Patents

Literature

329results about How to "Reduce pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

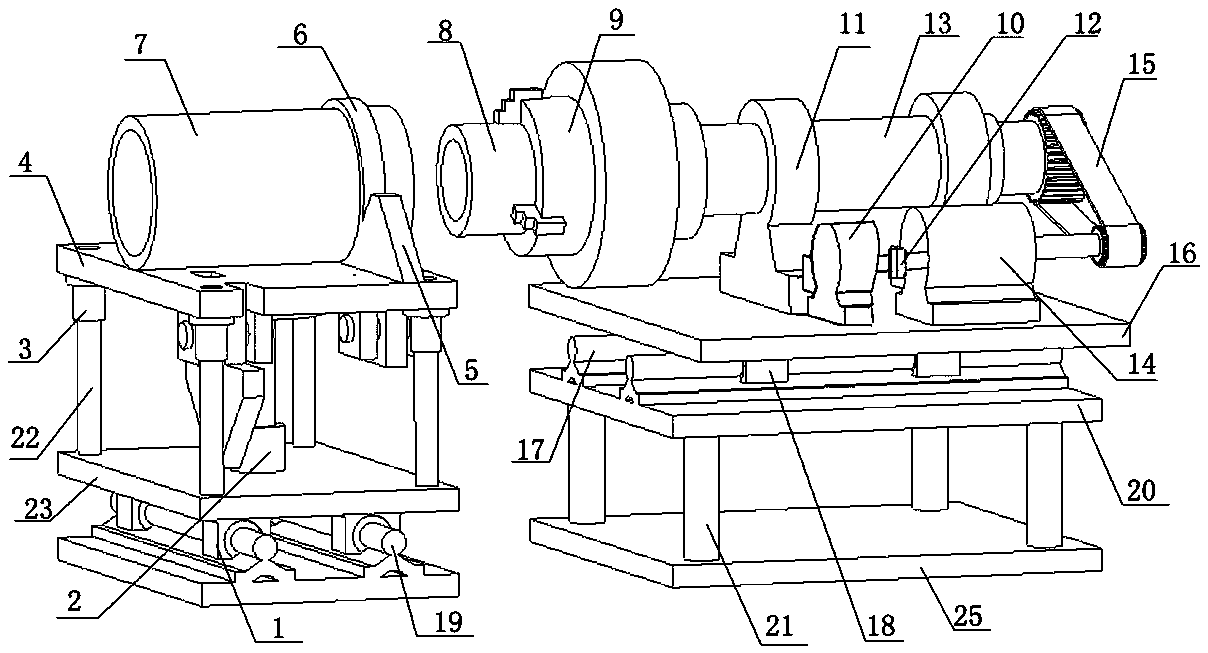

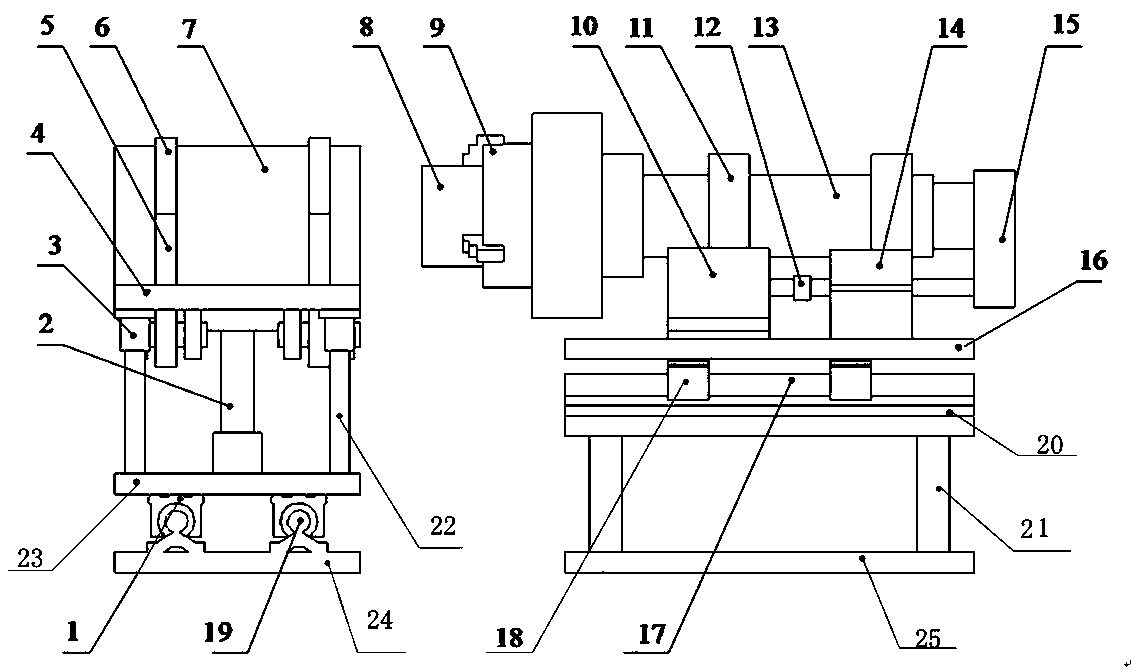

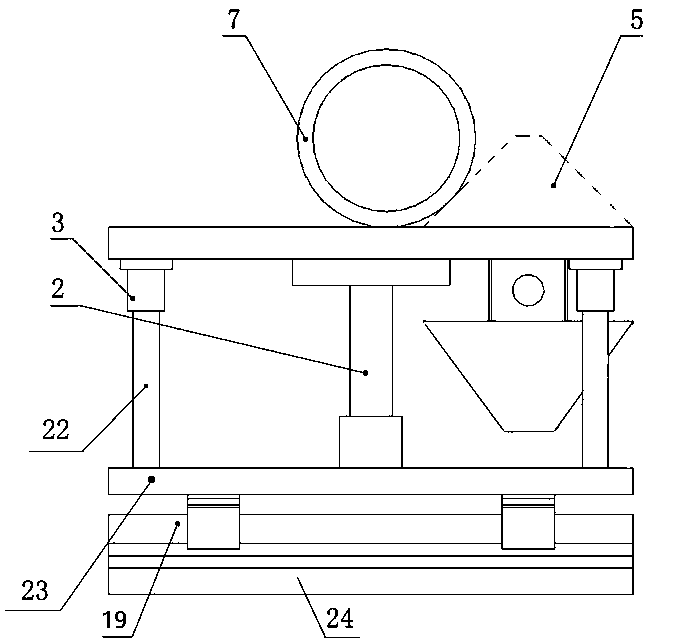

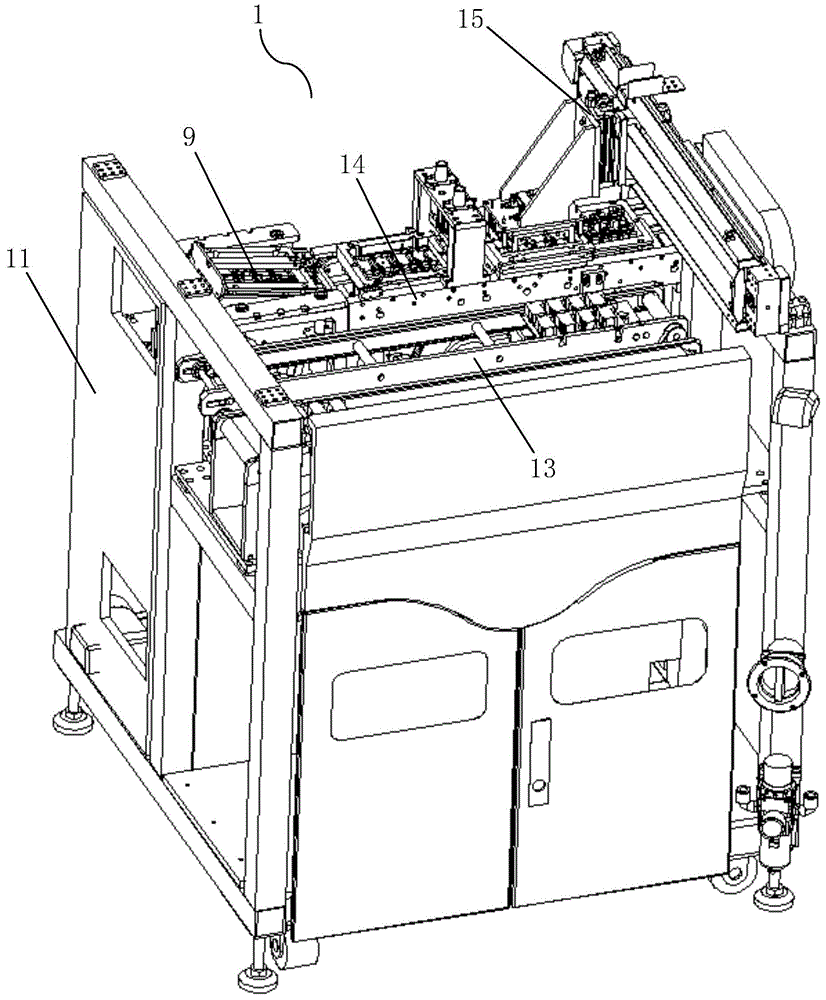

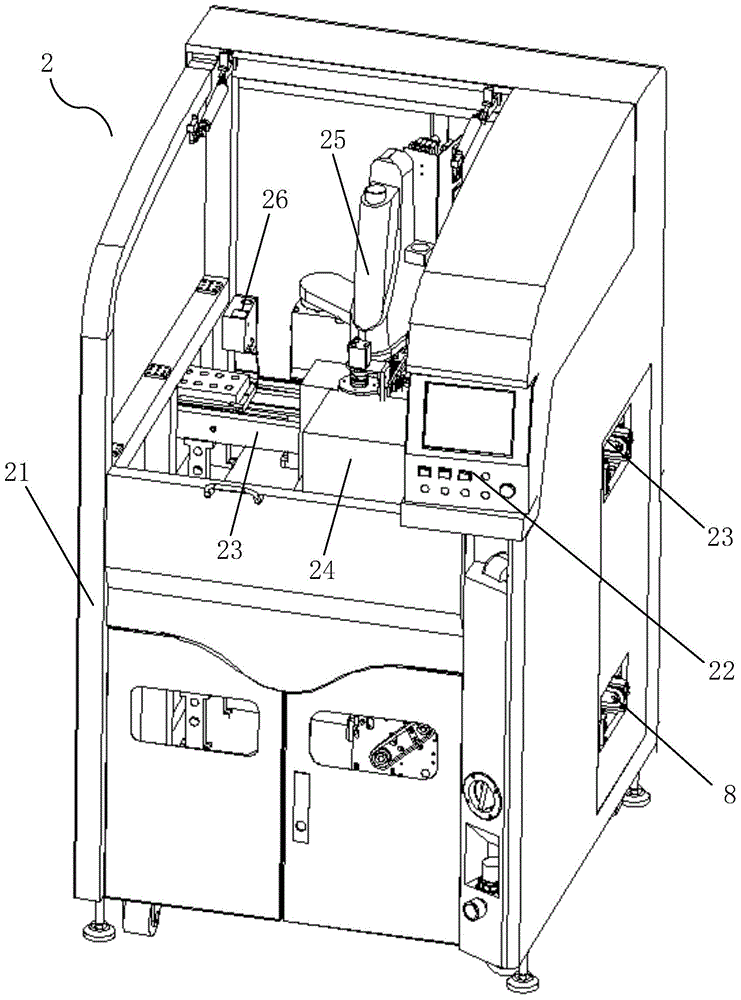

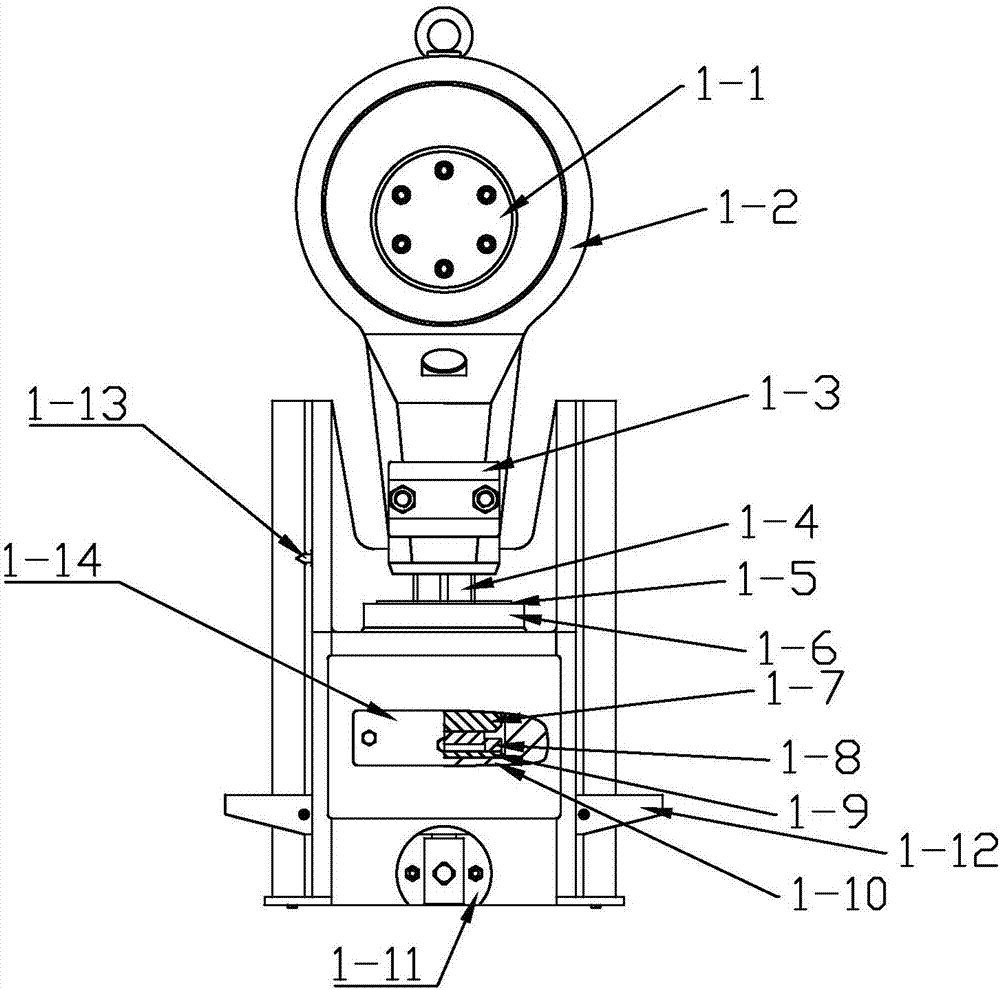

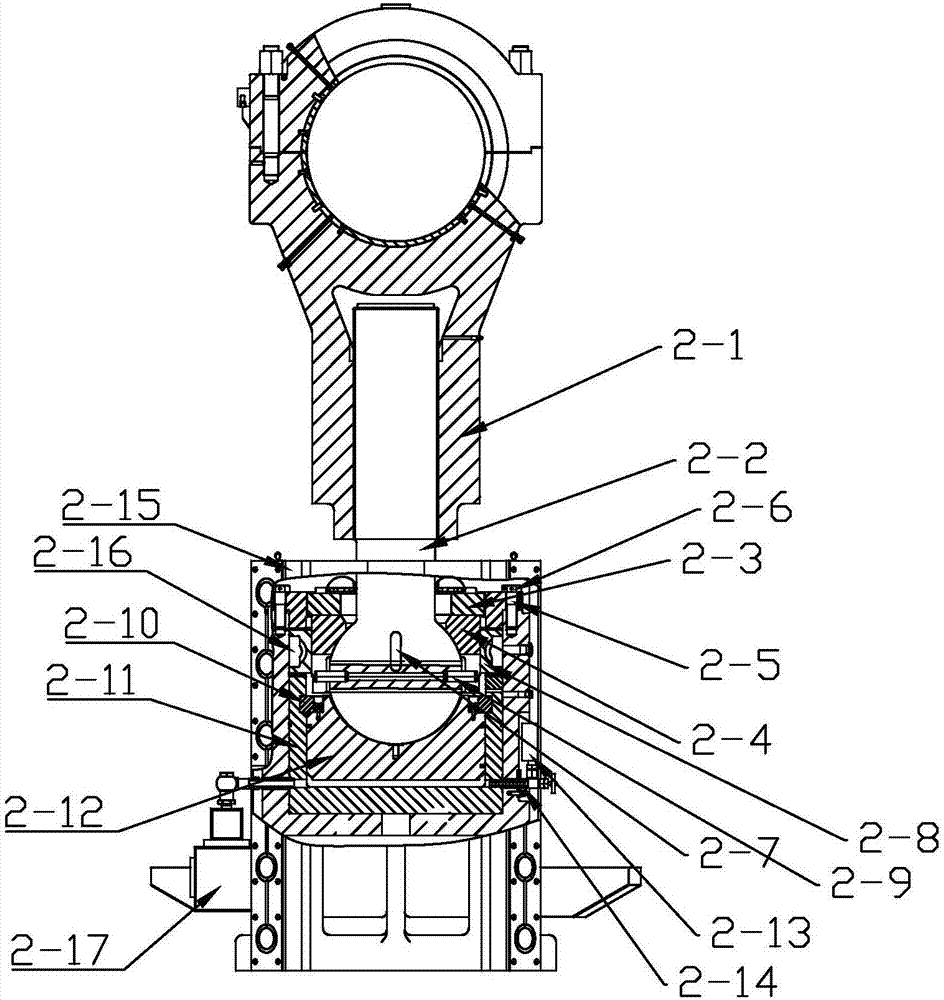

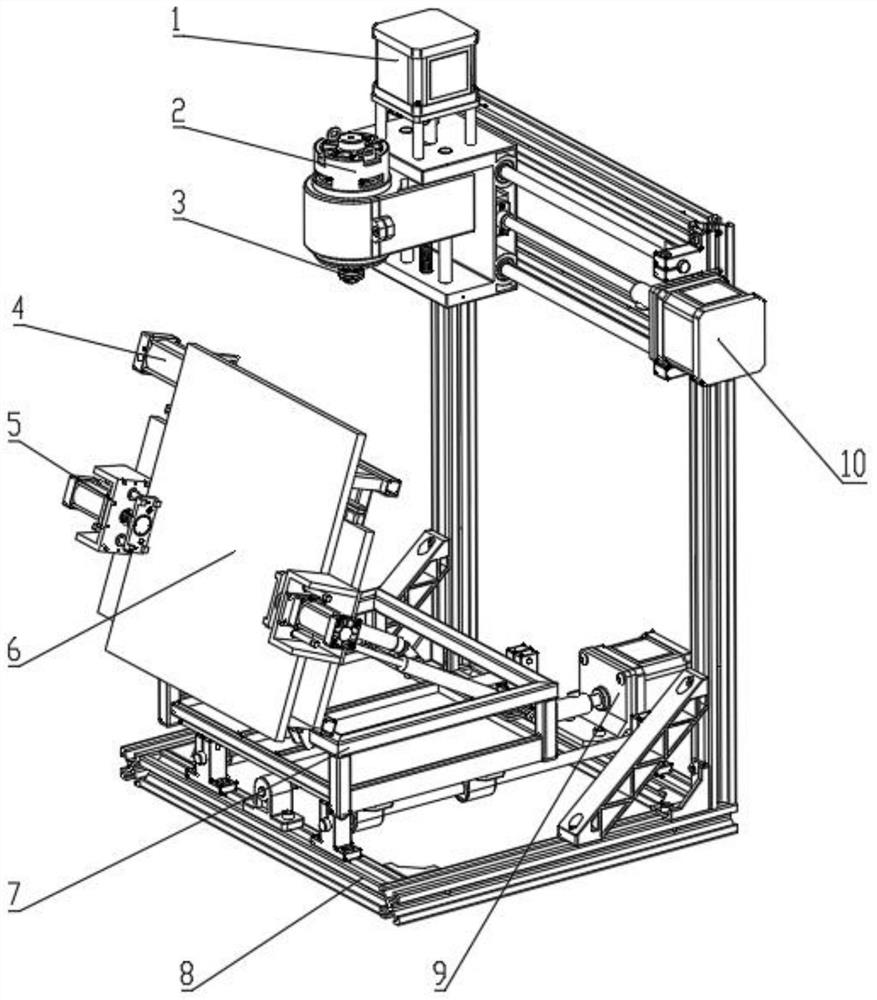

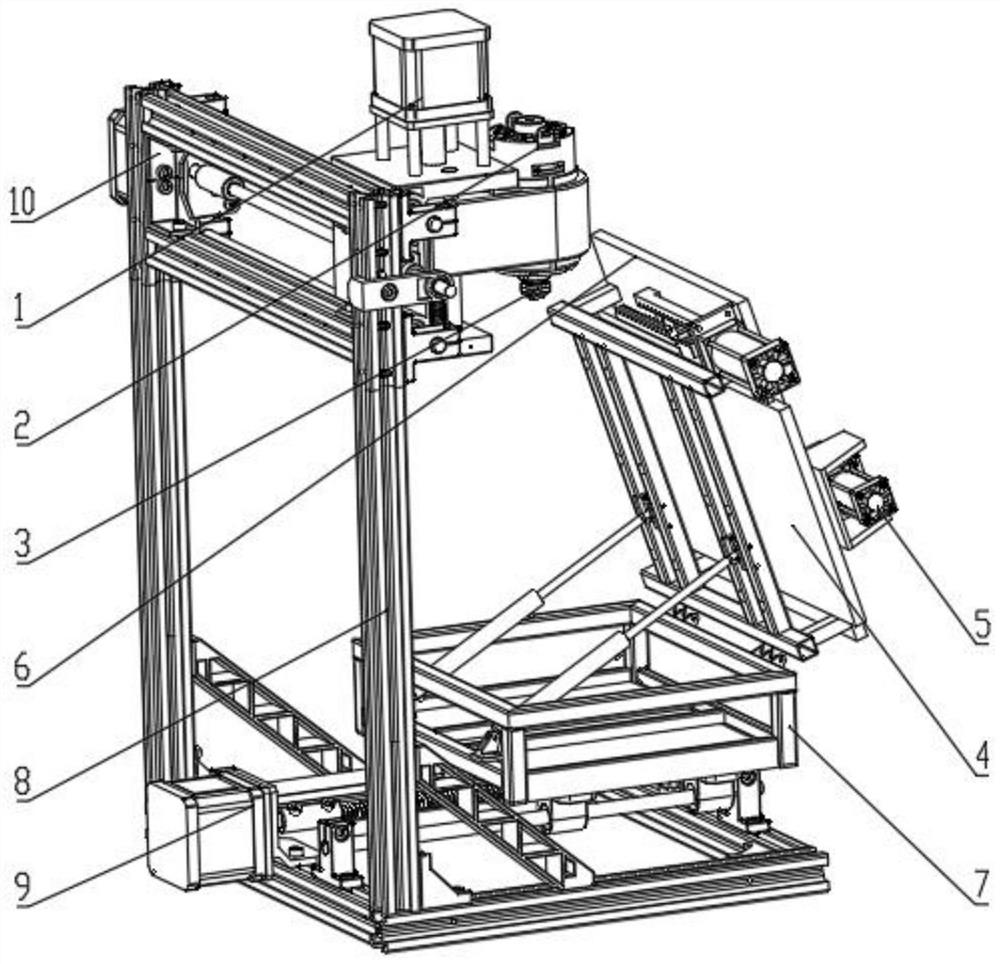

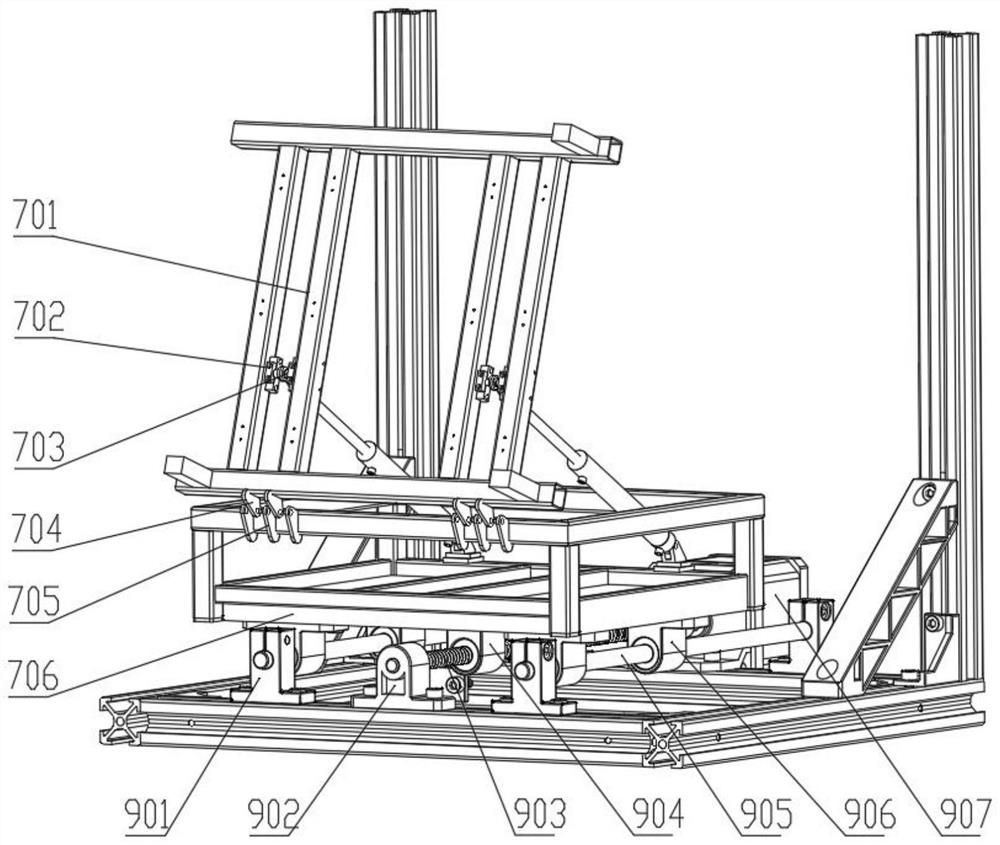

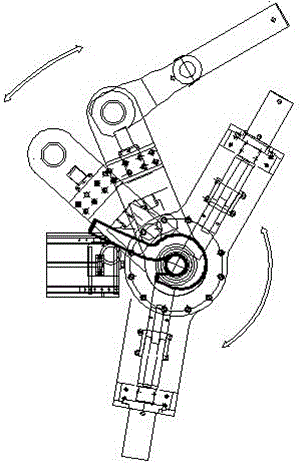

Self-adaptation flexible assembling device for hydraulic cylinder head body

InactiveCN109015468AFast and accurate vertical liftingQuick dockingWork holdersMetal working apparatusHydraulic cylinderCylinder head

The invention relates to the technical field of automatic machine assembling, in particular to a self-adaptation flexible assembling device for a hydraulic cylinder head body. The technical problem ofassembling of a cylinder barrel and a cylinder head body of a large multistage hydraulic cylinder is solved. The self-adaptation flexible assembling device comprises a cylinder barrel flexible clamping platform and a cylinder head body flexible clamping platform which are independent from each other and need to be used in cooperation with each other. The cylinder barrel flexible clamping platformis used for fixing a cylinder barrel, and the cylinder barrel flexible clamping platform can do perpendicular lifting motion and horizontal motion in the radial direction of the cylinder barrel. Thecylinder head body flexible clamping platform is used for fixing a cylinder head body, the cylinder head body flexible clamping platform can do horizontal motion along the axis of the cylinder barrel,the cylinder head body flexible clamping platform drives the cylinder head body to move towards the cylinder barrel and rotate synchronously, and finally the cylinder head body and the cylinder barrel can be assembled through thread connection. By means of the self-adaptation flexible assembling device, the historic problems that operation is complex, the assembling efficiency is low, the surface, making contact with a lifting clamp, of the cylinder barrel is likely to be damaged, and even the cylinder barrel is disengaged in the traditional cylinder barrel and cylinder head body assembling process can be effectively solved.

Owner:SHANXI UNIV

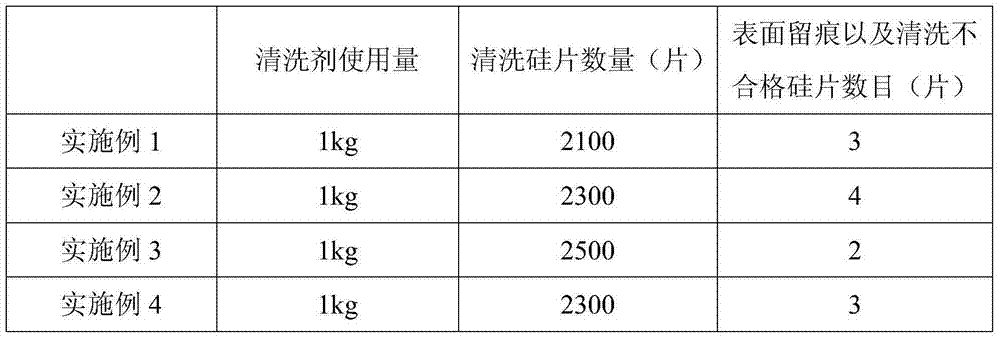

A reworking method on degraded products after the printing of crystal silicon solar battery

ActiveCN101217169AImprove pass rateImprove yieldFinal product manufactureSemiconductor devicesFailure rateSilver paste

The invention discloses a rework method of defective products of crystalline silicon solar cells after printing. The method includes the following three steps: an aluminum paste at the back surface of a cell is removed by using an HCl cleaning liquid; silver pastes at the positive and negative surfaces of the cell is removed by using isopropanol; the cell, the pastes of which is basically removed is treated with deep cleaning by using the deep cleaning liquid so as to thoroughly clean tiny impurities. The conversion efficiency of the cell can achieve the level of a normal cell by using the method for processing, and the appearance is not different from the normal cell, thus the invention achieves the purpose of rework cleaning. The failure rate of the silk screen printing of the cells is reduced to about 0.2 percent from original about 2 percent, thereby increasing the qualified rate and the yield of the silicon solar cells.

Owner:ZHEJIANG FORTUNE ENERGY

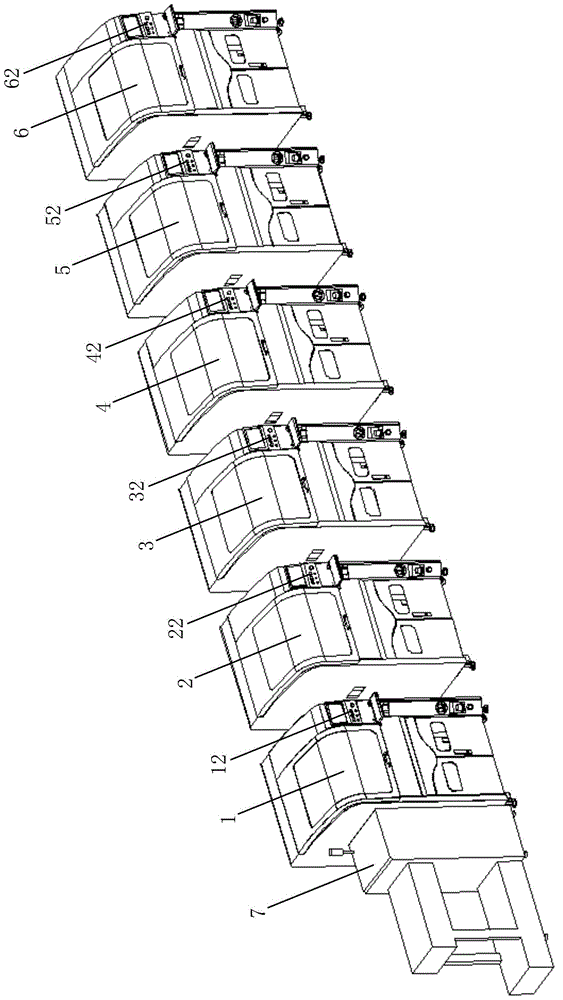

Novel multifunctional PCB production automation system

ActiveCN104822230AReduce labor intensityReduce in quantityLiquid surface applicatorsInsulating layers/substrates workingAdhesiveEngineering

The invention relates to a novel multifunctional PCB production automation system, comprising an automatic feeding system, a fully-automatic two-dimensional code sticking system, a height measuring system, an automatic adhesive dispensing curing system, an online automatic board-splitting cutting system, and a finished product sorting recovery system. The input ends and output ends of the above systems are connected in sequence. Control centers disposed on the above systems are connected with each other. The input end of the automatic feeding system is also provided with a large PCB feeding device. The large PCB feeding device is connected with the control center of the automatic feeding system. Thus, two-dimensional code marking on each PCB unit on a large PCB can be automatically completed, and good product detection, and cutting of the large PCBs can be automatically completed. The system can automatically complete finished products of PCB units, and the system is powerful in functions, high in automation degree, high in production efficiency, low in labor intensity, low in production cost, and high in qualified rate, and has assurance in product quality. A reversed design is used, thereby effectively preventing dusts generated in a cutting process from falling on the PCB, so the finished products are clean.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

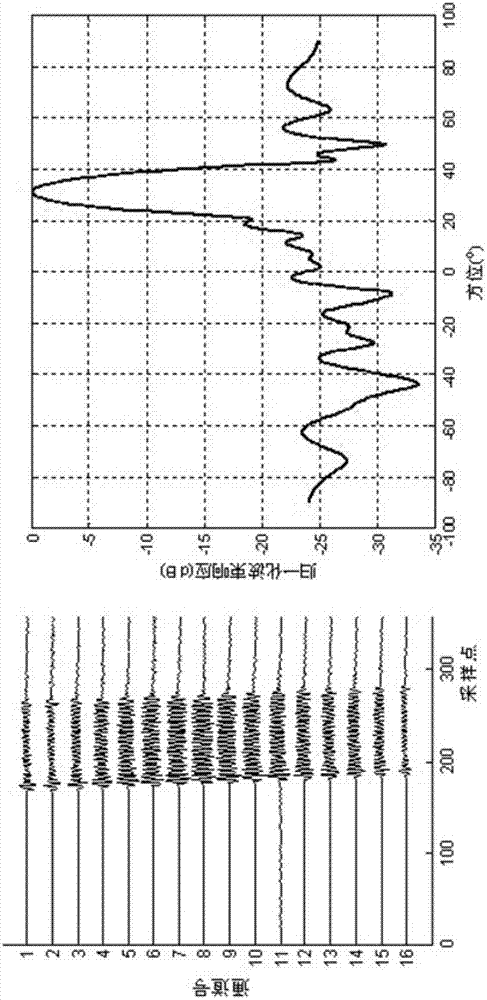

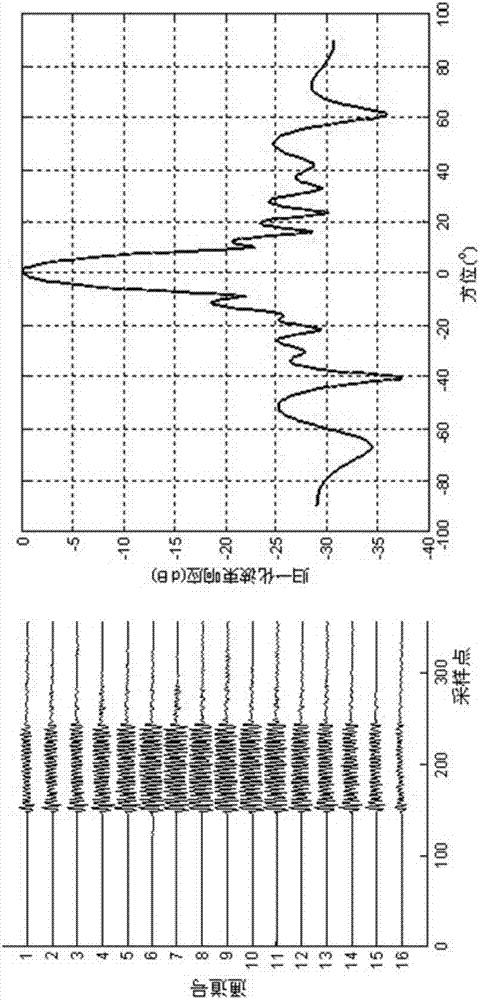

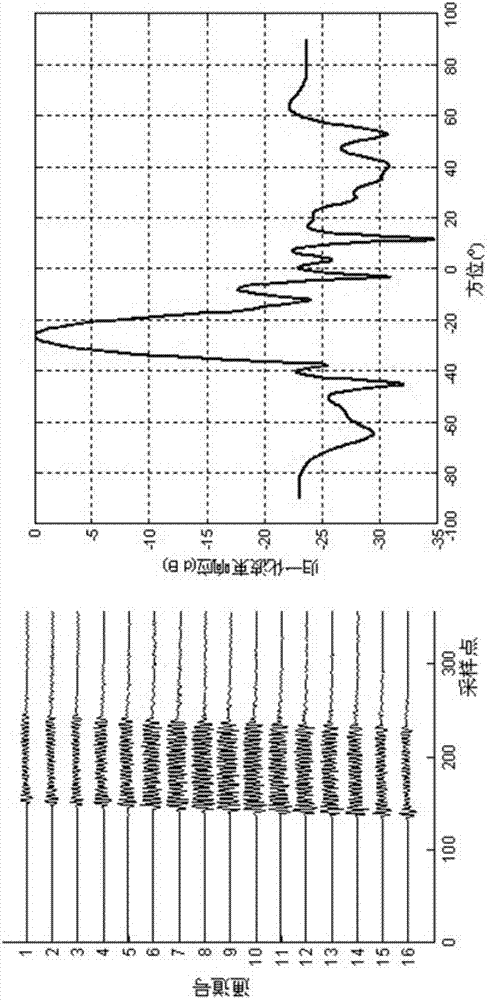

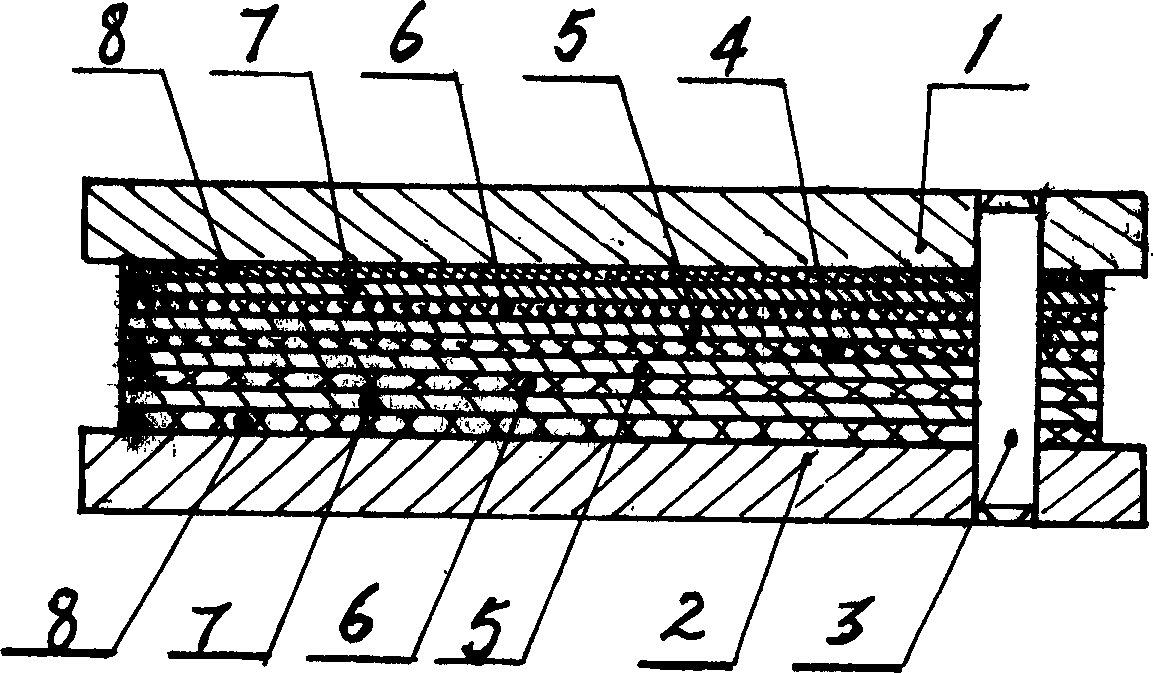

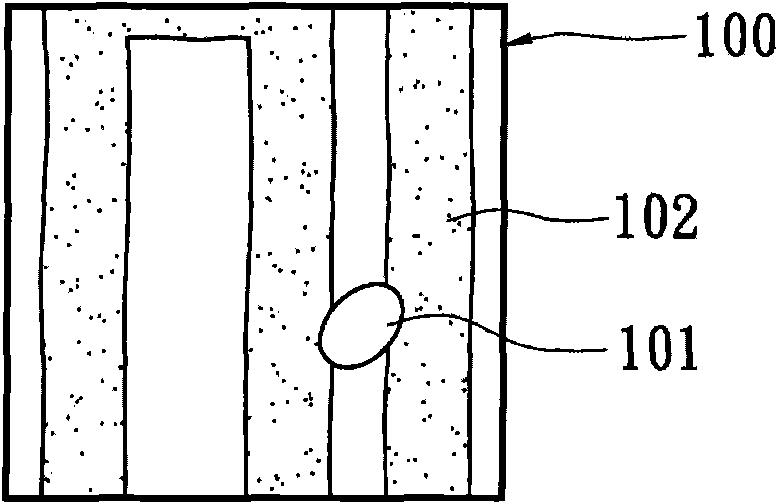

High-frequency closely-spaced piezoelectric film hydrophone array and production method thereof

ActiveCN103175601AImproved detection resolutionImprove electromagnetic compatibilityVibration measurement in fluidTransducerEngineering

The invention relates to the technical field of underwater sound transducers, in particular to a high-frequency hydrophone array applicable to underwater phased array camera and a production method thereof, and solves the technical problems that a large cardinal number of high-frequency hydrophone array elements need to be accurately located and disposed in a limited array area and charge sensed by efficient coupling array elements is required to pick up and receive high-frequency weak underwater sound signals. A piezoelectric device PVDF (polyvinylidene fluoride) film, a rigid backing and PCBs (printed circuit board) are jointed; the high-frequency PVDF hydrophone backing is made of copper to increase sensitivity; multiple layers of PCBs are used as a substrate; a large number of array element backings are integrally pre-processed; the array element backing clusters are positioned and fitted to the PCB substrate; the backing units are separated by secondary processing; decoupling bars are added among the separated units; the piezoelectric film is adhered to form an array; finally, watertight sealing is performed to form the high-frequency piezoelectric film hydrophone array. The high-frequency hydrophone array is applicable to high-frequency sonar receiving arrays for imaging sonar, multi-beam sonar, side-scan sonar and the like.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

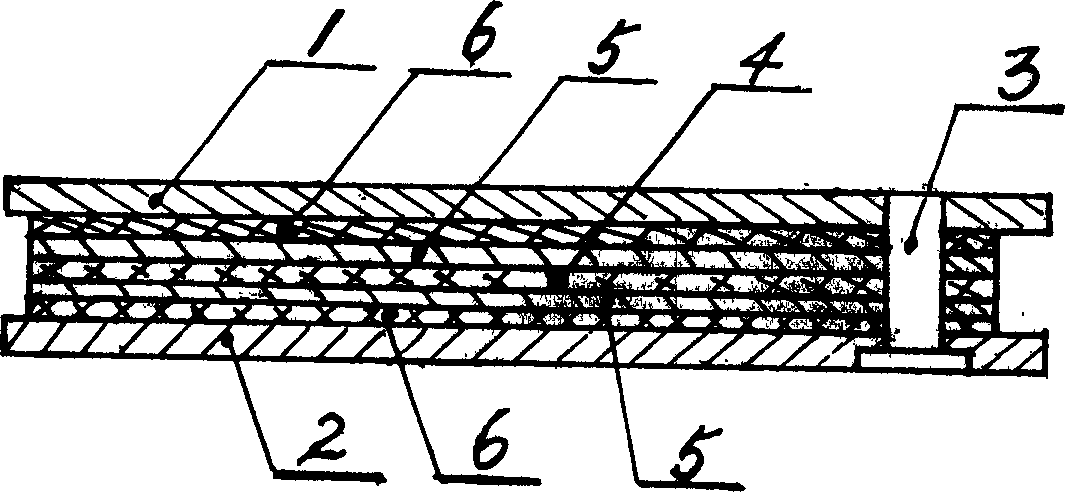

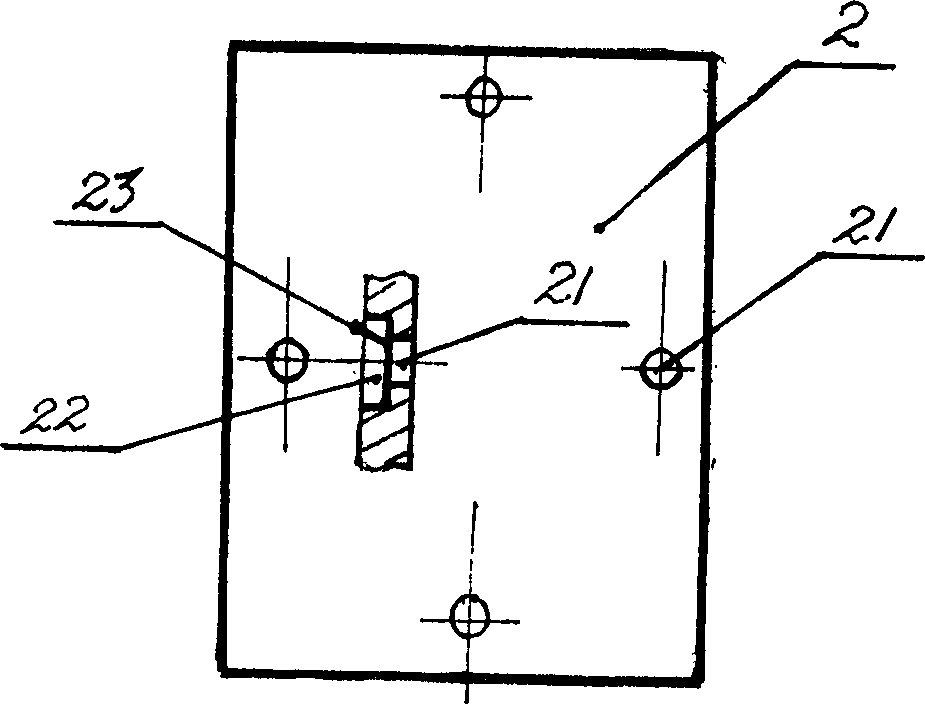

Laminated mould of multi-layer circuit board

InactiveCN1780535AEliminate defects prone to micro-dislocationsPrecise positioningPrinted circuit assemblingMultilayer circuit manufactureDigital controlMaterials science

The invention is made by means of following steps: takes high grade mirror surface stainless steel as material of lower mold plate and upper mold plate; the counter bore perpendicular to axial line of location hole is located at the bottom surface of location hole in the lower mold plate; the step locating pin is composed of the locating column and the foundation; the locating column is perpendicular to the foundation, and the upper mold plate and the lower mold plate are jointed through the step locating pin. Because the location holes in the lower mold plate and the up mold plate coincides with designing basis for each layer of circuit in multi layer circuit board, and is processed by using digital control equipment, the laminating mold has not only precise location, but also low weight, and can process 8 piece multi layer circuit board at on time by hot-pressed.

Owner:李小元

Key lifting switch device and assembling fixture and assembling technology thereof

ActiveCN101599379ASimple structureSimplify the assembly processContact operating partsEngineeringElectrical and Electronics engineering

The invention discloses a key lifting switch device, comprising a keycap, a retractable assembly positioned above a base plate, a switch mechanism for closing and opening the key signal corresponding to the keycap lifting action, the retractable assembly comprises a pair of frames which are impossible to contact with each other, are arranged in a reciprocal manner and form a cavity, the corresponding bottom edges of the two frames can be arranged in two sliding kits which are preset at the two sides of the base plate in a sliding manner, the respective corresponding top parts thereof are arranged with two pivoting-arranged kits which are preset on the bottom of the keycap in a pivoting manner; synchronous sliding pieces used for pressing the synchronous lifting of the pair of frames penetrates the cavity of the pair of the frames, one side thereof is arranged on the base plate and the other side thereof is limited to move along with the retractable movement of the bottom surface of the keycap. In addition, the invention also discloses an assembling fixture and an assembling technology corresponding to the switch device. Compared with the prior art, in the invention, the structure of the key lifting switch device is simplified, the assembling fixture and the assembling technology are improved, thus the production efficiency of keyboards and the finished product acceptability are further improved.

Owner:G TECH TECH

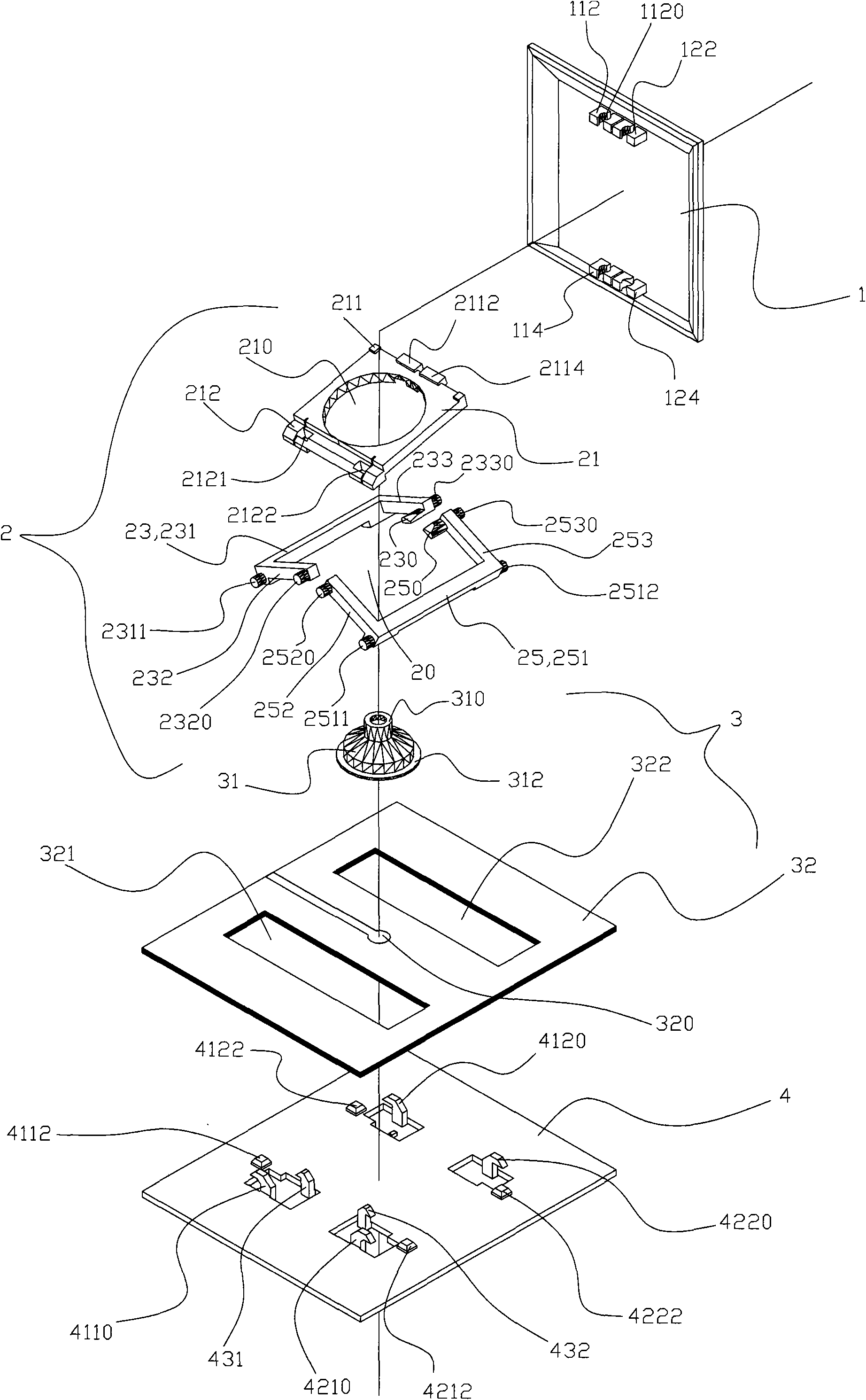

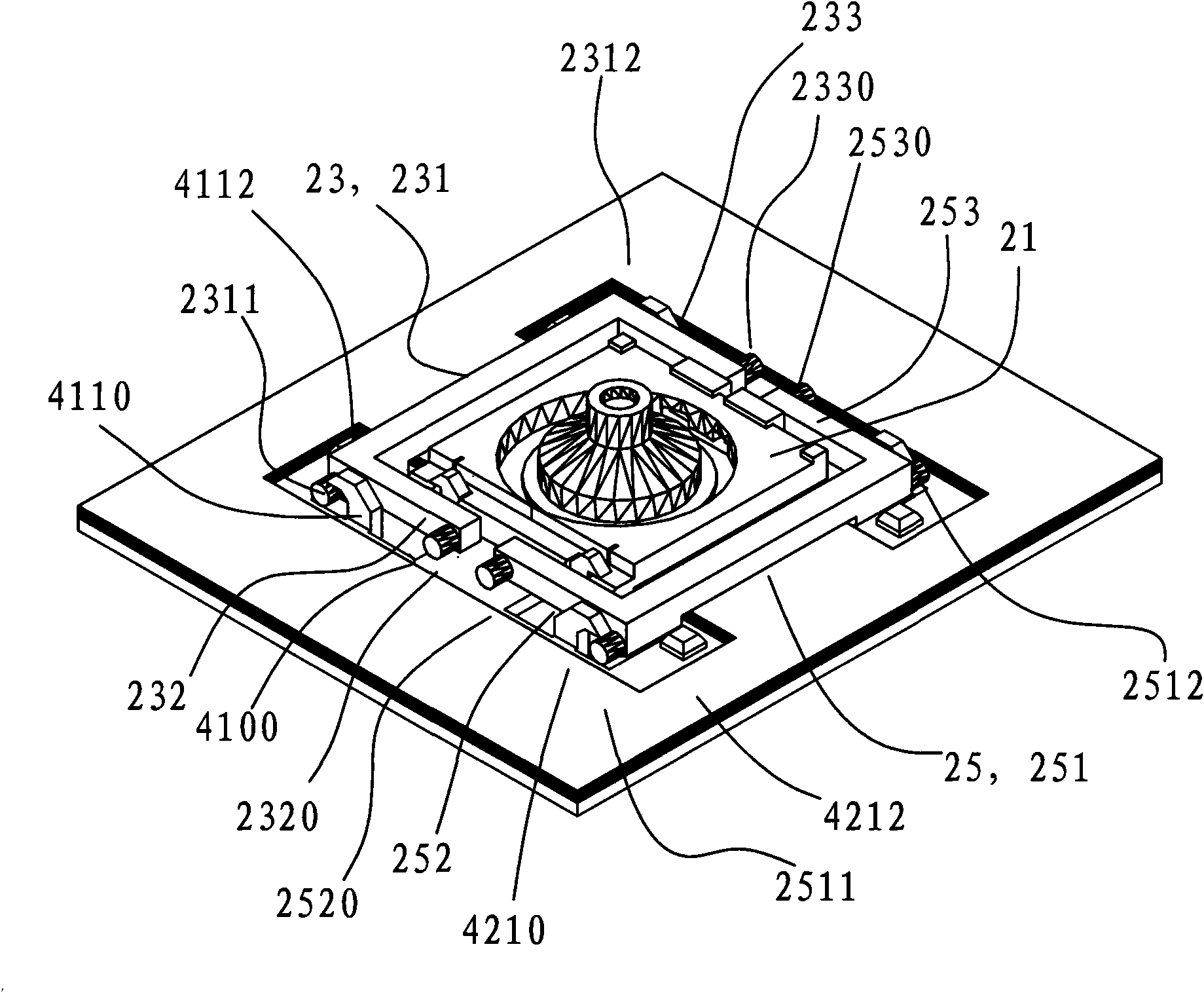

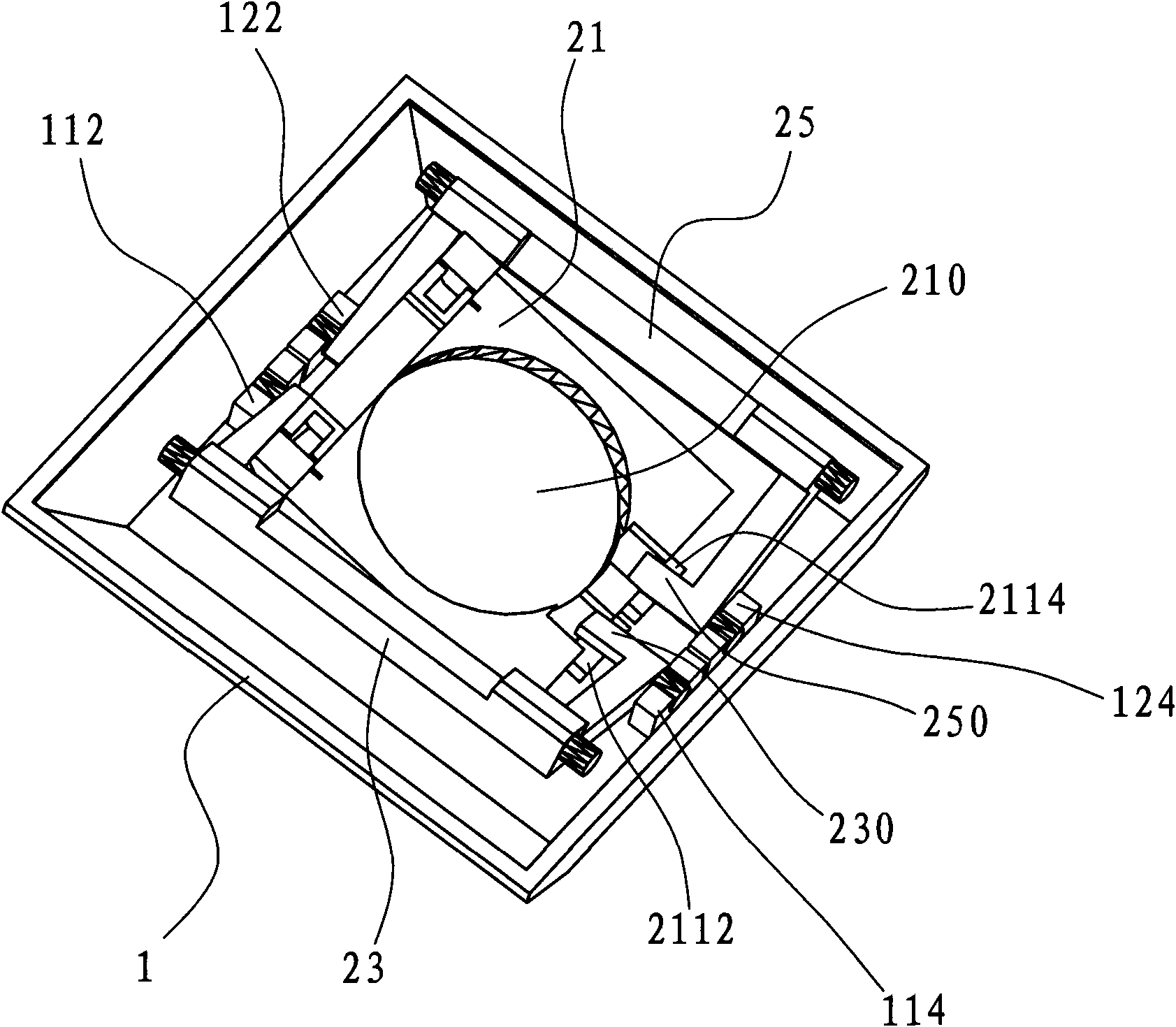

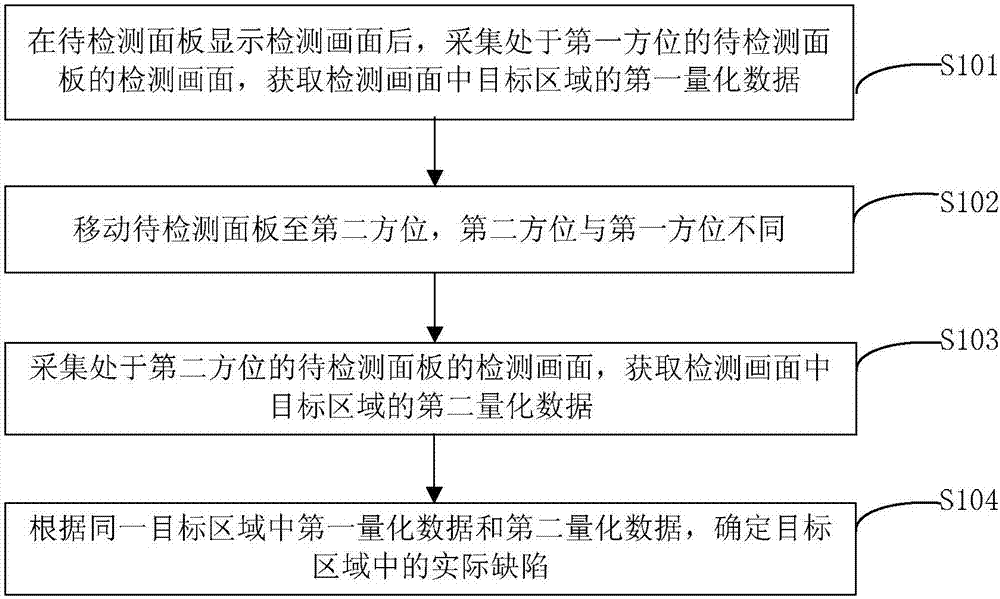

Defect detection method and device

ActiveCN107328791AReduce the chance of being judged as a defectReduce pass rateImage enhancementImage analysisComputer visionArtificial intelligence

The embodiment of the invention provides a defect detection method and device, relates to the field of optical automation defect detection, and can lower the excessive judgment rate of a defect through a simple defect detection method. The defect detection method comprises the following steps: after a detection picture is displayed on a panel to be detected, collecting the defection picture of the panel to be detected in a first direction, and obtaining the first quantized data of a target area in the detection picture; moving the panel to be detected to a second direction, wherein the second direct is different from the first direction; collecting the detection picture of the panel to be detected in the second direction, and obtaining the second quantized data of the target area in the detection picture; according to the first quantized data and the second quantized data in the same target area, determining practical defects in the target area.

Owner:BOE TECH GRP CO LTD +1

Crystalline silica solar energy cell PECVD rainbow film reworking method

ActiveCN102306687AImprove pass rateImprove yieldFinal product manufactureCleaning using liquidsRainbowMolecular physics

The invention relates to solar energy cell sheet processing. Concretely the invention is a crystalline silica solar energy cell sheet plasma enhanced chemical vapor deposition (PECVD) method rainbow film reworking method which is a cleaning process method of a cell sheet having a rainbow film on a surface, and the rainbow film is caused by abnormal discharge in a process of preparing a crystalline silica solar energy cell sheet by utilizing a plasma enhanced chemical vapor deposition method. The cell sheet which is processed by the reworking method is subjected to film plating, printing, and sintering anew, conversion efficiency of the cell sheet can reach a normal level of a cell sheet, appearance of the cell sheet is the same as a normal cell sheet, and a purpose of reworking cleaning is achieved.

Owner:湖南红太阳新能源科技有限公司

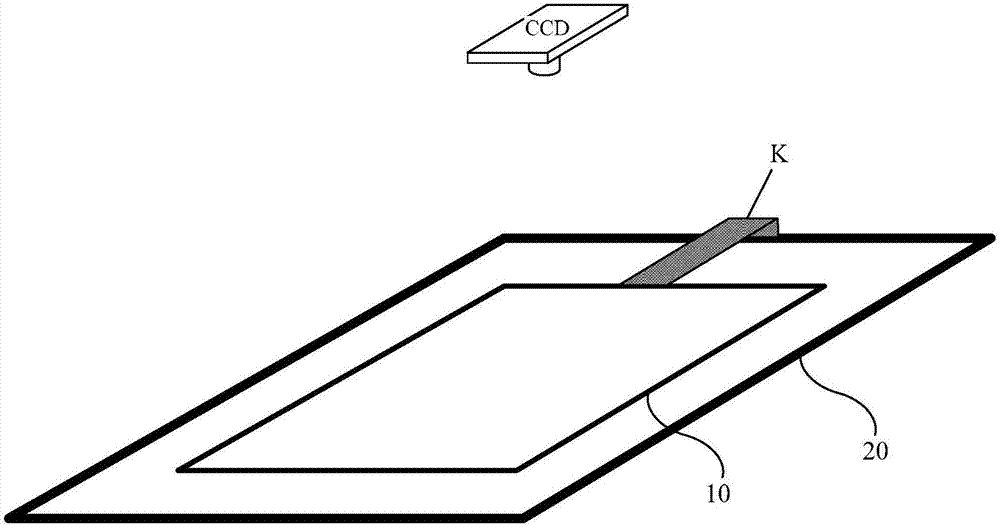

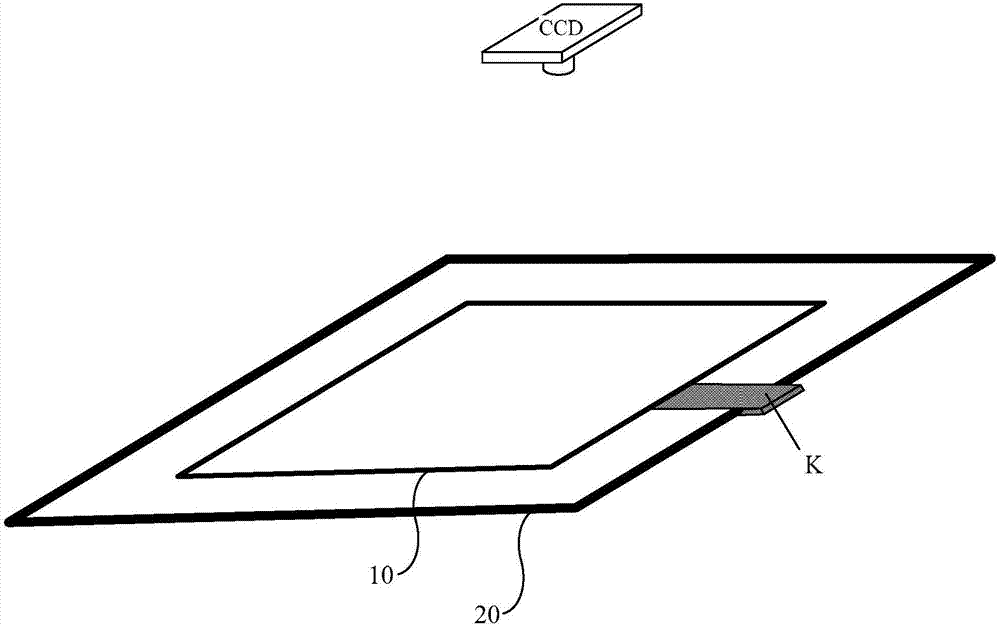

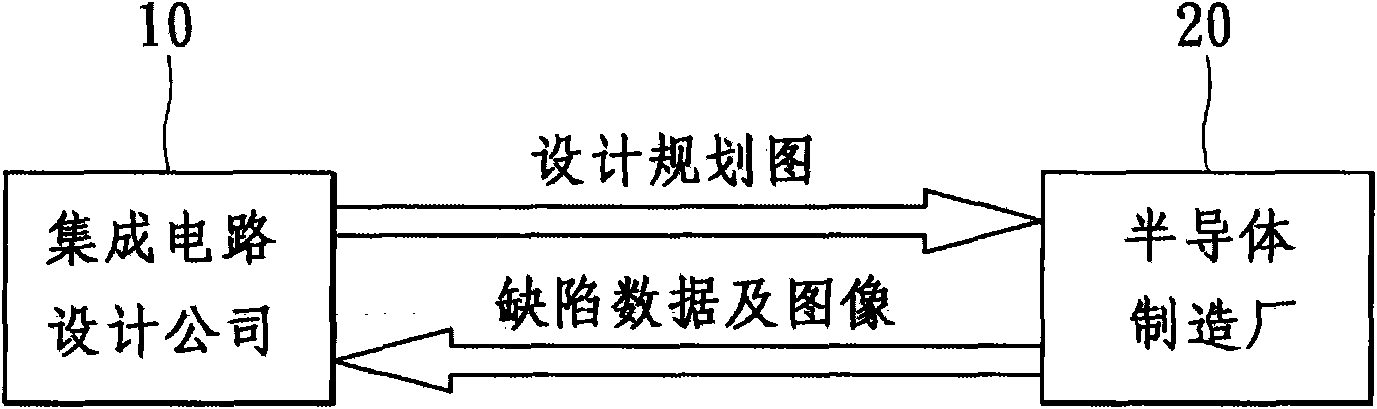

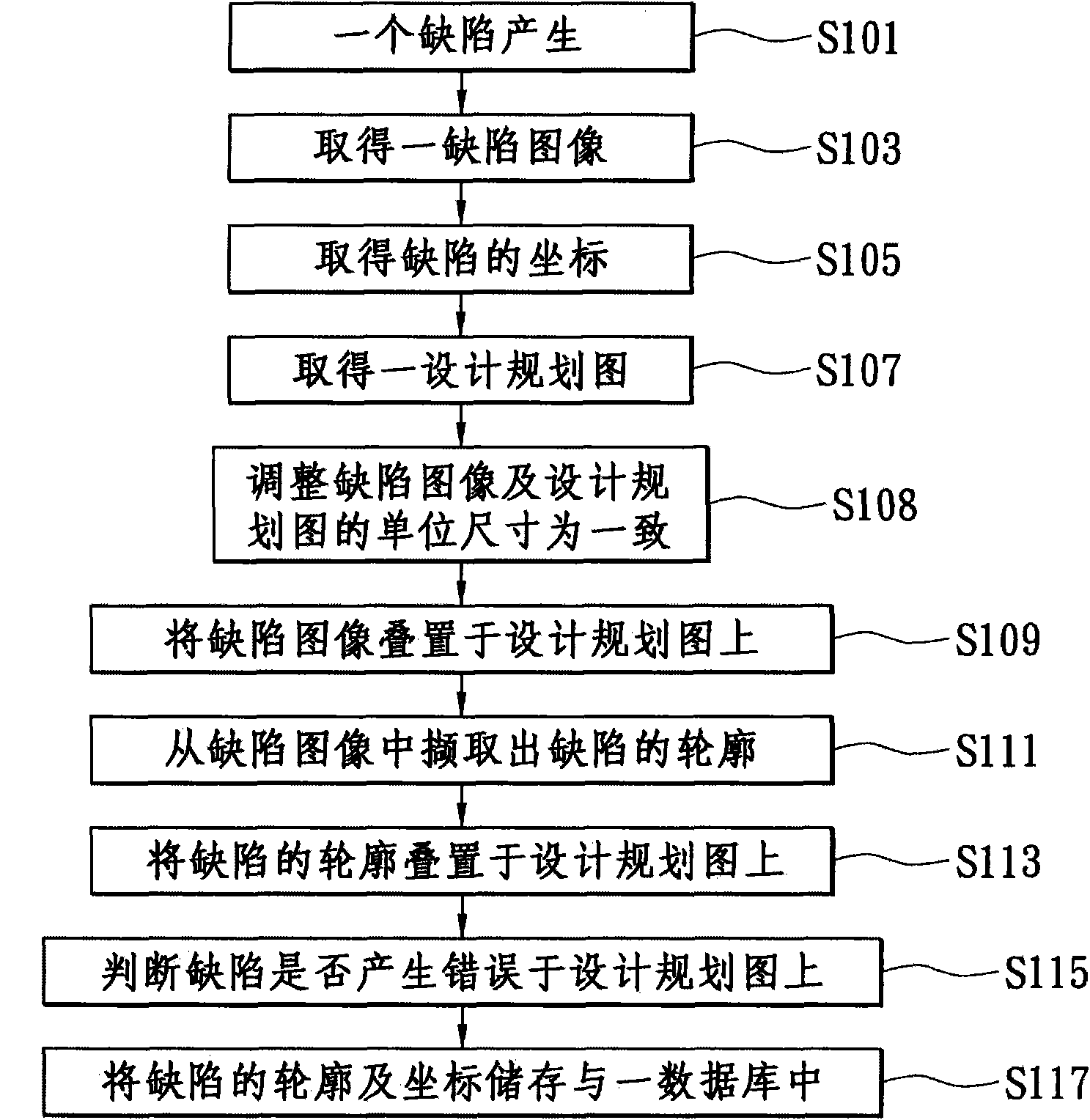

Application method of object manufacture defect

ActiveCN102142355AReduce pass rateAccurate estimateSemiconductor/solid-state device testing/measurementElectrical testingUnit sizeEngineering

The invention discloses an application method of object manufacture defects, comprising the following steps: obtaining a defect image in the object manufacturing process, wherein the defect image comprises a defect and a plurality of manufactured circuit patterns around the defect; obtaining the coordinate of the defect; obtaining a design planning drawing of the object, wherein the design planning drawing comprises a plurality of design circuit patterns; regulating the unit size of the defect image and the unit size of the design planning drawing to be consistent; capturing the outline of the defect from the defect image; according to the coordinate of the defect, setting the outline of the defect on the design planning drawing; and according to the overlapping situation of the outline of the defect and the design circuit patterns, judging whether the defect causes an open circuit fault or a short circuit fault on the design planning drawing or not. Thus, the health condition of the object can be monitored in the manufacture process and can be known before the manufacture process ends.

Owner:吕一云

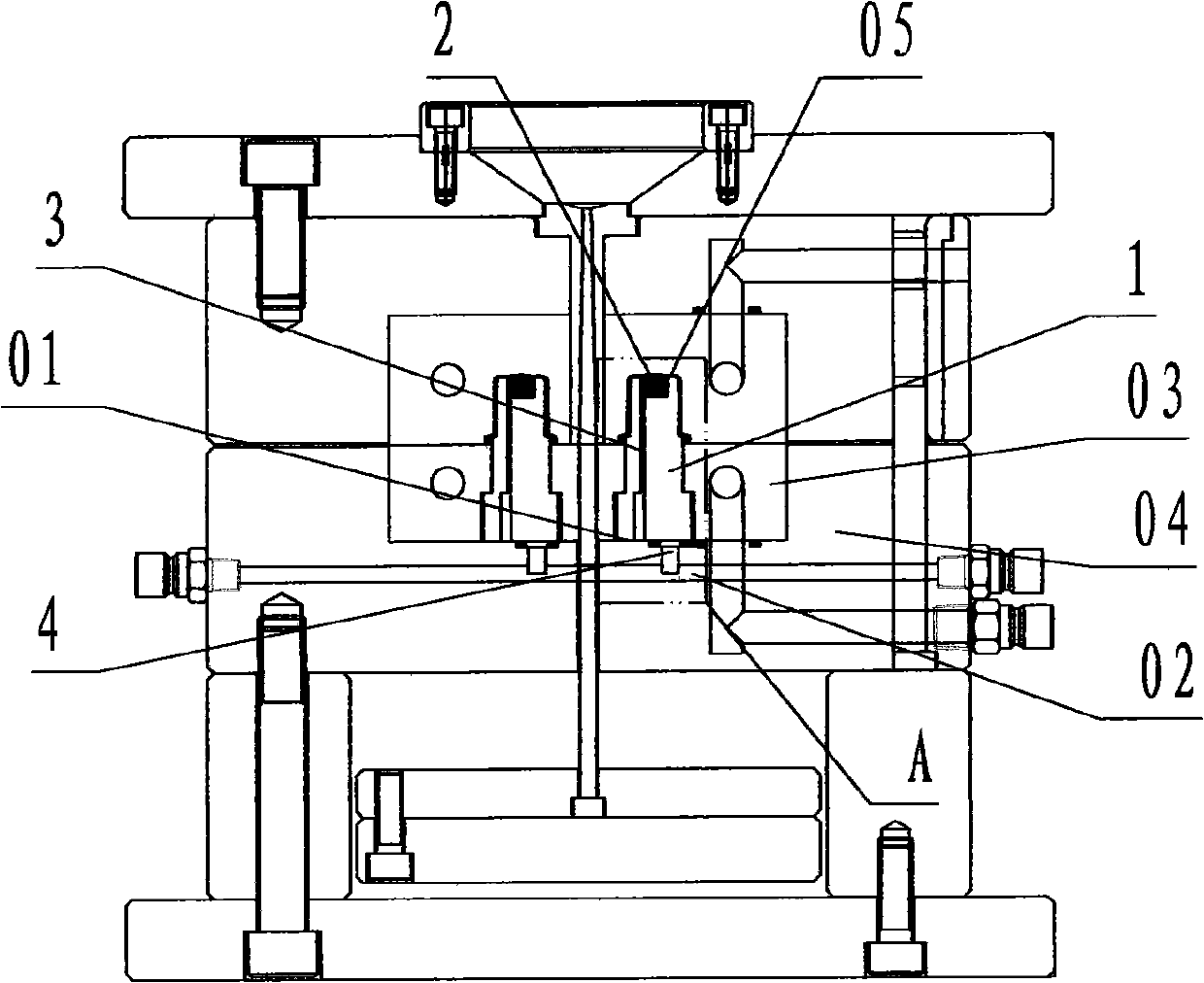

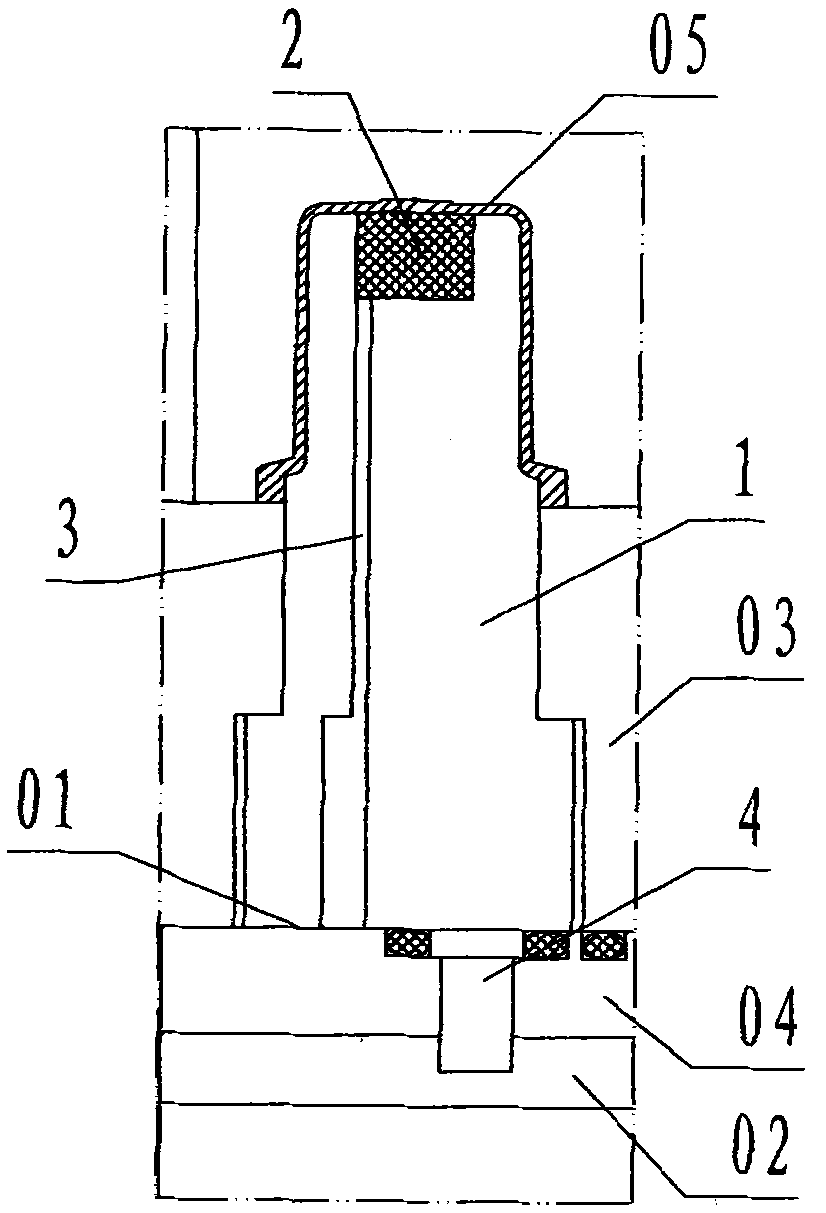

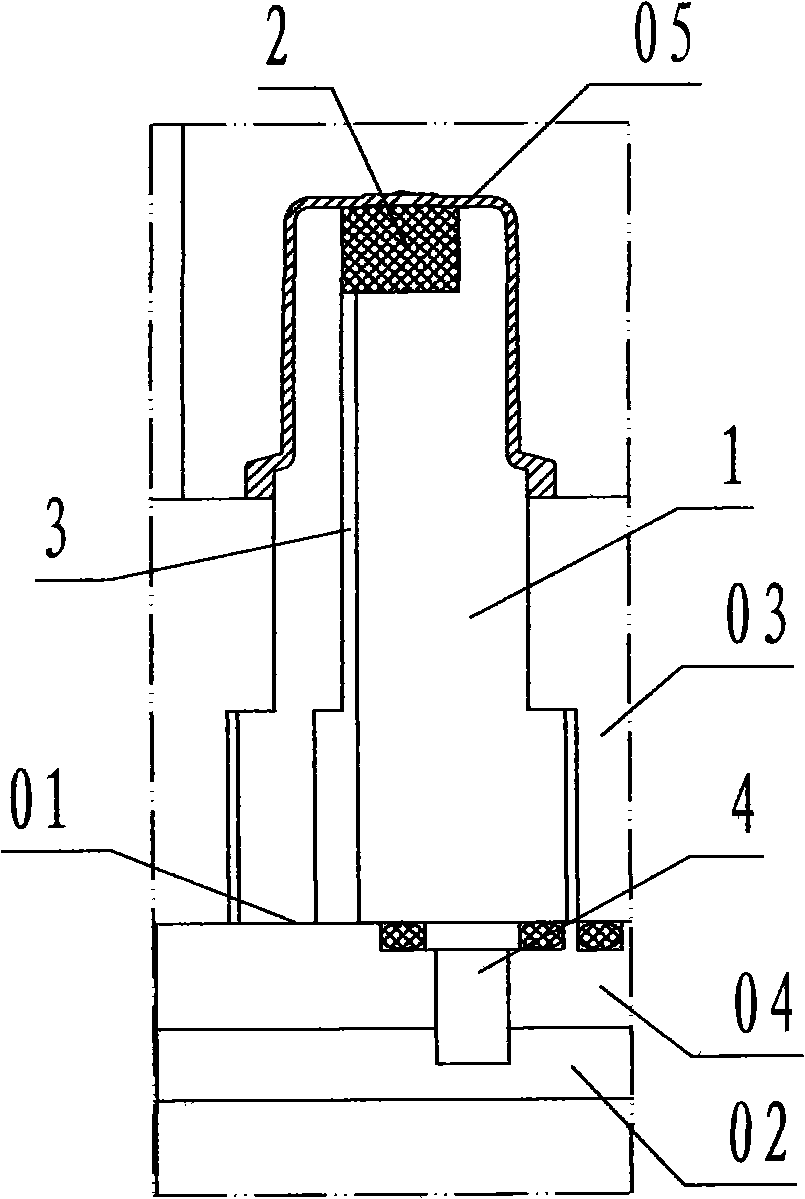

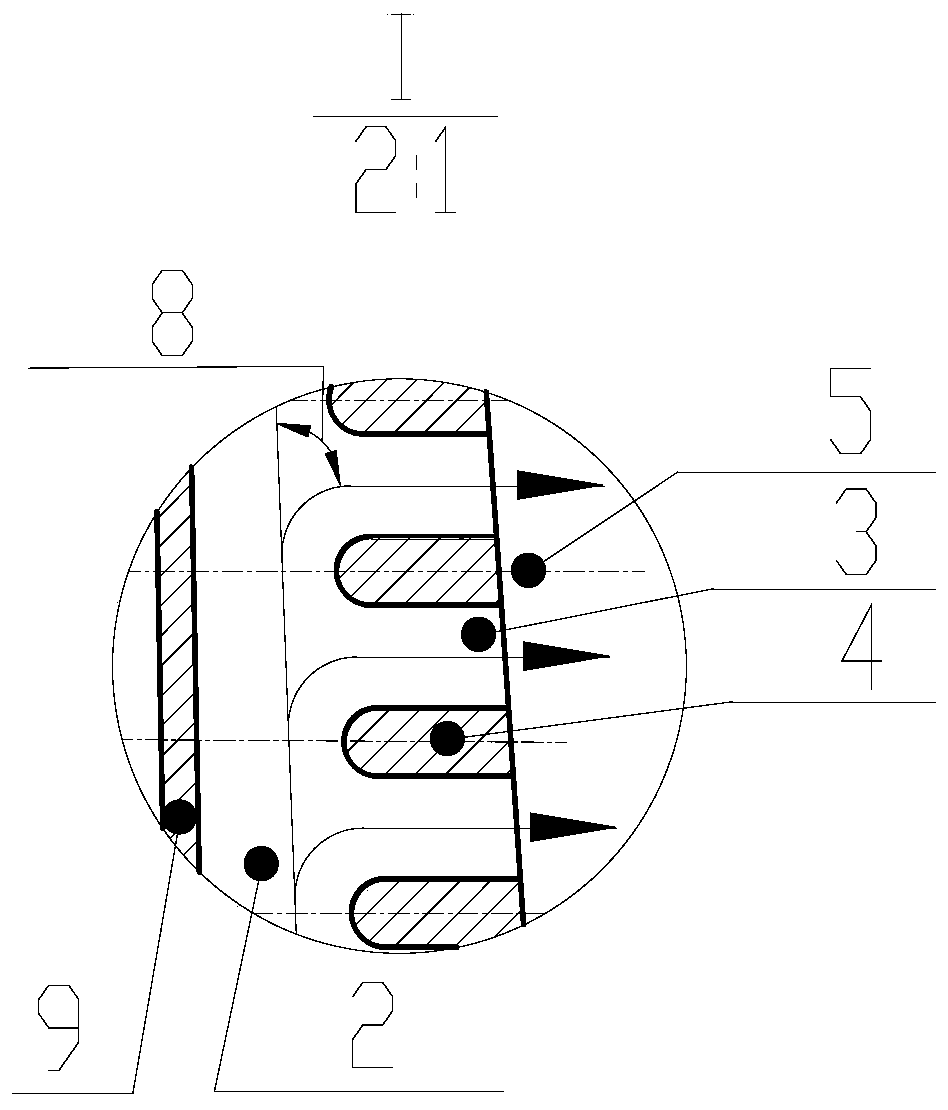

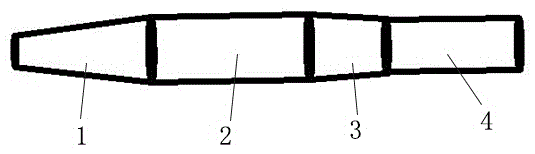

Injection mold core with air suction, discharge and rapid cooling functional structure

The invention provides an injection mold core with an air suction, discharge and rapid cooling functional structure. The injection mold core consists of a core body (1), a ventilated surface (2), an air suction and discharge channel (3) and a heat-conductive pin (4). In the injection mold core, the technical scheme that: the core body is made from a beryllium copper material with high heat conductivity; the ventilated surface which is made of porous ventilated steel is fixedly inlaid at the top of the core body; the air suction and discharge channel which is connected with a mold is reserved in the core body; and the heat-conductive pin which is directly inserted into a mold cooling water pipe is arranged at the bottom of the core body is adopted, so that the problems of low qualification rate, high cost and poor quality consistency of products in the molding of small-diameter deep-cavity injection products in the prior art are solved. The injection mold core with the air suction, discharge and rapid cooling functional structure provided by the invention fulfills the aims of improving the qualification rate, reducing the cost and ensuring the quality consistency of the products of the molding of the small-diameter deep-cavity injection products by increasing cooling rate and improving air suction and discharging conditions of the core body structurally.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

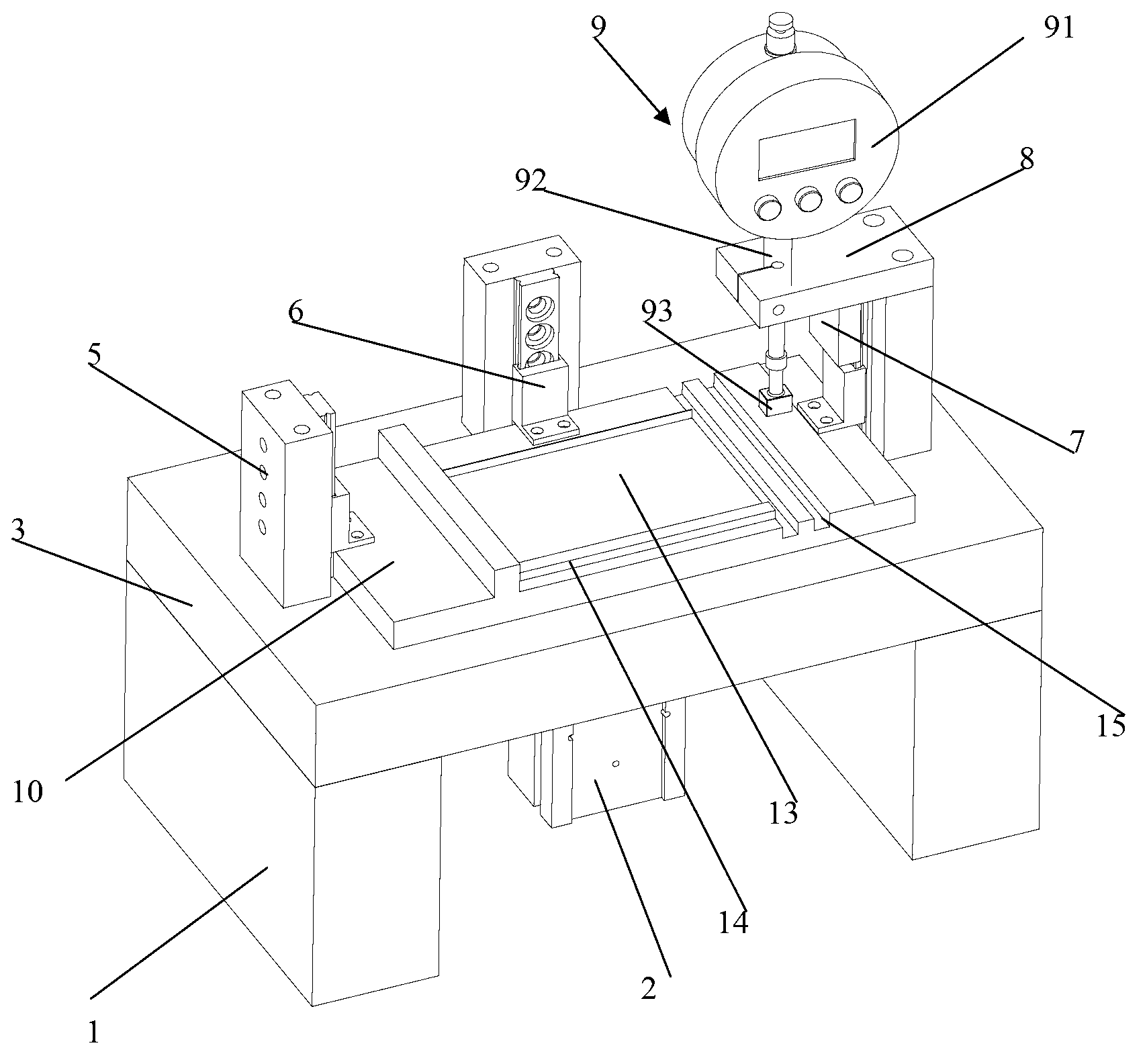

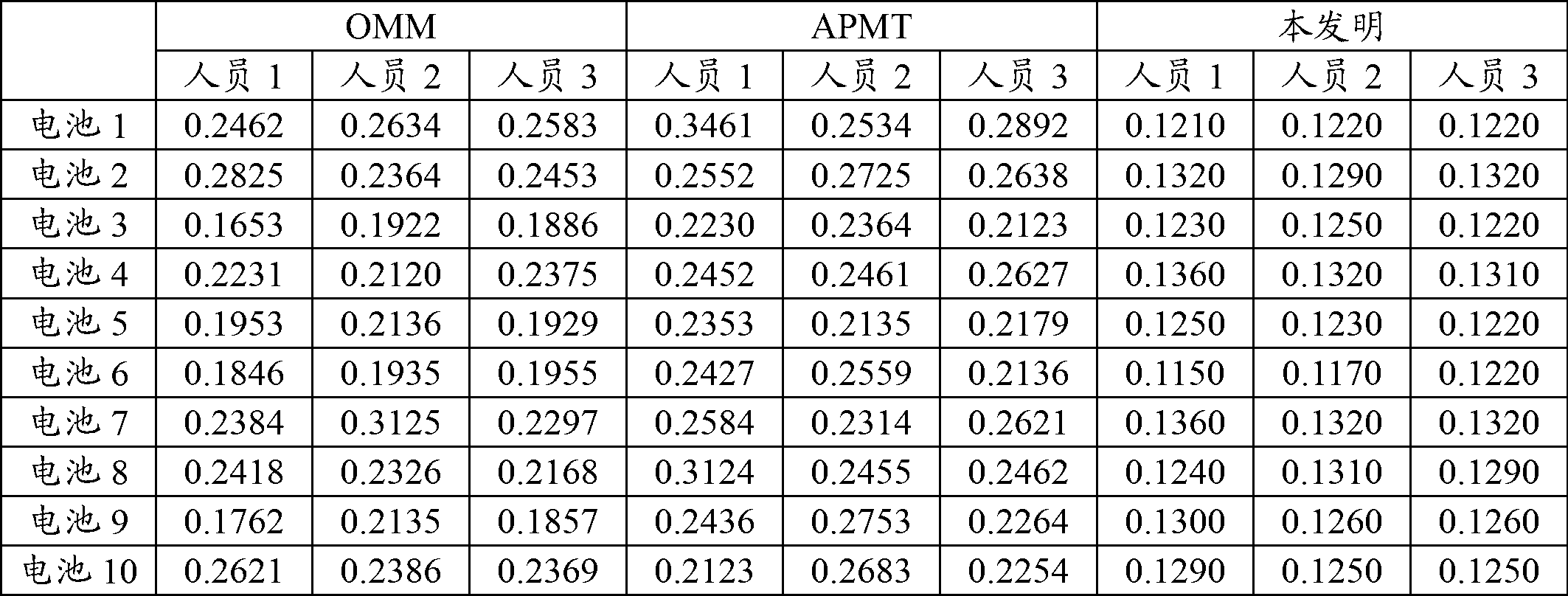

Device and method for measuring planeness of pole lug

ActiveCN103075950ASimple structureEasy to operateMechanical roughness/irregularity measurementsMeasurement deviceEngineering

The invention discloses a device for measuring the planeness of a pole lug. The device comprises a platform, a battery fixing plate and a digital display dial gauge, wherein the platform is supported by upright posts; the battery fixing plate can be driven to move up and down in the manner of being relative to the platform; the digital display dial gauge is fixedly arranged above the platform; the battery fixing plate comprises a horizontal loading plate, a U-shaped limit plate and a groove; the U-shaped limit plate is arranged on the horizontal loading plate; the groove is formed at the opening of the U-shaped limit plate and corresponds to a pole lug boss of a battery; the digital display dial gauge comprises a display screen, a measuring pole and a measuring block; the measuring pole is vertically arranged; the measuring block is fixedly connected with the measuring pole; and the width of the measuring block corresponds to the pole lug. The measuring device is simple in structure, convenient to operate and is particularly much lower than an optical instrument in cost, test is not affected by deflection, bending and warping of the pole lug, the accuracy is higher, and the speed is also much higher.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

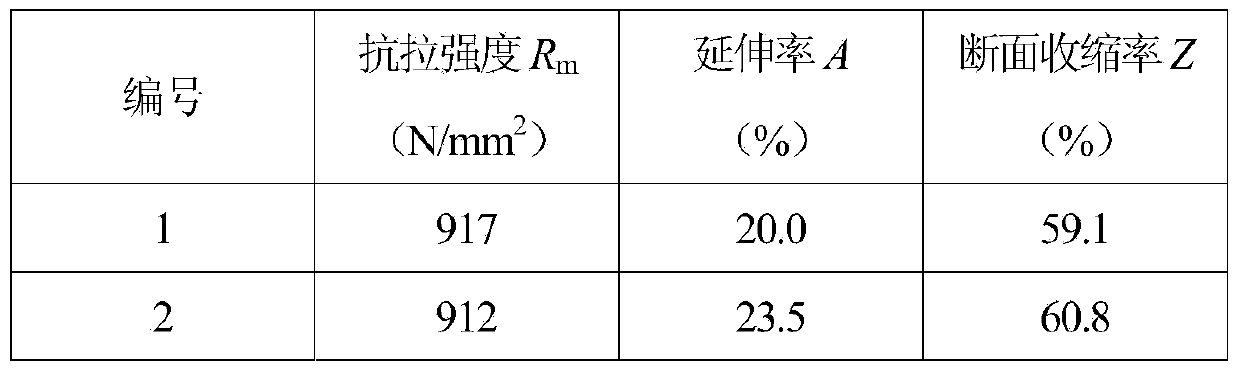

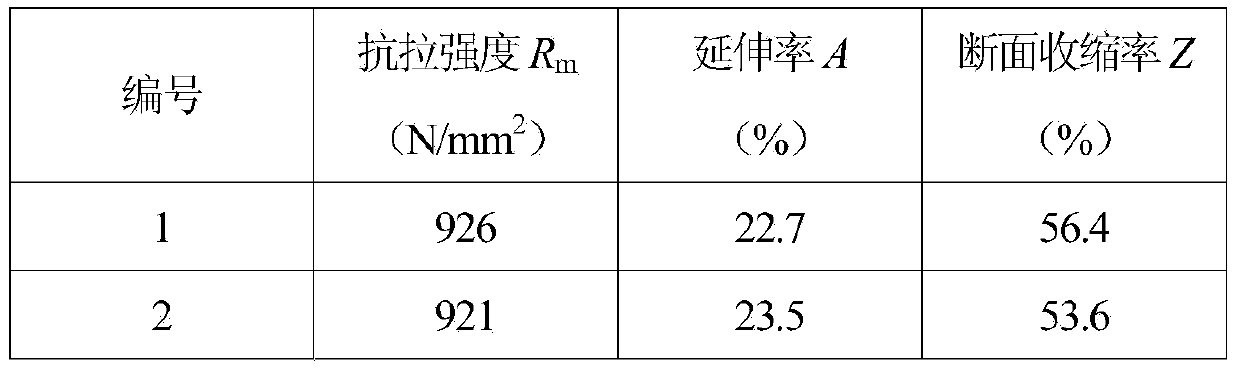

Preparation method of titanium alloy spring made of wire with specially-shaped section

The invention relates to a preparation method of a titanium alloy spring made of a wire with a specially-shaped section and belongs to the technical field of springs. The spring is formed by winding of the titanium alloy wire with the specially-shaped section; the titanium alloy wire comprises the components in percentage by mass as follows: 2-4 of Al, 6-10 of V, 4-8 of Cr, 2-6 of Mo, 2-6 of Zr, 0.1-0.3 of Fe, 0.03-0.15 of Si and the balance of Ti. The section of the titanium alloy spring wire can be rectangular, square, orthohexagonal or oval. The titanium alloy wire wound into the spring is prepared with forging, pressing and hot rolling technologies, the wire is subjected to solution treatment before being wound into the spring, and a finished product of the spring is subjected to aging and strengthening treatment. A titanium alloy which is used for preparing the spring can play a weight reduction role, and meanwhile, the titanium alloy has the good corrosion resistance and the long fatigue life in an ocean environment. With the adoption of the wire with the specially-shaped section, the section area can be increased under the condition that specifications of wires are similar, so that the rigidity of the spring is improved, and the usage requirement of the titanium alloy spring under the high workload can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

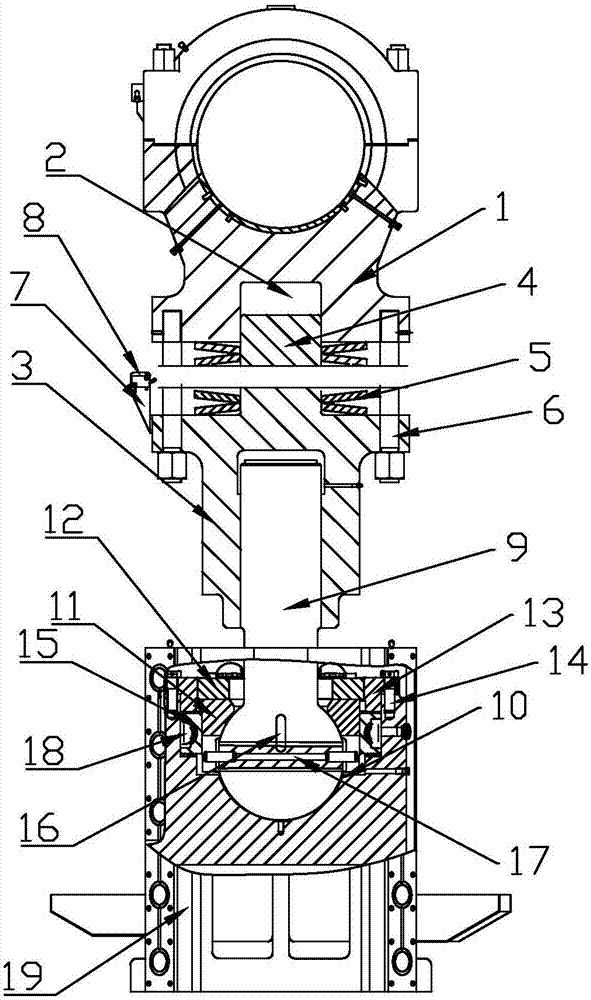

Mechanical press machine electromechanical overload protection and tensile device and method

ActiveCN106926511AImprove pass rateReduce manufacturing costPressesEnvironmental resistanceEngineering

The invention provides a mechanical press machine electromechanical overload protection and tensile device which comprises a press machine connection rod which is vertically arranged; and the bottom of the press machine connection rod is vertically provided with a blind hole, a guide rod is vertically arranged below the press machine connection rod, the top of the guide rod is provided with a movable rod matched with the blind hole, and the movable rod is movably installed in the blind hole. By the adoption of the above structure, the overload protection device is not arranged in a sliding block body any more, sliding block equipment does not need to be detached when being maintained and repaired after long-term use, maintenance and repairing operation is convenient, and the mechanical press machine electromechanical overload protection and tensile device has the advantages that the device is easy and reliable to install, unique in structure, safe and reliable, high in efficiency, low in cost, green and environmentally friendly, the service lives of a mechanical press machine and a die are prolonged, product forming quality is improved, and the like.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

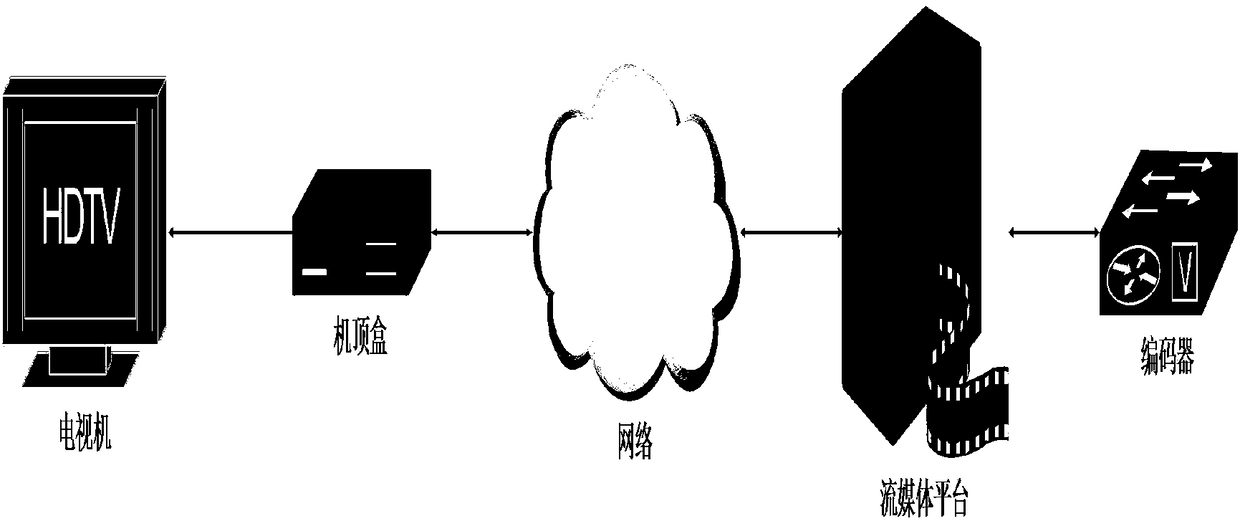

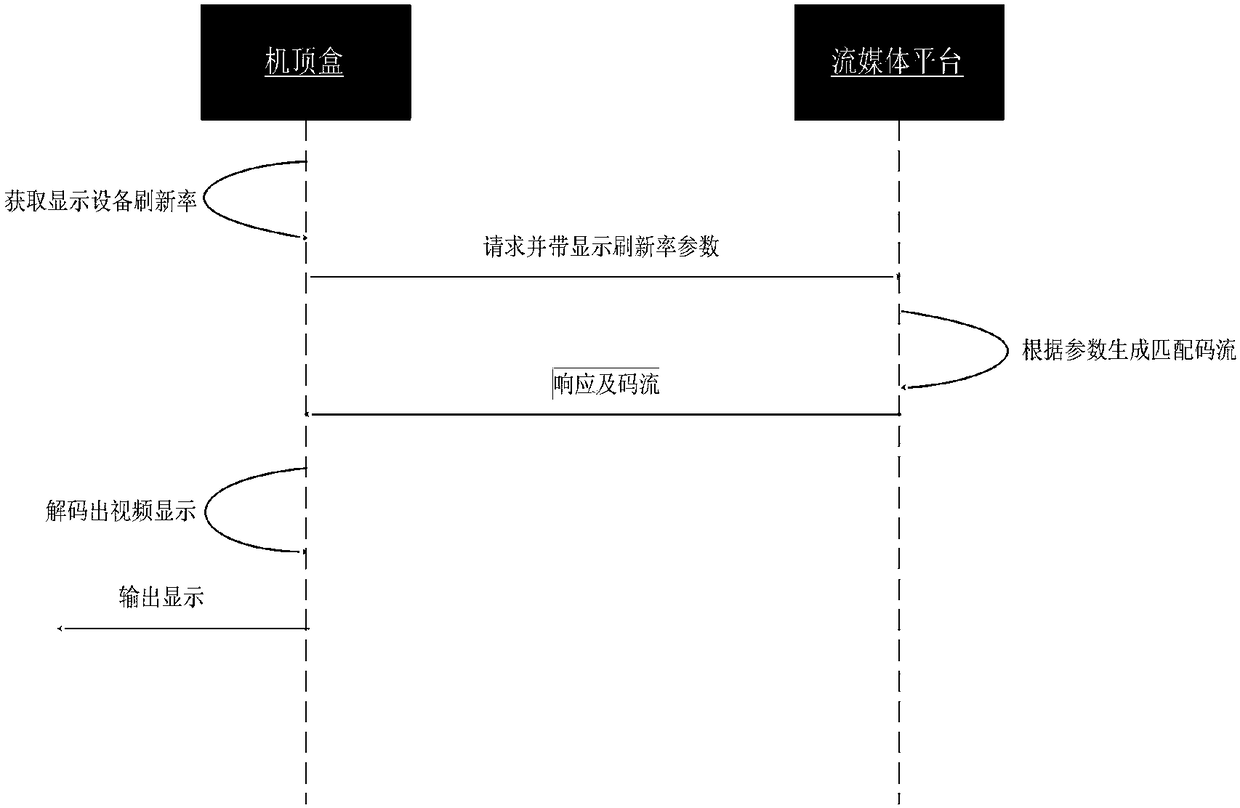

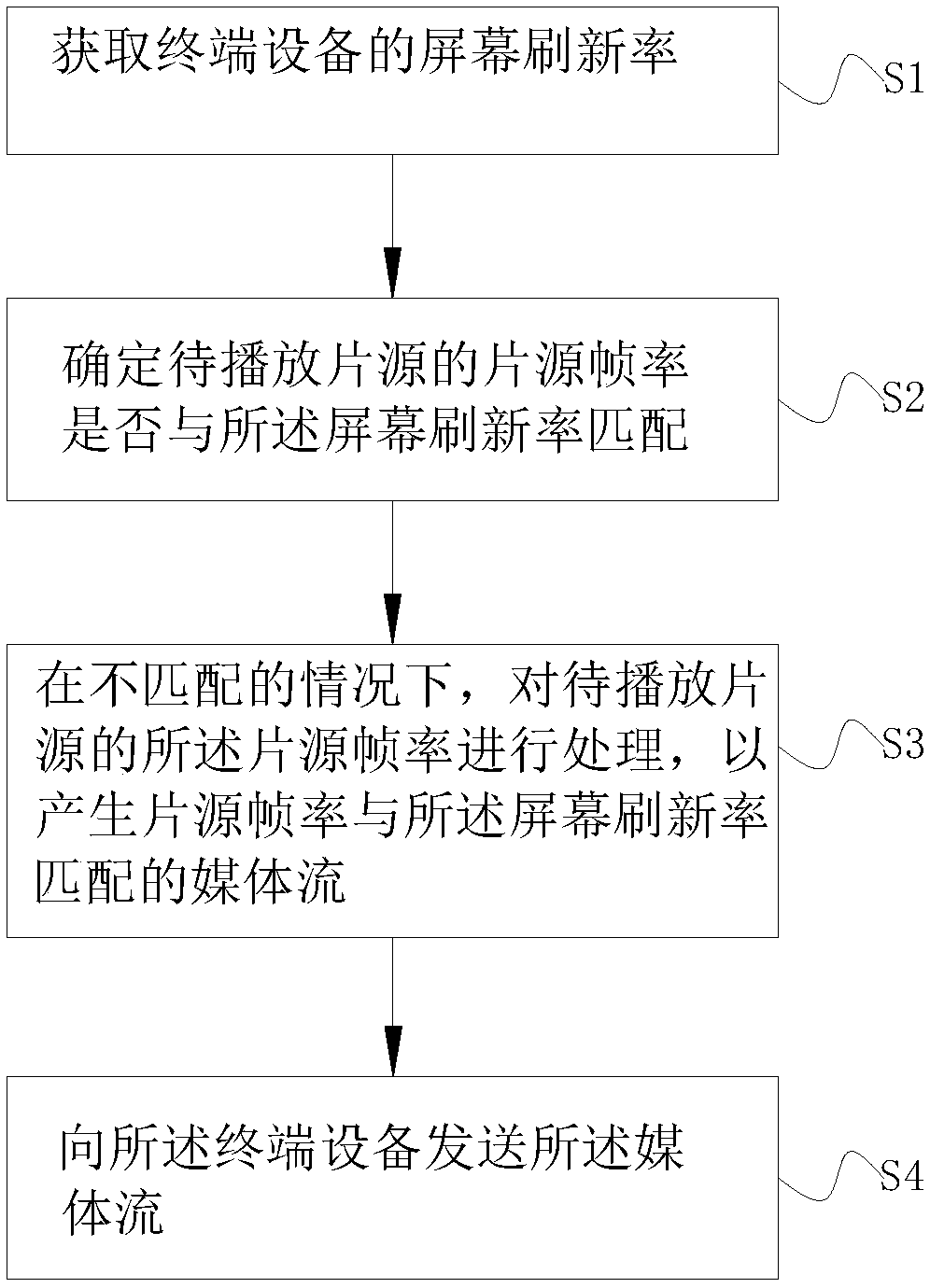

Video playing method and apparatus, computer equipment, and computer readable medium

InactiveCN108933952AWon't wasteData frame rate reductionSelective content distributionTerminal equipmentRefresh rate

The invention discloses a video playing method and apparatus, computer equipment, and a computer readable medium. The method includes steps: obtaining a screen refreshing rate of a terminal device; determining whether a film source frame rate of a to-be-played film source is matched with the screen refreshing rate; if not, processing the film source frame rate of the to-be-played film source to generate a medium stream whose the film source frame rate and the screen refreshing rate are matched; and transmitting the medium stream to the terminal device. According to the video method and apparatus, frame loss or frame insertion operation is performed on the film source frame rate of the to-be-played film source in a streaming media platform, and the screen frame rate and the film source refreshing rate of the to-be-played film source are matched so that the frame rate of the output media data is reduced, the transmission code rate is reduced, the bandwidth requirement is reduced, each frame interval of the decoded medium stream is large, the media stream is output and displayed, and the waste of bandwidth resources, decoding resources of set top boxes, and CPU resources due to frameloss is avoided.

Owner:ZTE CORP

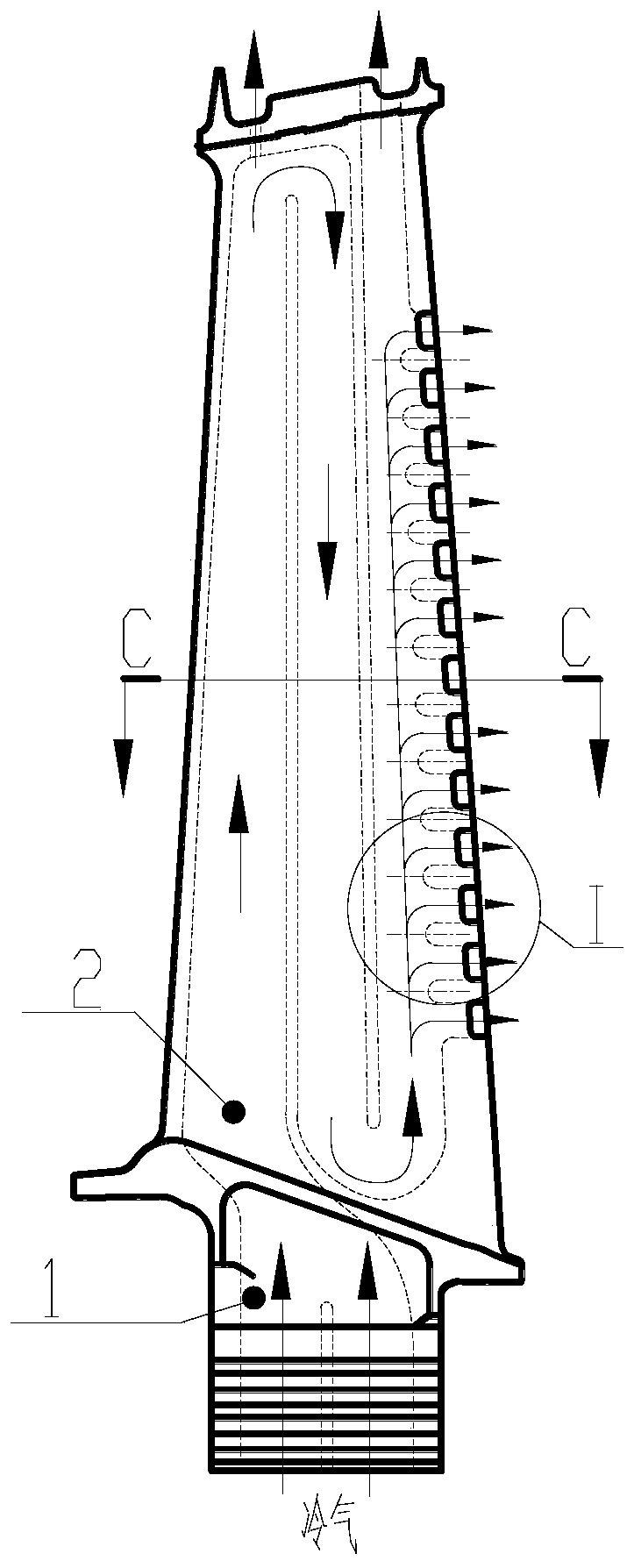

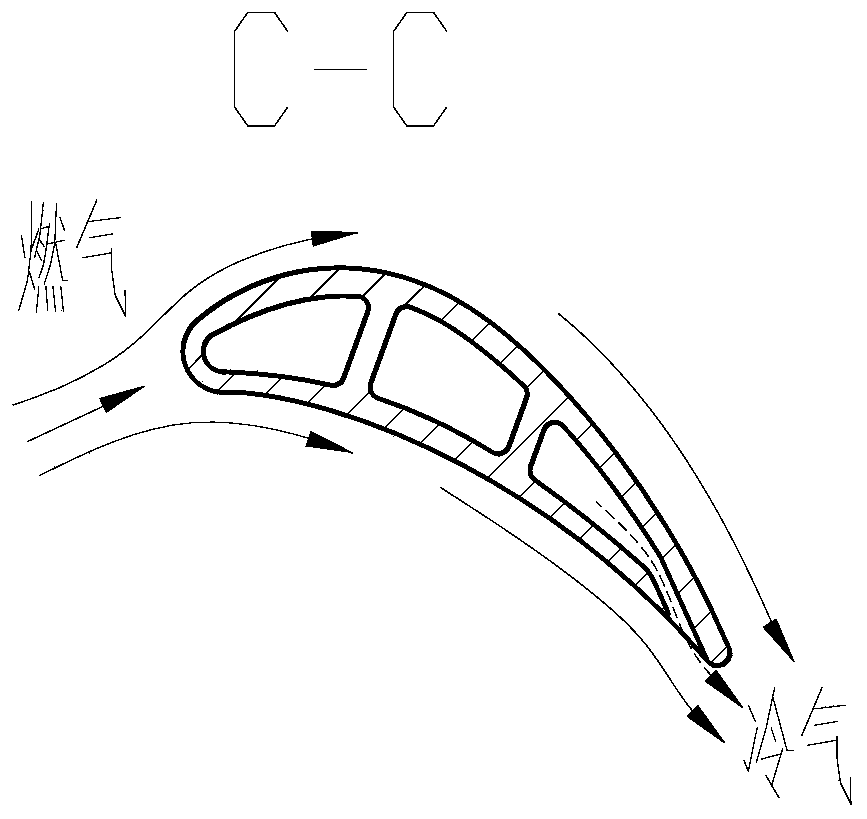

Tapered inclined exhaust splitting seam structure for turbine blade trailing edge

InactiveCN110925027AIncrease flow rateReduce blending lossBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a tapered inclined exhaust splitting seam structure for a turbine blade trailing edge. The inclined exhaustsplitting seam structure comprises a hollow turbine blade, an inner cavity cool air channel, a trailing edge exhaust splitting channel and trailing edge splitting seam partition ribs, wherein the inner cavity cool air channel is formed inside the hollow turbine blade, the trailing edge of the hollow turbine blade is provided with the trailing edge splitting seam partition ribs arranged side by side, and the trailing edge exhaust splitting seam channel is formed between the trailing edge splitting seam partition ribs arranged side by side for allowing cooling air to be discharged out of the blade and meanwhile carrying out air film coverage cooling on the blade trailing edge. According to tapered inclined exhaust splitting seam structure for the turbine blade trailing edge, the cool air canflow much smoothly, so that flow resistance and loss of the cool air in an cavity of the blade is reduced, and the flow resistance can be reduced by about 16%; and through designing an inclined exhaust trailing edge splitting seam into a tapered structure, the outflow speed of the cool air can be improved, internal convection heat exchange is strengthened, an air film coverage dead zone is reduced, in this way, comprehensive cooling effects of the blade trailing edge is further improved while blending loss is reduced, and heat exchange can be enhanced by about 8%.

Owner:DALIAN UNIV OF TECH

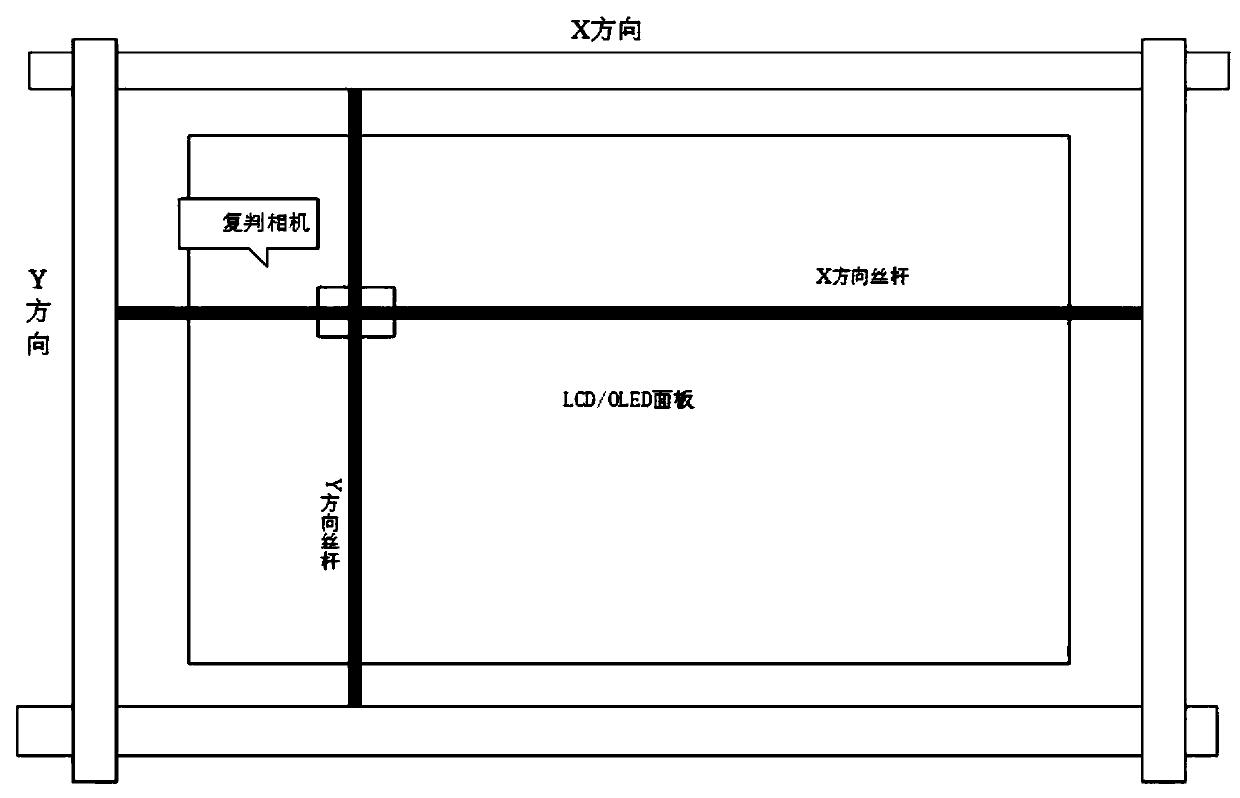

AOI (Automated Optical Inspection)-based display panel micro defect judgment method and device

InactiveCN109856156AAccurate classificationClass correct downgradeOptically investigating flaws/contaminationComputer scienceAutomated optical inspection

The invention belongs to the technical field of display defect detection and discloses an AOI (Automated Optical Inspection)-based display panel micro defect judgment method and device. According to the method and device of the invention, the position of a micro defect is detected through a large camera; secondary image acquisition is performed on the micro defect through a small camera; analysisprocessing is performed; and finally a defect type is outputted. With the method and device of the invention adopted, small defects can be accurately classified, and the correct degradation classification of panels can be realized.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

A reworking method on degraded products after the printing of crystal silicon solar battery

ActiveCN100505334CImprove pass rateImprove yieldFinal product manufactureSemiconductor devicesFailure rateSilver paste

The invention discloses a rework method of defective products of crystalline silicon solar cells after printing. The method includes the following three steps: an aluminum paste at the back surface of a cell is removed by using an HCl cleaning liquid; silver pastes at the positive and negative surfaces of the cell is removed by using isopropanol; the cell, the pastes of which is basically removed is treated with deep cleaning by using the deep cleaning liquid so as to thoroughly clean tiny impurities. The conversion efficiency of the cell can achieve the level of a normal cell by using the method for processing, and the appearance is not different from the normal cell, thus the invention achieves the purpose of rework cleaning. The failure rate of the silk screen printing of the cells is reduced to about 0.2 percent from original about 2 percent, thereby increasing the qualified rate and the yield of the silicon solar cells.

Owner:ZHEJIANG FORTUNE ENERGY

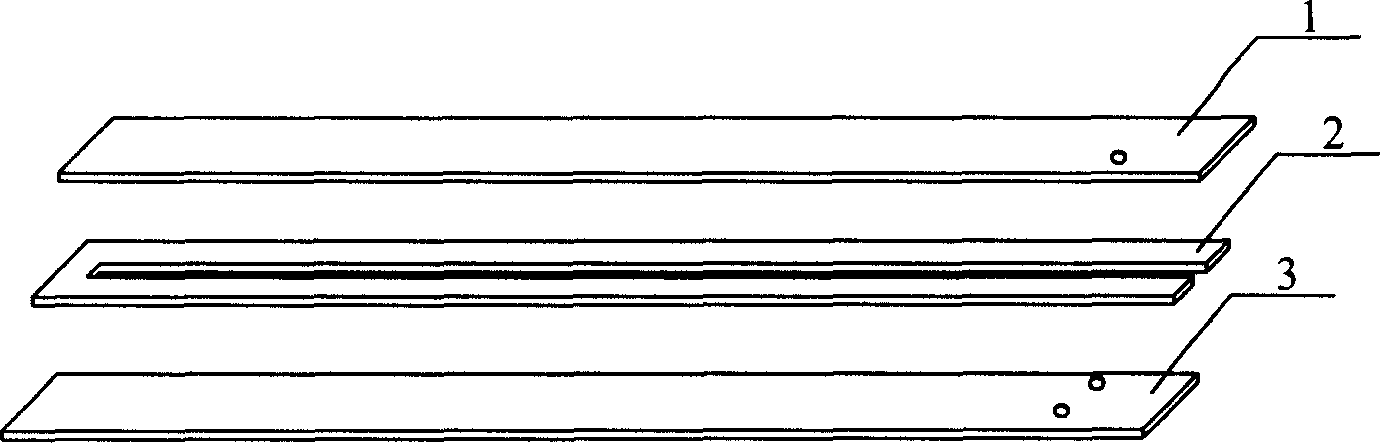

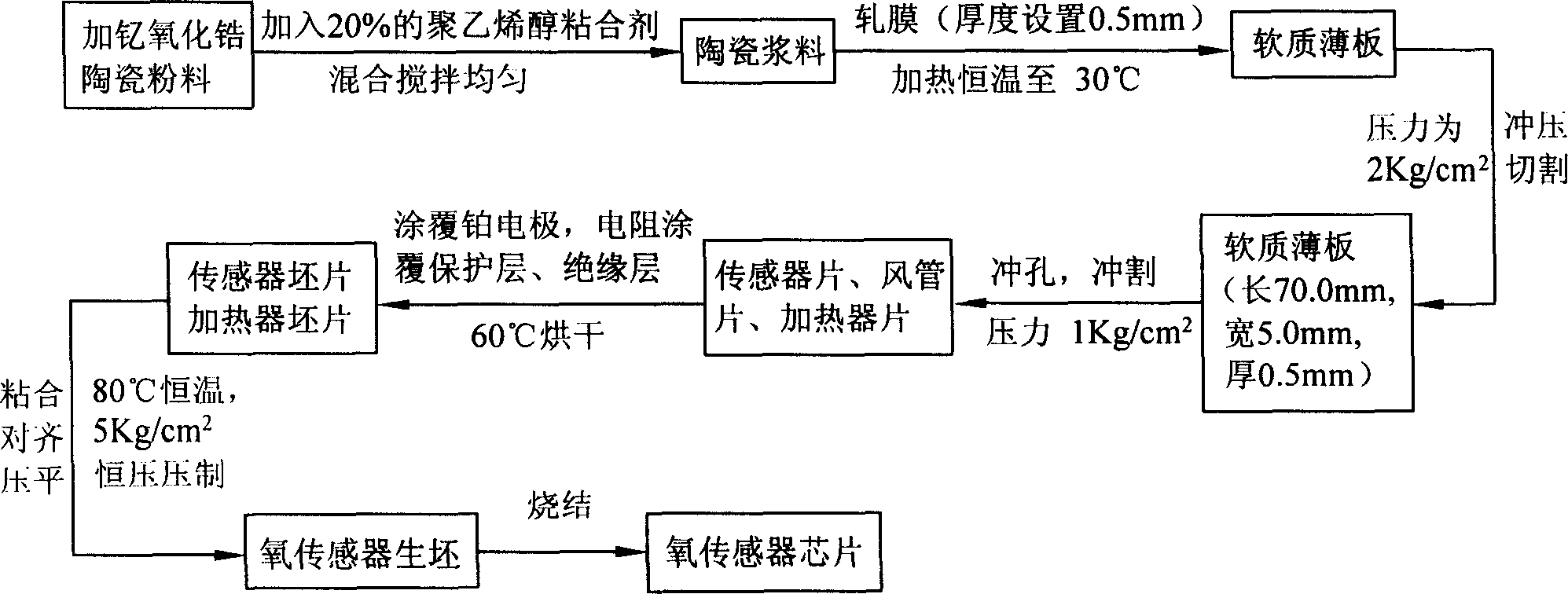

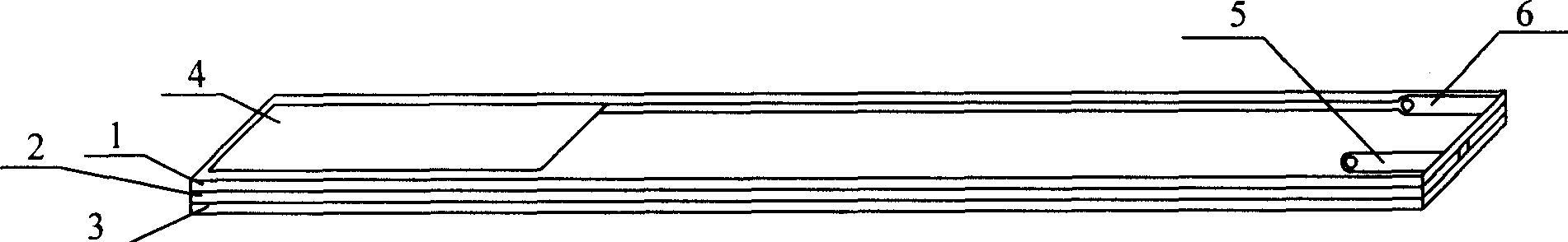

Method for fabricating sheet oxygen sensor

InactiveCN1865970AReduce pass rateSimple processMaterial analysis by electric/magnetic meansIn vehicleOxygen sensor

The disclosed manufacture method for a sheet-form oxygen sensor to control the air / fuel ratio in vehicle engine comprises: preparing slurry by Yb-added zirconia ceramic to obtain smooth thin plate by a rolling die, then using a punch to prepare thin slice, using a cutter to manufacture sensing slice, air-dust slice and heating slice; coating electrode on the sensing slice and heating resistance on heating slice, stitching three slices into sheet-form oxygen sensor, and finally, sintering at 1500Deg. This invention is simple and low cost, and has high one-time percent of pass.

Owner:SHANGHAI XINGHUA ARTWORK HANDWRITING&PAINTING ENGRAVING&PRINTING

Machining milling machine provided with overturning mechanism and machining method of machining milling machine

ActiveCN113182916AAuto slideReduce pass rateDriving apparatusMetal working apparatusMachine partsMachine

The invention relates to the technical field of milling machines, in particular to a machining milling machine provided with an overturning mechanism. The machining milling machine comprises a mounting frame, a power device, the overturning mechanism, a machining table, two fixing mechanisms, a tool seat and a length adjusting mechanism; the overturning mechanism is arranged in the middle of the lower end of the mounting frame; the machining table is arranged at the upper end of the overturning mechanism; the length adjusting mechanism is arranged in the middle of the lower end of the machining table; the two fixing mechanisms are symmetrically distributed on the two sides of the middle of the upper end of the machining table; the power device is arranged on the front side of the upper end of the mounting frame; and the tool seat is arranged in the middle of the lower end of the power device. The overturning mechanism is arranged to drive a machined part to be overturned to a designated angle, and thus the machined part automatically slides onto conveying equipment; the length adjusting mechanism is arranged, the length of the machining table is adjusted according to the length of the machined part, the contact area between the machining table and the machined part is large, and thus the machined part is stably supported and fixed. The invention further provides a machining method of the machining milling machine provided with the overturning mechanism.

Owner:沈阳大鹏重型设备科技有限公司

Double-glass assembly manufacturing method

InactiveCN105895739AAvoid prone to air bubblesAvoid displacement of cells on both sidesFinal product manufacturePhotovoltaic energy generationAdhesiveEngineering

The invention discloses a double-glass assembly manufacturing method, and the method comprises the steps: double-glass assembly laying, appearance inspection, EL testing, hot melting laminating, junction box installation, secondary EL testing, power testing, and finished product examination. The double-glass assembly laying specifically comprises the steps: firstly enabling a cut EVA glue film to be laid on bottom toughened glass; secondly enabling a required number of solar cells to be laid on the EVA glue film; thirdly enabling the plurality of cells to be connected in series through a bus bar to form a body; fourthly sequentially laying the EVA glue film and surface roughened glass on the solar cell string, and forming a solar double-glass assembly; and finally carrying out edge sealing through a high-temperature adhesive tape, and drilling. According to the invention, the high-temperature adhesive tape is used for fully pasting and sealing the periphery of the laid double-glass assembly, thereby effectively controlling the overflow quantity. The method greatly shortens the laminating time, and improves the production efficiency.

Owner:JIANGSU LINYANG PHOTOVOLTAIC TECH

Foamed glass ceramic material for wall and its production process

InactiveCN1389417AImprove performanceImprove mechanical propertiesConstruction materialCeramic materials productionMetallurgyGlass-ceramic

The present invention discloses a nucleated foamed glass wall body material, which is characterized byt aht its composition contains glass powder whose grain size d(0.9) is less than 130 meshes, flyash whose grain size d(0.9) is les than 120 meshes and non-metallic mineral powder whose grain size d(0.9) is less than 230 meshes. Its preparation method includes: grinding glass powder, flyash and non-metallic mineral powder, adding water and mixing them, under the condition of containing water content pressing and forming, drying and kilning, cutting blank and forming to obtain the invented product. It is suitable for industrial production.

Owner:NANJING UNIV +1

Mechanical processing method for dry cylinder liners

InactiveCN103769821AReduce weightReduce processing stepsCylinder headsCylindersEngineeringWater jacket

The invention discloses a mechanical processing method for dry cylinder liners. The method comprises the steps: shot blasting before a rough boring process to remove a coating layer and sundries from an external surface, so as to enable the external surface of a cylinder liner blank to be smooth and clean; during rough boring, locating by using a belt of a cylinder liner and the excircle blank surface of a water jacket part, so as to enable a three-point self-centering clamp to locate and clamp the blank excircle of the cylinder liner, and difference in the inner hole wall of the cylinder liner to be controlled within 0.5 mm. The method is adopted to process the dry cylinder liner, the blank weight of the cylinder liner can be reduced by more than 15%, three machining processes are eliminated on the basis of the original process, quality of the shoulder, the excircle and the inner hole of the cylinder liner can be effectively controlled, the passing rate of finished products of cylinder liners is improved to more than 90% from less than 85%, and the manufacturing cost of dry cylinder liners is reduced.

Owner:江苏爱吉斯海珠机械有限公司

Glaze for glazing sanitary ceramic toilet bowl pipeline wet blank

ActiveCN106186688AImprovement of glaze whitenessImprove per capita efficiencyPotassium feldsparCalcite

The invention discloses glaze for glazing a sanitary ceramic toilet bowl pipeline wet blank. The glaze is prepared from, by weight, 27-30 parts of quartz, 25-28 parts of potassium feldspar, 14-16 parts of calcite, 4-5 parts of dolomite, 3-4 parts of zinc oxide, 2-3 parts of aluminum oxide, 3-4 parts of kaolin and 14-16 parts of zirconium silicate. The glaze can be directly applied to the toilet bowl pipeline wet blank to achieve the applying effect of a common glaze material on a dry blank.

Owner:JOMOO KITCHEN & BATHROOM

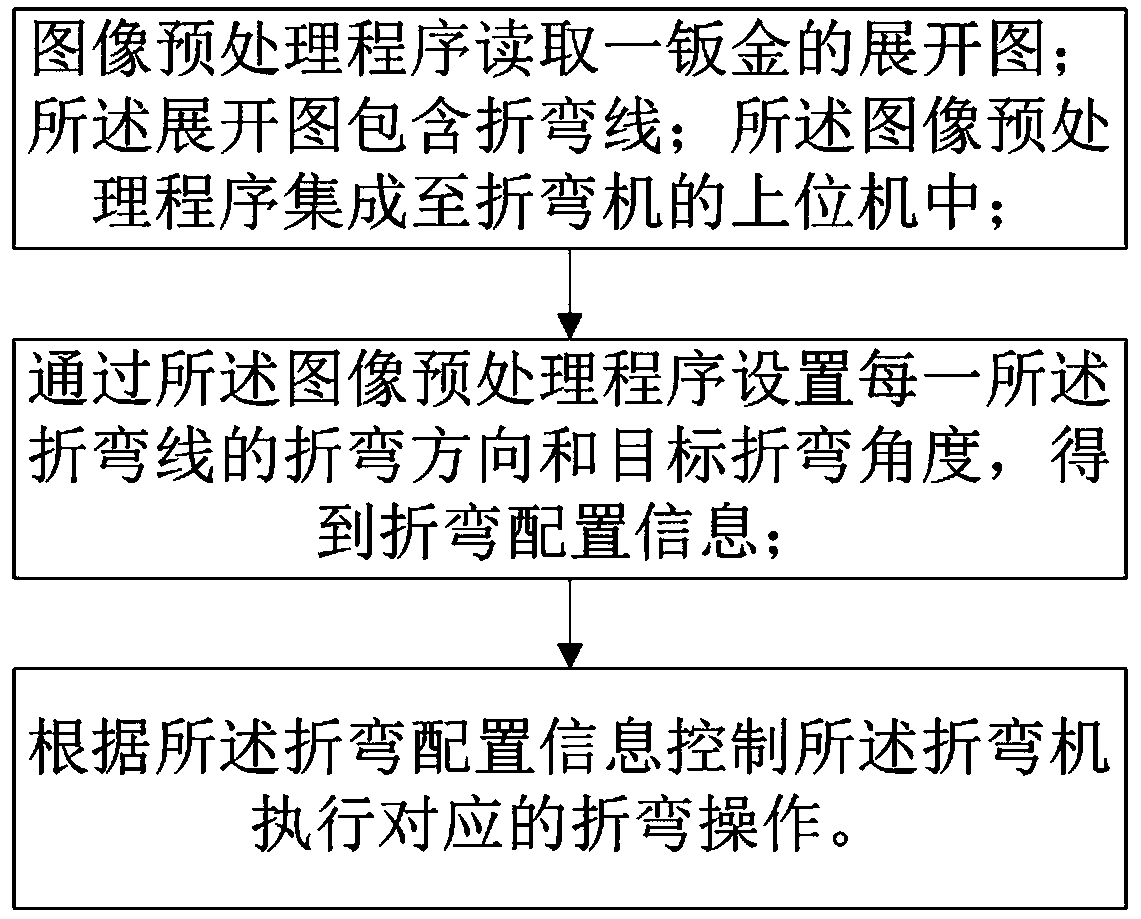

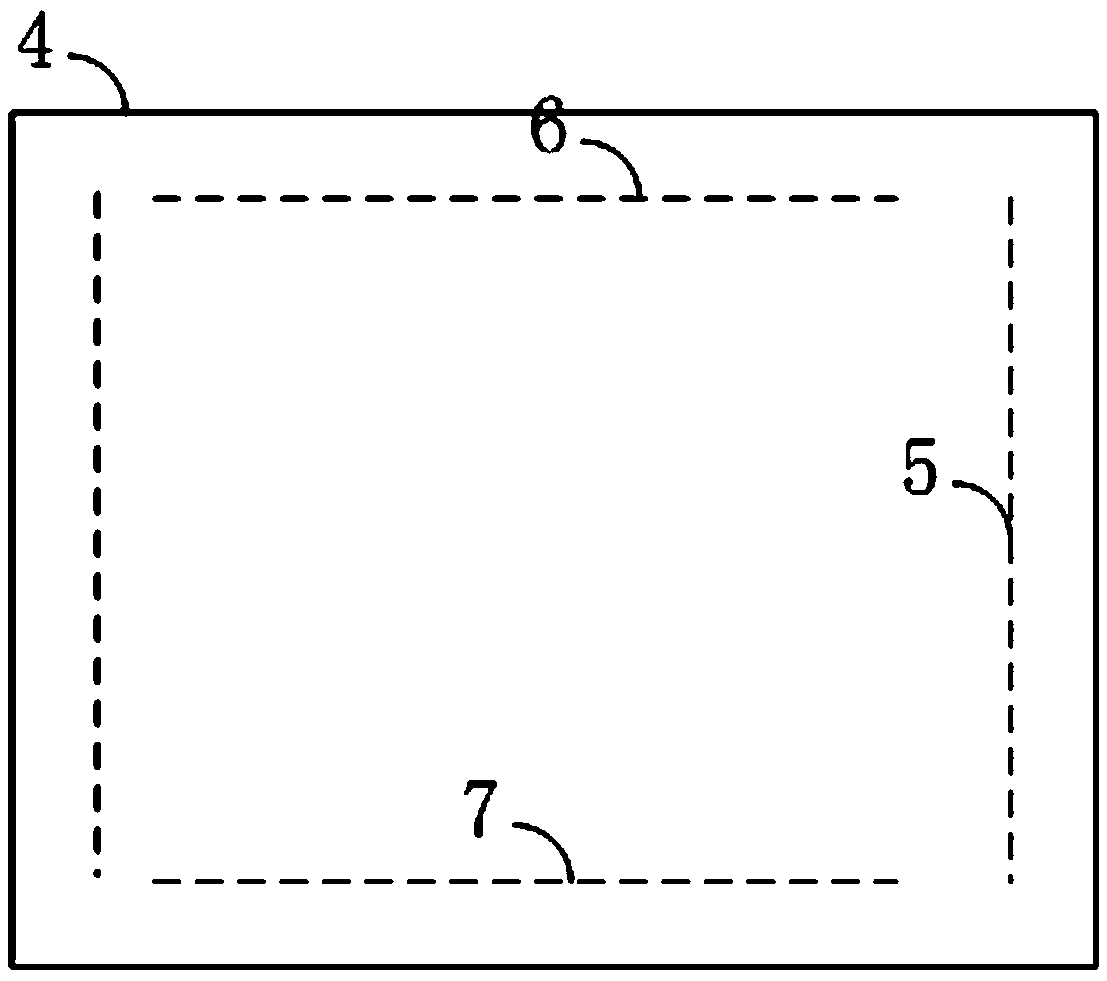

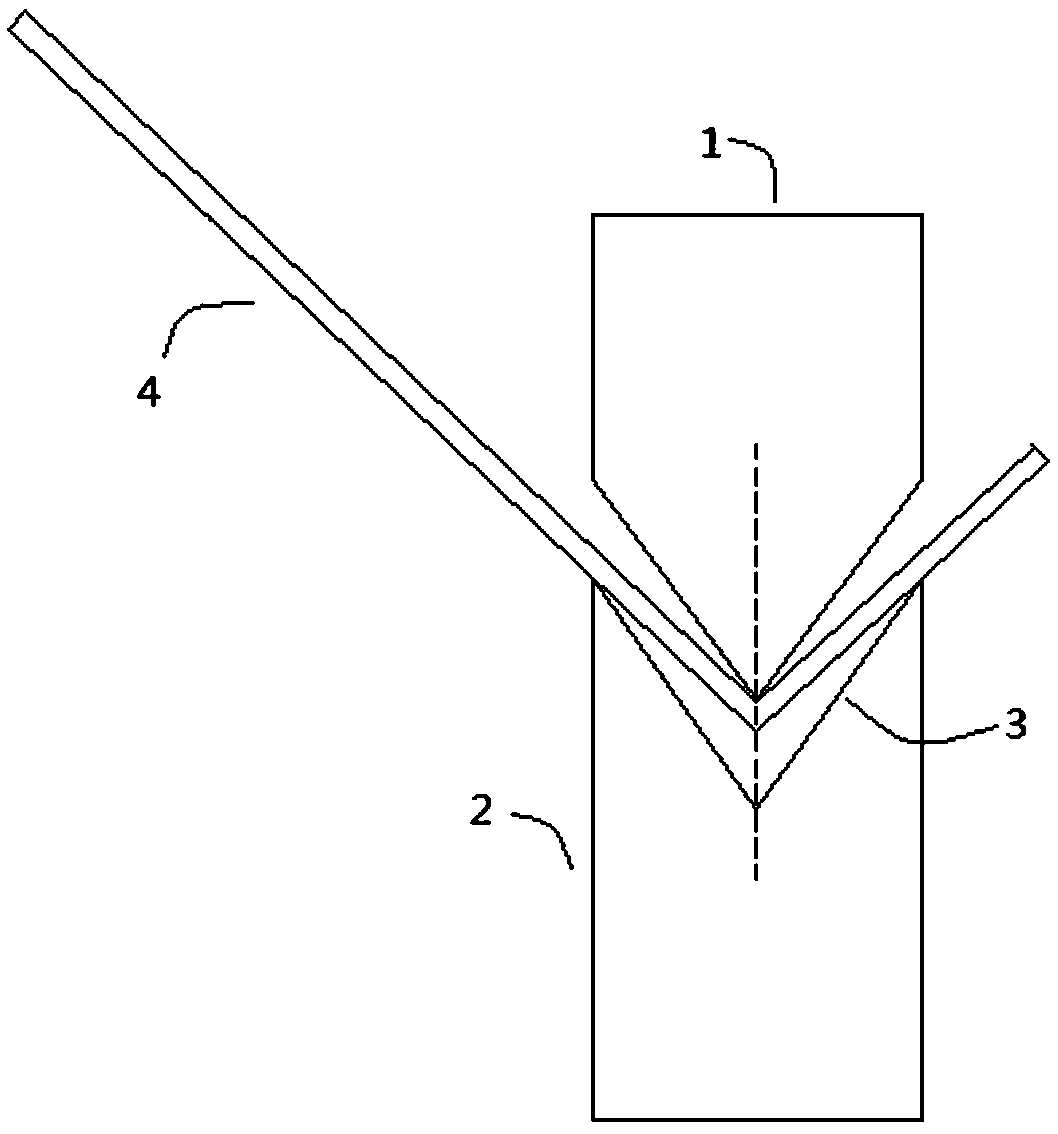

Metal plate bending method and terminal

ActiveCN109590357ALow costImprove efficiencyMetal-working feeding devicesMetal working apparatusEngineeringRead through

The invention relates to a metal plate bending method and terminal and belongs to the field of industrial automation. The metal plate bending method comprises the steps that an expanded view of a metal plate is read through an image preprocessing program, wherein the expanded view comprises bending lines, and the image preprocessing program is integrated into an upper computer of a bending machine; the bending direction and the target bending angle of each bending line are set through the image preprocessing program, so that bending configuration information is obtained; and the bending machine is controlled to implement corresponding bending operation through the bending configuration information. By means of the metal plate bending method, the bending production efficiency of the metal plate is improved, and the production cost is lowered.

Owner:福建渃博特自动化设备有限公司

Forging forming technology of lifting hook

InactiveCN104972038AImprove securityLow uniformityMetal-working apparatusHooksEngineeringEnergy consumption

The invention discloses a forging forming technology of a lifting hook. The technology includes the following steps that S1, round steel with a preset diameter is selected and is cut according to a preset length; S2, by means of an integral open die forging moulding bed and an open die forging hydraulic machine, the round steel cut in the S1 is drawn into variable-diameter round steel of the preset size; S3, a lifting hook bending machine is used for bending the variable-diameter round steel drawn in the S2 and manufacturing the variable-diameter round steel into a lifting hook blank meeting requirements; S4, by means of a die forging pressure machine and a forming forging die, the lifting hook blank in the S3 is forged into the lifting hook; S5, by means of the pressure machine and a trimming die, the lifting hook formed in the S4 is trimmed, and a finished lifting hook blank is obtained. By means of the forging forming technology, safety performance is greatly improved, production efficiency is greatly improved, manufactured drawn blanks are good in uniformity, the percent of pass is high, energy consumption is reduced, and efficiency is improved.

Owner:刘娜

Silicon rubber internal release agent and preparation method thereof

The invention discloses a silicon rubber internal release agent and a preparation method thereof. The main component of the silicon rubber internal release agent is polydimethyl-methyl trifluoropropyl silicone oil, due to very low surface tension and excellent thermal stability of the polydimethyl-methyl trifluoropropyl silicone oil, the prepared silicon rubber internal release agent can be applied in a harsh temperature environment, has high safety, and is nonirritating and harmless. The silicon rubber internal release agent provided by the invention has the advantages of stable chemical properties, easy dispersion, low adding proportion and the like. When the silicon rubber internal release agent is used for preparation of uniform films and complex-shaped objects, formed products with accurate size and high qualified rate can be obtained.

Owner:安徽东爵有机硅有限公司

Cleaning agent for solar energy monocrystalline silicon wafer

ActiveCN103710179AReduce corrosionIncrease acid and alkali consumptionSurface-active non-soap compounds and soap mixture detergentsPotassium hydroxideCleansing Agents

The invention discloses a cleaning agent for a solar energy monocrystalline silicon wafer. The cleaning agent comprises the following components of potassium hydroxide, a surfactant, a penetrating agent and a chelating agent. The cleaning agent has a good cleaning effect for the monocrystalline silicon wafer and is low in use cost. Compared with other silicon wafer-cleaning agents, the cleaning agent provided by the invention can simplify a cleaning process, does not pollute the environment and has no harm to human health.

Owner:长沙艾森设备维护技术有限公司

Rubber adhesive strip for shoes and preparation method thereof

InactiveCN102382598AEffective bondingAdhesivelyNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a rubber adhesive strip for shoes. For the rubber adhesive strip, natural rubber, butadiene styrene rubber, accelerating agent M, accelerating agent DM, accelerating agent TMTD, sulphur, solid ancient malone, anti-aging agent BLE-C, argil, zinc oxide, stearic acid, machine oil, calcium carbonate, carbon black N330, scorch retarder CTP and salicylic acid are selected, and the rubber strip meeting the standard requirement is formed by dicing, plastifying, roling, plastifying again, rolling again, rubber refining, wingding and dividing. The rubber strip disclosed by the invention is adhered on the periphery of a dried sponge innersole coated with natural rubber glue, a dried upper with upper corners brushed with the natural rubber glue is sleeved on a shoe tree, and the sponge innersole adhered with the rubber adhesive strip is placed at the bottom of the shoe tree and pulled by hand or machine to be adhered with the upper. With the adoption of the rubber adhesive strip, a polyester filament yarn upper can be effectively and firmly adhered with the sponge innersole, and the percent of pass of the finished shoes can reach more than 99%.

Owner:QINHUANGDAO JIHUA 3544 SHOES

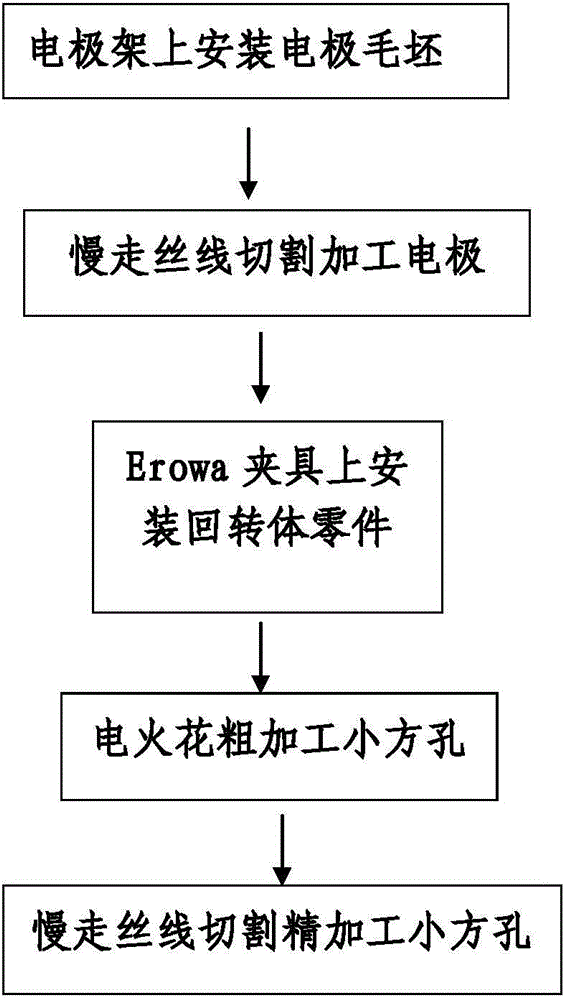

Machining method for radial high-precision small square holes of rotary part

ActiveCN105643032ASimple processReduce manufacturing costElectrical-based machining electrodesOther manufacturing equipments/toolsElectric dischargeWire cutting

The invention discloses a machining method for radial high-precision small square holes of a rotary part. The machining range is 0.3-3.0 mm, the machining thickness is less than 1.5 mm, the root Rmax is 0.08, and the radial coplanarity degree of the opposite holes is within 0.01 mm. According to the machining method for the radial high-precision small square holes of the rotary part, on the basis of machining the small square holes through traditional electric spark forming, the small square holes are machined roughly on an electric discharge machining machine tool through an EROWA fixture and a homemade electrode stand to reserve margins for finish machining; by using the characteristics and advantages of machining the workpiece through the EROWA fixture and slow speed wire cutting, slow speed wire cutting is added into the finish machining process for the small square holes, accordingly, the purpose that the radial coplanarity degree of the opposite holes is within 0.01 mm is achieved, and the small square holes are regular in shape. Compared with a traditional machining method, the machining method for the radial high-precision small square holes of the rotary part is high in efficiency and stable in quality, and the qualified rate reaches 99% or higher.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

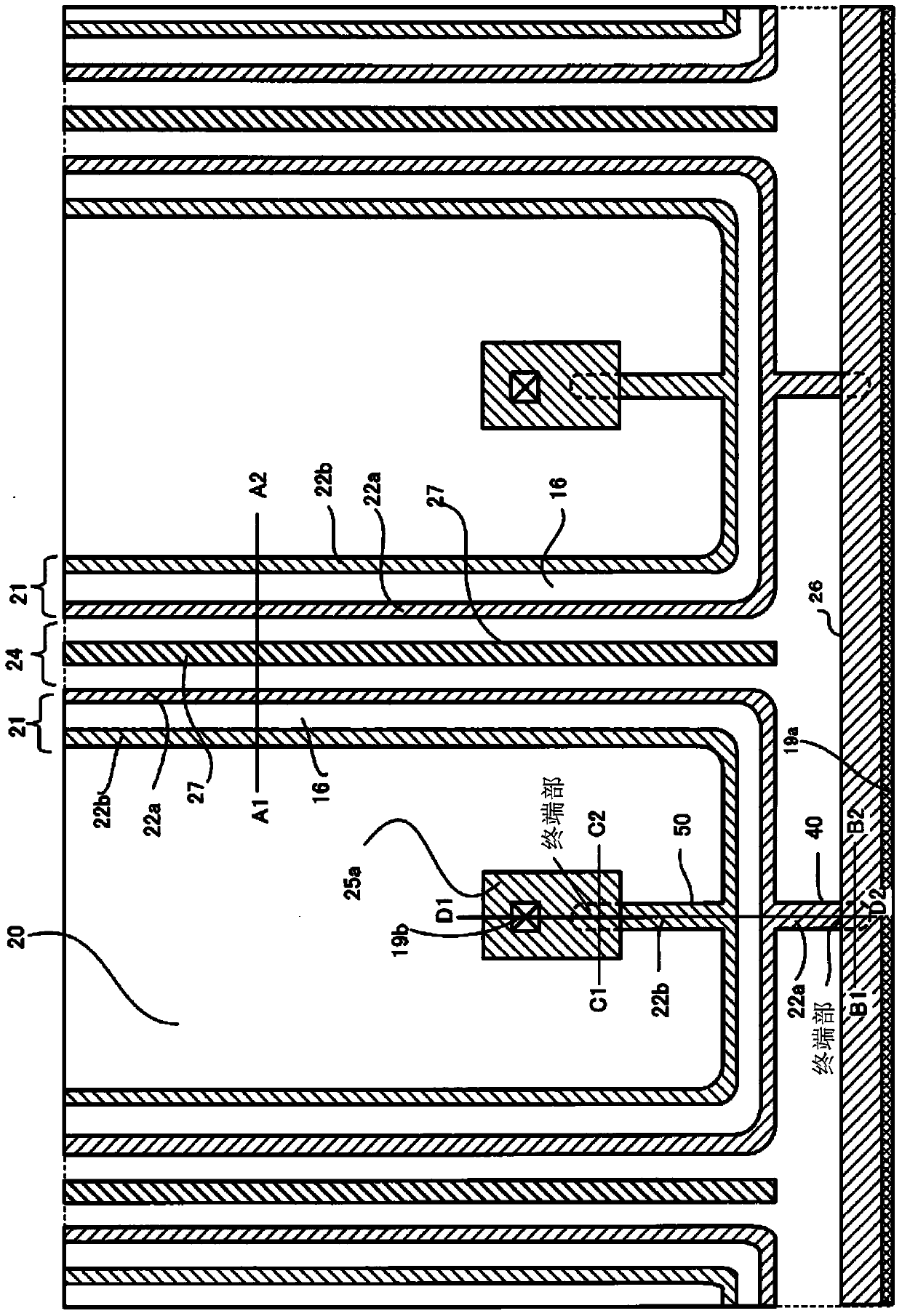

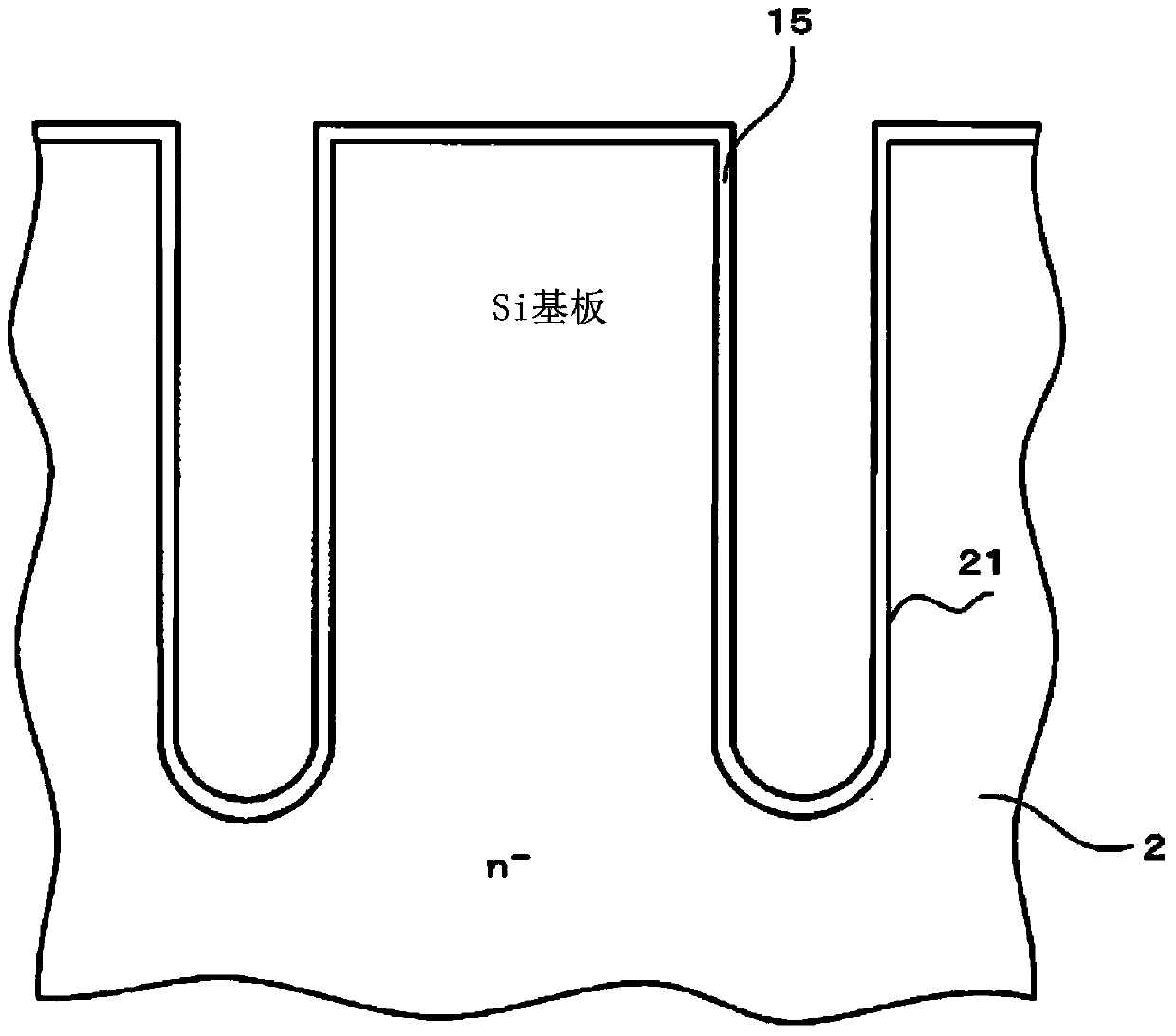

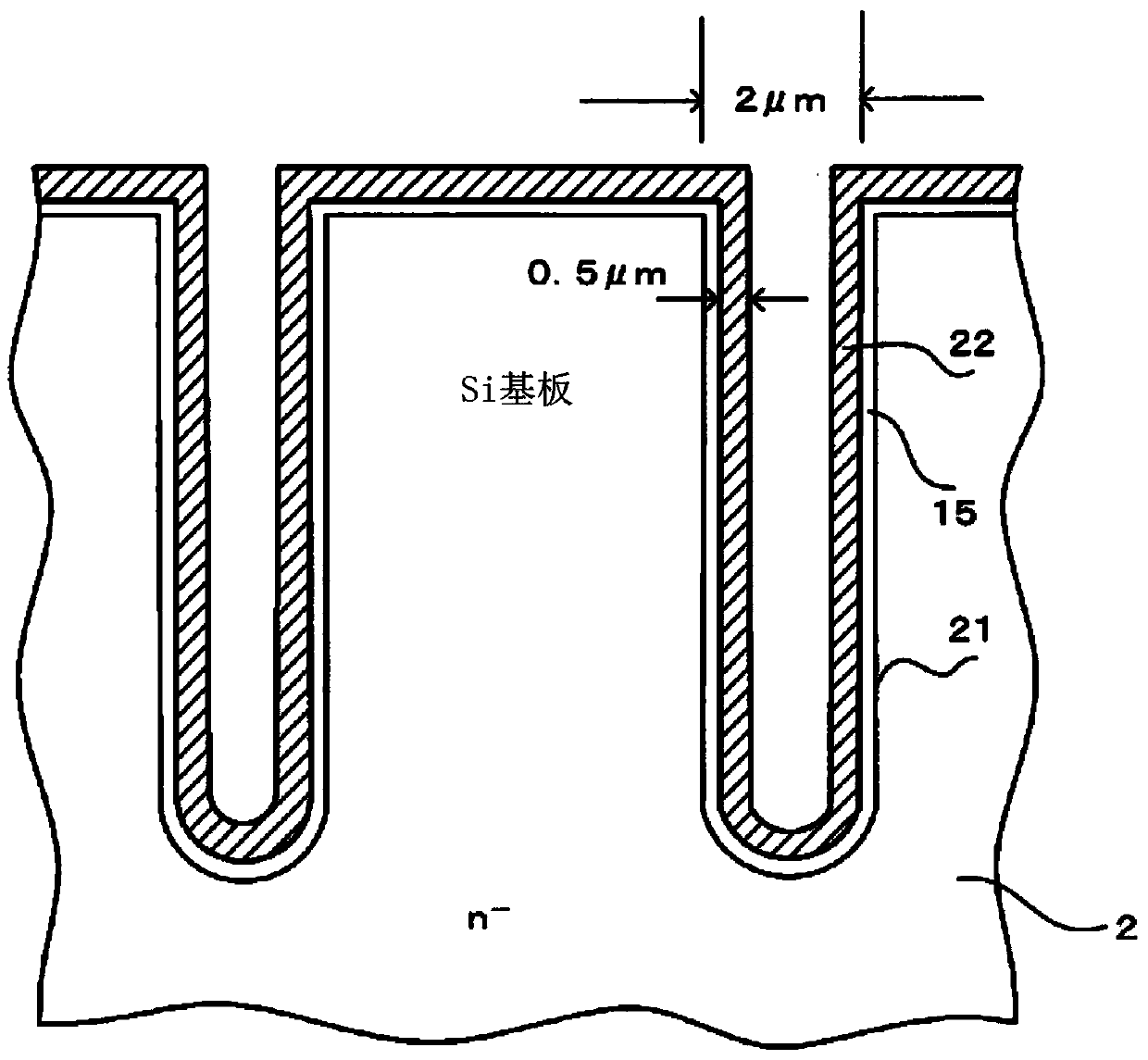

Semiconductor device

ActiveCN104221153ALow costReduce pass rateSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceSemiconductor

This semiconductor device is characterized in being provided with: a first gate electrode (22a), which is provided on the inner side of a first insulating film, said first gate electrode being provided along one side wall of a first trench (21), and which is provided inside of a second trench (40); a shield electrode (22b), which is provided on the inner side of a second insulating film, said shield electrode being provided along the other side wall of the first trench (21), and which is provided inside of a third trench (50); a gate runner, which has a part thereof provided on the first gate electrode (22a) by having the second trench (40) extended, and which is connected to the first gate electrode (22a); and an emitter polysilicon layer (25a), which has a part thereof provided on the shield electrode (22b) by having the third trench (50) extended, and which is connected to the shield electrode (22b). Consequently, turn-on characteristics are improved with an increase of a small number of process steps, while suppressing cost increase and deterioration of yield rate.

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com