range of 1mg / m<2> to 100mg / m<2>.

Owner:NIHON PARKERIZING +1

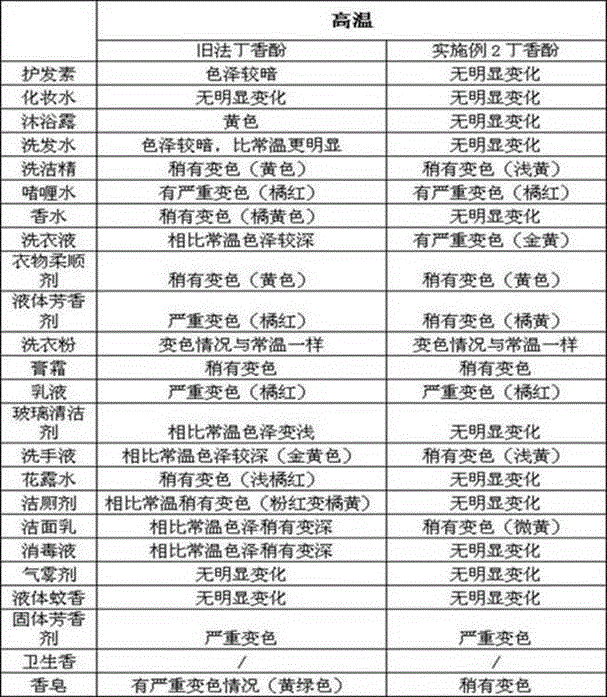

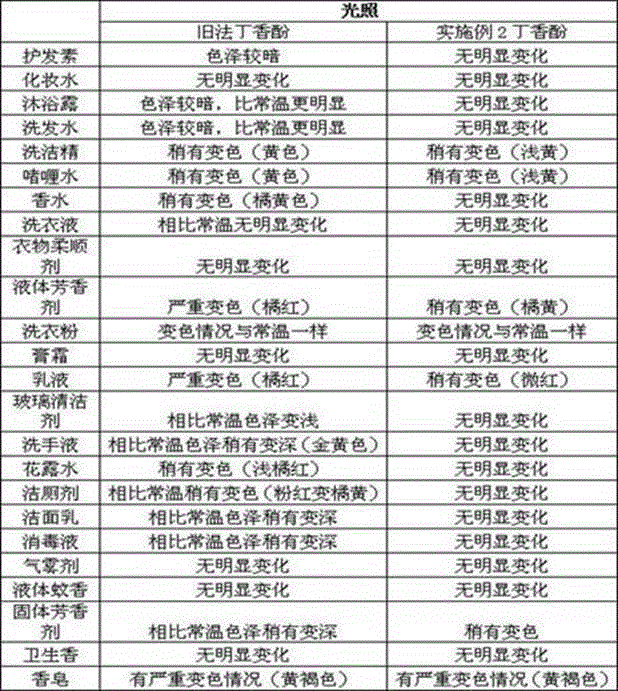

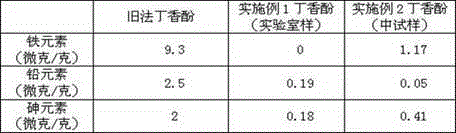

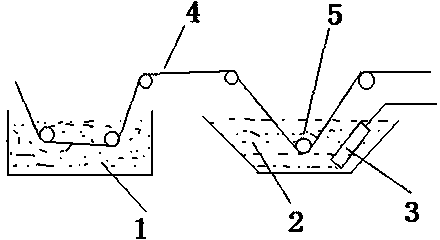

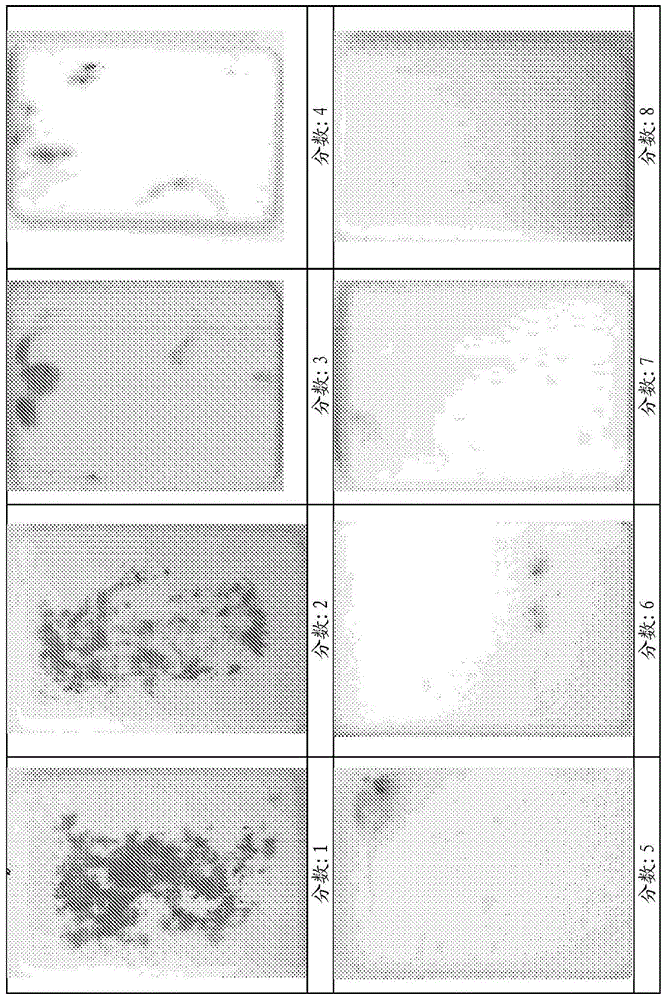

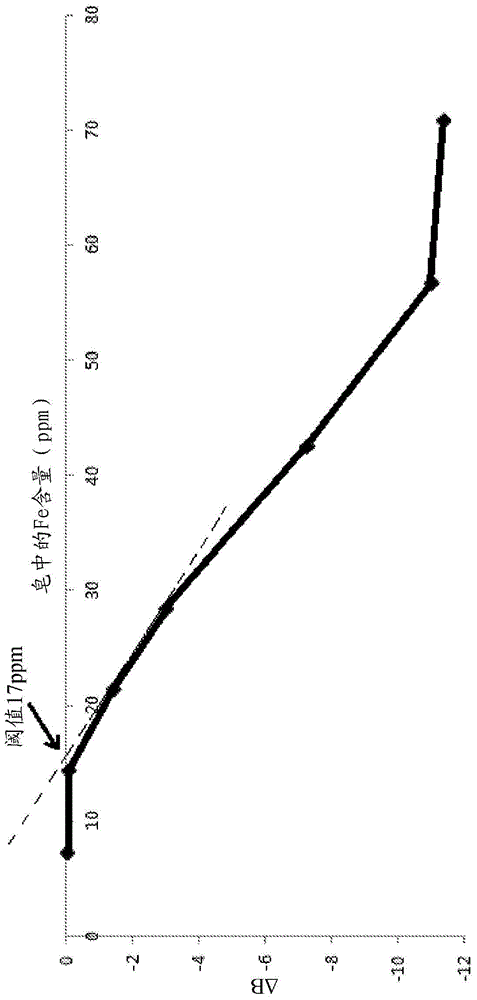

Production process of eugenol for flavoured product

ActiveCN104628542AImproves tarnish resistanceWide range of applicationsEther separation/purificationEssential-oils/perfumesIonChemistry

The invention discloses a production process of eugenol for a flavoured product. The production process disclosed by the invention comprises the following steps of: decompressing and distilling by taking clove leaf oil as the raw material, then, adding sodium hydroxide to stir and react, standing to layer, neutralizing a water layer by using sulphuric acid solution to obtain crude carophyllin, adding EDTA-2Na complex metal ion again, and finally, decompressing, distilling and rectifying to obtain the final product, namely eugenol. Compared with the eugenol product produced by using the existing production process, the metal ion content of the eugenol produced by the production process disclosed by the invention is greatly reduced; and the colour change resistant property and the safety property of the product are obviously increased.

Owner:厦门琥珀香精股份有限公司

Two-component paint with high temperature resistance and preparation method

InactiveCN106280986AImproves tarnish resistanceImproved cold and heat resistance and convenient performanceAnti-corrosive paintsZinc phosphateAlcohol

The invention relates to paint with high temperature resistance and a preparation method, in particular to two-component paint with high temperature resistance and a preparation method. The two-component paint with high temperature resistance is prepared from a first component and a second component, wherein the first component is prepared from phenyl methyl silicone resin, a wetting dispersant, a copper chromite black pigment, mica powder, barium phosphonate, zinc phosphate, glass powder and n-butyl acetate in proportion; the second component is prepared from gamma-aminopropyltriethoxysilane and absolute ethyl alcohol in equal proportion through mixing, the two components in a ratio being (100:1)-(105:1) in parts by weight are mixed, and the two-component paint with high temperature resistance is obtained. The temperature resistance, the discoloration resistance and the alternate cooling and heating resistance of the two-component paint with high temperature resistance are greatly improved, and adhesive force and corrosion resistance of the two-component paint with high temperature resistance are excellent.

Owner:SHANDONG DIGAO PAINT IND CO LTD

Process of ultrasonic wave electroplating of copper foil

The invention discloses a process of ultrasonic wave electroplating of copper foil. An electroplating solution is prepared, and cerous oxalate is added into the electroplating solution; ultrasonic cleaning with deionized water is carried out before electroplating; during electroplating, the cathode current density is 2.5A / dm3; the electroplating solution is oscillated and stirred by ultrasonic wave of 700-1200 w and 20-35 KHz. The process of the invention adopts ultrasonic wave stirring, which increases the current density, reduces concentration polarization, improves brightness, enables easy escape of hydrogen at the cathode surface, reduces burrs and pin holes, and obtains an electroplating layer with finer and uniform crystal particles.

Owner:江西省首诺铜业有限公司

Method for extracting biomarker for diagnosing pancreatic cancer, computing device therefor, biomarker for diagnosing pancreatic cancer and device for diagnosing pancreatic cancer including the same

ActiveCN105101948AImproves tarnish resistanceExtended shelf lifeCosmetic preparationsToilet preparationsMicroRNAOncology

Disclosed are a method for extracting a biomarker for diagnosing pancreatic cancer, a computing device therefor, a biomarker for diagnosing pancreatic cancer and a device for diagnosing pancreatic cancer including the same. More particularly, disclosed are a method for extracting a biomarker for diagnosing pancreatic cancer using genes specifically expressed in pancreatic cancer patients or microRNAs obtained from blood or tissues paired with the genes, a computing device therefor, a biomarker for diagnosing pancreatic cancer and a device for diagnosing pancreatic cancer including the same.

Owner:THE PROCTER & GAMBLE COMPANY

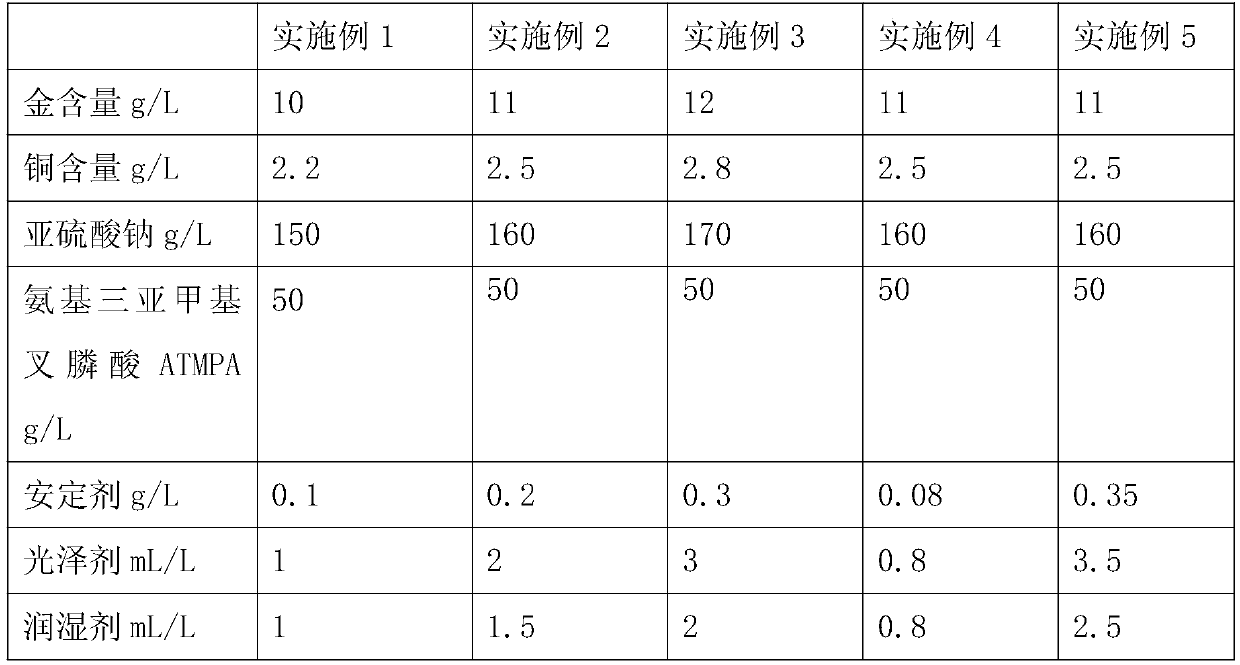

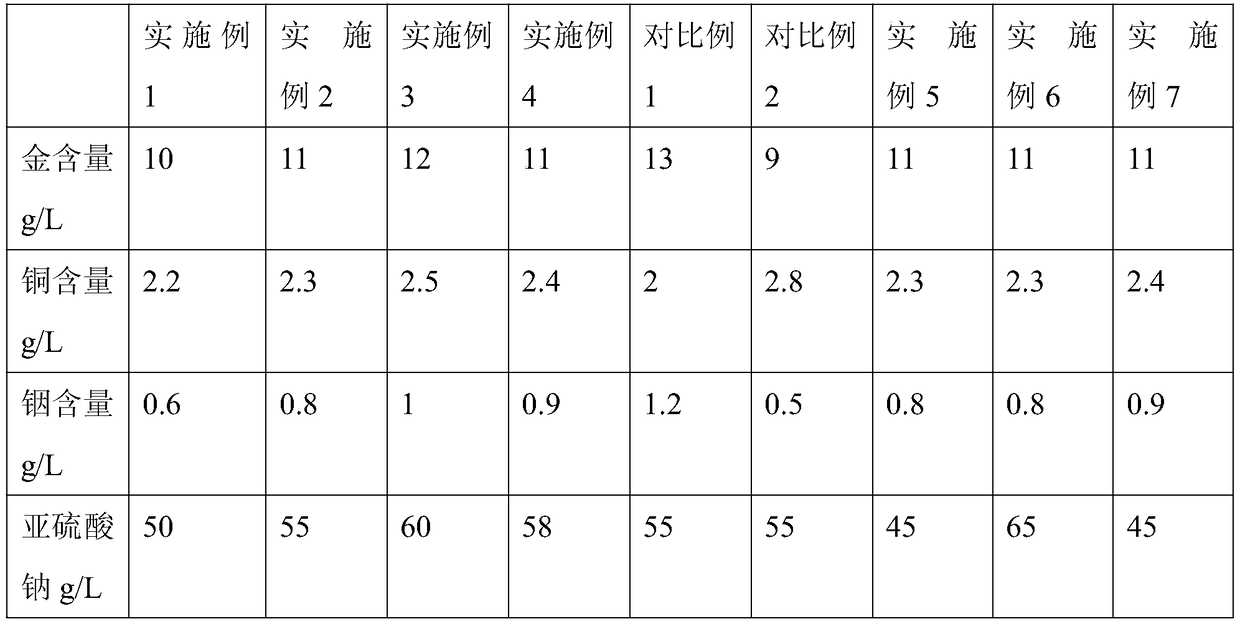

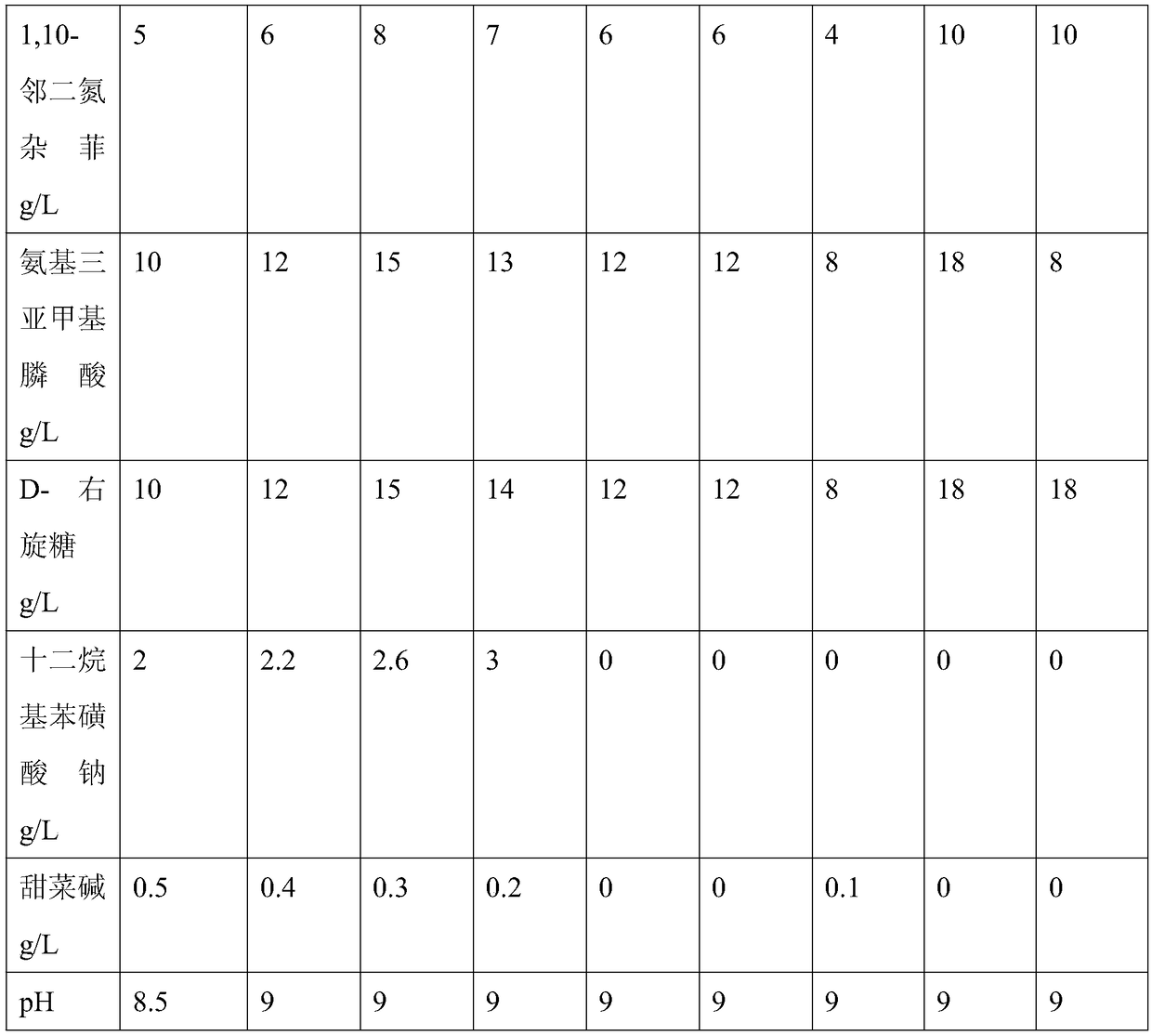

Cyanide-free 18k gold electrocasting solution and preparation method and application thereof

The invention discloses a cyanide-free 18k gold electrocasting solution and a preparation method and application thereof. The cyanide-free 18k gold electrocasting solution is prepared from the raw materials by volume: 10-12 g / L of gold, 2.2-2.5 g / L of copper, and 0.6-1 g / L of indium. The electrocasting solution is high in stability, high in dispersibility, and high in covering power. The electrocasting solution can be prepared in advance, and therefore labor intensity is lowered, production efficiency is improved, and the quality of ornaments is improved. Toxic substances containing cyanide are not adopted, and therefore security is high. The gold content is easy to control, and therefore gold loss is reduced, and yield is improved. Hardness of a 18k gold ornament is improved, and stability of the ornament during wearing is better guaranteed, and embedded gemstones are prevented from loosing. The corrosion resistance, decoloring resistance and abrasion resistance of the 18k gold ornament are obviously improved.

Owner:NANJING INST OF PROD QUALITY INSPECTION +1

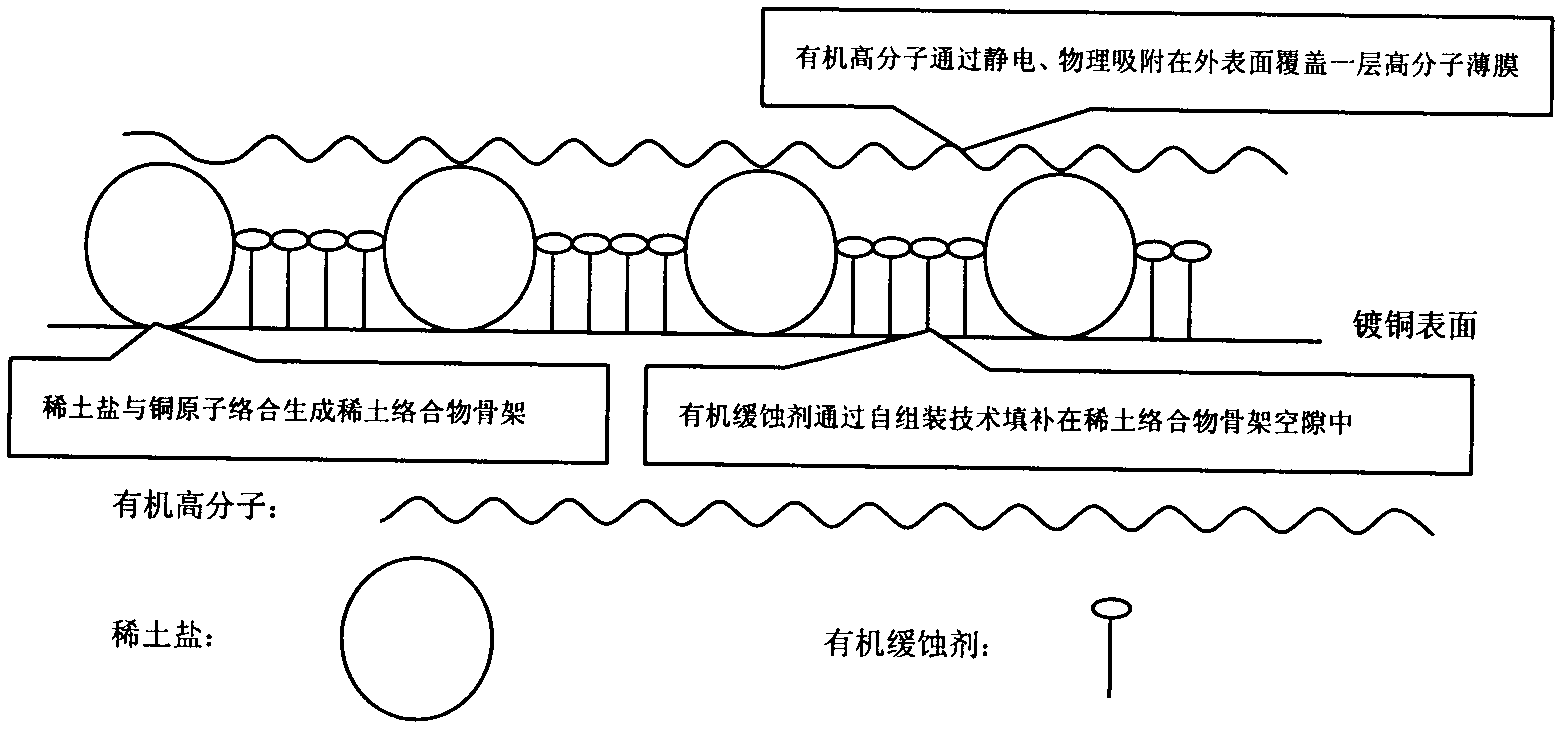

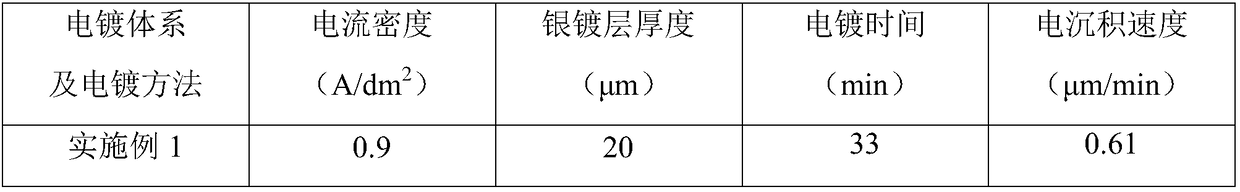

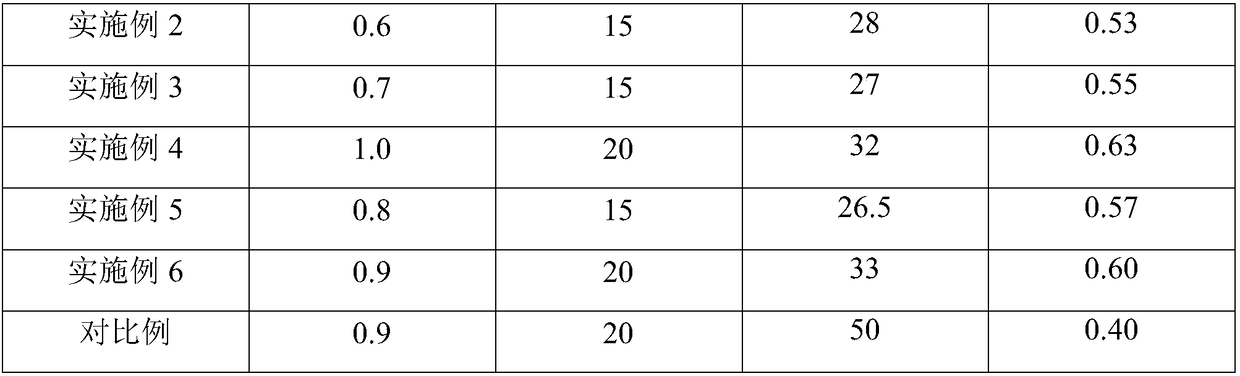

Novel water-soluble plated-copper protective agent and preparation method thereof

ActiveCN103147075AImprove the protective effectHigh resistance to salt sprayMetallic material coating processesCopper platingRare earth

The invention relates to a novel water-soluble plated-copper protective agent and a preparation method thereof. A use method of the novel water-soluble plated-copper protective agent comprises the following steps that a solute rare-earth salt and an organic inhibitor form a rare-earth complex skeleton on the surface of plated copper in the presence of water as a solvent; the organic inhibitor on the surface and the rare-earth complex skeleton on the surface of the plated copper are combined into a self-assembled film; and an organic polymer film is covered on the self-assembled film by physical absorption. The three-dimensional film structure formed on the surface of the plated copper can effectively prevent the corrosion caused by harmful gas in air on the surface of the plated copper and improve salt mist resistance and anti-discoloration performances of the surface of the plated copper. A nonpolar molecule group at the end of the self-assembled film effectively improves lubricity of the surface of the plated copper, reduces an insertion and extraction force and does not influence electrical conductivity and welding performances of the plated copper.

Owner:西安创联华特表面处理技术有限责任公司

Fastness rose gold target and preparation method thereof

InactiveCN104032273AImprove wear resistance and oxidation resistanceIncreased anti-tarnish effectVacuum evaporation coatingSputtering coatingAg elementIridium

The invention discloses a fastness rose gold target and a preparation method thereof. The fastness rose gold target contains Au, Ir and Cu. According to the fastness rose gold target, the iridium (Ir) is used for replacing an Ag element one of main elements in rose gold to form Au-Ir-Cu series rose gold. According to the fastness rose gold target, the wear resistance and the oxidation resistance of a film layer are improved, the fastness effect is effectively improved, and the service life and the use effect of a decoration are prolonged.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

A kind of alkaline cyanide-free silver-plating electroplating solution and silver-plating method

InactiveCN107313084BImprove current efficiencyImprove electroplating production efficiencySuberedamine BEthylenediamine

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com