Patents

Literature

46results about How to "Beautifully made" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersion polyols for hypersoft polyurethane foam

InactiveUS6063309AElegantly producedHighly suitableOther chemical processesChemistryPOLYOXYETHYLENE ETHER

Dispersion polyols which are liquid-liquid dispersions containing a first polyol having a substantially polyoxypropylene internal block having an equivalent weight in excess of about 700 Da and a high oxyethylene-content external block, and a second polyol which is a substantially polyoxyethylene polyol containing minimally 50 weight percent oxyethylene moieties. The dispersion polyols are stable and exhibit broad processing latitude when preparing hypersoft polyurethane foams. The dispersion polyols are advantageously prepared in situ, preferably in the presence of a double metal cyanide oxyalkylation catalyst.

Owner:COVESTRO NV

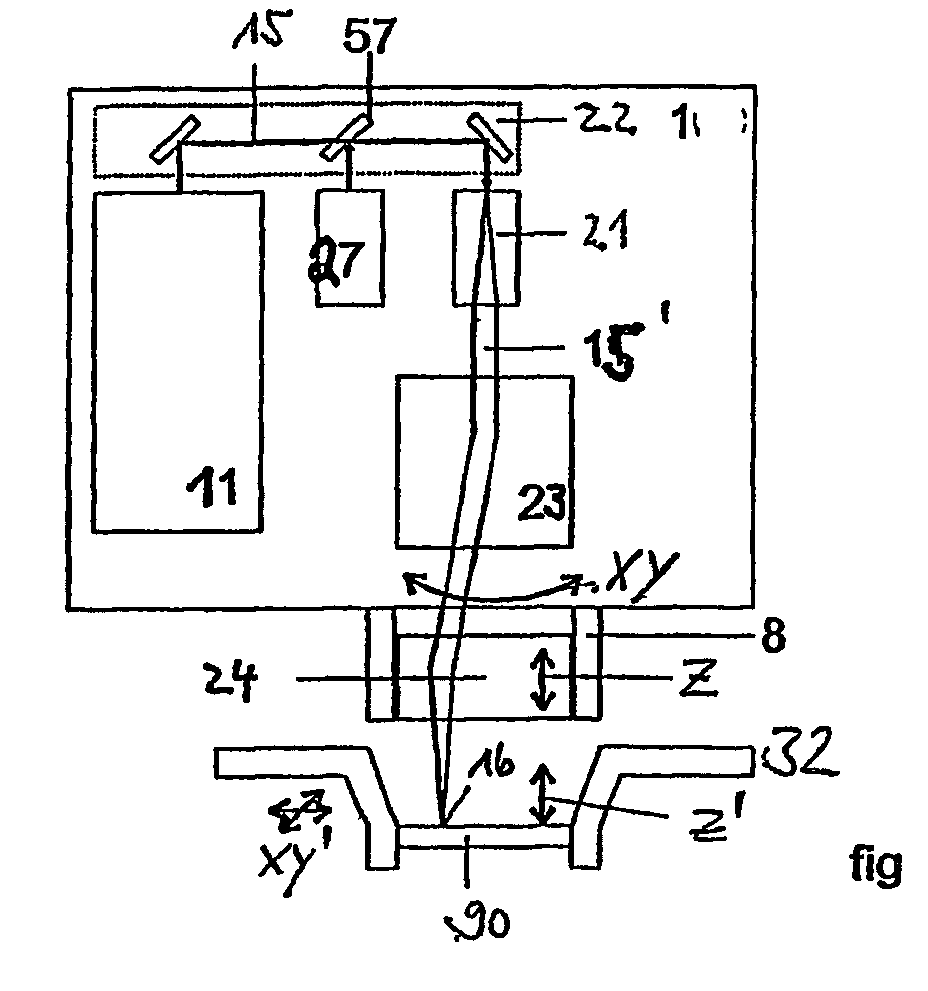

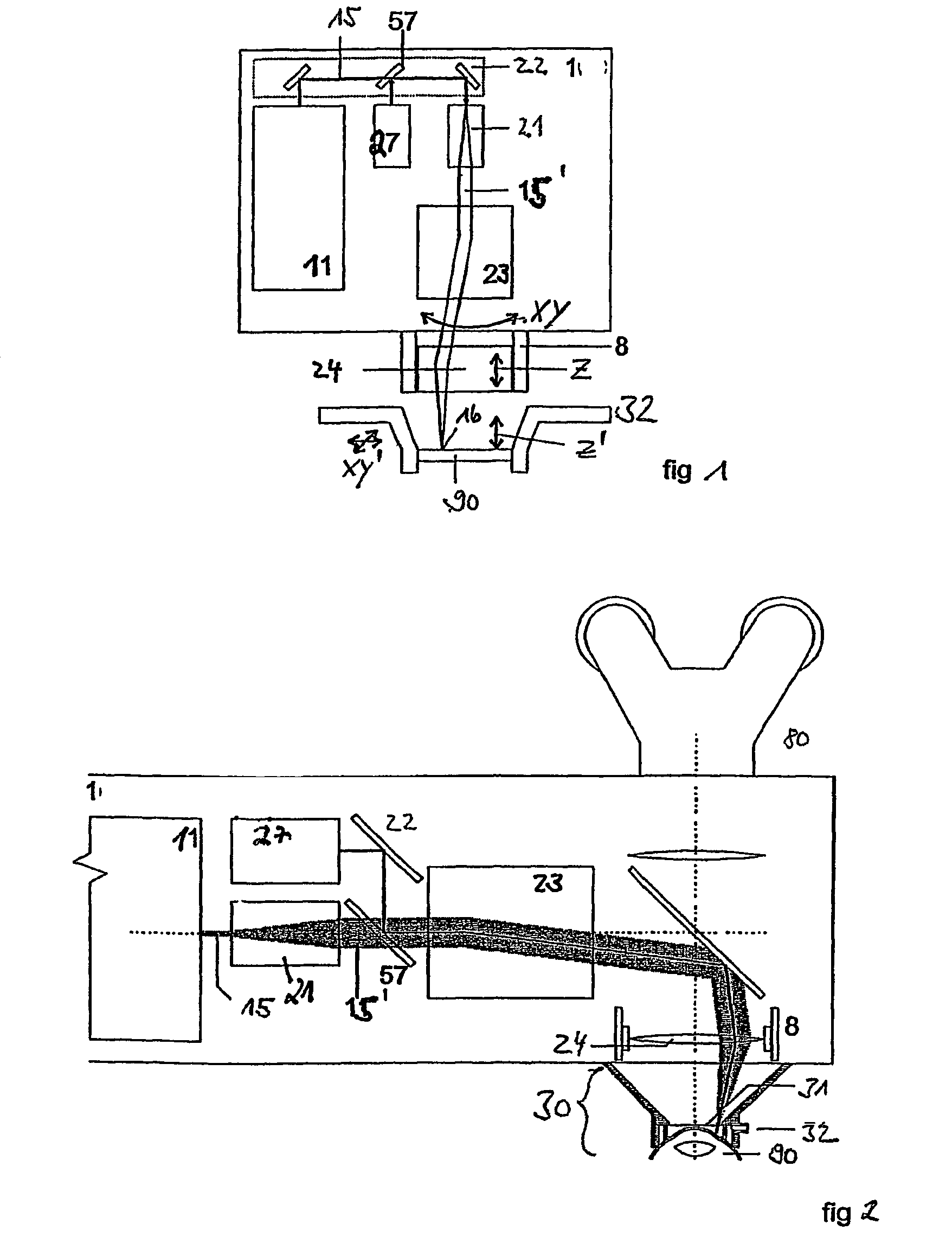

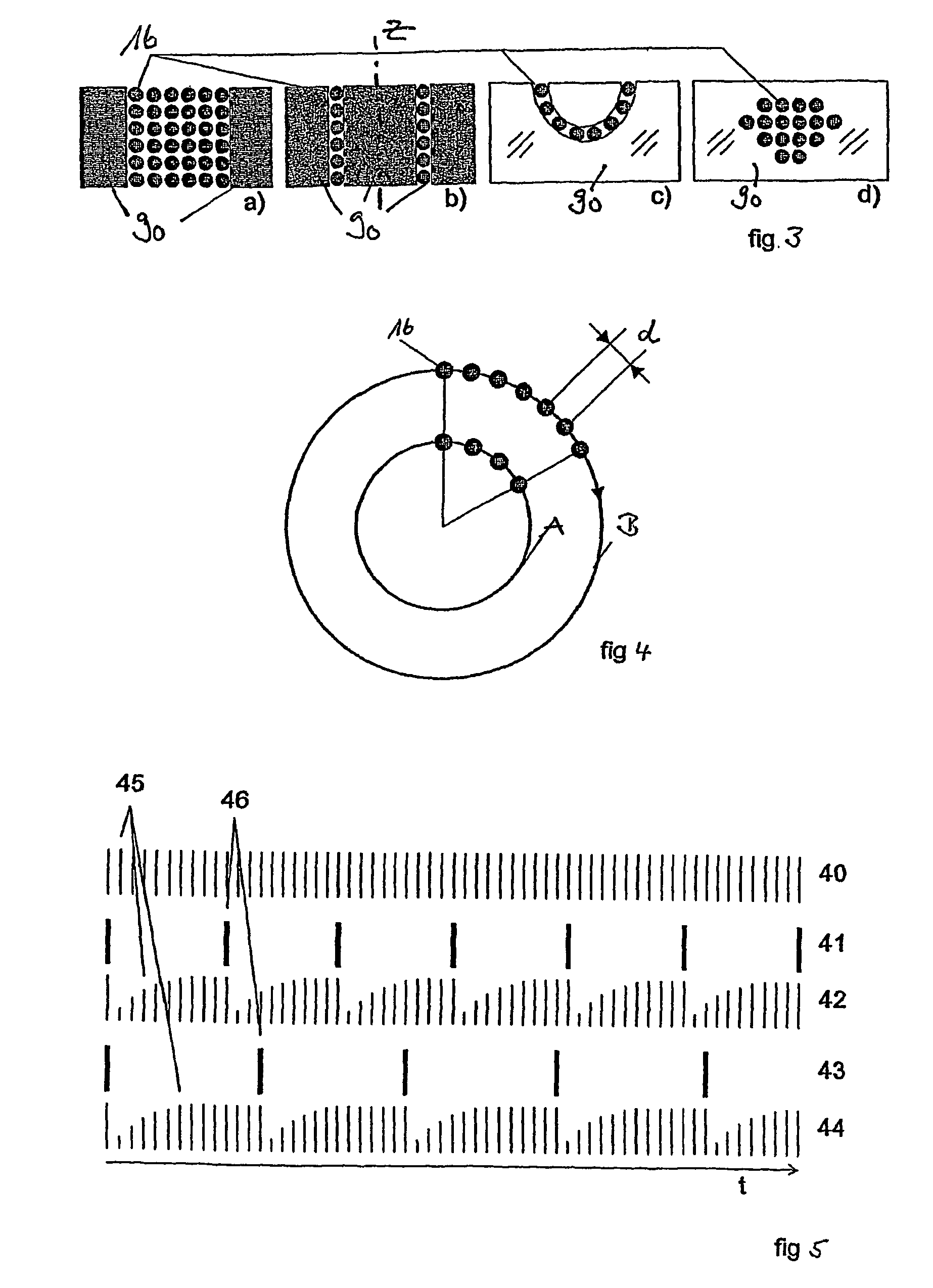

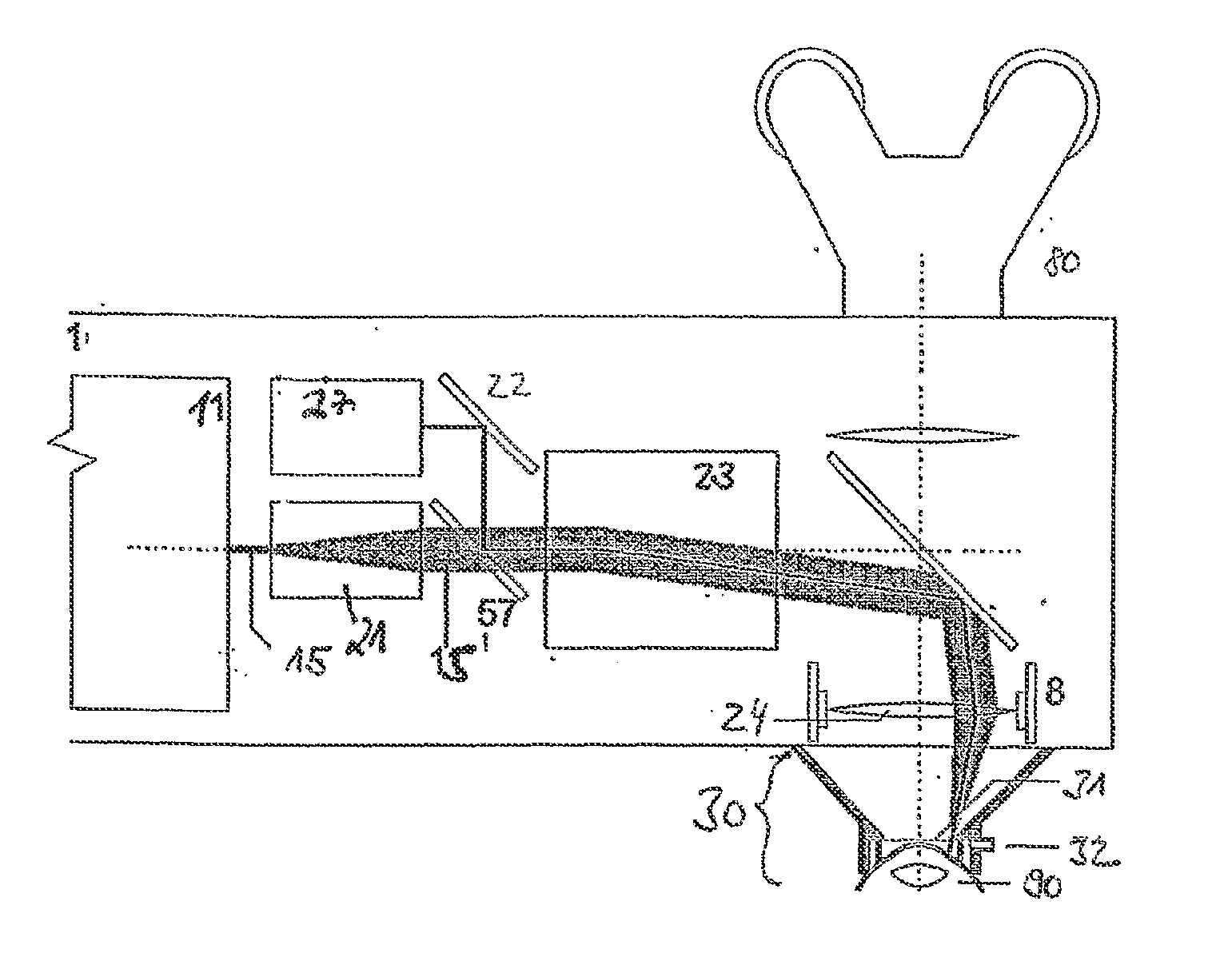

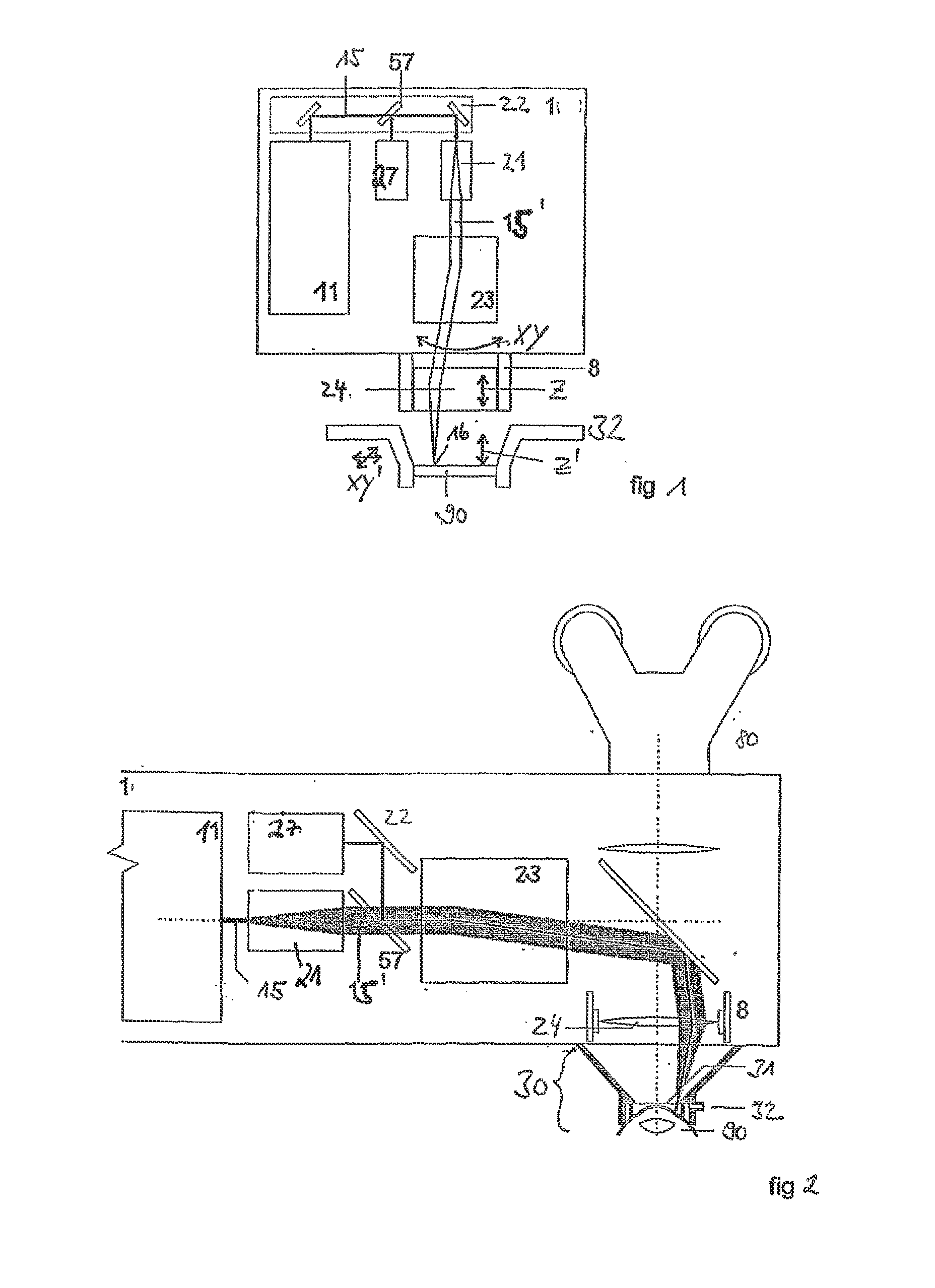

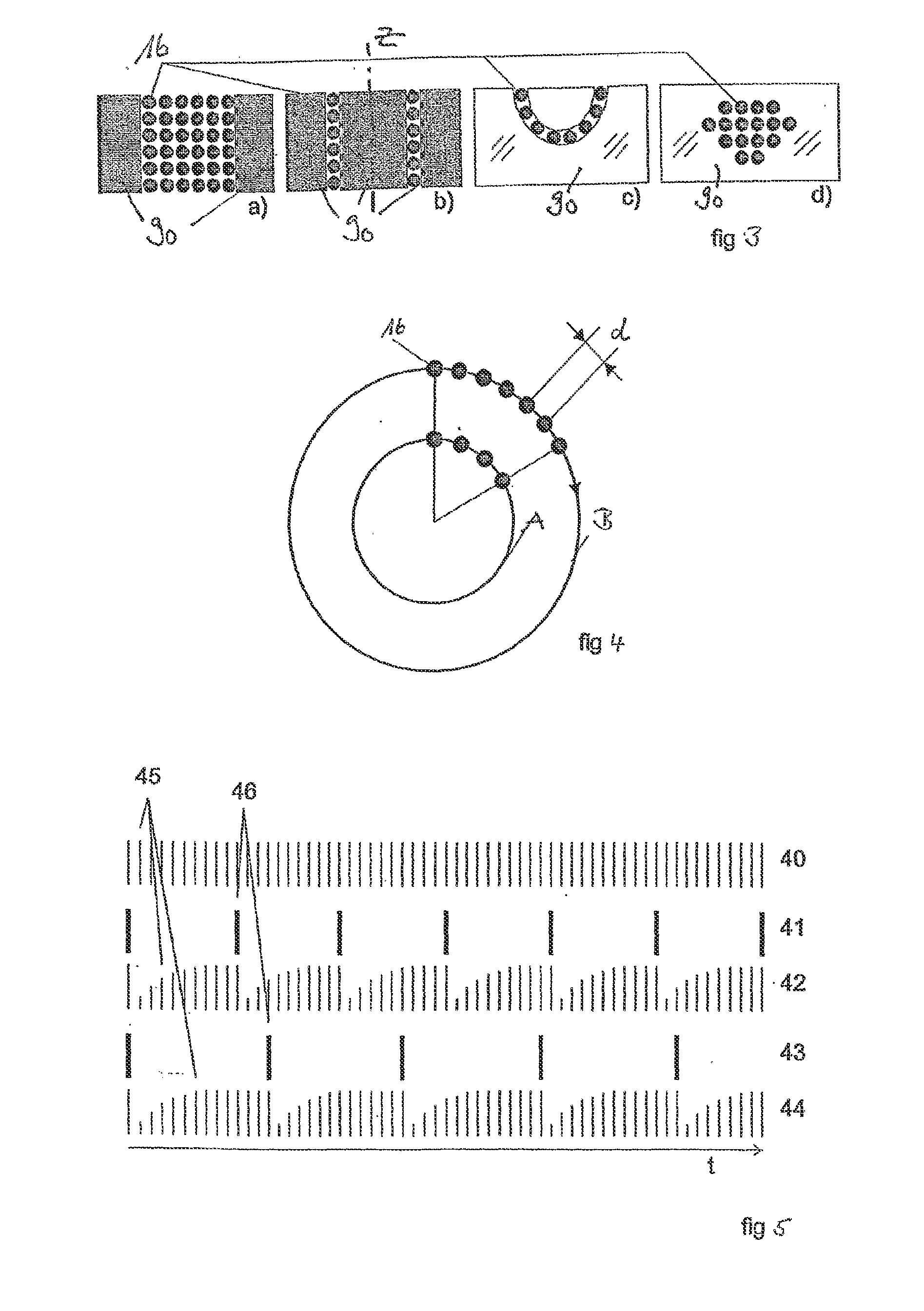

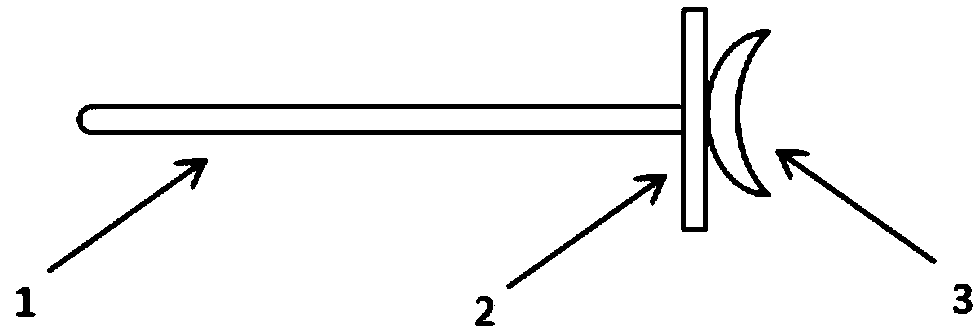

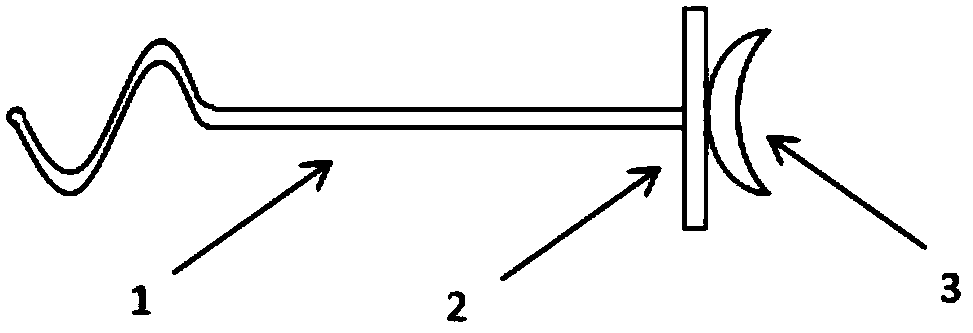

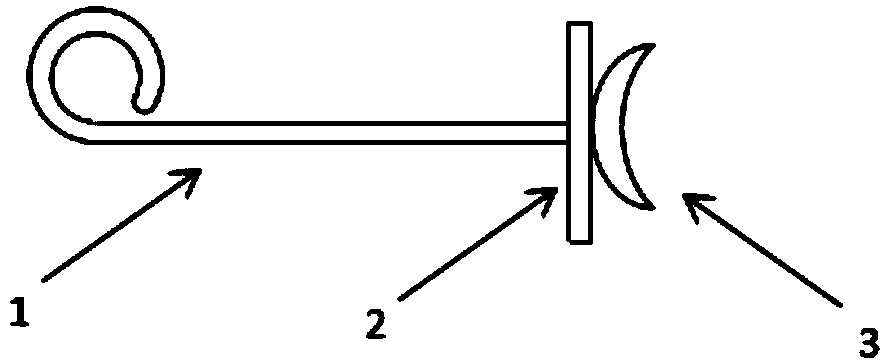

Femtosecond laser system for the exact manipulation of material and tissues

ActiveUS8585686B2High precision machiningLower areaLaser surgeryLaser detailsFemto second laserPulsed laser

A a device for the exact manipulation of material, especially of organic material. includes a pulsed laser system with a radiation source, said radiation source being a cavity-dumped fs oscillator.

Owner:CARL ZEISS MEDITEC AG

Dispersion polyols for hypersoft polyurethane foam

InactiveUS6218444B1Beautifully madeLong maintenance periodOther chemical processesPolymer sciencePtru catalyst

Dispersion polyols which are liquid-liquid dispersions containing a first having a substantially Polyoxypropylene internal block having an equivalent weight in excess of about 700 Da and a high oxyethylene-content external block, and a second polyol which is a substantially polyoxyethylene polyol containing minimally 50 weight percent oxyethylene moieties. The dispersion polyols are stable and exhibit broad processing latitude when preparing hypersoft polyurethane foams. The dispersion polyols are advantageously prepared in situ, preferably in the presence of a double metal cyanide oxyalkylation catalyst.

Owner:COVESTRO NV

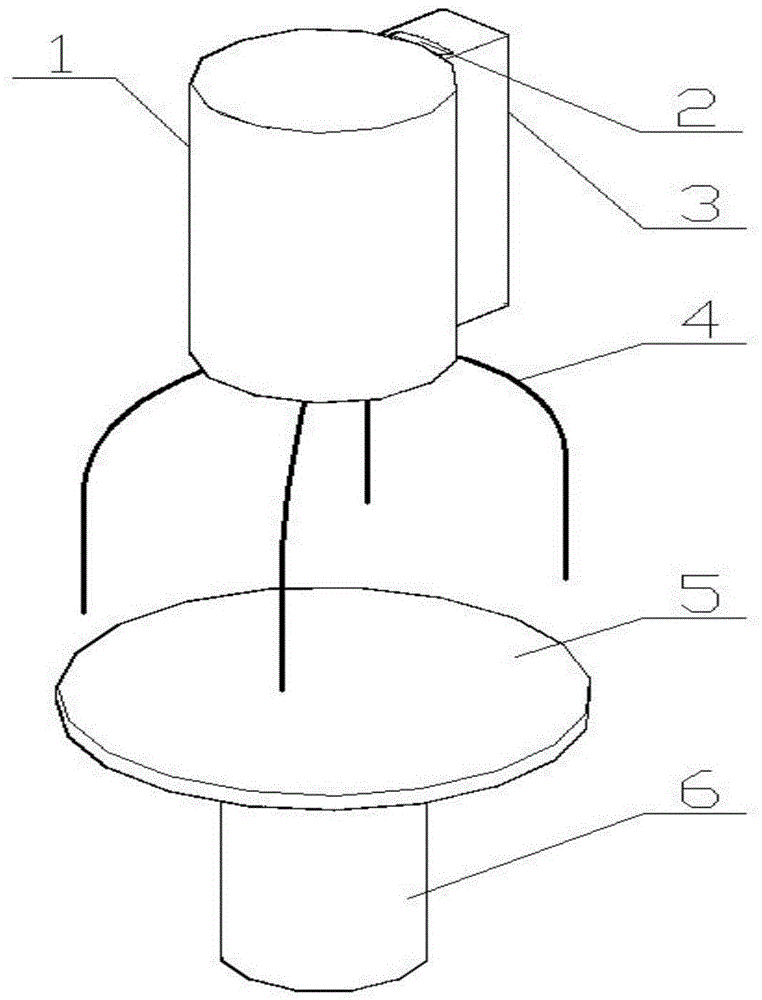

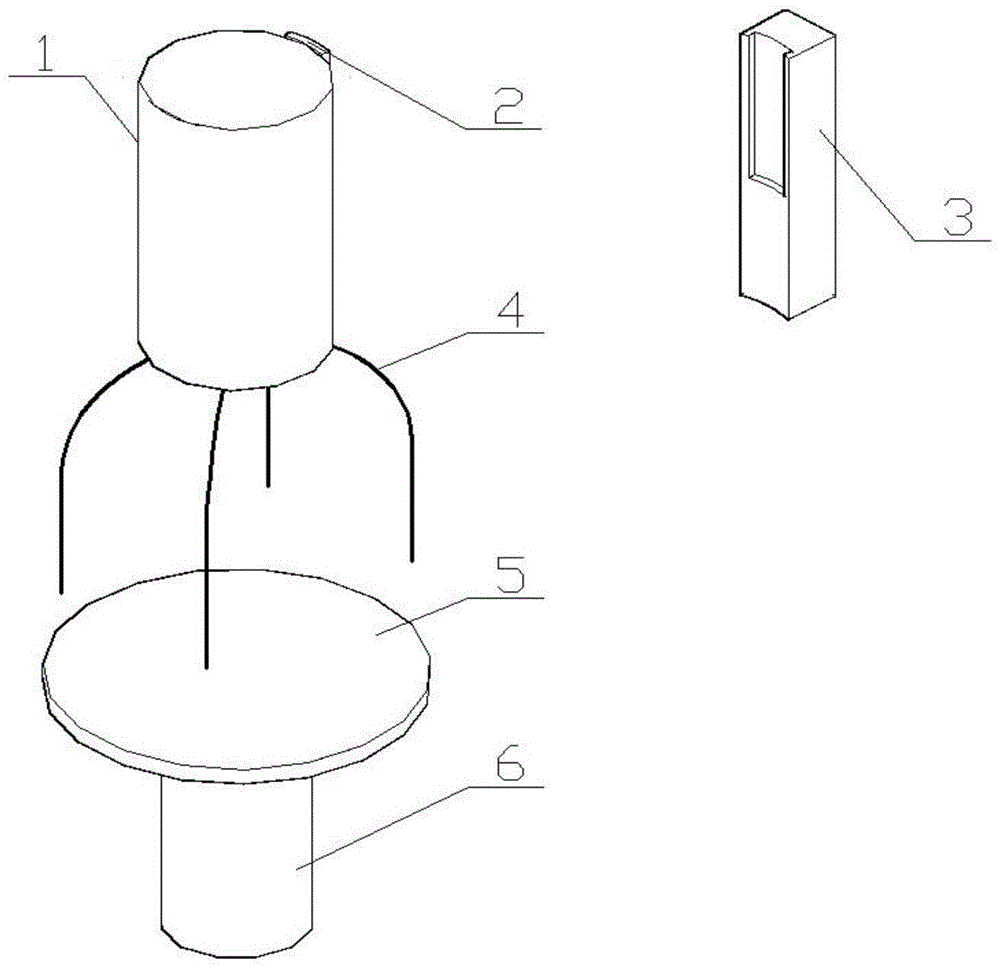

Method for collecting and preparing 1m original whole specimen of multi-gravel soil

ActiveCN109187068AThe method is easy to understandEasy to operateWithdrawing sample devicesPreparing sample for investigationSoil scienceSoil horizon

The invention relates to a method for collecting and preparing a 1m original whole specimen of multi-gravel soil. The method comprises the steps of collecting a field specimen and preparing an indoorspecimen. The method is characterized in that a 'field shooting-numb fixing-gravel gluing-in situ pasting' method is adopted for collecting and preparing the specimen. The method provided by the invention is popular and easy to understand and is easy for operation; a soil column is restored by referring to photos, so that the natural texture of soil column is kept; the profile is taken out layer by layer from top to bottom, the operation is convenient and the soil layer structure is not damaged.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

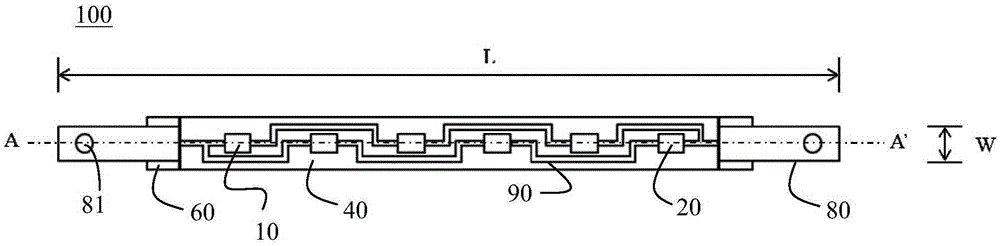

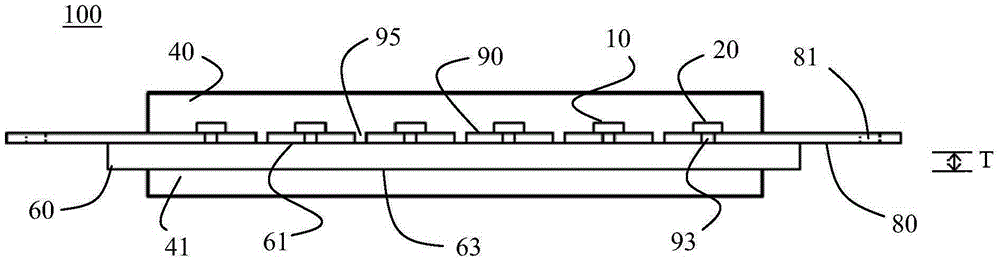

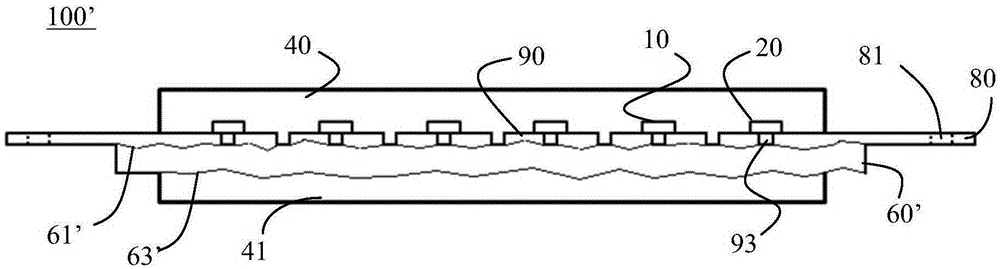

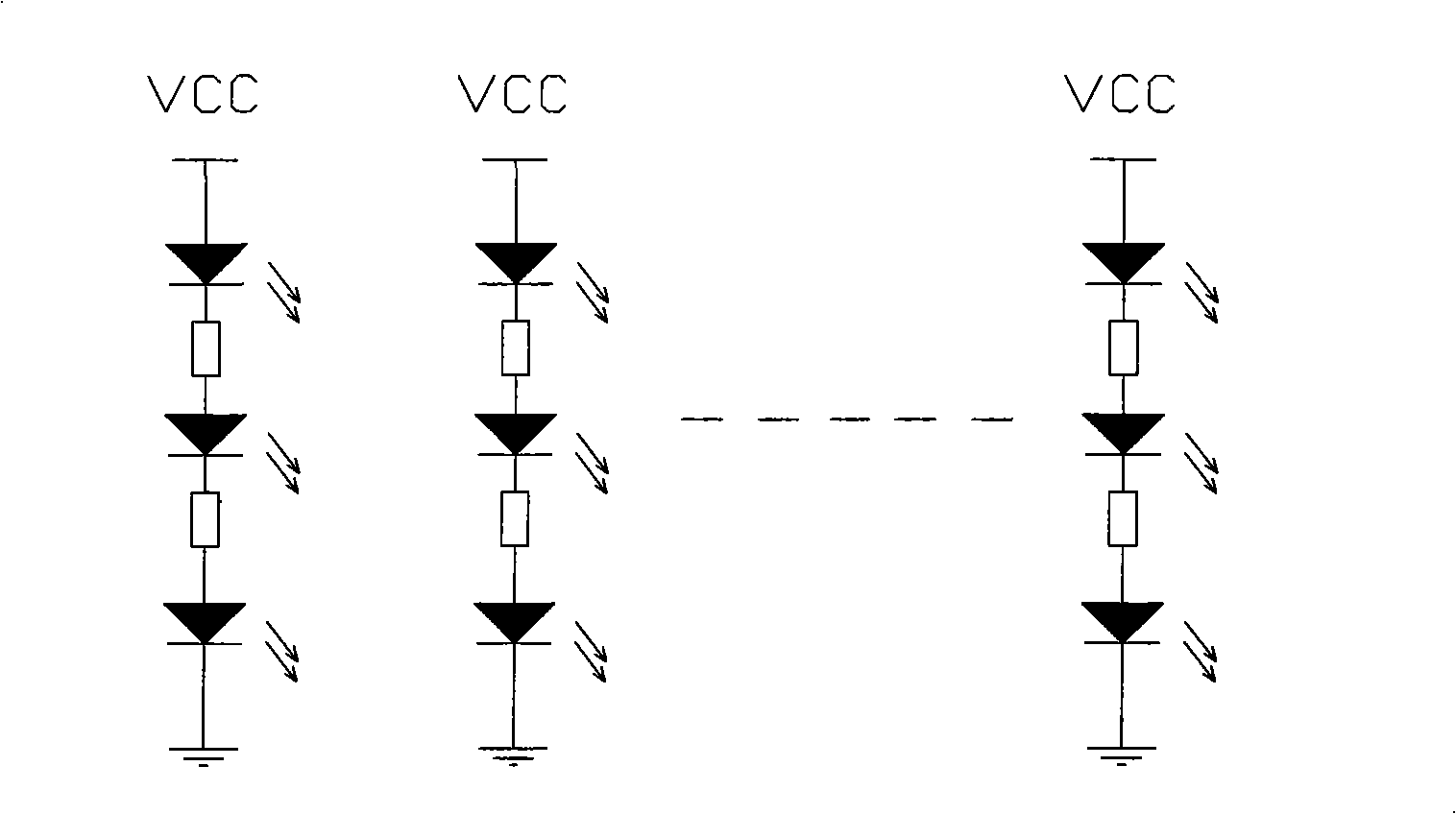

Flexible lamp filament for light emitting device and fabrication method of flexible lamp filament

InactiveCN105430904AExpand the range of exposureMeet actual needsPrinted circuit assemblingElectric circuit arrangementsEngineeringLight-emitting diode

The invention discloses a flexible lamp filament for a light emitting device and a fabrication method of the flexible lamp filament. The flexible lamp filament comprises a flexible substrate, a conductive layer, a first group of light emitting units and wrapping layers, wherein the flexible substrate has a predetermined length, a predetermined width and a predetermined thickness and is provided with an upper surface and a lower surface, the conductive layer is arranged on the upper surface of the substrate, the first group of light emitting units are arranged on the upper surface of the substrate and pass through the conductive layer to form electric connection, and the wrapping layers are arranged on the upper surface of the substrate and completely cover the first group of light emitting units. The lamp filament disclosed by the invention can be randomly bent, has a wider light emitting angle, and is beneficial for design and fabrication of the light emitting device which is attractive and free.

Owner:JINGYANG LIGHTING CO LTD

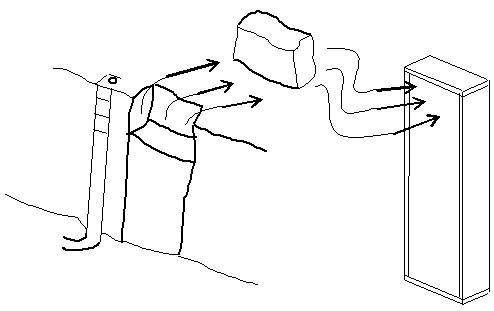

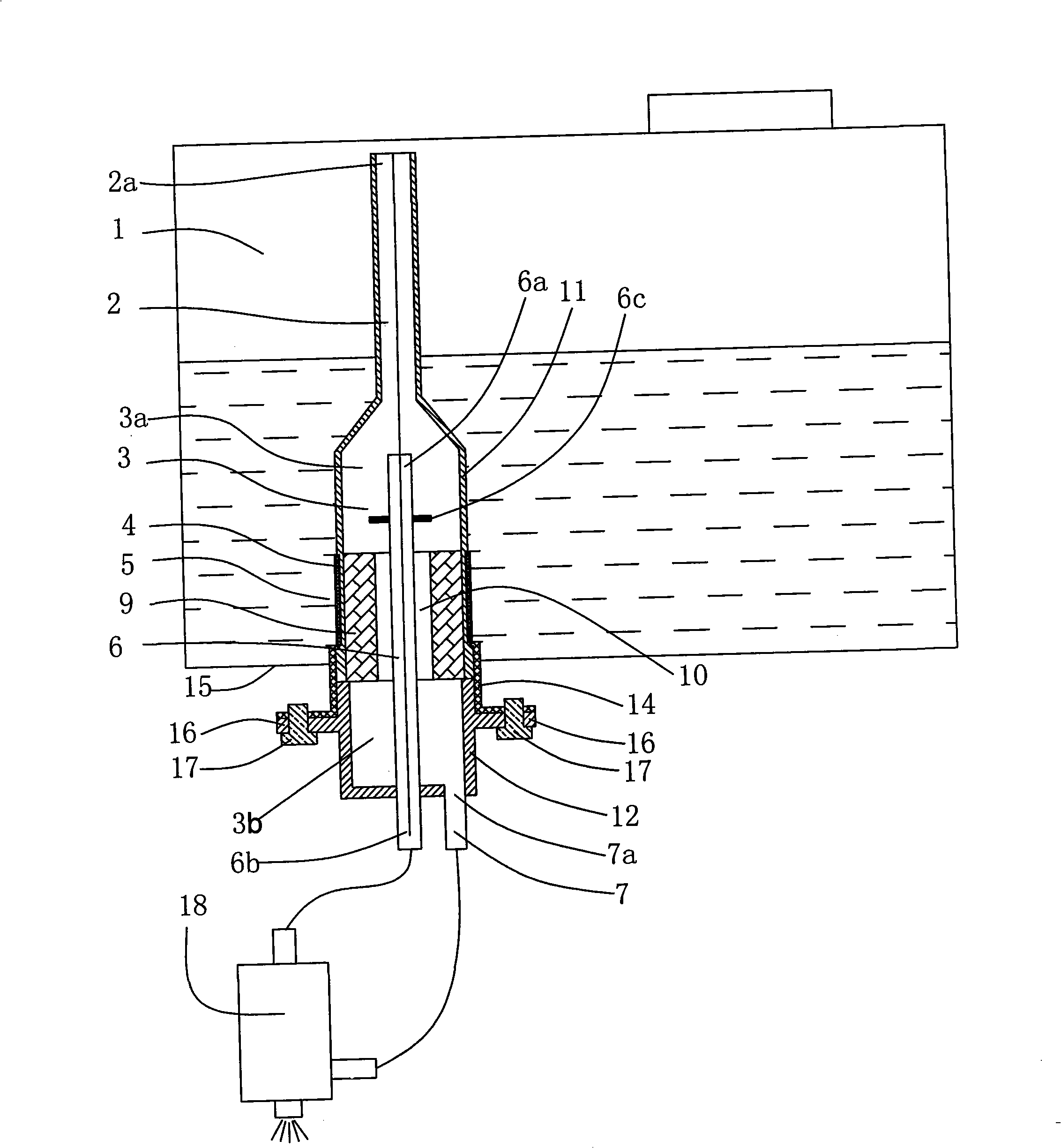

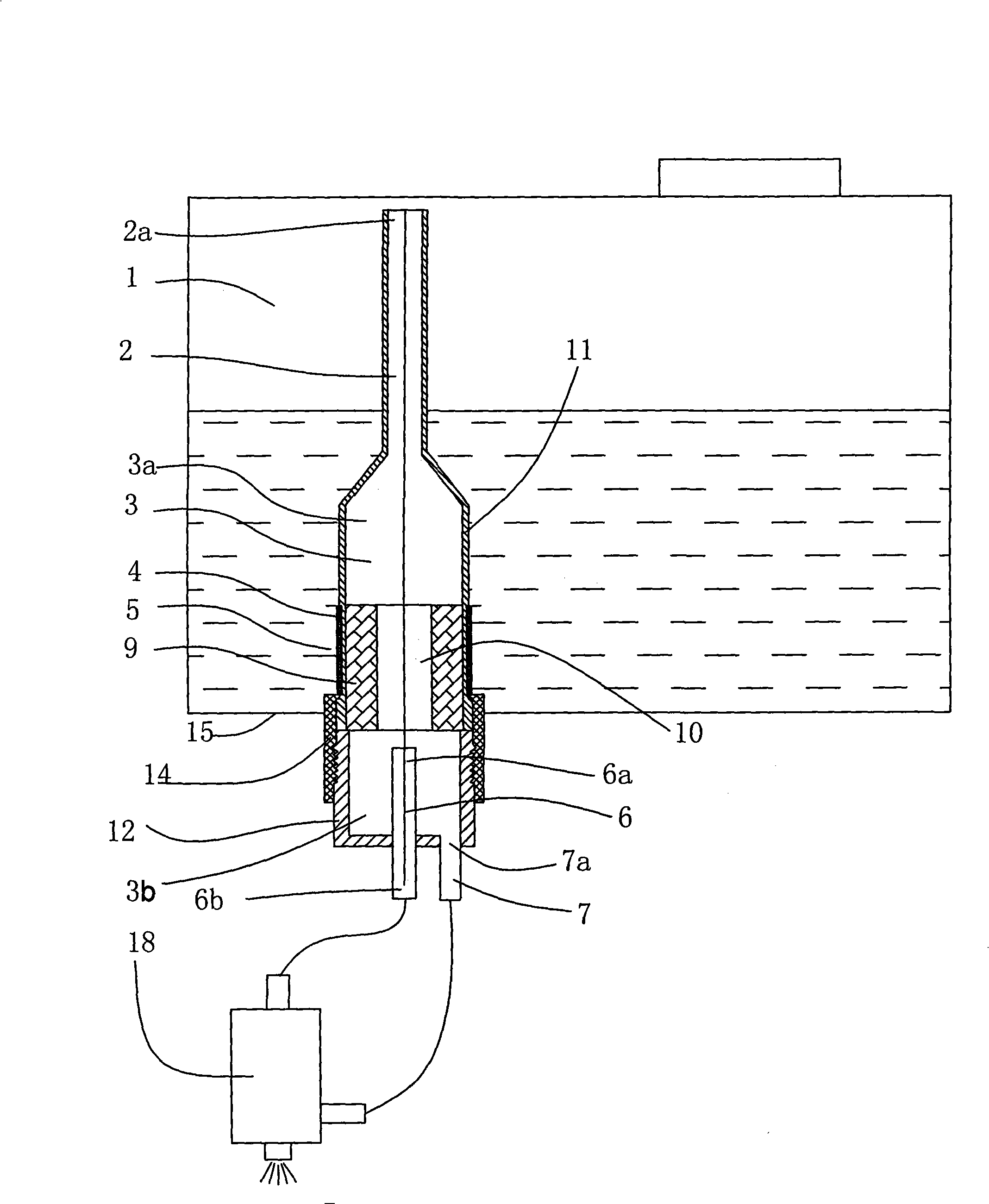

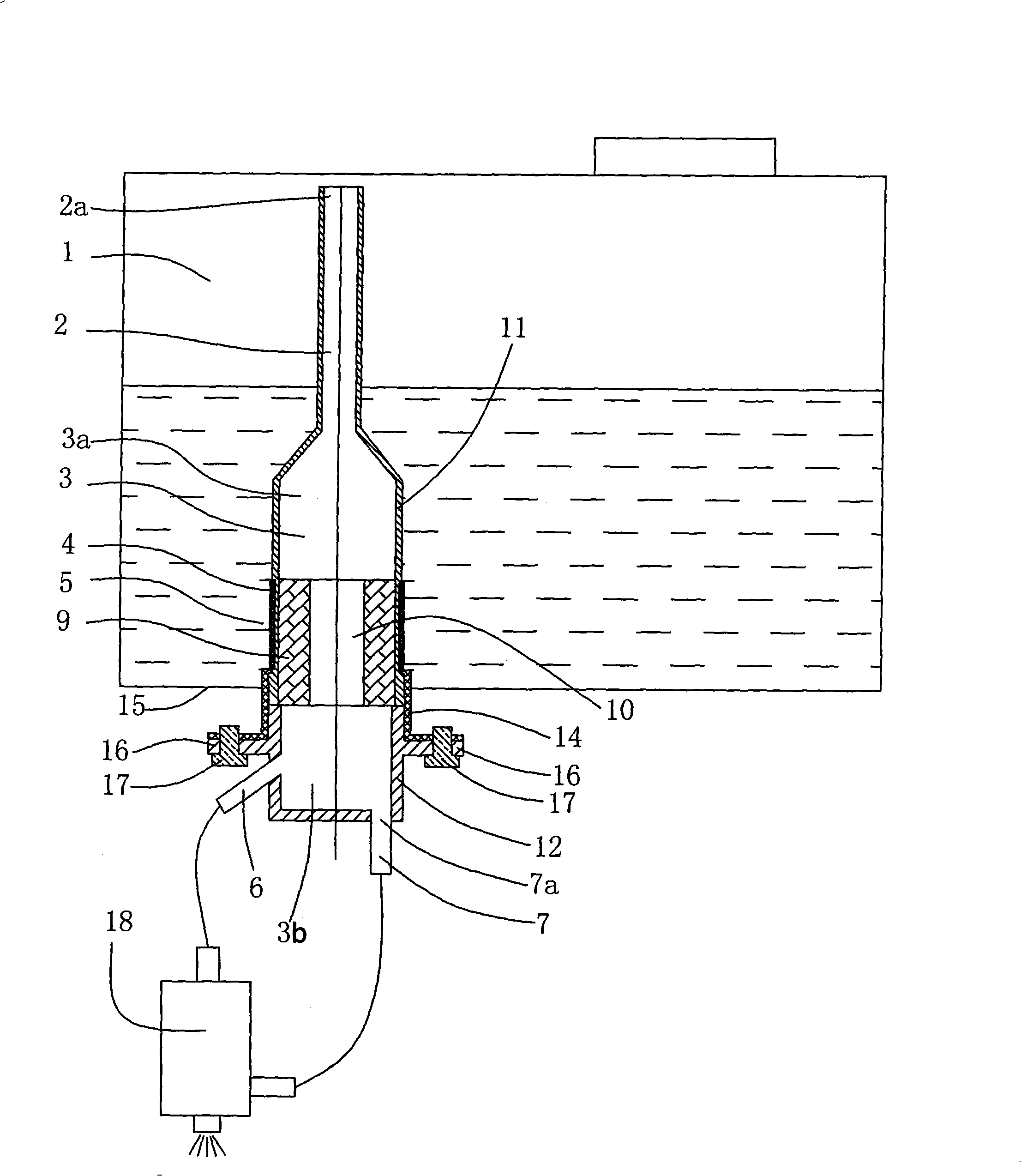

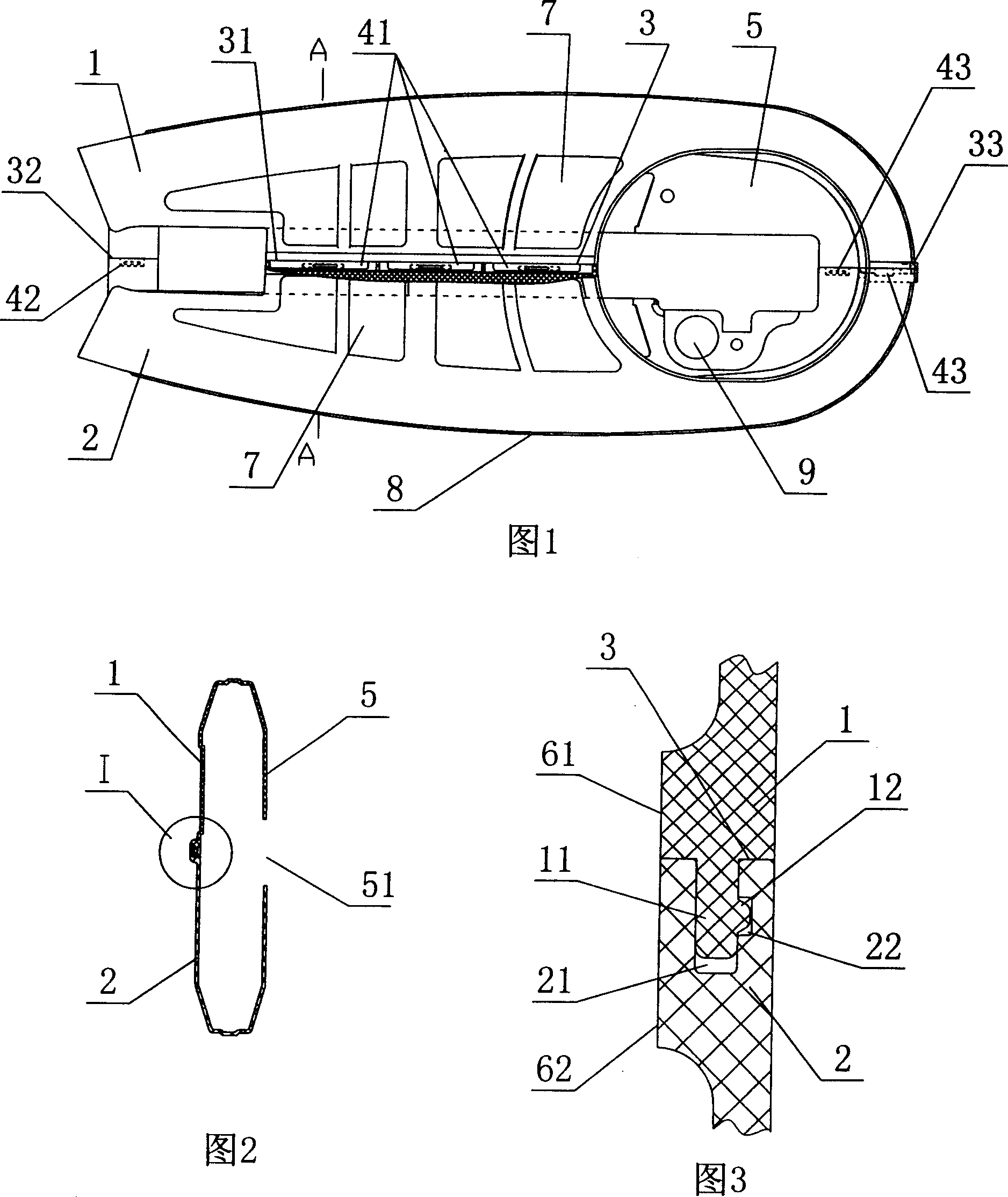

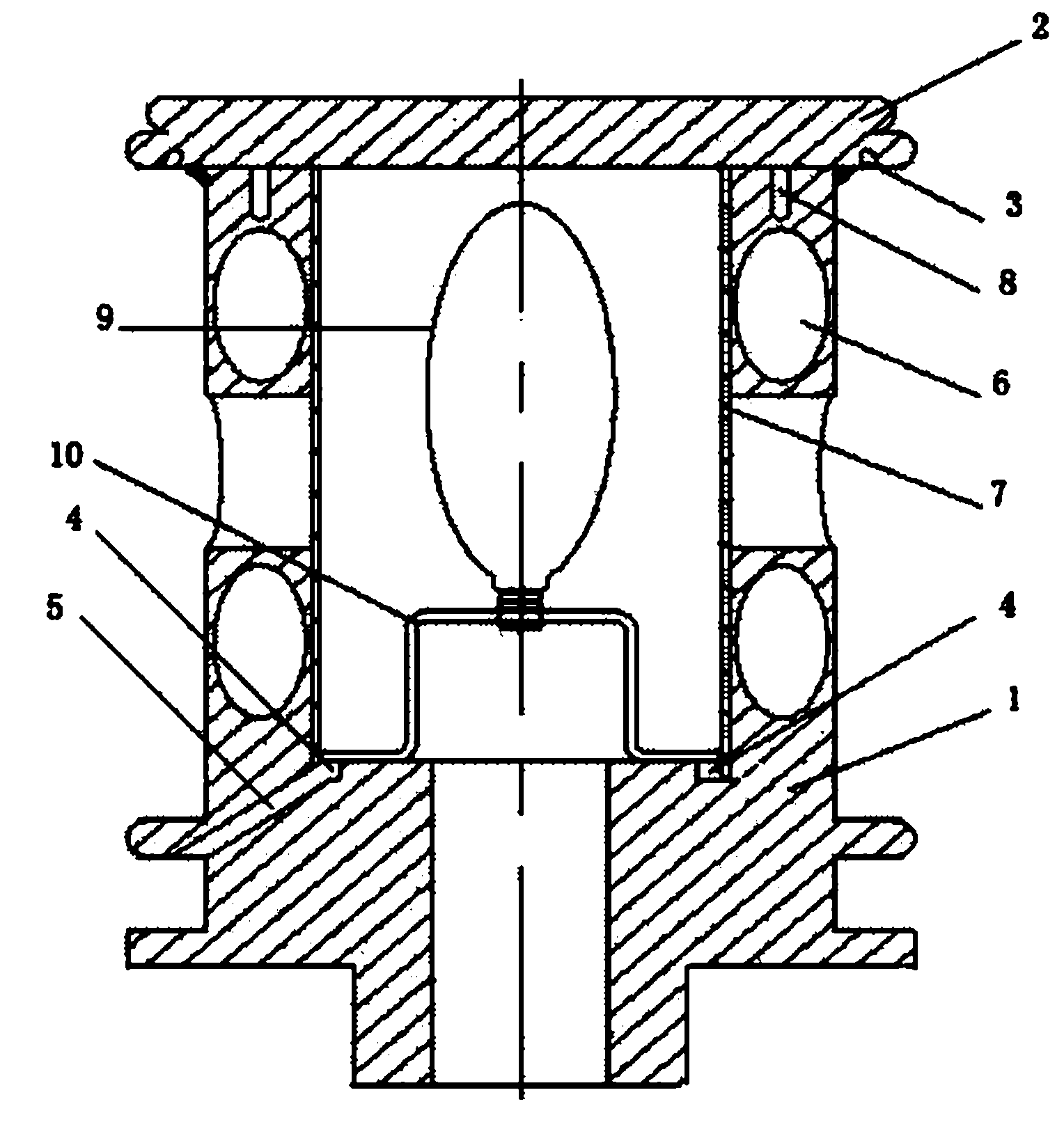

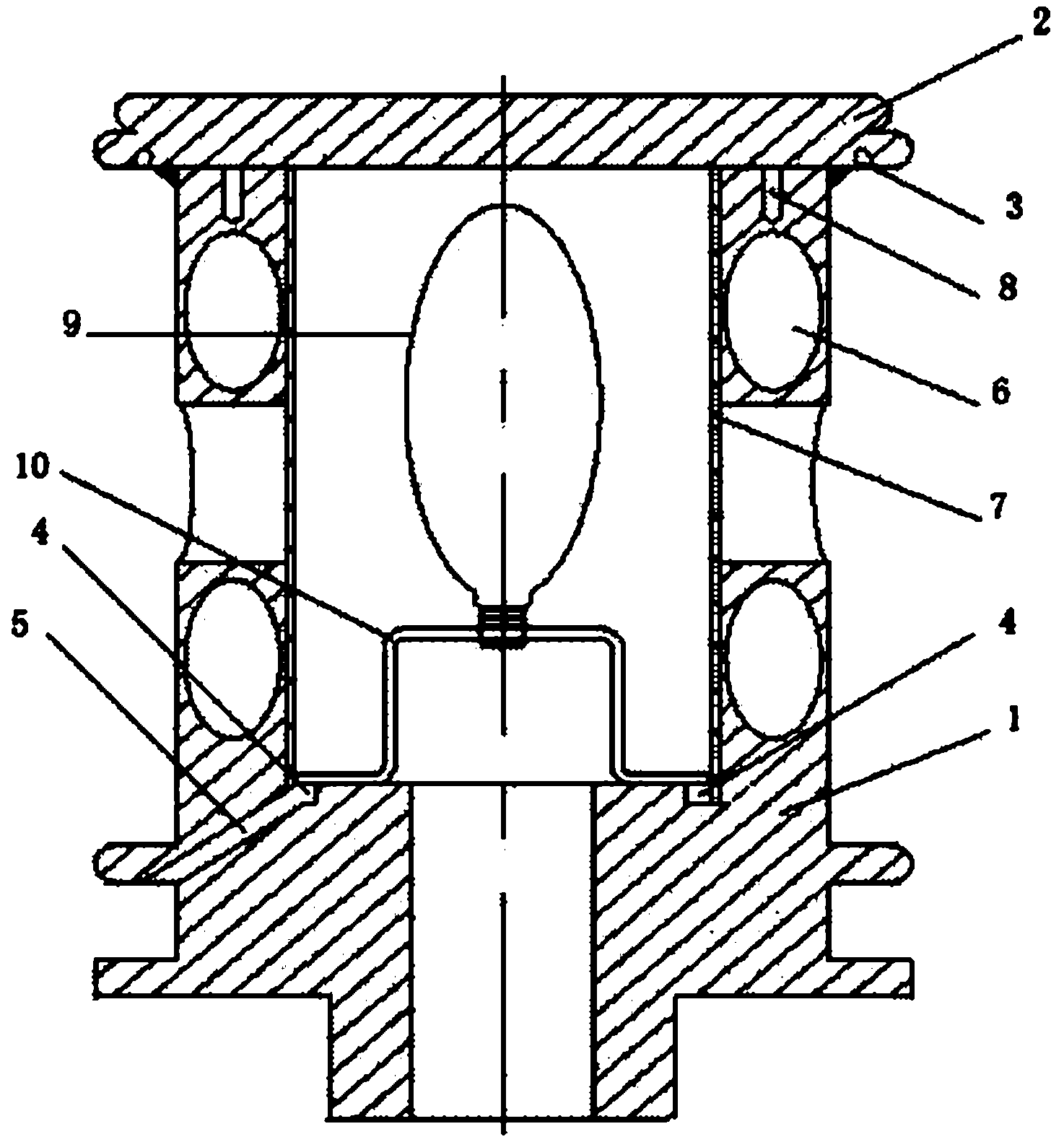

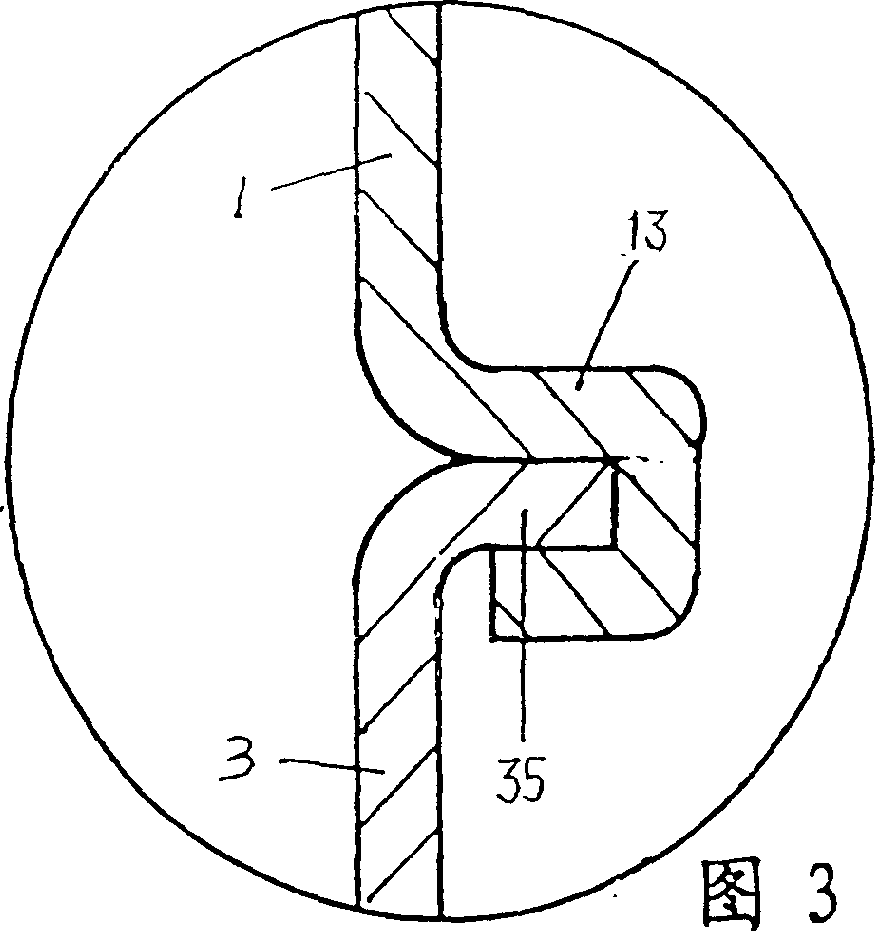

Filtrating type vapor-liquid separating device

InactiveCN101311522AGuaranteed to workExtended service lifeLiquid degasificationMachines/enginesVapor liquidSprayer

A filtering gas-liquid separation device belongs to the technical field of fuel supply of an engine which includes an exchange cubage and an oil return tube used for receiving the return oil of the fuel sprayer; an exhaust channel is arranged above the exchange cubage; an oil outlet tube used for supplying oil to a fuel sprayer is arranged below the exchange cubage; an oil inlet used for leading the fuel to enter the device from an oil box is arranged in a fuel box; a multiple fuel filters are arranged between the oil inlet and the exchange cubage; the outlet of the oil return tube is arranged in the exchange cubage so as to lead the distance to be larger than the size of the largest confusion area of the liquid of the oil return tube and lead the air bladders of the oil return tube to be incapable of entering the oil outlet tube. The invention can be suitable for a pulse electric fuel spraying system which not only ensures the fuel steams to be exhausted in time, increase the filtering of multiple fuels and lead the fuel spraying system to work reliably, but also can carry out complete protection on the fuel sprayer and obtain further improvements on the productive performance and beautiful performance simultaneously.

Owner:塞尔福(厦门)工业有限公司

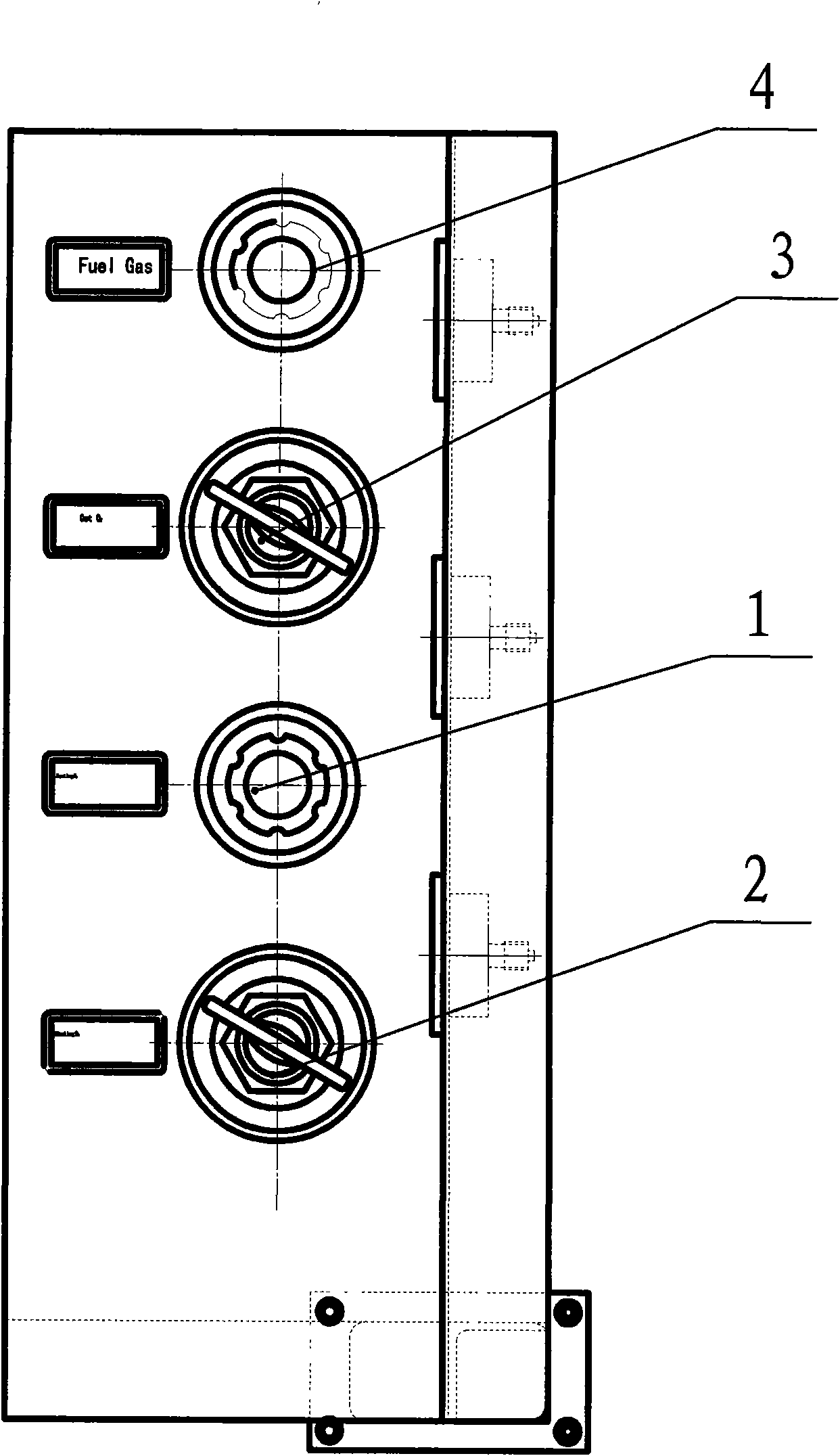

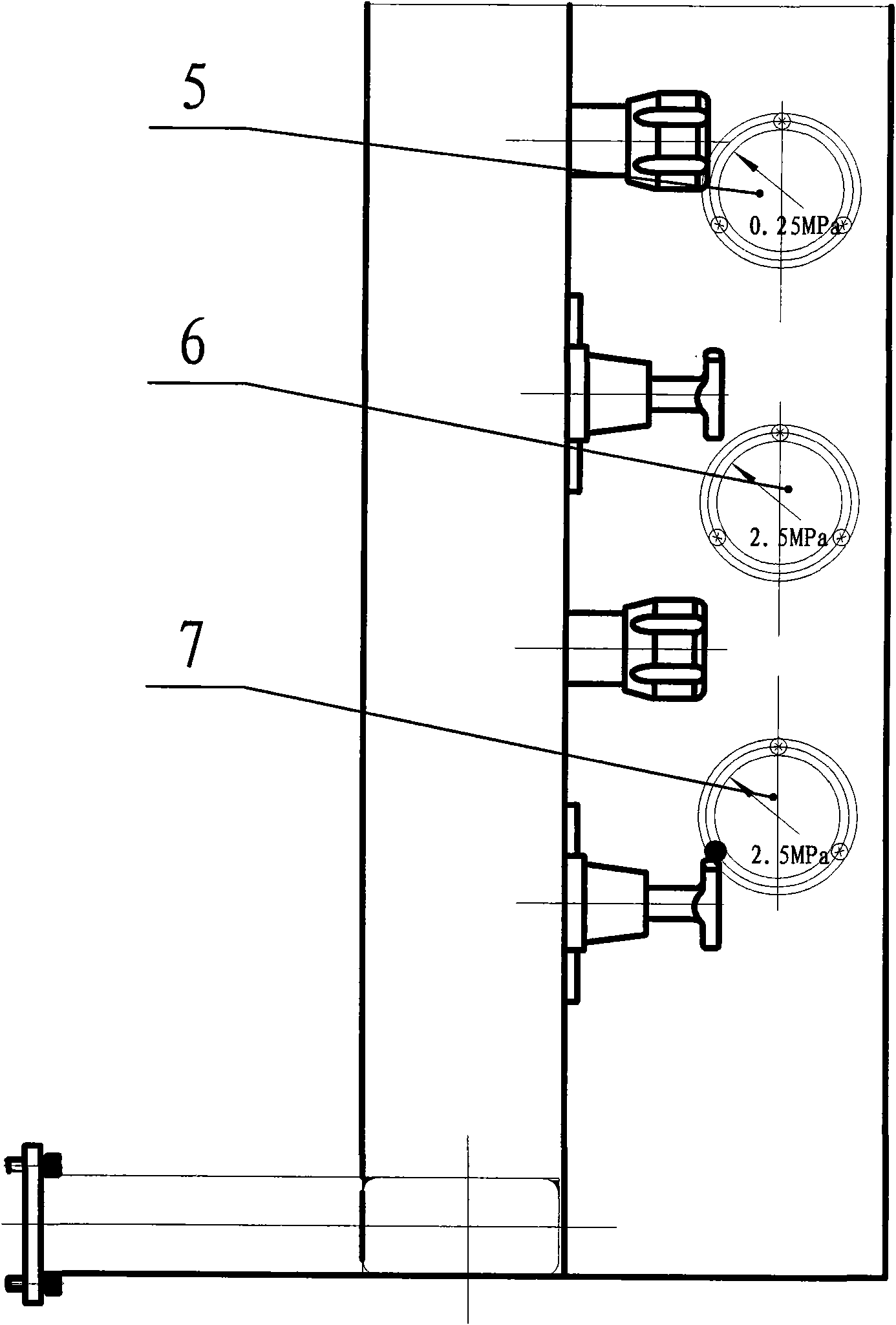

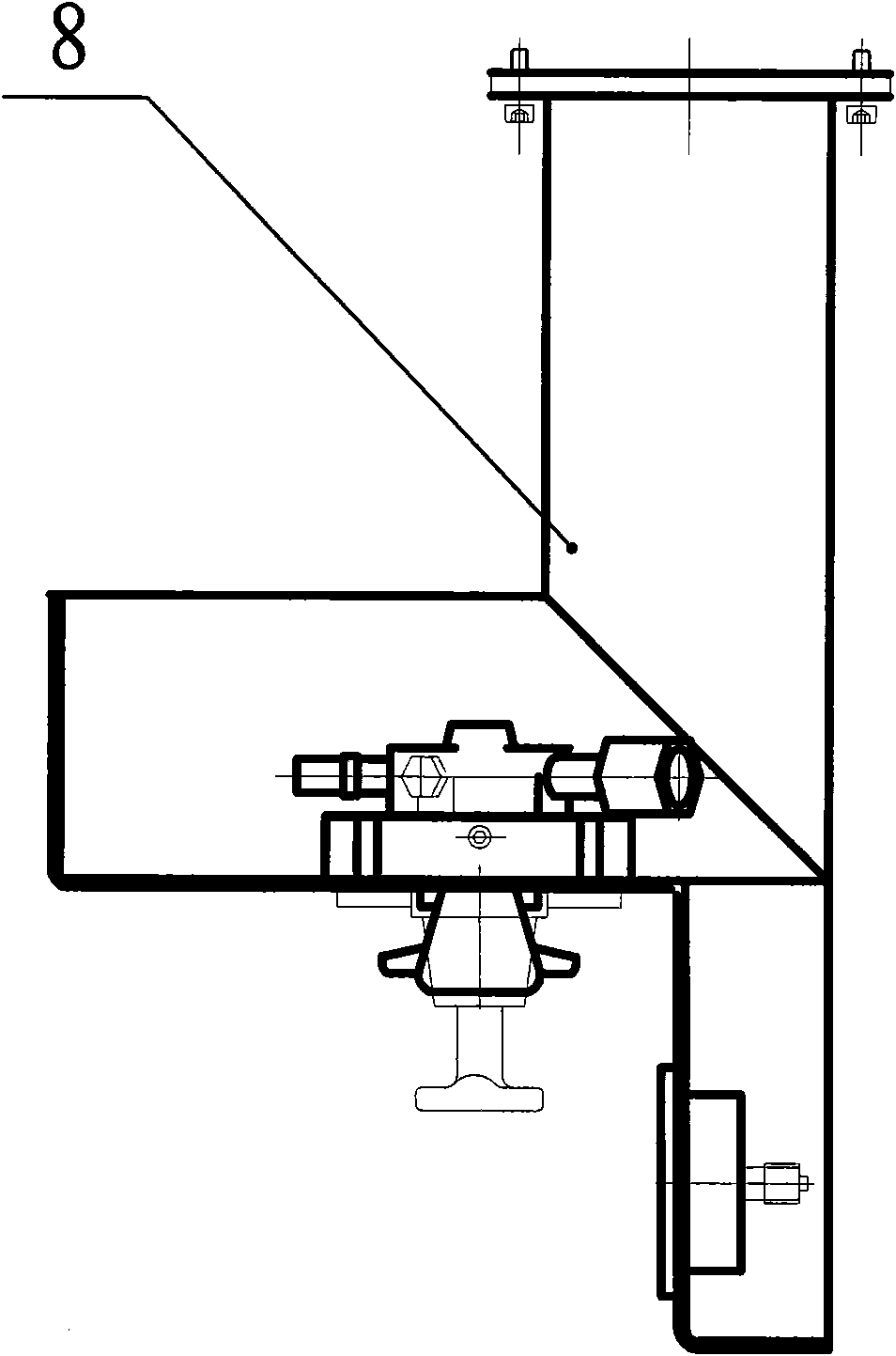

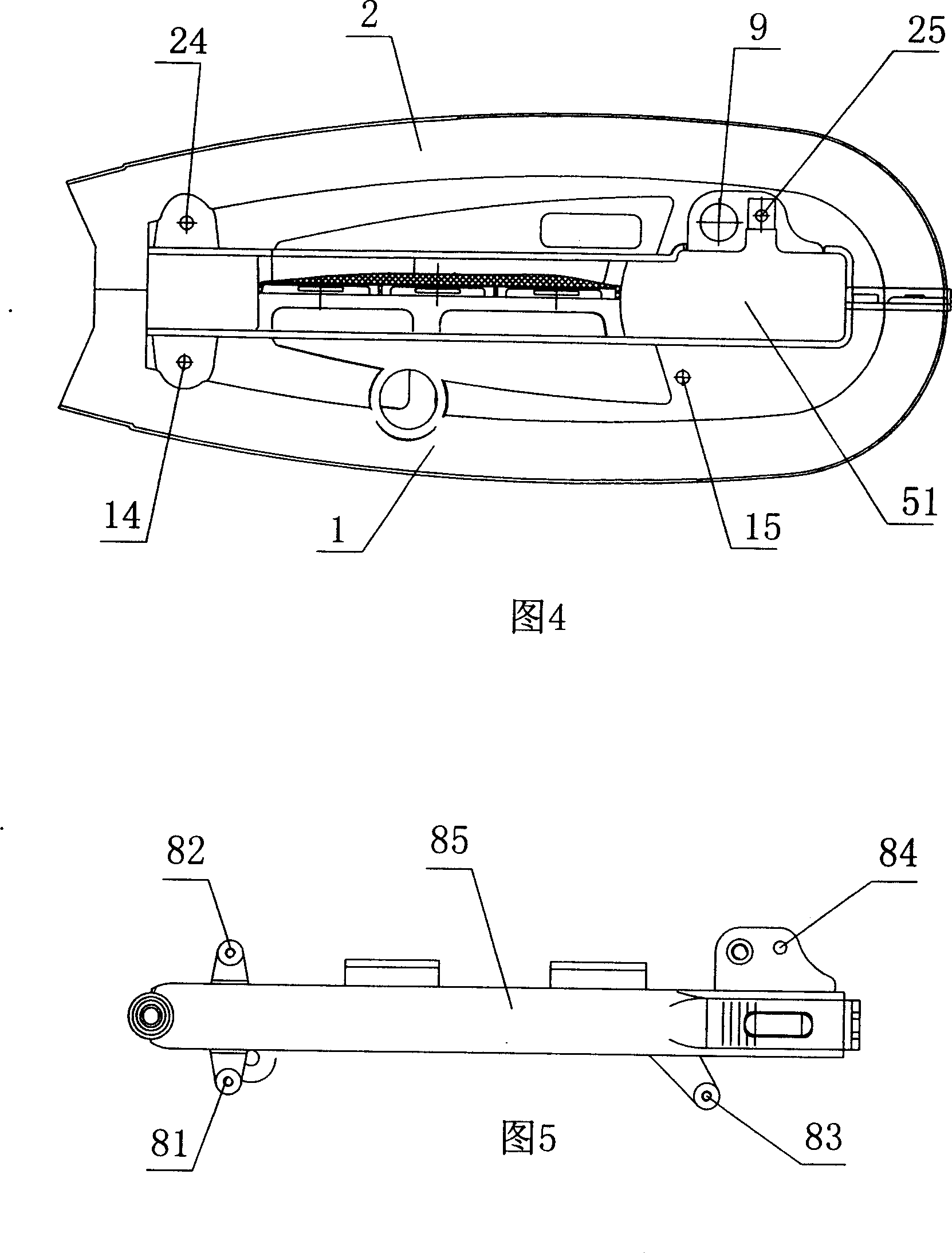

Mounting structure of gas control valve of cutting machine

InactiveCN101637841ASimple installation structureIntuitive installation structureGas flame welding apparatusEngineeringControl valves

The invention relates to a mounting structure of a gas control valve of a cutting machine. The mounting structure is characterized by comprising a low preheating oxygen relief valve, a high preheatingoxygen relief valve, a cutting oxygen relief valve, a fuel gas relief valve, a preheating oxygen pressure gauge, a cutting oxygen pressure gauge, a fuel gas pressure gauge and an mounting plate; andthe mounting plate is respectively provided with the low preheating oxygen relief valve, the high preheating oxygen relief valve, the cutting oxygen relief valve and the fuel gas relief valve on sidesat sides, and a front surface of the mounting plate is respectively provided with the preheating oxygen pressure gauge, the cutting oxygen pressure gauge and the fuel gas pressure gauge. The mountingplate has a rectangular structure and formed by flanging plates. The mounting structure of a gas control valve of a cutting machine has simple and visual structure, convenient adjustment, simple assembly, high and low pressure switching and the rectangular mounting plate with beautiful appearance and space saving.

Owner:WUXI HUALIAN PRECISION MACHINERY

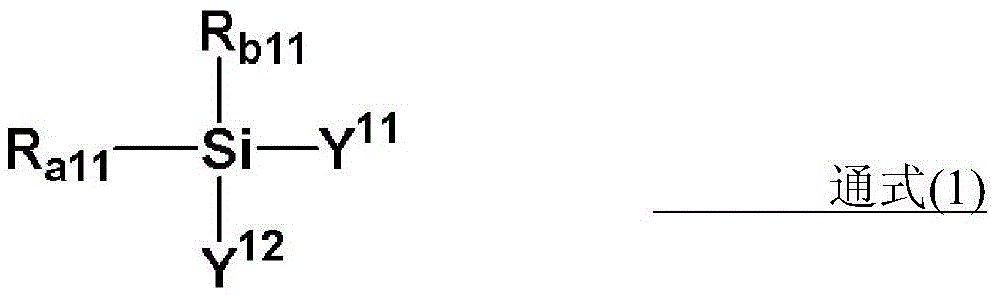

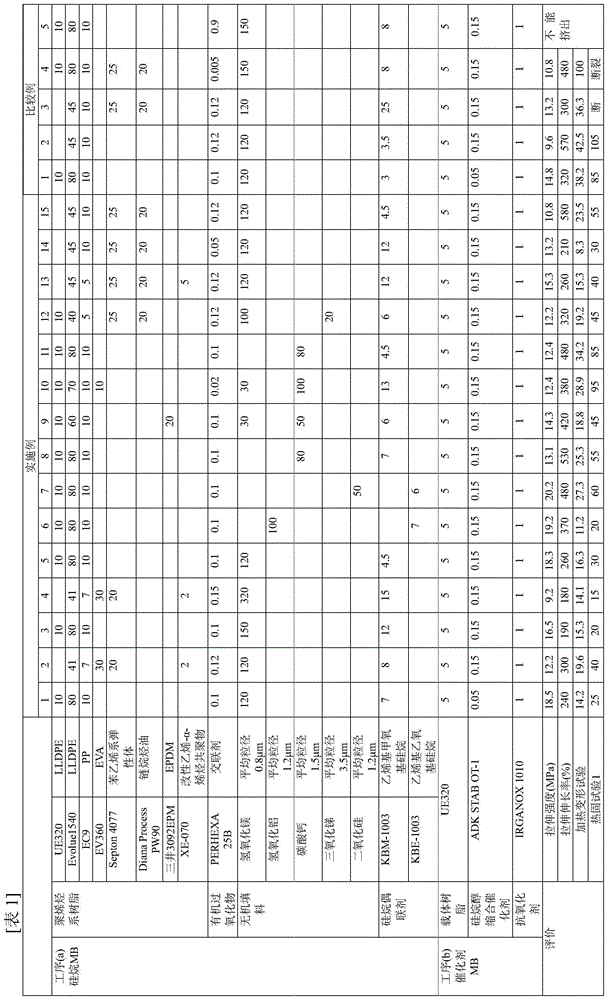

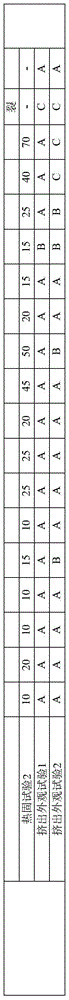

Heat-resistant silane crosslinked resin molded article and method for producing same, heat-resistant silane crosslinking resin composition and method for producing same, silane master batch, and heat-resistant product produced using heat-resistant silane crosslinked resin molded article

A production method involving step (a) of melt-kneading 100 parts by mass of a polyolefin resin with 0.01 to 0.6 part by mass inclusive of an organic peroxide, 10 to 400 parts by mass inclusive of an inorganic filler, and more than 4 parts by mass and 15.0 parts by mass or less of a silane coupling agent at a temperature that is equal to or higher than the decomposition temperature of the organic peroxide to prepare a silane master batch; a silane master batch produced by the production method; a heat-resistant silane crosslinked resin molded article; a heat-resistant silane crosslinking resin composition; and a heat-resistant product.

Owner:FURUKAWA ELECTRIC CO LTD

Water containing nanometer SOD and its preparation method

InactiveCN1597558AIncrease elasticityGood antiviral effectWater/sewage treatment by substance additionPreservativeHuman health

A water containing nano-SOD for taking care of human health is prepared through proportionally adding nano-SOD to water and stirring.

Owner:王成余

Femtosescond laser system for the exact manipulation of material and tissues

ActiveUS20140088574A1Simple laserBeautifully madeLaser surgeryLaser detailsFemto second laserPulsed laser

A device for the exact manipulation of material, especially of organic material, includes a pulsed laser system with a radiation source, said radiation source being a cavity-dumped fs oscillator.

Owner:CARL ZEISS MEDITEC AG

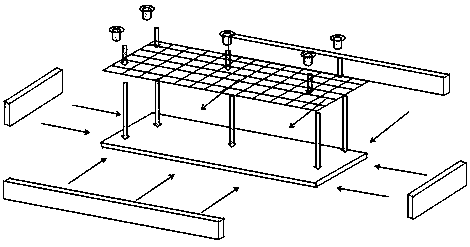

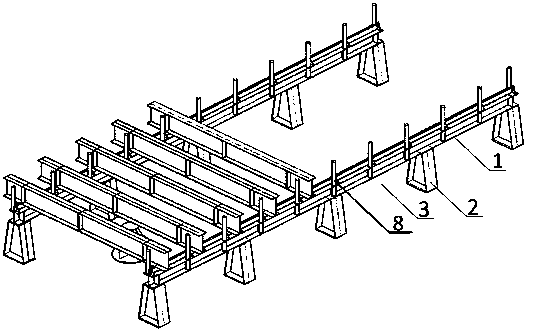

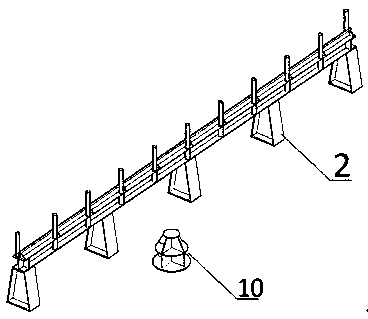

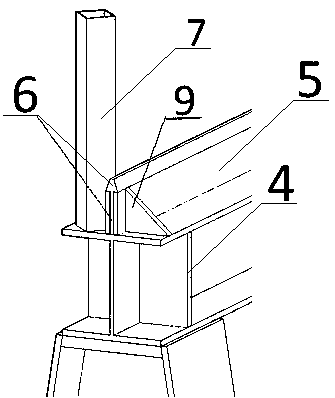

Overturning-free coating jig frame of conventional steel structure building component

The invention discloses an overturning-free coating jig frame of a conventional steel structure building component. A jig frame body and a round stool are included, and the lower surface of the lowerwing edge, in the longitudinal direction, of the rig frame body is provided with jig frame legs; spaced square stiffened plates are arranged in a web plate area of the jig frame body; non-welded longitudinal steel plates are arranged on the upper surface of the upper wing edge of the jig frame body; a coating protecting pad is sandwiched between the longitudinal steel plates; a safety locking pinpenetrating through the upper wing edge of the rig frame body is arranged on the opposite face of the square stiffened plates; triangular stiffened plates are arranged on the upper surface of an upperwing plate corresponding to the square stiffened plates and the upper surface of the other side; the round stool comprises a top pedal, a middle pedal and a bottom plate; the diameter of the top pedal is smaller than the diameter of the middle pedal and the diameter of the bottom plate; a trapezoidal stiffened plate is arranged between the top pedal and the middle pedal; and a lower stiffened plate is arranged between the middle pedal and the bottom plate and corresponds to the position of the trapezoidal stiffened plate. Due to the overturning-free coating jig frame, the coating constructionefficiency is improved by 30%, the construction difficulty is lowered, and appearance of a coating is improved; and therefore jig frame manufacturing is easy, maintaining is convenient, and the construction safety is improved.

Owner:SHANGHAI CONSTR JIANGSU STEEL STRUCTURE CO LTD

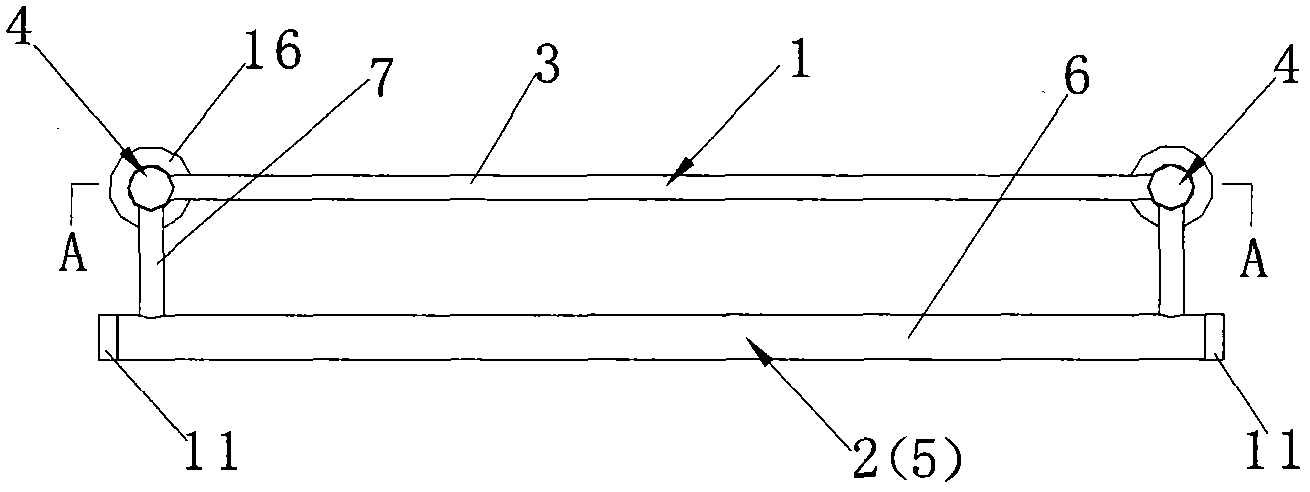

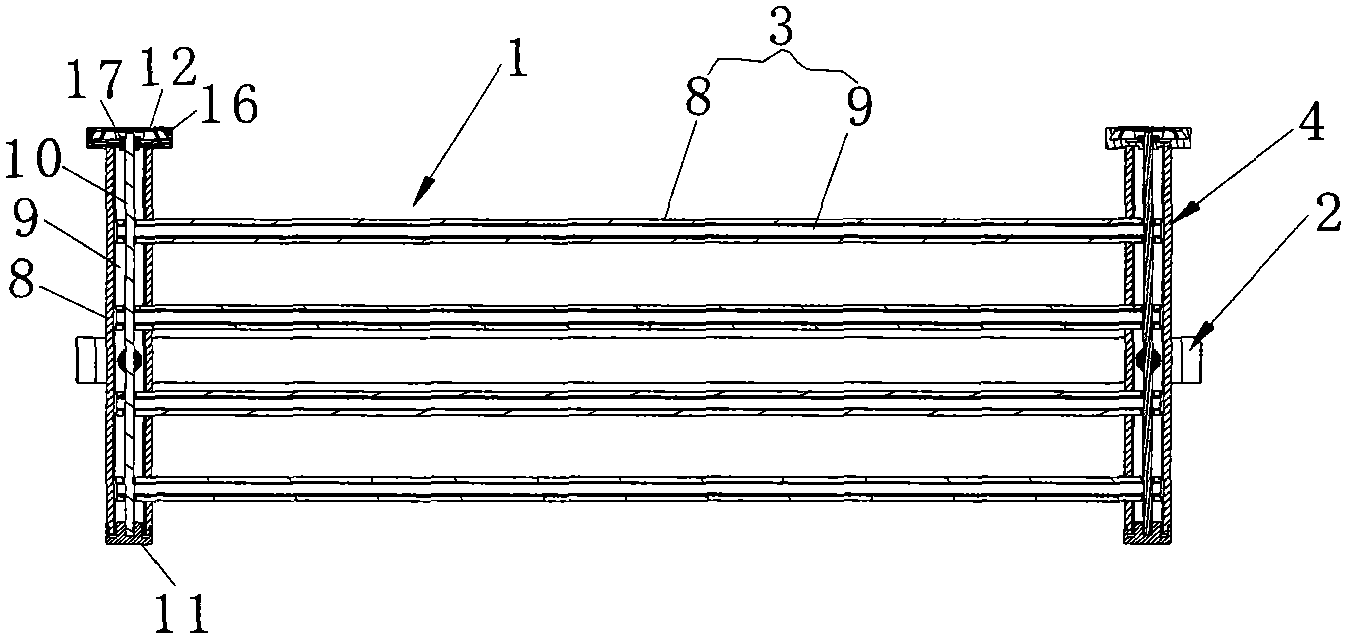

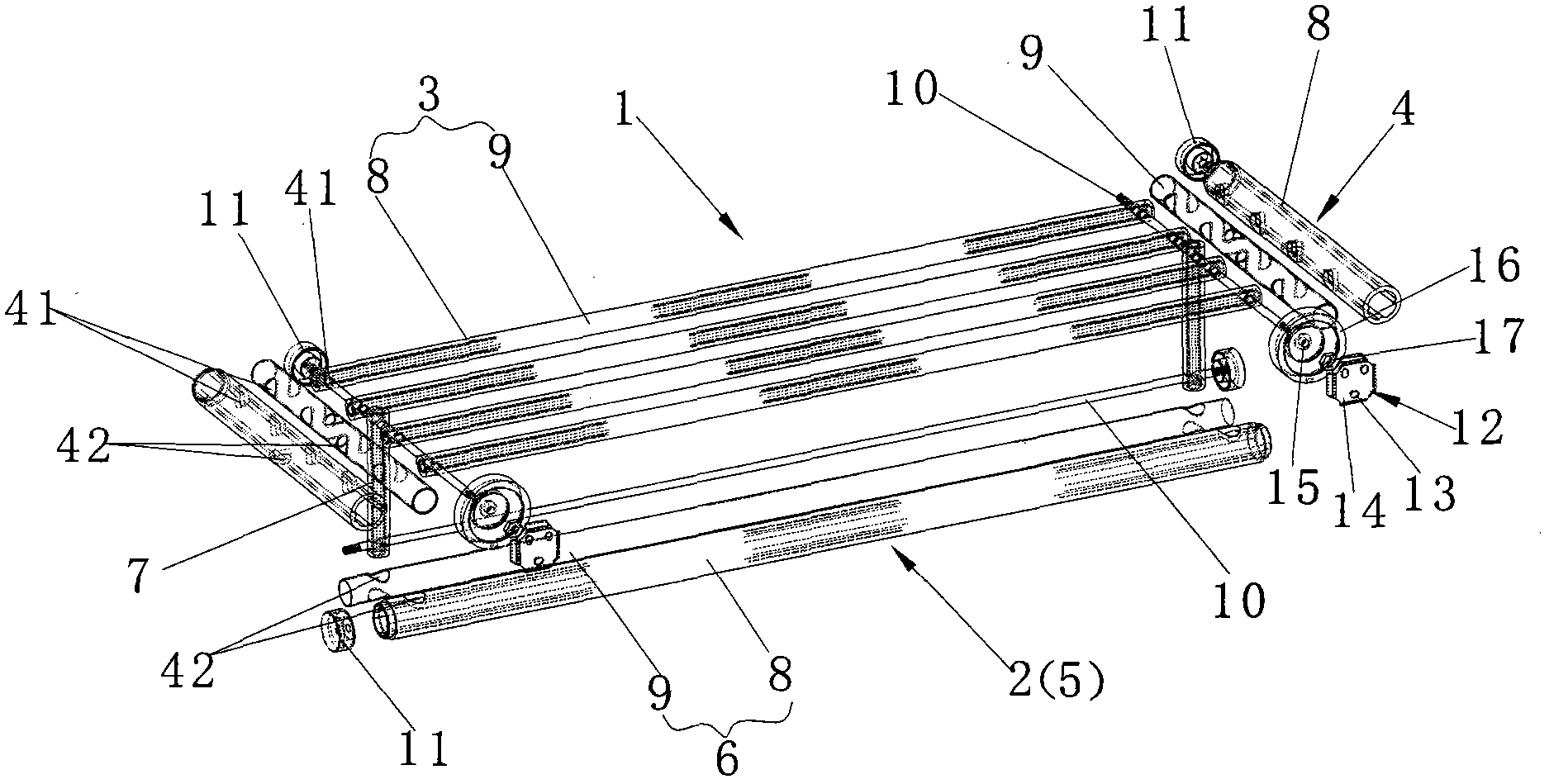

Method for making novel connecting rods and clothing hanger adopting connecting rods

The invention relates to a method for making novel connecting rods of racks which are used for accommodating daily necessaries, clothing and towels in kitchens or washrooms, and belongs to the field of furniture supplies. Each connecting rod adopting the method comprises an outer pipe (8) and an inner pipe (9). Firstly, the inner pipe (9) is made of metal materials with higher tenacity; secondly, the outer pipe (8) is made of artificial wood materials outside the inner pipe (9) and attached to the outer side of the inner pipe (9). Meanwhile, the invention further discloses a clothing hanger made of the connecting rods. The novel connecting rods provided by the invention are made of metal materials and wood materials, are low in cost, have the functions of good moisture proofing and corrosion prevention, are easy and convenient to make, and are beautiful. Besides, various horizontal supporting rods, fixed rods, horizontal rods and connecting rods of same type, which are made of wood, can be made into various color and various patterns.

Owner:柳亚平

Skin penetration wearing medicine-carrying accessory on basis of shape memory polymers

The invention relates to a skin penetration wearing medicine-carrying accessory on the basis of shape memory polymers, and particularly belongs to the field of shape memory composite materials. The skin penetration wearing medicine-carrying accessory comprises a shape memory needle, a needle base and an ornament. The shape memory needle and the ornament are fixed to two sides of the needle base. The skin penetration wearing medicine-carrying accessory has the advantages that sterilization and anti-inflammation medicines are carried in shape memory needle materials, and accordingly the affectedpart inflammation probability can be reduced; the shape memory needle materials are excellent in biocompatibility and biodegradability, and accordingly rejection or allergic reaction can be prevented; the shape memory needle materials have shape memory functions and can be recovered to be in initial shapes under the effect of certain thermal stimulation, and accordingly the skin penetration wearing medicine-carrying accessory is convenient to remove; the shape memory needle can be used as a piercing needle, the skin penetration wearing medicine-carrying accessory is in attractive appearance,and users can wear the skin penetration wearing medicine-carrying accessory after piecing is carried out on the users.

Owner:HARBIN INST OF TECH

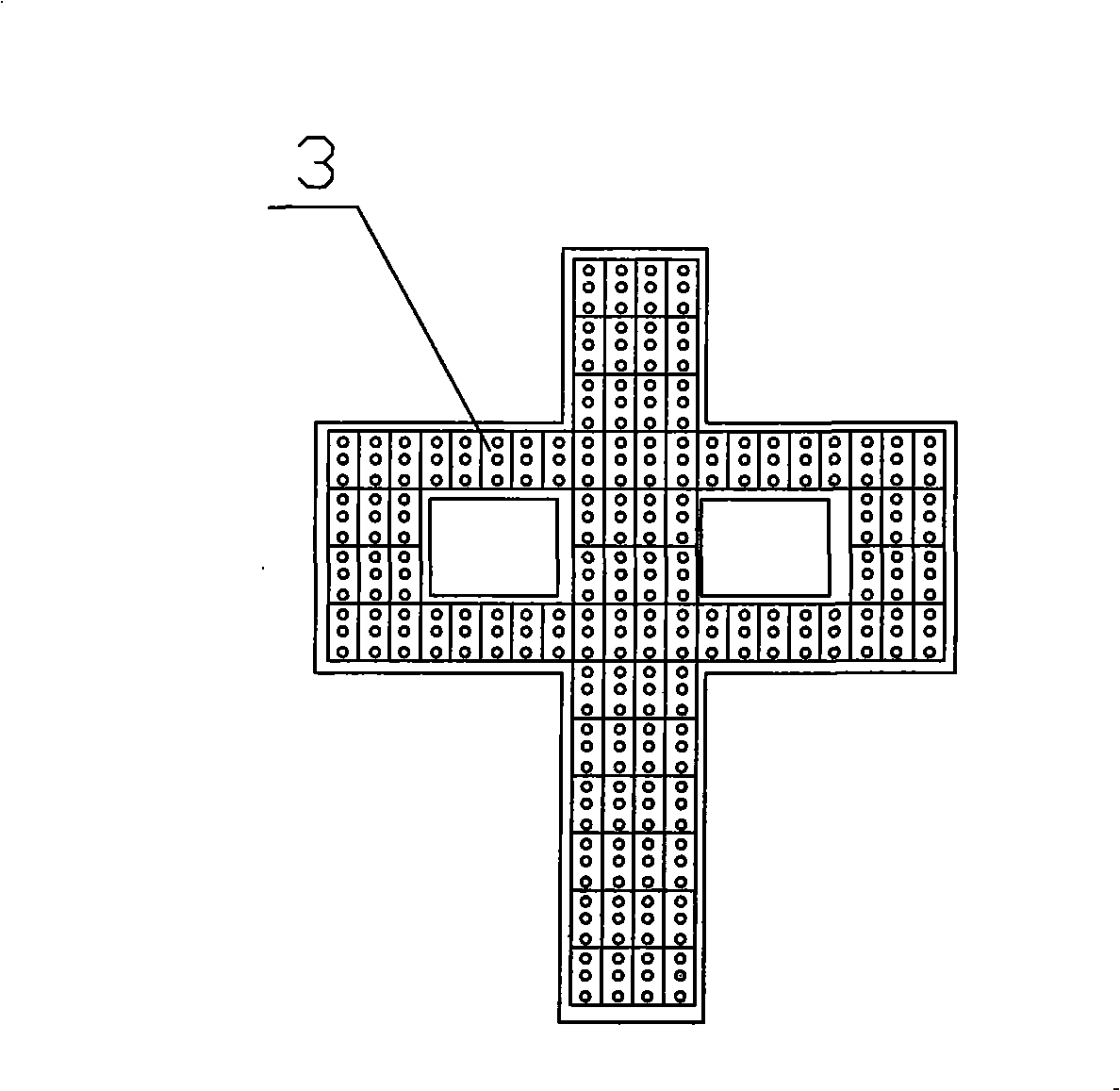

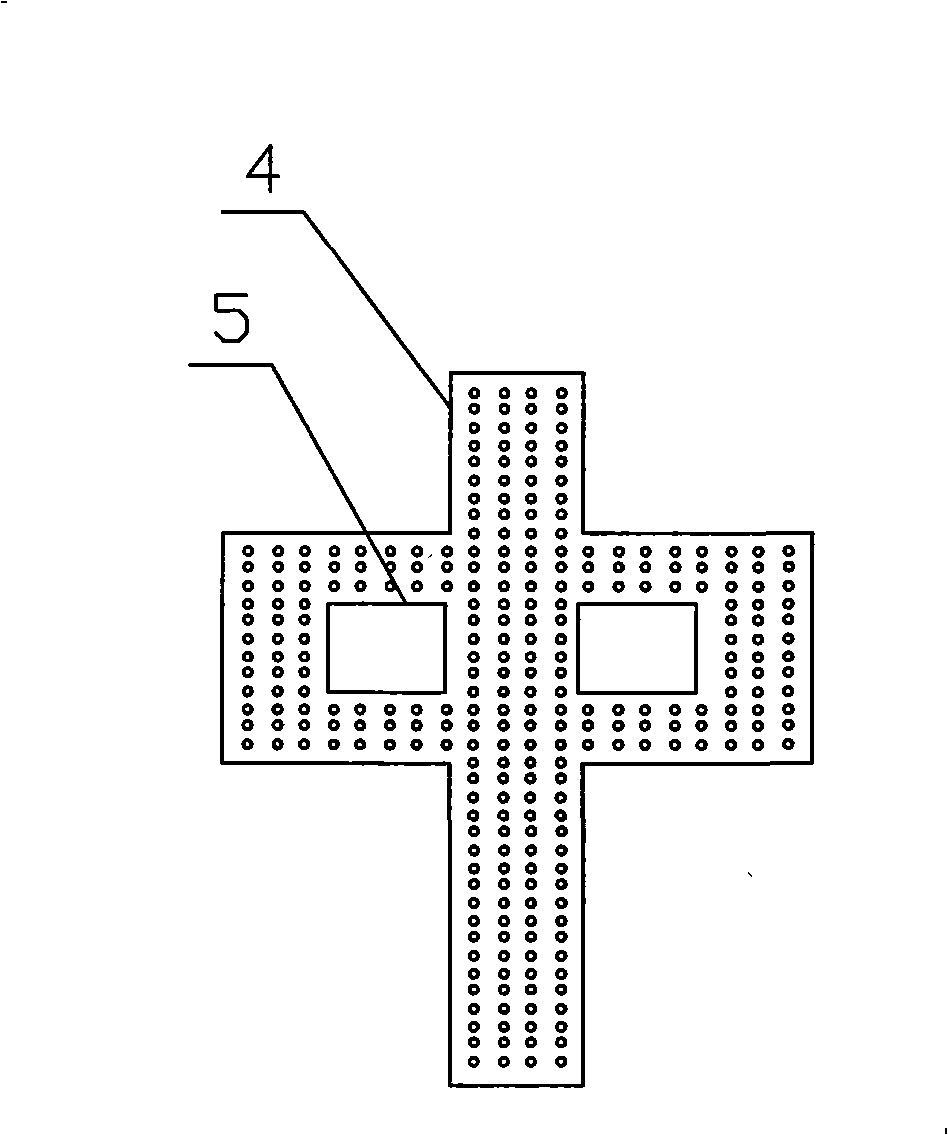

Injection moulding font advertisement lamp box device and its making method

InactiveCN101261795AEasy to manufactureBeautifully madePoint-like light sourceElongate light sourcesElectrical resistance and conductanceEngineering

The invention relates to an injection font advertising light box device and a manufacture method thereof, which comprises a shut outer contour cast frame used for forming the font and a plurality of small built-in shut cast frames, wherein an LED lamp circuit board is arranged in the font cavity, a transparent light board is covered over the front face of the font cavity, and a base plate is arranged on the bottom face. The circuit of the integrated LED lamp circuit board of invention is connected by a plurality of LED lamp series units in parallel on the whole circuit board to compose the required font shape, wherein the LED lamp series unit consists of three LED lamps connected in series and a resistance arranged between two adjacent LED lamps. This structure design overcomes the deficiency that the current LED font advertising luminescent font is formed through gluing together a plurality of luminescent units and has the advantages of more convenient and quick manufacture of the luminescent font, beautiful appearance as well as good quality of products and stable and reliable application.

Owner:林忠红

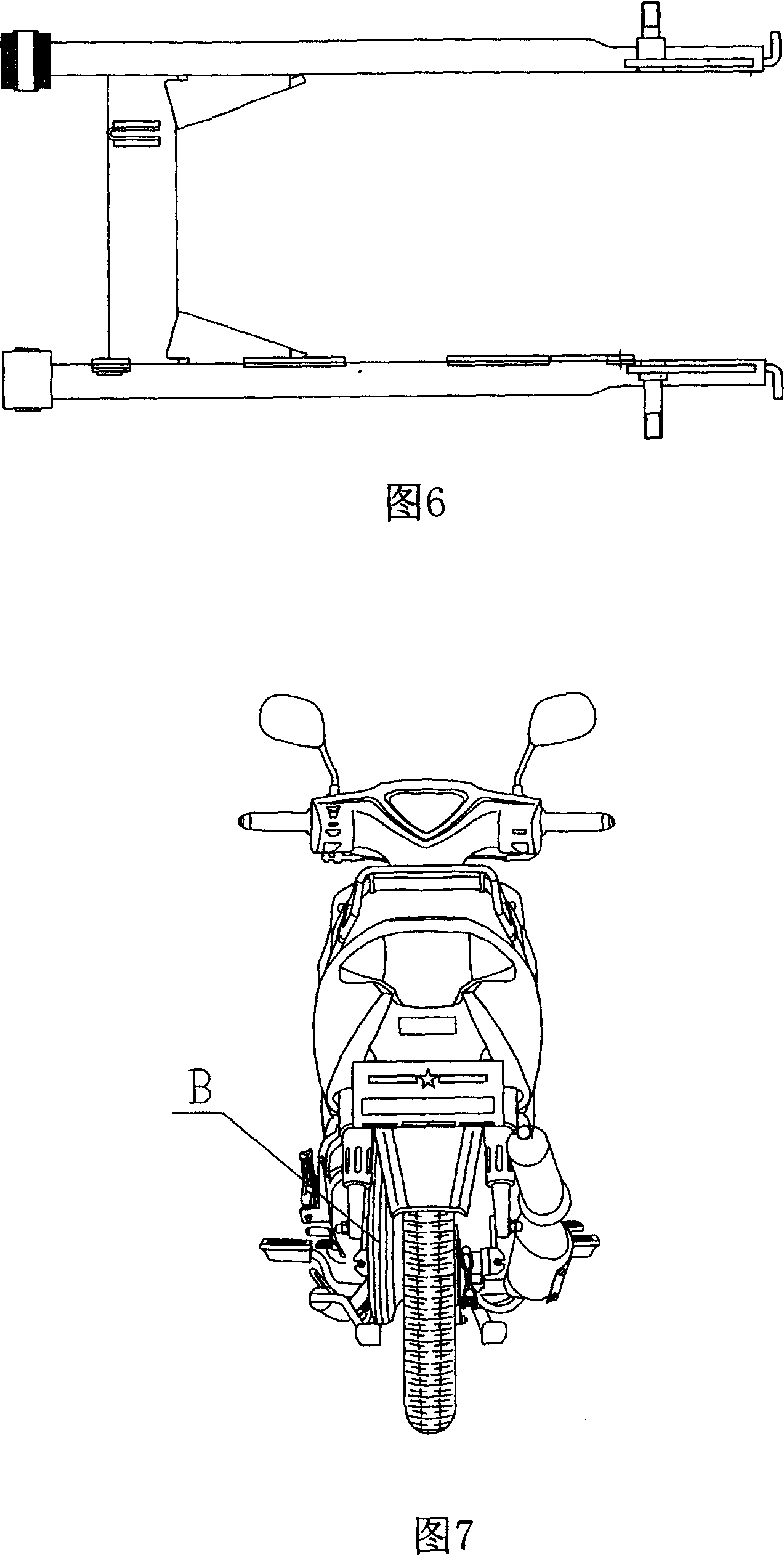

Plastic chain guard

The plastic chain guard for motorcycle consists of several prefabricated blocks connected through tongueandgroove. The plastic chain guard has reduced friction noise, high integrity, simple manufacture, easy installation, low cost and other advantages.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

Fresh animal medicine epoxy resin specimen manufacturing method and specimen manufacturing equipment

PendingCN111213633ABeautifully madePrevent discolorationDead animal preservationEducational modelsAdhesive glueNaked eye

The invention discloses a fresh animal medicine epoxy resin specimen making method and specimen making equipment. The method comprises the following steps: S1) material preparation: making 0.05-0.1 mmtransparent silk thread; S2) pretreatment: treating a fresh animal product with a preservative, fixing the treated fresh animal product on the transparent silk thread, and suspending the fresh animalproduct in a mold through the transparent silk thread; S3) glue injection: pouring an epoxy resin glue into the mold until the liquid level of the top layer is convex; and S4) demouding: taking out the solidified fresh animal product specimen, and polishing the top surface and the edge into a mirror surface by using a polishing machine to obtain a finished product. According to the preparation method of the fresh animal medicine epoxy resin specimen, the transparent silk threads made of the same material as the specimen glue are used for fixing the decoction pieces and the labels, so that after the specimen is prepared, the transparent silk threads are difficult to see clearly by naked eyes in the specimen, and the prepared specimen is attractive.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

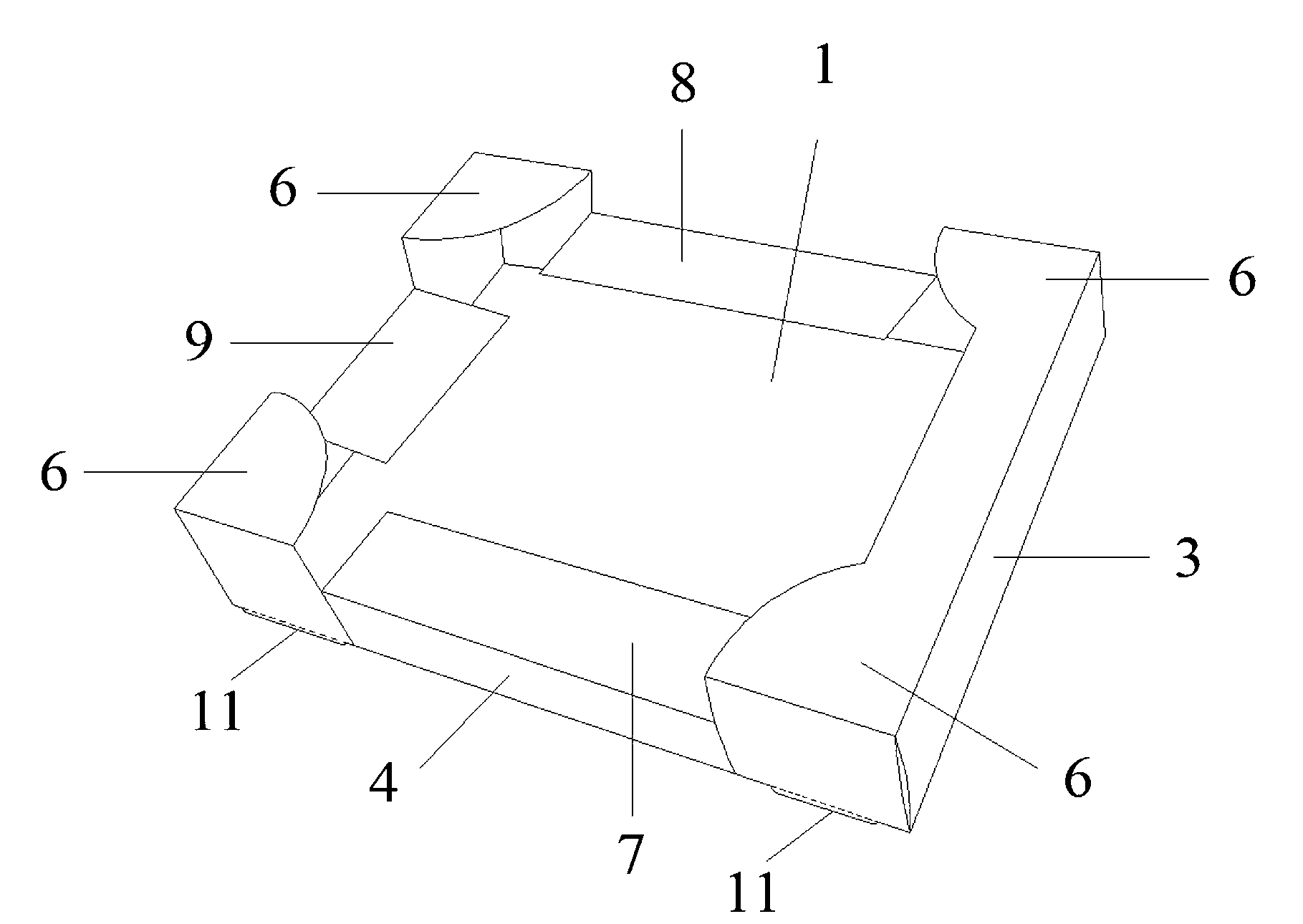

Packing box

The invention discloses a packing box which is characterized in that the packing box is made of a paperboard blank with a broken line. The packing box comprises a rectangular bottom face, upper, lower, left and right side walls integrally connected with four edges of the bottom face, and four top angle protective plates formed by folding adjacent two side walls and used for forming a top face of the packing box. The packing box further comprises upper, left and right base plates. The left and right side walls are provided with slots, and the upper and lower side walls are provided with plug boards matched with the slots. The packing box provided by the invention has the beneficial effects that the packing box is integrally formed by folding a paper material, and is reasonable in design, attractive in appearance and simple, convenient and quick to manufacture, and is particularly suitable for packing articles such as picture frames; the base plates can be used to prevent articles in both sides of the base plates from being contacted and rubbed so that abrasion among articles can be reduced; adjacent side walls are matched with the plug board through the slots to mould the packing box, so that the packing box can be unfolded conveniently to form a panel which occupies small space, the packing box is not damaged, and the repeating utilization factor is high.

Owner:SUZHOU ORIGIN IND DESIGN

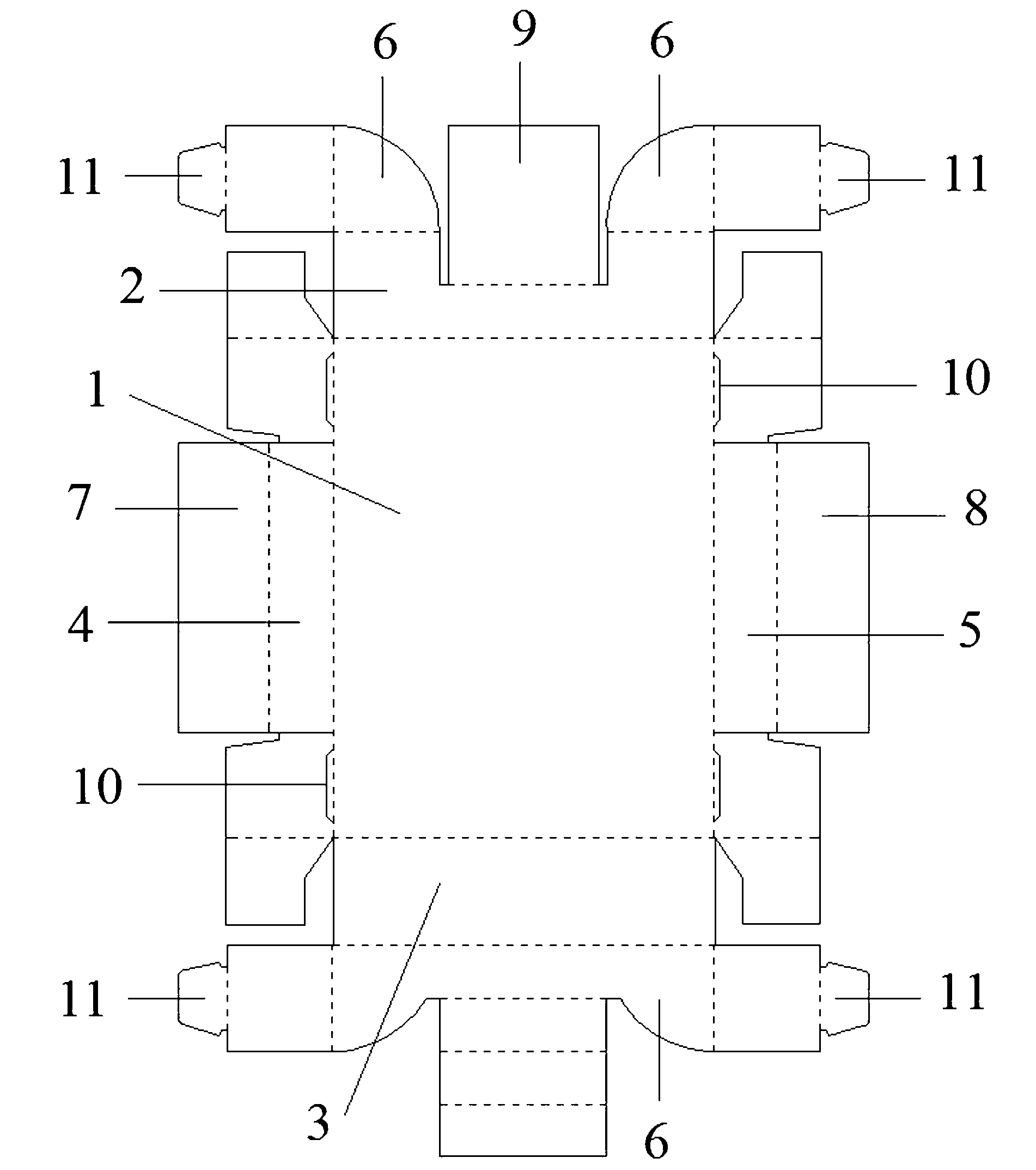

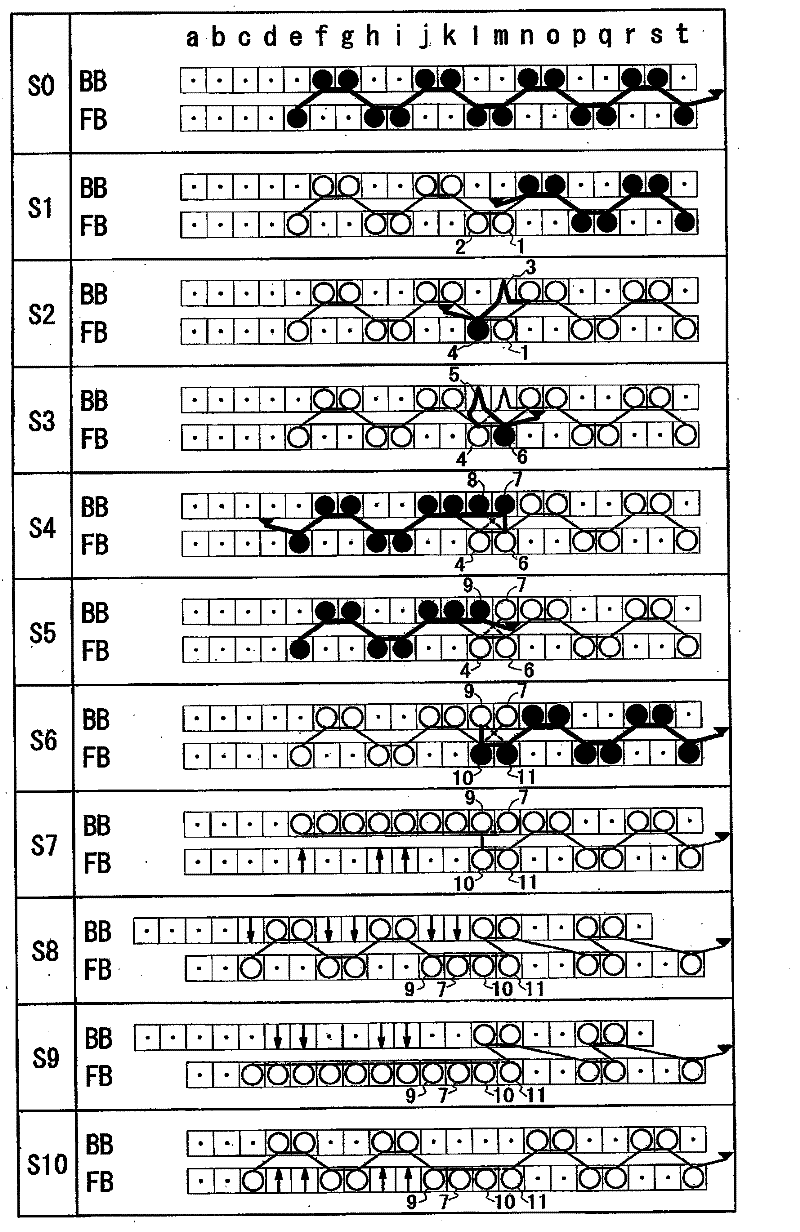

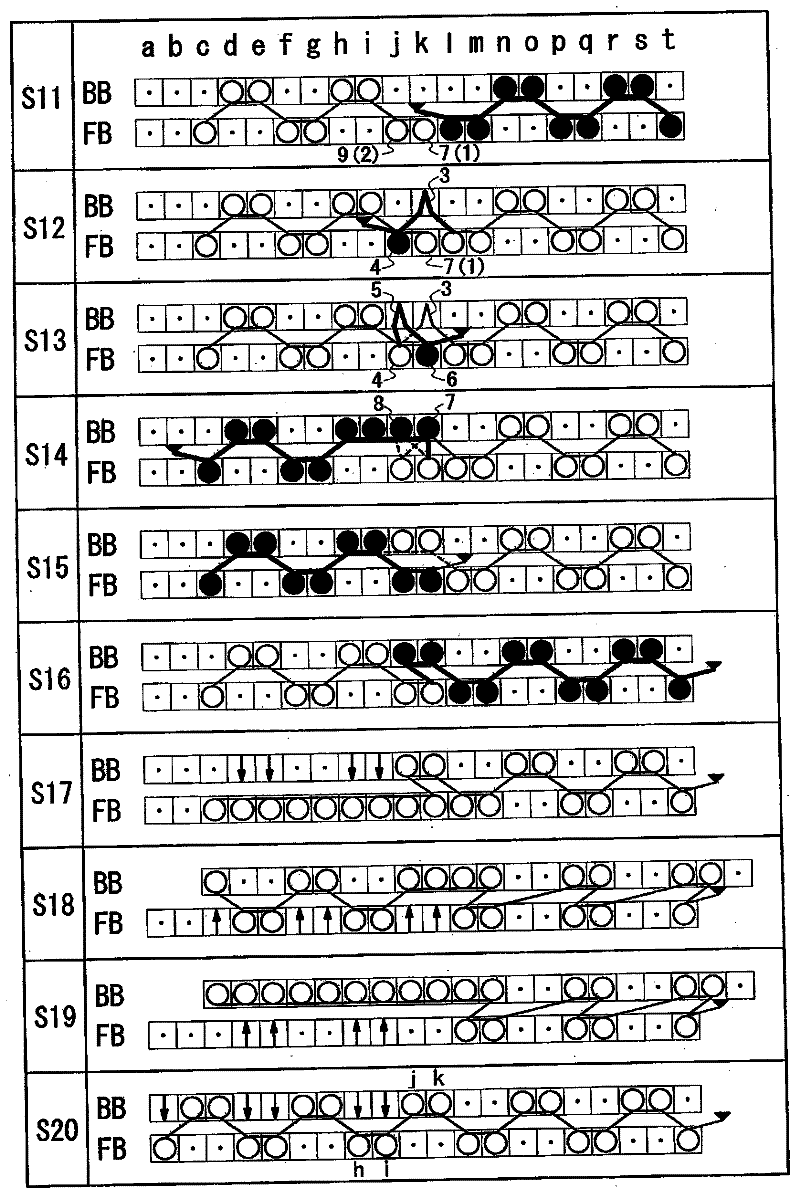

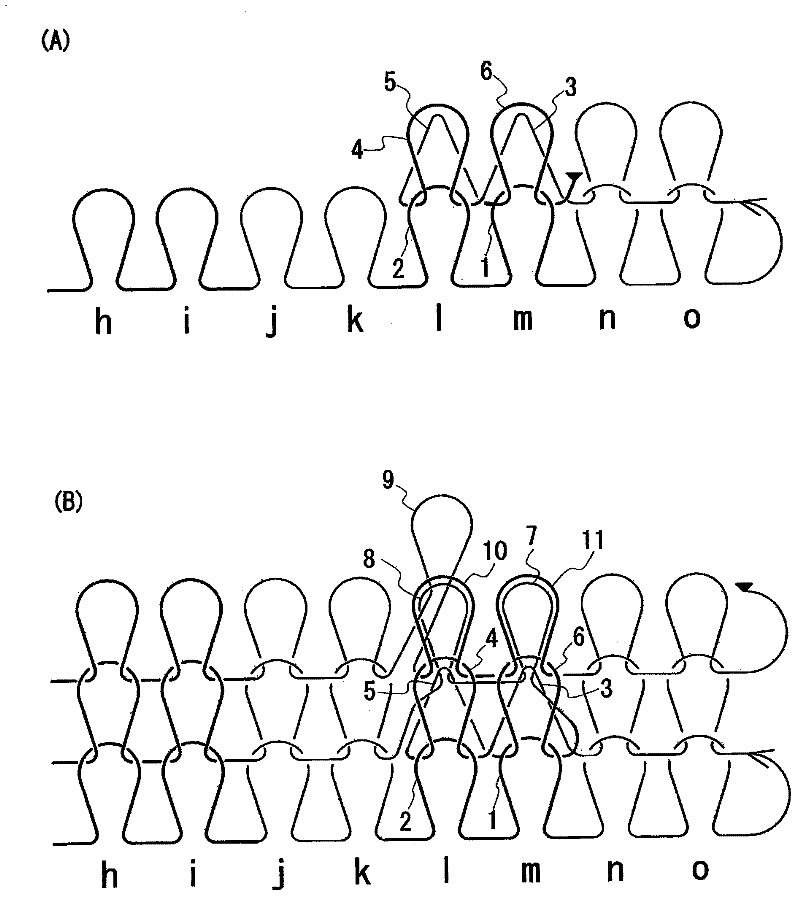

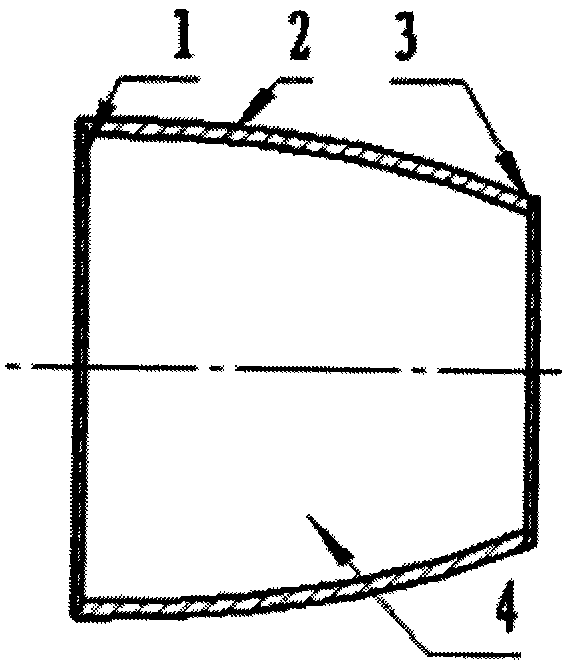

Needle setting method and knitted fabric

InactiveCN102264963AAesthetic coordinationImprove distributionFlat-bed knitting machinesEngineeringMechanical engineering

Provided is a method of increasing the number of internal stitches using a weft knitting machine, the method being able to increase the number of internal stitches without creating holes in the portions at which the additional stitches are formed and with a difference in external appearance between the front side and the rear side of the knitted fabric reduced. Also provided is a knitted fabric produced using the method. The method sets a start point stitch (1) and an end point stitch (2) and performs the following steps [1-3]: [1] a preparation step for forming stitches (4, 6) which follow both the start point stitch (1) and the end point stitch (2) and also forming hooked stitches (3, 5) on knitting needles located at positions substantially facing knitting needles with which the start point stitch (1) and the end point stitch (2) are engaged, [2] an additional-stitch forming step for forming new stitches (7, 9)(additional stitches) at the hooked stitches (3, 5), and [3] an additional-stitch arranging step for distributing the additional stitches (7, 9) which are formed by the additional-stitch forming step and the stitches (4, 6 (10, 11)) which are formed by the preparation step, the stitches (7, 9)(4, 6 (10, 11)); being distributed by racking of a needle bed and by stitch transfer so that the positions of the stitches (7, 9)(4, 6 (10, 11)) do not overlap with each other inthe longitudinal direction of the needle bed.

Owner:SHIMA SEIKI MFG LTD

Landscape lamp for hydroelectric power station dam

InactiveCN102155690AGuaranteed identityEnsure coordinationSpecial ornamental structuresOutdoor lightingPower stationHigh intensity

The invention relates to an outdoor lamp fitting, namely a landscape lamp for a hydroelectric power station dam. The landscape lamp comprises an electrical appliance part, a granite hollow transmitting lamp body and a granite lamp crown on the lamp body; the bottom part of the granite lamp crown along the circumference direction is provided with a water dropping groove which tilts outward, thus the water fell off from the lamp crown can not flow in the lamp body; the lowest position in the inner part of the lamp body along the circumference direction is provided with a water collecting groove; the water collecting groove is provided with a water drain hole internally, thus slant rain water and frozen melt water can be drained timely; and a light permeable shade of acrylic material is lined in the granite hollow transmitting lamp body. Granite materials are adopted for the lamp crown and the lamp body of the landscape lamp, and are the same with the materials of a granite rail column head below the lamp crown and the lamp body, and identity and harmony of the main body are ensured; and the landscape lamp has the characteristics of high intensity, corrosion resistance, water resistance, mosquitoes resistance, dust-proof and long service life.

Owner:YUNFENG POWER PLANT

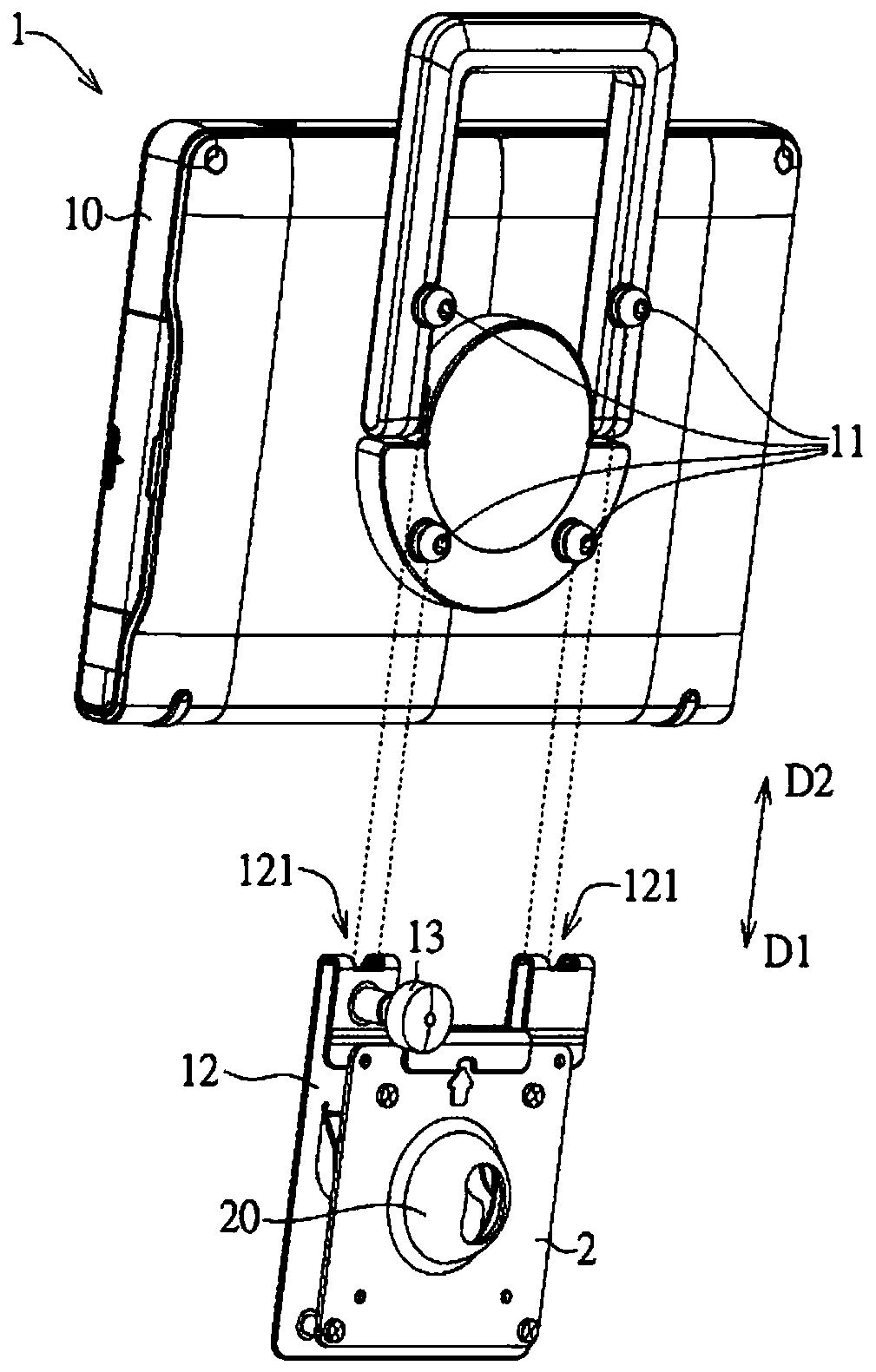

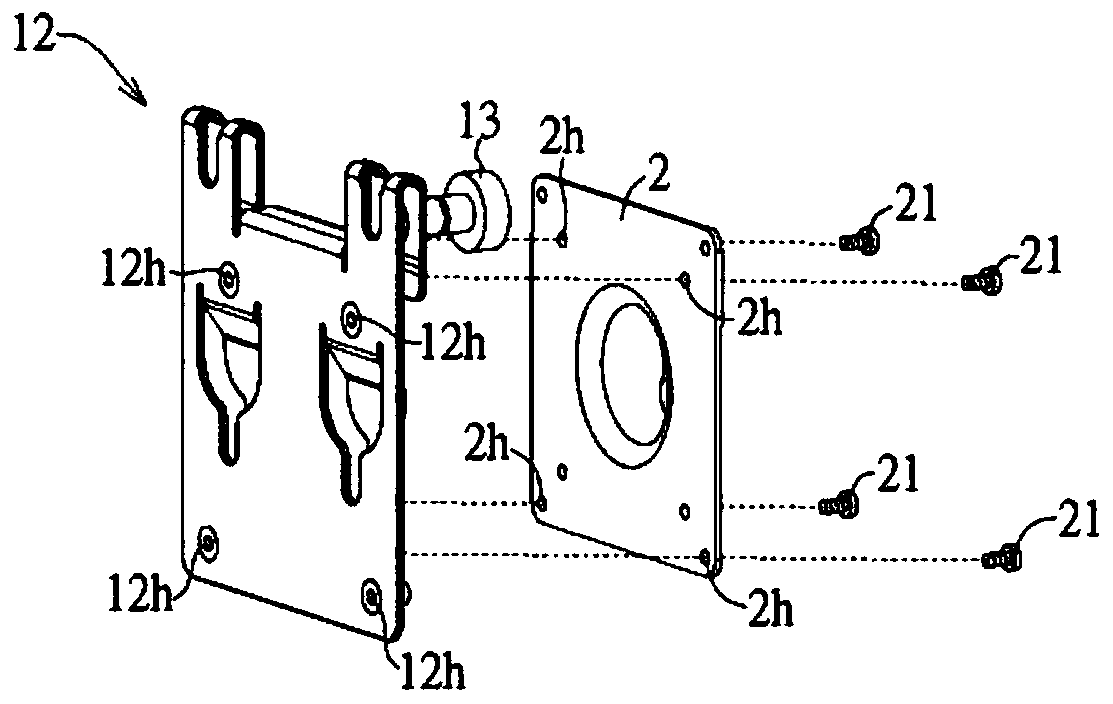

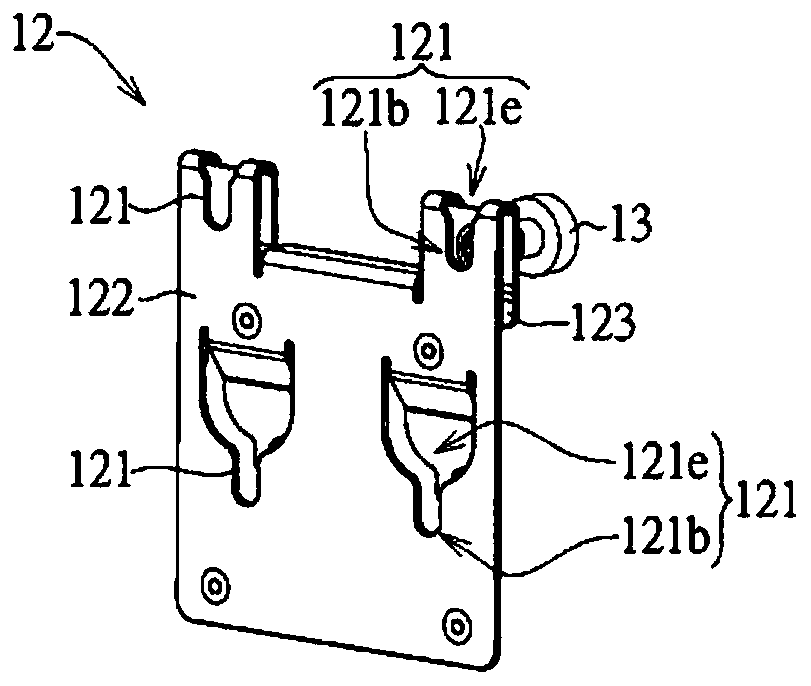

Detachable Electronics

ActiveCN106708196BEasy to assemble and disassembleEasy to manufactureDigital data processing detailsStructural engineeringMechanical engineering

The invention provides a detachable electronic product which comprises display equipment, guide parts, a bearing frame and an insertion pin. The guide parts are locked and fixed on the display equipment, and fixing holes are formed in the guide parts. Sliding rails are arranged on the bearing frame and are suitable for sliding in of the guide parts so that the display equipment can be detachably arranged on the bearing frame. The insertion pin is arranged on the bearing frame, when the guide parts slide in the sliding rails, the insertion pin is suitable for insertion into the fixing holes of the guide parts so as to fix the display equipment on the bearing frame, the operation is simple and convenient, and the product is also relatively attractive and has safety.

Owner:QISDA SUZHOU +1

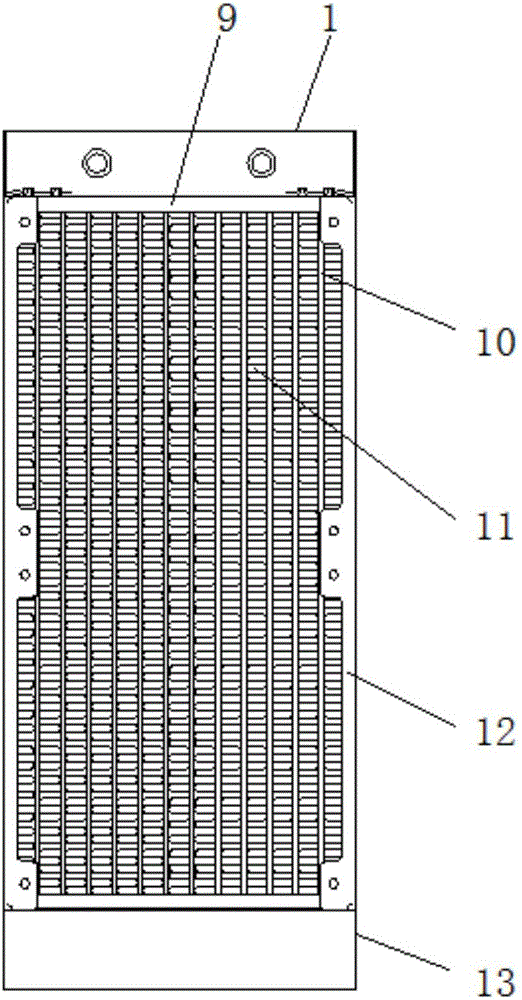

Manifold square pipe for cooling CPU

InactiveCN106774747ASmooth appearanceNice appearanceDigital data processing detailsEngineeringSoldering

The invention discloses a manifold square pipe for cooling a CPU. The pipe comprises a manifold. A left upper water chamber is arranged at the left side in the manifold. A right lower water chamber is arranged at the right side in the manifold. An water inlet hole is formed in the center of the side of the left upper water chamber. An water outlet hole is arranged in the center of the side of the right upper water chamber. Twelve rows of cooling holes are formed in the top portion of the manifold. The lower side of the manifold is fixedly connected with a cooling box through bolts. The center of the cooling box is buckled with multiple cooling pipes. Cooling bands are arranged between the cooling pipes. The left and right sides of the cooling box are fixedly connected with two side plates through screw nuts. The lower side of the cooling box is fixedly connected with a lower water chamber through bolts. The manifold square pipe for cooling a CPU has the advantages of being simple to produce, not prone to create wasted material, beautiful in appearance, and good in brass soldering effect. The arrangement of the left upper water chamber and the right lower water chamber in the manifold can achieve the function of circulated cooling, and the cooling efficiency is high.

Owner:JIANGXI XINTIAN AUTO IND

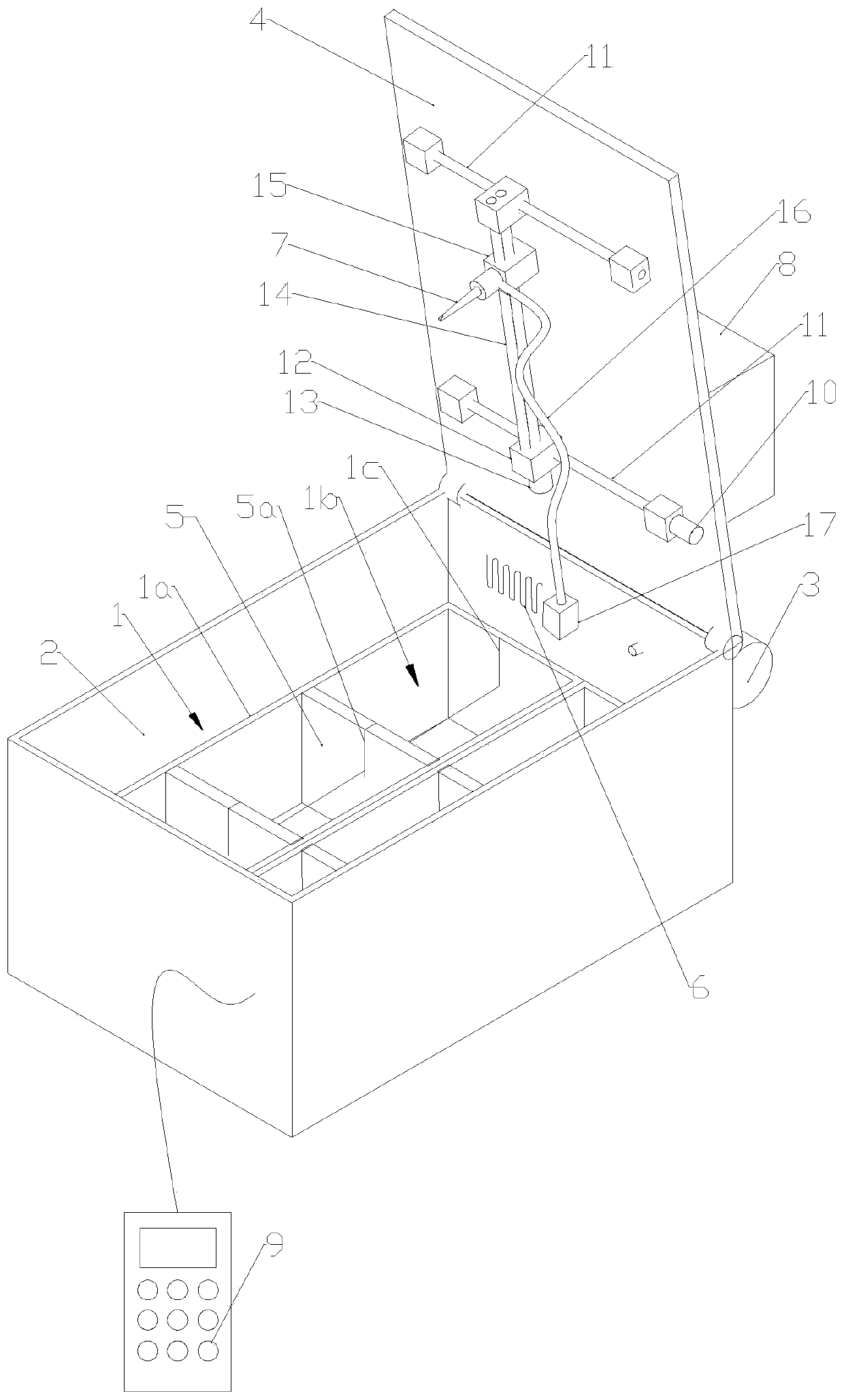

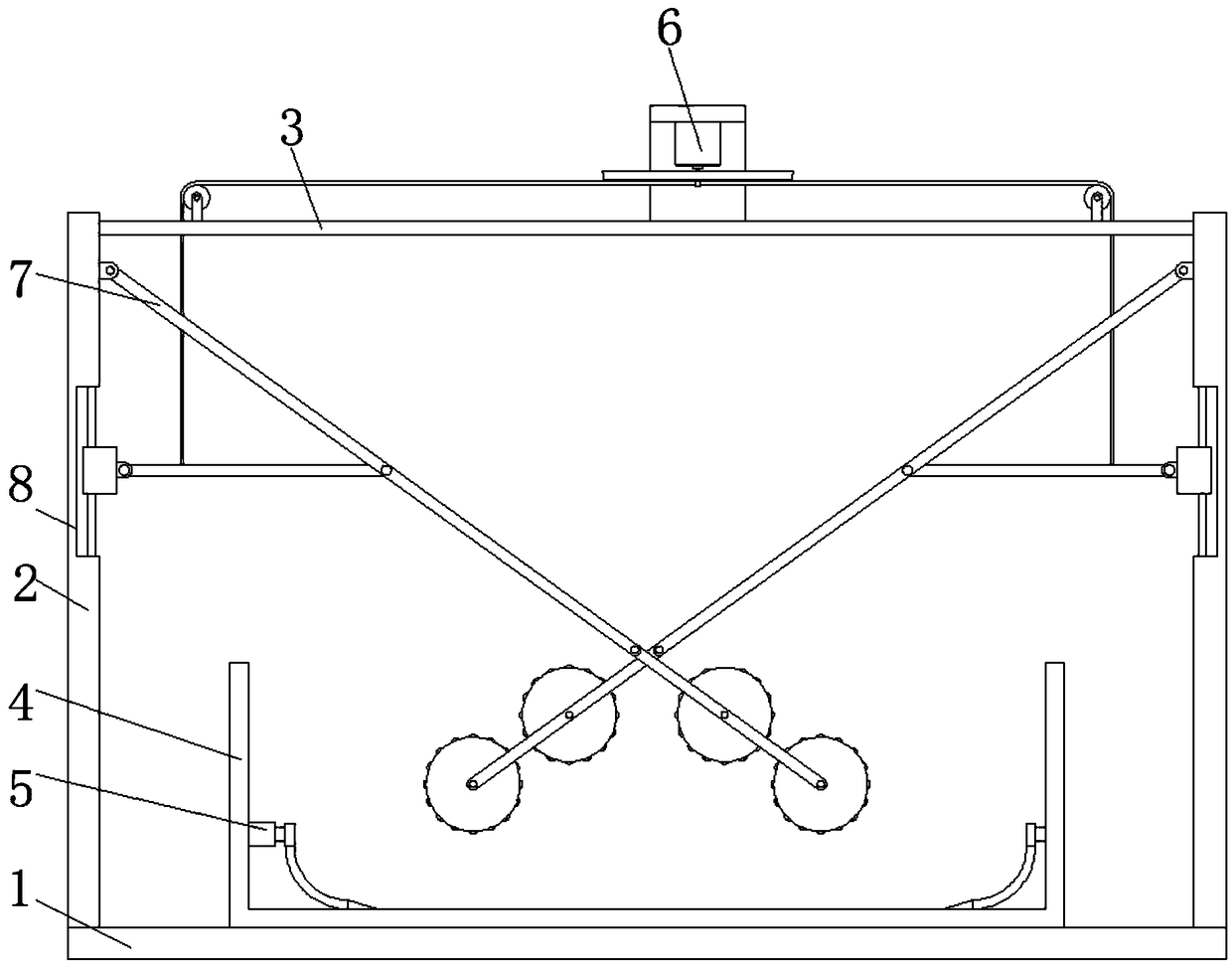

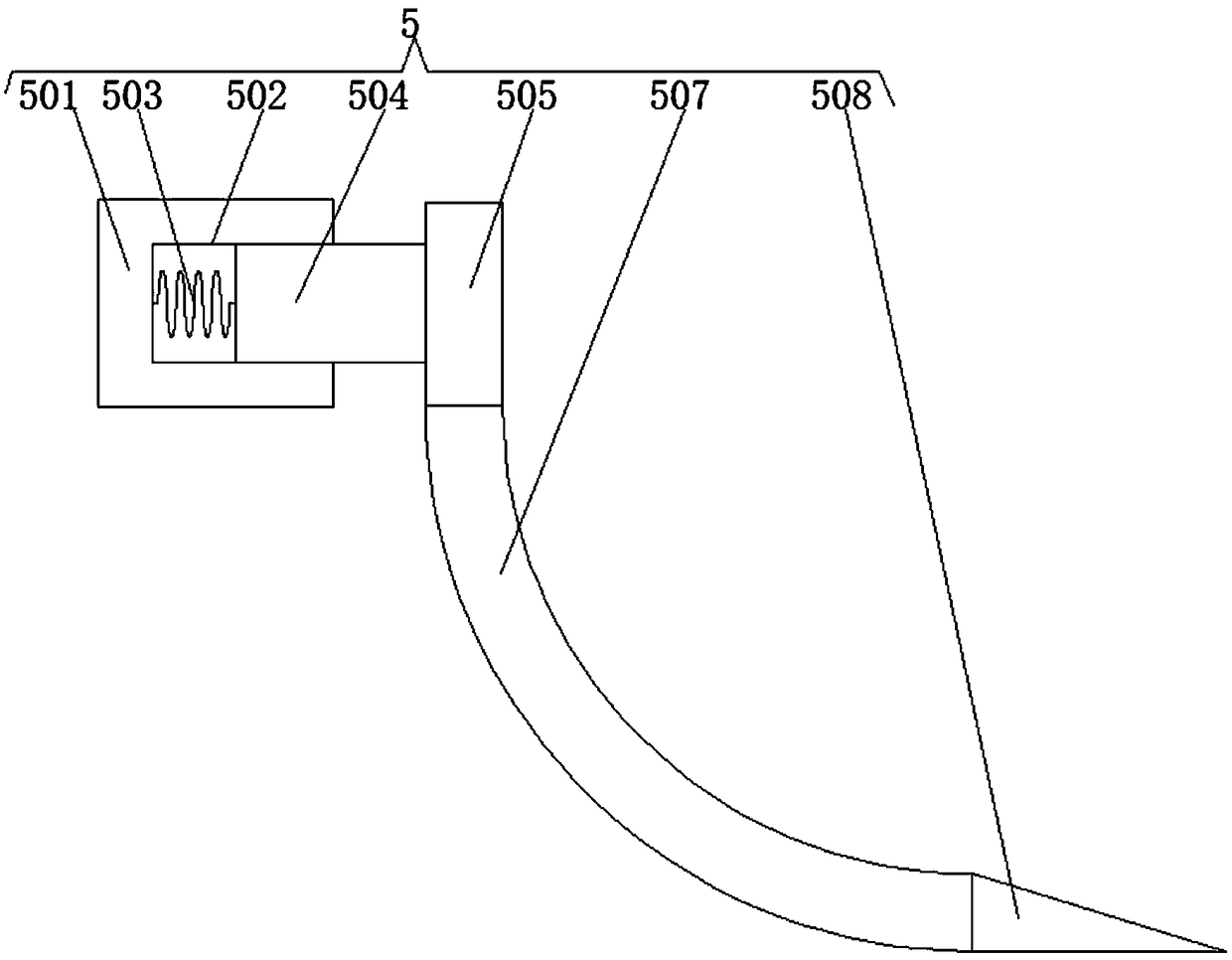

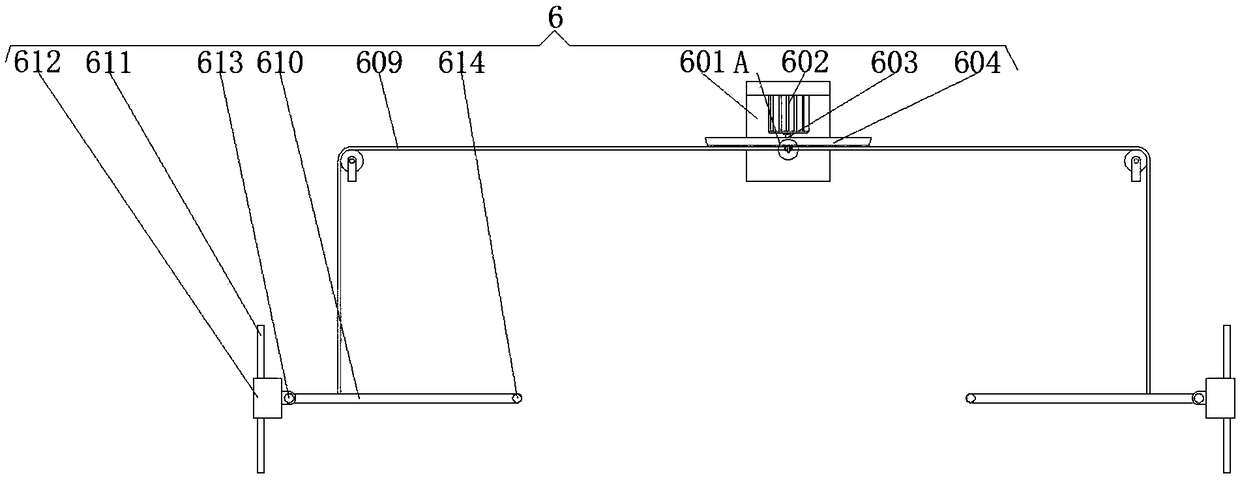

Forming mechanism for 3D cake printer

InactiveCN104664580AImprove spraying efficiencyImprove production efficiencyFood shapingEngineeringMechanical engineering

The invention discloses a forming mechanism for a 3D cake printer; the forming mechanism comprises a bracket, a storage tank and a forming platform, wherein the storage tank is installed on the bracket; the forming platform is used for holding a cake to be processed; a clamping groove is arranged on the bracket; a clamping block is arranged at the edge of the storage tank; the storage tank is clamped on the clamping groove of the bracket through the clamping block; an extrusion mechanism is arranged in the storage tank; the extrusion mechanism comprises a pressure plate for extruding cake making raw materials in the storage tank; the top of the pressure plate is connected to a cylinder; the pressure plate moves under the action of the piston rod of the cylinder; four openings are uniformly formed at the bottom of the storage tank; a downward discharging mouth is installed at the position of each opening in a communicating manner; a computer controlled electromagnetic valve is installed on each discharging mouth; and a driver for driving the forming platform to rotate is installed at the bottom of the forming platform. The forming mechanism is capable of forming the circumferential surfaces of cakes very effectively, and is beneficial to making cakes having nice appearances.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

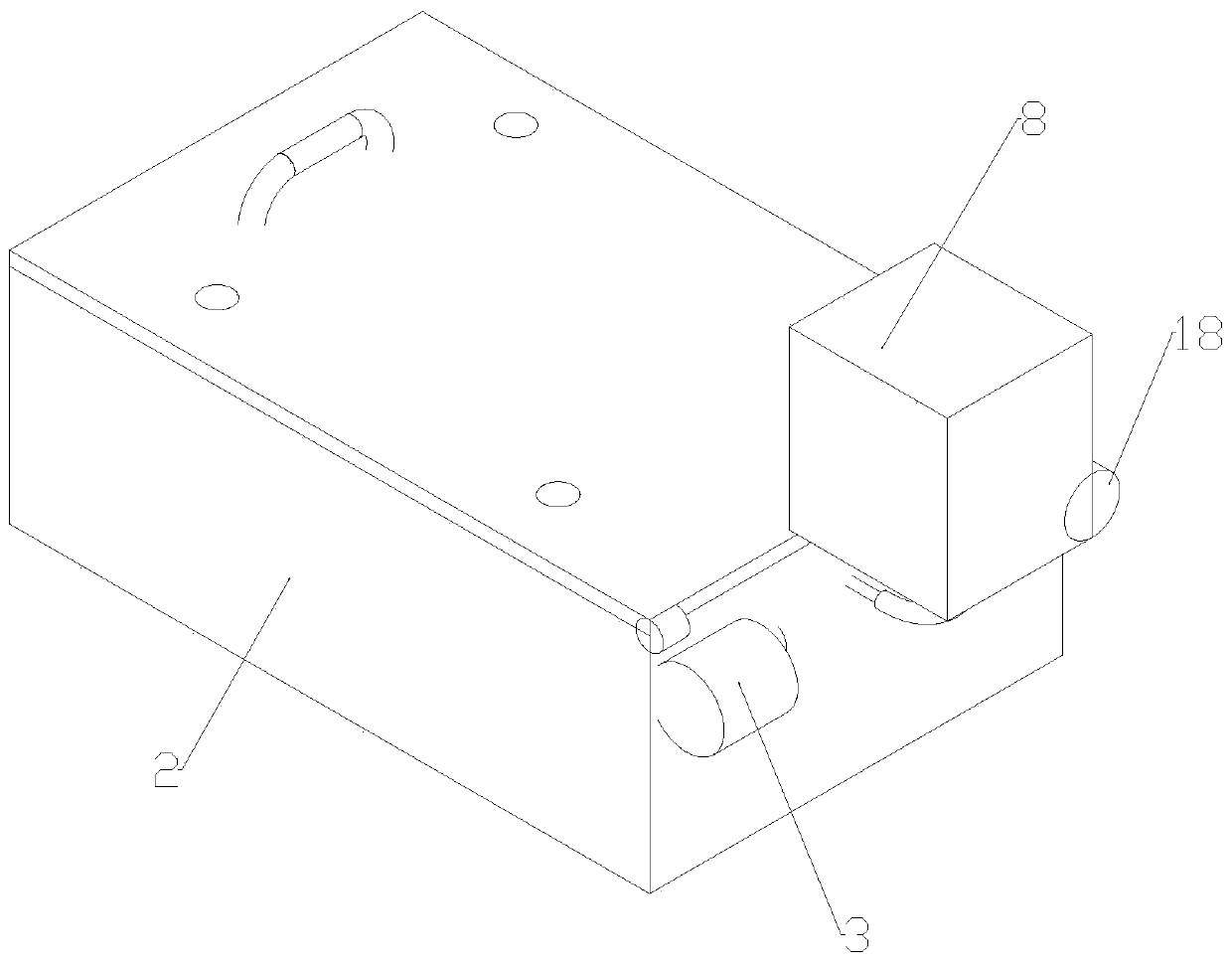

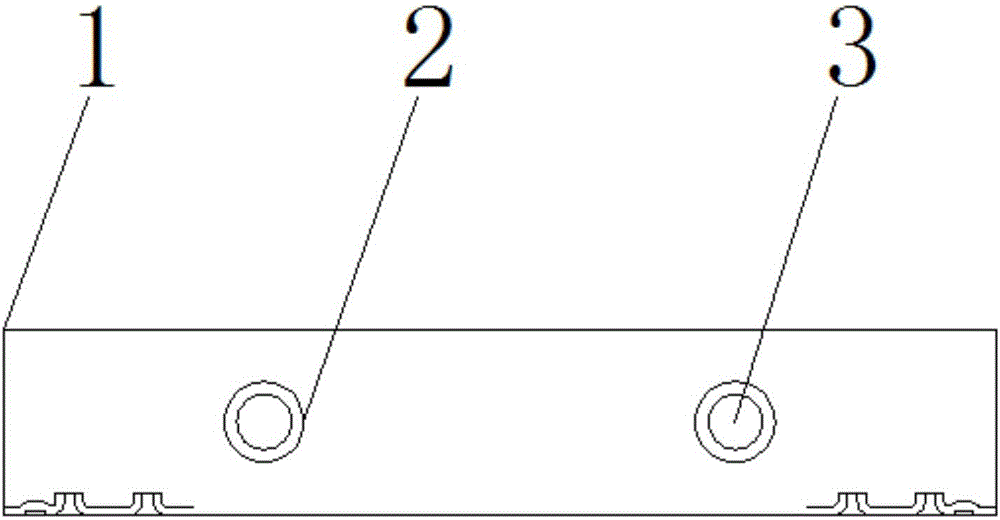

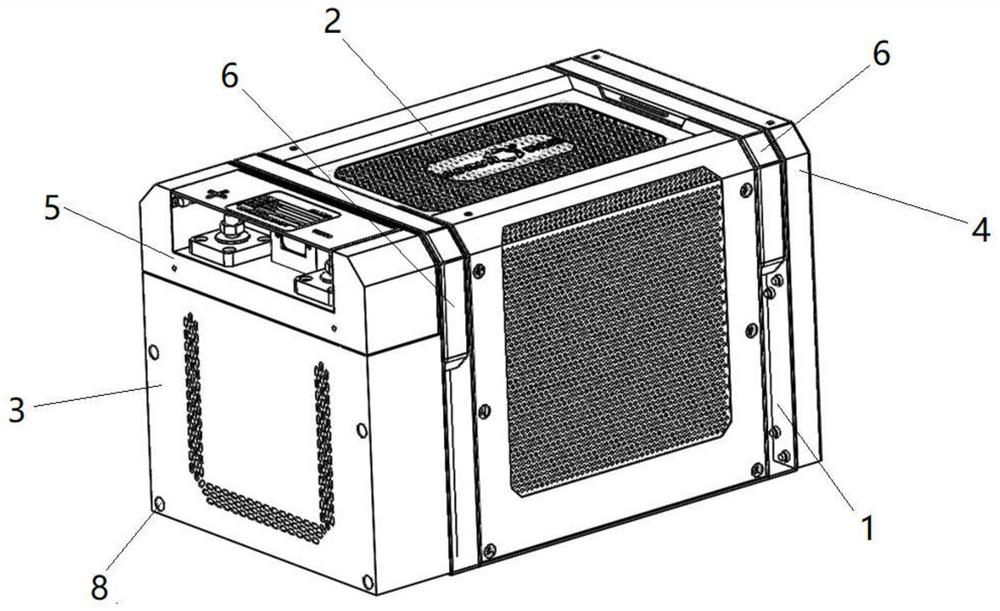

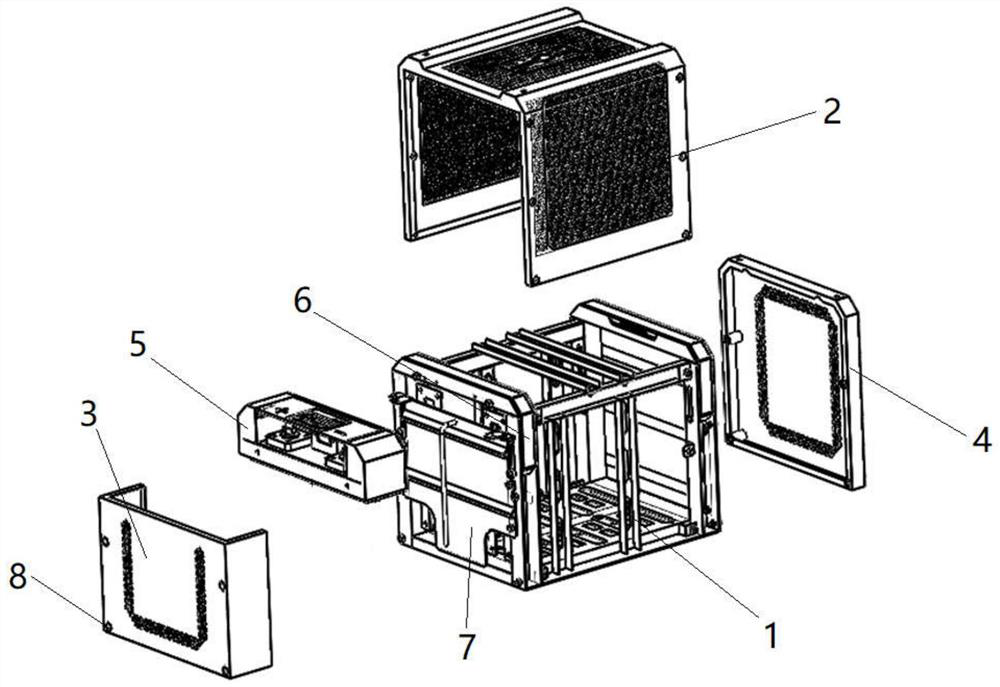

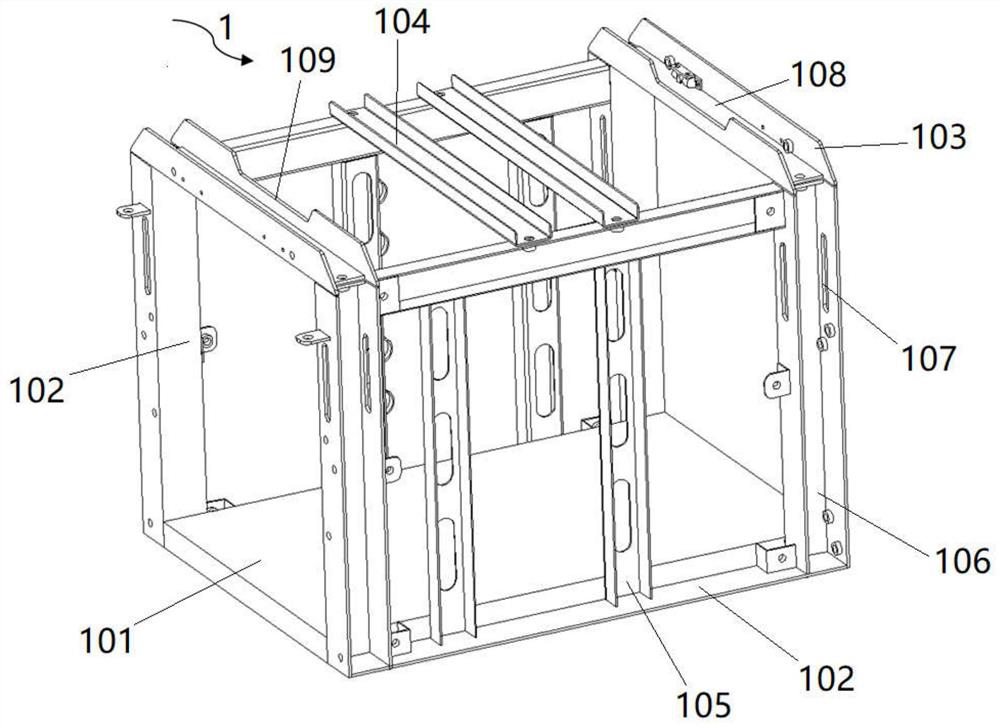

Battery pack case and battery pack

ActiveCN110112344BBeautifully madeSimple structureCell component detailsControl theoryMechanical engineering

The invention provides a battery pack case, which includes a battery pack module fixing frame, a top cover, a left end cover, a right end cover and an outlet box, the battery pack module fixing frame includes a bottom plate, and side support frames are vertically arranged on both sides of the bottom plate , the two ends of the top of the two side support frames are respectively fixed together by cross beams, the two ends of the battery pack module fixed frame are respectively provided with battery protection baffles, and the outlet box is fixed on the left end of the battery pack module fixed frame near the top position , the left end cover closes and covers the left end of the battery pack module fixing frame which is located below the outlet box, the right end cover closes and covers the right end of the battery pack module fixing frame, and the top cover covers both sides of the battery pack module fixing frame and the part between the two beams . Also provided is a battery pack made using the battery pack case of the present invention. The battery pack case of the present invention has simple and novel structure, convenient installation and high strength, and the battery pack made by using the same is easy to manufacture and easy to maintain and replace.

Owner:先进储能材料国家工程研究中心有限责任公司

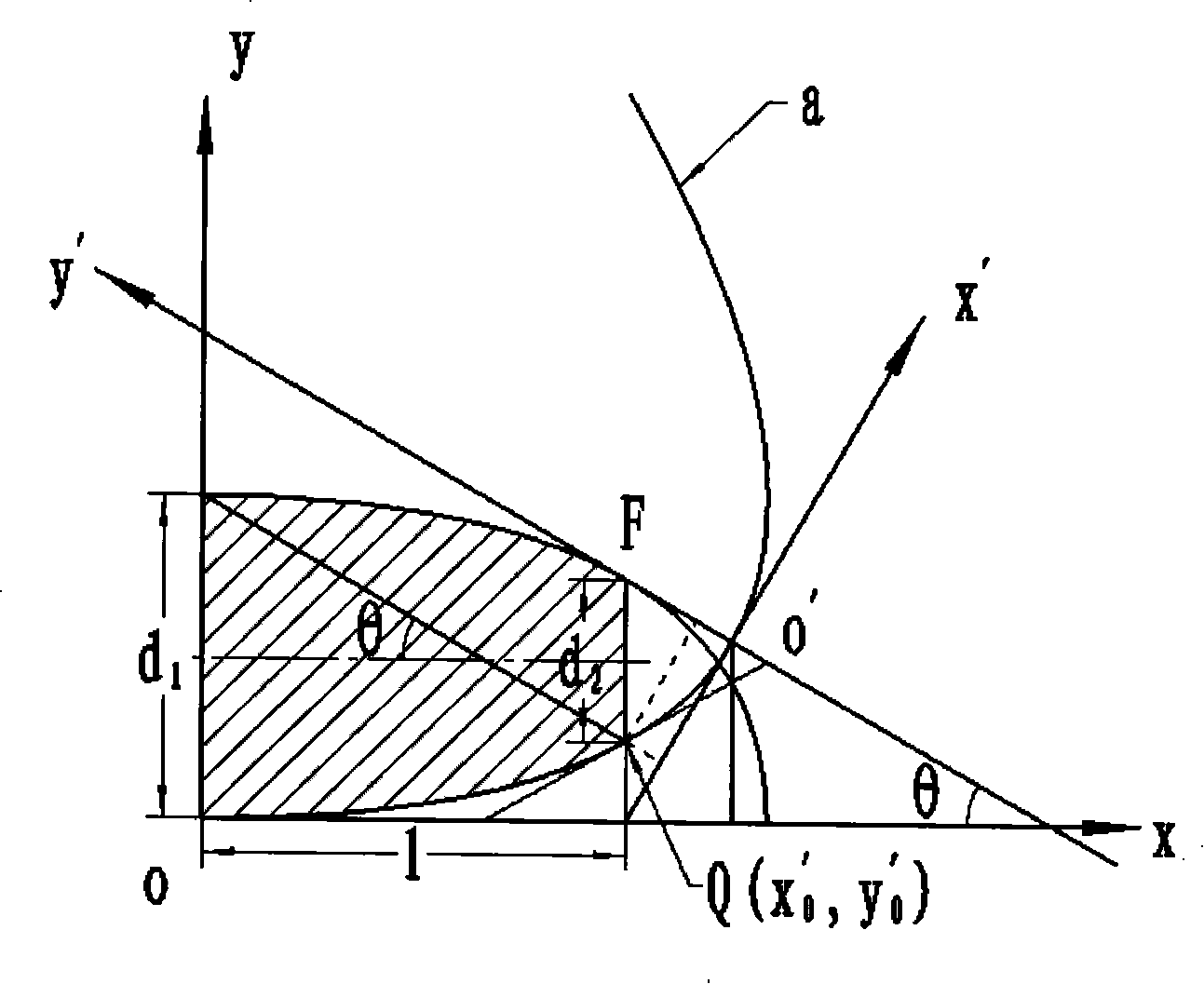

Selective solar energy tunnel for exterior wall surface

InactiveCN101307623BTo achieve the purpose of heatingReach blockSolar heating energyRoof covering using slabs/sheetsThermal insulationSelective reflection

The invention relates to a selective solar tunnel used for an external metope, consisting of a light-gathering body which can absorb thermal insulation air, a heat-absorbing plate which is arranged at the bottom of the light-gathering body, and a transparent top cover which seals the light-gathering body. Selective reflection is generated according to the difference of the solar altitude; the solar altitude is low in winter, thereby light beams are all reflected into the solar tunnel and the radiant energy of the light beams is converted into heat energy; the solar altitude is high in spring,in summer and in autumn and particularly in summer, the light beams are all reflected out of the tunnel and no heat is absorbed. The selective solar tunnel has a simple structure and low cost and hasno moving element. Various selective building elements can be conveniently and beautifully prepared by embedding a plurality of selective solar tunnels in the form of arrays into external surfaces such as building blocks, thermal insulation tiles, external wall panels and so on. A building built by application of the elements can absorb solar energy in winter, thereby the building reduces and even completely bears heating heat load; in summer, the building can be prevented from receiving solar radiation and be insulated, thereby the heat load of an air conditioner is reduced; the energy consumption of the building is greatly reduced; and the energy is saved.

Owner:CHINA UNIV OF MINING & TECH

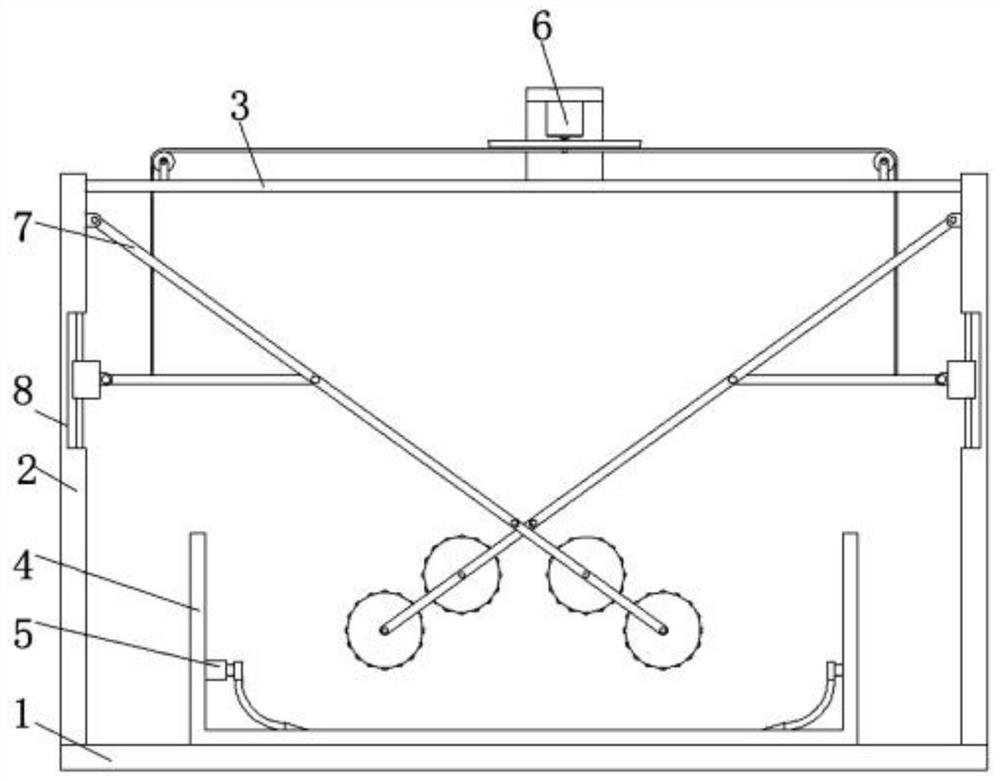

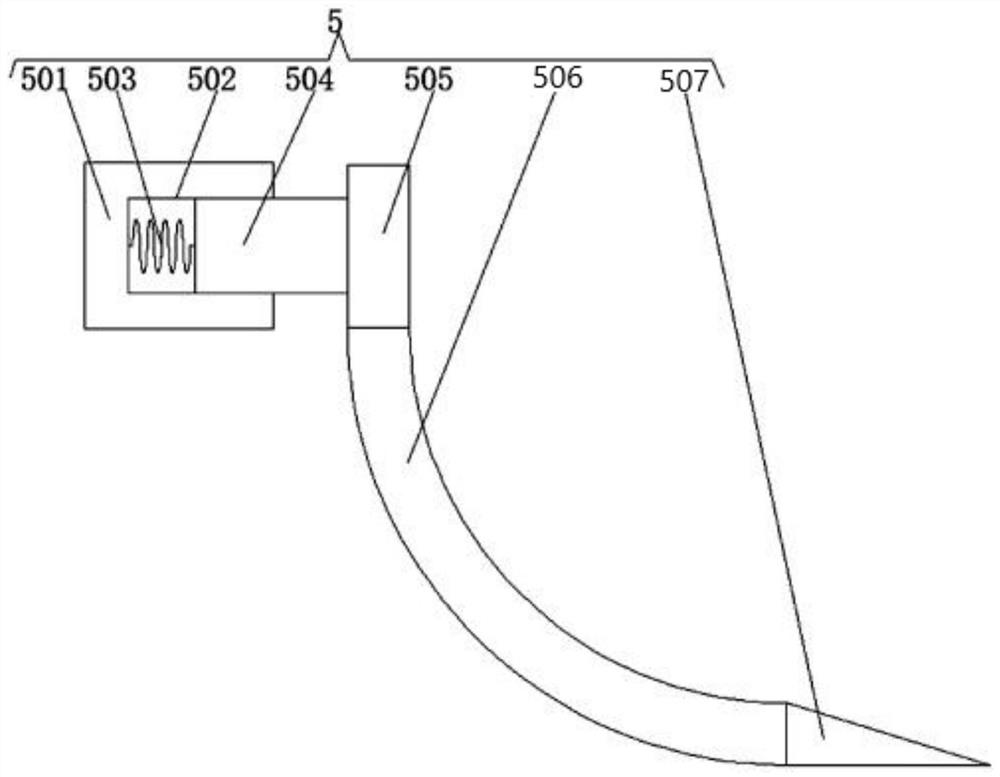

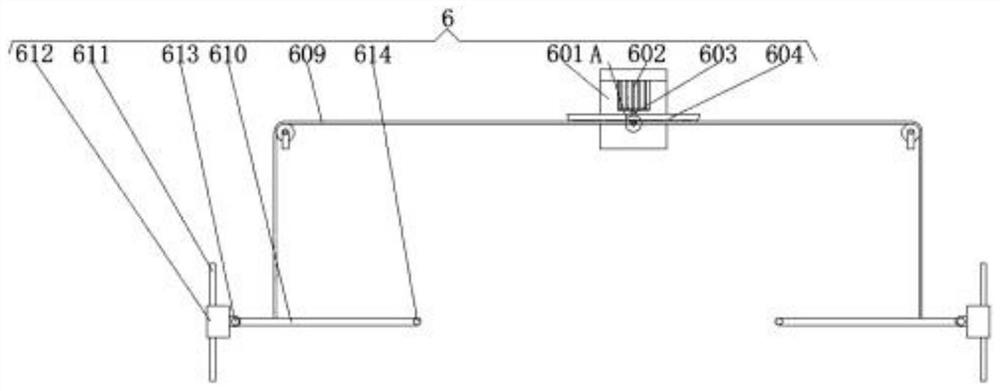

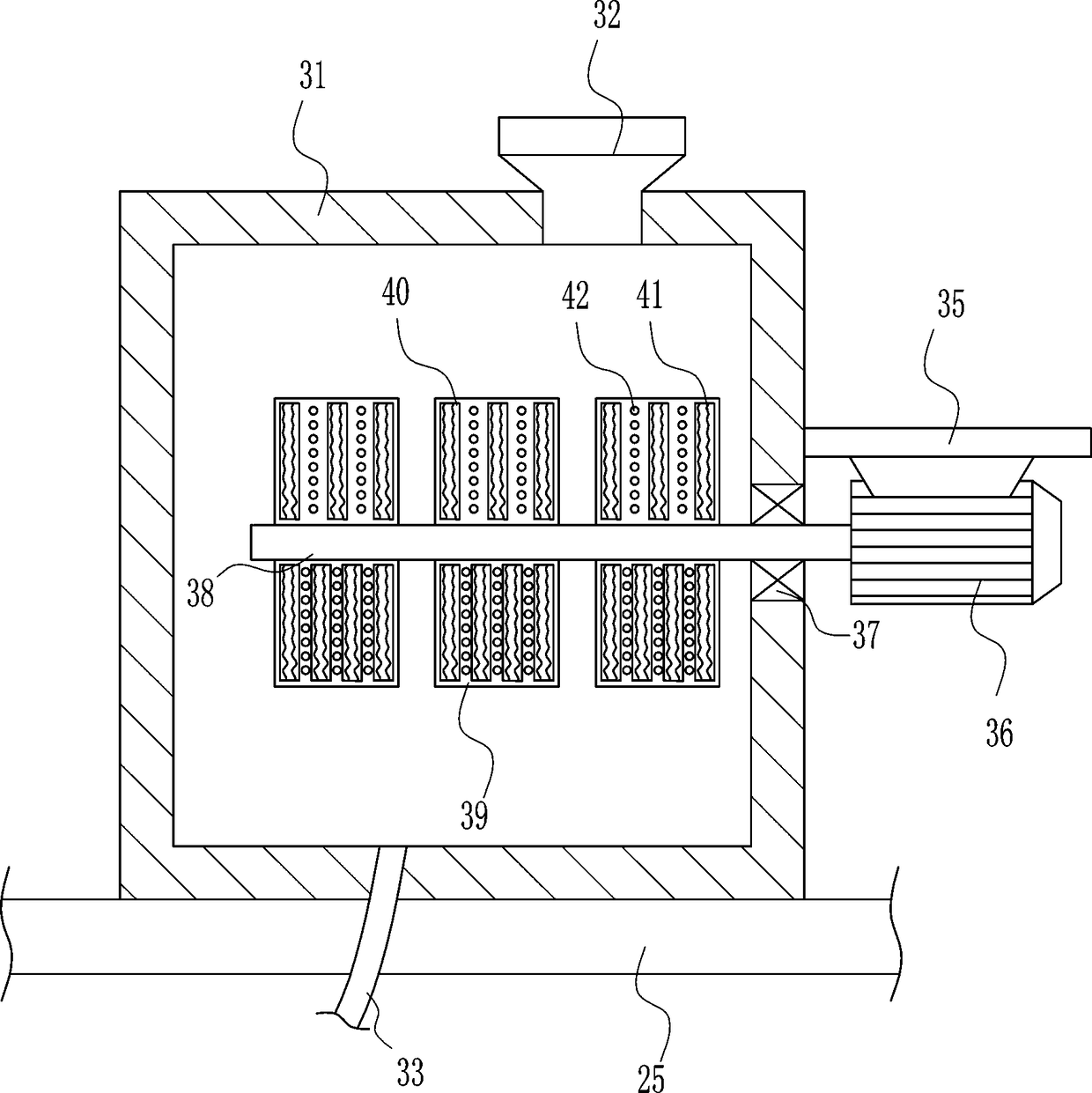

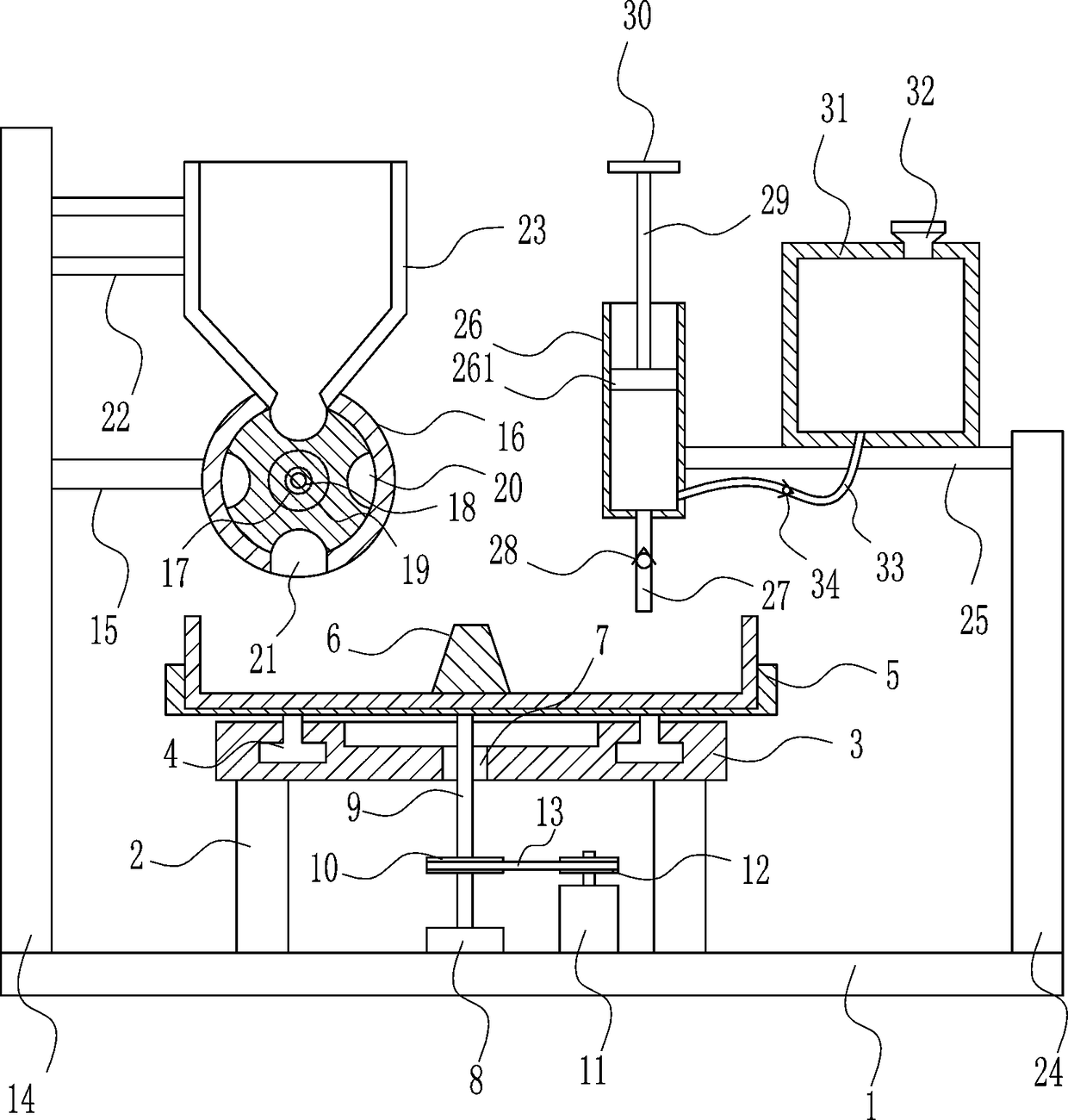

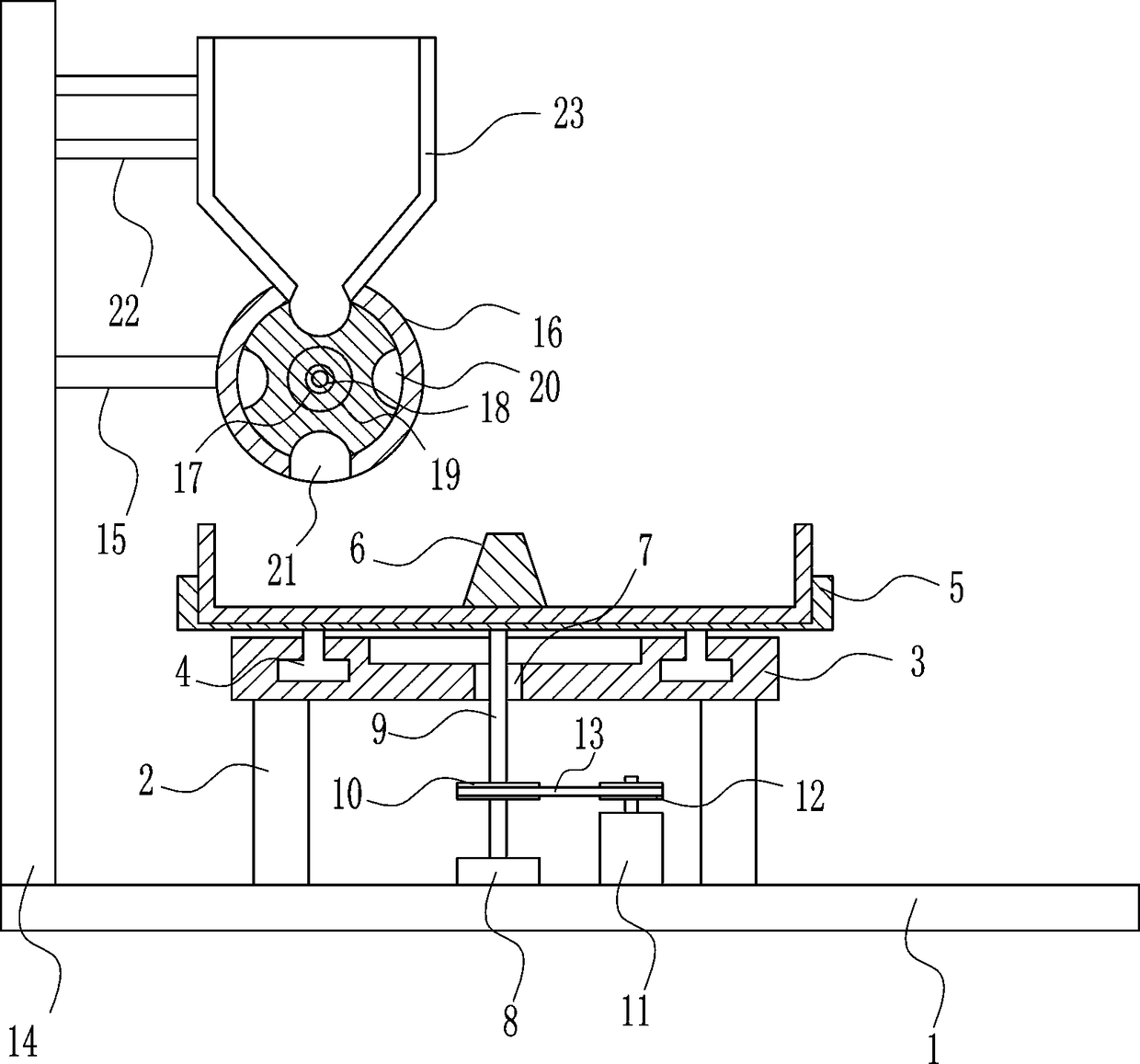

Glutinous rice cake processing device based on reciprocating secondary hammering acting force and use method

InactiveCN113208038ABeautifully madeSave human effortFood shapingAgricultural engineeringStructural engineering

Owner:刘中雷

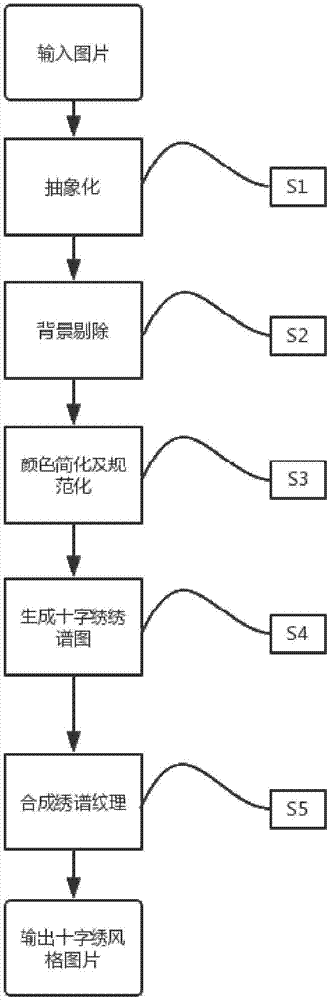

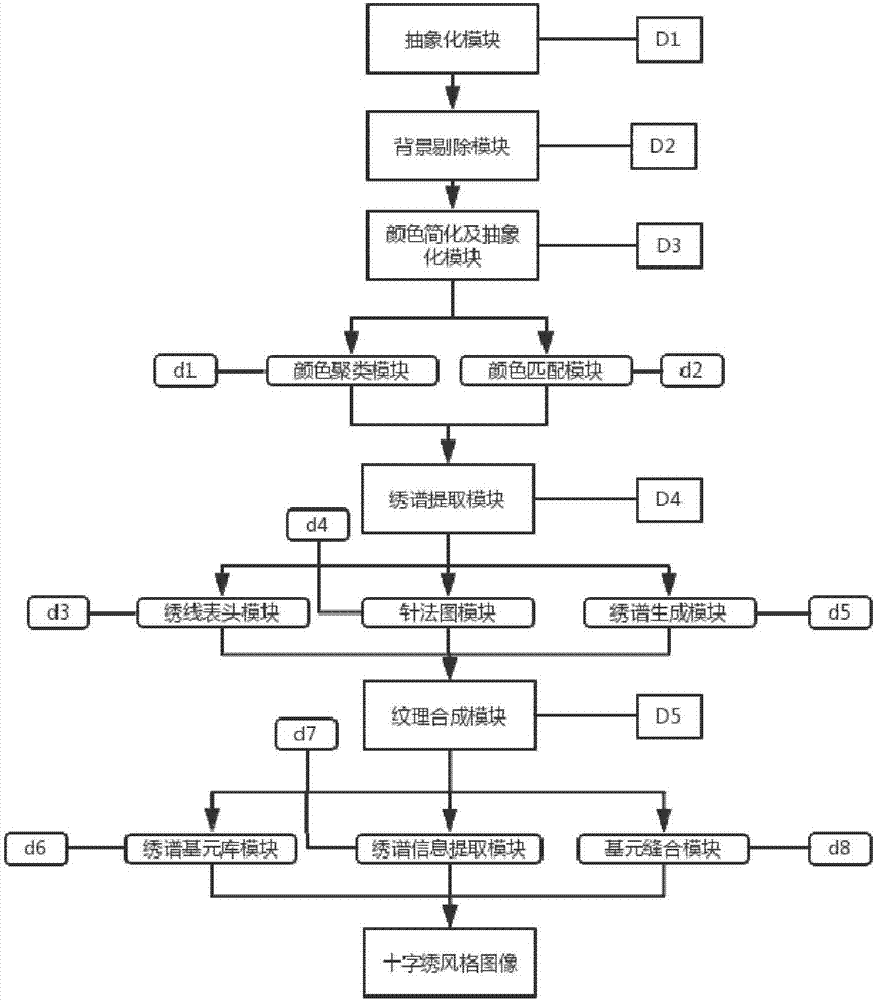

Texture sewing-based image cross-stitch stylization method and apparatus

InactiveCN106920209AArranged naturally and tightlySimplify the creative processGeometric image transformationBackground imageVisual feedback

The invention discloses a texture sewing-based image cross-stitch stylization method and apparatus. The method comprises the steps of abstracting an input image to obtain an abstracted image; performing background removal operation on the abstracted image to obtain a shielded background image and an abstracted foreground image; performing color simplification and standardization processing on the abstracted foreground image to obtain a color standardization image; performing embroidery book extraction operation on the color standardization image to obtain a cross-stitch embroidery book image; and performing embroidery book-guided texture synthesis processing on the cross-stitch embroidery book image to obtain a cross-stitch style image. By adopting the method and the apparatus, the image can be subjected to stylization processing, and the image with the cross-stitch style is synthesized, so that people can obtain rough visual feedback and know rough appearance of embroidered cross-stitch before starting embroidering; and, in the stylization processing process, an embroidery book of the cross-stitch can be automatically extracted, so that certain dull and burdensome work of designers is reduced and a creation process is greatly accelerated.

Owner:SUN YAT SEN UNIV

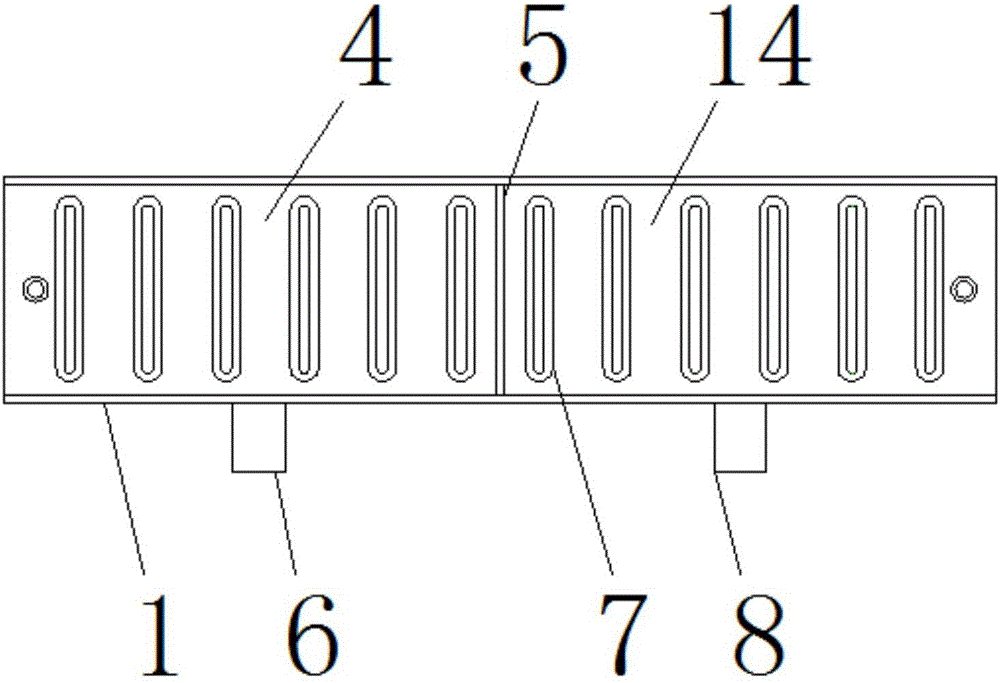

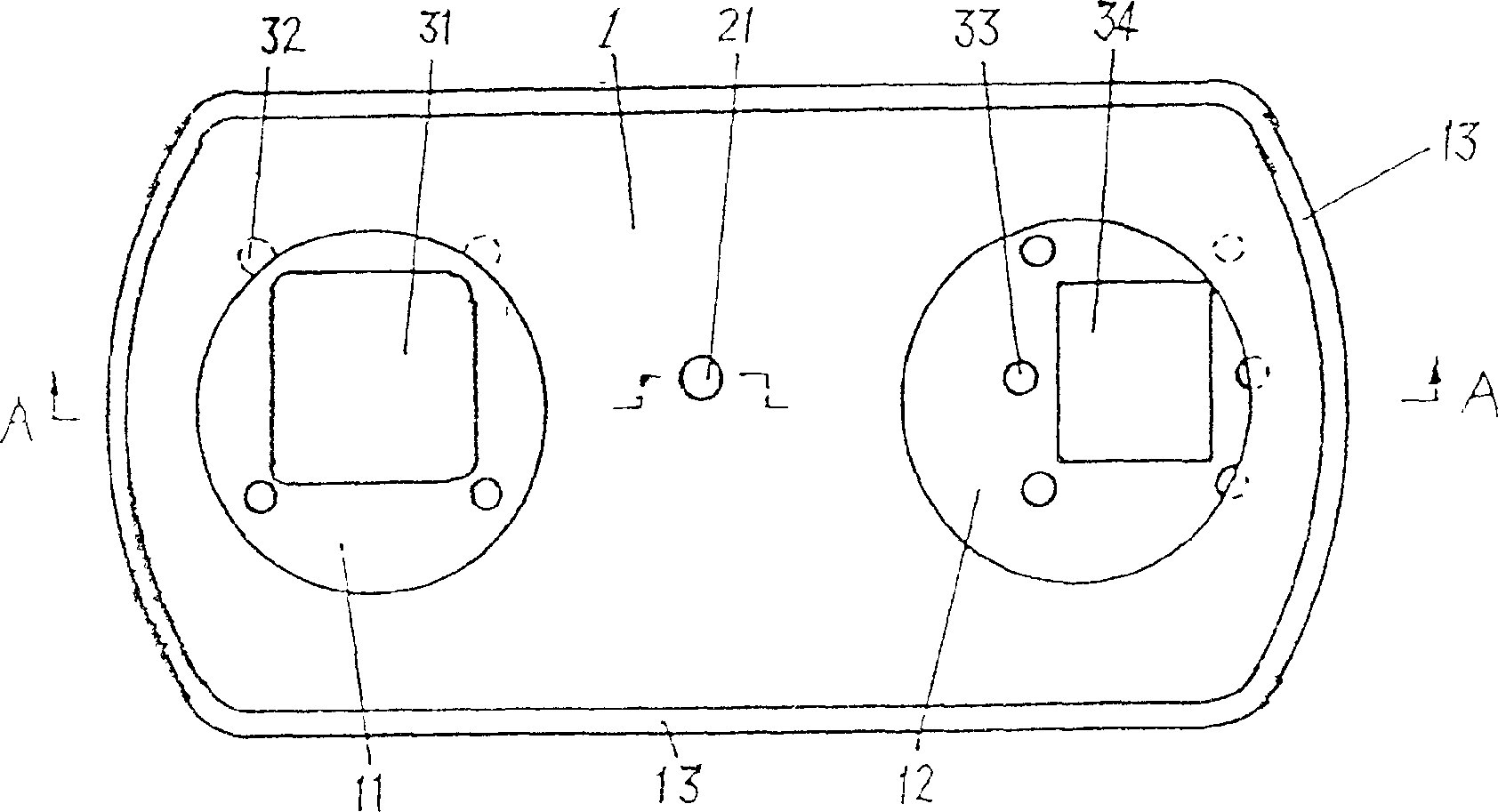

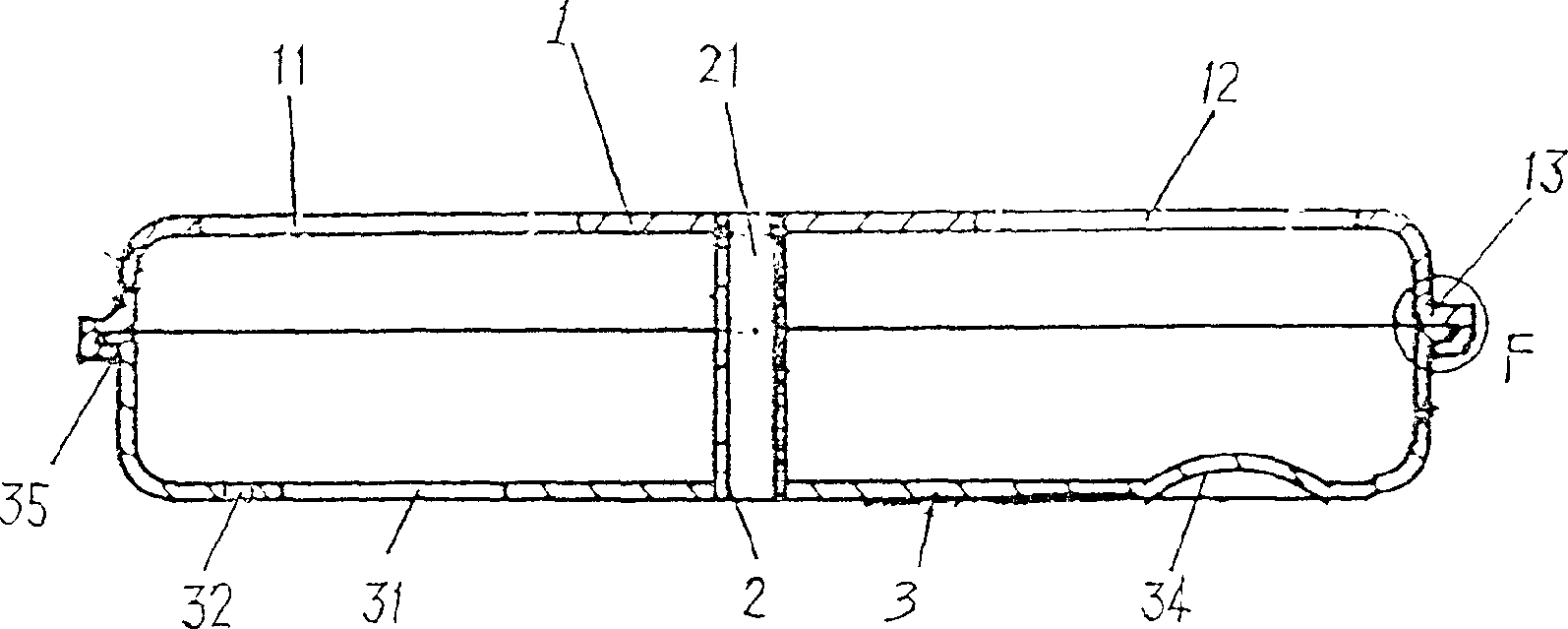

Evaporation-type water tank of IC engine

InactiveCN1161537CTo achieve the effect of watertightMake sure it doesn't leakMachines/enginesEngine cooling apparatusEvaporationEngineering

A water tank for evaporation-type IC engine is composed of top cover and lower main body. Said top cover has water feeding inlet and rivetted edge. Said lower main body has a cooling water outlet communicated with engine, fixing holes for fixing it to diesel oil engine by screw bolts, and rivetted edge. A hollow tube is linked between said top cover and lower main body. Its advantages include uniform rivetting force, high sealing and integral strongth, and beautiful appearance.

Owner:蒋尧夫

Ciba processing device based on reciprocating secondary hammering action force

The present invention relates to the technical field of Ciba processing devices, and discloses a Ciba processing device based on reciprocating secondary hammering action force. The device comprises abottom plate; the left and right sides of the top of the bottom plate are fixedly connected to side plates; the tops of the side plates are fixedly connected to a top plate; the top of the bottom plate is fixedly connected to a pressing cylinder; and left and right buffer pressing mechanisms are arranged on the left and right sides of the inner wall of the pressing cylinder. The device solves theproblem that the only single reciprocating hammering in the process of hammering cannot enable Ciba to get soft after hammering although can save manpower, and meanwhile, and can damage the flexibility of Ciba caused by excessive force. By the operation of reciprocating secondary hammering, the device simulates the manual operation and saves the labor. The device performs the operation of reciprocating secondary hammering, simulates the manual operation, and saves manpower. Therefore, in the operation process, the device performs secondary slight hammering after the first heavy beating, and the reciprocating operation can make Ciba soft after hammering. At the same time, the device does not damage the flexibility of Ciba, so that the Ciba is more beautiful in the manufacturing process.

Owner:湖州国峰智能科技有限公司

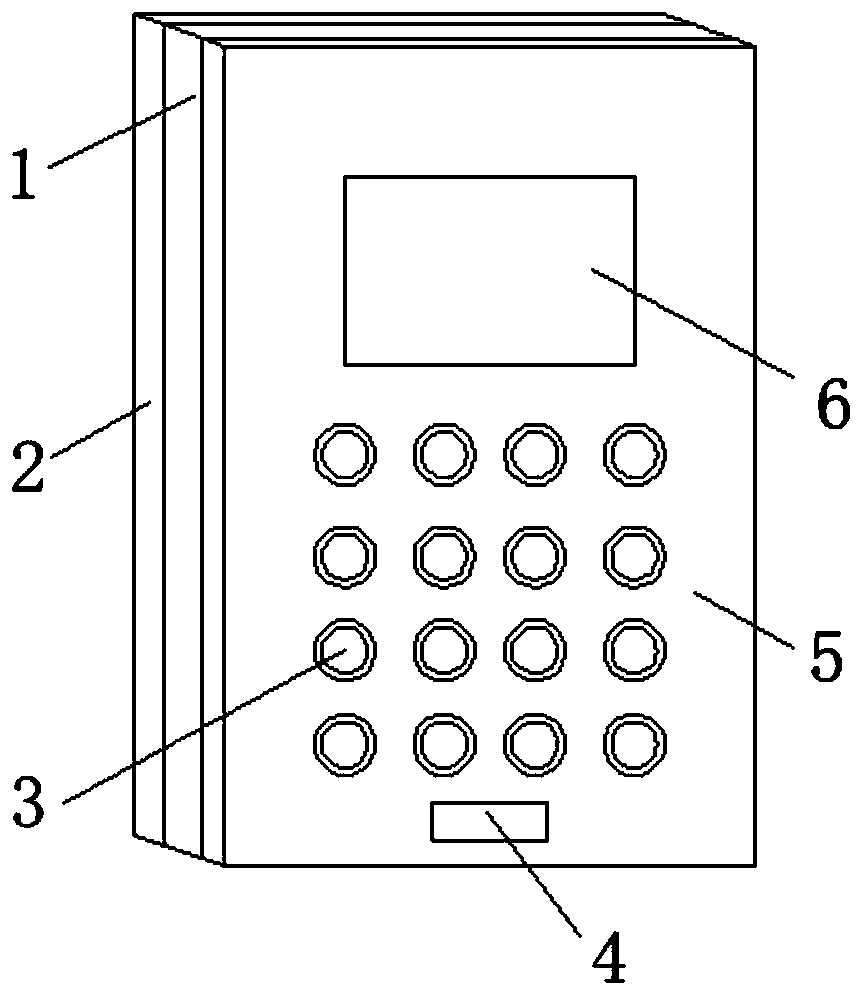

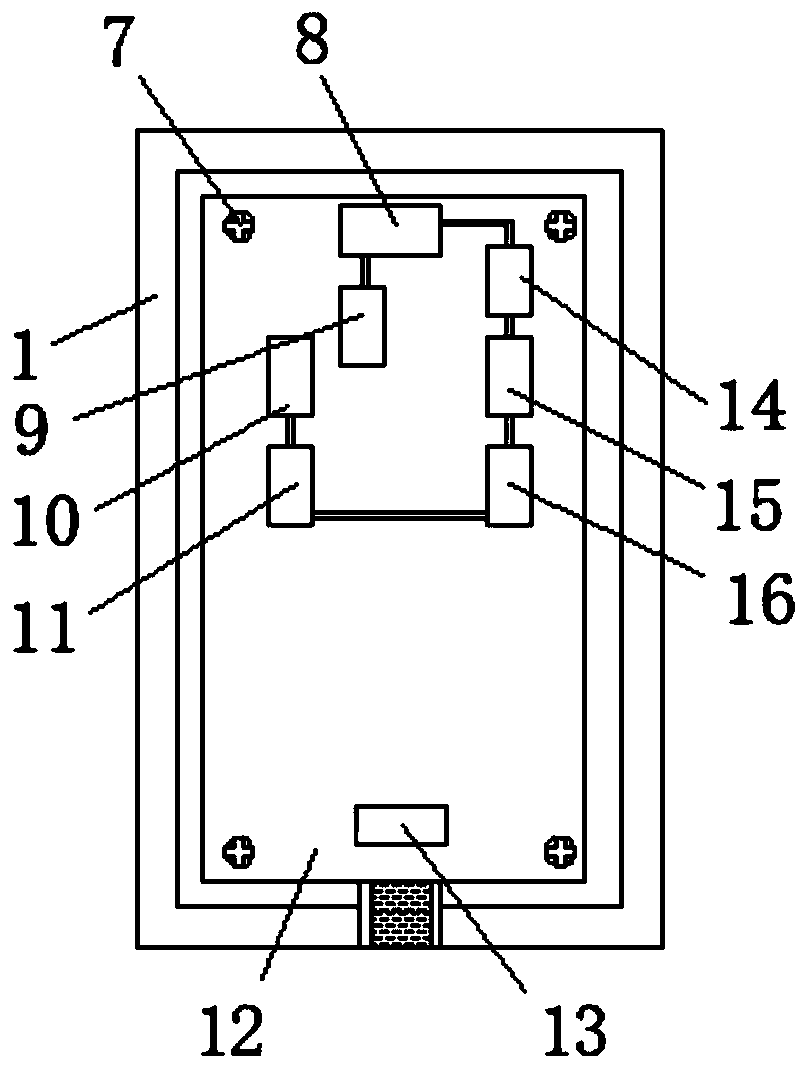

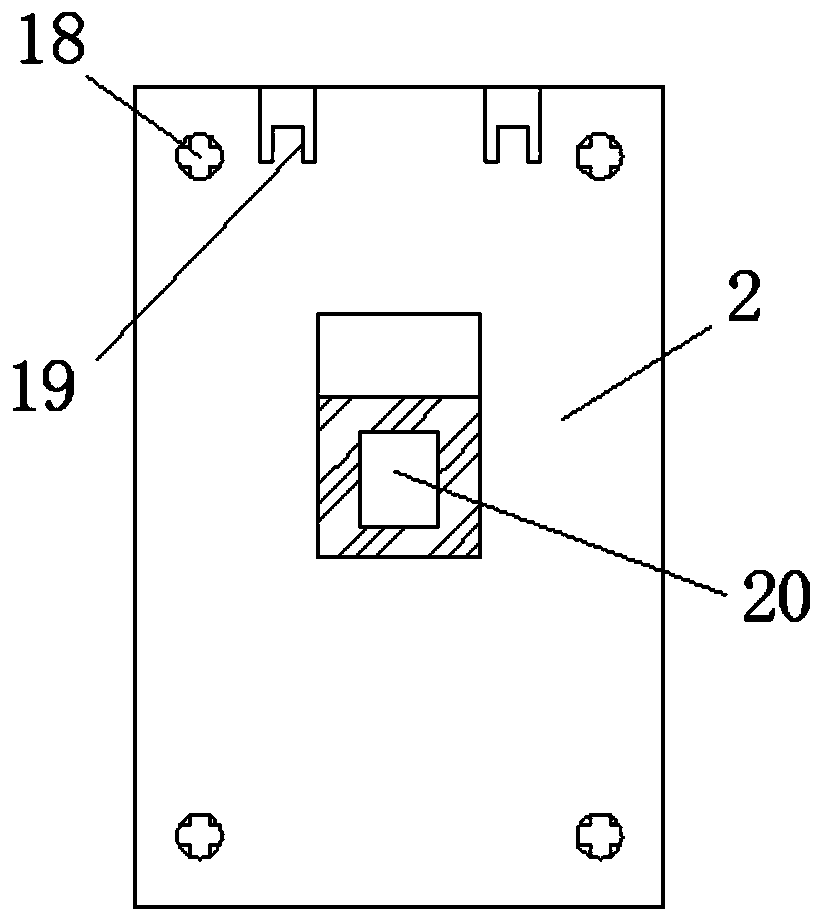

Safety switch with infrared image palmprint

InactiveCN111524727AAvoid loss of useBeautifully madeElectric switchesAcquiring/reconising fingerprints/palmprintsPalm printEngineering

The invention discloses a safety switch with infrared image palmprint. The safety switch comprises a safety switch front shell, wherein a safety switch rear shell base is arranged on one side of the safety switch front shell, a safety switch wall hanging plate is arranged on one side of the safety switch rear shell base, operation buttons are arranged on a surface of the safety switch front shell,a card reader is arranged at bottoms of the operation buttons, and a display screen is arranged on a surface of the safety switch front shell. The infrared image palmprint safety switch is advantagedin that various intelligent electric appliances or devices in a room can be prevented from being used after non-living body replacement verification such as photos succeeds, so use loss of the intelligent electric appliances is avoided, and infrared image palmprint or palmprint verification has the non-contact characteristic and is clean and sanitary.

Owner:深圳市英泰斯达智能技术有限公司

Ashtray manufacturing equipment

The invention belongs to the technical field of ashtray manufacturing, and particularly relates to ashtray manufacturing equipment. The ashtray manufacturing equipment is time-saving and labor-savingand is attractive in manufacturing. The ashtray manufacturing equipment comprises a bottom plate, supports, an annular sliding rail, sliding blocks, a fixing box, a mold and the like; the supports aresymmetrically arranged on the left side and the right side of the upper side of the bottom plate, the annular sliding rail is arranged at the upper ends of the supports, the sliding blocks are uniformly connected in the annular sliding rail in a sliding mode, the fixing box is arranged at the upper end of the sliding blocks, the mold is arranged on the fixing box, and a small hole is formed in the middle of the annular sliding rail. According to the ashtray manufacturing equipment, the beneficial effects of time saving and labor saving and attractive appearance are achieved; a first motor isarranged to control the mold to rotate, a second motor controls small balls to fall, and the number of the falling balls can be adjusted according to different requirements, so that the pattern designof an ashtray is realized; a stirring plate can be used for mixing and stirring glue in a glue box; and a heating wire can be used for heating the glue in the glue box so as to prevent solidification.

Owner:黄锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com