UV transfer printing wood floor and manufacturing method thereof

A production method and wood-based technology, which is applied in the printing, printing, and printing process of producing special varieties of printed matter, can solve problems such as poor light fastness, poor three-dimensional layering, and unclear texture, and achieve low cost and high decorative pattern. The synchronization error is small and the effect of protecting the earth's forest resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings. The coating materials used in the following specific examples are all provided by Zhuhai Dongcheng Photocuring Material Co., Ltd., wherein the UV model series are commonly used UV curing coatings, and the BD model series are special special materials made by Zhuhai Dongcheng Photocuring Material Co., Ltd. UV curable coatings. The QBJ1-30F-1 used for transfer printing is a special adhesive for heat transfer printing provided by 3M Company of the United States.

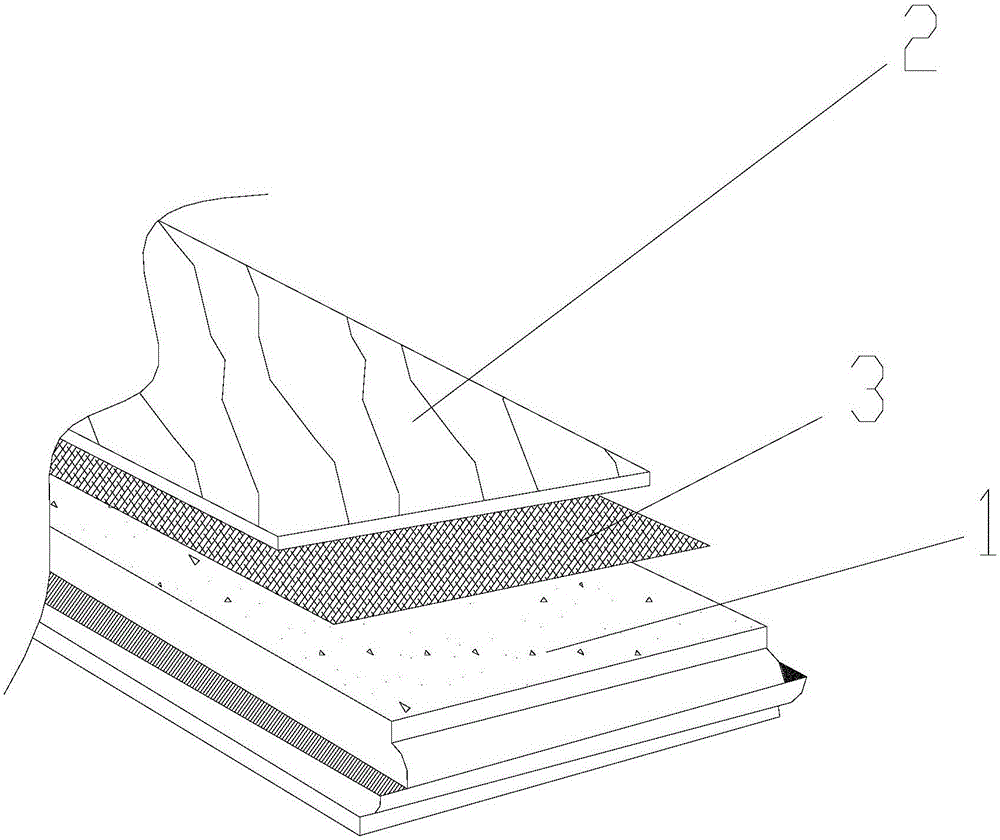

[0046] figure 1 A UV transfer printing wooden floor according to an embodiment of the present invention is schematically shown. As shown in the figure, the transferred wooden floor is mainly composed of a wooden substrate 1 and a wear-resistant surface layer 2 bonded on the wooden substrate 1 .

[0047] Wherein, there is a transfer layer 3 between the wooden substrate 1 and the wear-resistant surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com