Ceramic material and preparation method and application thereof

A technology of ceramic materials and microwave dielectric ceramics, which is applied in the formulation and preparation of new functional ceramic materials, can solve the problems of ceramic machinability requirements, cannot meet the requirements of 5G, etc., and achieves good machinability and wide sintering process window. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

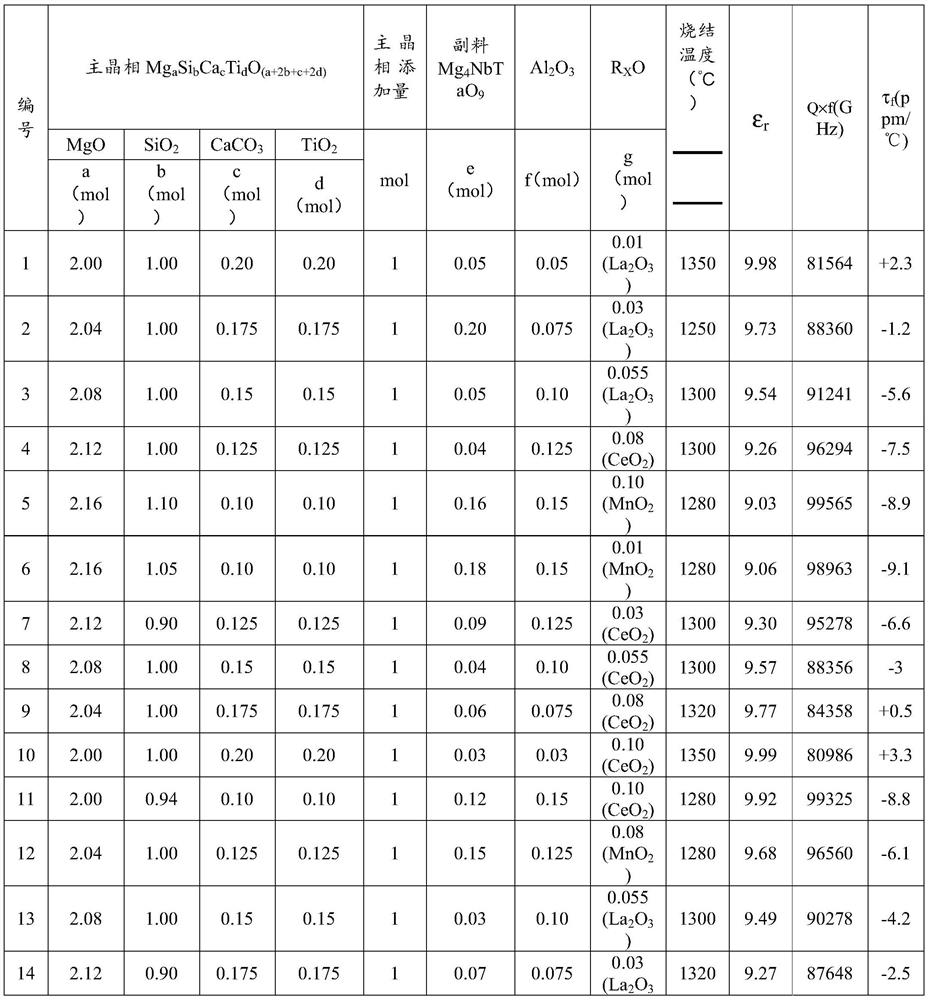

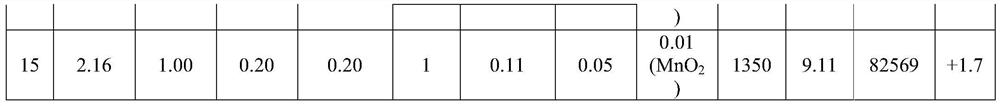

Image

Examples

Embodiment 1

[0024] The chemical general formula of present embodiment ceramic material is: {Mg a Si b Ca c Ti d o (a+2b+c+2d)}(main crystal phase)-eMg 4 NbTaO 9 (Auxiliary material)-fAl 2 o 3 -gR x O(R x O is for La 2 o 3 , CeO 2 , MnO 2 One of them), take a=2.00, b=1, c=0.2, d=0.2, e=0.05, f=0.05, g=0.01.

[0025] The preparation process of the microwave dielectric ceramic material in this embodiment is as follows:

[0026] (1) Main crystal phase Mg a Si b Ca cTi d o (a+2b+c+2d) Preparation: select raw materials MgO and SiO with a purity of 99.8% 2 , CaCO 3 、TiO 2 , according to the stoichiometric ratio of the main crystal phase, that is, select a=2.00, b=1.0, c=0.20, d=0.20, first calculate the quality of the main crystal phase raw materials required; put the accurately weighed raw materials into the ball mill jar Inside; add pure water and zirconia grinding balls, the weight ratio of the three is: material: ball: pure water = 1:4:1.5; ball mill for 4 hours, mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com