Preparation method for cyanide-free 18 k gold jewelries

A jewelry and alloy technology, applied in the field of preparation of cyanide-free 18k gold jewelry, can solve the problems of poor dispersion, low yield, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

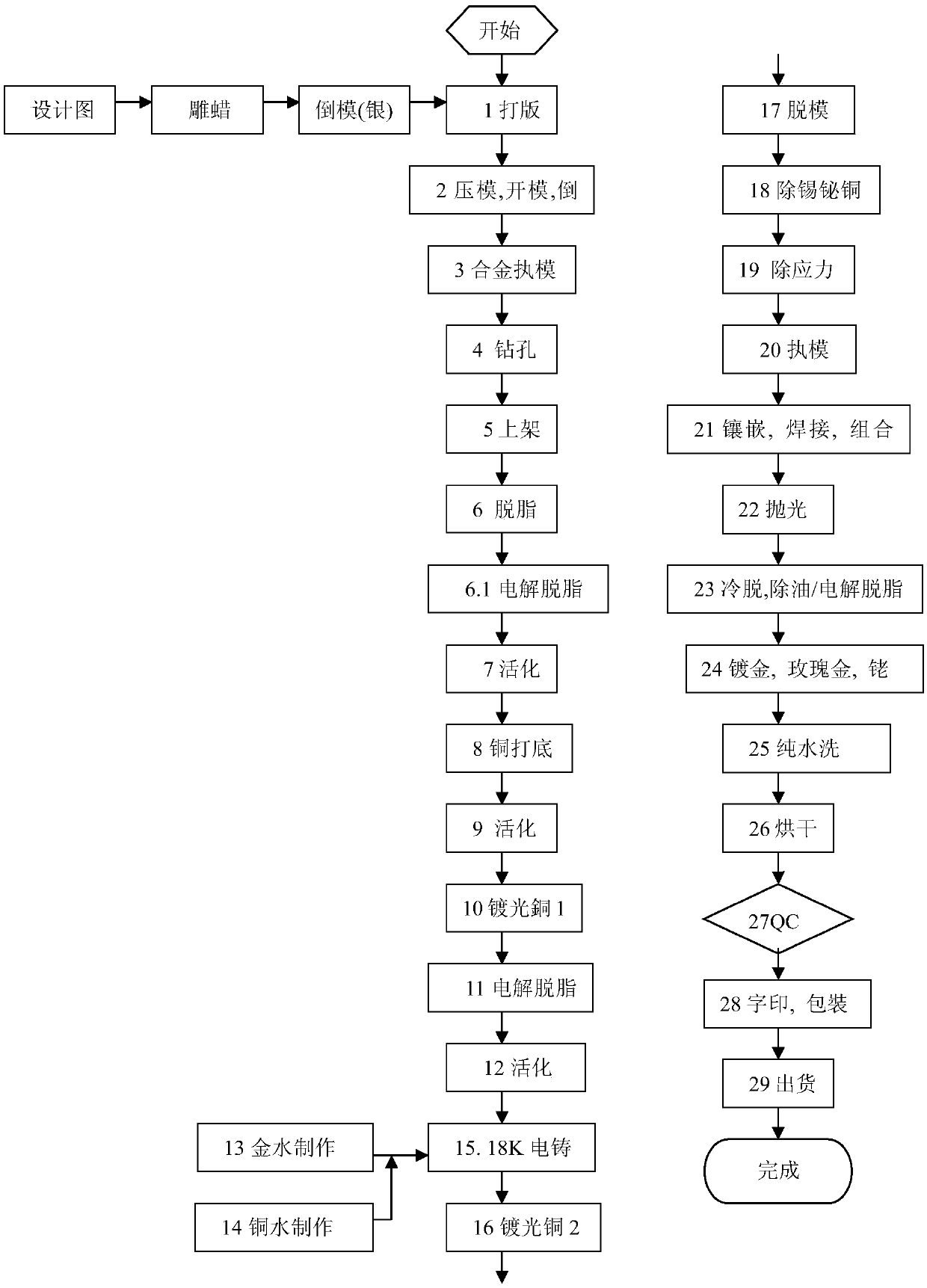

Method used

Image

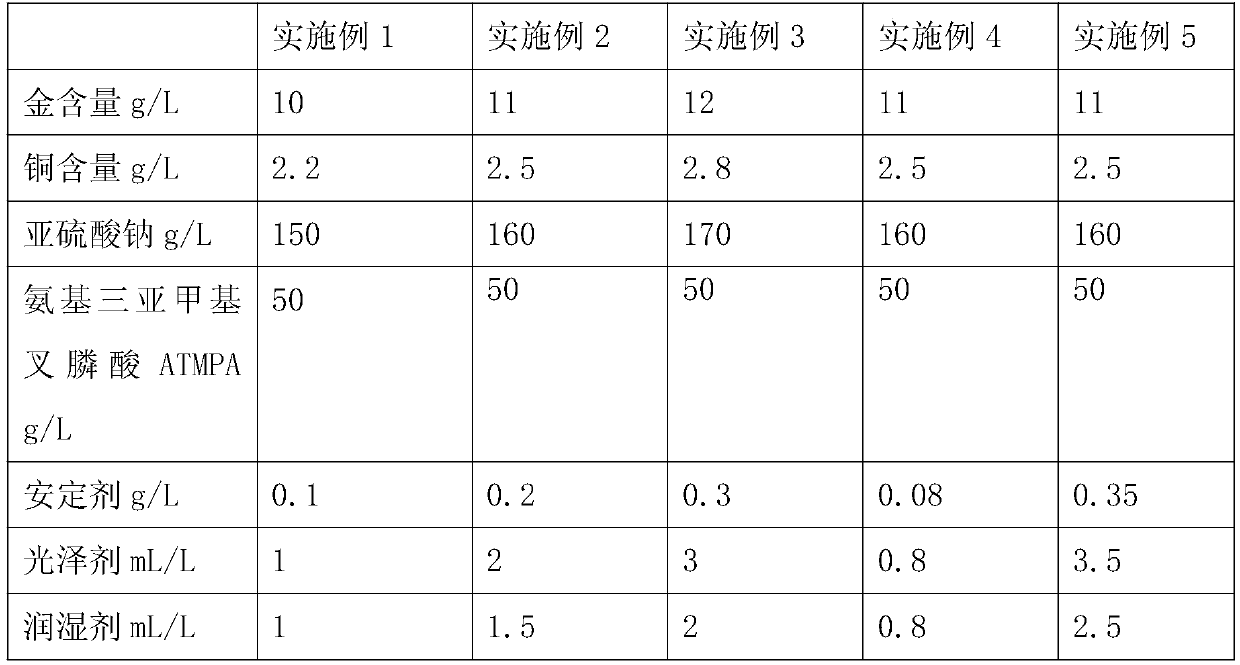

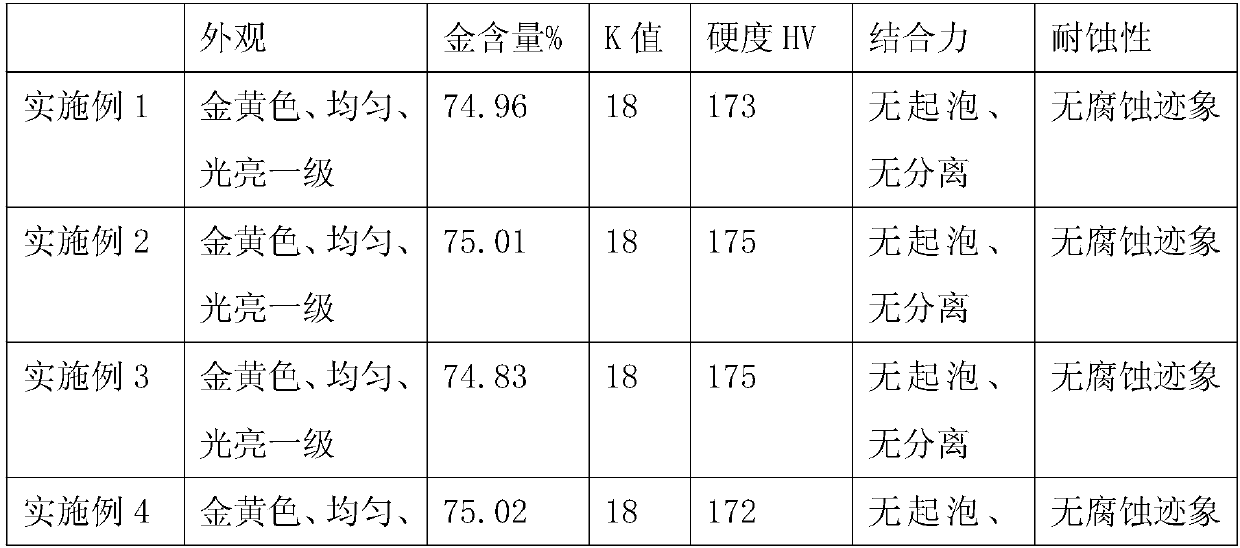

Examples

Embodiment 1

[0102] A preparation method of cyanide-free 18k gold ornaments, comprising the following steps connected in sequence:

[0103] 1 dozen

[0104] Before making the plate, the wax carver carves a wax plate according to the designer's design drawing, or prints it into a wax plate by 3D, and casts it into a silver plate through lost wax, and then the silver plate is trimmed and cleaned by the master plate maker as the master plate.

[0105] 2 Compression mold, mold opening, mold reverse

[0106] Embed the prepared master plate between two semi-raw vulcanized rubbers, and apply a release agent (Datian brand oil-based release agent ORDA-350A) between the two semi-raw vulcanized rubbers, and press for 10 hours at 150 ° C. It is fully matured and shaped. After the molding is completed, take out the master plate, and use tools such as cutters, scalpels, and carving knives to divide the hardened silica gel to form liquid alloy backflow grooves and exhaust fine grooves, which is the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com