Heat-resistant silane crosslinked resin molded article and method for producing same, heat-resistant silane crosslinking resin composition and method for producing same, silane master batch, and heat-resistant product produced using heat-resistant silane crosslinked resin molded article

A resin molding, silane cross-linking technology, applied to heat-resistant silane cross-linking resin molding and its production, heat-resistant silane cross-linking resin composition and its production, silane masterbatch, and the use of heat-resistant In the field of heat resistance products of permanent silane cross-linked resin moldings, it can solve problems such as increased extrusion load, uneven reaction, and increased compounding of inorganic fillers to achieve excellent flame retardancy and mechanical properties, excellent flame retardancy, and appearance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

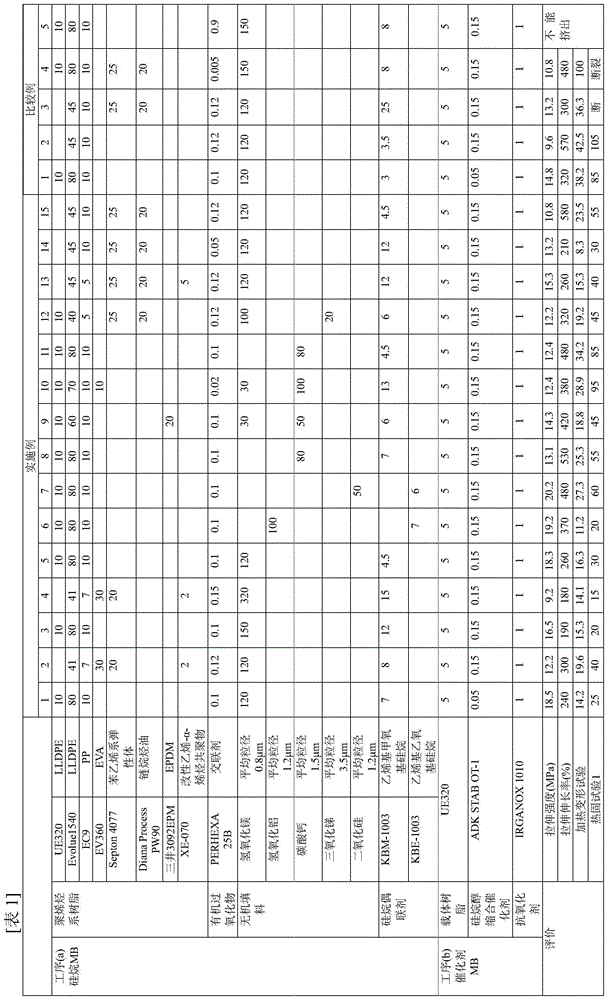

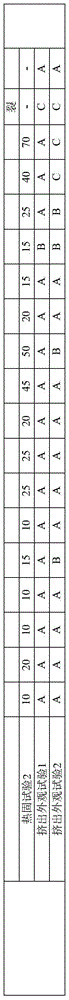

Embodiment 1~15 and comparative example 1~5

[0212] First, put the organic peroxide, inorganic filler and silane coupling agent into a 10L Henschel mixer manufactured by Toyo Seiki according to the mass ratio shown in Table 1, and mix at room temperature (25°C) for 1 hour to obtain a powder mixture.

[0213] Next, according to the mass ratio shown in Table 1, the powder mixture thus obtained and the polyolefin resin were put into a 2L Banbury mixer manufactured by NipponRoll MFG. After kneading for about 12 minutes at a temperature higher than or equal to 180°C to 190°C, it is discharged at a material discharge temperature of 180°C to 190°C to obtain a silane masterbatch (also referred to as silane MB) (step (a)). The obtained silane MB contains at least two types of silane crosslinkable resins in which a silane coupling agent is graft-reacted on an olefin resin.

[0214] On the other hand, according to the mass ratio shown in Table 1, the carrier resin "UE320", the silanol condensation catalyst, and the antioxidant wer...

Embodiment 16

[0222] Silane MB (step (a)) and catalyst MB were prepared in the same manner as in Example 1 above using the components shown in Table 2 in the mass ratio (parts by mass) shown in Table 2.

[0223] Next, the obtained silane MB and catalyst MB were charged into an airtight ribbon mixer, and were dry-blended at room temperature (25° C.) for 5 minutes to obtain a dry blend. At this time, the mixing ratio of silane MB and catalyst MB was 5 parts by mass of carrier resin of catalyst MB based on 100 parts by mass of polyolefin resin of silane SM (see Table 2). Next, this dry blend was put into a 40mm extruder with L / D=24 (compression part screw temperature 190°C, head temperature 200°C), and was coated with a wall thickness of 1mm while melting and mixing in the extruder screw. The outside of the 1 / 0.8TA conductor was used to obtain an electric wire (uncrosslinked) with an outer diameter of 2.8 mm (step (b) and step (c)).

[0224] The obtained electric wire (uncrosslinked) was left...

Embodiment 17

[0227] Using the components shown in Table 2 in the mass ratio (parts by mass) shown in Table 2, an electric wire in which the outer periphery of the conductor was coated with the heat-resistant silane crosslinkable resin composition was obtained in the same manner as in Example 1 above ( 2.8 mm outer diameter, non-crosslinked) (process (a), process (b) and process (c)).

[0228] The obtained electric wire was left to stand for 72 hours in an atmosphere at a temperature of 23° C. and a humidity of 50% (step (d)).

[0229] In this way, an electric wire having a sheath made of a heat-resistant silane crosslinked resin molded product was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com