Patents

Literature

33results about How to "High Qf value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

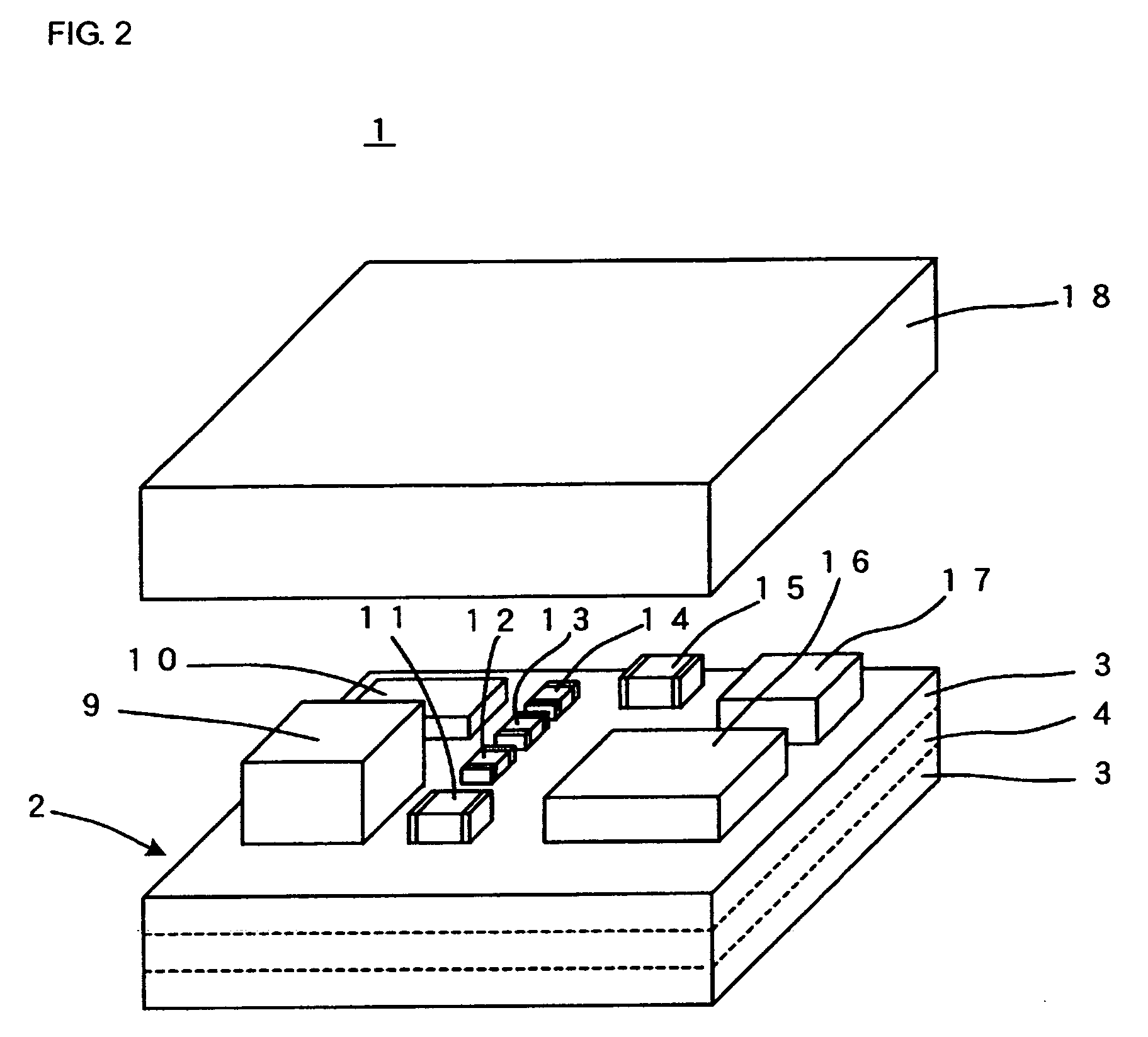

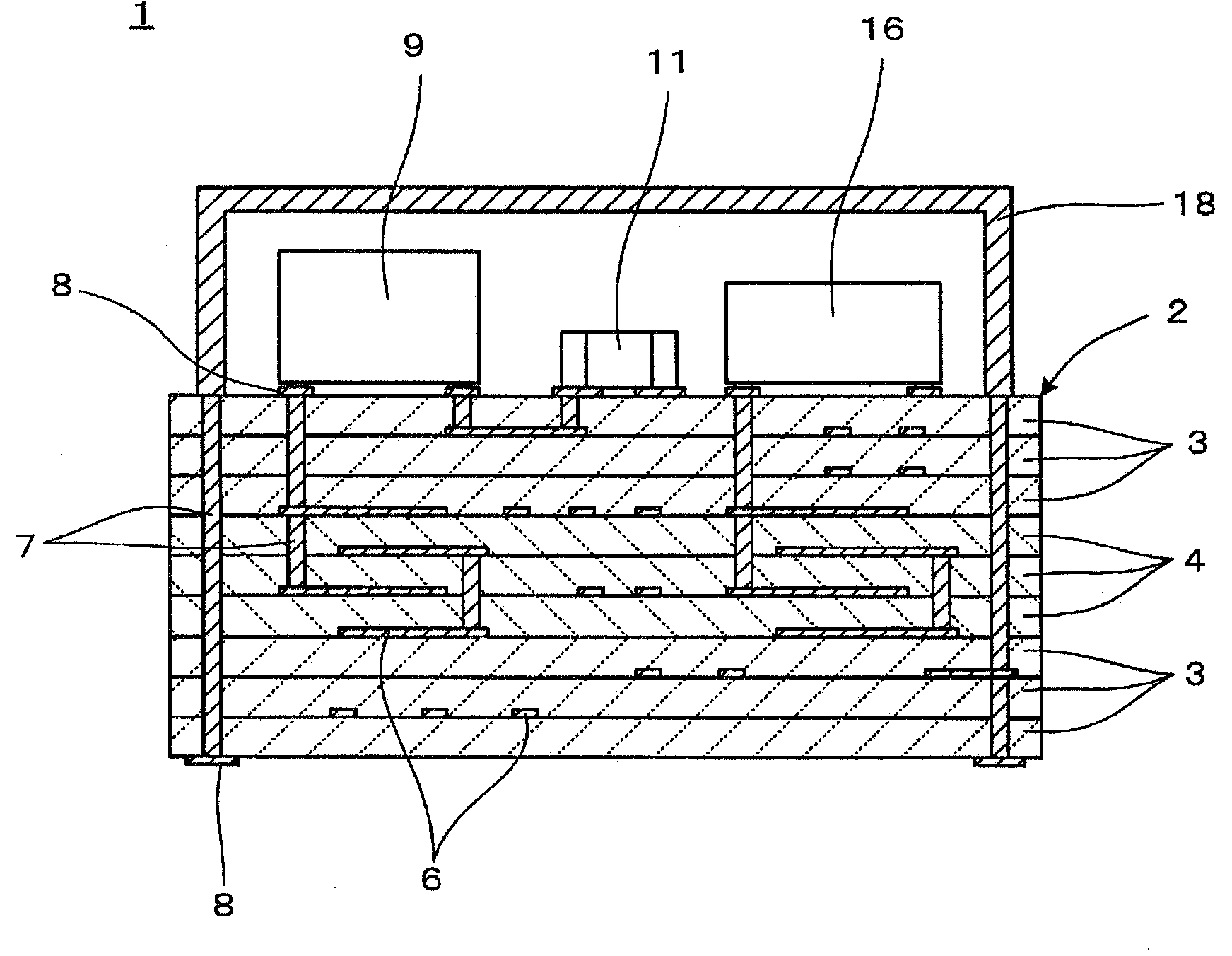

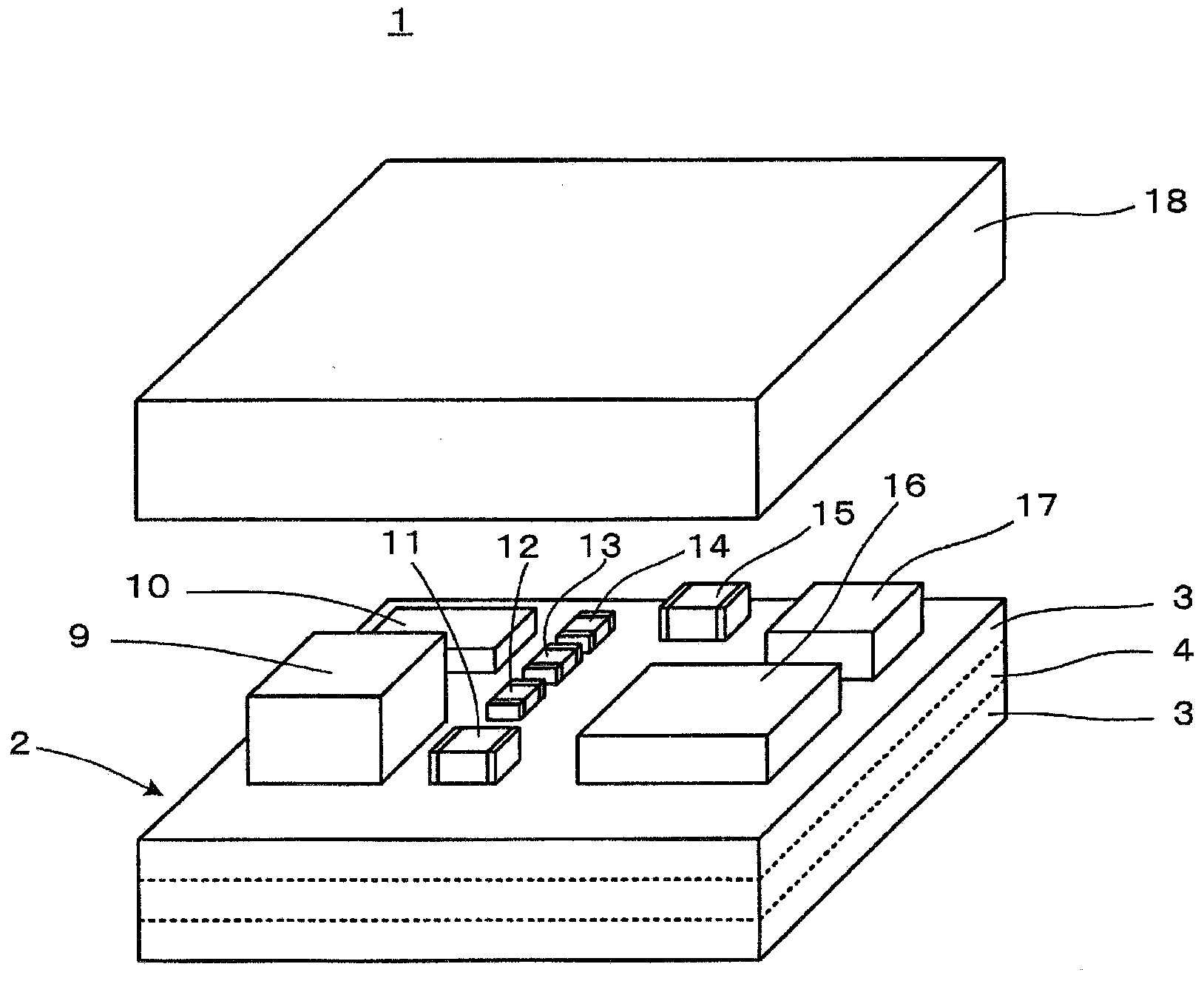

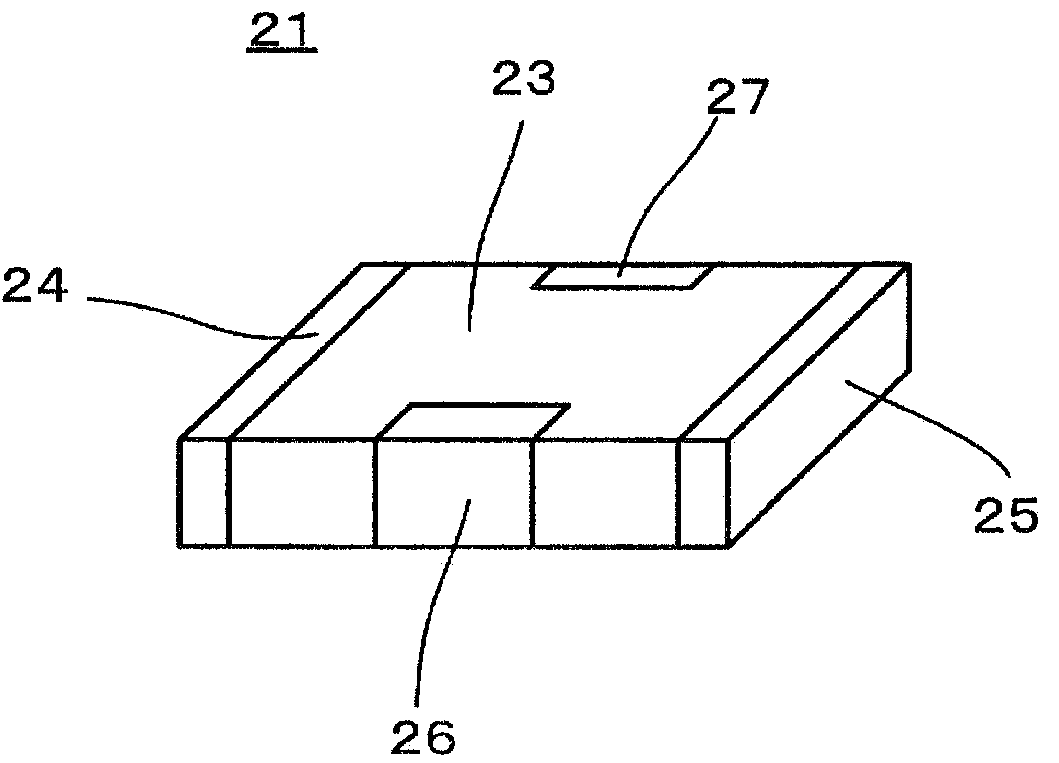

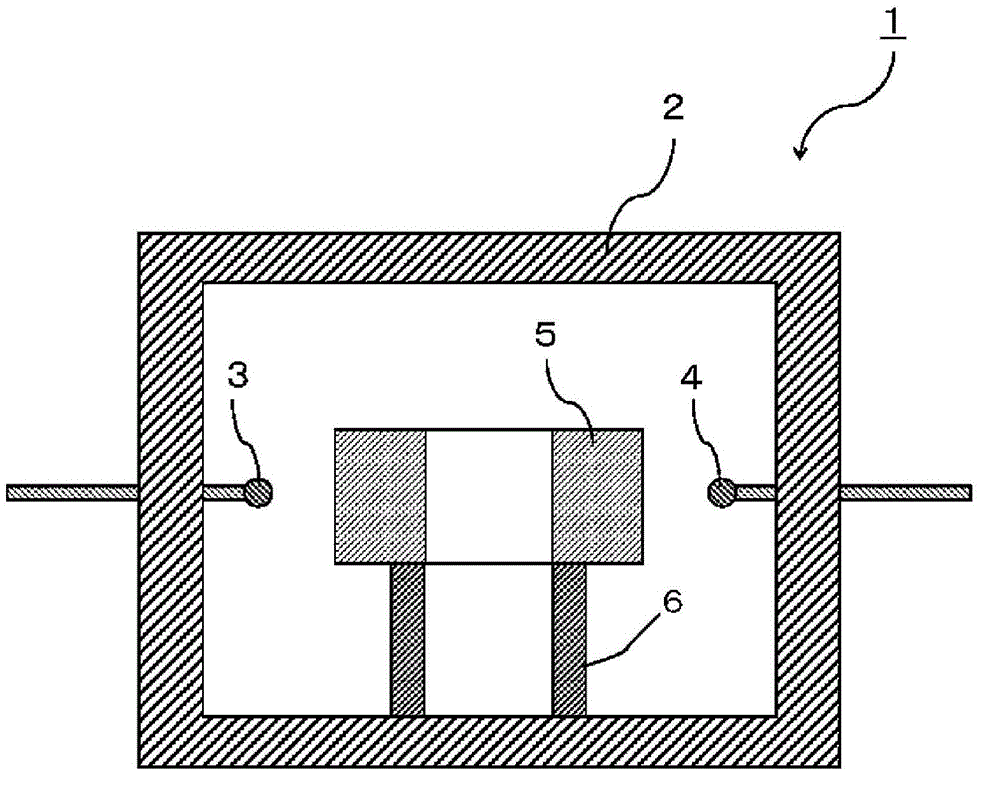

Insulating ceramic composition, insulating ceramic sintered body, and multilayer ceramic electronic component

InactiveUS20060293168A1High Qf valueLow dielectric constantFixed capacitor dielectricStacked capacitorsOlivineForsterite

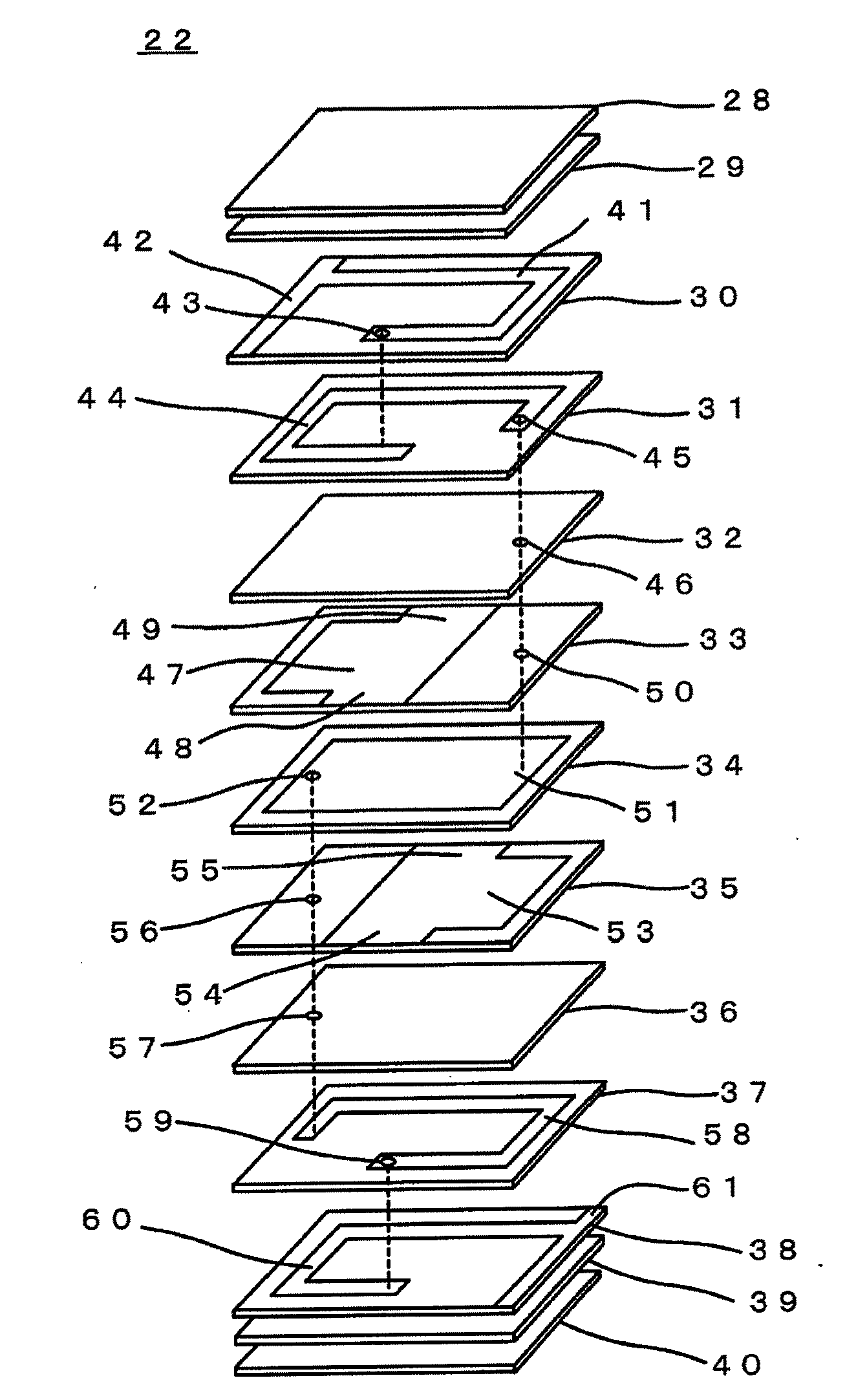

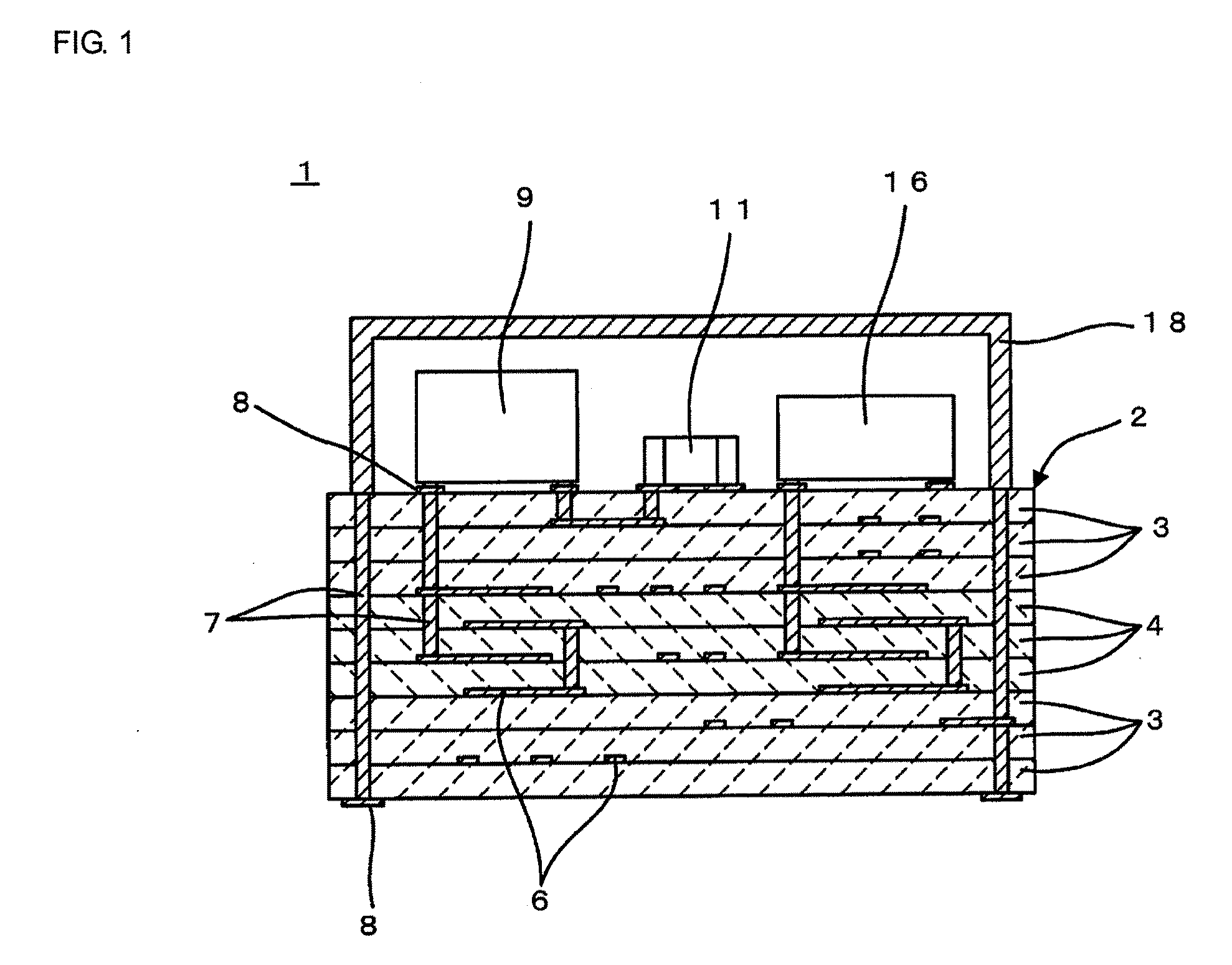

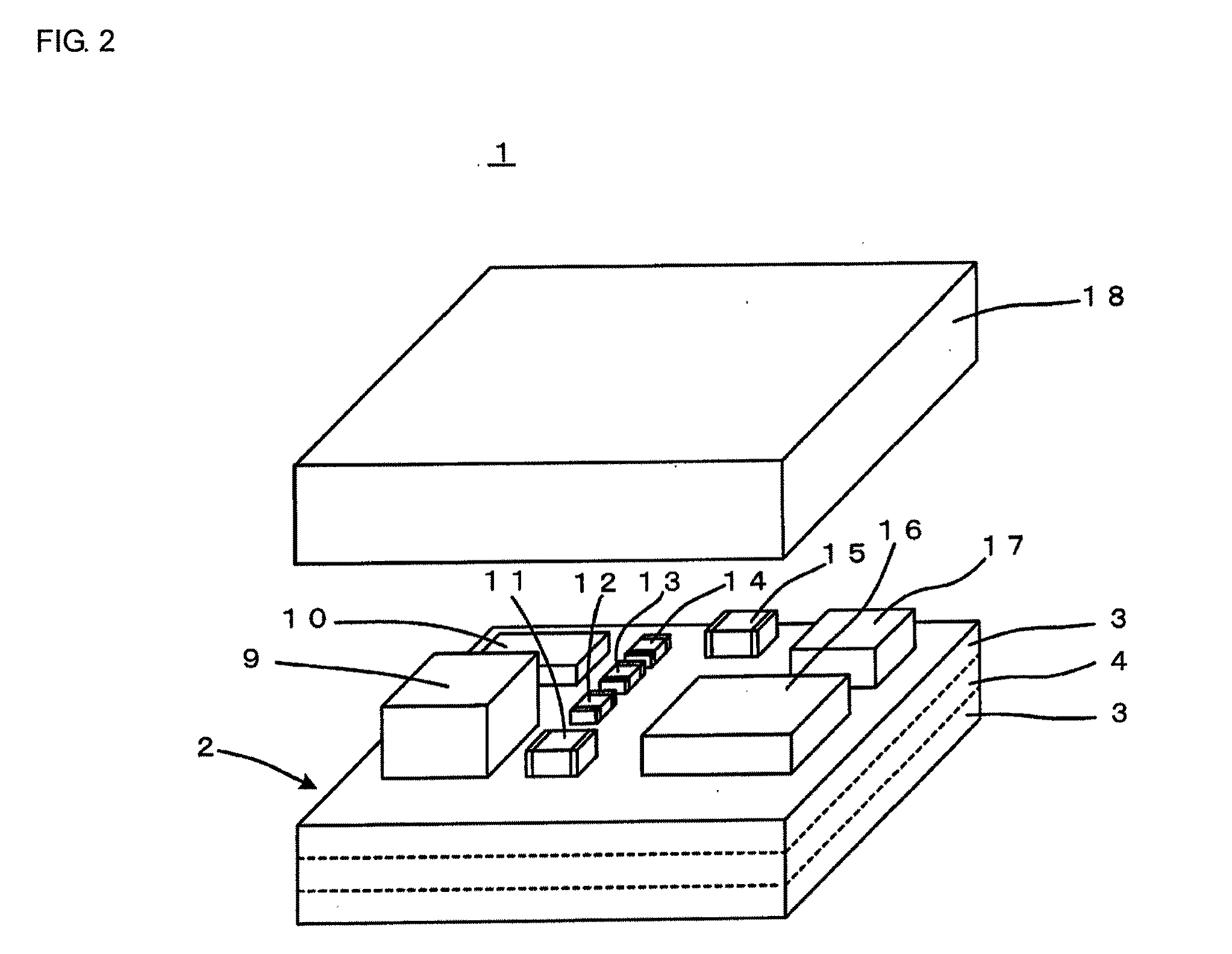

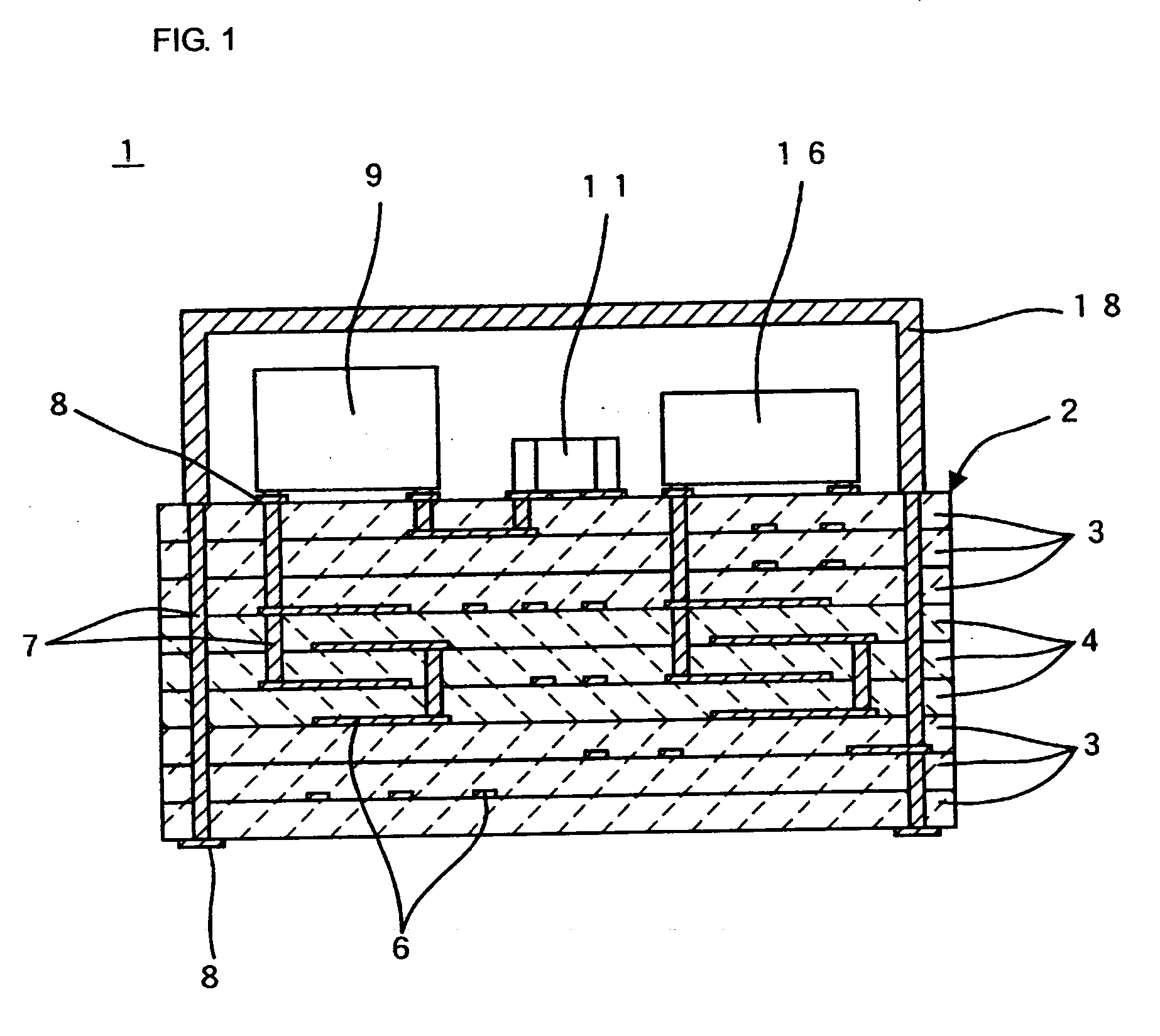

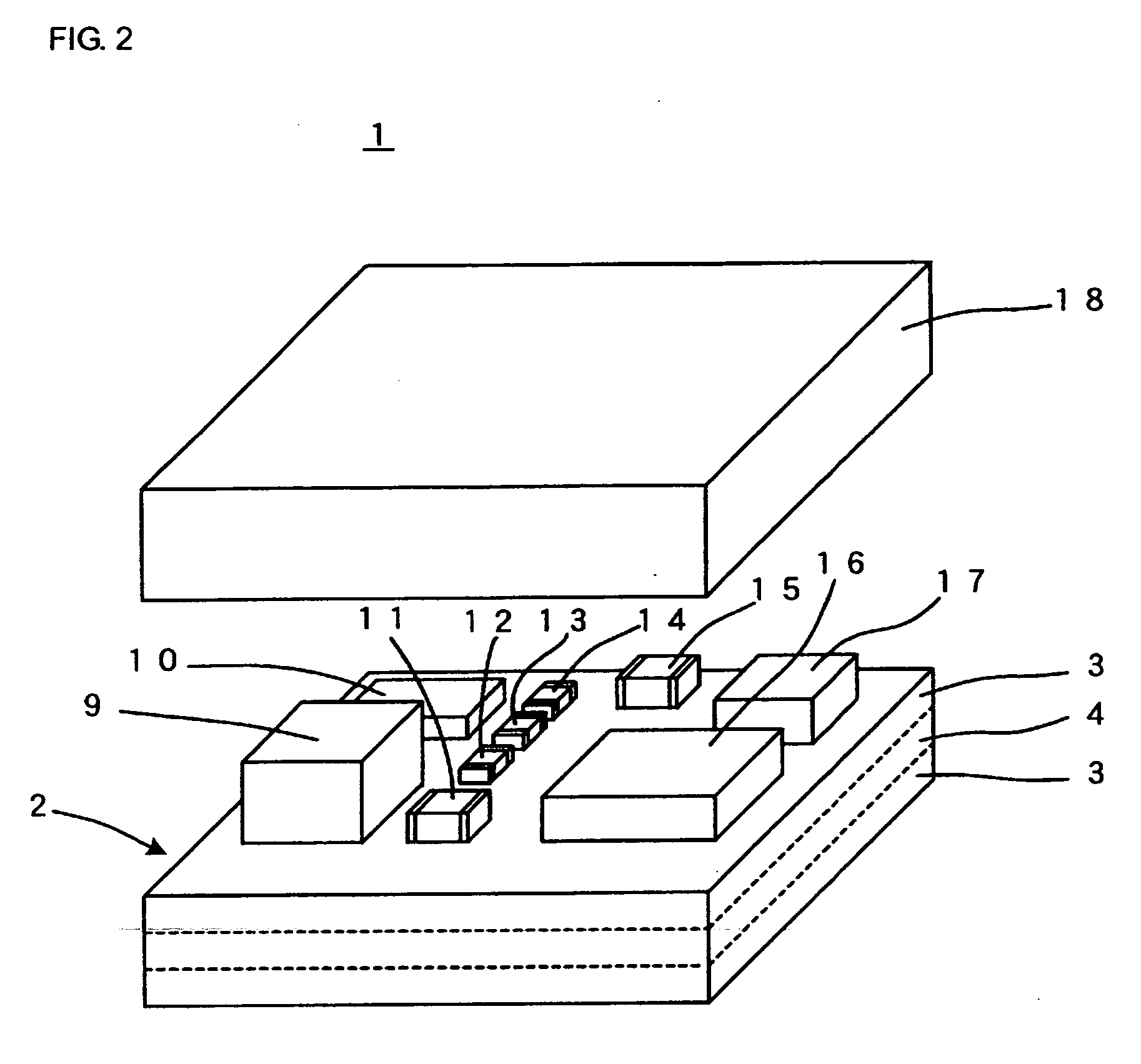

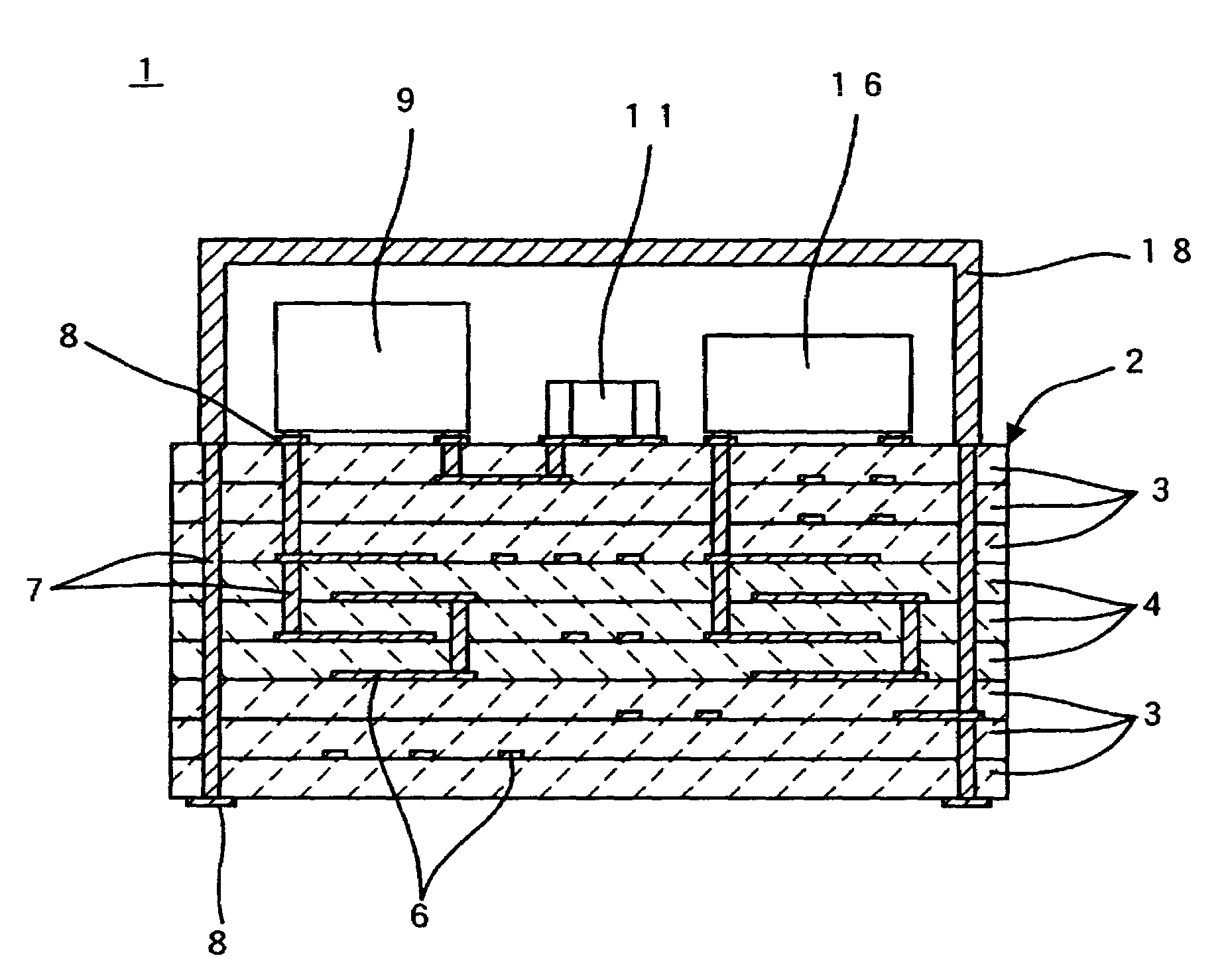

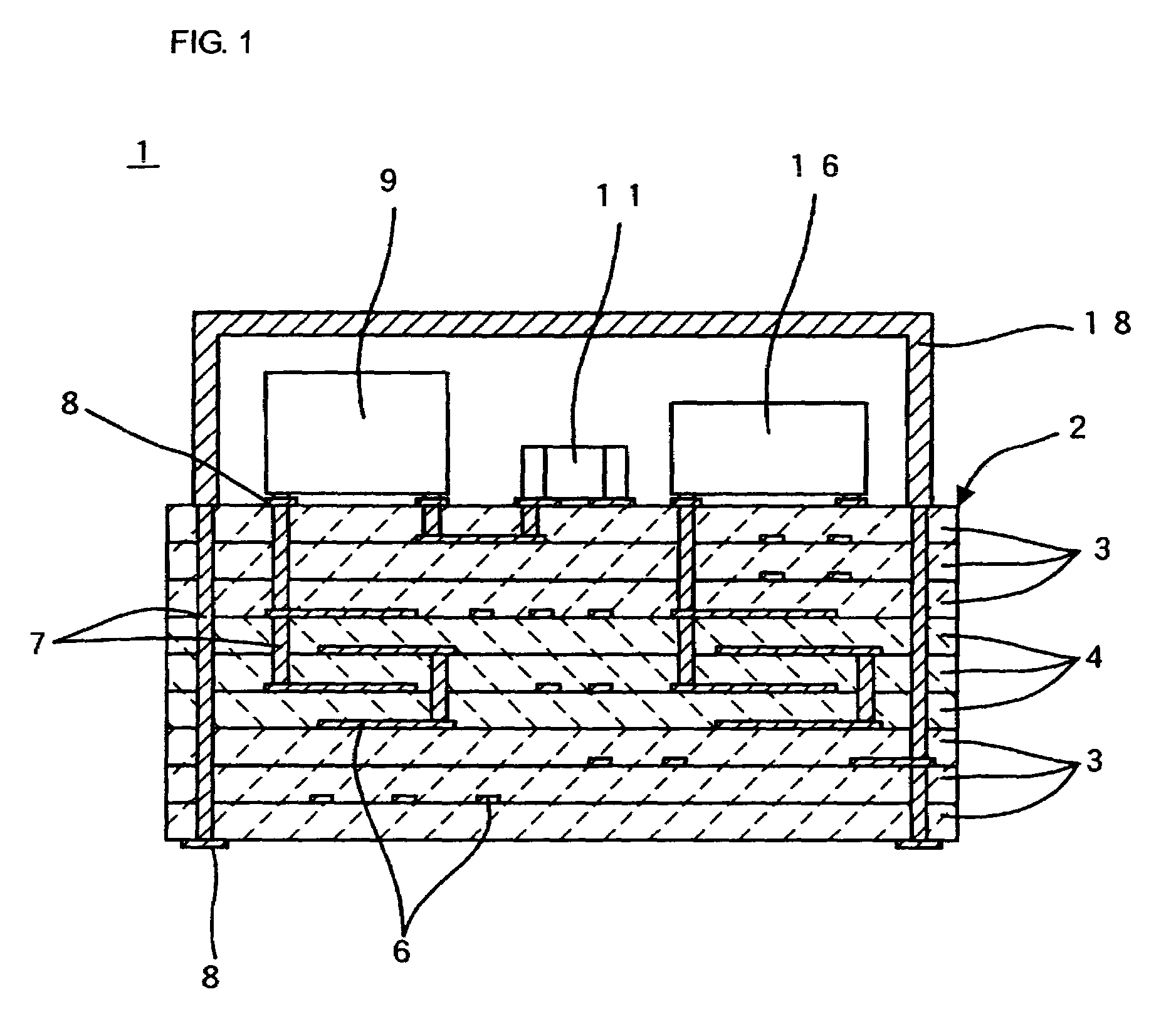

An insulating ceramic composition forming insulating ceramic layers (3) stacked in a multilayer ceramic substrate (2) used in a monolithic ceramic electronic component, such as a multilayer ceramic module (1). The insulating ceramic composition contains a first ceramic powder mainly containing forsterite, a second ceramic powder mainly containing at least one compound selected from the group consisting of CaTiO3, SrTiO3, and TiO2, and a borosilicate glass powder. The borosilicate glass powder contains 3 to 15 percent by weight of lithium in terms of Li2O, 30 to 50 percent by weight of magnesium in terms of MgO, 15 to 30 percent by weight of boron in terms of B2O3, 10 to 35 percent by weight of silicon in terms of SiO2, 6 to 20 percent by weight of zinc in terms of ZnO, and 0 to 15 percent by weight of aluminum in terms of Al2O3. The insulating ceramic composition can be fired at a temperature of 1000° C. or less, and the resulting sintered compact has a low relative dielectric constant, a resonance frequency with a low temperature coefficient, and a high Q value.

Owner:MURATA MFG CO LTD

Low temperature sintered (Ca, Mg) SiO3 microwave dielectric ceramic and its prepn process

InactiveCN1673174AMeet the design requirementsLower sintering temperatureCeramicsDielectricCommunications system

The present invention relates to low temperature sintered microwave dielectric ceramic for dielectric antenna, filter and other RF elements and devices in mobile communication system and its preparation process. The low temperature sintered microwave dielectric ceramic has (Ca, Mg)SiO3 as main component, CaTiO3 for regulating the temperature coefficient of frequency, and Li2CO3 and V2O5 as sintering assistant. The present invention features Li2CO3 and V2O5 lowering the sintering temperature of the ceramic system to below 900 deg.c, special technological process improving the characteristic of powder and slurry matching with silver electrode, the dielectric constant of 8-10, quality factor higher than 25000 GHz, the temperature coefficient of resonant frequency approaching zero, low cost, etc.

Owner:ZHEJIANG UNIV +1

Insulating ceramic composition, insulating ceramic sintered body, and mulitlayer ceramic electronic component

InactiveUS7351674B2Low dielectric constantHigh Qf valueFixed capacitor dielectricStacked capacitorsCeramic sinteringLithium

An insulating ceramic composition forming insulating ceramic layers (3) stacked in a multilayer ceramic substrate (2) used in a monolithic ceramic electronic component, such as a multilayer ceramic module (1). The insulating ceramic composition contains a first ceramic powder mainly containing forsterite, a second ceramic powder mainly containing at least one compound selected from the group consisting of CaTiO3, SrTiO3, and TiO2, and a borosilicate glass powder. The borosilicate glass powder contains 3 to 15 percent by weight of lithium in terms of Li2O, 30 to 50 percent by weight of magnesium in terms of MgO, 15 to 30 percent by weight of boron in terms of B2O3, 10 to 35 percent by weight of silicon in terms of SiO2, 6 to 20 percent by weight of zinc in terms of ZnO, and 0 to 15 percent by weight of aluminum in terms of Al2O3. The insulating ceramic composition can be fired at a temperature of 1000° C. or less, and the resulting sintered compact has a low relative dielectric constant, a resonance frequency with a low temperature coefficient, and a high Q value.

Owner:MURATA MFG CO LTD

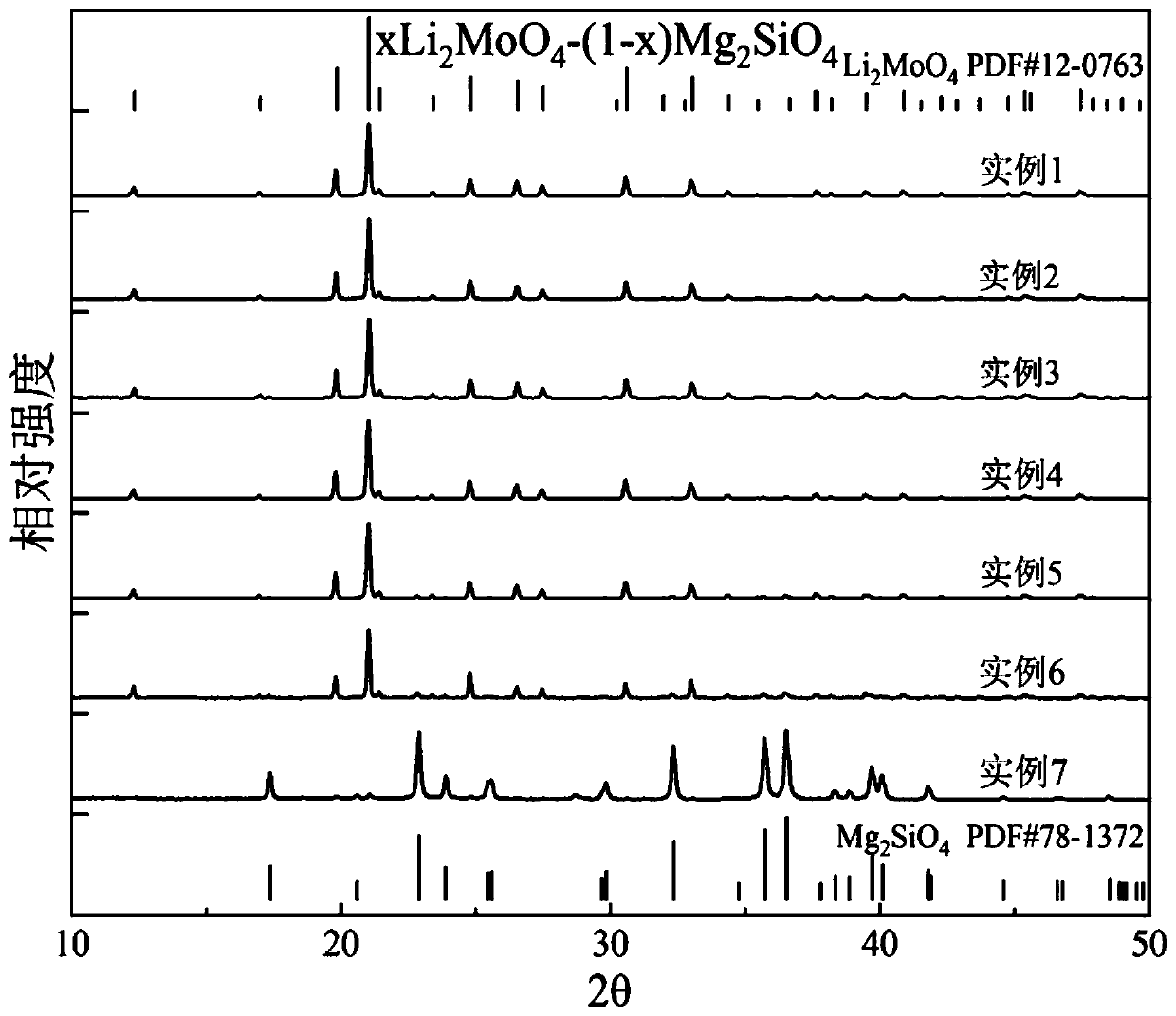

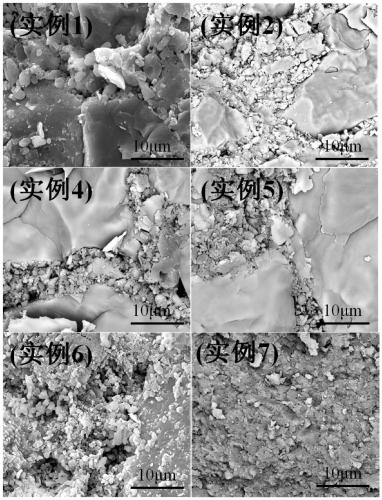

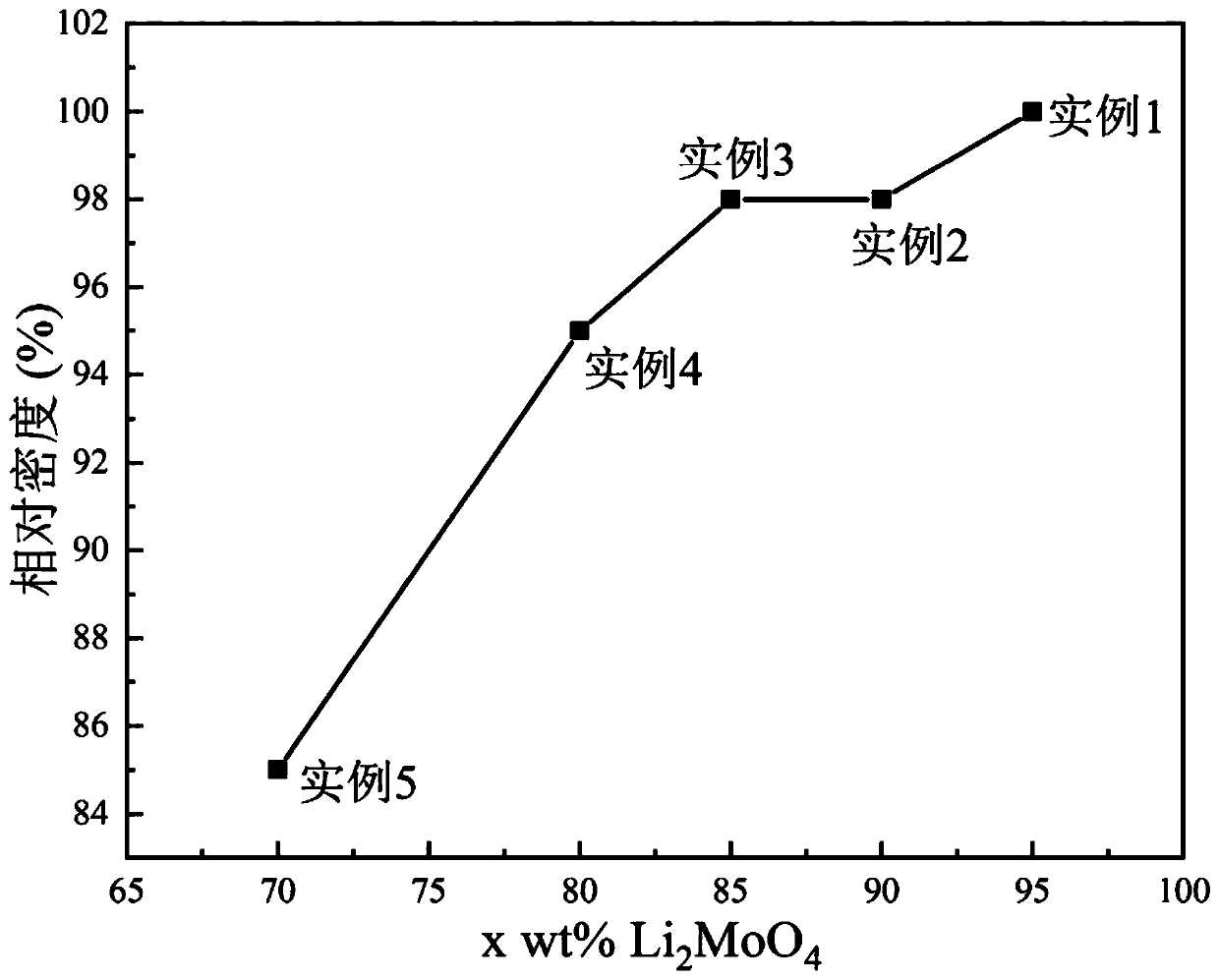

Li2MoO4-Mg2SiO4-based composite ceramic microwave material and preparation method thereof

ActiveCN110183227AExcellent microwave dielectric propertiesHigh dielectric constantComposite ceramicSilicon dioxide

The invention discloses a Li2MoO4-Mg2SiO4-based composite ceramic microwave material and a preparation method thereof. A chemical general formula of the composite ceramic can be written as xLi2MoO4-(1-x)Mg2SiO4, wherein x=10 wt%, 50 wt%, 70 wt%, 80 wt%, 85 wt%, 90 wt% or 95 wt%. The method comprises the following steps: firstly weighing magnesium oxide and silicon dioxide according to a certain stoichiometric ratio, performing ball milling for uniformization, performing drying, and performing pre-sintering to obtain Mg2SiO4; and weighing the prepared Mg2SiO4 and a Li2MoO4 raw material according to a certain weight ratio, adding 15 wt% of deionized water, performing uniform mixing, performing heat pressing on the mixture at 200 DEG C and 500 MPa for 60 min, and performing drying at 120 DEGC for 24 h to remove residual water to obtain the ultra-low-temperature cold sintered xLi2MoO4-(1-x)Mg2SiO4 composite ceramic material. Compared with traditional high-temperature solid-phase sintering(often higher than 1000 DEG C or more), the method provided by the invention has a sintering temperature in the range from room temperature to 200 DEG C; and the method provided by the invention hasa simple process, saves energy and can be widely applied to production of Li2MoO4-Mg2SiO4 composite ceramic substrates.

Owner:HANGZHOU DIANZI UNIV

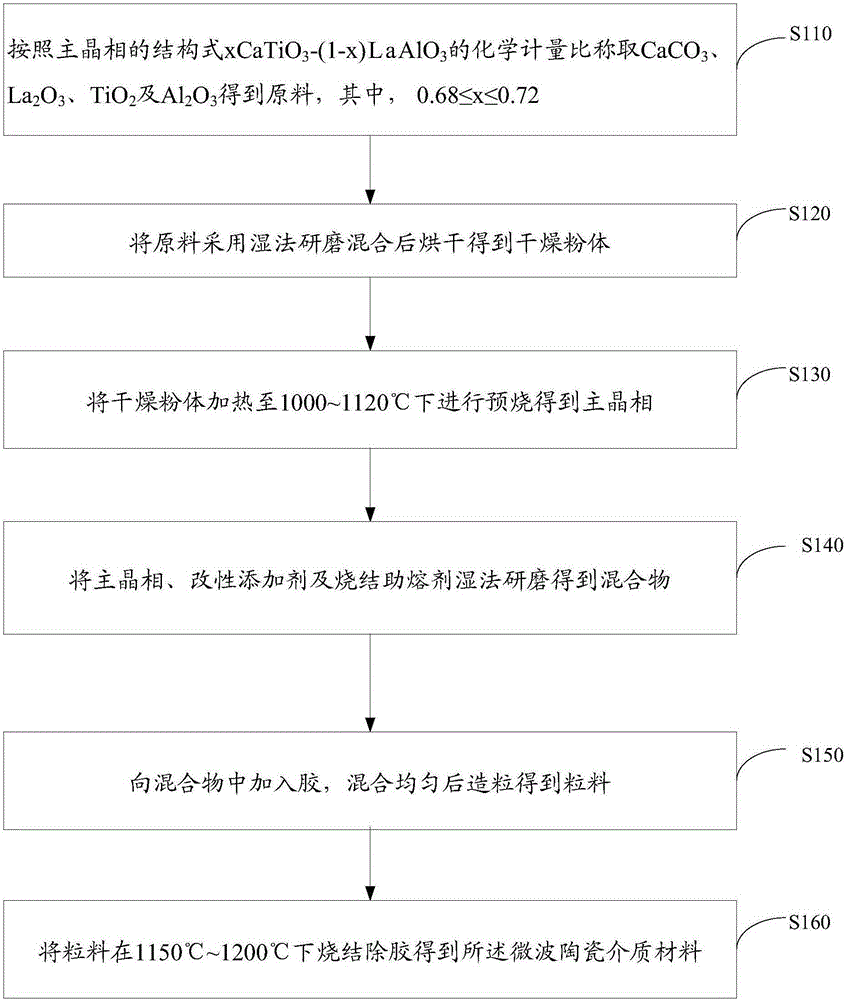

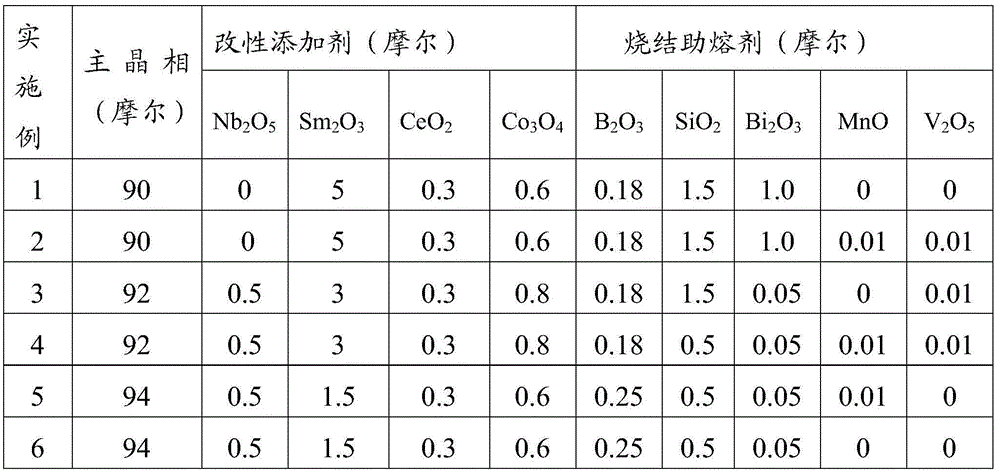

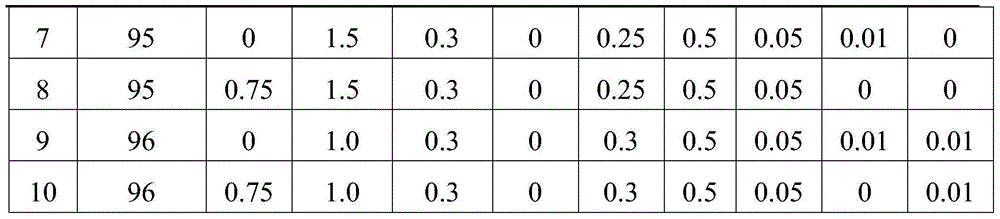

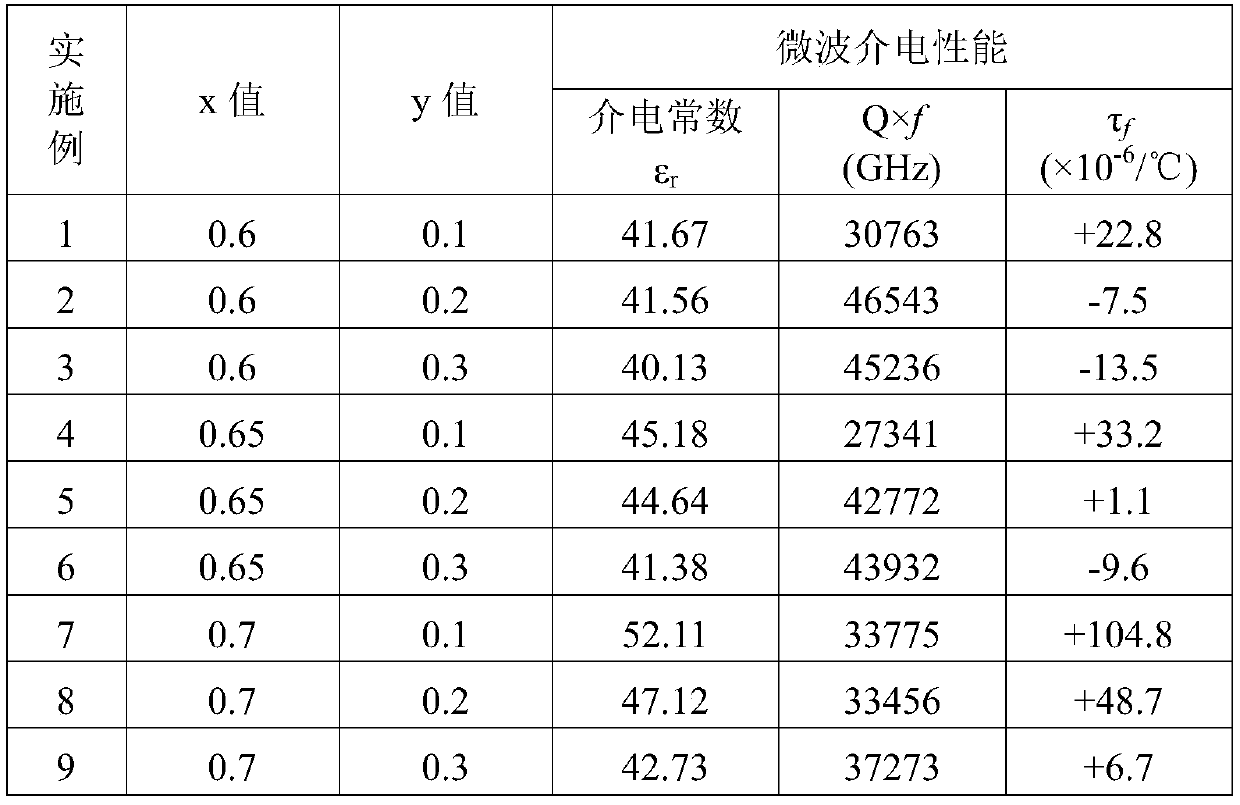

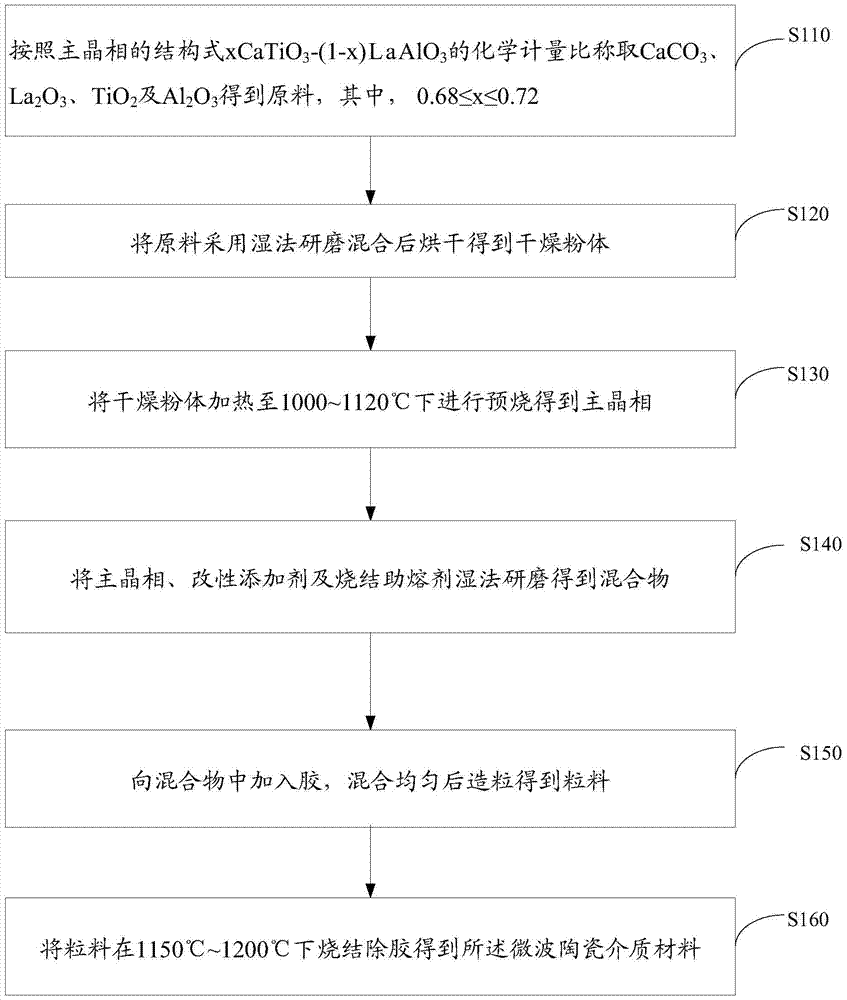

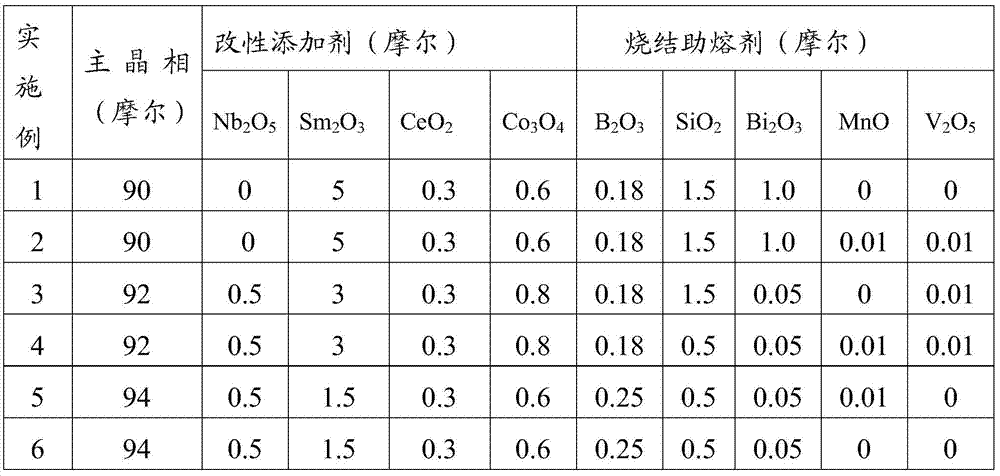

Microwave ceramic dielectric material and preparation method thereof

The invention provides a microwave ceramic dielectric material and a preparation method thereof. The microwave ceramic dielectric material comprises a main crystal phase, a modifying additive and a sintering cosolvent, and a structural formula of the main crystal phase is xCaTiO3-(1-x)LaAlO3, wherein x is greater than or equal to 0.68 and less than or equal to 0.72; according to molar content in microwave dielectric ceramic, the modifying additive comprises 0-1.0% of Nb2O5, 1-5% of Sm2O3, 0.1-0.5% of CeO2 and 0-1% of Co3O4, and the sintering cosolvent comprises 0-2% of B2O3, 0.5-4% of SiO2, 0-1% of Bi2O3, 0-0.5% of MnO and 0-0.5% of V2O5. The microwave ceramic dielectric material can be sintered at 1150 DEG C-1200 DEG C, cost can be saved, and high Qf value of 43000GHz-48000GHz can still be maintained.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Microwave dielectric material with near-zero temperature coefficient of resonance frequency

The invention discloses a microwave dielectric material with a near-zero temperature coefficient of resonance frequency. TiO2, ZnO, Nb2O5 and ZrO2 are adopted as the raw materials, the expression of atarget synthetic compound is (Zr1-xTix)1-y(Zn1 / 3Nb2 / 3)yO2, wherein x=0.6-0.7, and y=0.1-0.3. The preparation method includes: firstly proportioning the raw materials according to a stoichiometric equation, carrying out ball milling, drying and sieving, performing presintering at 1050DEG C, then carrying out ball milling and drying, conducting granulation, and then performing pressing into a greenbody; and heating the green body to 1250DEG C at a rate of 5DEG C / min, carrying out heat preservation for 30min, then performing cooling to 1150DEG C at a rate of 10DEG C / min, conducting heat preservation for 12h, and then performing cooling to obtain the microwave dielectric material with a near-zero temperature coefficient of resonance frequency. The invention adopts two-stage sintering, firstly the green body is heated to a high temperature and is subjected to heat preservation for a short period of time, and then heat preservation is carried out at a low temperature for a long time, so that the ceramic reaches high density, meanwhile, the residual stress between two phases is reduced, and the defect of low Qf value of a two-phase composite microwave dielectric ceramic material is effectively improved.

Owner:TIANJIN UNIV

Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

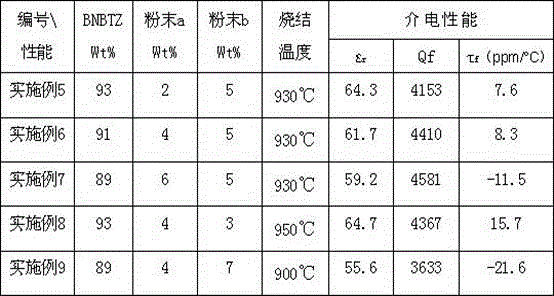

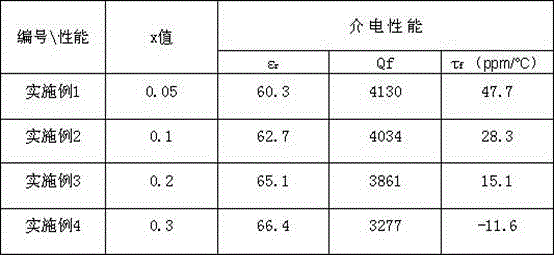

InactiveCN105565808AResonant frequency temperature coefficient adjustableHigh Qf valueDielectricMicrowave

The present invention discloses a low-temperature co-fired microwave dielectric ceramic material very suitable for LTCC process production and a preparation method thereof. The low-temperature co-fired microwave dielectric ceramic material comprises 87-97wt% of Ba4 (Nd1.0-XBix) 9.33 (Ti0.9Zr0.1) 18O54, 0-6wt% of powder a and 3-7wt% of powder b, the powder a is a pre-calcined body, comprises Nd2O3 and Al2O3 in the molar ratio of 1:1, and has a chemical general formula of NdAlO3; and the powder b is a pre-calcined body, comprises BaO, CuO and B2O3 in the molar ratio of 1:1: 1, and has a chemical general formula of BaCu (B2O5). The low-temperature co-fired microwave dielectric ceramic material is free of glass melting and low in manufacturing cost, the sintering temperature is lower than 950 DEG C, the low-temperature co-fired microwave dielectric ceramic material can be matched with silver for co-firing, relative dielectric constant is 55-70, Qf value is 3000-5000GHz, and the resonance frequency temperature coefficient is adjustable.

Owner:东莞成电创新电子科技有限公司

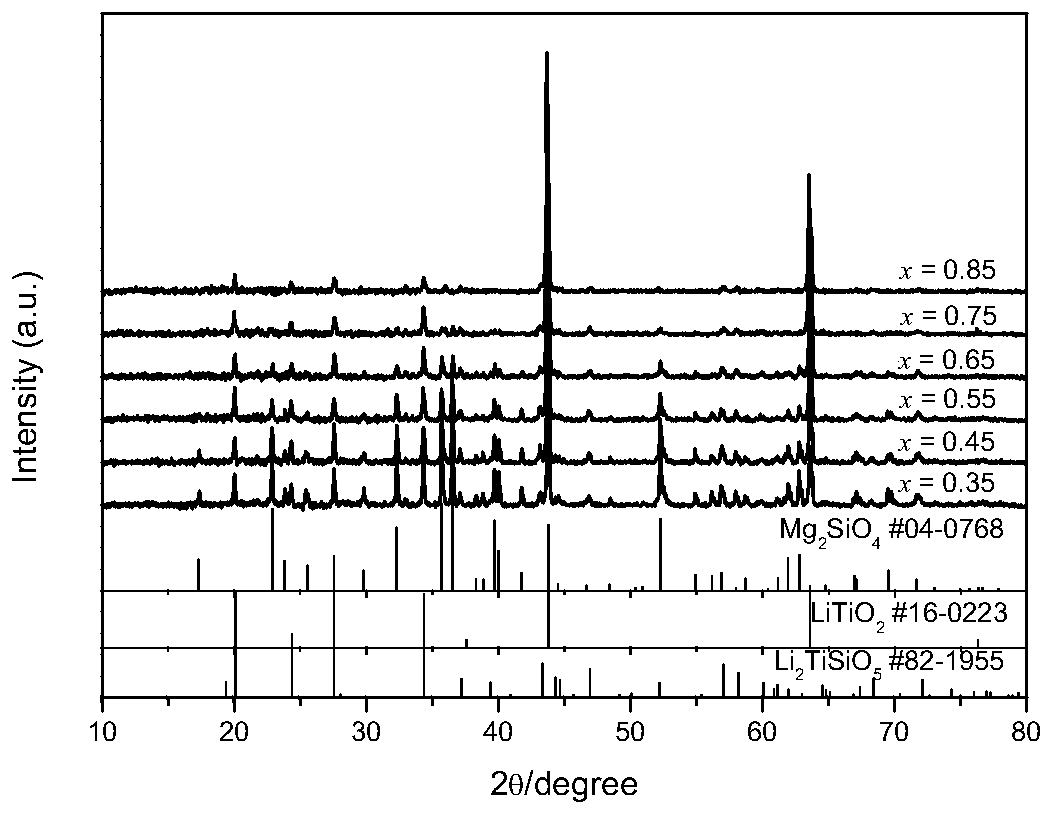

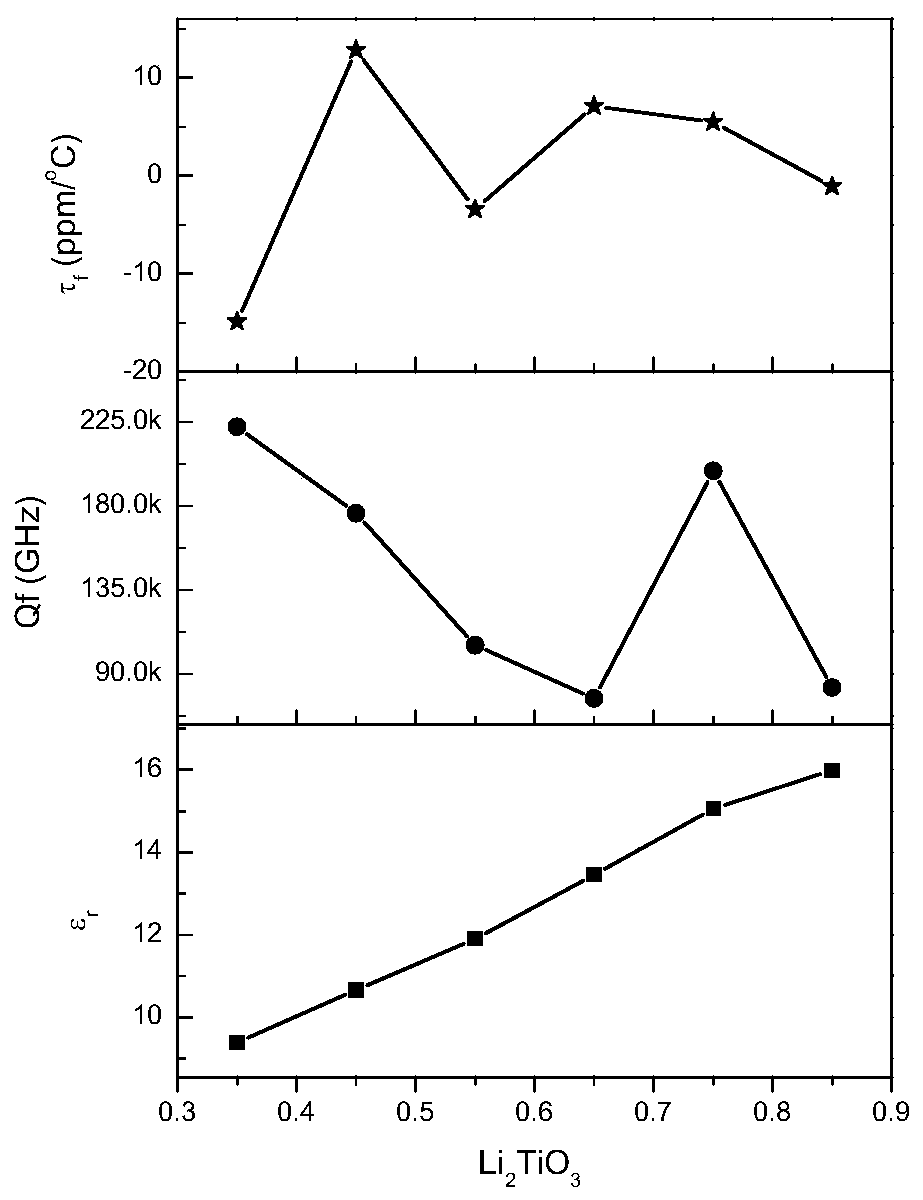

a mg 2 sio 4 -li 2 tio 3 Composite system LTCC material and preparation method thereof

The invention belongs to the field of microwave electronic ceramic materials and its manufacture, in particular to a Mg 2 SiO 4 -Li 2 TiO 3 Composite system LTCC material and its preparation method. The LTCC material provided by the invention is based on Mg 2 SiO 4 and Li 2 TiO 3 Composite system, obtained by solid phase method; achieve sintering temperature of 800-950°C lower than 960°C (Ag melting point), ε r =9.0~18.0, and has a high Qf value of 50,000~250,000GHz and near zero τ f =‑15~15ppm / ℃, it has high application prospect and value in the field of LTCC technology. It can be widely used in LTCC substrates, laminated microwave devices and modules.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Rapidly-molded microwave dielectric ceramic and preparation method thereof

The invention discloses rapidly-molded microwave dielectric ceramic and a preparation method thereof. A biological molecular material, a plasticizer and de-ionized water are mixed to obtain a crosslinking framework for gel casting; the biological molecular material and the plasticizer can form a hydrogen bond in a solution; the hydrogen bond is used as the plasticizer to improve the strength of agreen body; independently mixing ceramic powder and the residual de-ionized water, and a condition that the ceramic powder is directly mixed with the crosslinking framework for the gel casting to generate an adhering phenomenon is avoided, so that the ceramic powder can be sufficiently and uniformly mixed with the crosslinking framework; finally, ceramic is rapidly formed at certain temperature through adhering and sintering, the sample preparation time is greatly shortened and defects caused by the fact that organic matters are not adhered completely are avoided at the same time, so that themicrowave dielectric ceramic with good performance can be obtained; compared with a sample prepared by utilizing a traditional solid-phase method utilizing the same powder, a microwave dielectric ceramic sample prepared by the method has better performance; the dielectric loss is reduced by 26.01 percent, the Q-unloaded is improved by 35.6 percent and the QF (Quality Factor) value is improved by 76.85 percent.

Owner:XI AN JIAOTONG UNIV

Microwave ceramic filer element and production method thereof

InactiveCN110304904AImprove performanceGood electrical propertiesWaveguide type devicesHigh humidityMicrowave

The invention discloses a microwave ceramic filer element. The microwave ceramic filer element is composed of the following raw materials in percentage by weight: 5%-15% of Mg, 5%-15% of Sm, 5%-15% ofCa, 5%-15% of Zn, 5%-15% of Al, 5%-15% of Sr, 0.01%-0.1% of La, 0.01%-0.1% of Mn, 0.01%-0.1% of Sn, 0.01%-0.1% of Co, 0.01%-0.1% of Bi, 30%-40% of Ti, 0.01%-0.1% of Cu, 0.01%-0.1% of Ni, 0.01%-0.1% of Sn, 0.01%-0.1% of Pb, 0.1%-0.9% of Zr, 0.1%-0.9% of Nd, 0.1%-0.9% of Ta and 0.1%-0.9% of Ce. The raw materials are mixed according to a certain ratio, through working procedures of ball milling, drying, synthesizing, tabletting, firing and the like, energy consumption is greatly reduced, and a finished product with an ultrahigh Qf value can be obtained, has an outstanding electrical property, mechanical property and thermal property, especially has high mechanical strength, resistance to high and low temperature and high humidity, resistance to radiation, high dielectric strength and good aging performance, has the advantages of high stop-band suppression, low pass-band insertion loss, a wide frequency band, high power, a far spurious pass-band, in-band flat group delay and small size, is excellent in comprehensive performance, uniform in element and higher in reliability, and has important industrial application values.

Owner:深圳市九天盈科通信技术有限公司

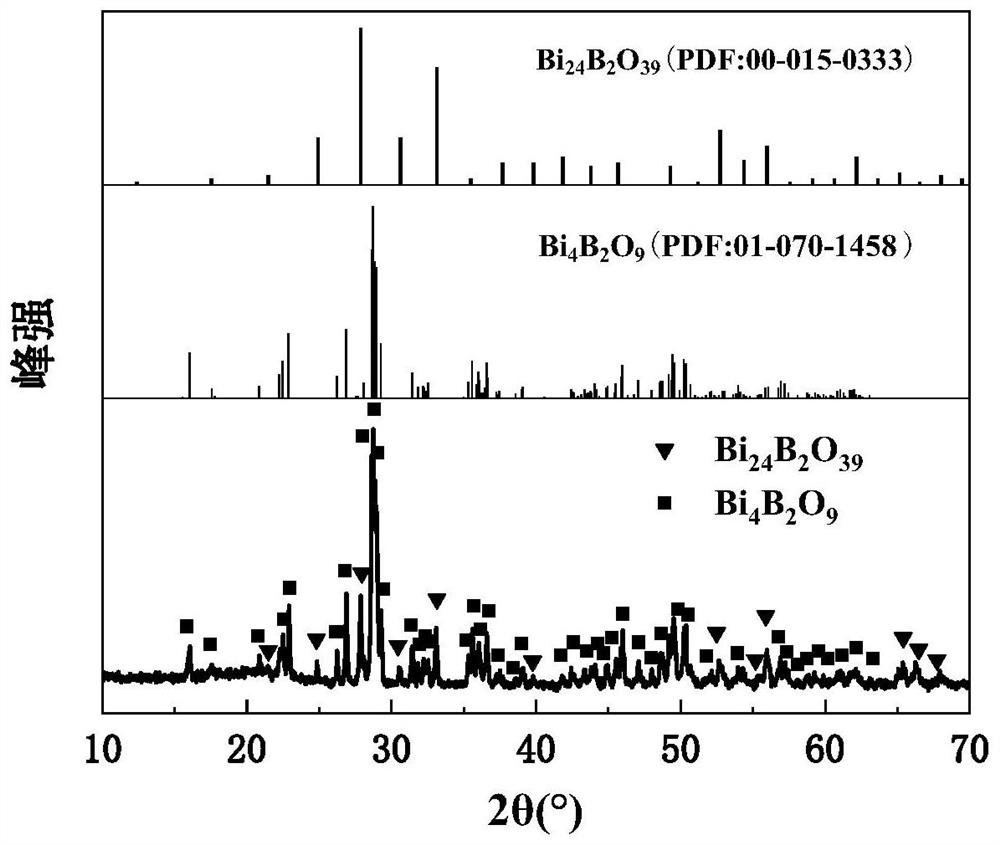

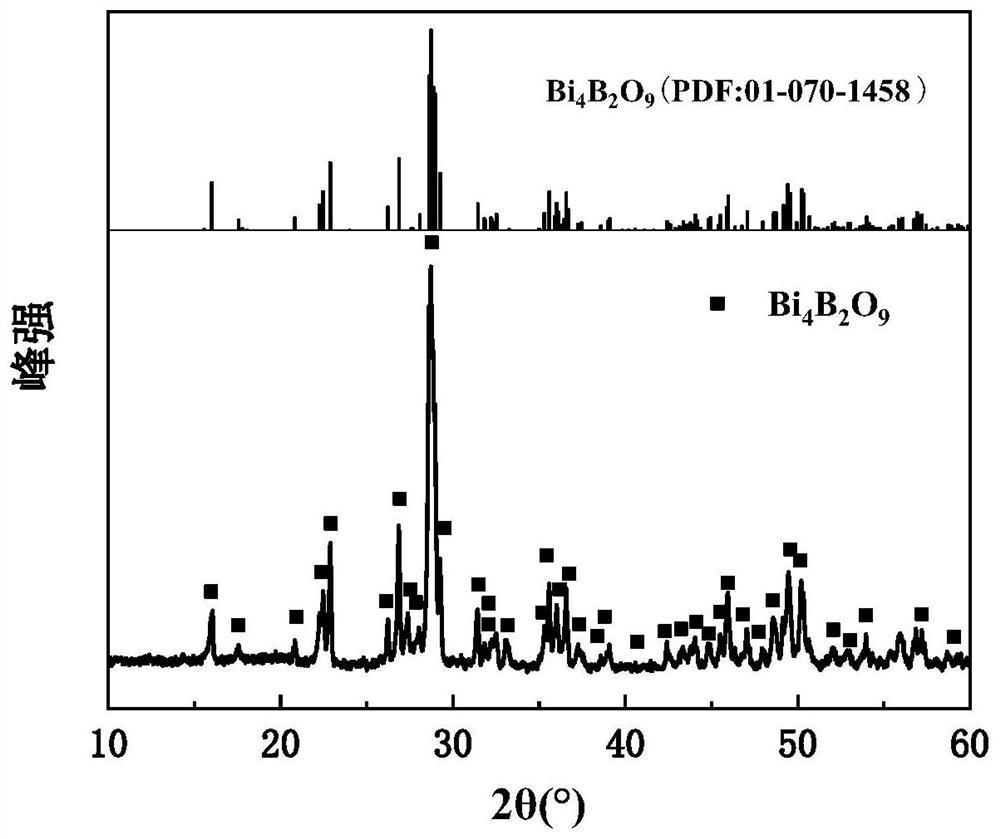

Microwave dielectric material suitable for ultralow-temperature sintering and preparation method thereof

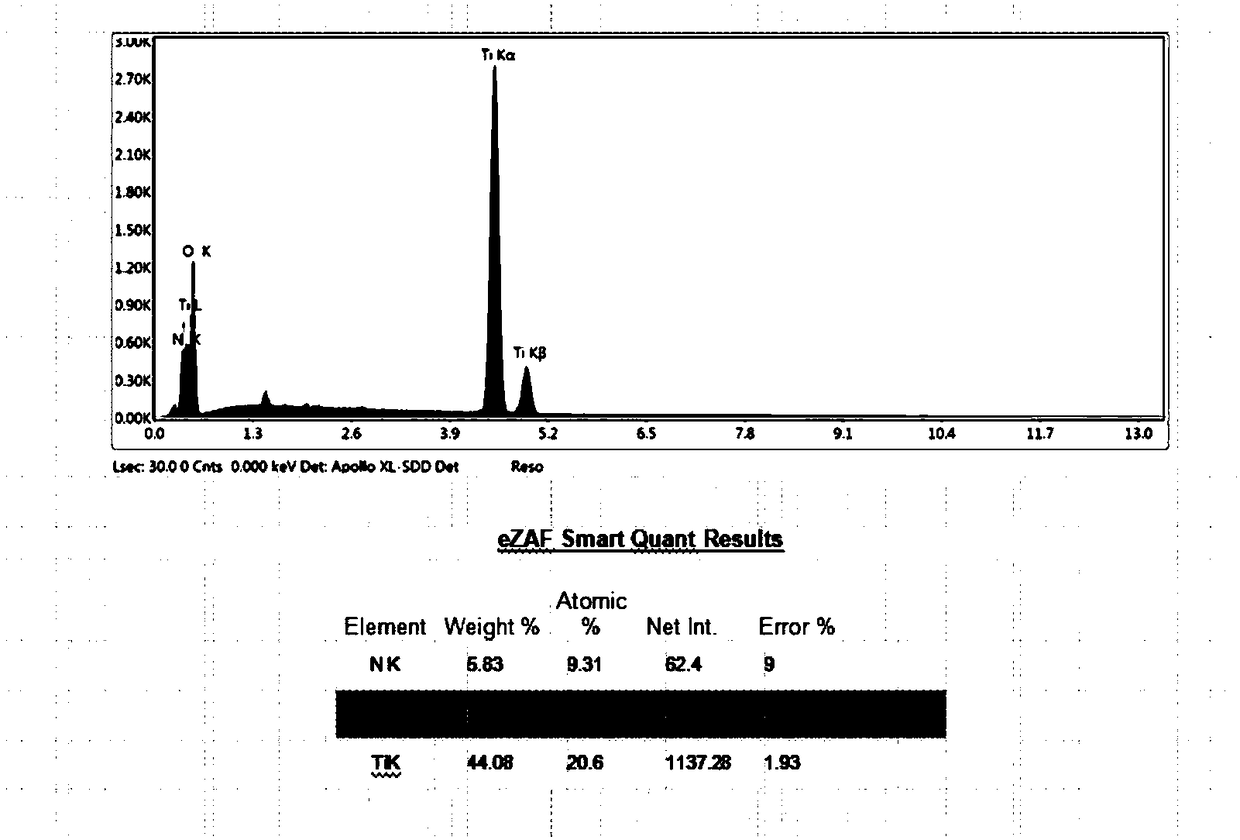

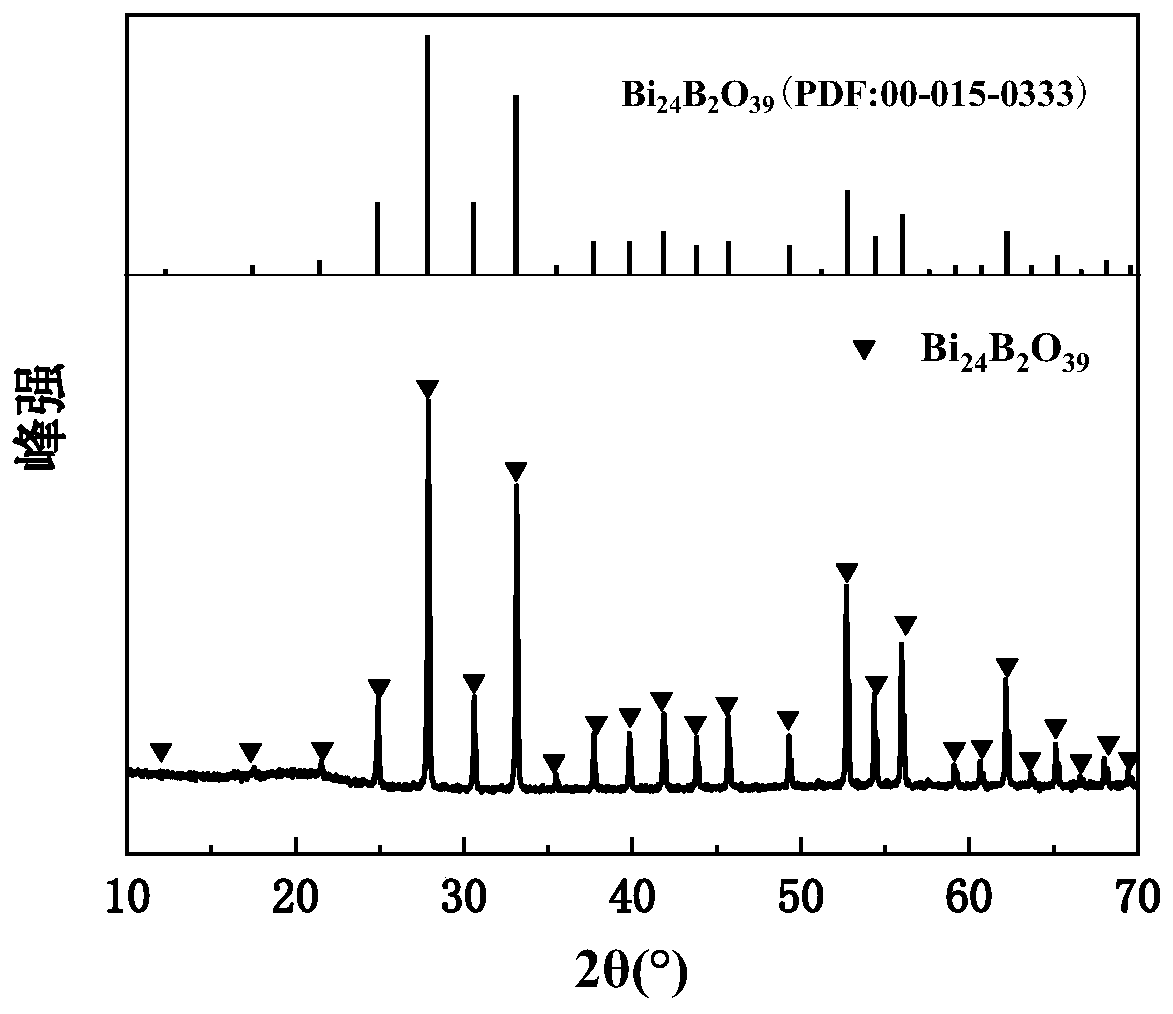

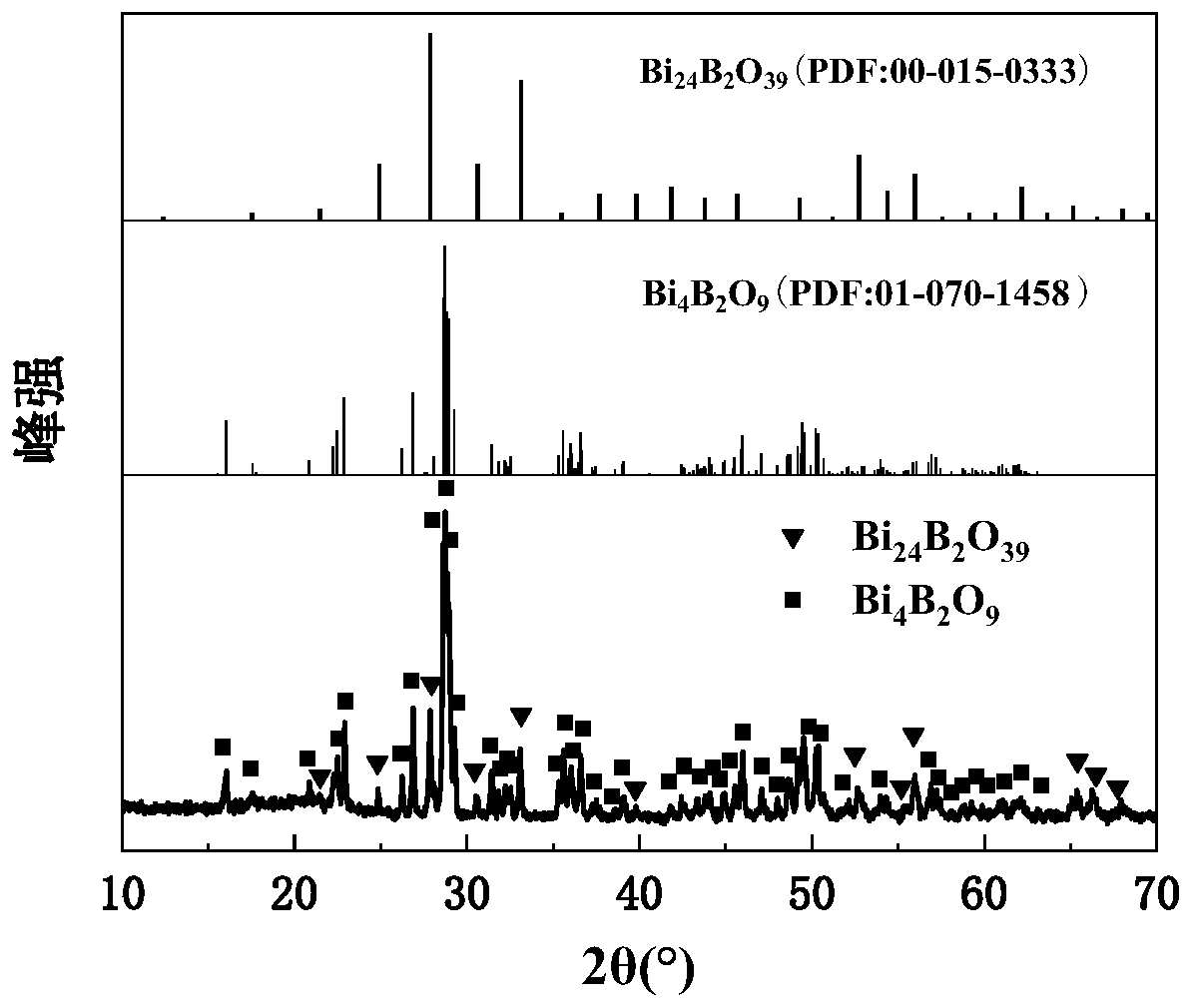

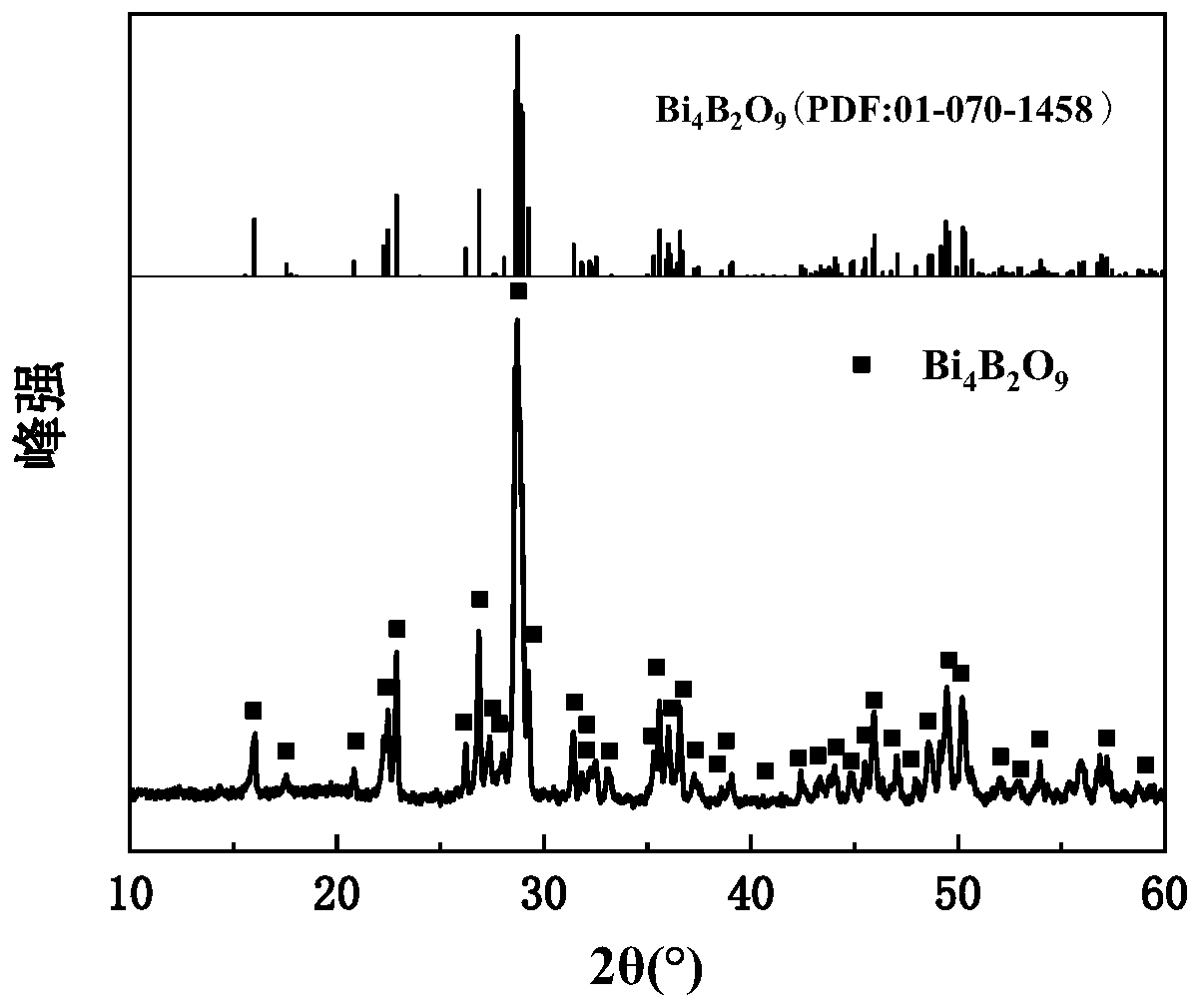

The invention relates to a microwave dielectric material suitable for ultralow-temperature sintering and a preparation method thereof, the microwave dielectric material is a Bi2O3-B2O3 system, the molar ratio of Bi2O3 to B2O3 of the microwave dielectric material is x: y, x is greater than or equal to 1 and less than or equal to 12, and y is greater than or equal to 1 and less than 4. The preparation method comprises the following steps: (1) taking B2O3 and Bi2O3 as raw materials, mixing the B2O3 and the Bi2O3 according to a molar ratio of x: y, putting the powder into a ball milling tank, carrying out ball milling, and then pre-sintering to obtain pre-sintered ceramic powder; and (2) carrying out wet ball milling treatment on the pre-sintered ceramic powder obtained in the step (1), drying, adding an adhesive, granulating, tabletting, discharging the adhesive, and sintering to obtain the microwave dielectric material. The preparation process is simple, the preparation cost is low, thehigh-performance microwave dielectric material suitable for ultralow-temperature sintering is successfully developed by adopting an improved solid-phase reaction method, and the preparation method atultralow temperature provides convenience for integration of the substrate and a microwave circuit.

Owner:WUHAN UNIV OF TECH

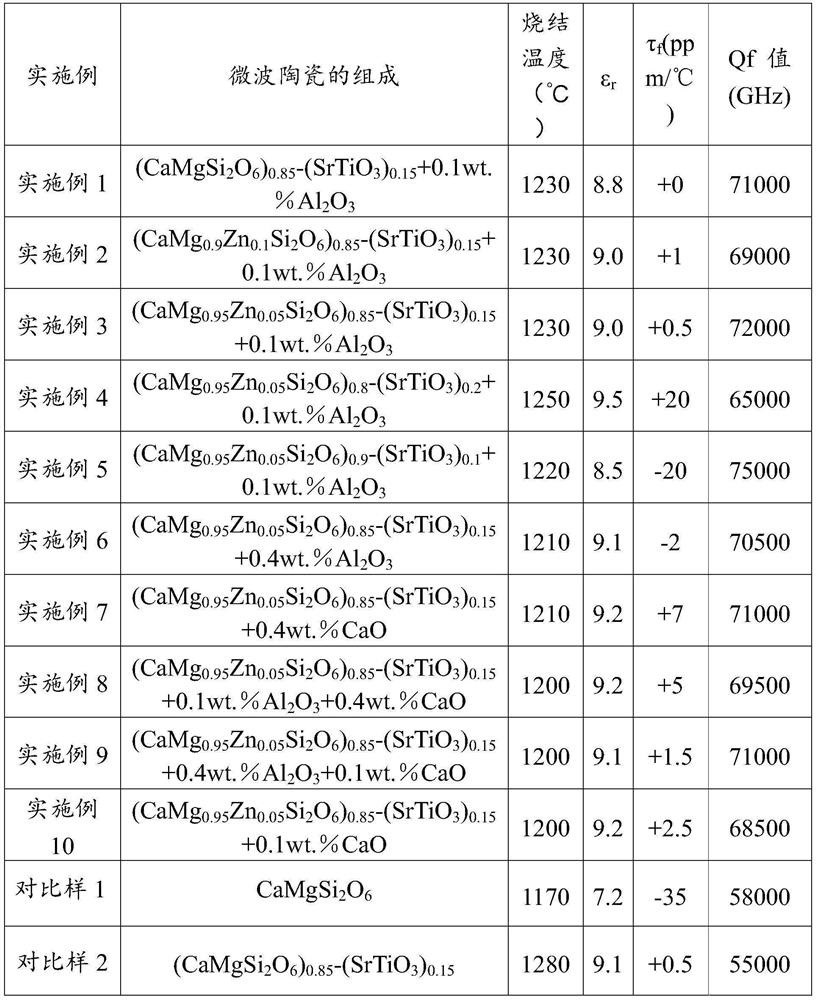

Microwave ceramic and preparation method thereof

ActiveCN112876229AGood microwave dielectric propertiesHigh Qf valueMicrowave dielectric propertiesElectric properties

The invention provides microwave ceramic and a preparation method thereof. The microwave ceramic comprises the following components in parts by weight: 100 parts of silicate titanate complex and 0.1-0.4 part of a metal oxide, the silicate titanate complex is (CaMg < 1-x > Zn < x > Si<2>O<6>) < y >-(SrTiO<3>) < 1-y >; the metal oxide is Al2O3 and / or CaO; wherein 0 < = x < = 0.1, and 0.8 < = y < = 0.9. Compared with the traditional microwave ceramic, the microwave ceramic disclosed by the invention can obtain better microwave dielectric property and higher Qf value, so that the loss is lower, the temperature coefficient of resonance frequency can be adjusted as required, the preparation process is simple, and large-scale mass production can be realized.

Owner:南宁国人射频通信有限公司 +1

Composite multilayer ceramic electronic component

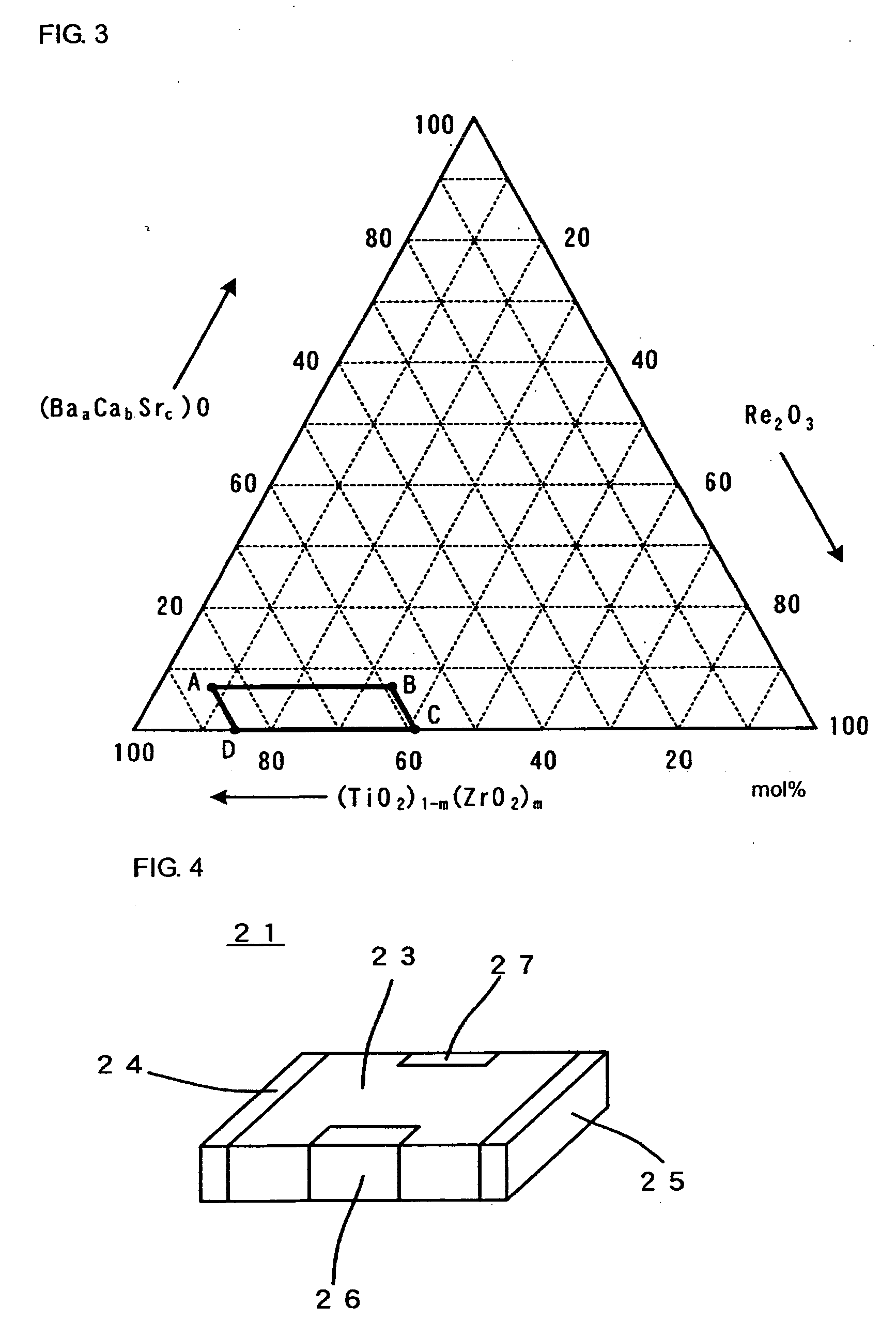

InactiveCN104144898AImprove insulation reliabilityHigh Qf valueFixed capacitor dielectricSemiconductor/solid-state device detailsRare-earth elementAlkaline earth metal

Owner:MURATA MFG CO LTD

A kind of zhts microwave dielectric ceramic and preparation method thereof

ActiveCN109761601BStable structureContinuously adjustable dielectric constantDielectric lossDielectric ceramics

The invention provides a ZHTS microwave dielectric ceramic and a preparation method thereof. The ZHTS microwave dielectric ceramic has a general formula shown in formula (I): Zr x f y Ti 2 sn z o 8+2x+2y+2z ; wherein, 0≤y≤0.03, 0≤z≤0.5, x+y+z=1. Compared with the prior art, the ZHTS microwave dielectric ceramic provided by the present invention uses the compound oxide of the above-mentioned specific general formula as the main material, and by adjusting the content of Zr, Hf, and Sn, the dielectric constant can be around 40, and the temperature coefficient of frequency can be achieved. It is continuously adjustable; moreover, Hf partly replaces Zr to activate the lattice structure to increase the Qf value; the ZHTS microwave dielectric ceramic structure is stable, has a specific dielectric constant and a high Qf value, and the temperature coefficient of the resonant frequency is continuously adjustable. Experimental results show that the dielectric constant of ZHTS microwave dielectric ceramics provided by the present invention is between 38 and 43, Qf > 51500 GHz, and can be as high as 68600 GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, the Qf value of this system is larger , low dielectric loss; at the same time, the resonant frequency temperature coefficient is continuously adjustable between -10.9ppm / ℃~+23ppm / ℃.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Microwave dielectric ceramics with medium dielectric constant and ultra-low dielectric loss, preparation method and application thereof

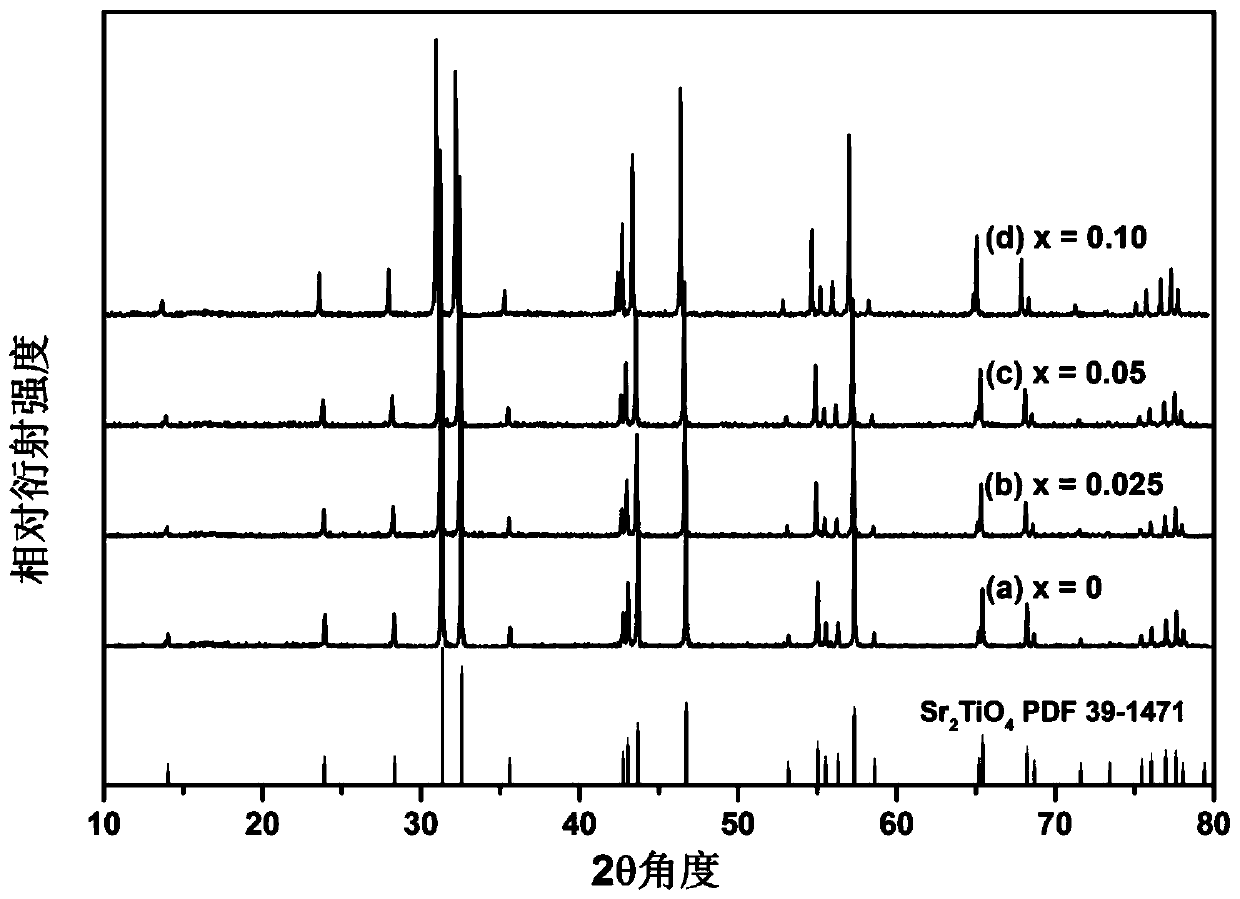

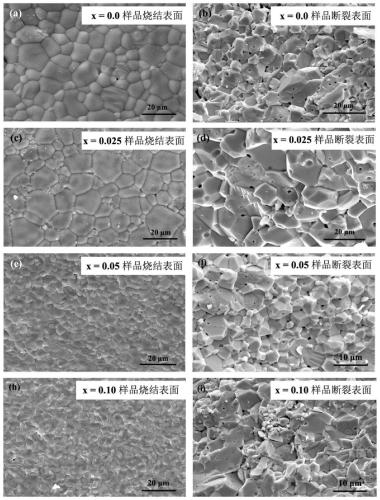

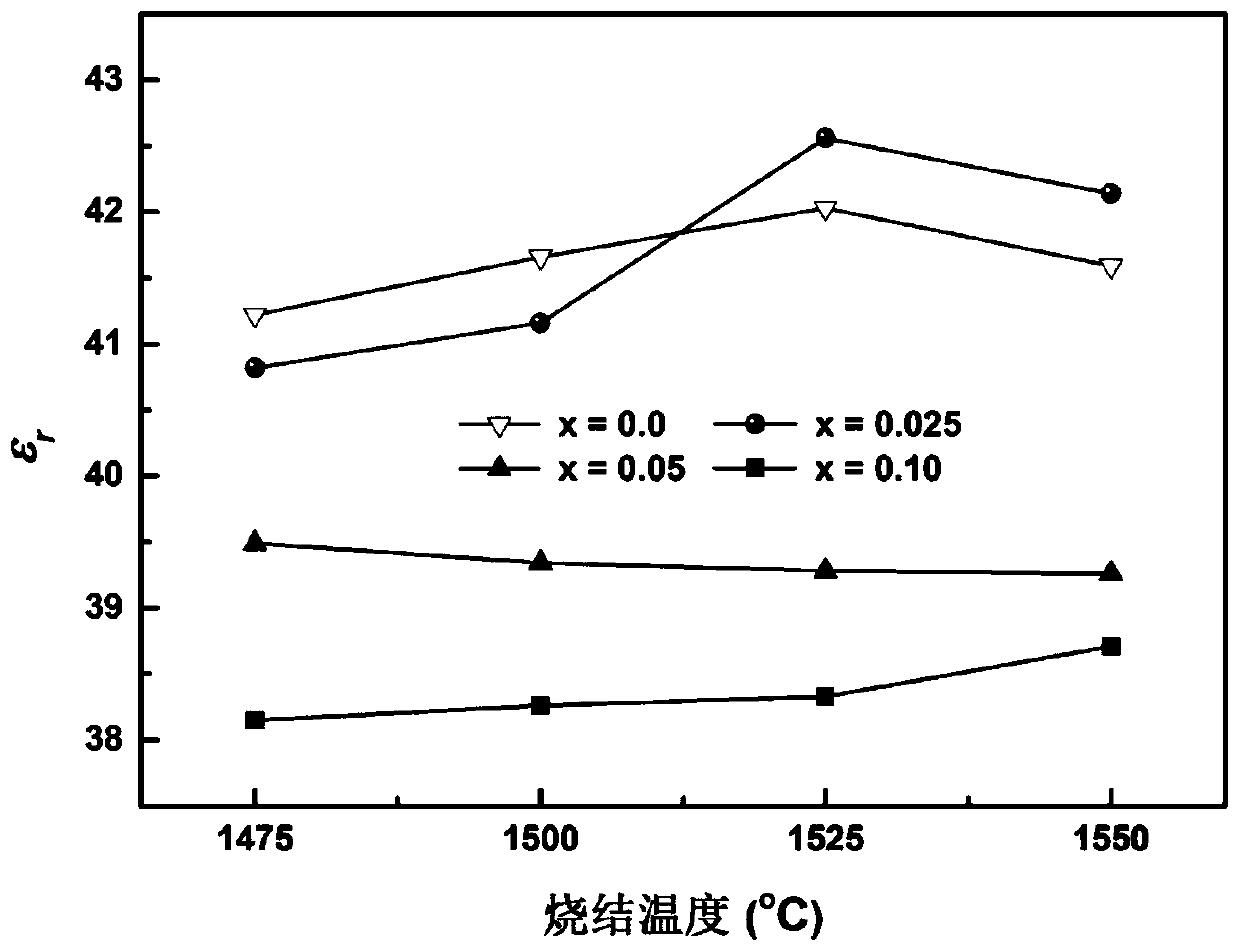

ActiveCN108249917BExcellent microwave dielectric propertiesHigh dielectric constantCeramicsDielectric lossPermittivity

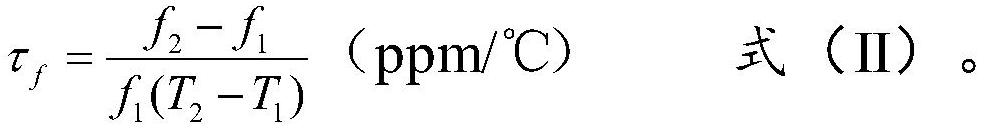

The invention discloses a microwave dielectric ceramic with middle permittivity and ultralow dielectric loss, and a preparation method and application thereof. The microwave dielectric ceramic is characterized in that the chemical expression formula is Sr2(Ti1-xZrx)O4, wherein x is more than 0 and less than 0.1. The preparation method of the microwave dielectric ceramic comprises the following steps: preparing SrCO3, TiO2 and ZrO2 on the basis of the stoichiometric ratio in the chemical expression formula; performing continuous ball milling for 24h; then drying; screening; roasting the prepared powder for 1-3h under the temperature of 1200-1250; performing secondary ball milling; screening; pressing the prepared powder into a blank; and roasting for 1-3h under the temperature of 1475 to 1550 DEG C to obtain a ceramic block. According to the preparation method, the outstanding permittivity and quality factor combination of the prepared Sr2(Ti0.975Zr0.025)O4 ceramic is superior to thoseof other microwave dielectric material systems, so that the microwave dielectric ceramic can be widely applied to elements of wireless communication equipment, such as a microwave resonator and a microwave filter; and the microwave dielectric ceramic is extremely high in application value in the fields of base station communication and satellite communication.

Owner:宁波猎知乐科技咨询有限公司

Microwave ceramic dielectric material and preparation method thereof

The invention provides a microwave ceramic dielectric material and a preparation method thereof. A microwave ceramic dielectric material, comprising a main crystal phase, a modification additive and a sintering flux, the structural formula of the main crystal phase is: xCaTiO3-(1-x)LaAlO3, wherein, 0.68≤x≤0.72; according to the In terms of molar percentages in microwave dielectric ceramics, the modified additives include 0-1.0% Nb2O5, 1-5% Sm2O3, 0.1-0.5% CeO2 and 0-1% Co3O4; The sintering flux includes 0-2% of B2O3, 0.5-4% of SiO2, 0-1% of Bi2O3, 0-0.5% of MnO and 0-0.5% of V2O5 in terms of mole percentage in ceramics. The above-mentioned microwave ceramic dielectric material can be sintered at 1150° C. to 1200° C., which saves cost, and can still maintain a relatively high Qf value of 43000 GHz to 48000 GHz.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

A low-temperature sintered composite microwave dielectric ceramic material and its preparation method

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Low-temperature sintering microwave medium ceramic material and preparation method thereof

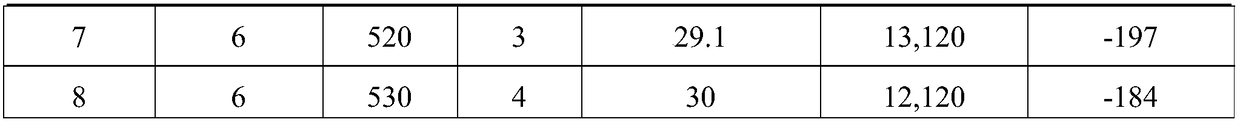

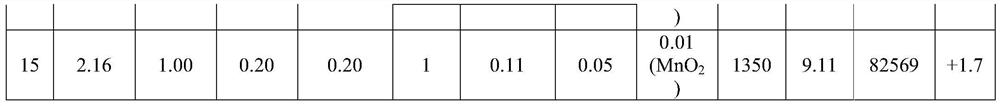

The invention belongs to the field of functional ceramics and in particular relates to a low-temperature sintering microwave medium ceramic material and a preparation method thereof. The material hasa chemical formula of BiW0.5Te3Ol2. The low-temperature sintering microwave medium ceramic material provided by the invention has an ultralow sintering temperature (480-530 DEG C), a low dielectric constant (26-30), a high-quality factor (6,754-13,120GHz), and a negative frequency temperature coefficient (minus 86-197*10<6> / DEG C), can be applied to an MLCC (Multiplayer Ceramic Chip Capacitor) compensation type substrate material, has good commercial values, and can be used as an MLCC compensation substrate material. The invention further provides a preparation method. The material is simple in process, free of pollution in the process, applicable to industrial production and wide in application prospect.

Owner:ZIBO YUHAI ELECTRONICS CERAMIC

Ceramic material and preparation method and application thereof

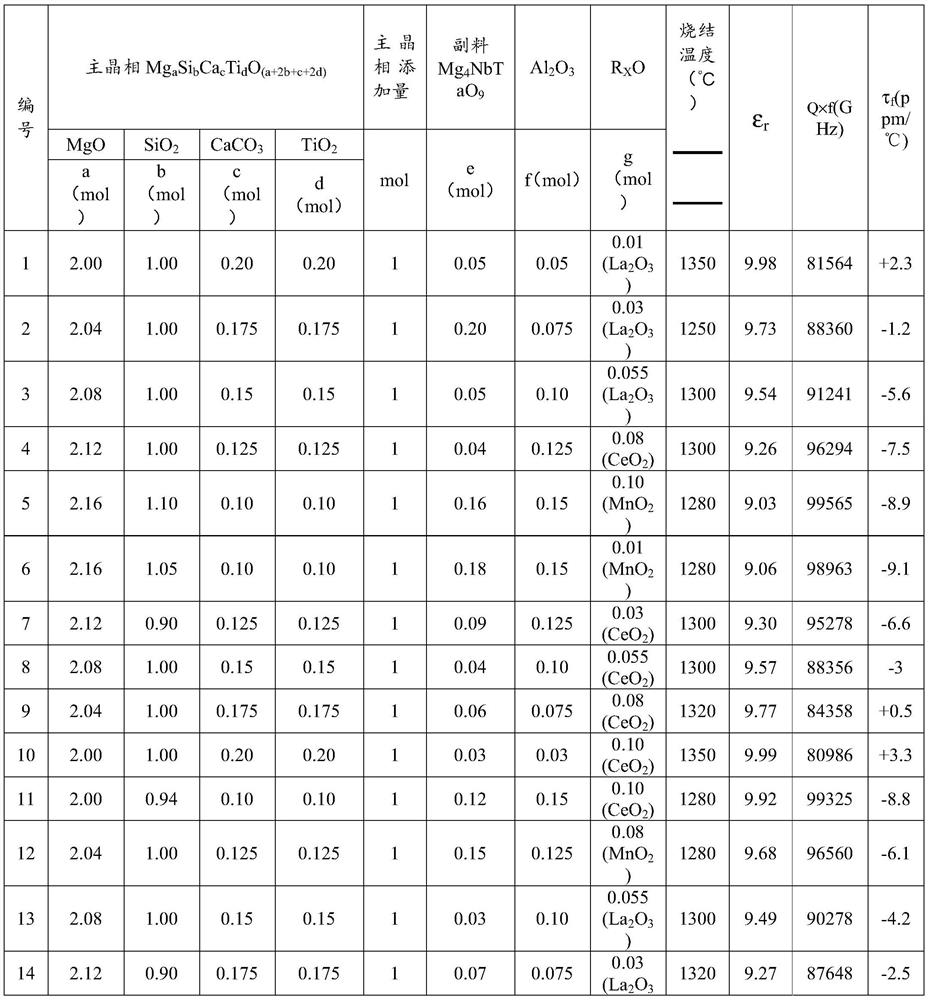

The invention discloses a ceramic material. According to the invention, MgaSibCacTidO(a+2b+c+2d) is used as a basic formula, and Mg4NbTaO9-Al2O3 and the like are compositely doped, so that the obtained low-dielectric-constant microwave ceramic material has the following properties: the relative dielectric constant is 8-10, the Qf is 80000-100000, the temperature coefficient of resonance frequencyis 0+ / -10ppm / DEG C, a wide sintering process window and good machinability are achieved. Meanwhile, the invention also discloses a preparation method of the ceramic material.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

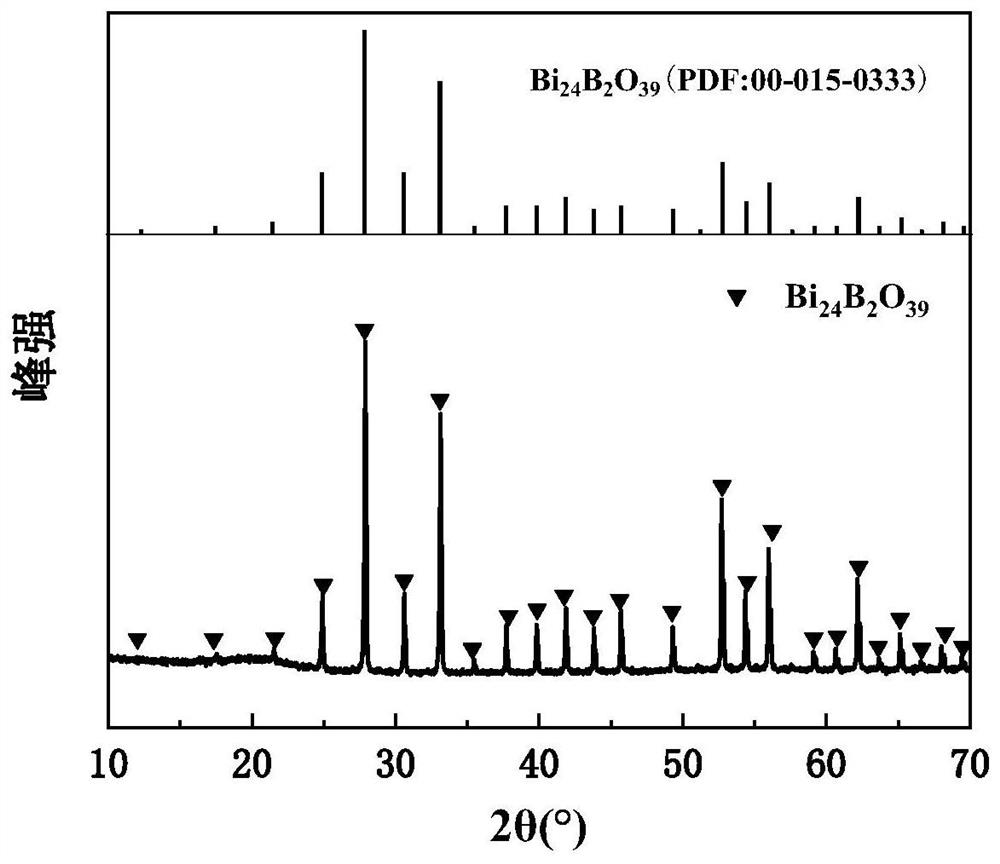

Microwave dielectric material suitable for ultra-low temperature sintering and preparation method thereof

The invention relates to a microwave dielectric material suitable for ultra-low temperature sintering and a preparation method thereof. The microwave dielectric material is Bi 2 o 3 -B 2 o 3 system, the Bi of the microwave dielectric material 2 o 3 and B 2 o 3 The molar ratio between is x:y, wherein: 1≤x≤12, 1≤y<4. Its preparation method comprises the steps: (1) with B 2 o 3 with Bi 2 o 3 as raw material, according to Bi 2 o 3 and B 2 o 3 The molar ratio between is x: y for batching, the powder is put into a ball mill jar, ball milled, and then pre-fired to obtain a pre-fired ceramic powder; (2) the pre-fired ceramic powder obtained in step (1) , performing wet ball milling again, adding binder to granulate after drying, debinding and sintering after tableting to obtain the microwave dielectric material. The invention has a simple preparation process and low preparation cost, and successfully develops a high-performance microwave dielectric material suitable for ultra-low temperature sintering by adopting an improved solid-state reaction method, and the preparation method at ultra-low temperature provides the integration of the substrate and the microwave circuit. convenient.

Owner:WUHAN UNIV OF TECH

Preparation method of single phase nano-CaTiO3 powder using collosol-gel low temperature synthesis

Owner:ZHEJIANG UNIV

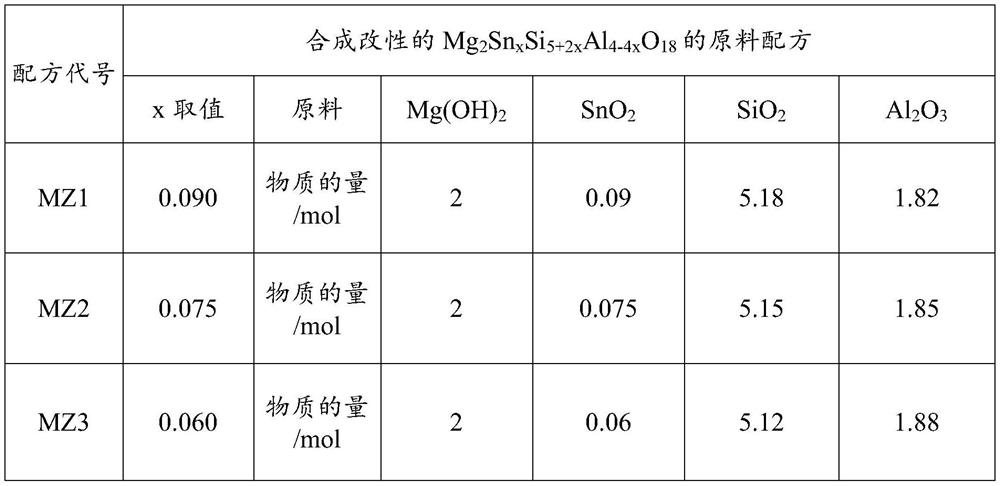

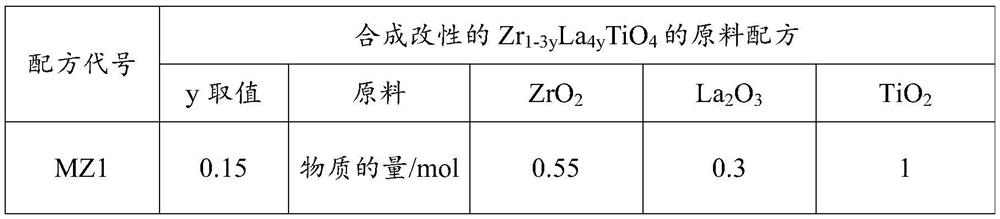

A kind of zmat series microwave ceramic material and its preparation method and application

The invention provides a ZMAT series microwave ceramic material and a preparation method thereof, which relate to the field of information functional materials. The ceramic material includes a main crystal phase and modified additives, and the main crystal phase includes a main material and an auxiliary material. The general chemical formula of the main crystal phase is Mg 2 sn x Si 5+2x Al 4‑ 4x o 18 ·aZr 1‑3y La 4y TiO 4 , where 0.05 <x<0.1,0.1<y<0.3,0.01<a<0.05。其中mg2Sn x Si 5+2x al 4‑4x o 18 The general chemical formula of the main material, Zr 1‑3y La 4y TiO 4 The general chemical formula of the auxiliary material. The mass fraction of the main crystal phase in the ceramic material is 98-99.5 wt%, and the mass fraction of the modification additive in the ceramic material is 0.5-2 wt%. Modified additives are selected from SrCO 3 、BaCO 3 、TiO 2 , Nb 2 o 5 , Sb 2 o 3 and MnCO 3 One or more mixtures of these. Ceramic material of the present invention is a kind of lead-free environment-friendly material, and it adopts solid phase method to synthesize main material Mg 2 sn x Si 5+2x al 4‑4x o 18 and auxiliary material Zr 1‑3y La 4y TiO 4 , to prepare a uniform powder ceramic material. After the powder is sintered, the room temperature dielectric constant is between 5 and 8, the Qf value is ≥60000GHz, and the temperature coefficient τf (-40~85℃): ±10ppm / ℃ microwave ceramics The material meets the relevant microwave performance requirements of microwave devices.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

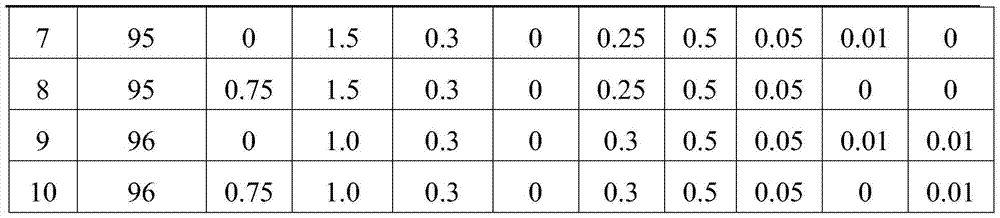

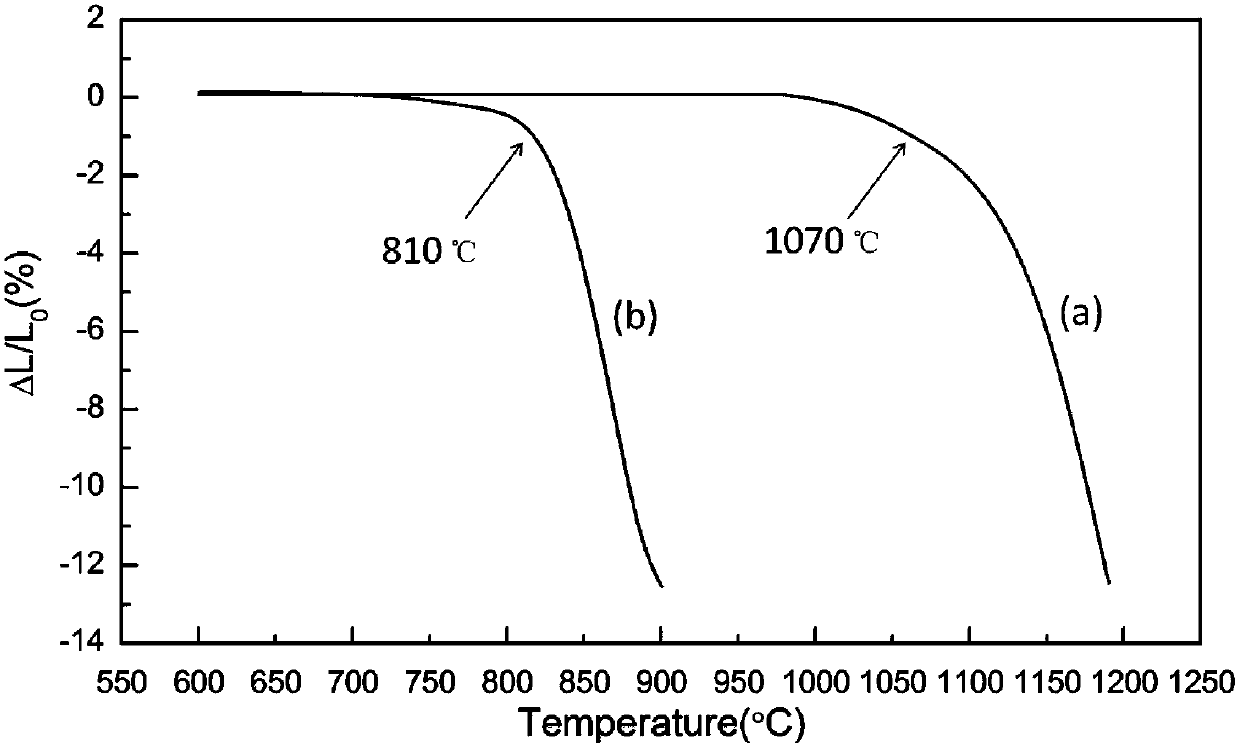

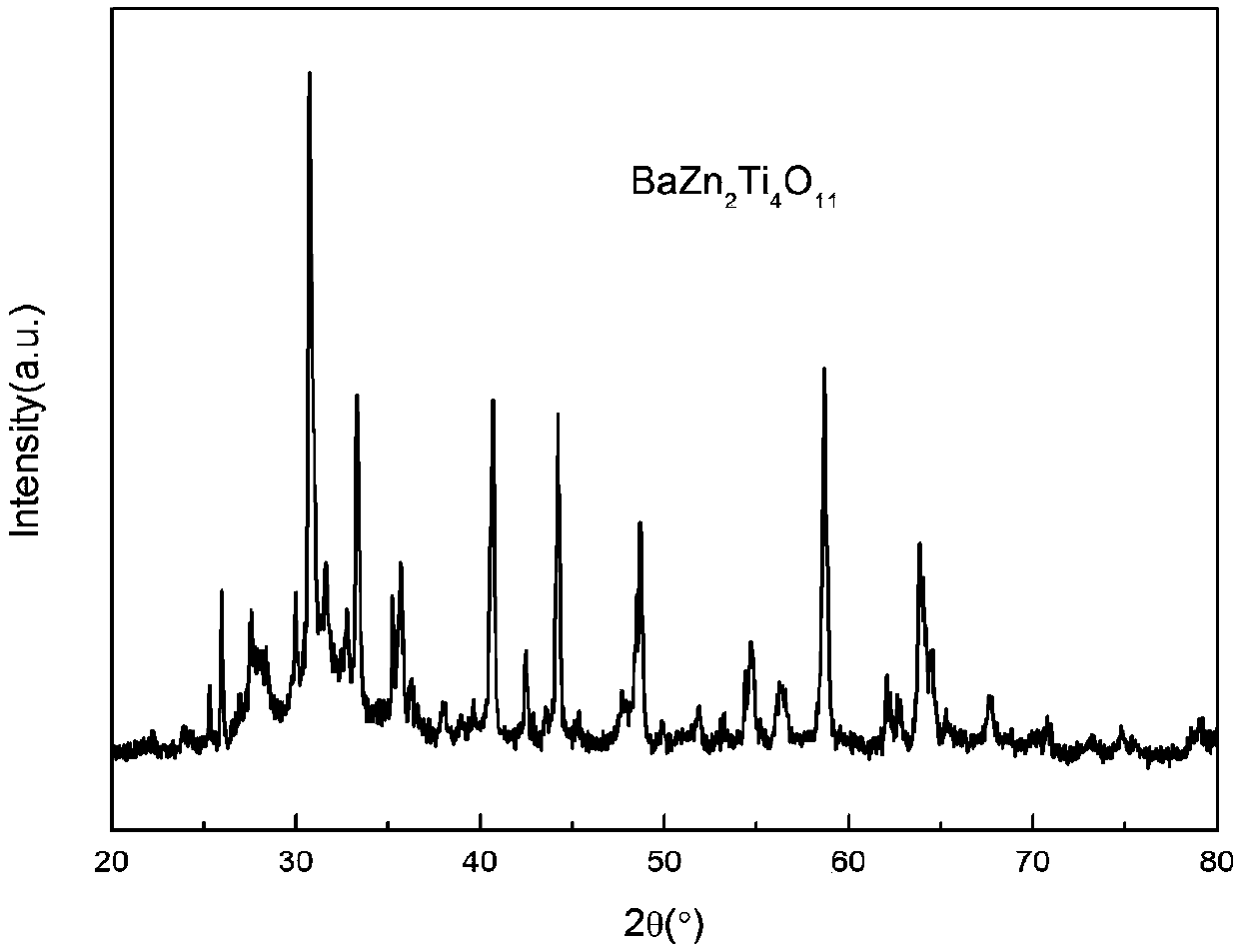

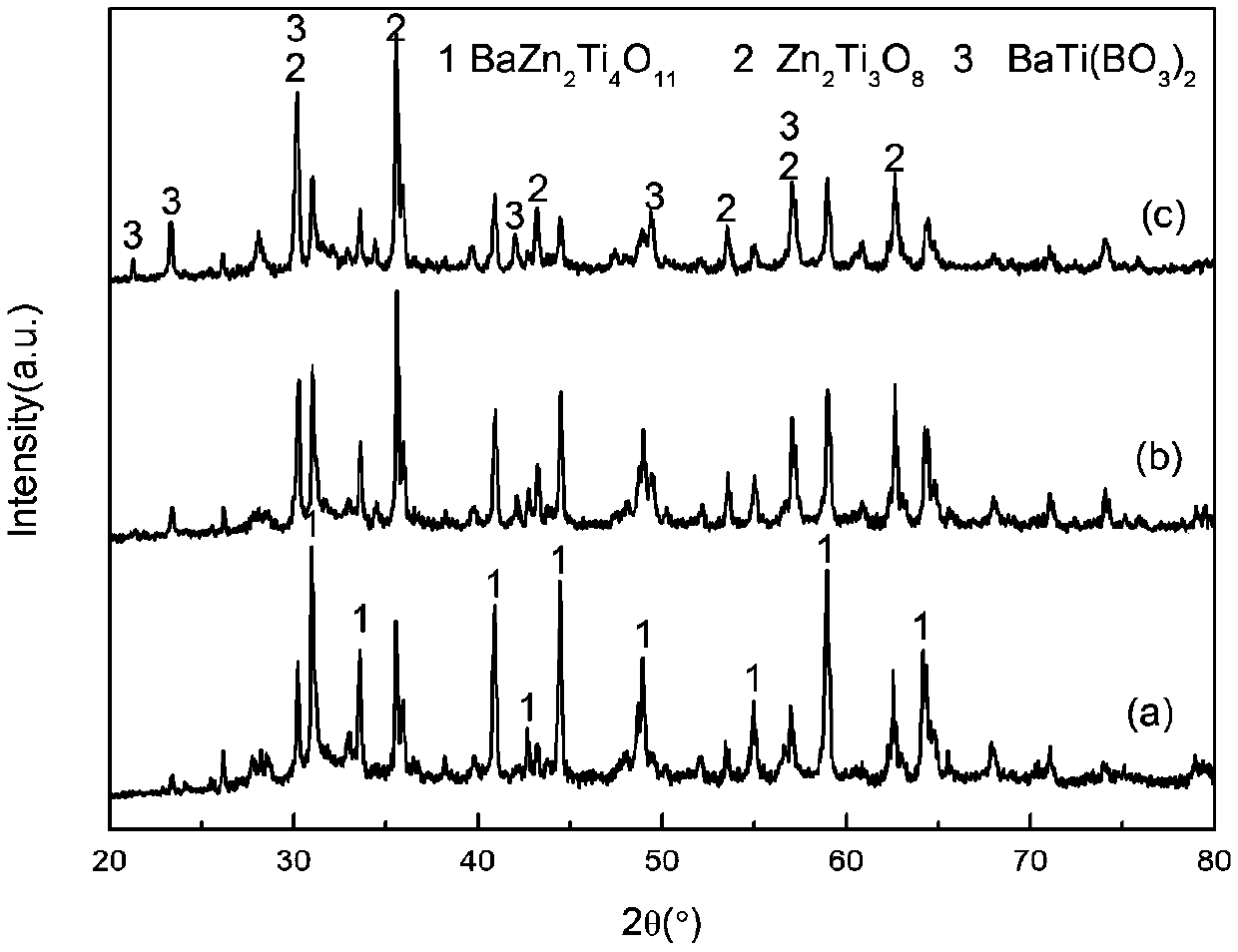

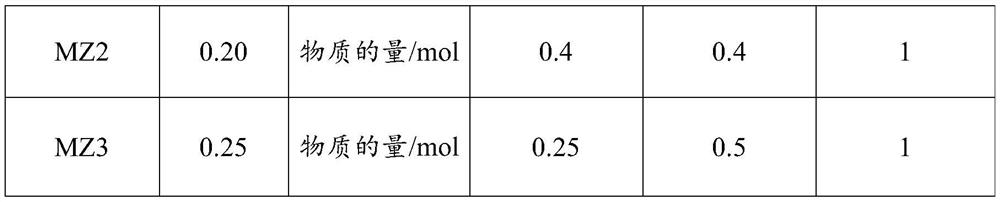

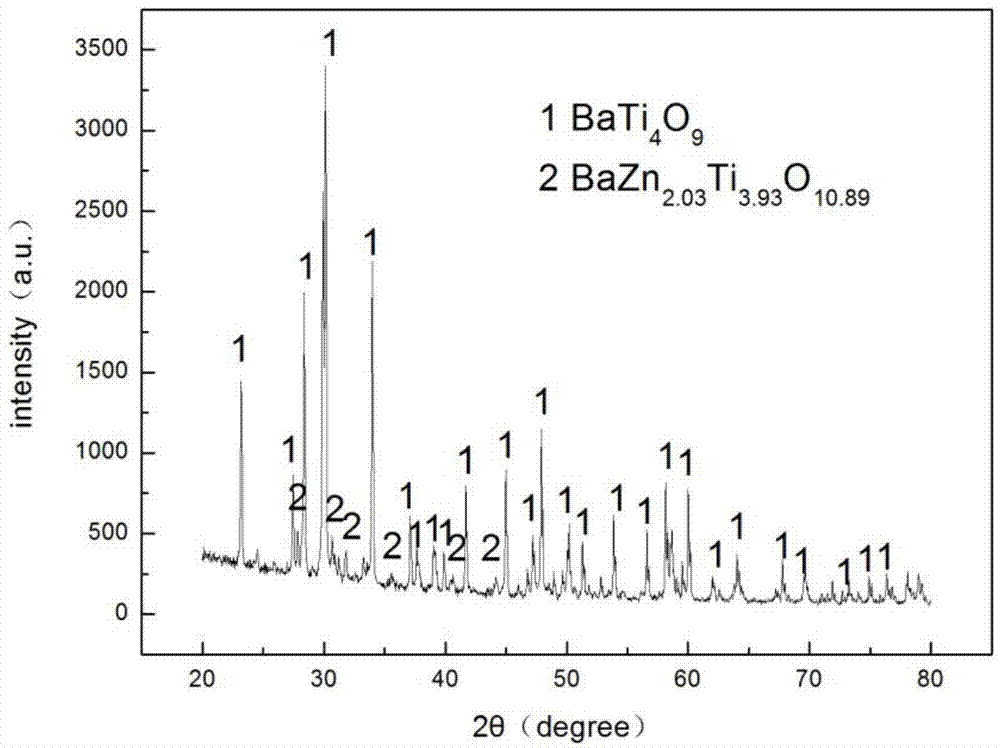

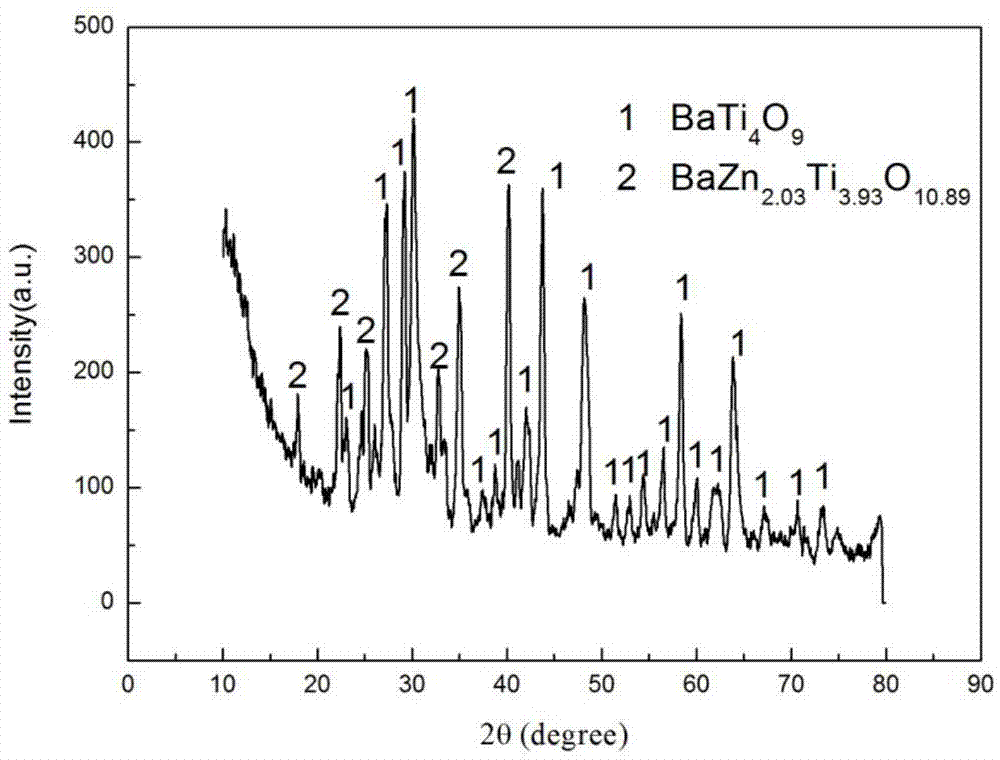

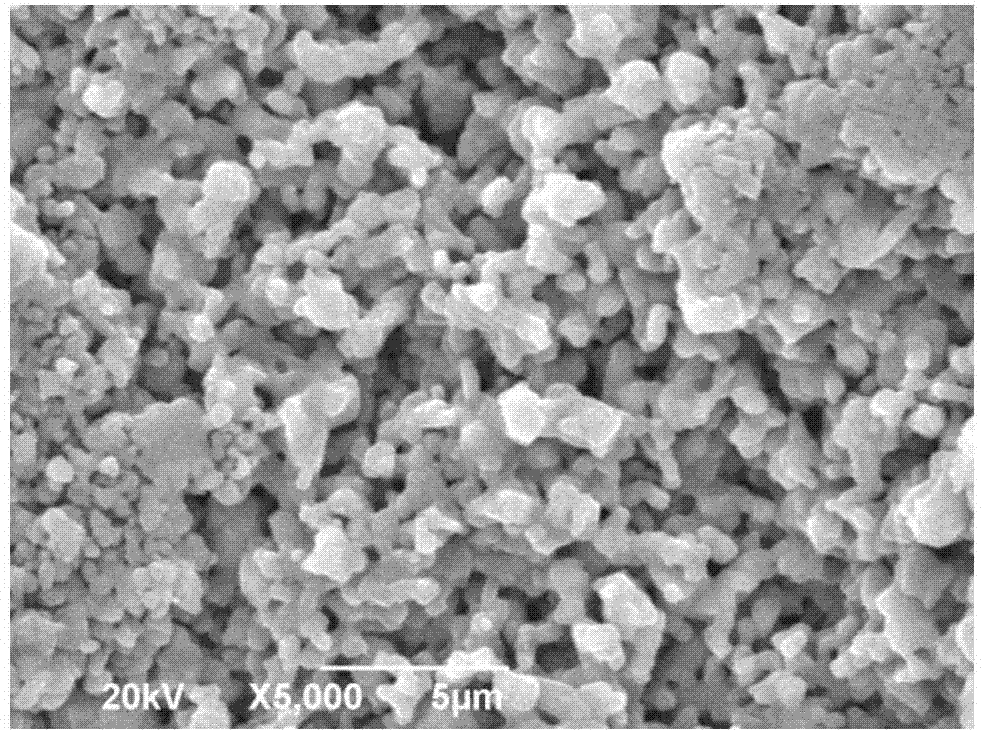

Zinc barium titanate system ceramic low temperature sintering material and preparation method thereof

The present invention discloses a zinc barium titanate system microwave dielectric ceramic material and a preparation method thereof, and relates to an electronic material technology. The chemical composition of the material is (1-x)BaTi4O9-xBaZn2Ti4O11-yM, wherein x is more than or equal to 0.15 and is less than or equal to 0.25 (molar ratio ), M is a firing reduction agent, y is more than or equal to 0.0531 and is less than or equal to 0.1005 (weight ratio), components of the firing reduction agent comprise, by weight, 44.25-53.47% of Li2CO3, 4.82-9.19% of SiO2, 33.24-37.71% of B2O3, 0.88-0.94% of ZnO, 3.75-9.83% of Al2O3, and 0.3-1% of additives such as MnCO3 and CuO, and a weight ratio of the MnCO3 to the CuO is 3:4-3:6. The present invention further provides the concrete method for producing the material. The prepared microwave dielectric ceramic has characteristics of low sintering temperature (less than or equal to 900 DEG C) and excellent dielectric property, and can be used for manufacturing of low temperature co-firing ceramic systems, multilayer dielectric resonators, microwave antennas, filters and other microwave devices, wherein the excellent dielectric property comprises that: a dielectric constant of 20-30 is adjustable, a quality factor is high, and a resonant frequency temperature coefficient is small.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of metal compound and microwave dielectric ceramic and preparation method thereof

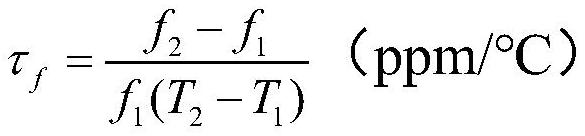

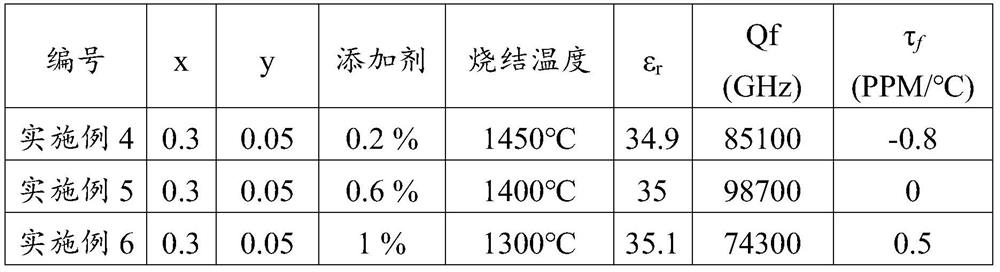

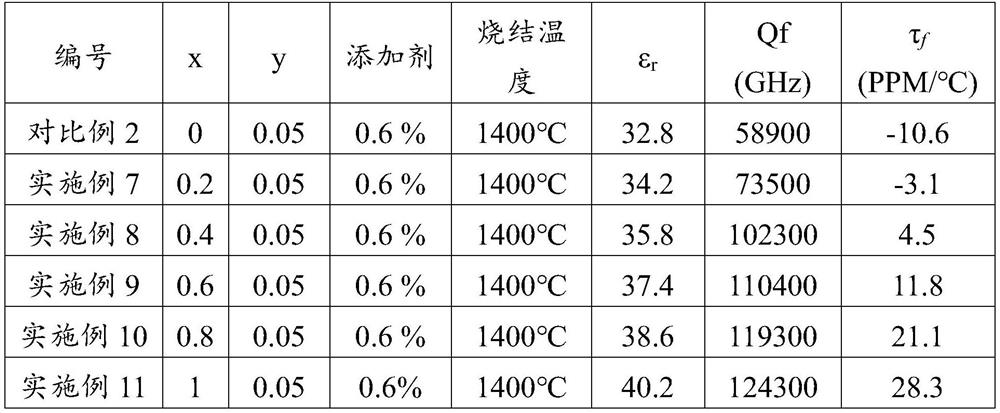

This application belongs to the technical field of microwave dielectric ceramics. The application provides a metal compound, a microwave dielectric ceramic and a preparation method thereof, and the microwave dielectric ceramic of the application includes a metal compound having the following general structure: (1-y)Ba 3 Zn x co 1‑x Nb 2 o 9 ‑yBa 8 CoNb 6 o 24 , where, x=0~1, y=0~0.1, by introducing Ba 8 CoNb 6 o 24 The new phase of non-stoichiometric ratio can be sintered in the liquid phase, which inhibits the volatilization of components, so that the prepared microwave dielectric ceramic has a stable B-site 1:2 long-range ordered structure and improves the Qf value. The microwave dielectric ceramic dielectric constant of this application is between 32.8 and 40.2, Q×f>56500GHz, up to 124300GHz, has the advantages of high Qf value and low dielectric loss, and the temperature coefficient of resonance frequency is -10.6PPM / ℃~ Continuously adjustable between +28.3PPM / ℃. The preparation method of the present application is simple, the manufacturing cost is low, meets the requirements of environmental protection, is non-toxic, and has no pollution to the environment; the sintering temperature is low, and the performance of the product can be guaranteed without long-term annealing, and the performance of the prepared product can be avoided due to volatilization of components. deterioration.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

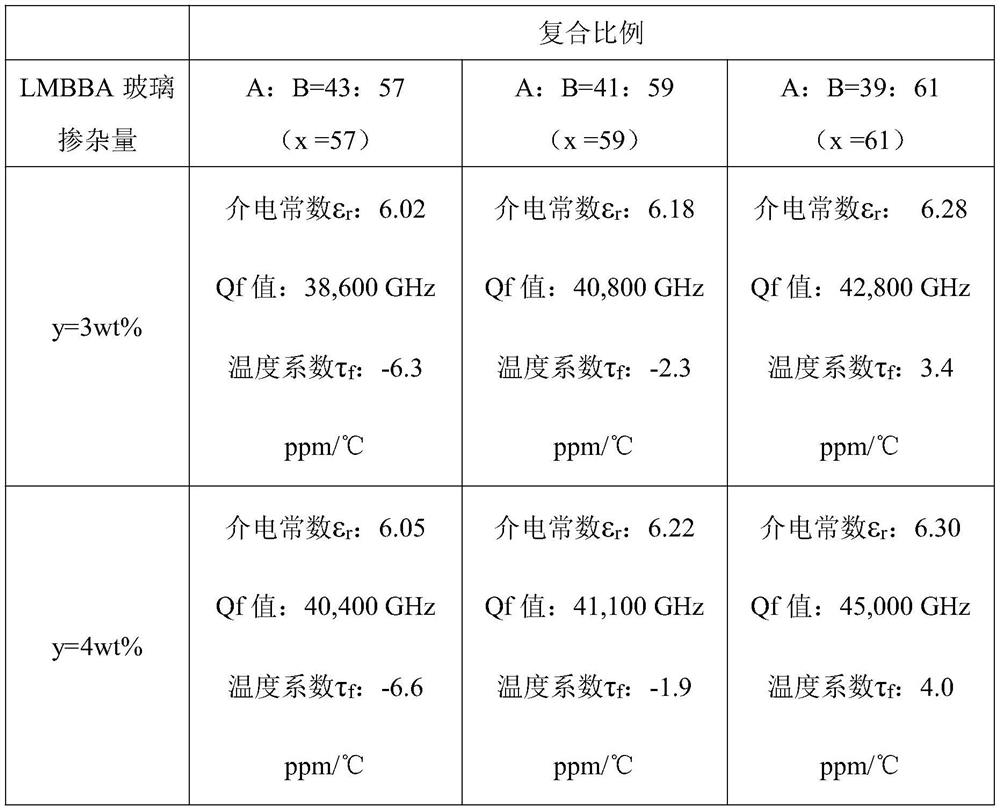

A kind of near-zero temperature coefficient low dielectric LTCC material and preparation method thereof

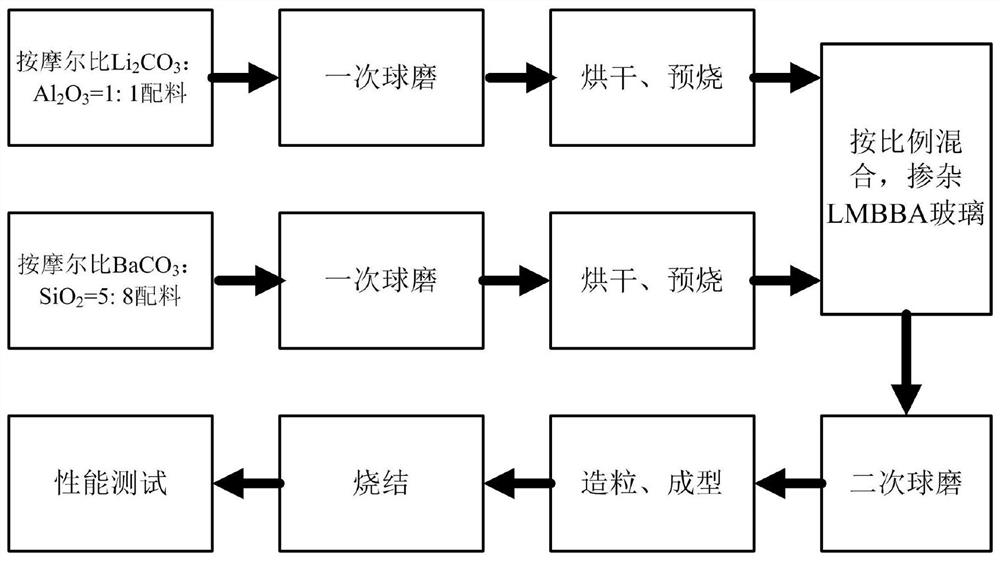

The invention provides a near-zero temperature coefficient low dielectric LTCC material and a preparation method thereof, wherein the low dielectric LTCC material contains γ-LiAlO 2 and Ba 5 Si 8 o 21 A two-phase mixed ceramic material is sintered by adding 2 to 4 wt% of the two-phase mixed ceramic material with LMBBA glass as a flux, and the general chemical formula is (1‑x)LiAlO 2 –xBa 5 Si 8 o 21 -yLMBBA, x=57~61wt%, y=2~4wt%; Sintering temperature is 900 ℃; The composition of described LMBBA glass is Li 2 CO 3 ‑MgO‑Bi 2 o 3 -B 2 o 3 ‑Al 2 o 3 . Has a near-zero resonant frequency temperature coefficient (τ f =-6.6~4ppm / °C) and high Qf value characteristics, can be sintered at 900°C to achieve densification, and has a low dielectric constant, which has good application prospects in LTCC integrated substrates and devices.

Owner:YANCHUANG PHOTOELECTRIC TECH GANZHOU

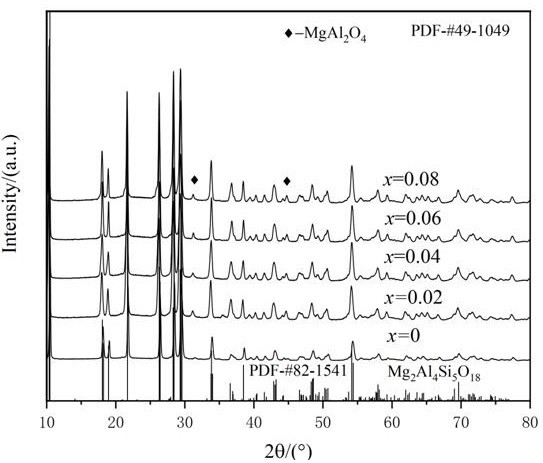

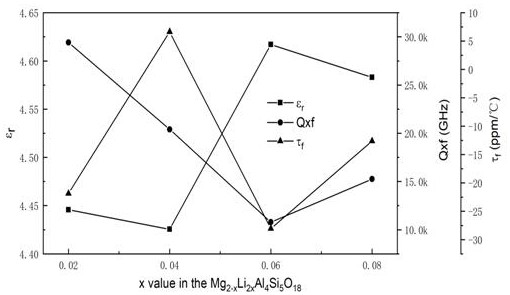

Cordierite microwave dielectric material with ultralow dielectric constant and near-zero temperature coefficient of resonance frequency and preparation method of cordierite microwave dielectric material

ActiveCN114835480AImproved resonant frequency temperature coefficientHigh Qf valueChemical industryCordieriteSolid state reaction method

The invention discloses a cordierite microwave dielectric material with an ultralow dielectric constant and a near-zero temperature coefficient of resonance frequency, and belongs to the technical field of microwave electronic ceramic materials, the chemical composition of the material is Mg2-xLi2xAl4Si5O18, x is greater than 0 and less than or equal to 0.08, and the preparation method comprises the following steps: weighing MgO, Al2O3, Li2CO3 and SiO2 raw materials according to the stoichiometric ratio of the chemical formula; and then carrying out a series of processes such as ball milling, drying, calcining, secondary ball milling, drying, granulation forming, rubber discharging and sintering, and adopting a solid-phase reaction method. According to the difference of x, the material contains two phases, namely Mg2Al4Si5O18 and MgAl2O4, the material has an adjustable dielectric constant between 4.22 and 4.76 and a near-zero resonance temperature coefficient (-7.0 ppm / DEG C), so that the material has a wide application prospect in the fields of 5G communication, Internet of Things, millimeter wave communication and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Low temperature sintered (Ca, Mg) SiO3 microwave dielectric ceramic and its prepn process

InactiveCN1273408CMeet the design requirementsLower sintering temperatureCeramicsDielectricCommunications system

The present invention relates to low temperature sintered microwave dielectric ceramic for dielectric antenna, filter and other RF elements and devices in mobile communication system and its preparation process. The low temperature sintered microwave dielectric ceramic has (Ca, Mg)SiO3 as main component, CaTiO3 for regulating the temperature coefficient of frequency, and Li2CO3 and V2O5 as sintering assistant. The present invention features Li2CO3 and V2O5 lowering the sintering temperature of the ceramic system to below 900 deg.c, special technological process improving the characteristic of powder and slurry matching with silver electrode, the dielectric constant of 8-10, quality factor higher than 25000 GHz, the temperature coefficient of resonant frequency approaching zero, low cost, etc.

Owner:ZHEJIANG UNIV +1

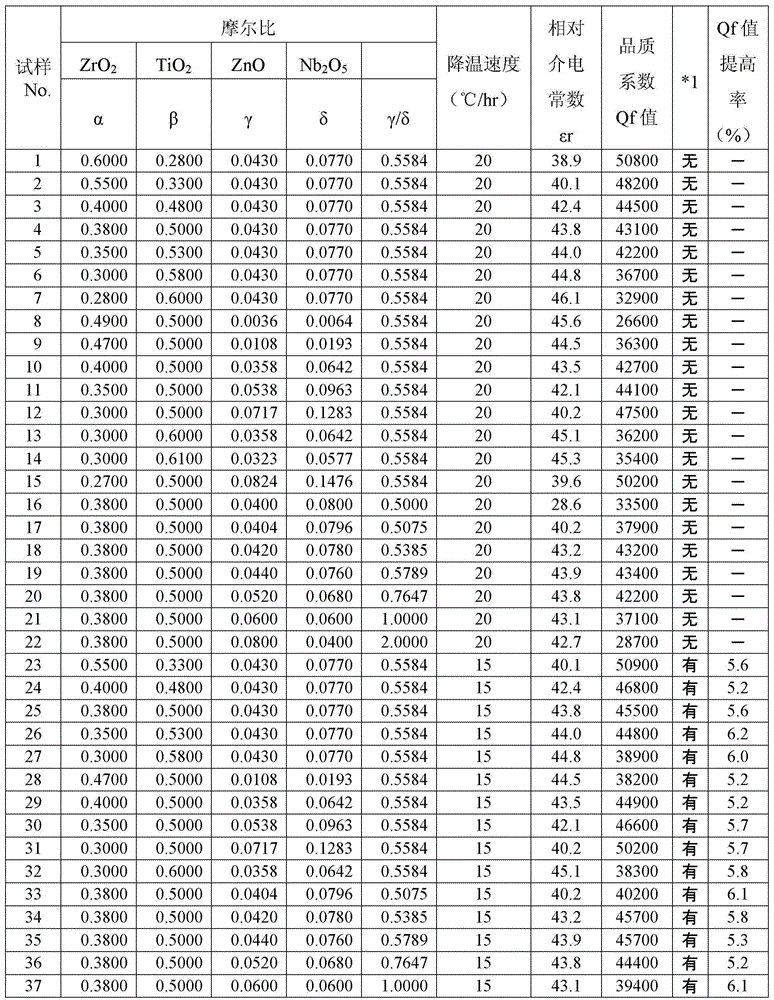

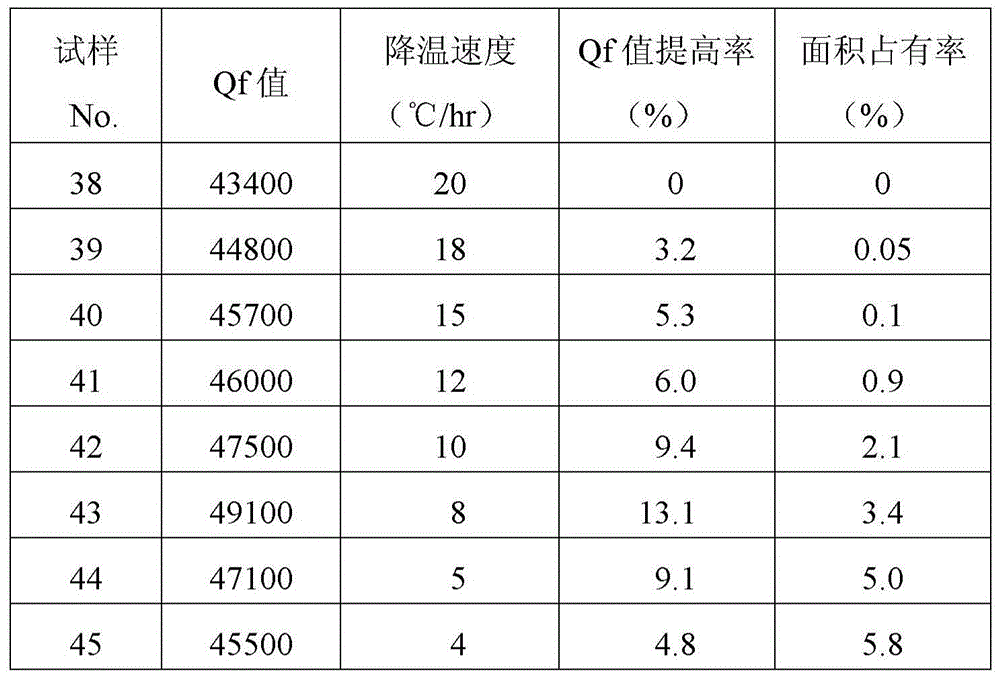

Dielectric ceramic and dielectric filter provided with same

InactiveCN103492346BHigh Qf valueImprove performanceImpedence networksZirconium compoundsRare-earth elementPolymer science

[Problem] To provide, using a material which does not contain any rare earth element, a dielectric ceramic which exhibits a relative permittivity (er) of 40 to 46 and an enhanced Qf value; and to provide a dielectric filter provided with the same. [Solution] A dielectric ceramic comprising a sintered body such that when the composition is represented by the compositional formula aZrO2·ßTiO2· ?ZnO·dNb2O5, the molar ratios a, ß, ? and d satisfy 0.3000=a=0.5500, 0.3300=ß=0.6000, 0.0108=?=0.0717, 0.0193 =d=0.1283, a+ß+?+d=1, and 0.5<? / d=1, wherein areas having Zn concentrations of 5% or more occupy at least some of the surface of the sintered body.

Owner:KYOCERA CORP

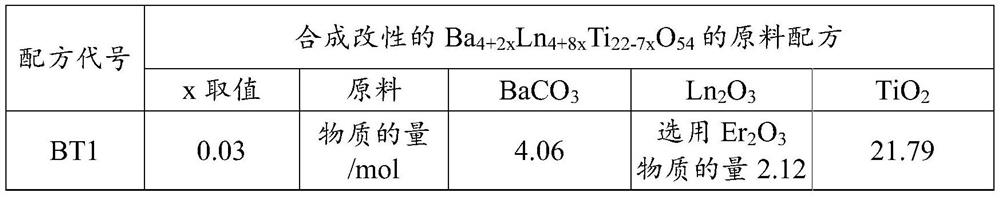

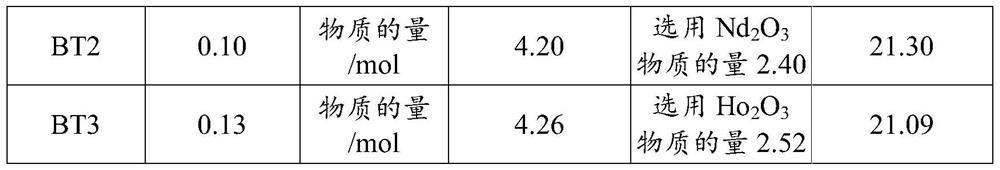

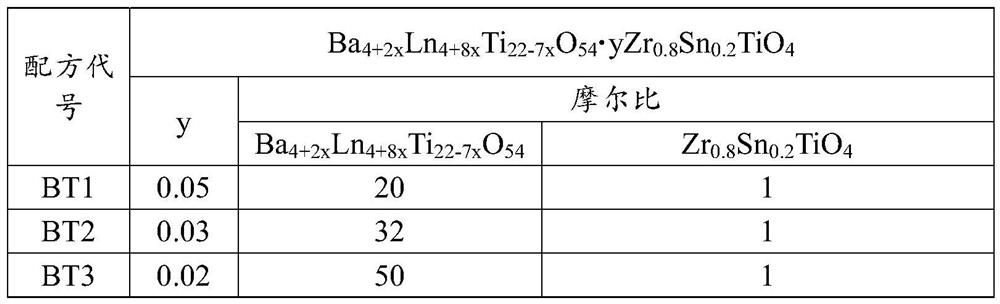

Ceramic material with high dielectric constant and high Qf value as well as preparation method and application thereof

The invention provides a ceramic material with a high dielectric constant and a high Qf value and a preparation method thereof, and relates to the field of information function materials. The ceramicmaterial comprises a main crystalline phase and a modified additive. The main crystalline phase includes a main material and an auxiliary material. The general chemical formula of the main crystal phase is Ba4+2xLn4+8xTi22-7xO54. yZr0.8Sn0.2TiO4, wherein x is larger than 0 and smaller than 0.13, and y is larger than 0 and smaller than 0.05. Ba4+2xLn4+8xTi22-7xO54 is the chemical general formula ofthe main material, and Ln is selected from one or more of La, Y, Sm, Dy, Ho, Er and Nd. Zr0.8Sn0.2TiO4 is used as a chemical formula of an auxiliary material. The mass fraction of the main crystal phase in the ceramic material is 99-99.5 wt%, and the mass fraction of the modified additive in the ceramic material is 0.5-1wt%. The main material and the auxiliary material are respectively synthesized by adopting a solid-phase method to prepare a uniform powdery ceramic material, the powdery ceramic material is sintered to obtain the ceramic material with high dielectric constant and high Qf value, and the material can meet the requirements of microwave devices on high dielectric constant and high Qf value.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com