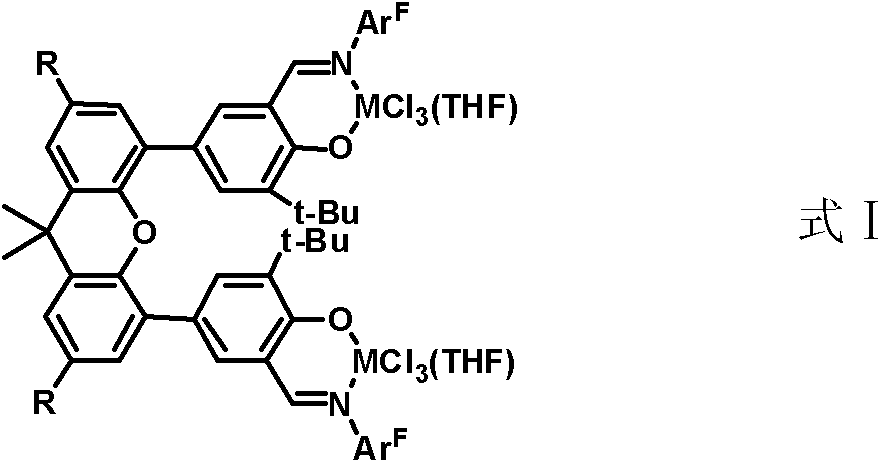

Bimetallic catalyst precursor and application thereof to olefin polymerization or copolymerization

A bimetallic catalyst and catalyst technology, which is applied in the field of olefin coordination polymerization, can solve the problems such as the inability to effectively regulate the proportion of comonomers, and achieve high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

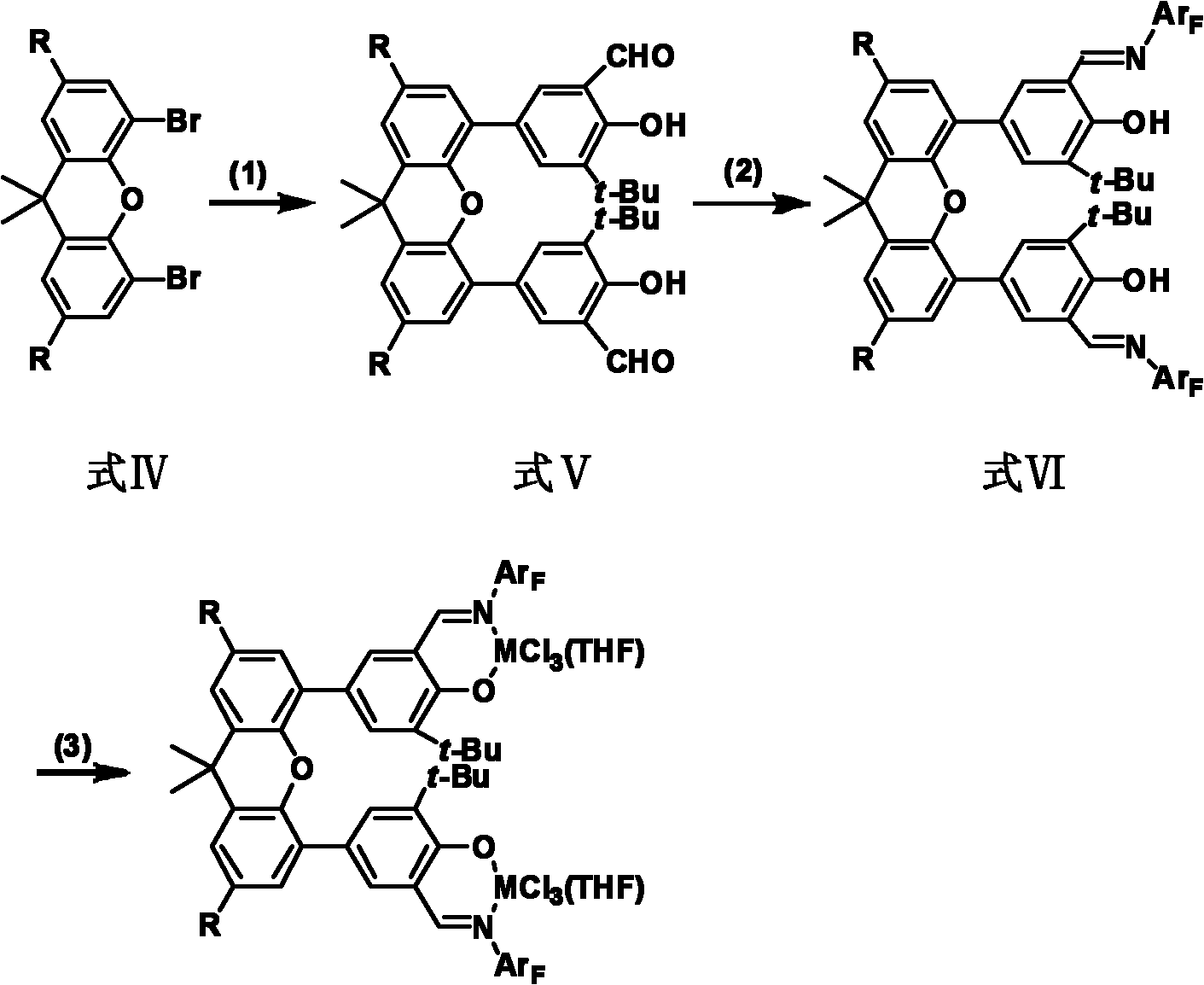

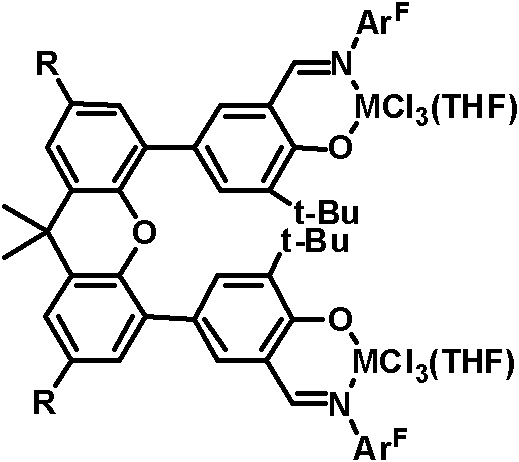

[0046] The preparation of bimetallic catalyst precursor shown in formula II

[0047] With 4,5-dibromo-2,7-di-tert-butyl-9,9-dimethyl-9H-oxanthene as the starting material, in the presence of palladium catalyst with 3-tert-butyl-5 -(4,4,5,5-Tetramethyl-1,3,2-dioxaborolane-2-substituted) salicylaldehyde was obtained by Suzuki coupling to 5,5'-(2,7-ditert Butyl-9,9-dimethyl-9H-xanthene-4,5-disubstituted)bis(3-tert-butylsalicylaldehyde). Then, under the catalysis of p-toluenesulfonic acid, it is condensed with pentafluoroaniline to obtain (E)-4,4'-(2,7-di-tert-butyl-9,9-dimethyl-9H-oxanthene-4 , 5-disubstituted) bis(3-tert-butyl-(E)-salicylaldehyde pentafluoroaniline). Then react with di(tetrahydrofuran)titanium tetrachloride in dichloromethane to obtain bimetallic catalyst precursor II. Such as figure 2 As shown, the specific synthesis steps are as follows:

[0048] 1) Preparation of 5,5'-(2,7-di-tert-butyl-9,9-dimethyl-9H-oxanthene-4,5-disubstituted) bis(3-tert-butyl salic...

Embodiment 2

[0057] Synthesis of polyethylene: evacuate the 250ml polymerization bottle after heating and drying, and pass nitrogen twice, and then pass ethylene gas after vacuuming, and then add 6.8ml of toluene solution of methylaluminoxane (MAO) in sequence (concentration is 1.47 mol / l), 23.2ml of toluene through anhydrous and oxygen-free treatment, 20ml of toluene solution of metal catalyst II (0.55mg / ml). Feed ethylene with a pressure of 1 atm under magnetic stirring, and react at 25°C for 10 minutes under this pressure, then add an acidified solution of ethanol to terminate the reaction, and obtain 0.054 g of a polymer with an activity of 4.1×104 g·mol -1 h -1 .

[0058] The melting point measured by DSC is 137°C; the M value of polyethylene measured by GPC w 5.1×10 5 ,M w / M n is 15.2.

Embodiment 3

[0060] Synthesis of polyethylene: evacuate the 250ml polymerization bottle after heating and drying, and pass nitrogen twice, and then pass ethylene gas after vacuuming, and then add 6.8ml of toluene solution of methylaluminoxane (MAO) in sequence (concentration is 1.47 mol / l), 23.2ml of toluene through anhydrous and oxygen-free treatment, 20ml of toluene solution of metal catalyst II (0.55mg / ml). Feed ethylene with a pressure of 1 atm under magnetic stirring, and react at 25°C for 5.0 min under this pressure, then add an acidified solution of ethanol to terminate the reaction, and obtain 0.027 g of a polymer with an activity of 4.1×10 4 g·mol -1 h -1 .

[0061] The melting point measured by DSC is 136°C; the M value of polyethylene measured by GPC w 4.0×10 5 ,M w / M n is 7.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com