High-molecular polymer and preparation method thereof

A technology of high molecular polymer and polymerization reaction product, applied in the field of high molecular polymer and its preparation, can solve the problems of general effect and poor heat resistance, and achieve the effects of reducing motion, improving polymerization activity and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

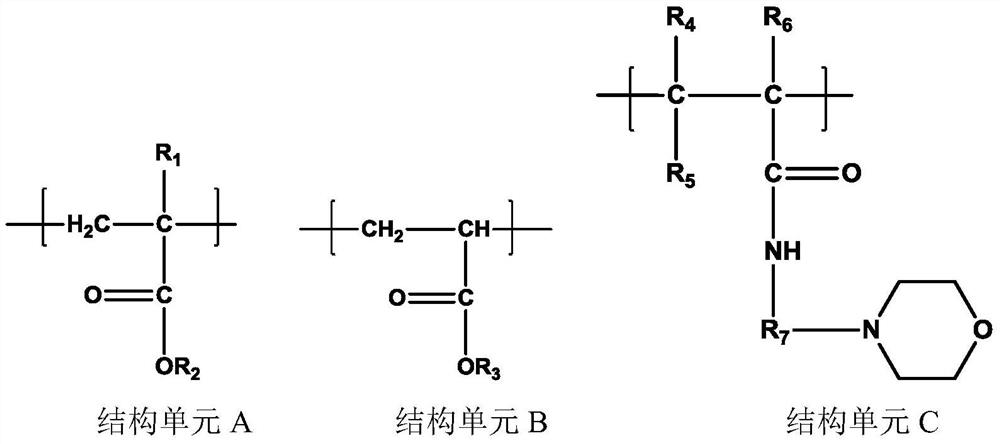

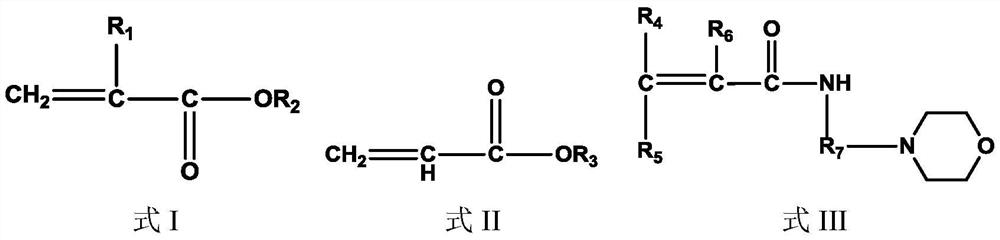

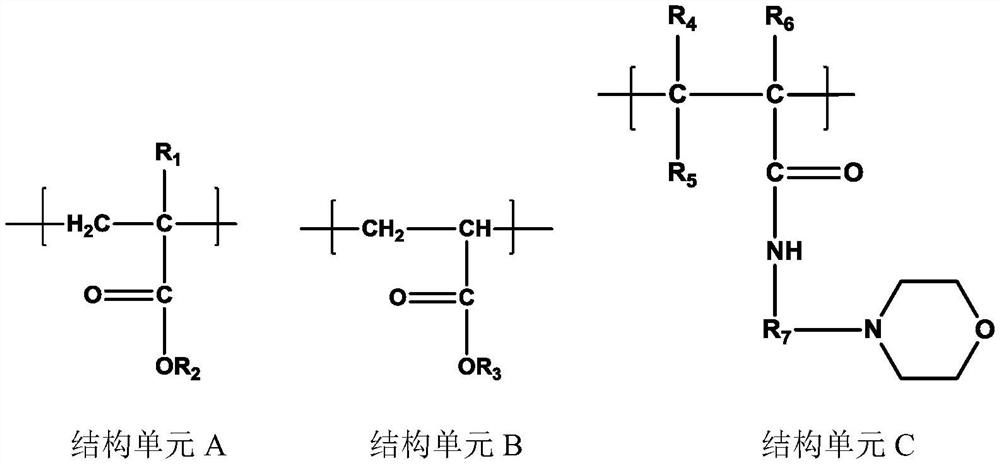

Method used

Image

Examples

Embodiment 1

[0066] (1) Pre-polymerization: Rectify methyl methacrylate monomer I, methyl acrylate monomer II and N-(N'-methinemorpholine) methacrylamide monomer III separately to remove the polymerization inhibitor Impurities such as agents. Take 80 parts of monomer I, 10 parts of monomer II, 10 parts of monomer III, 0.01 part of initiator azobisisobutyronitrile, and 0.01 part of chain transfer agent n-dodecyl mercaptan, stir well until they are evenly mixed and add them into the reaction kettle , pass nitrogen gas for 15 minutes to remove dissolved oxygen, control the reaction temperature at 80°C, and react for 60 minutes under stirring;

[0067] (2) Secondary polymerization: move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 40°C, and the reaction time to 30h;

[0068] (3) High-temperature post-treatment: the polymethyl methacrylate obtained in step (2) is further heated to 110° C. for high-temperature post-treatment to fully pol...

Embodiment 2

[0070] (1) Pre-polymerization: Rectify methyl methacrylate monomer I, methyl acrylate monomer II and N-(N'-methinemorpholine) methacrylamide monomer III separately to remove the polymerization inhibitor Impurities such as agents. Take 90 parts of monomer I, 5 parts of monomer II, 5 parts of monomer III, 0.15 parts of initiator azobisisobutyronitrile, and 0.15 parts of chain transfer agent n-dodecyl mercaptan, stir well until they are evenly mixed and add them into the reaction kettle , pass nitrogen gas for 15 minutes to remove dissolved oxygen, control the reaction temperature at 80°C, and react for 60 minutes under stirring;

[0071] (2) Secondary polymerization: move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 50°C, and the reaction time to 30h;

[0072] (3) High-temperature post-treatment: the polymethyl methacrylate obtained in step (2) is further heated to 130° C. for high-temperature post-treatment to fully pol...

Embodiment 3

[0074] (1) Pre-polymerization: Rectify methyl methacrylate monomer I, methyl acrylate monomer II and N-(N'-methinemorpholine) methacrylamide monomer III separately to remove the polymerization inhibitor Impurities such as agents. Take 90 parts of monomer I, 5 parts of monomer II, 5 parts of monomer III, 0.01 part of initiator dibenzoyl peroxide, and 0.01 part of chain transfer agent n-dodecyl mercaptan, stir well until they are evenly mixed and add them into the reaction kettle , pass nitrogen gas for 15 minutes to remove dissolved oxygen, control the reaction temperature at 90°C, and react for 30 minutes under stirring;

[0075] (2) Secondary polymerization: move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 50°C, and the reaction time to 30h;

[0076] (3) High-temperature post-treatment: the polymethyl methacrylate obtained in step (2) is further heated to 130° C. for high-temperature post-treatment to fully polymeriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com