Preparation method of titanium alloy spring made of wire with specially-shaped section

A technology of titanium alloy spring and special-shaped section, which is applied in the direction of making spring from wire, wire processing and application, can solve the problem of low stiffness coefficient of titanium alloy spring, increase the cross-sectional area of wire, stable performance, and difficult to control spring precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the titanium alloy ingot is forged into a forged bar with a diameter of 70 mm, and the forged bar is rolled into a square wire with a cross-section of 12.5 mm×12.5 mm by a special-shaped profile rolling equipment.

[0029] (1) Forging: At 1170°C, the temperature is kept for 3 hours, and the forging process is used to forge the titanium alloy ingot into a φ70mm bar;

[0030] (2) Hot rolling: keep the temperature at 900°C for 1 hour, and use the hot rolling process to roll the titanium alloy forged bar into a square wire with a cross-section of 12.5mm×12.5mm through rolling equipment.

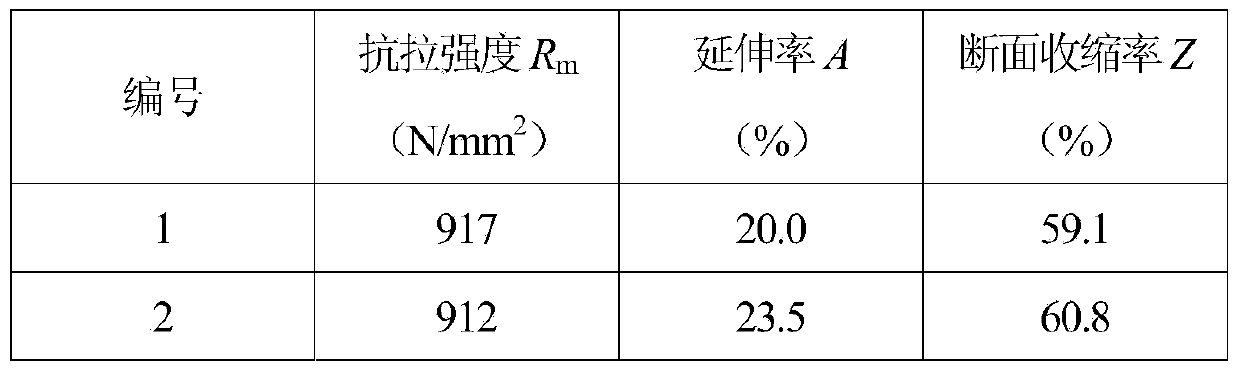

[0031] (3) Solution treatment: The rolled bar was subjected to solution treatment at 830°C for 10 min, and the tensile properties of the solution wire were measured. The specific results are shown in Table 1.

[0032] Table 1 Tensile properties of wire after solution treatment

[0033]

[0034] It can be seen from Table 1 that the wire has good plasticity after solu...

Embodiment 2

[0040]In this embodiment, the titanium alloy ingot is forged into a forged rod with a diameter of 60 mm, and the forged rod is rolled into a hexagonal wire with a side length of 7.5 mm by special-shaped rolling equipment.

[0041] (1) Forging: At 1140°C, heat preservation for 4 hours, using forging process, forging titanium alloy ingots into φ60mm rods;

[0042] (2) Hot rolling: heat preservation at 880°C for 2 hours, using a hot rolling process, rolling the titanium alloy forged rod through rolling equipment into a hexagonal wire with a side length of 7.5mm;

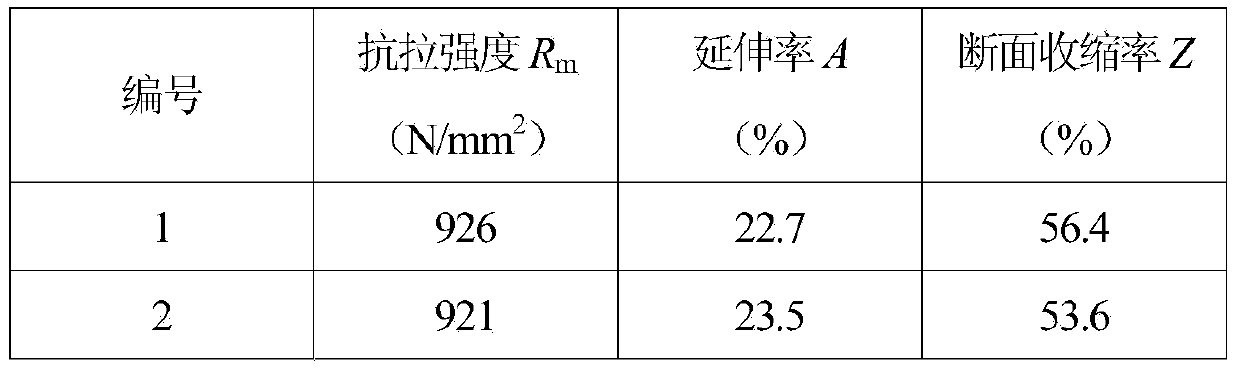

[0043] (3) Solution treatment: heat preservation at 820° C. for 15 minutes, carry out solution treatment on the wire, and measure the tensile properties of the wire in solution state. The specific results are shown in Table 3.

[0044] Table 3 Tensile properties of wire after solution treatment

[0045]

[0046] It can be seen from Table 3 that the plasticity of the wire after solution treatment is good, especially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com