Method for preparing copper-tin alloy powder through diffusion

A copper-tin alloy and diffusion alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of sintering segregation and coarsening, uneven phase structure, affecting the performance of tool carcass, etc., to prevent component segregation, reduce The yield of finished products and the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

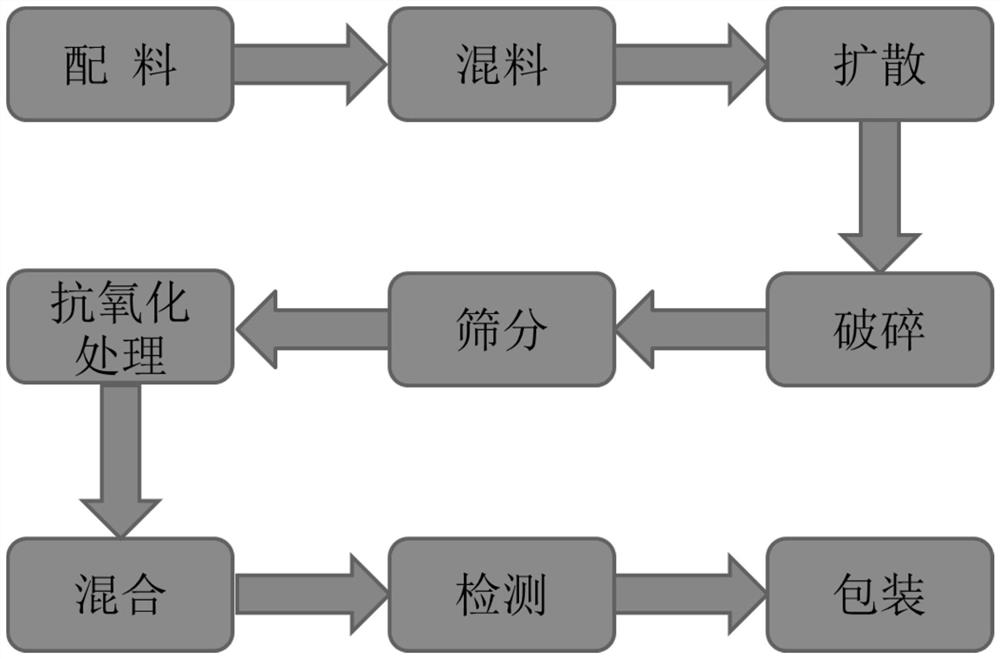

[0036] A method for preparing copper-tin alloy powder by diffusion, comprising the following steps:

[0037] Step 1: Weighing 89.7% of copper powder, 10% of tin powder, and 0.3% of copper-gadolinium alloy powder in terms of mass percentages, and mixing them; wherein, the copper powder is electrolytic copper powder with a particle size of -200 to -400 mesh; The tin powder is atomized tin powder, with a particle size of -200 to -400 mesh; the particle size of copper-gadolinium alloy powder is -400 to -600 mesh (among them, adding a minus sign before the mesh number means that it can pass through the mesh of the mesh, such as -200 mesh: can pass through 200 mesh sieve).

[0038] Step 2: Add the mixed powder into a dry ball mill for ball milling, the mass ratio of the balls to the mixed powder is 7:3, the ball milling time is 8h, and the ball milling speed is 80r / min; the diameter of the balls is The weight ratio of the three diameters is The material of the grinding ball is 3...

Embodiment 2

[0044] A method for preparing copper-tin alloy powder by diffusion, comprising the following steps:

[0045] Step 1: Weighing 84.5% of copper powder, 15% of tin powder, and 0.5% of copper-gadolinium alloy powder according to mass percentage, and mixing them; wherein, the copper powder is electrolytic copper powder with a particle size of -200 to -400 mesh; The tin powder is atomized tin powder with a particle size of -200 to -400 mesh; the particle size of copper gadolinium alloy powder is -400 to -600 mesh.

[0046] Step 2: Add the mixed powder into a dry ball mill for ball milling, the mass ratio of the balls to the mixed powder is 7:3, the ball milling time is 6h, and the ball milling speed is 65r / min; the diameter of the balls is The weight ratio of the three diameters is The material of the grinding ball is 304 stainless steel;

[0047] Step 3: Put the mixed powder after ball milling into the reduction furnace for diffusion. The protective atmosphere is hydrogen-nitro...

Embodiment 3

[0052] A method for preparing copper-tin alloy powder by diffusion, comprising the following steps:

[0053] Step 1: Weighing 79.2% of copper powder, 20% of tin powder, and 0.8% of copper-gadolinium alloy powder according to mass percentage, and mixing them; wherein, the copper powder is electrolytic copper powder with a particle size of -200 to -400 mesh; The tin powder is atomized tin powder with a particle size of -200 to -400 mesh; the particle size of copper gadolinium alloy powder is -400 to -600 mesh.

[0054] Step 2: Add the mixed powder into a dry ball mill for ball milling, the mass ratio of the balls to the mixed powder is 3:2, the ball milling time is 6h, and the ball milling speed is 60r / min; the diameter of the balls is The weight ratio of the three diameters is The material of the grinding ball is 304 stainless steel;

[0055] Step 3: Put the mixed powder after ball milling into the reduction furnace for diffusion. The protective atmosphere is hydrogen-nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com