Machining method for radial high-precision small square holes of rotary part

A processing method and technology of a rotary body, applied in the field of mechanical processing, can solve problems such as complex electrode processing technology, irregular shape of square holes, poor dimensional consistency, etc., and achieve good consistency, low part pass rate, and high processing dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

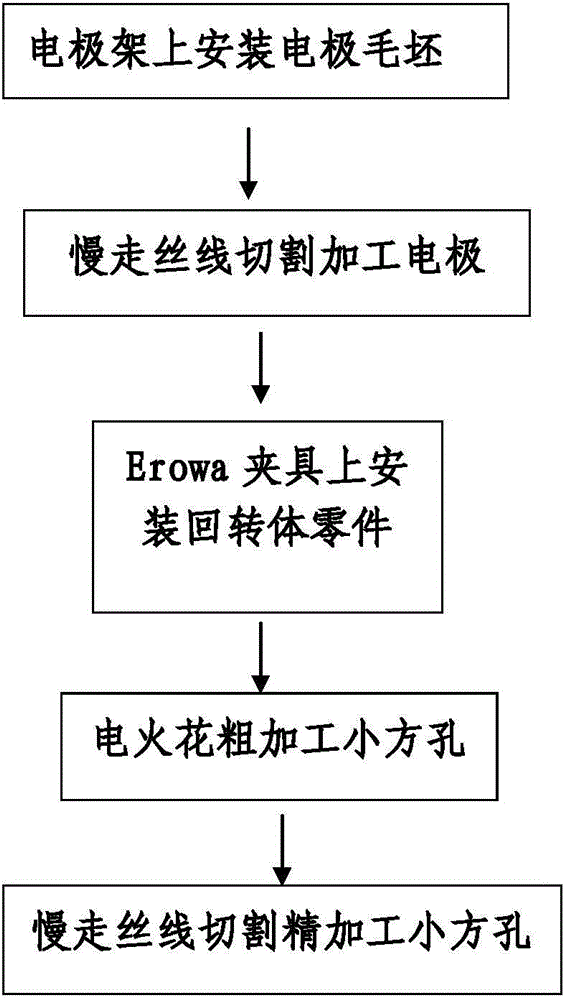

Image

Examples

specific Embodiment approach

[0015] 1. The outer circle is from the size of the outer grinding to the The inner diameter is from wire cutting and honing processing size to

[0016] 2. Electrode processing requires the following steps:

[0017] Electrode material: copper tungsten alloy

[0018] 1) Electrode blank processing: wire cutting and flat grinding are used to process it into a strip shape of 40×5×2mm.

[0019] 2) Clamp the electrode blank in the electrode frame and tighten it with screws.

[0020] 3) Use the alignment function of the slow wire machine tool to determine the center on both sides of the electrode, which is the processing origin of the electrode. The parameters are set as follows:

[0021] Machine tool: AgieCharmilles ROBFIL2030SI, Switzerland

[0022] Electrode wire: Galvanized copper wire

[0023] Wire speed: 6.8m / min

[0024] Wire tension: 0.48N

[0025] Spray pressure: 0

[0026] Pulse width: 3.0μs

[0027] Pulse interval: 6.6μs

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com