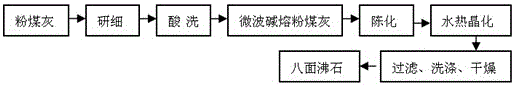

Method for making coal ash into faujasite through microwave alkali fusion-hydro-thermal synthesis

A faujasite and hydrothermal synthesis technology, which is applied in the field of solid waste resource utilization, can solve the problems of low conversion rate of Si and Al, high calcination temperature, and low synthesis temperature, and achieve short calcination and crystallization time, The production process is simple and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Grind the fly ash to -75 μm.

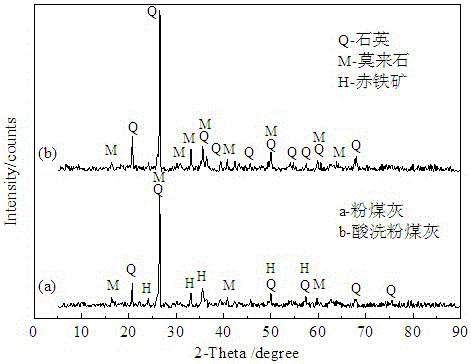

[0029] The content of ferric oxide in the fly ash used in this experiment is relatively high. In order to eliminate the influence of iron impurities on the synthetic zeolite, the fly ash was pickled to remove impurities. Mix 15% hydrochloric acid and fly ash at a liquid-solid ratio of 10:1, stir at a constant temperature of 200 r / m for 1 h at 80 °C, filter, wash with deionized water until neutral, and dry.

[0030] Weigh 5g of hydrochloric acid-treated fly ash and 6g of sodium hydroxide and mix them evenly in a mass ratio of 1:1.2, then transfer them into a silicon carbide crucible, and place the crucible in a microwave box-type high-temperature reactor at a temperature of 450°C Under the conditions of microwave alkali fusion for 15 minutes, after the alkali fusion product is cooled, grind it finely.

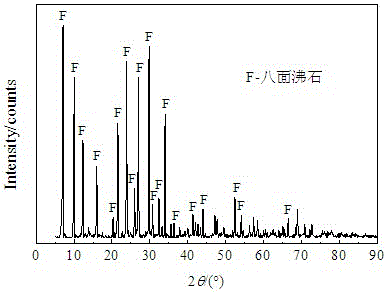

[0031] Add 70 mL of deionized water to the alkali-melted fly ash, even if the concentration of sodium hydroxide is 2.1 mol / L, and stir it ...

Embodiment 2

[0036] Grind the fly ash to -75 μm.

[0037] Mix 15% hydrochloric acid and fly ash at a liquid-solid ratio of 5:1, stir at a constant temperature of 200 r / m for 2 h at 90 °C, filter, wash with deionized water until neutral, and dry.

[0038] Weigh 5g of hydrochloric acid-treated fly ash and 6g of sodium hydroxide and mix them in a mass ratio of 1:1.2, then transfer them into a silicon carbide crucible, and place the crucible in a microwave box-type high-temperature reactor at a temperature of 550°C Under the condition of microwave alkali fusion for 60 minutes, after the alkali fusion product is cooled, grind it finely.

[0039] Add 80 mL of deionized water to the alkali-melted fly ash, even if the concentration of sodium hydroxide is 1.9 mol / L, and stir it magnetically at room temperature at 400 r / m for 5 h.

[0040] Heat the alkali-melted fly ash suspension at 95°C for 14 hours to crystallize.

[0041] The reaction product was cooled to room temperature, filtered, washed wi...

Embodiment 3

[0044] Grind the fly ash to -75 μm.

[0045] Mix 15% hydrochloric acid and fly ash at a liquid-solid ratio of 5:1, stir at a constant temperature of 200 r / m for 2 h at 85 °C, filter, wash with deionized water until neutral, and dry.

[0046] Weigh 5g of hydrochloric acid-treated fly ash and 6g of sodium hydroxide and mix them in a mass ratio of 1:1.2, then transfer them into a silicon carbide crucible, and place the crucible in a microwave box-type high-temperature reactor at a temperature of 350°C Under the condition of microwave alkali fusion for 60 minutes, after the alkali fusion product is cooled, grind it finely.

[0047] Add 90 mL of deionized water to the alkali-melted fly ash, even if the concentration of sodium hydroxide is 1.7 mol / L, and stir it magnetically at room temperature at 400 r / m for 4 h.

[0048] Heat the alkali-melted fly ash suspension at 90°C for 12 hours to crystallize.

[0049] The reaction product was cooled to room temperature, filtered, washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com