Double-glass assembly manufacturing method

A technology of double-glass components and manufacturing methods, which is applied in the manufacture of electrical components, semiconductor devices, and final products, can solve problems such as unevenness and easy delamination, and achieve the effects of increasing yield, increasing production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

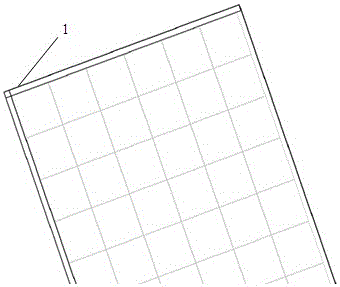

[0023] Such as figure 1 As shown, a manufacturing method of a double-glass module, which includes double-glass module laying, visual inspection, EL test, hot-melt lamination, installation of junction box, secondary EL test, power test and finished product inspection;

[0024] The laying steps of the double-glass module specifically include: first laying the cut EVA adhesive film on the bottom tempered glass; then laying the required number of solar cell strings on the EVA adhesive film; secondly, connecting the solar cell strings The strips are connected in series as a whole; EVA adhesive film and surface layer tempered glass are laid sequentially on the solar cell string again to form a solar double-glass module; finally, a high-temperature adhesive tape 1 is used for edge sealing and drilling; the width of the high-temperature adhesive tape 1 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com