Injection mold core with air suction, discharge and rapid cooling functional structure

A functional structure, rapid cooling technology, applied in the field of core structure, can solve problems such as difficulty in maintaining consistent product quality, poor suction and exhaust, and inability to set cooling water channels, so as to improve cooling speed and heat exchange efficiency, cooling speed and Improve heat exchange efficiency and avoid the effect of slow indirect heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

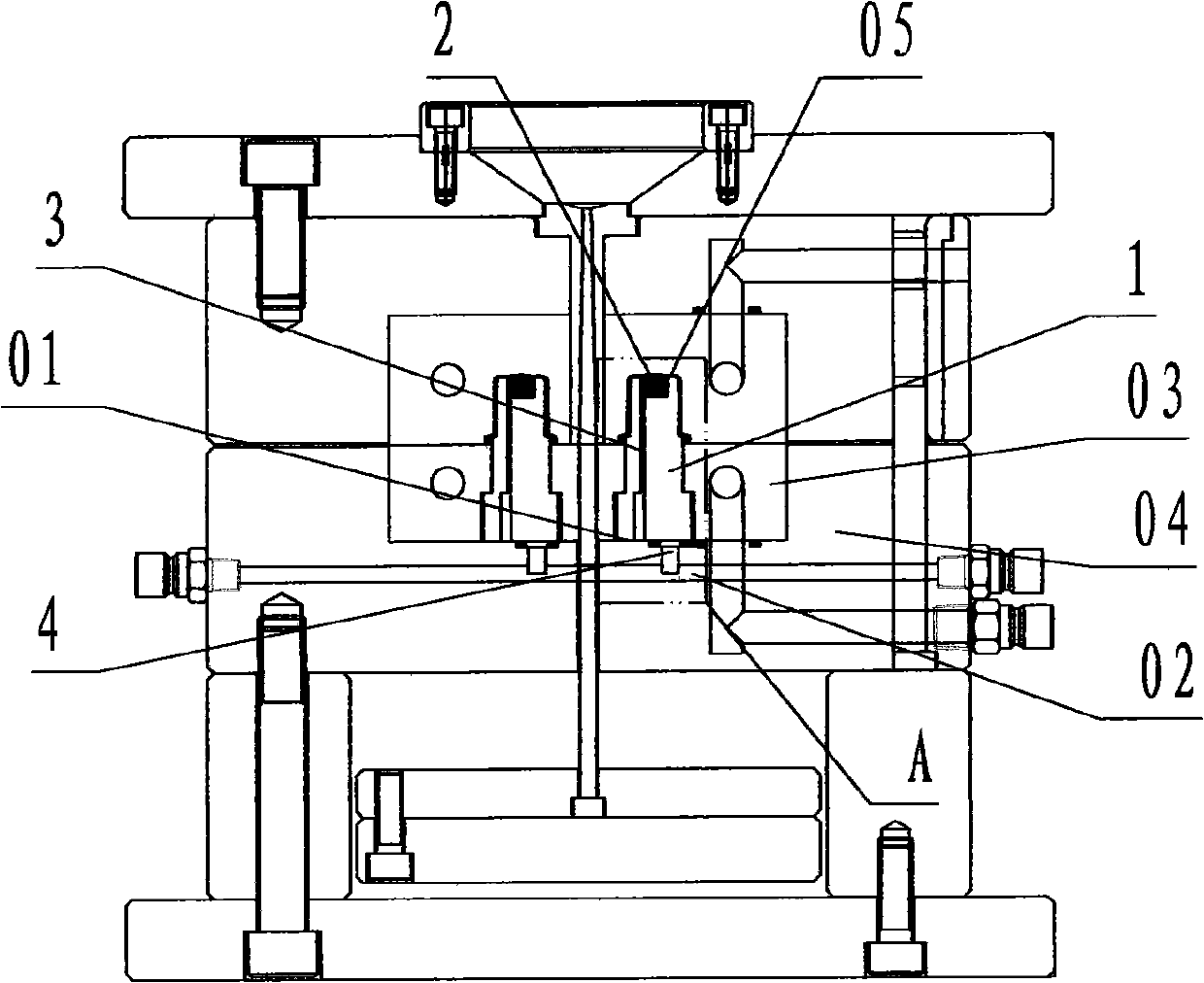

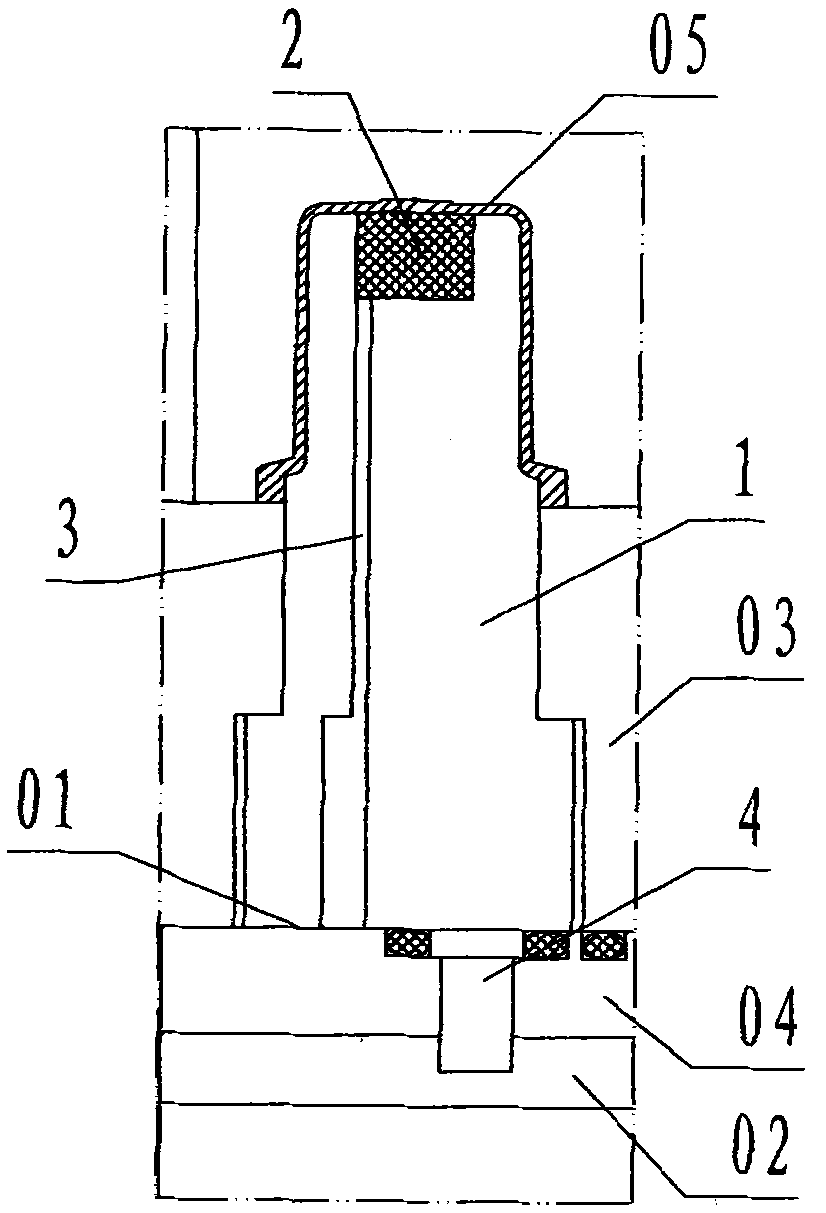

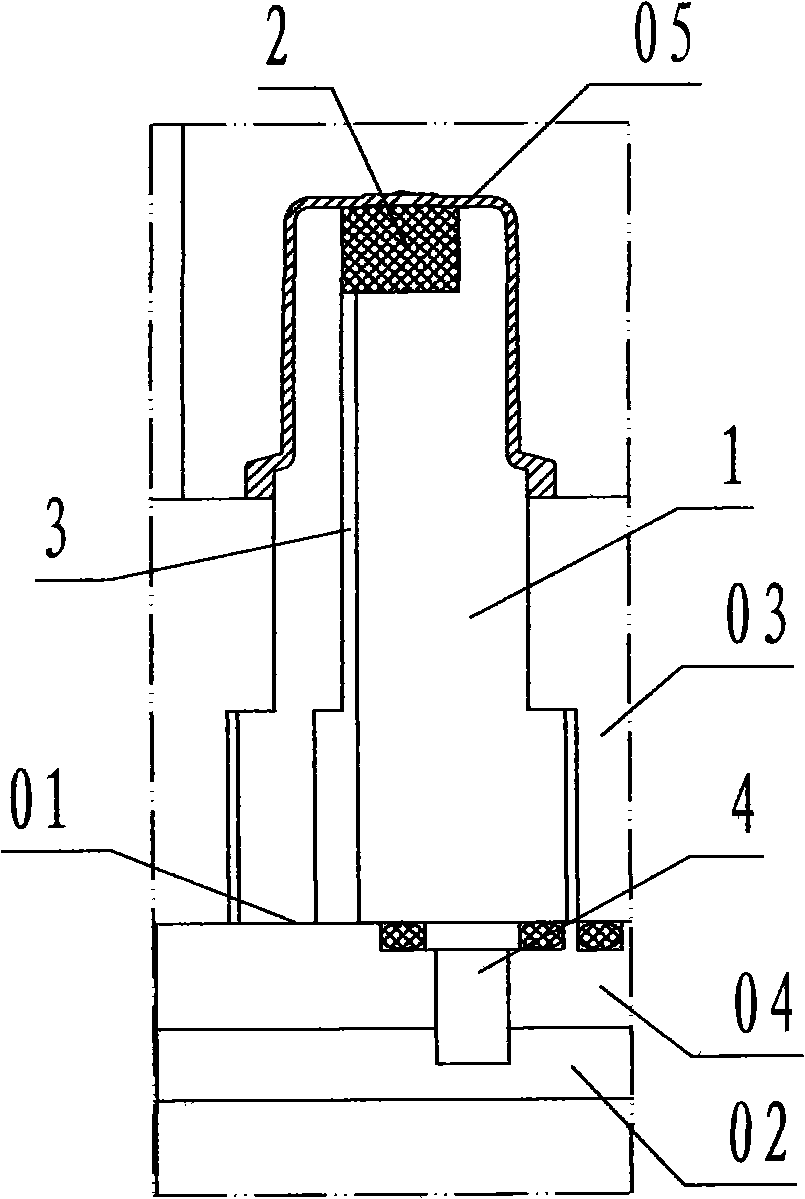

[0016] refer to Figure 1 ~ Figure 2 , a kind of injection mold core of the present invention has suction and exhaust, fast cooling function structure, is made up of core body 1, air-permeable surface 2, suction and exhaust channel 3, heat conduction pin 4, wherein: described core Body 1 is a cylindrical beryllium-copper core whose shape and outer surface conform to the inner shape and inner surface of the product; the top of the core body is fixedly inlaid with a porous gas-permeable steel, the outer surface and the inner surface of the top of the product The air-permeable surface 2 that matches the profile; the bottom of the core body is provided with a heat conduction pin 4 protruding downwards, the diameter of which is smaller than the size of the core body cylinder, and a circular stepped cylinder; the inside of the core body is provided with The upper end communicates with the air-permeable profile 2 and the lower end communicates with the edge of the bottom of the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com