Method for preparing organic ammonium metal halide film

A metal halide, organic ammonium technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of inability to use flexible substrates, achieve violent molecular motion, reduce production costs, and have fewer defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

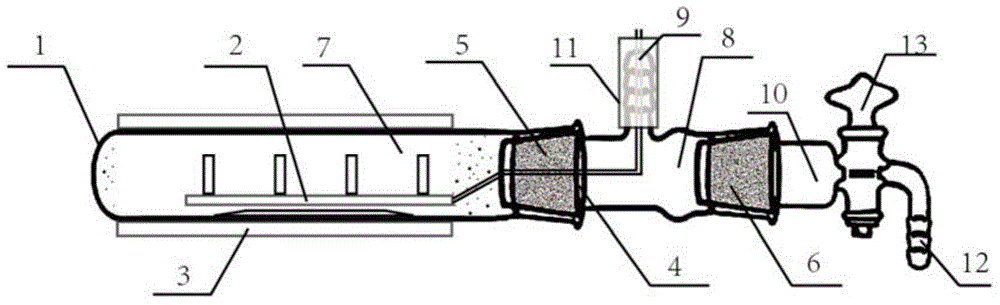

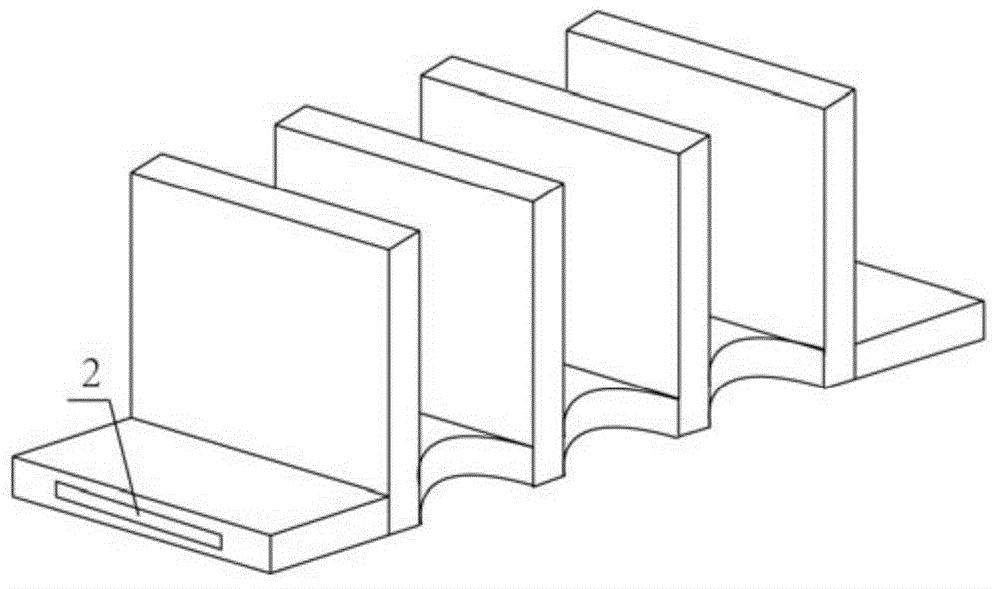

[0042] A method for preparing an organic ammonium metal halide film, which is prepared by a semi-closed carrier-free hot-wall low-pressure chemical vapor deposition (HW-LPCVD) process, comprising the following steps:

[0043] 1) Cleaning of quartz slices: Ultrasonic cleaning of quartz slices with acetone, isopropanol, and deionized water for 30 minutes, drying with compressed air, and ozone treatment for 10 minutes; 0.23g PbI 2 Dissolve in 0.5mL anhydrous DMF, heat to 60°C, and magnetically stir for 30 minutes; spin-coat PbI on a cleaned 2.5cm×2.5cm quartz glass at 6000rpm 2 DMF solution for 30s; heat the substrate on a hot stage at 100°C for 5 minutes, cool to room temperature naturally, and spin-coat the PbI 2 The quartz slices were transferred to an argon-filled glove box.

[0044] 2) Put the preparation device into the glove box and open the valve, weigh 0.02 g of CH 3 NH 3 I, place evenly in the area covered by the heating mantle.

[0045] 3) PbI 2 The quartz slice i...

Embodiment 2

[0054] A method for preparing an organic ammonium metal halide film, which is prepared by a semi-closed carrier-free hot-wall low-pressure chemical vapor deposition (HW-LPCVD) process. The steps are basically the same as in Example 1, except that the quartz plate The cleaning method is as follows:

[0055] Ultrasonic cleaning of quartz plates with acetone, isopropanol, and deionized water for 30 minutes, drying with compressed air, and ion bombardment for 10 minutes; -4 Prepare a layer of 80nm PbI on the cleaned 2.5cm×2.5cm quartz at a rate of 0.1nm / s under Pa background pressure 2 Thin film, the source-base distance is 40cm, the source is loaded on a tungsten boat, the substrate distribution adopts a rotating spherical distribution, and its thickness is controlled by a calibrated quartz crystal oscillator. The substrate temperature is 80°C, then the PbI 2 The quartz slices were transferred to an argon-filled glove box.

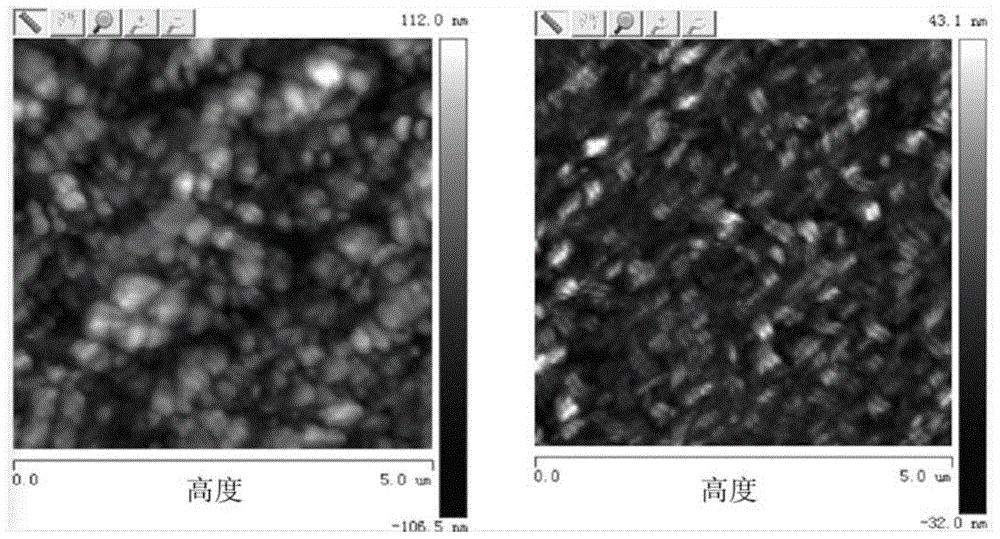

[0056] Image 6 CH prepared by carrier-free hot-wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com