Patents

Literature

109 results about "Gold jewelry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

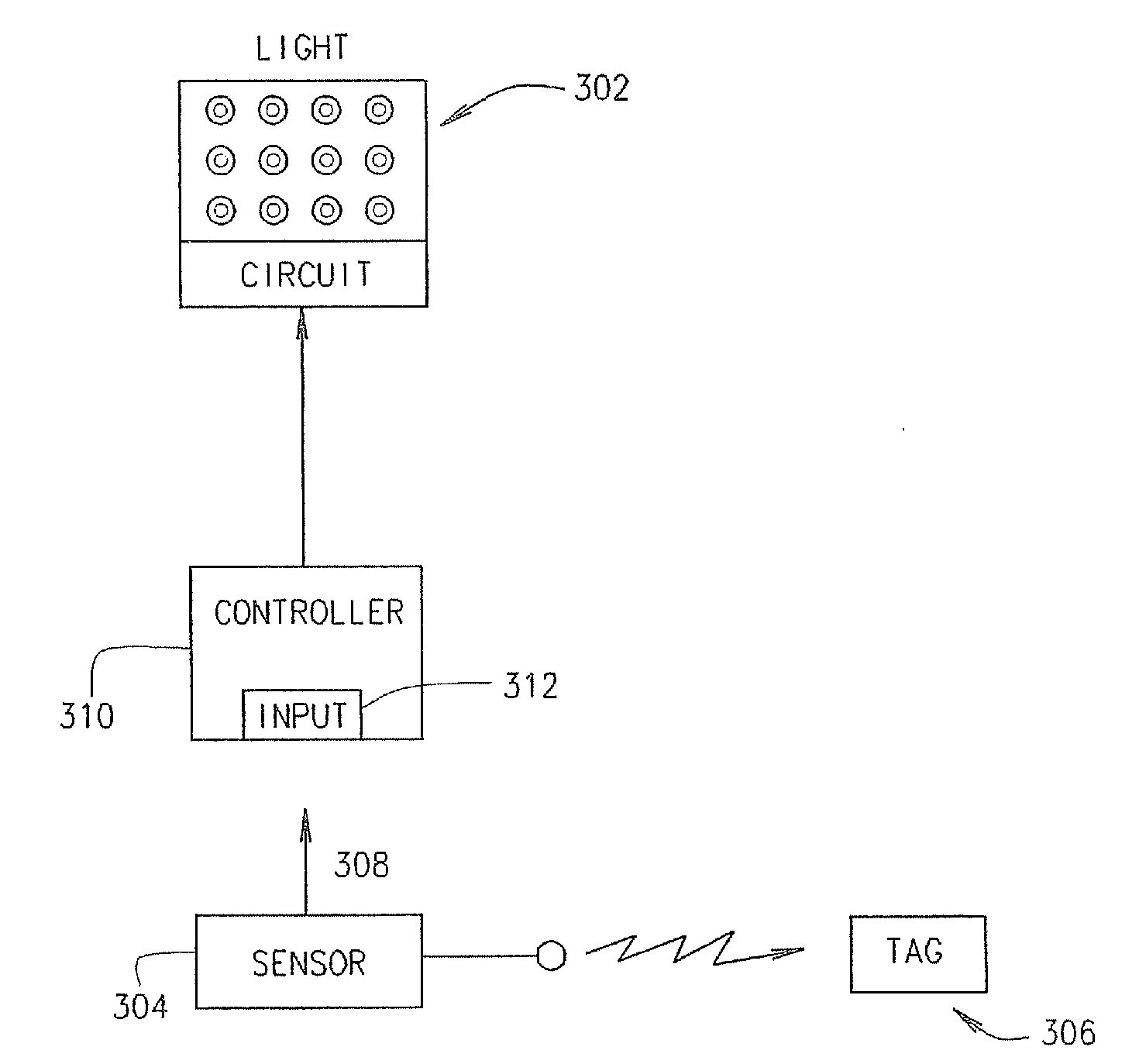

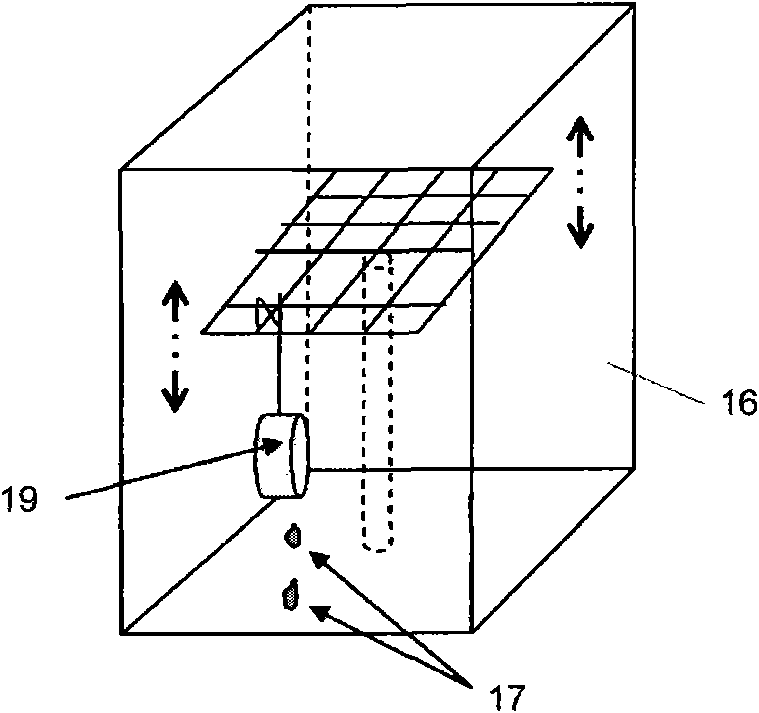

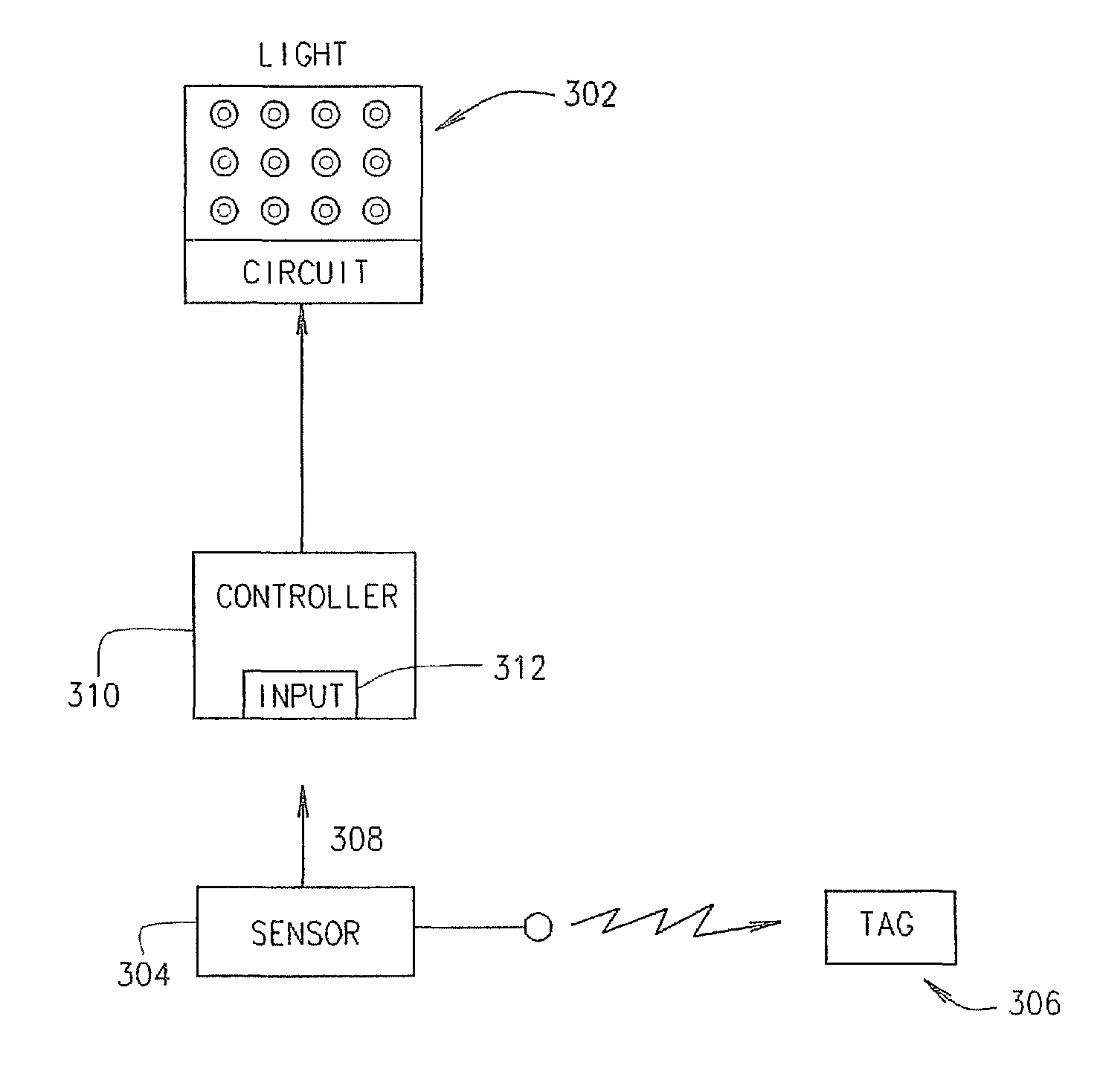

Adjustable lighting for displaying products

InactiveUS20080012722A1Reduce power consumptionStable and controllableElectric signal transmission systemsElectroluminescent light sourcesRed meatUltrasonic sensor

A system and method for controlling a variable light source where a variation in the light source can be triggered by utilizing a product identifier, such as for example RFIDs associated with the product being displayed to tell the controller to control the variable display case lighting to vary its color / intensity to change the lighting to best showcase the product; or utilizing UPC codes, scanned using a handheld device to accomplish the same objective; or utilizing motion / infrared / ultrasonic sensors particularly when lighting is to be turned off to conserve on power consumption. For example, red meat and poultry each may require their respective different lighting to be best displayed; thus red meat products may have a different RFID than poultry items; and gold jewelry items may have a different RFID than sterling silver jewelry items.

Owner:WALMART APOLLO LLC

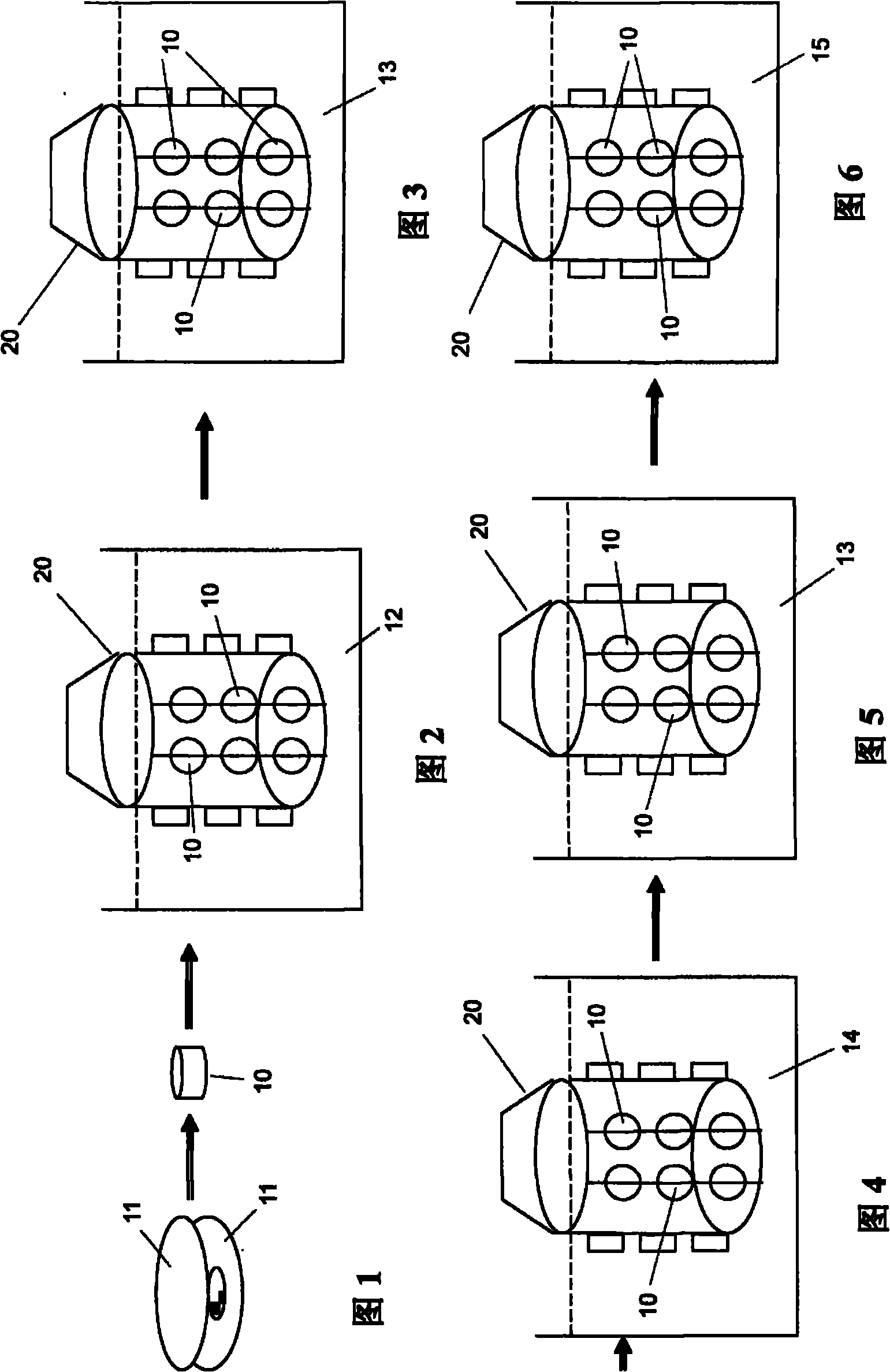

Technical for manufacturing jewelry by using hard gold

InactiveCN101810387AHigh hardnessIncrease elasticityJewelleryElectroforming processesManufacturing technologyEngineering

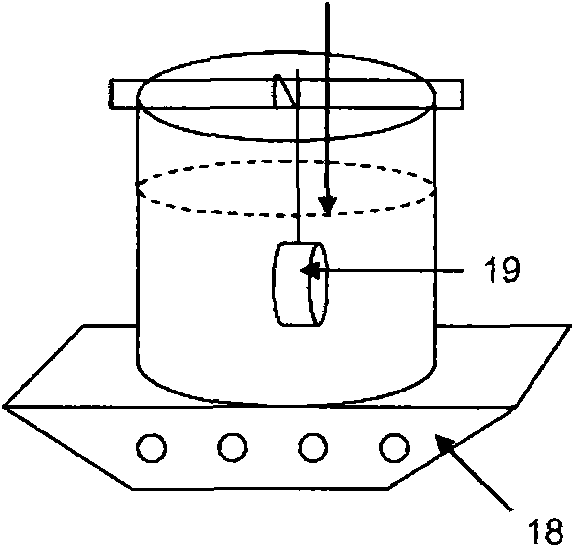

The invention provides a process for manufacturing jewelry by using hard gold. The technique mainly comprises the following steps of: 1, molding; 2, opening a jelly mould; 3, injecting wax; 4, trimming the wax; 5, applying silver oil; 6, manufacturing a raw blank; 7, removing the wax; 8, removing silver; 9, welding; 10, modifying the mould; 11, picking stones and embedding stones; 12, treating the surface; and 13, carving by laser. The method ensures that the molecular structure of gold changes by utilizing hard gold jewelry manufacturing technology and applying the metal reinforcing technology in aerospace science and technology to jewelry manufacture and adjusting temperature, pH value, current, pulse power supply, additive and other technical parameters of electrotyping solution in an electrotyping process, thereby effectively improving the hardness and the elasticity of the gold. On the premise of ensuring the purity of the gold, the hardness of the gold is 4 times that of the traditional gold, so that the technique requirements of the fashion jewelry design are met. The gold jewelry and art decorations manufactured by the method cannot be easily scratched or deform, so that the artistic quality of the jewelry and decorations can be greatly improved.

Owner:惠州市博艺黄金珠宝有限公司

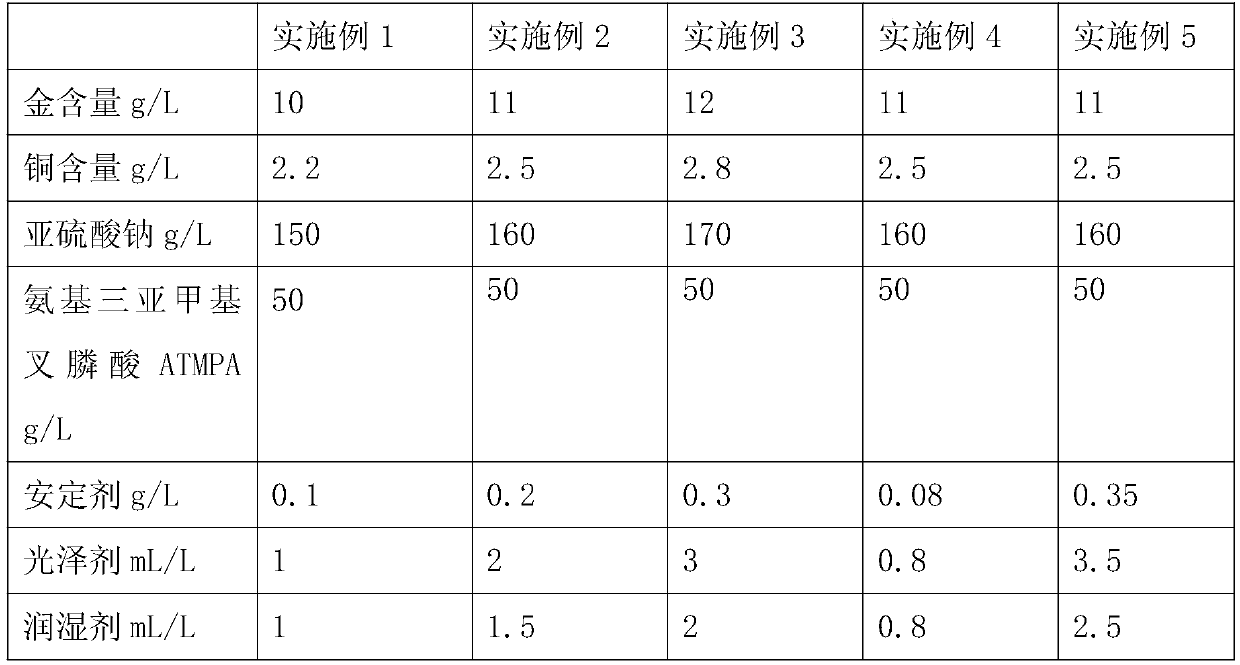

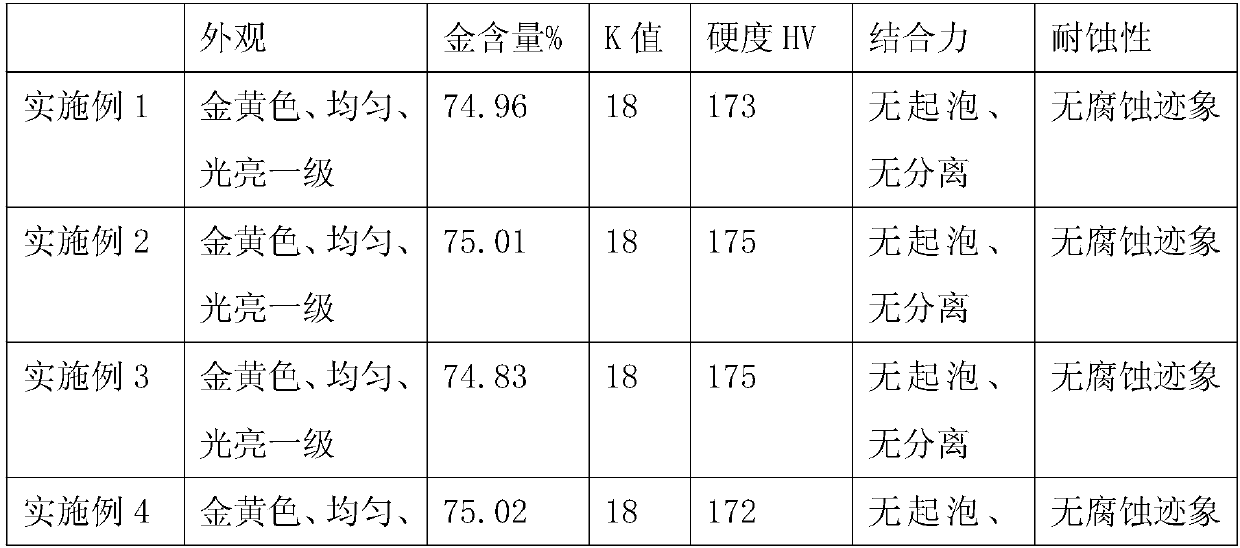

Formulation of electroforming solution, preparation method of electroforming solution and process control condition of electroforming solution

The invention relates to a formulation of a BT48 hard gold electroforming solution, a preparation method of the electroforming solution and a process control condition of the electroforming solution. The BT48 hard gold electroforming solution is prepared by using a novel formulation, a novel preparation method and a novel process control condition. According to the technical scheme of the invention, electroformed 999 pure gold jewelry has the characteristics that: the hardness is up to HV100, the surface is smooth, the thickness is smaller than that of the prior jewelry, and the mass is 60 to 70 percent of that of the prior jewelry of the same volume, so a client can spend less money on the 999 pure gold jewelry of the same shape. In addition, the raw materials of formulation can be purchased easily, so the production is more convenient.

Owner:SHENZHEN BATAR INVESTMENT HLDG GRP CO LTD

Method for manufacturing hard gold jewelry

The invention relates to a method for forming hard gold jewelry, which comprises the steps of: forming a mandrel made of low-melt materials, electrically plating a gold layer on the mandrel, electrically plating a copper layer on the gold layer, forming a hole penetrating through the electrical plating layers to reach the mandrel, melting the mandrel and ensuring that the mandrel is charged from one or more holes.

Owner:PINO ALIPRANDINI HK

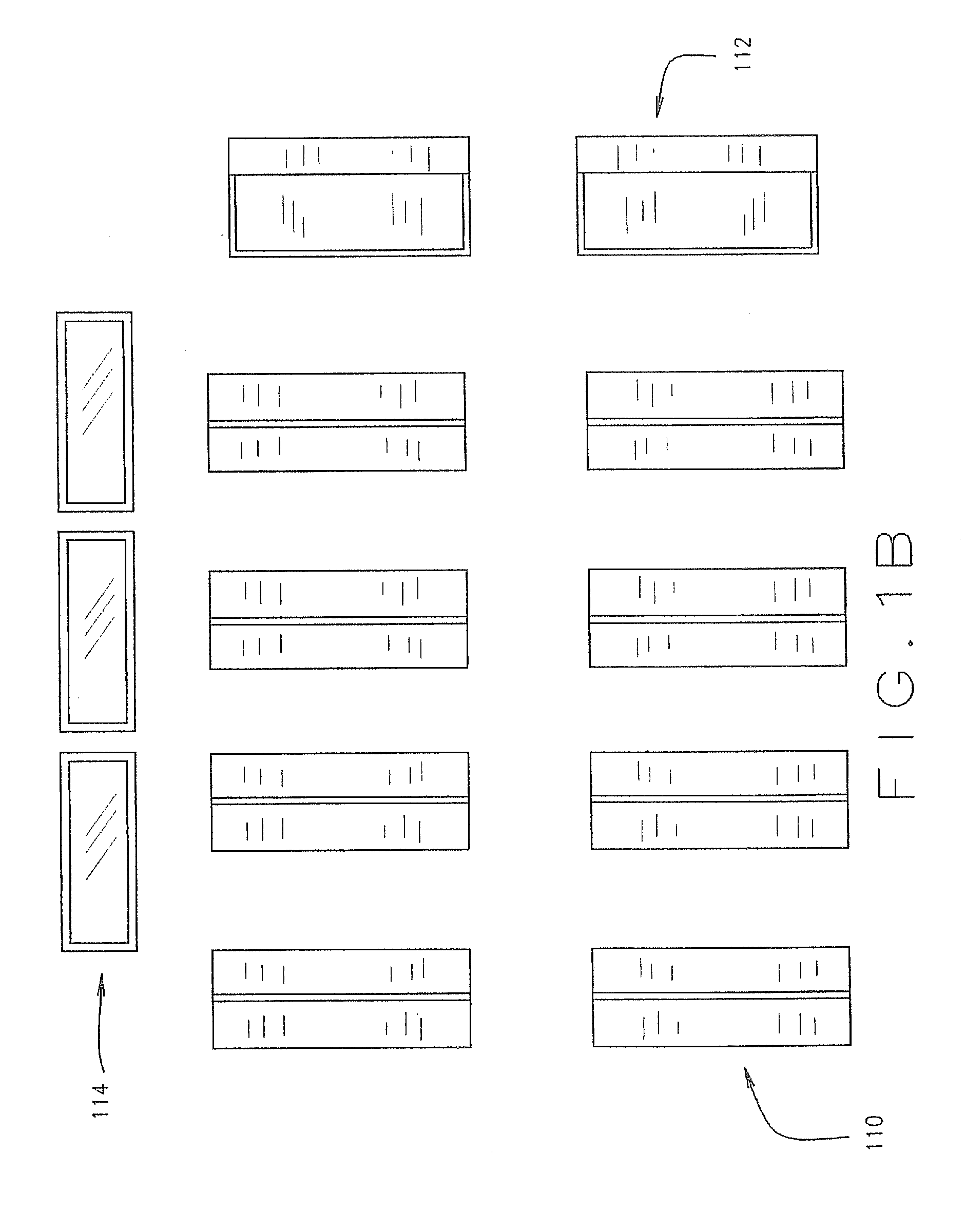

Adjustable lighting for displaying products

InactiveUS8248214B2Reduce power consumptionStable and controllableElectric signal transmission systemsElectroluminescent light sourcesUltrasonic sensorProduct Identifier

A system and method for controlling a variable light source where a variation in the light source can be triggered by utilizing a product identifier, such as for example RFIDs associated with the product being displayed to tell the controller to control the variable display case lighting to vary its color / intensity to change the lighting to best showcase the product; or utilizing UPC codes, scanned using a handheld device to accomplish the same objective; or utilizing motion / infrared / ultrasonic sensors particularly when lighting is to be turned off to conserve on power consumption. For example, red meat and poultry each may require their respective different lighting to be best displayed; thus red meat products may have a different RFID than poultry items; and gold jewelry items may have a different RFID than sterling silver jewelry items.

Owner:WALMART APOLLO LLC

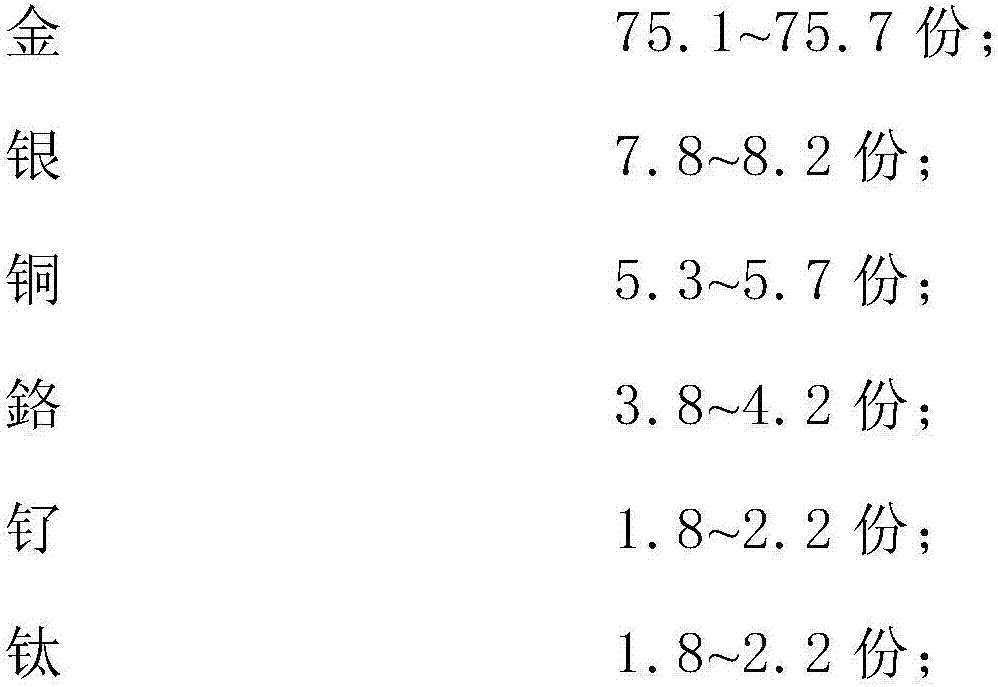

Microalloy strengthened hard pure gold and preparation method thereof

The invention provides a hard pure gold material for pure gold jewelry. The hard pure gold material is prepared from, by mass, 0.1-0.4% of calcium, 0.5-0.8% of titanium, 0.01-0.1% of rare earth elements and the balance gold, wherein the gold content is 99.0% or above. In the preparation process, by introducing the trace element calcium, a dispersed cluster structure is formed in a pure gold matrix, and the structure can effectively promote precipitation of a nano-scale gold titanic compound strengthening phase, so that the hardness and strength of the pure gold are greatly improved. The pure gold in the design is suitable for conventional jewelry processing processes and can be applied to various kinds of pure gold jewelry.

Owner:SHANGHAI QIJIU NEW MATERIAL TECH CO LTD

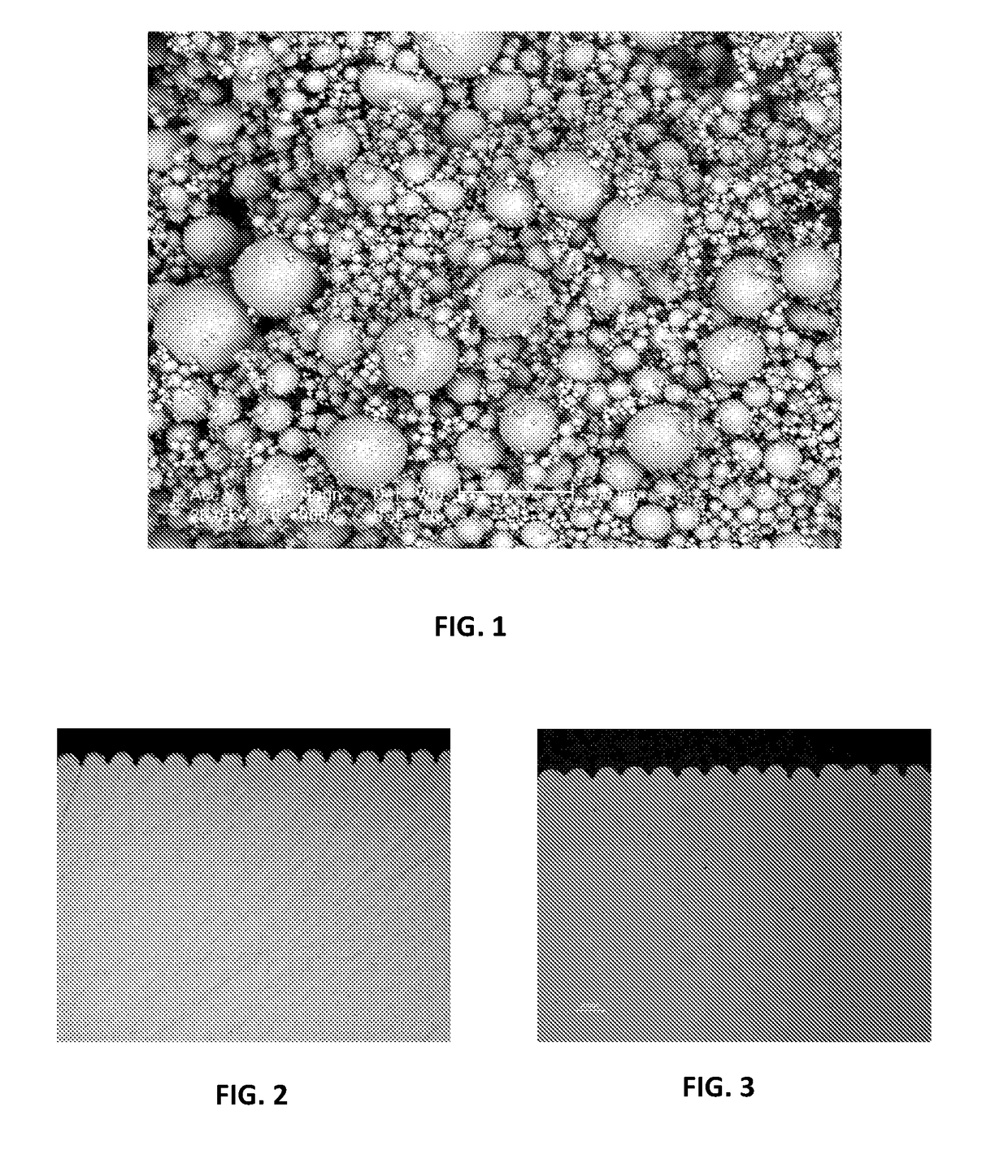

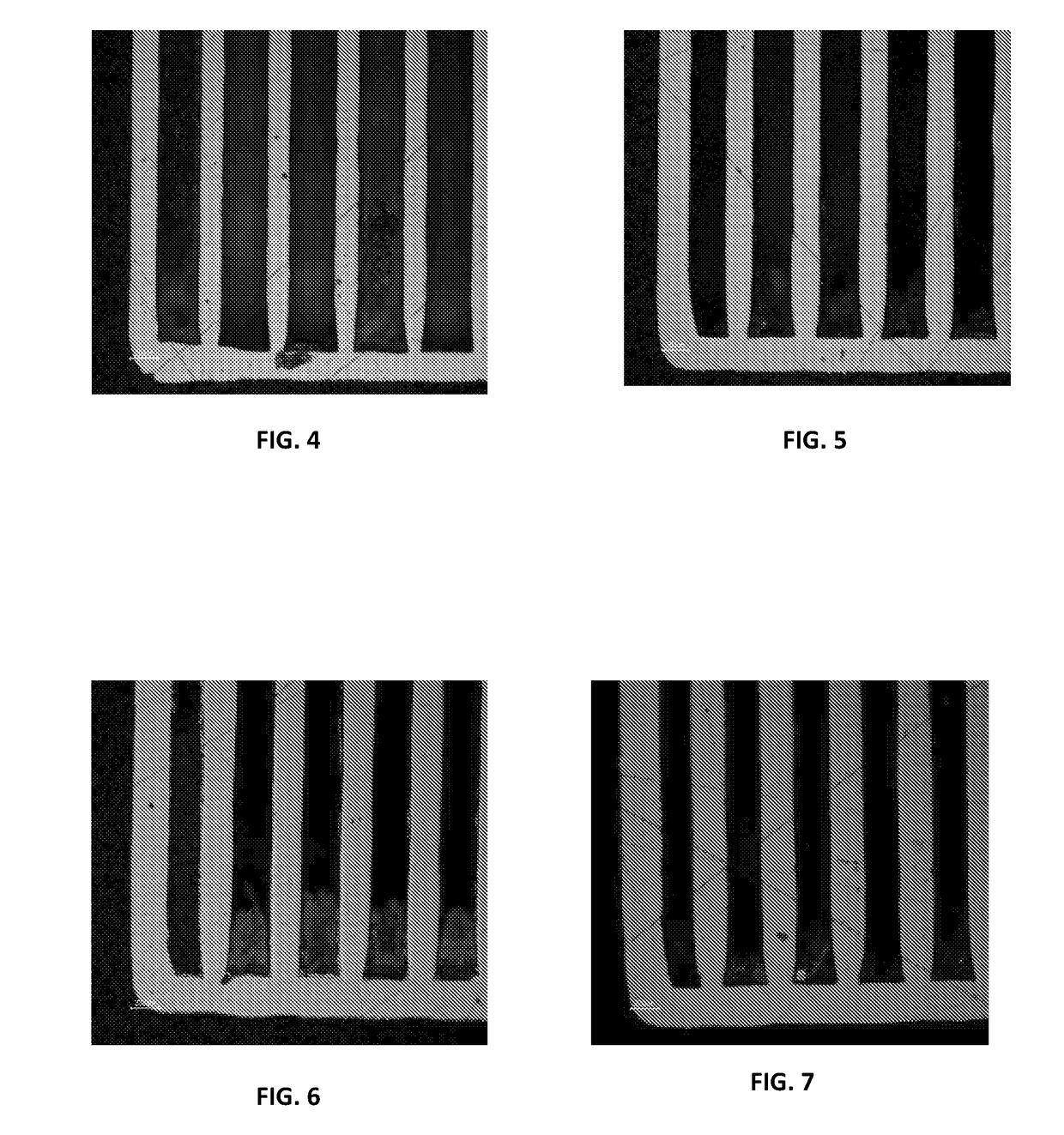

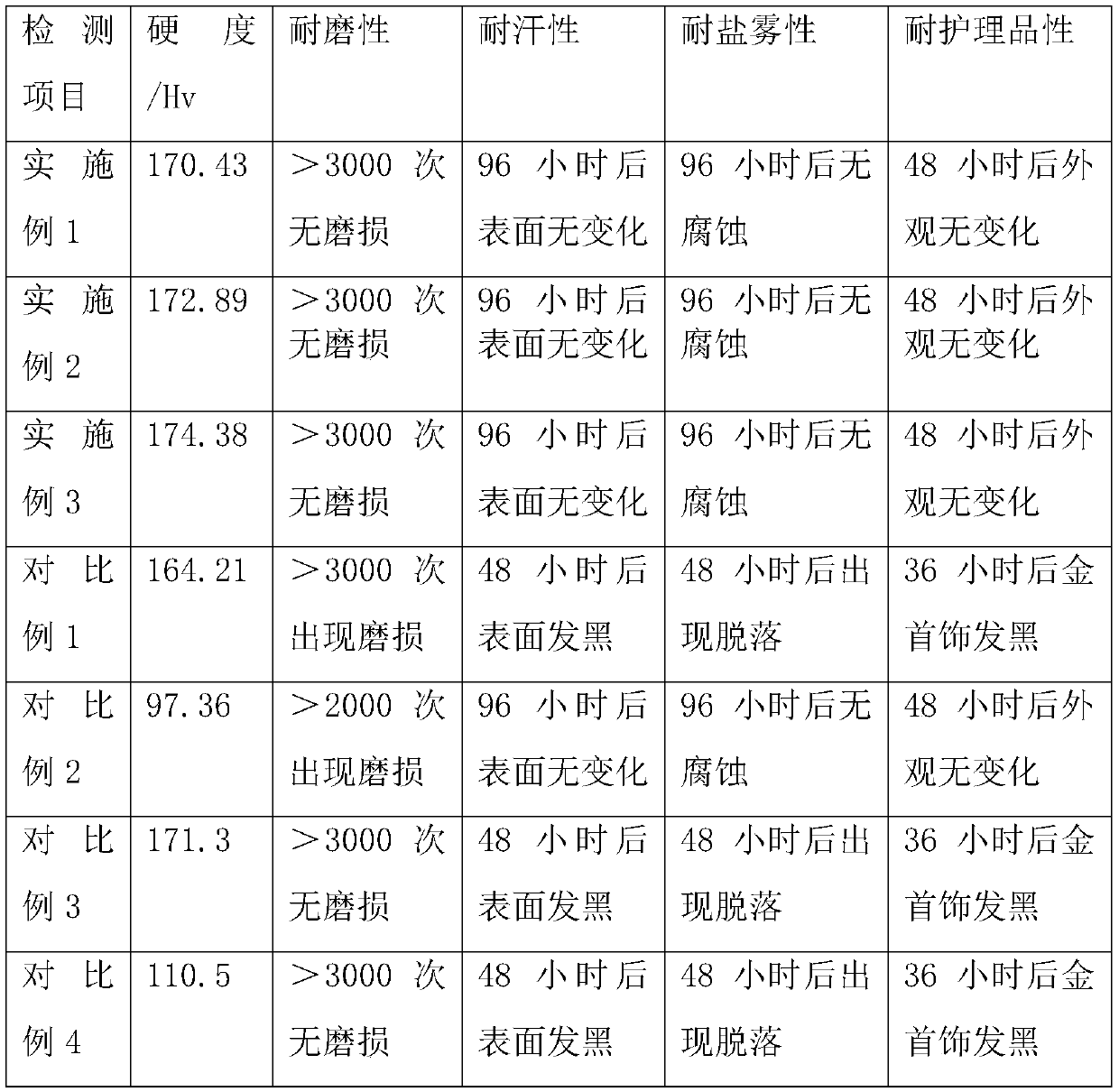

Use of gold powder alloys for manufacturing jewellery items by selective laser melting

ActiveUS20170164700A1Reduce percentageReduce the amount requiredAdditive manufacturing apparatusIncreasing energy efficiencyGold jewelrySelenium

A method of manufacturing yellow, red or white gold jewelry items layer by layer by selective laser melting (SLM) of a 18K, 14K, 10K or 9K gold powder alloy. The alloy comprises: (A) 37.5% to 38.5% by weight or 41.7% to 42.5% by weight or 58.5% to 59.5% by weight or 75% to 76% by weight of gold; and (D) 0.01% to 5% by weight, preferably 0.01% to 3% by weight of at least one metalloid, which may be germanium, silicon, boron, tellurium, phosphorous and selenium.

Owner:PROGOLD

Processing technology of reverse moulding gold jewelry with purity being 99.999%

The invention belongs to the field of jewelry processing, and in particular relates to a processing technology for molded gold jewelry with a purity of 999.99‰. The present invention pays attention to the cleanliness of the environment in the preparation process, and uses the steel used in the process , Iron tools are replaced with diamonds, special tools, to avoid the reaction with the gold material, resulting in the loss of the purity of the gold material, and the gold jewelry with a purity of 999.99‰ is obtained, which greatly improves the quality, purity and ornamental value of the gold jewelry. user experience.

Owner:SHANDONG ZHAOJIN GOLD & SILVER REFINERY

Processing technology of gold jewelries

The invention discloses a processing technology of gold jewelries, and relates to the technical field of jewelry processing. The processing technology of the gold jewelries comprises the following steps of S1, sheeting; S2, melting; S3, removing nitrate; S4, exhausting air; S5, washing chlorine; S6, preparing sodium gold sulfide; S7, regulating pH; S8, regulating stability; S9, blanking and pouring mold; S10, electroplating: during electroplating, selecting a ruthenium iridium titanium mesh as the anode, wherein electroplate liquid comprises the following components by mass concentration: 20-50g / L of electroforming liquid prepared in the step S8, 25-45g / L of a plating bath agent, 40-100g / L of a complexing agent, 20-70g / L of a hardening agent and 30-50g / L of a brightening agent; and S11, demoulding. The processing technology of the gold jewelries adopts a cyanide free production technology, and the product has good toughness, is not easy to break, and has light weight and high hardness.The technology is advanced, so the processed gold jewelries have the advantages of high hardness, good wear resistance, high gloss and long-lasting gloss.

Owner:深圳市金久缘珠宝有限公司

Processing process of chain type gold jewelry with purity of 99.999%

The invention belongs to the field of jewelry processing, and in particular relates to a processing process of chain type gold jewelry with purity of 99.999%. The processing process comprises the steps of melting raw material gold, cutting, polishing, forming chains, polishing, nailing and sanding, embroidering, forming chains, electroplating and detecting quality. The environmental cleanliness is emphasized in the preparation process, and the steel and iron tools used in the technological process are changed into diamond special tools, so that loss of gold material purity caused by reaction with the gold material is avoided, the gold jewelry with purity of 99.999% is prepared, the quality, the purity and the ornamental value of the gold jewelry are greatly improved, and the user experience is improved.

Owner:SHANDONG ZHAOJIN GOLD & SILVER REFINERY

Manufacturing method of 18K gold and 18K gold jewelry

The invention discloses a manufacturing method of 18K gold and 18K gold jewelry. The manufacturing method comprises the following steps of (a) preparing raw materials according to metal components of the raw materials and the weight part ratio of the metal components; (b) smelting the raw materials under the protection of inert gases; (c) pouring molten liquid metal to a forming die under the protection of inert gases, and casting so as to form a blank; (d) repairing the blank so as to prepare semi-finished jewelry; (e) electroplating the semi-finished jewelry, so that the external color of the semi-finished jewelry returns to be golden; and (f) performing surface treatment on the electroplated semi-finished jewelry so as to form finished jewelry. According to the manufacturing method of the 18K gold jewelry, smelting is performed by adopting the metal components and matching of the raw materials, and finally, electroplating treatment is performed, so that the color of the surface of the prepared 18K gold jewelry is the same as that of gold, the surface of the prepared 18K gold jewelry is difficult to decolor, and the prepared 18K gold jewelry has the advantages of elasticity, difficulty in deformation and high hardness.

Owner:SHENZHEN FUQI JEWELRY

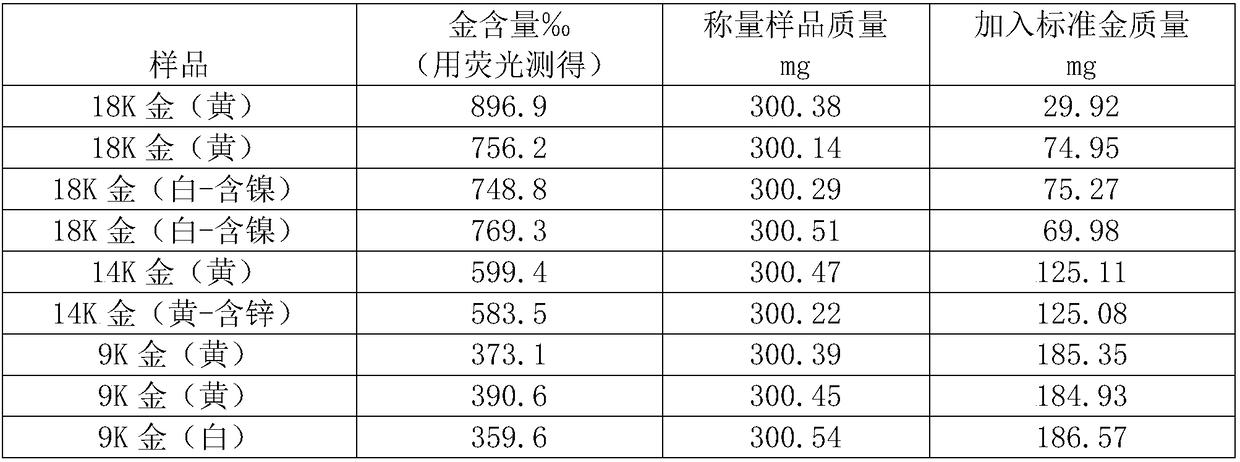

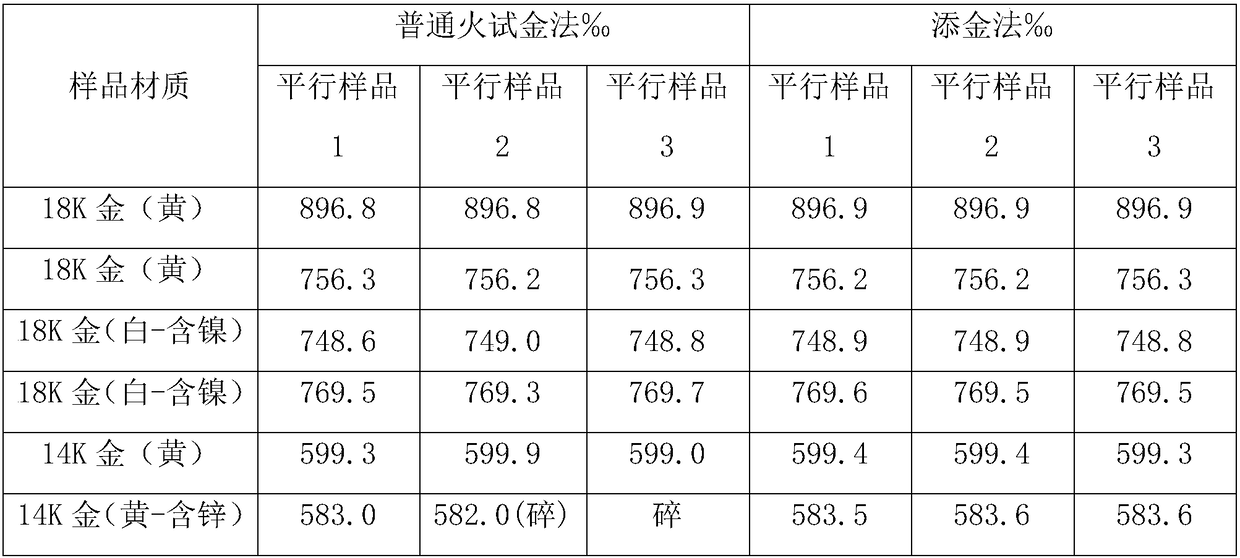

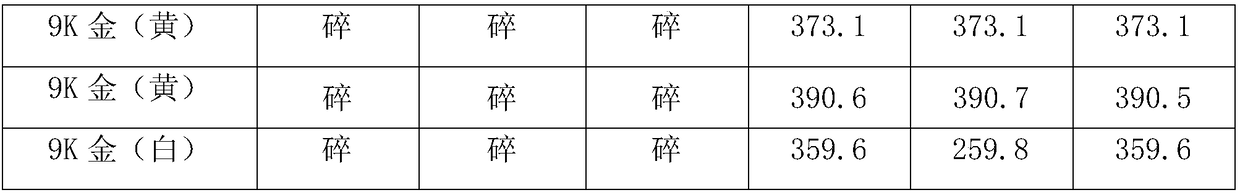

Method for detecting gold content in K gold jewelry by fire assaying gold-adding method

PendingCN108562512AImprove toughnessImprove accuracyMaterial analysis using wave/particle radiationMaterial weighingSuccessful completionGold content

The invention relates to a method for detecting gold content in K gold jewelry by a fire assaying gold adding method. The method comprises the following steps: adding proper amounts of gold and silverto a sample, using lead as a collecting agent, oxidizing and cupelling in a porous cupel, absorbing lead oxide and impurities by the cupel, smelting the retained gold and silver to obtain precious metal balls, rolling into slices and rolling up into small rolls, placing into nitric acid, and gradually dissolving silver to obtain the mass of gold. By the gold-adding method, accuracy of the experiment and parallelism of the data can be greatly enhanced, convenience is brought to daily precious metal jewelry detection work, and smooth and successful completion of the detection work is guaranteed.

Owner:华津国检(深圳)金银珠宝检验中心有限公司 +1

Gold jewelry processing technology

The invention discloses a gold jewelry processing technology which includes following steps: 1) gold melting: burning gold in a high-temperature-resistant quartz crucible on acetylene fire to smelt the gold into a single material being suitable for processing jewelry; 2) mould pouring: melting the gold material with a high-frequency or medium-frequency centrifugal pouring machine and pouring the molten god material into a gypsum to form a casting; 3) polishing: polishing the surface of the casting with a magnetic polishing machine or a cylinder polishing machine; 4) mould finishing: welding, filing and hammering the casting with a swage iron to shaping the deformation and crude surface of the casting; 5) press-polish: contacting the gold surface and rubbing the workpiece with an agate pen to glossing the surface of the workpiece; 6) pattern lathing: sculpturing patterns on the surface of the product with a pattern lathe mounted with a diamond pattern lathing cutter; and 7) inspection and finished product storage in storerooms. The gold jewelry processing technology is simple to carry out. Gold jewelry produced through the technology is high in glossiness. The technology saves cost for manufacturers and can satisfy consumer demand.

Owner:卢家雄

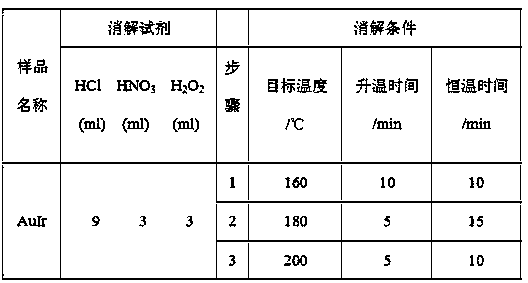

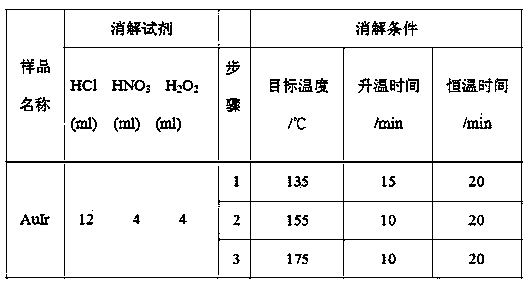

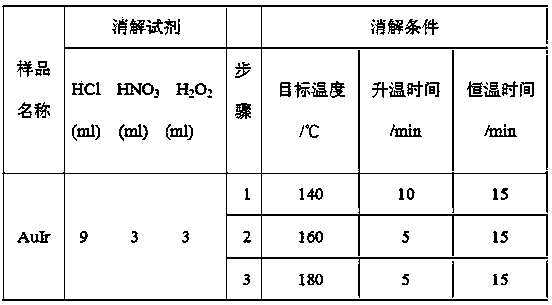

Method for determining content of Ir in gold jewelry by microwave digestion ICP-AES (Inductively Coupled Plasma-Atomic Emission Spectrometry)

InactiveCN104075933AFully digestedDetermination of complete digestion by inductively coupled plasma optical emission spectrometerPreparing sample for investigationAnalysis by thermal excitationOptical emission spectrometrySolvent

The invention relates to a method for determining the content of Ir in gold jewelry by microwave digestion ICP-AES (Inductively Coupled Plasma-Atomic Emission Spectrometry). The method comprises the following steps: preparing a digestion reagent, performing digestion step by step, testing by an ICP-AES instrument, drawing a standard curve, and testing in parallel according to the steps to obtain an average value. The method for determining the content of Ir in gold jewelry by microwave digestion ICP-AES takes HNO3, HCl and H2O2 as solvents and adopts step-by-step digestion, so that the Ir dissolving rate is high, and the complete digestion of a sample is achieved; the method is applied to practice, and obtains a satisfied result.

Owner:NAT GOLD & DIAMOND TESTING CENT

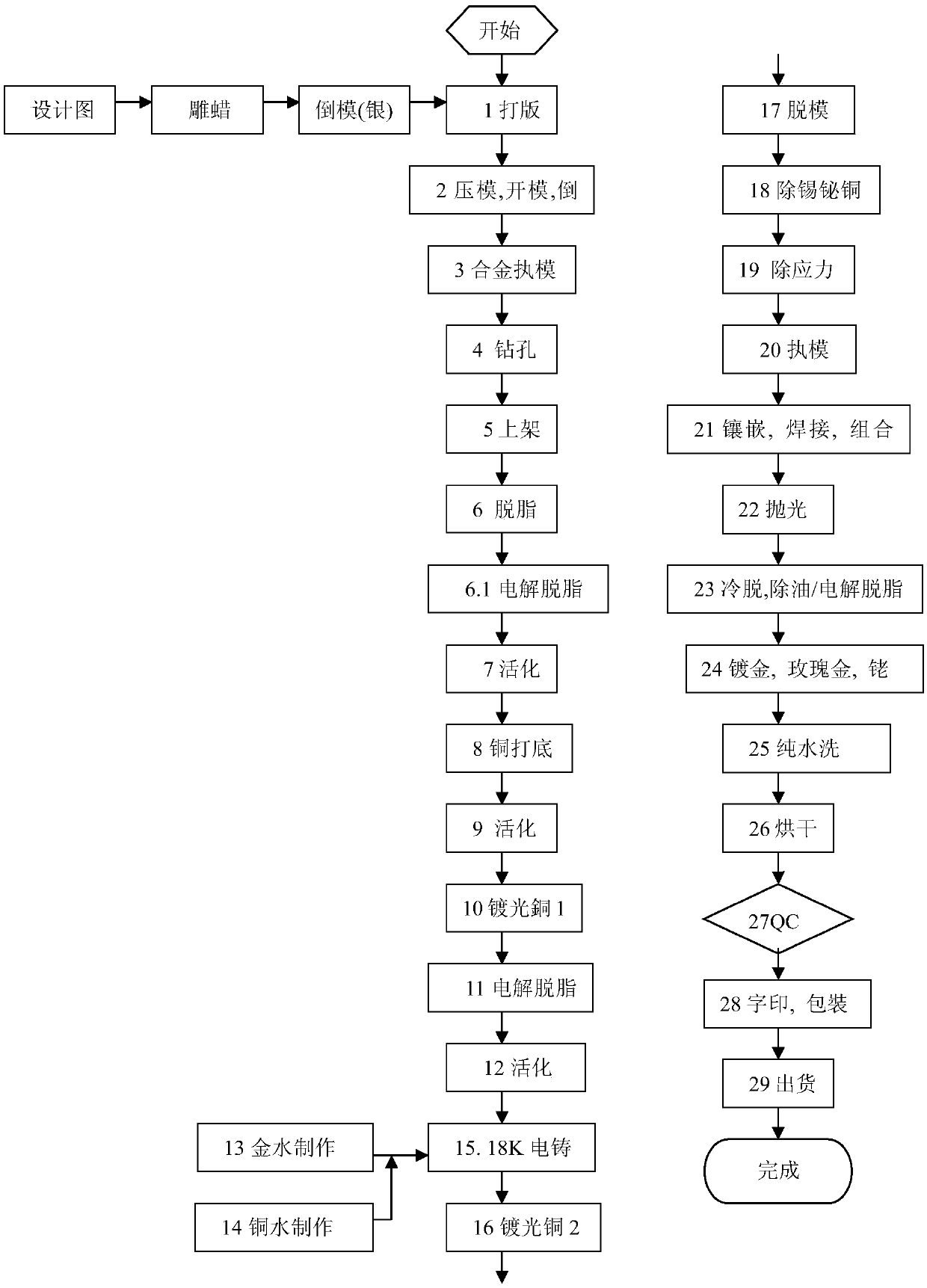

Preparation method for cyanide-free 18 k gold jewelries

The invention discloses a preparation method for cyanide-free 18 k gold jewelries. The preparation method comprises the steps of plate making, mold pressing, opening and reversing, alloy mold carrying, drilling, loading, degreasing, primary activation, copper bottoming, secondary activation, gloss copper 1 plating, electrolytic degreasing, ternary activation, gold water preparation, molten copperpreparation, 18 k electroforming, gloss copper 2 plating, demolding, tin bismuth copper removal, distressing, mold carrying, embedding, welding, combination, polishing, cooling, deoiling, electrolyticdegreasing, gold plating, pure water washing, drying, quality inspection, character printing, packing and delivery in sequence; and then, the cyanide-free 18 k gold jewelries are obtained. The preparation method is simple in process and easy to operate, obviously improves the jewelry quality, reduces the gold loss, and contains no cyanide-contained poisonous substance in the preparation process to achieve environmental protection and safety; the hardness and the toughness of the 18 k gold jewelries are prominently improved to preferably guarantee the stability of the jewelries in the wearingprocess; and further, electroforming liquid is excellent in stability, dispersibility and deep plating capacity, can be prepared beforehand for future use, and improves the production efficiency.

Owner:NANJING INST OF PROD QUALITY INSPECTION

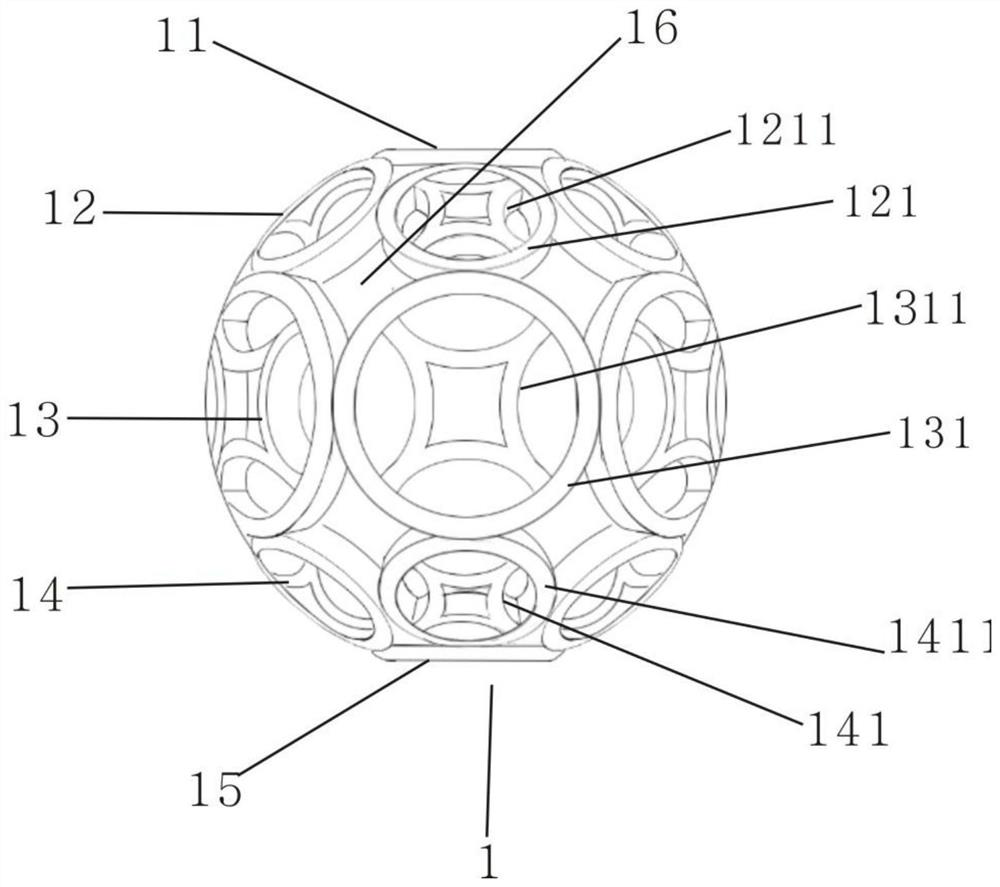

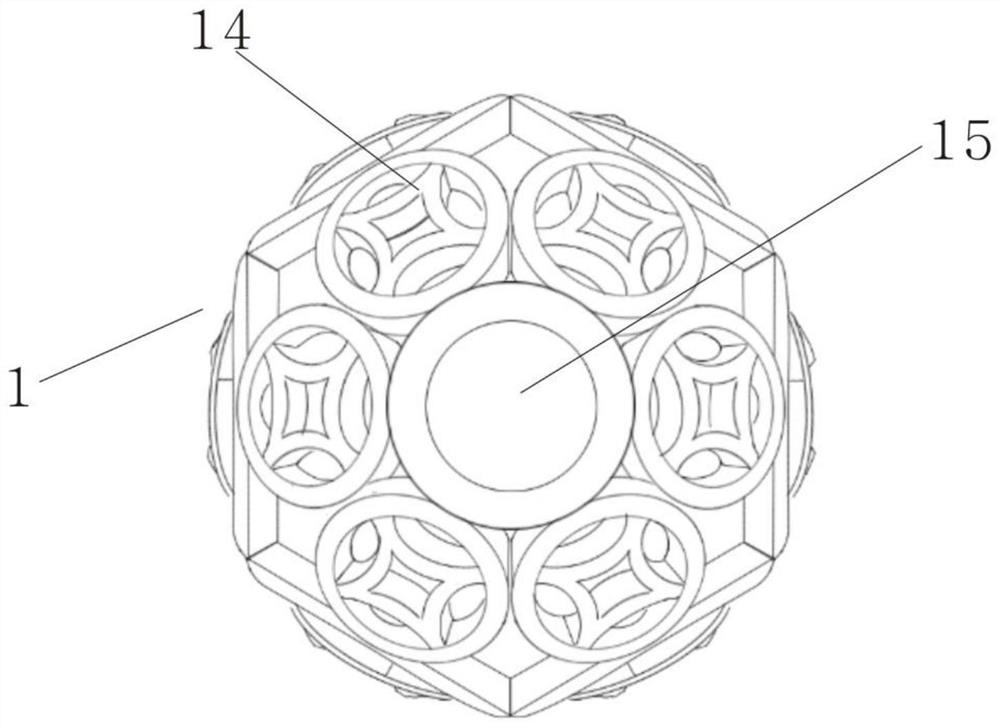

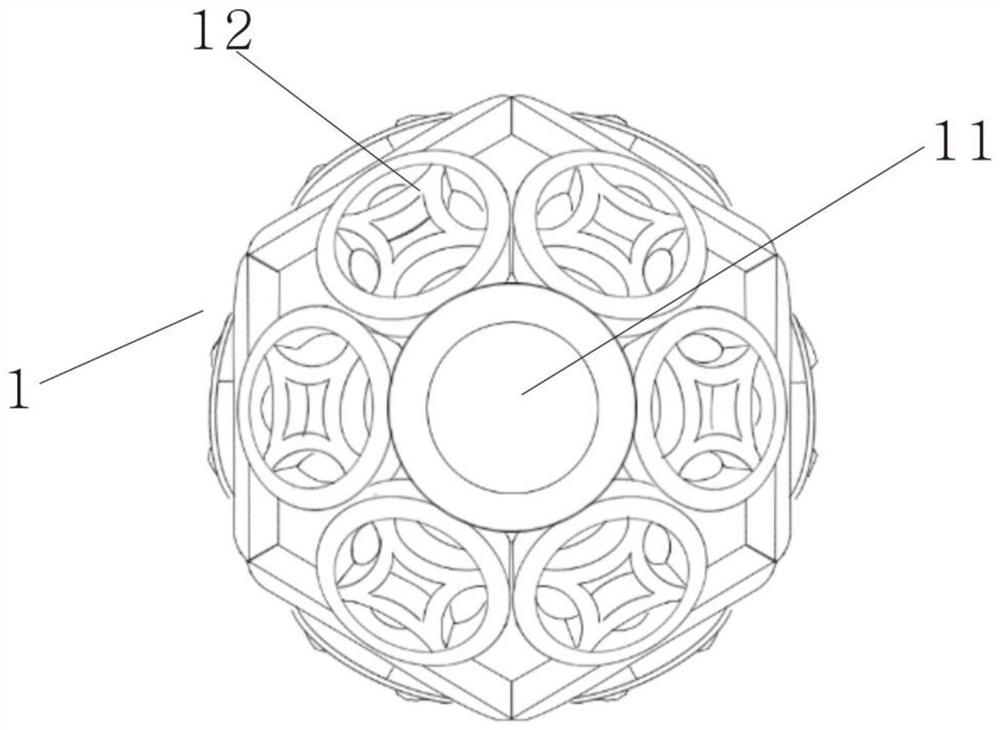

Integrally electroformed hard gold jewelry and manufacturing method thereof

PendingCN111657642AOvercome the problem of small hardnessHigh hardnessJewelleryElectroforming processesGold jewelryMaterials science

The invention discloses an integrally electroformed hard gold jewelry and a manufacturing method thereof, belongs to the technical field of jewelries, and particularly relates to an integrally electroformed hard gold jewelry and a manufacturing method thereof. The jewelry comprises an outer container and an inner container, the outer container is provided with a containing cavity, and the inner container is arranged in the containing cavity and fixedly connected with the outer container. Compared with the prior art, firstly, integrated electroforming is adopted for one-time forming, the problem that the pure gold is small in hardness is solved, and the pure gold has the advantages of being high in purity and hardness, secondly, the structure of the inner container and the outer container is adopted, the internal space of the outer container is reasonably utilized, and the structure of the product is more stable, thirdly, the outer container structures are fixedly connected in a pairwise tangent mode, so that the product structure has beneficial stability and finally, welding is not needed in the manufacturing process, and the problem that large-area welding cannot be achieved in the hard gold jewelry manufacturing process is solved.

Owner:曹株源

K-gold jewelry cyanogen-free electrolytic polishing solution and electrolytic polishing method thereof

The invention discloses a K-gold jewelry cyanogen-free electrolytic polishing solution and an electrolytic polishing method thereof, the polishing solution is a water solution with the following material proportion: 50 to 150g / L of thiourea, 3 to 15ml / L of sulphuric acid or 20 to 50ml / L of phosphoric acid or 20 to 50g / L of tartrate. The invention has the advantages of no need of using potassium cyanide, thus being non-toxic, and also no need of uniformly managing recycled waste liquid intensively by related government departments, thus being environment-friendly and safe; the waste liquid can be easily recycled and can be repeatedly used; medicines used by the method and the polishing solution have low cost and are easily purchasable, and need not to be examined and approved by related government and public security departments, and the method and the polishing solution are easy to be popularized; and the method and the polishing solution can be widely used for removing black layers on gold and white gold from 10K to 24K or red K-gold.

Owner:谢良和

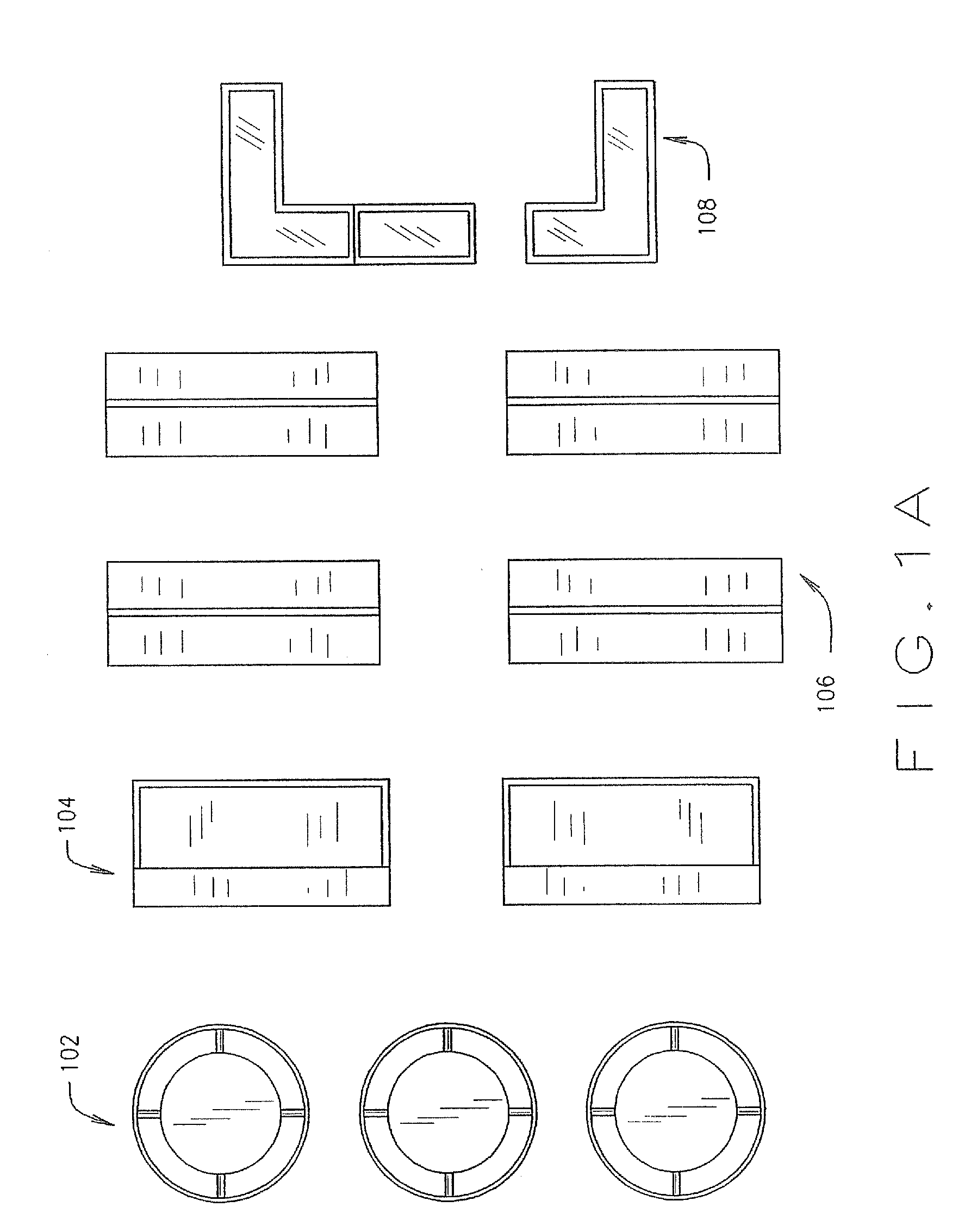

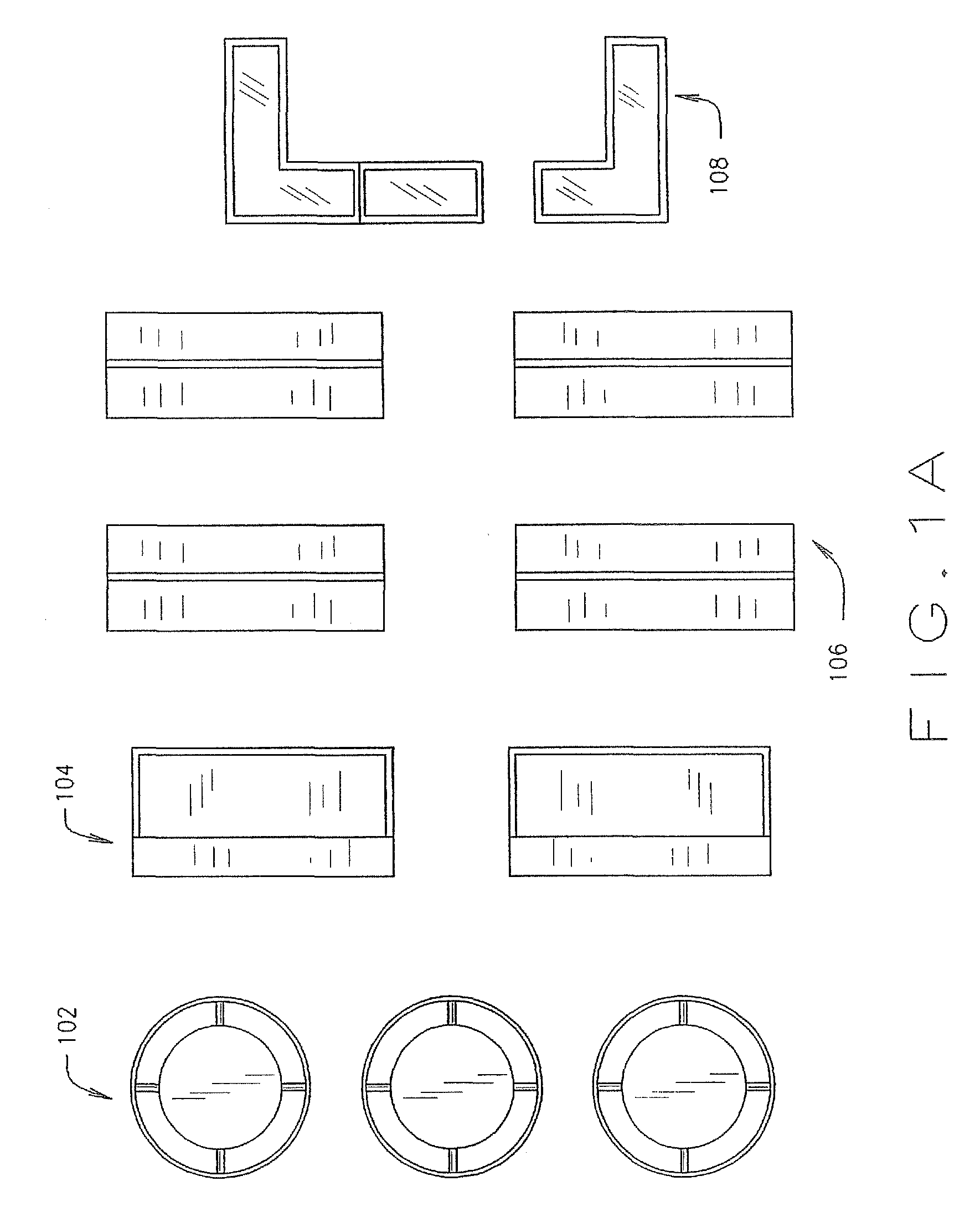

Processing process for phantom gold or karat gold jewelry

ActiveCN104738921ABeautiful light and shadow effectNew aesthetic connotationJewelleryLight irradiationGold jewelry

The invention relates to the technical field of metal jewelry processing, and in particular relates to a processing process for phantom gold or karat gold jewelry. The processing process for processing the phantom gold or karat gold jewelry can be used for bringing phantom effects on the jewelry and increasing the aesthetic property. The processing process comprises the following steps: (A) dissolving a gold raw material or a karat gold raw material at a high temperature, and cooling gold or karat gold through an oil slot under a required shape; (B) extruding the cooled gold or karat gold with the required thickness and width through a tablet press; (C) shaping the shape of the blank of the gold or karat gold through equipment; (D) fixing the shaped blank by a clamp, putting the shaped blank on a 5-axis CN machine tool, putting the 5-axis CNC machine tool on a horizontal zero-scale position; and (E) selecting a diamond cutter for the 5-axis CNC machine tool, setting the rotation speed of the diamond cutter to 400 revolutions per second to 500 revolutions per second, programming a program, and cutting the blank at an angle between 88 degrees and 120 degrees. The processing process has the beneficial effects that mirror surface effects are brought to the gold or karat gold, so that the jewelry has a shadow under the light irradiation.

Owner:ZHOU LIU FU JEWELRY CO LTD +1

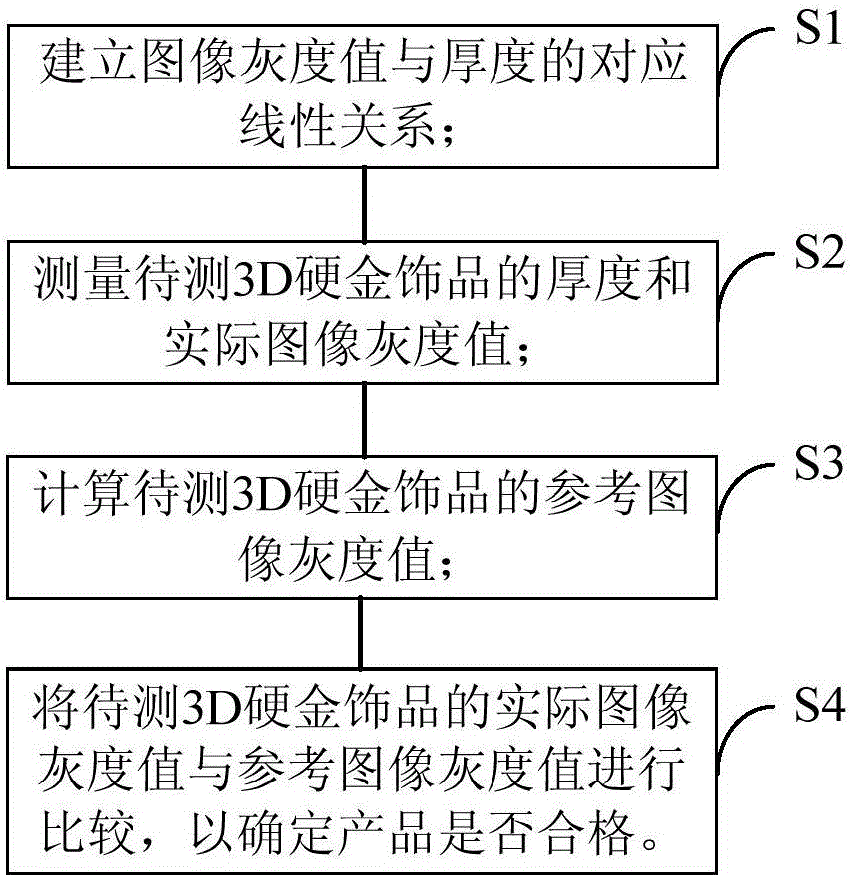

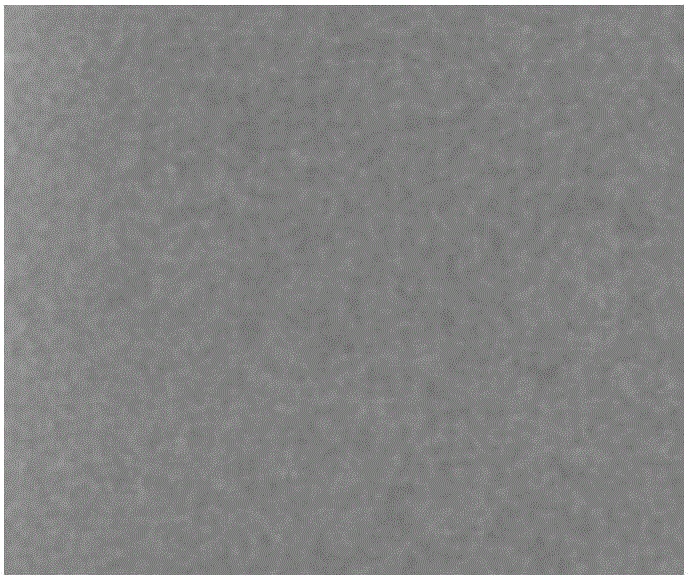

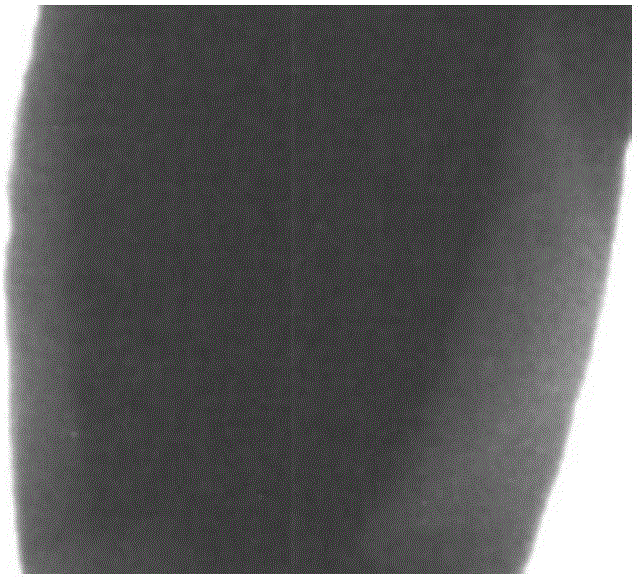

Method for detecting internal defects of 3D (Three-dimensional) hard gold jewelry based on X rays

InactiveCN106841241AAvoid the disadvantages of consumable materialsLow costMaterial analysis by transmitting radiationGold contentX-ray

The invention provides a method for detecting internal defects of 3D (Three-dimensional) hard gold jewelry based on X rays. The method comprises the following steps: S1, preparing multiple 3D hard gold samples of different thicknesses, respectively performing X-ray test on the samples by adopting an X-ray imagescope so as to obtain image gray values corresponding to the samples of different thicknesses under the same test condition, and establishing a linear function according to a corresponding relationship between the image gray values and the thickness; S2, measuring the actual thickness of to-be-detected 3D hard gold jewelry, and measuring through the X-ray imagescope so as to obtain an actual image gray value of the to-be-detected 3D hard gold jewelry; S3, calculating a corresponding reference image gray value under the actual thickness value according to the corresponding linear function relationship between the image gray value and the thickness; S4, comparing the actual image gray value of the to-be-detected 3D hard gold jewelry with the reference image gray value, wherein the product gold content is qualified if the relative difference value is less than or equal to 0.5%, otherwise the product is a suspicious defective product. According to the method, whether silver is included in the 3D hard gold jewelry can be preliminarily screened.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

Manufacturing method of gold jewelry composed of silver base inlaid with gold

The invention discloses a manufacturing method of gold jewelry composed of a silver base inlaid with gold. The gold jewelry at least comprises pendants, chain bracelets, anklets, bracelets, rings, earrings, ear studs, large necklaces and hairpins. The manufacturing method comprises the following steps of carving a carved pattern according to a design drawing, an outlet oil pressure cutting mold and upper and lower medium-pressure molds, carrying out oil pressure molding to obtain a gold statue, carrying out wax carving or silver sample plate manufacture according to a design drawing, carrying out gel mold pressing, carrying out wax injection, carrying out pouring reverse-molding to obtain a silver base, processing a gold statue-shaped groove in the silver base, putting the gold statue into the gold statue-shaped groove in the silver base, inserting pins into gold pinholes so that inlaying is finished, carrying out seamless welding so that assembling and fixing of the whole gold jewelry are finished, and carrying out acid treatment and brushing treatment on the surface of the gold jewelry. The manufacturing method can realize manufacture of elegant gold jewelry composed of the silver base inlaid with gold.

Owner:SHENZHEN JINYI CULTURE DEV

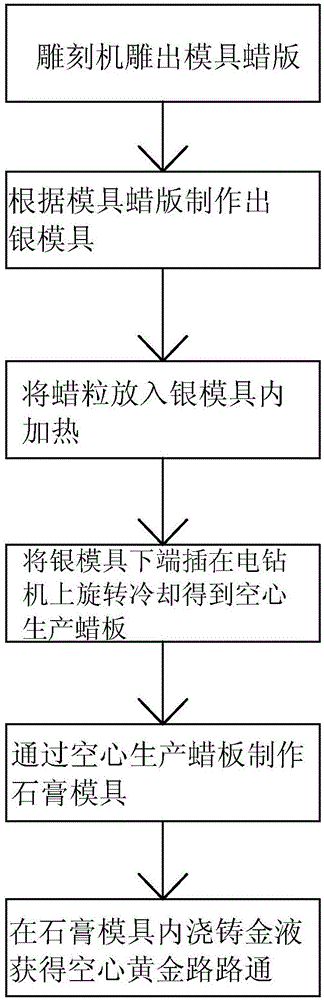

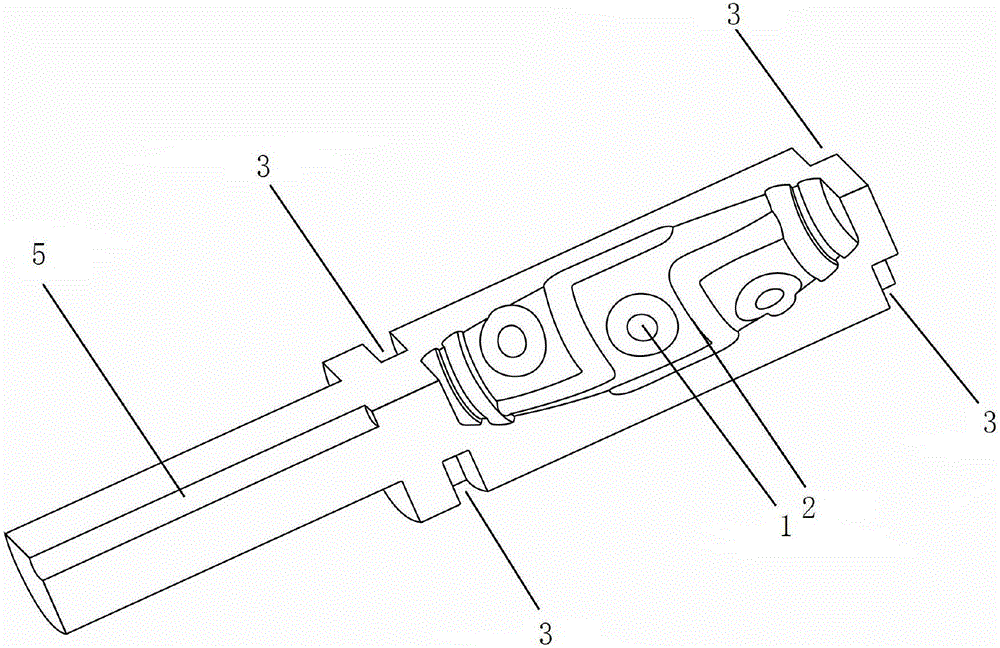

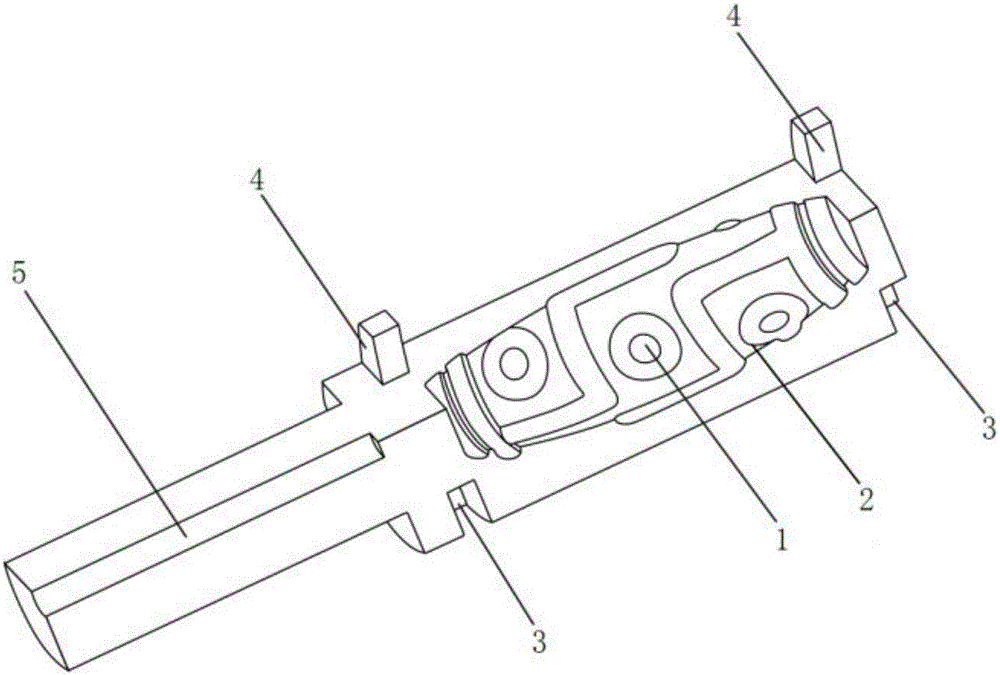

Hollow plain gold jewelry Lulu Tong manufacturing method

ActiveCN106424587AIncreasing the thicknessComplete appearanceFoundry mouldsFoundry coresWaxCentrifugal force

The invention discloses a hollow plain gold jewelry Lulu Tong manufacturing method. The hollow plain gold jewelry Lulu Tong manufacturing method comprises the following steps of: firstly carving a mold wax block by using a carving machine; manufacturing a corresponding silver mold by using the mold wax block; putting wax granules weighed out in the lockable silver mold and heating the silver mold; then clamping the heated silver mold on an electrical drilling machine and rotating the silver mold, uniformly distributing molten wax liquid on the inner wall of the silver mold by using rotating centrifugal force, and cooling the silver mold to obtain a hollow Lulu Tong production wax block; then putting the hollow production wax block in gypsum to manufacture a gypsum mold with a pouring gate; and finally pouring liquid gold into the gypsum mold after heating the gypsum mold and vaporizing the hollow production wax block, cooling the mold and clearing out the gypsum to obtain the hollow gold Lulu Tong. Due to adoption of the above mode, the hollow plain gold jewelry Lulu Tong manufacturing method has the beneficial effects that the hollow plain gold jewelry Lulu Tong manufacturing method can cause a production flow to be relatively simple and products to have uniform thickness and complete appearance; the weight of the products can be customized by controlling the weight of the production wax block according to the difference of weight of customized products; and the manufacturing method is convenient to operate, reduces production cost and improves production efficiency.

Owner:SUZHOU DONGWU GOLD CULTURE DEV

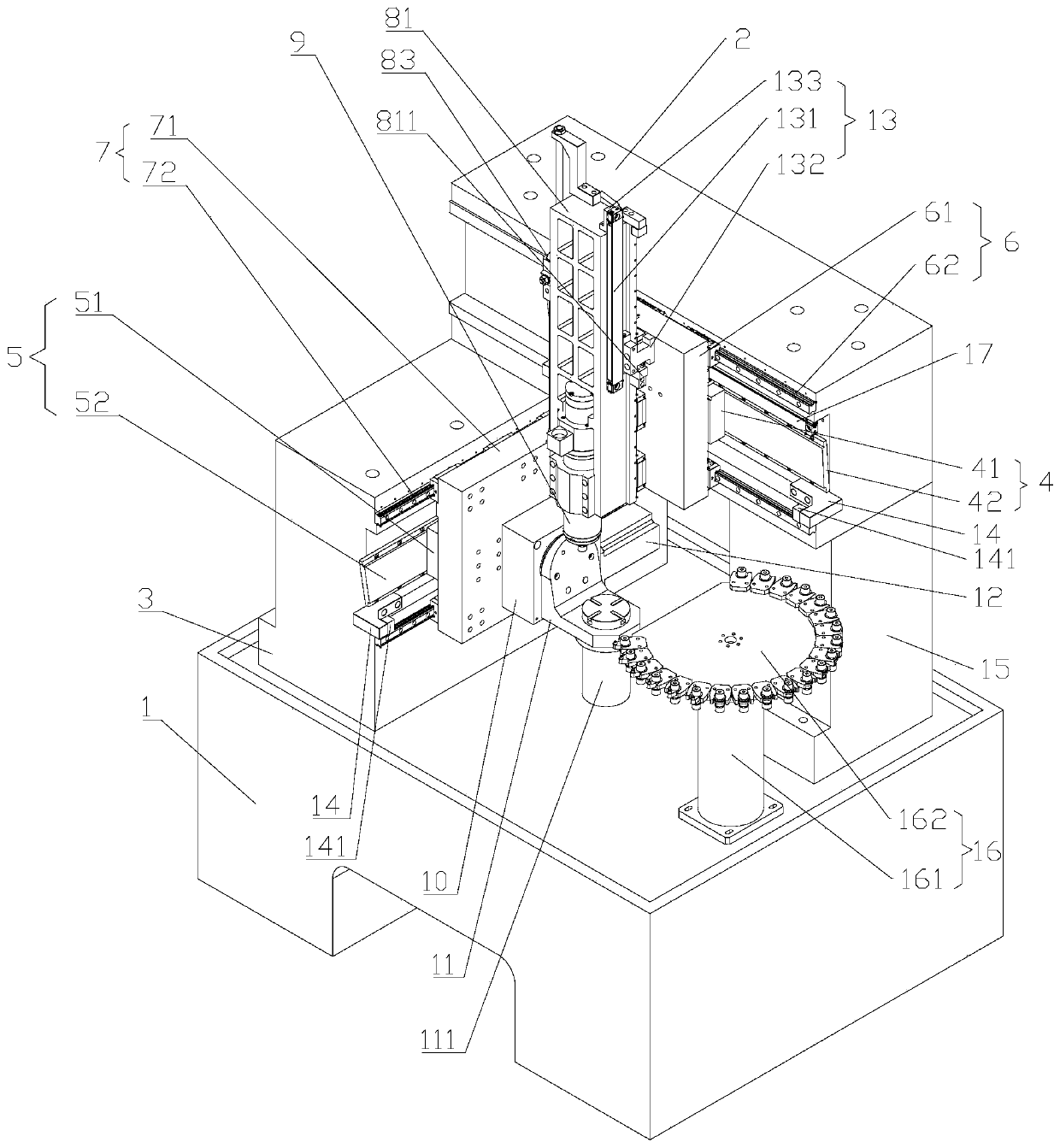

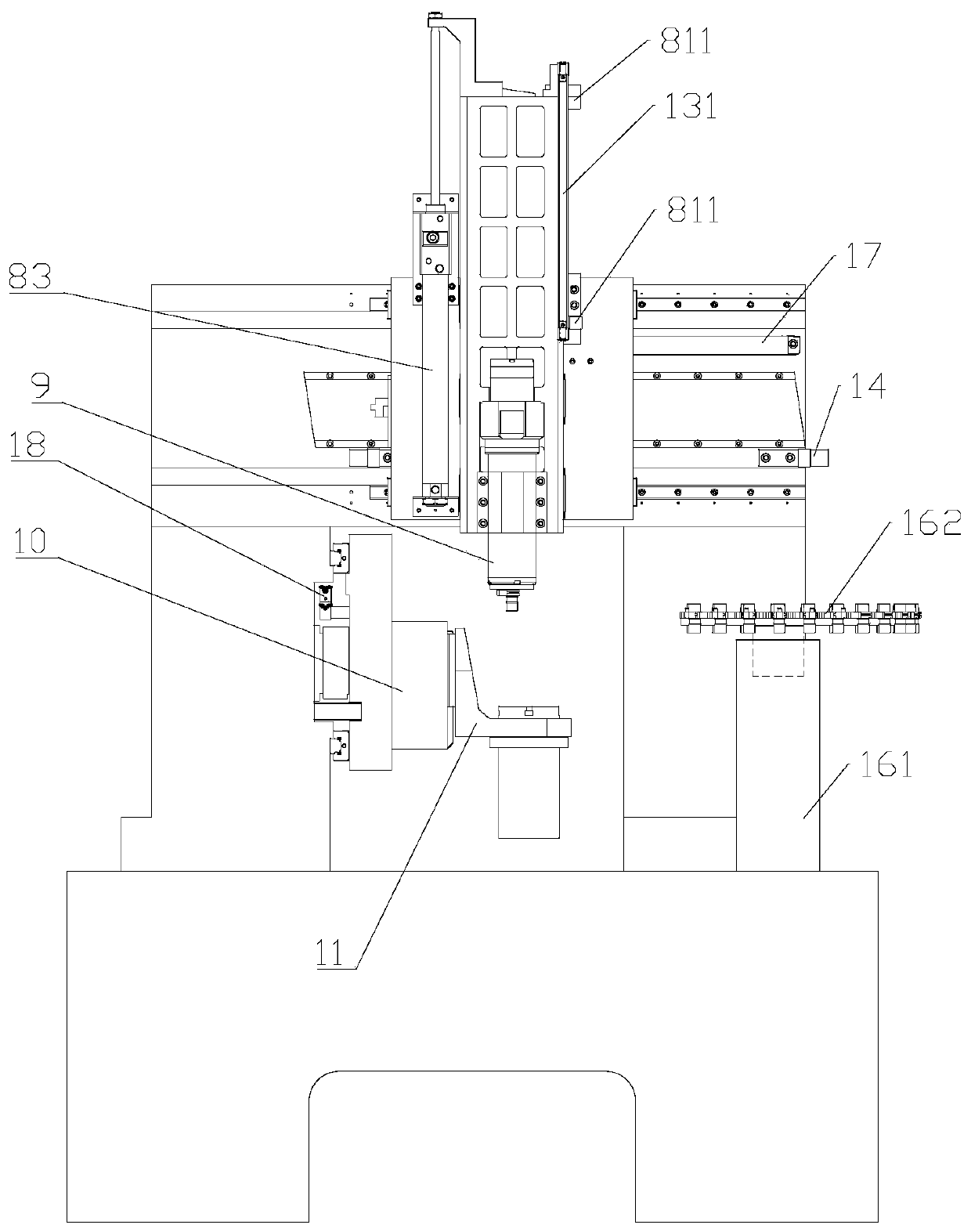

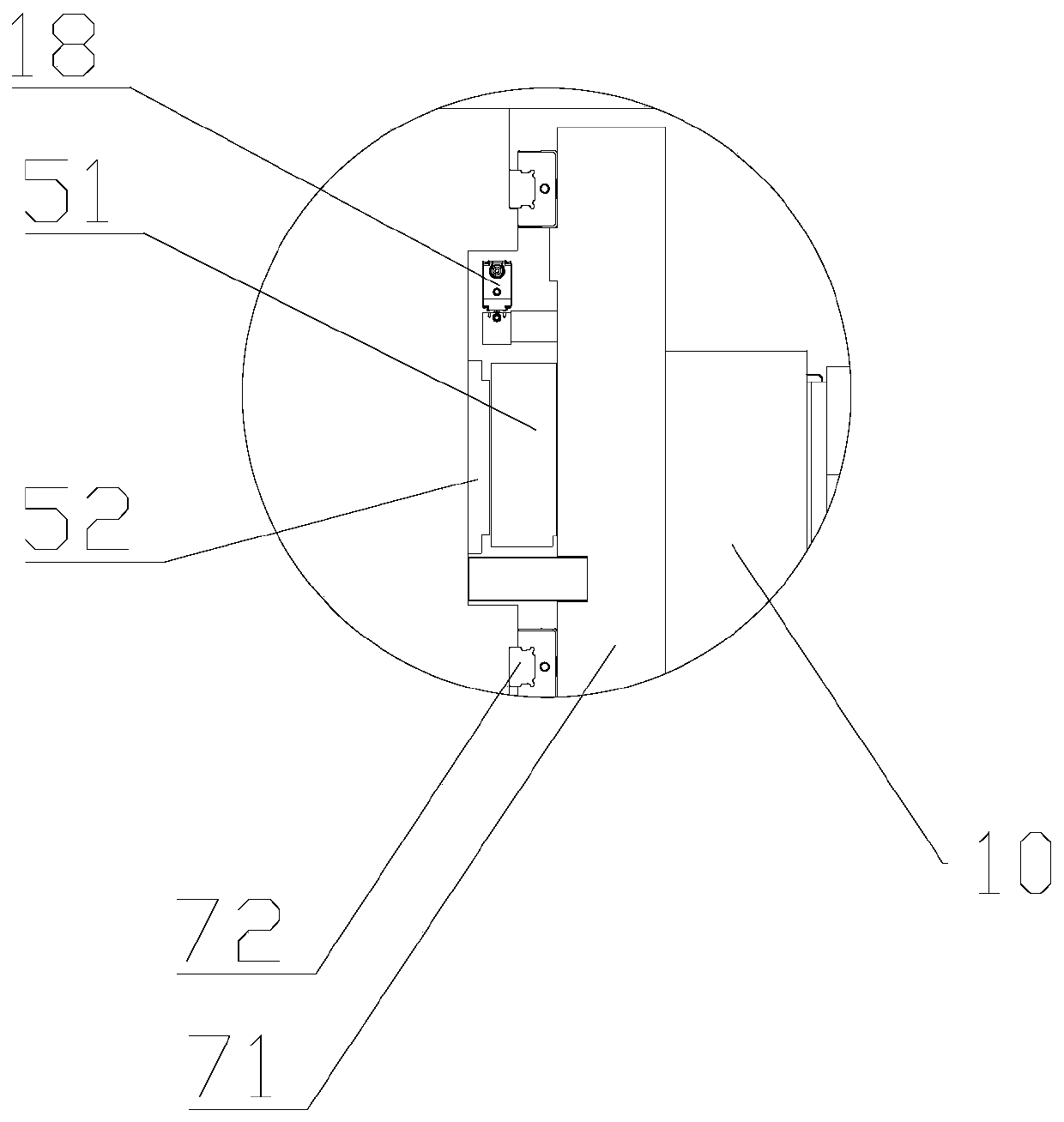

Gold jewelry five-axis turning and milling integrated machining center

PendingCN110561121ARealize the processing effectRealize the integration of turning and millingOther manufacturing equipments/toolsReducerEngineering

The invention provides a gold jewelry five-axis turning and milling integrated machining center. The gold jewelry five-axis turning and milling integrated machining center comprise a lathe bed, a Y-axis installing base fixed to the top of the lathe bed, an X-axis installing base fixed to the top of the Y-axis installing base and a Y-axis moving assembly, wherein the X-axis installing base is provided with an X-axis moving assembly, a Z-axis moving assembly and a main shaft assembly for machining; the Y-axis moving assembly is arranged on the Y-axis installing base and comprises a second planker used for reciprocating along the Y axis, the second planker is provided with a rotation table rotating around the C axis and a first speed reducer making the rotation table rotate around the A axis,the first speed reducer is fixed to the second planker, the rotation table is fixedly connected with the output end of the first speed reducer through a connecting frame, and a drive device of the first speed reducer is a first motor. The gold jewelry five-axis turning and milling integrated machining center has a high-precision turning and milling function, multi-direction omnibearing machiningcan be achieved, and the highlight effect is good.

Owner:珠海市瑞德盛数控科技有限公司

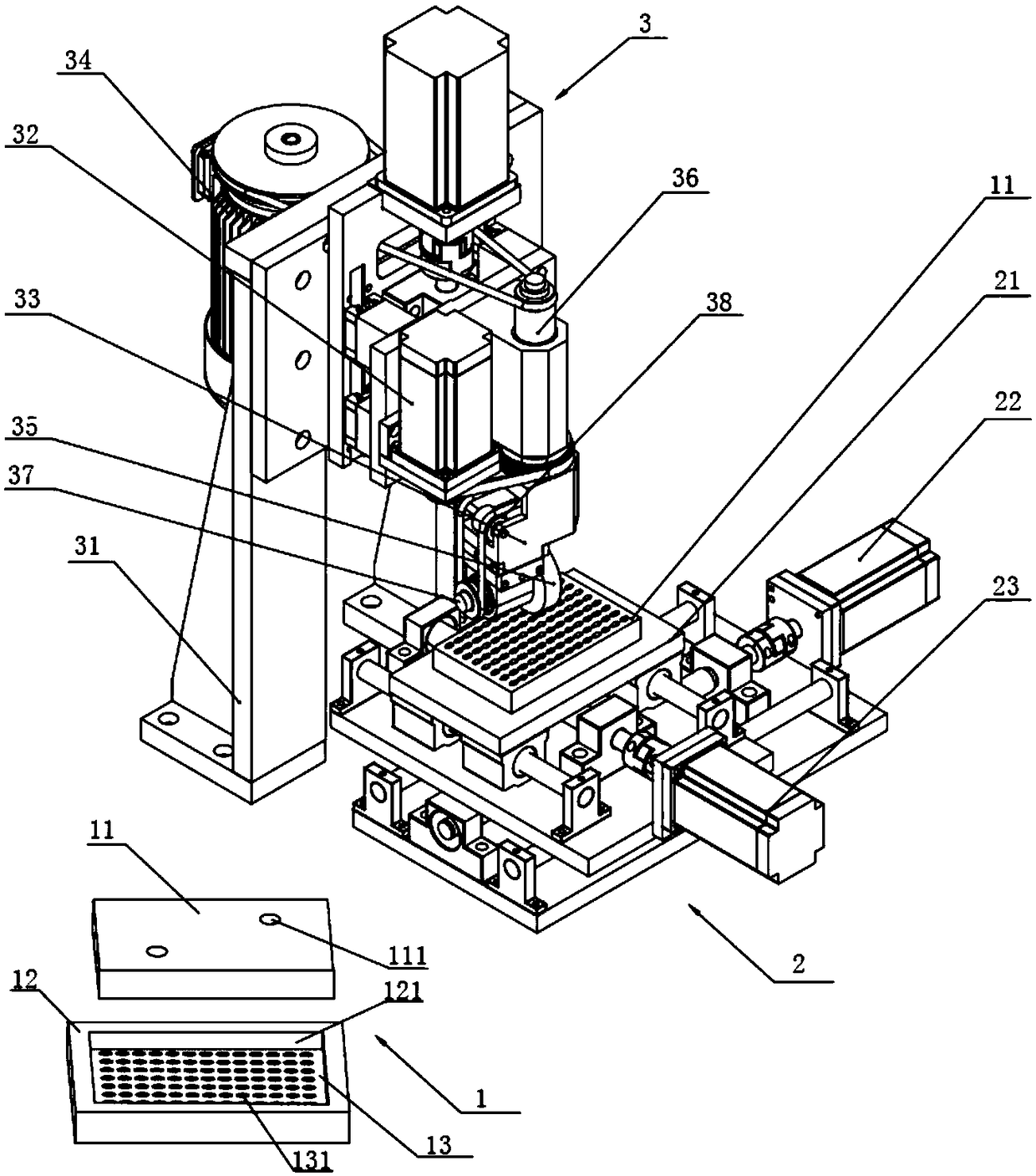

Semi-automatic patterning machine

The invention belongs to the technical field of gold jewelry processing and particularly relates to a semi-automatic patterning machine. The semi-automatic patterning machine comprises a workpiece fixing mechanism, a feeding mechanism and a patterning mechanism, wherein the workpiece fixing mechanism comprises a patterning piece fixing plate, an external positioning plate and a mould plate; the feeding mechanism comprises a worktable, an X-axis servo motor and a Y-axis servo motor; the patterning mechanism comprises a patterning frame which is provided with a rotating cutter driven by a C-axisservo motor, the rotating cutter is provided with a patterning cutting disk driven by a driving motor, and the patterning cutting disk is provided with a cutting blade. The semi-automatic patterningmachine is simple in structure and easy to operate and can achieve scale and semi-automatic jewelry piece feeding during which time and labor can be saved; the servo motors drive the worktable to moveand further to achieve automatic patterning operation on jewelry pieces, thereby greatly improving the production efficiency and achieve uniform patterning and stable quality.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD

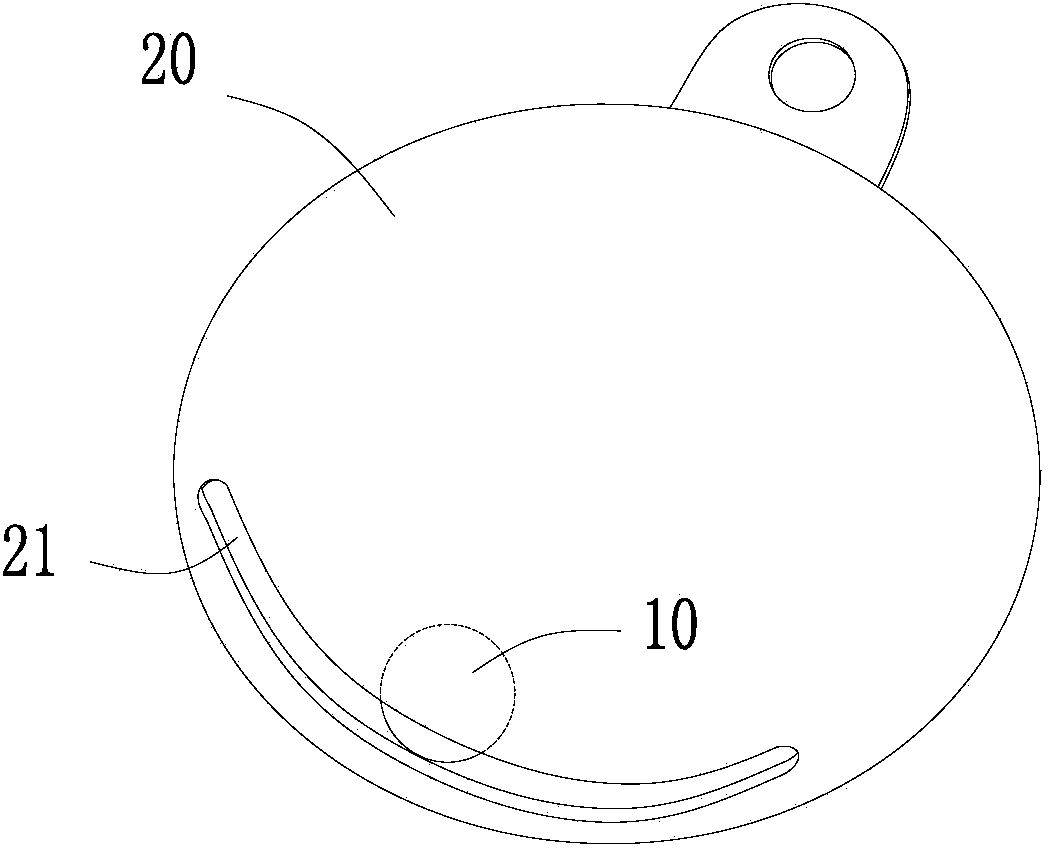

Gold jewelry bell and production method for same

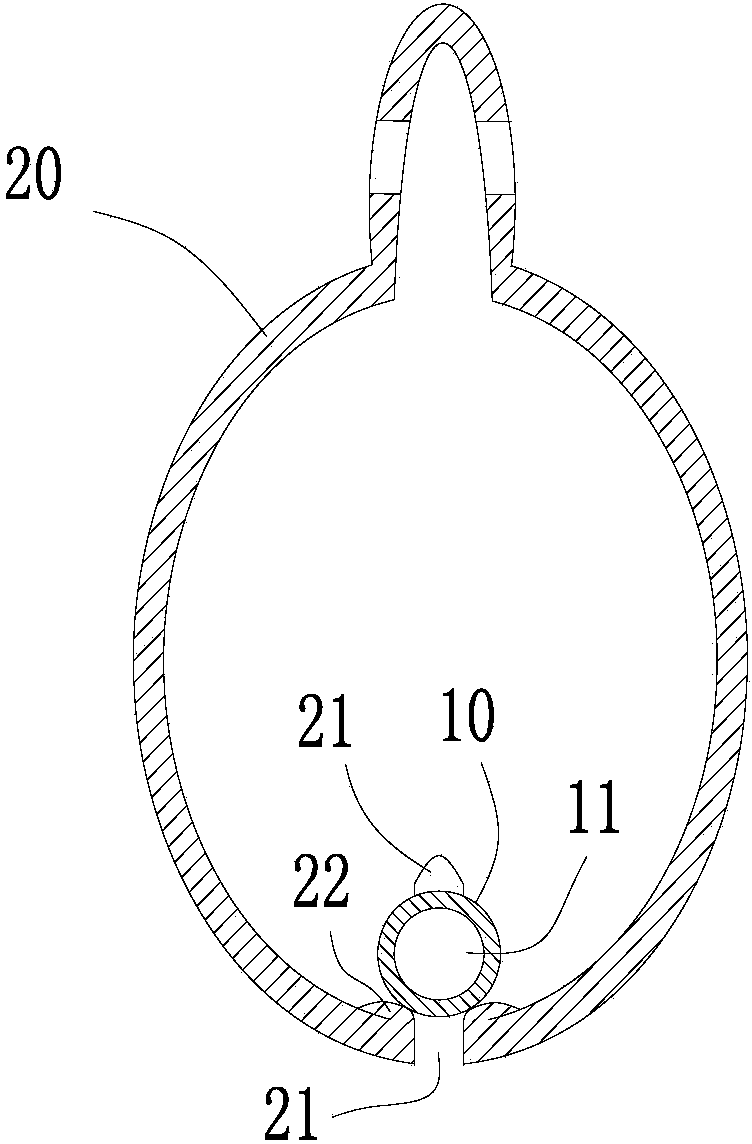

InactiveCN103637512AWithout breaking integrityReflect the perfect shapeWatch chainsOrnamental chainsWaxGold jewelry

The invention discloses a gold jewelry bell, which comprises a hollow bell body and a small ball in the bell body, wherein a seam is formed in the bell body. The gold jewelry bell is characterized in that the small ball is a hollow ball body, wherein the length of the seam is at least twice the diameter of the small ball; the wall thicknesses of the small ball and the bell body are 0.15 to 0.5mm; the bell body and the small ball are produced by a gold electroforming technology; preferably, one or two small balls are arranged. The invention also provides a production method for the bell. The method mainly comprises the following steps of producing the hollow small ball, and placing the small ball in a wax mold for a subsequent process when the bell is produced. The bell produced by the method can ring loud, the true quality of a pure gold jewelry is maintained, and the gold jewelry bell can ring as the name implies to meet the requirements of multiple customers. According to the production method, the small ball is ingeniously arranged in the hollow bell body, so that damage to the integrity of the bell is avoided, and the perfect appearance and wonderful sound effects of the gold jewelry bell are shown.

Owner:SHENZHEN ENFU JEWELRY

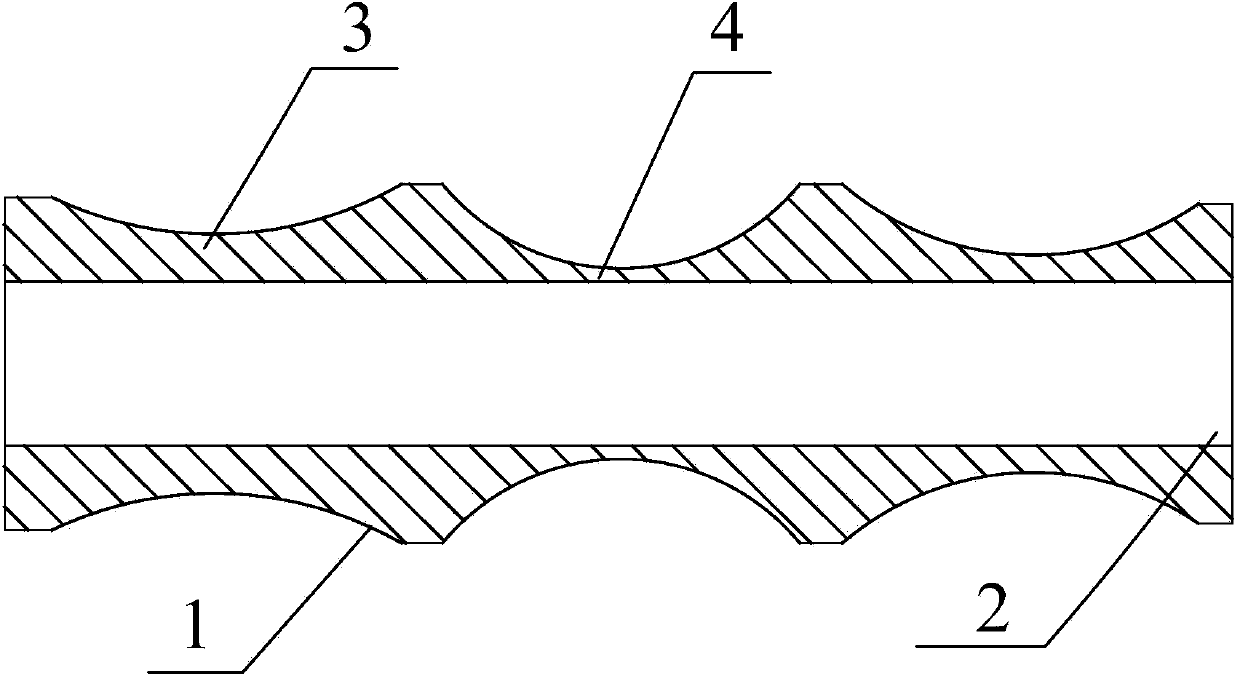

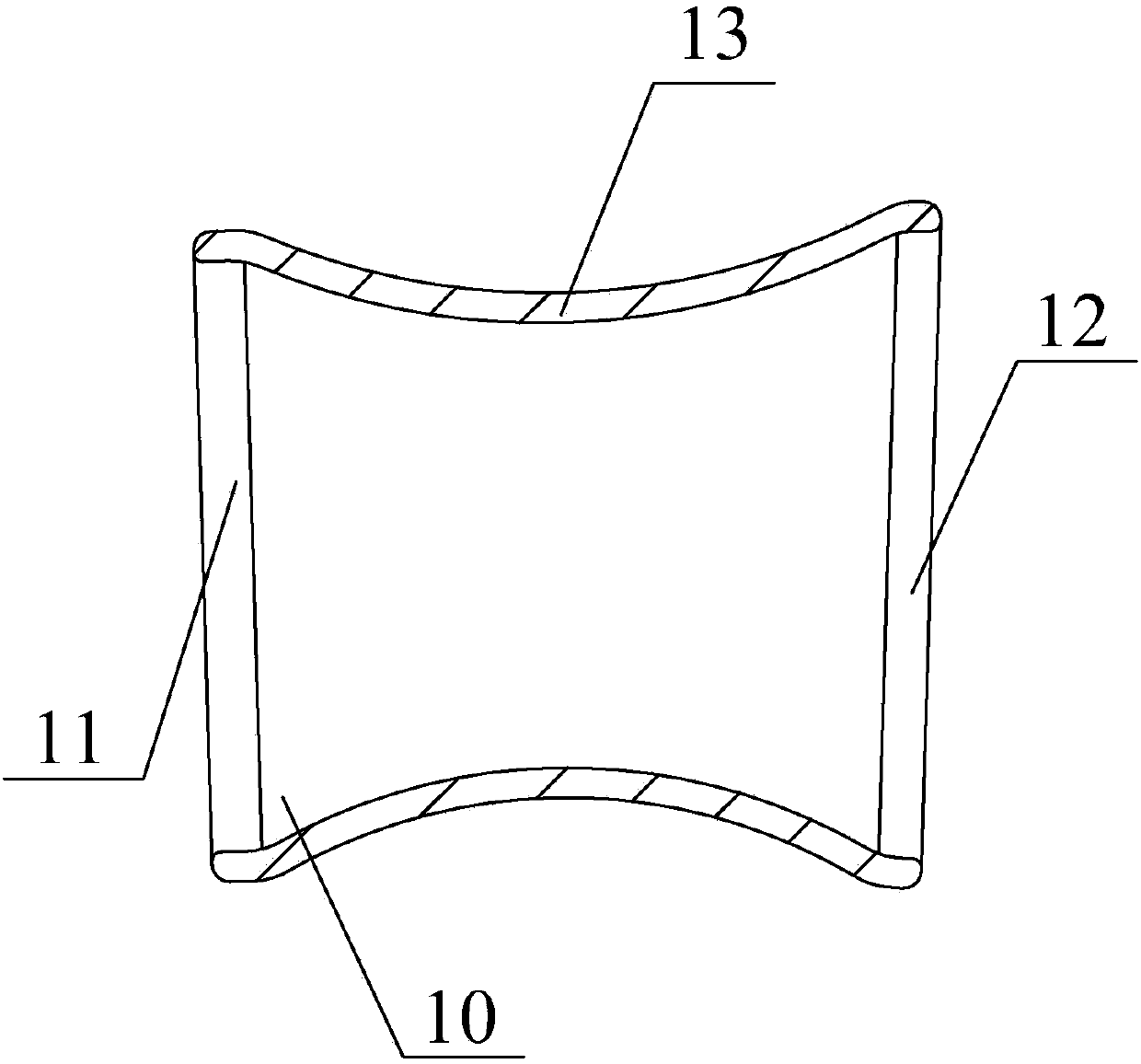

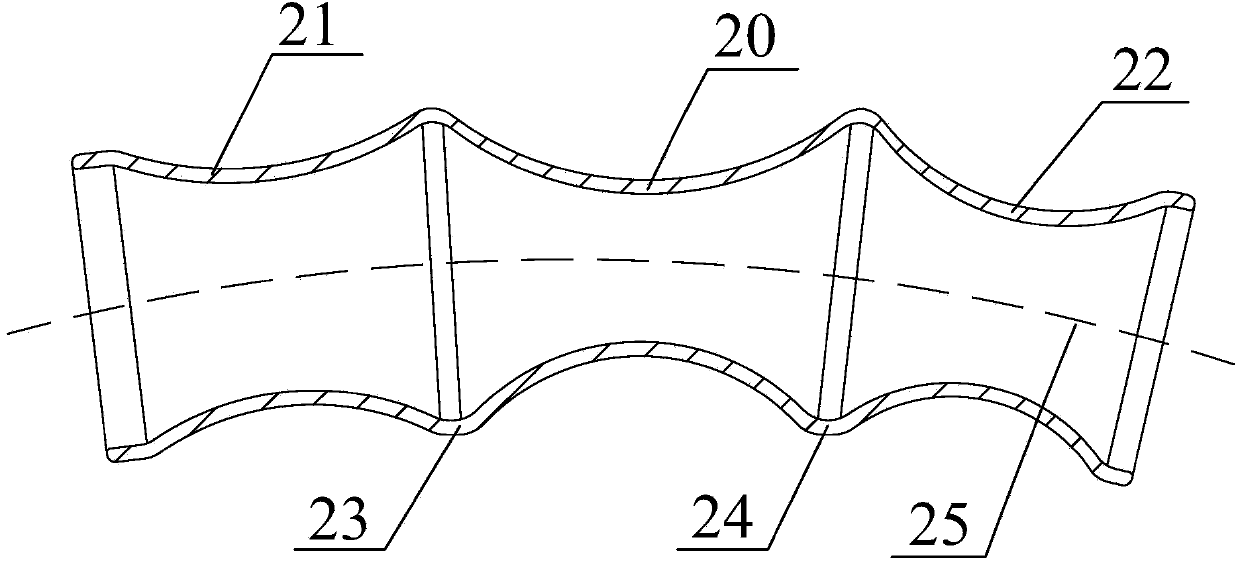

Gold jewelry and processing method thereof

The invention discloses a gold jewelry which comprises a barrel, wherein the barrel comprises at least one cylindrical component; each cylindrical component comprises a barrel wall; and the wall thickness at all parts of the cylindrical component is equal, so that the compressive strength of the cylindrical components is greatly improved. The invention further discloses a processing method of the gold jewelry, which comprises the steps of manufacturing an inner cavity mold in a shape of an inner cavity of each cylindrical component, and an outer cavity mold in a shape of an outer cavity of each cylindrical component, pouring first wax into the inner cavity mold to form an inner cavity wax mold with the same shape as the inner cavity of each cylindrical component, fixing the inner cavity wax mold in a mold cavity of the outer cavity mold, allowing a gap value between the inner cavity wax mold and the mold cavity to be constant and equal, pouring second wax into a gap to form an outer cavity wax mold with the same shape as the barrel wall of each cylindrical component, and manufacturing the cylindrical component according to the outer cavity wax mold. The wall thickness of the obtained cylindrical components at all the parts is equal. The producing method can manufacture the cylindrical components with the equal wall thickness value.

Owner:SHENZHEN BATAR INVESTMENT HLDG GRP CO LTD

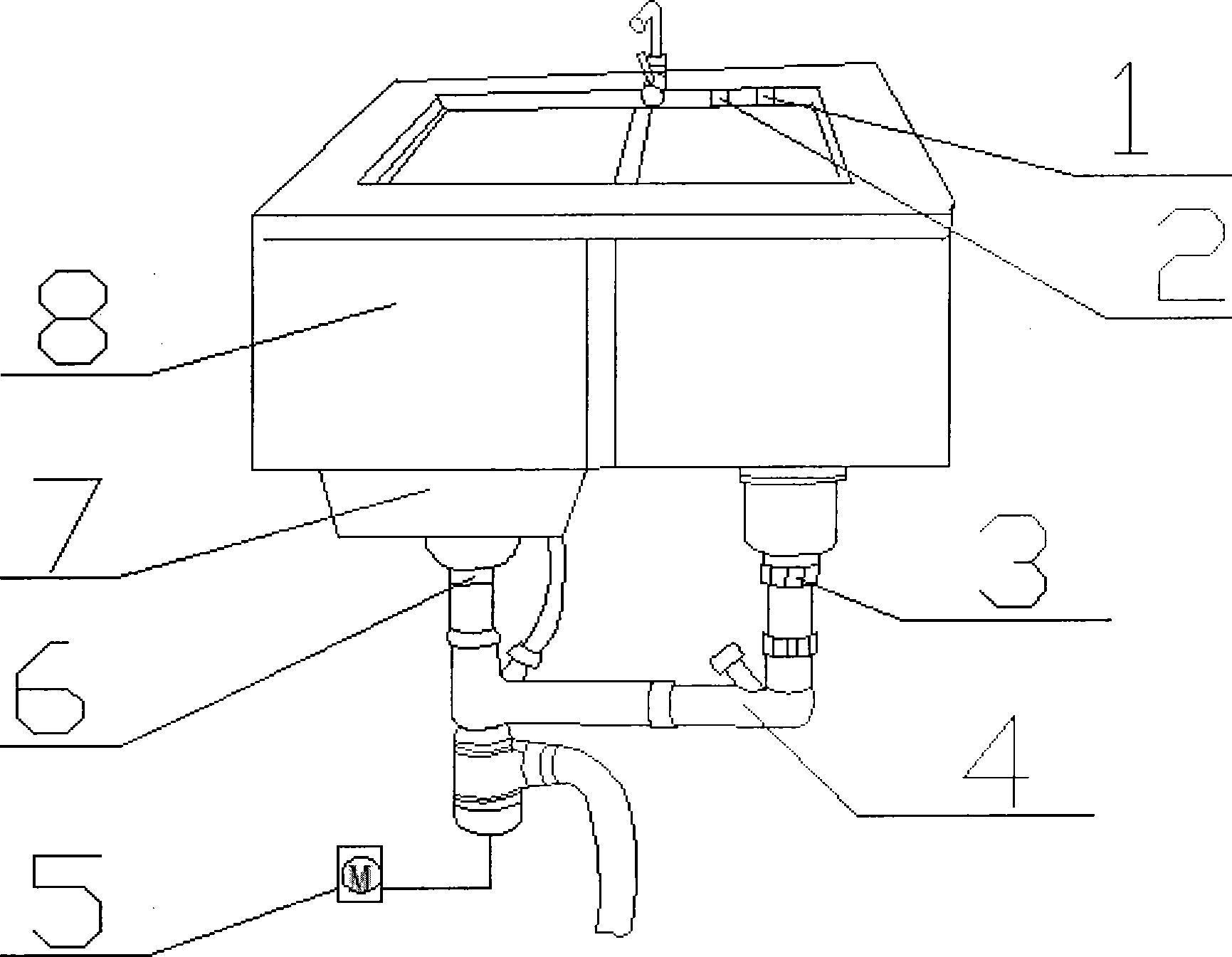

Novel intelligent washing machine for kitchens

InactiveCN104013374ABreak the limitation of only washing dishesReduce volumeKitchen equipmentTableware washing/rinsing machinesLeft halfEngineering

The invention discloses a novel intelligent washing machine for kitchens. The novel intelligent washing machine for kitchens comprises an automatic water draining switch, a one-key-type pneumatic switch, a first automatic water draining device, a water draining pipe, a motor, a second automatic water draining device, an ultrasonic wave emitter and a manual water groove, wherein the automatic water draining switch and the one-key-type pneumatic switch are arranged at the upper end of the manual water groove, and the first automatic water draining device is arranged on the upper side, connected with the bottom end of the right half end of the manual water groove, of a water pipe; the motor is connected with the ultrasonic wave emitter through a wire; the second automatic water draining device is arranged at the upper end, connected with the bottom end of the left half end of the manual water groove, of the water pipe and on the lower side of the ultrasonic wave emitter. According to the novel intelligent washing machine for kitchens, the situations that dead space can not be washed by a traditional household dishwasher, and only dishes and chopsticks can be washed are changed, and the novel intelligent washing machine for kitchens not only can be used for washing dishes but also can be used for washing vegetables, fruits, gold jewelry, false teeth and the like, and breaks the limitation that the traditional dishwasher can only be used for washing dishes.

Owner:SHENZHEN AOMACSI ELECTRONICS TECH CO LTD

Machining process of oil pressing type gold jewelry with purity of 99.999 percent

The invention belongs to the field of jewelry machining and in particular relates to a machining process of oil pressing type gold jewelry with the purity of 99.999 percent. According to the machining process, raw materials are subjected to steps of melting, oil pressing, molding, polishing, sanding, embroidering, press polishing and quality checking and the cleanliness of an environment is regarded in a preparation process; steel and iron type tools used in a technological process are replaced with a special diamond type tool; a condition that the tool reacts with gold so that the loss of the purity of the gold is caused is avoided, and the gold jewelry with the purity of 99.999 percent is prepared; the quality, purity and ornamental property of the gold jewelry are greatly improved and user experience is improved.

Owner:SHANDONG ZHAOJIN GOLD & SILVER REFINERY

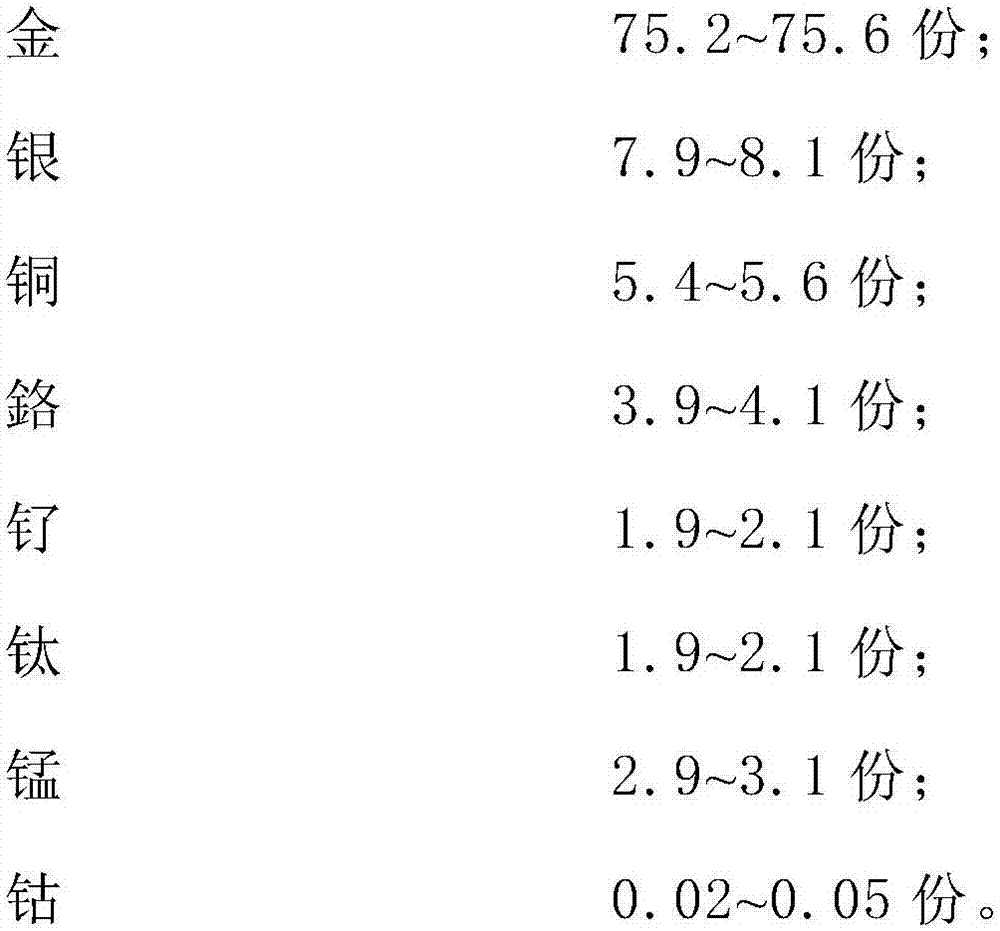

Rose-bengal 18 K gold and preparation method thereof

The invention relates to the technical field of alloys and in particular relates to rose-bengal 18 K gold. The rose-bengal 18 K gold comprises the following ingredients in percentage by weight: 15.5-20.8 percent of copper, 1.5-2.8 percent of sliver, 0.11-0.25 percent of cerium, 0.13-0.21 percent of titanium, 0.04-0.16 percent of cobalt, 0.1-0.17 percent of indium, 0.1-0.5 percent of neodymium and the balance of gold and inevitable impurities. The invention further provides a synthetic method of the rose-bengal 18 K gold alloy. The rose-bengal 18 K gold alloy is good in high temperature tolerance and long in service life and resists high temperature, oxidation and creep deformation. The manufactured gold jewelry is low in price, high in hardness and lasting in color and luster and can be worn for a long term.

Owner:北海嘉华珠宝有限公司

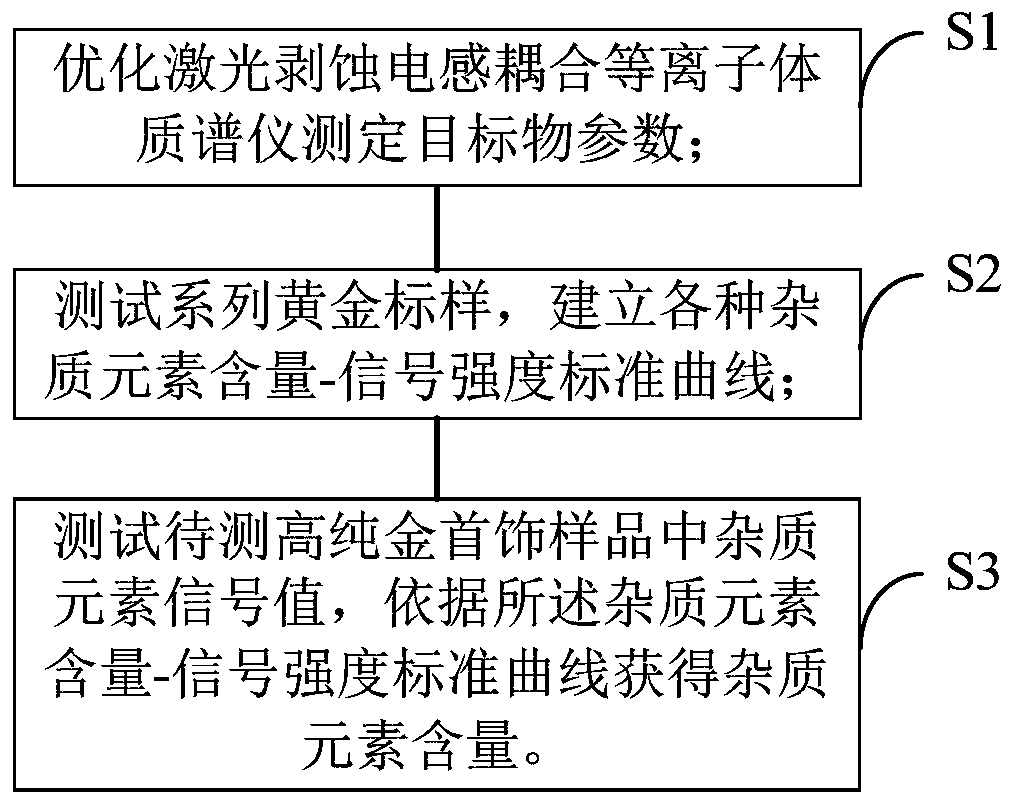

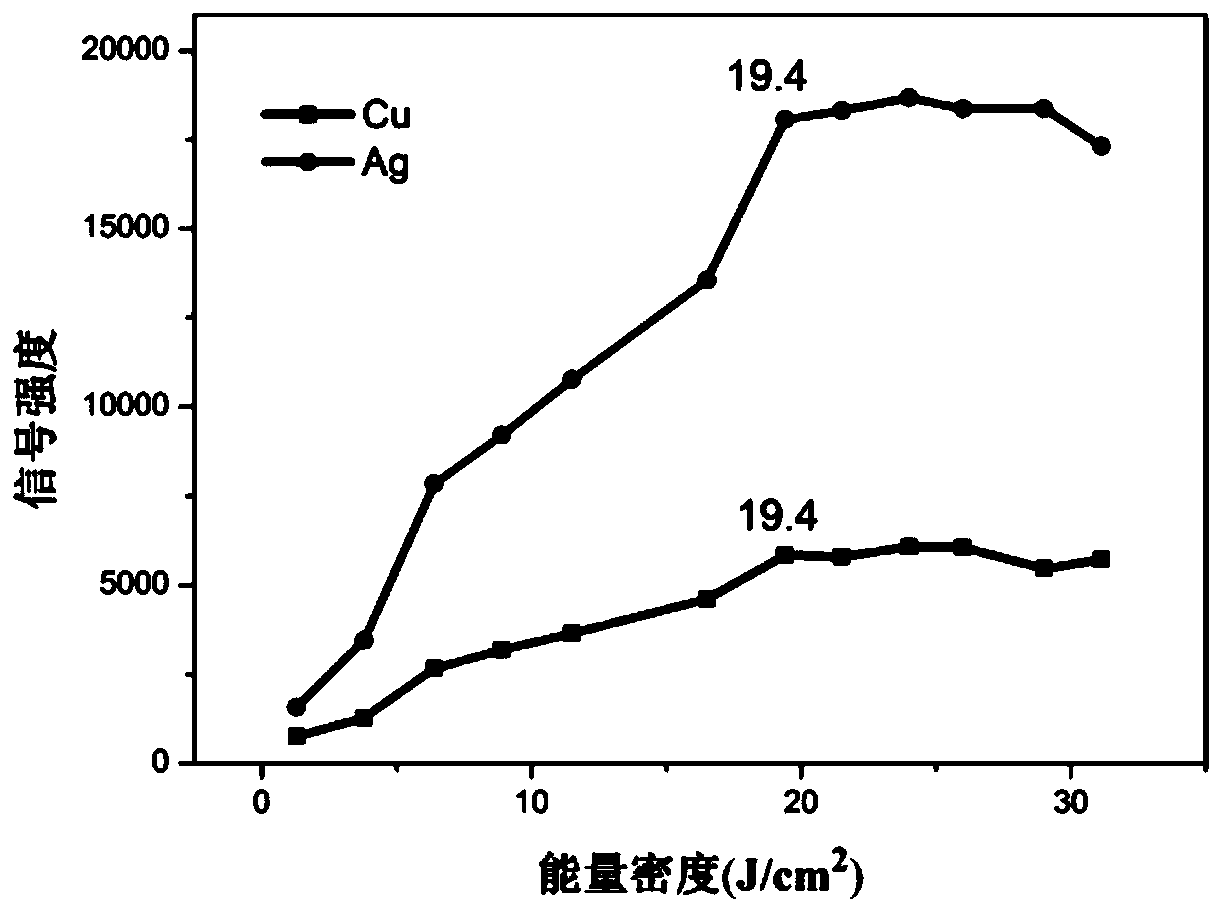

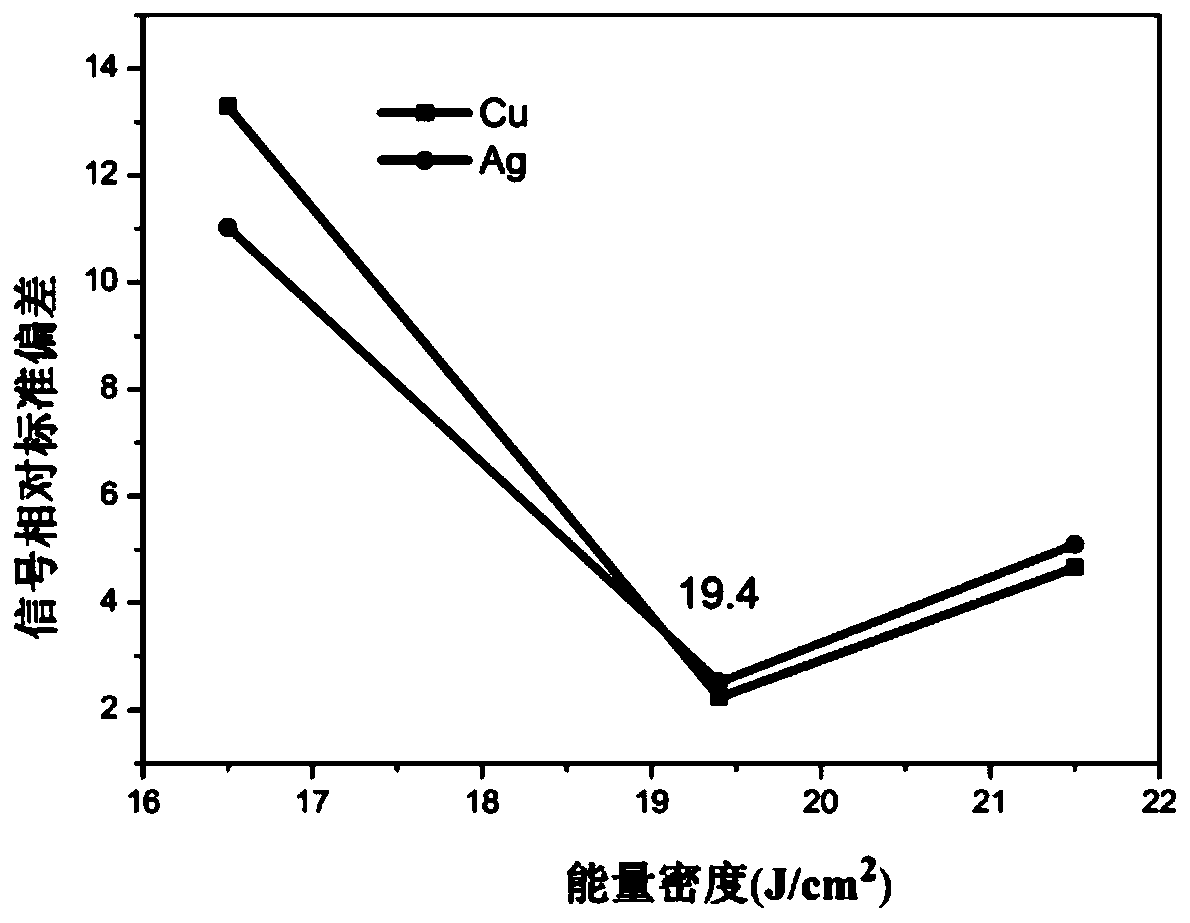

Method for determining content of impurity elements in high-purity gold jewelry

InactiveCN110907527AReduce damageLow detection limitMaterial analysis by electric/magnetic meansLight spotPhysical chemistry

The invention provides a method for determining the content of impurity elements in a high-purity gold jewelry. According to the method, a laser denudation inductively coupled plasma mass spectrometeris adopted for measurement, and the method comprises the following steps of S1, optimizing the denudation light spots, the denudation energy and the denudation frequency parameters of a target objectmeasured by the laser denudation inductively coupled plasma mass spectrometer; S2, testing a series of gold standard samples by adopting the optimized experimental parameters, and establishing a content-signal strength standard curve of various impurity elements in the gold samples; S3, testing the signal values of the impurity elements in the to-be-tested high-purity gold jewelry sample, and obtaining the content of the impurity elements through the content-signal intensity standard curve. According to the method, the sample dissolving pretreatment is omitted, the sample damage belongs to micro-damage, the damage degree is extremely low, the introduction of external pollution sources is avoided by direct carrying out the solid test, and the method has the advantages of being environmentfriendly, real-time, micro-damage and accurate in element determination and is a new application of the laser denudation inductively coupled plasma mass spectrometer in the field of precious metal detection.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

Method for processing gold jewelries

The invention discloses a method for processing gold jewelries. The method comprises the following steps: (1) melting gold, namely burning gold in a high-temperature quartz crucible by utilizing the flame of acetylene to melt the gold into a single auxiliary part suitable for processing a jewelry; (2) reversing a mold, namely melting the gold auxiliary by utilizing a high frequency or medium frequency centrifugal casting machine, and pouring the molten gold into a plaster mold to cast a casting; (3) polishing, namely polishing the casting surface by using a magnetic polishing machine or cylinder polishing machine to generate gloss; (4) benching, namely soldering, rasping and hammering the casting by utilizing swage and doming block to finish deformation and rough surface in the casting process; (5) performing press-polishing, namely contacting the gold surface with an agate pen, and rubbing the workpiece to enable the workpiece surface to generate gloss; and (6) embroidering; and (7) blasting fine quartz sands onto the exposed polished metal surface at high pressure to make a hazy and mild surface process. The method is simple in operation, the gold jewelries manufactured by the method has high gloss, cost is saved for manufacturers, and the requirement of consumers can be met.

Owner:HAIAN KEHAO TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com