Novel water-soluble plated-copper protective agent and preparation method thereof

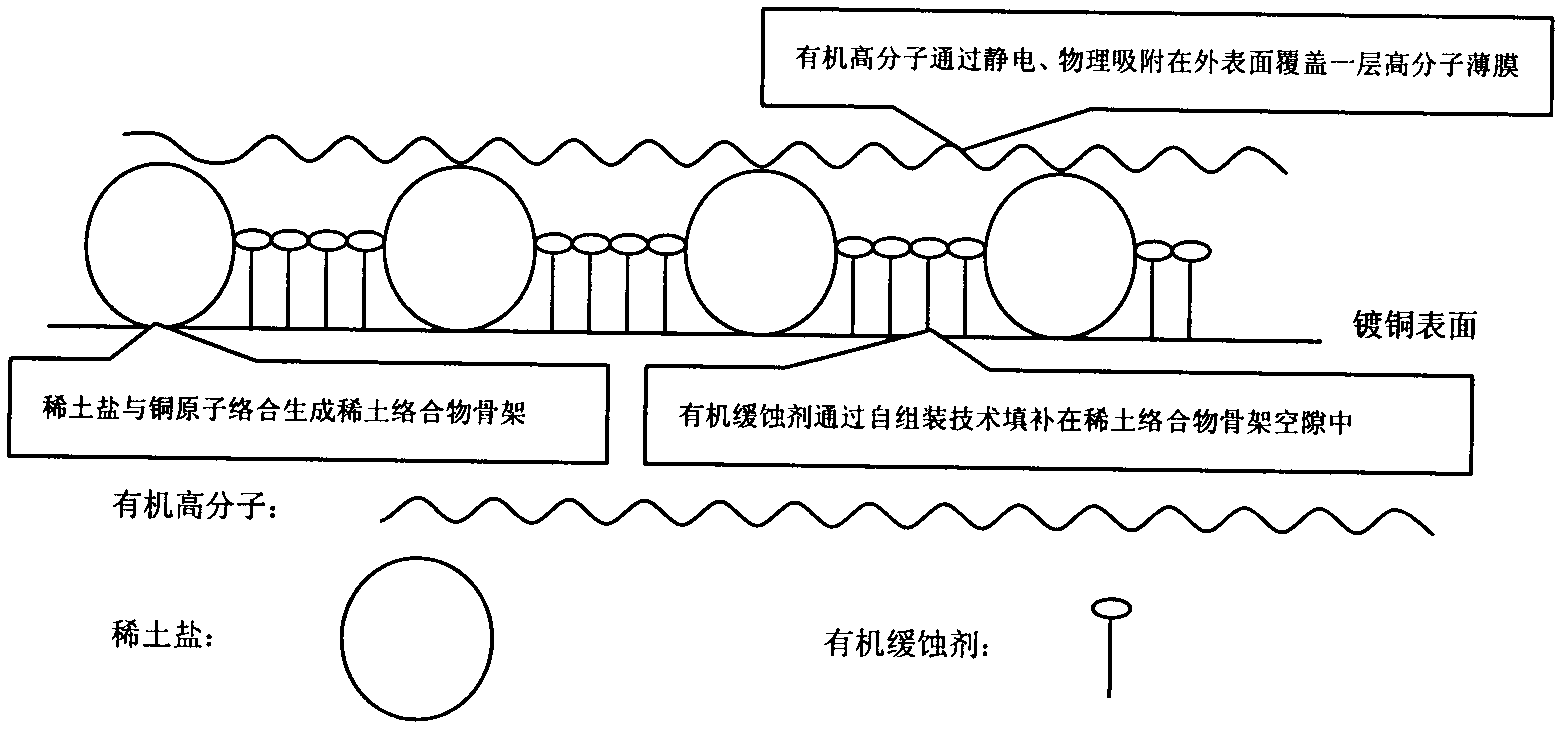

A water-soluble and protective agent technology, applied in the coating process of metal materials, etc., can solve the problems of poor salt spray resistance on the surface of copper-plated products, increase the contact resistance of electrical contact surfaces, and destroy the atmospheric ozone layer, so as to improve salt spray resistance And anti-discoloration performance, reduce adverse effects, ensure the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Prepare 1000 g of protective agent.

[0052] The ingredients are prepared according to the following mass ratios: rare earth salt lanthanum chloride 6g, neodymium chloride 6g; organic corrosion inhibitor benzotriazole 75g, imidazole 75g, polyethylene wax 100g, surfactant OP10150g, the rest is deionized 588g of water.

[0053] The preparation process of this embodiment is:

[0054] 1. Add 40% deionized water into the reactor and heat to 45~50℃;

[0055] 2. Accurately weigh 6g each of the rare earth salt lanthanum chloride and neodymium chloride, add the above-mentioned deionized water, stir to dissolve, and obtain a colorless and transparent solution A;

[0056] 3. Accurately weigh 75g of organic corrosion inhibitor benzotriazole and add it to the reaction solution, stir at 45~50℃ until it dissolves, and obtain light yellow solution B;

[0057] 4. Accurately weigh 75g of the organic corrosion inhibitor imidazole and 150g of the surfactant OP10. After mixing, heat at 40~4...

Embodiment 2

[0069] Example 2 Prepare 1000 g of protective agent.

[0070] The ingredients are prepared according to the following mass ratio: rare earth salt yttrium chloride 2.5g, neodymium chloride 2.5g; organic corrosion inhibitor benzotriazole 75g, dodecylamine 150g, polyethylene wax 150g, surfactant OP10200g, the rest is deionized water 420g.

[0071] The preparation process of this embodiment is:

[0072] 1. Add 60% deionized water into the reactor and heat to 45~50℃;

[0073] 2. Accurately weigh 2.5g each of the rare earth salt yttrium chloride and neodymium chloride, add deionized water at 45~50℃, stir to dissolve, and obtain a colorless transparent solution A;

[0074] 3. Accurately weigh 75g of organic corrosion inhibitor benzotriazole and add it to the reaction solution, stir at 45~50℃ until it dissolves, and obtain light yellow solution B;

[0075] 4. Accurately weigh 150g of organic corrosion inhibitor laurylamine and 10200g of surfactant OP. After mixing, heat at 40~45℃ until the mixt...

Embodiment 3

[0080] Example 3 Prepare 1000 g of protective agent.

[0081] The ingredients are prepared according to the following proportions: rare earth salt yttrium chloride 10g, lanthanum chloride 10g; organic corrosion inhibitor benzotriazole 50g, phenylimidazole 50g, dodecylamine 100g, polyethylene wax 200g, surface Active agent OP10180g, the rest is 400g deionized water.

[0082] The preparation process of this embodiment is:

[0083] 1. Add 50% deionized water into the reactor and heat to 45~50℃;

[0084] 2. Accurately weigh 5g each of the rare earth salt yttrium chloride and lanthanum chloride, add deionized water at 45~50℃, stir to dissolve, and obtain a colorless transparent solution A;

[0085] 3. Accurately weigh 50g of the organic corrosion inhibitor benzotriazole, add it to the reaction solution, stir at 45~50℃ until it dissolves, and obtain light yellow solution B;

[0086] 4. Accurately weigh 50g of organic corrosion inhibitor phenylimidazole, 100g of dodecylamine, and surfactant OP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com