AOI (Automated Optical Inspection)-based display panel micro defect judgment method and device

A technology of display panel and judgment method, applied in the direction of optical testing flaws/defects, etc., can solve the problem of inability to accurately classify and detect small defects, achieve fast, effective and accurate detection and judgment of small defects, improve resolution and clarity, reduce The effect of over-detection and missed-detection rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

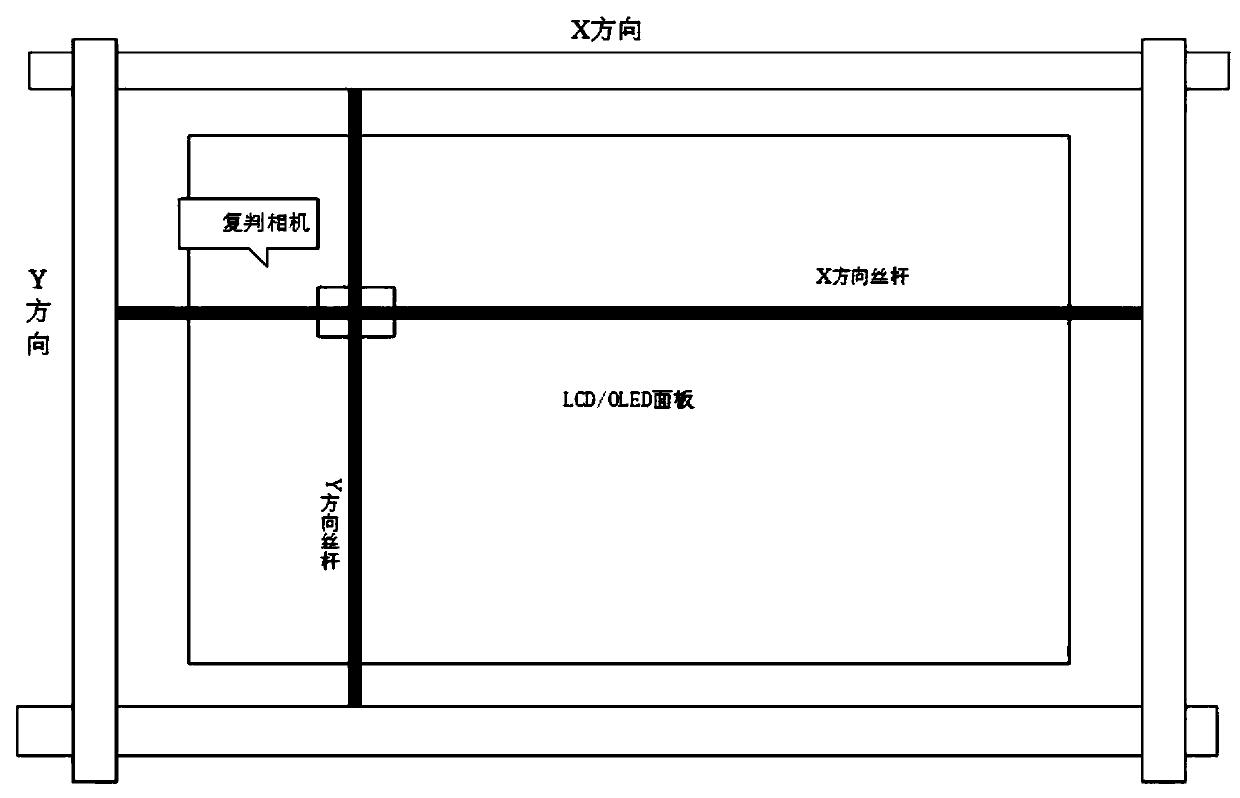

[0043] In the panel AOI equipment produced by major equipment manufacturers, the ratio of panel pixels to image pixels is usually 1:3, that is, a single subpixel image on the panel only accounts for 3*3=9 pixels, while in the application of microscopic defect detection and classification, The customer requires the detection accuracy to reach 0.25subpixel of the panel, and the image corresponding to the large camera is 0.25 / 3*9=0.75pixel. However, in the image processing process of large cameras, it is difficult to achieve a detection accuracy of 0.75 pixel considering factors such as the accuracy of the algorithm, the influence of noise, and the halo phenomenon of the liquid crystal image. In addition, defects such as Cell foreign matter, double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com