Patents

Literature

64results about How to "Shorten lamination time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

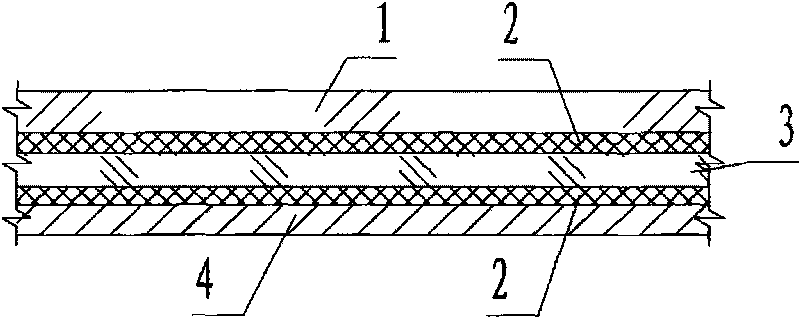

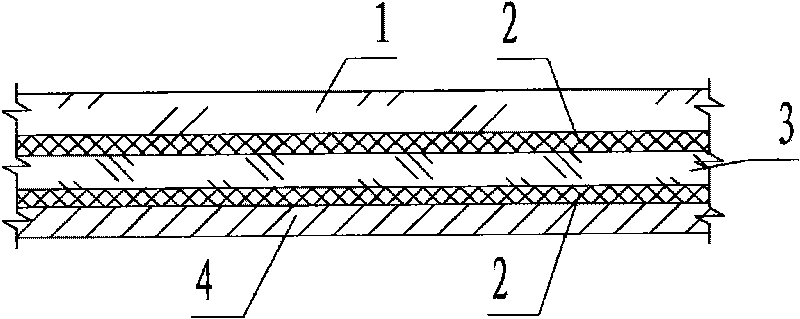

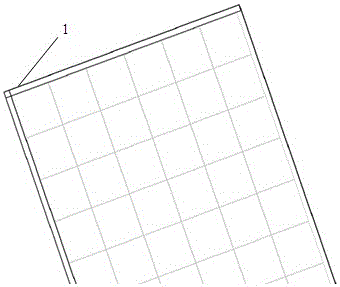

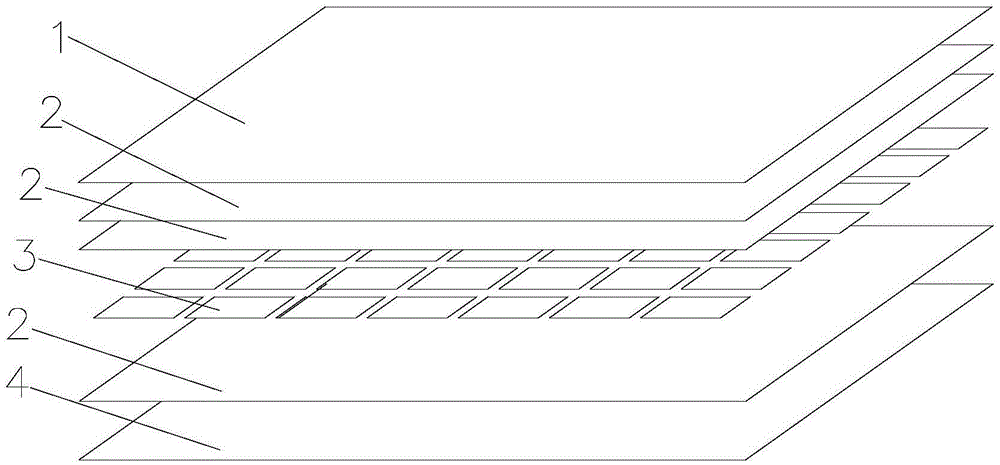

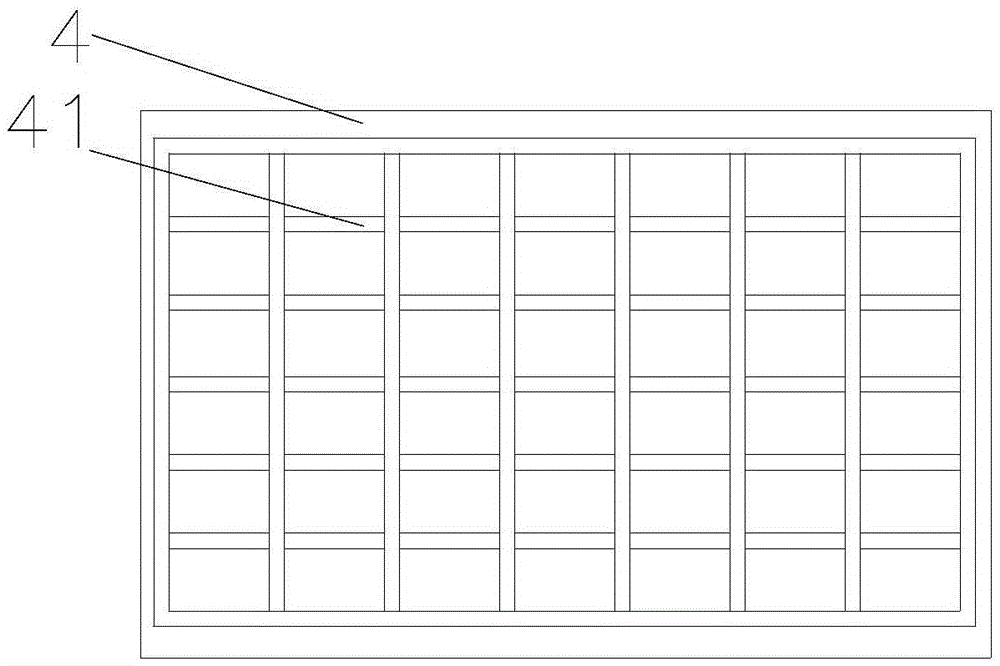

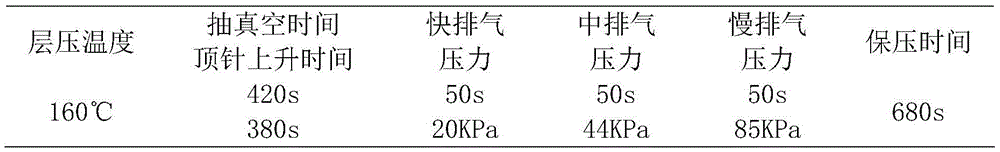

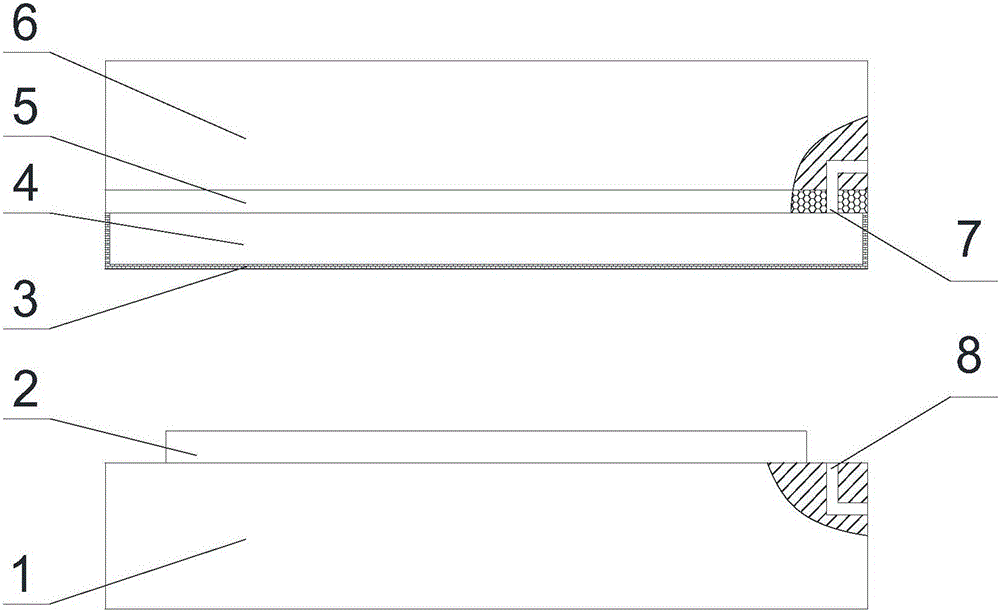

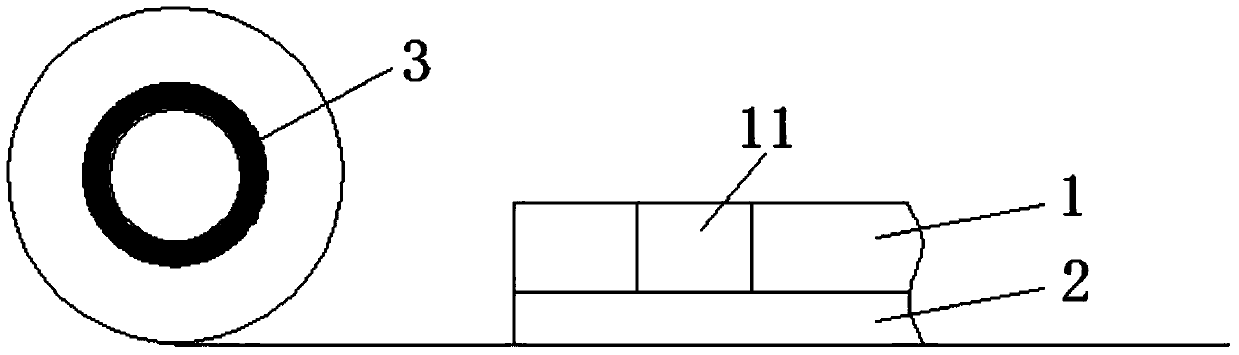

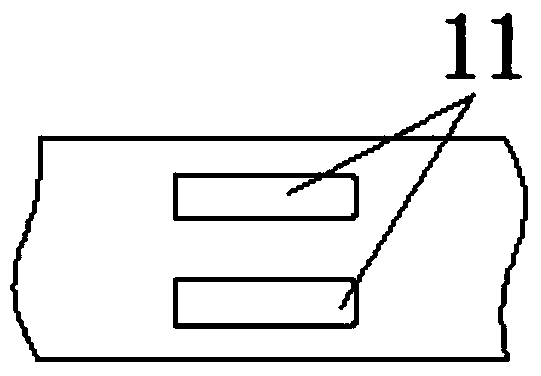

Laminated structure and laminating technology of solar panel component

ActiveCN101740651AOvercome longevityOvercoming the low photoelectric conversion rateFinal product manufacturePhotovoltaic energy generationEngineeringCrystalline silicon

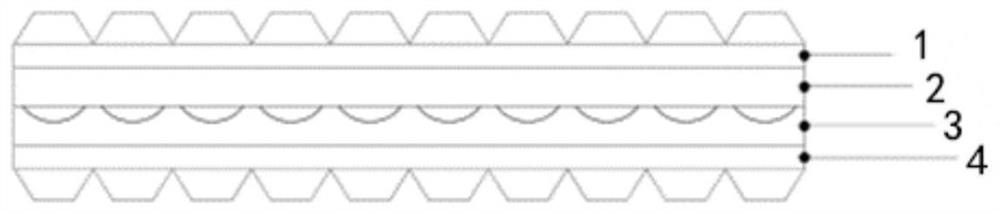

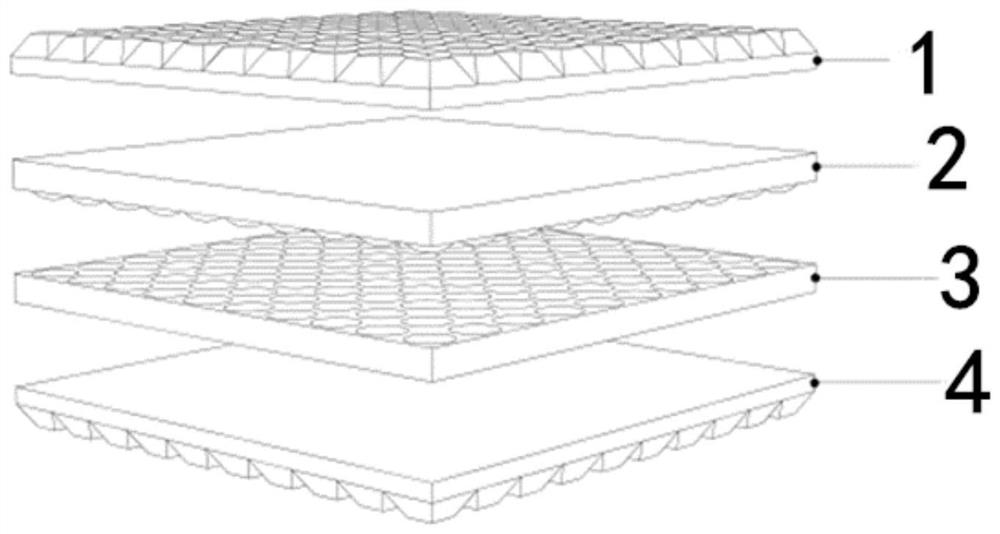

The invention discloses a laminated structure and laminating technology of a solar panel component. The laminated structure comprises coated and toughened glass (1), an EVA (2), a single crystalline silicon solar cell (3), an EVA (2) and a BBF back film (4) which constitute the five-layer structure. The laminating technology method comprises the following steps: exhausting and heat-conglutinating, laminating and cooling, aerating for decompression, and taking out the finished product. The invention uses the coated and toughened glass to replace the common toughened glass, uses the BBF back film which has high crosslinking degree to EVA to replace the TPT back film and adopts the corresponding technical scheme of the laminating technology so that the use of the coated and toughened glass can increase the photoelectric conversion efficiency of the component and the use of the BBF back film can increase the bonding strength so as to prolong the service life of the component, reduce the laminating and heat-conglutinating time, increase the production efficiency of the component and ensure to achieve the aim of increasing the photoelectric conversion efficiency, service life and production efficiency of the solar panel component.

Owner:RISEN ENERGY (YIWU) CO LTD

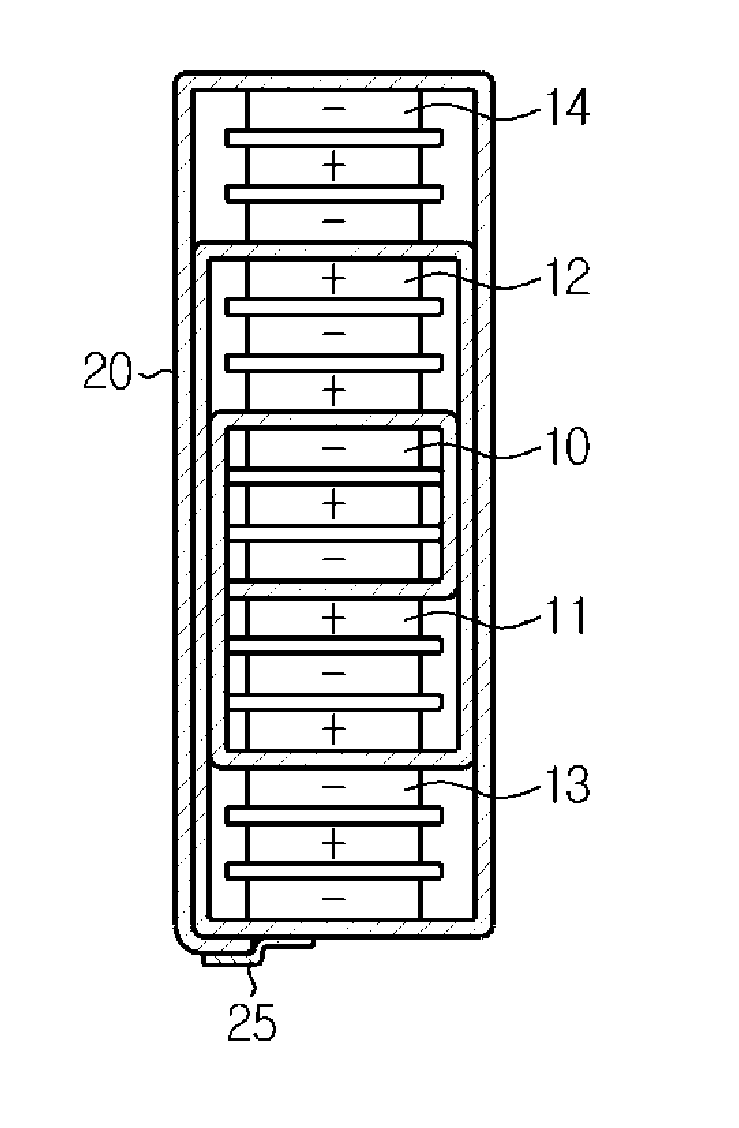

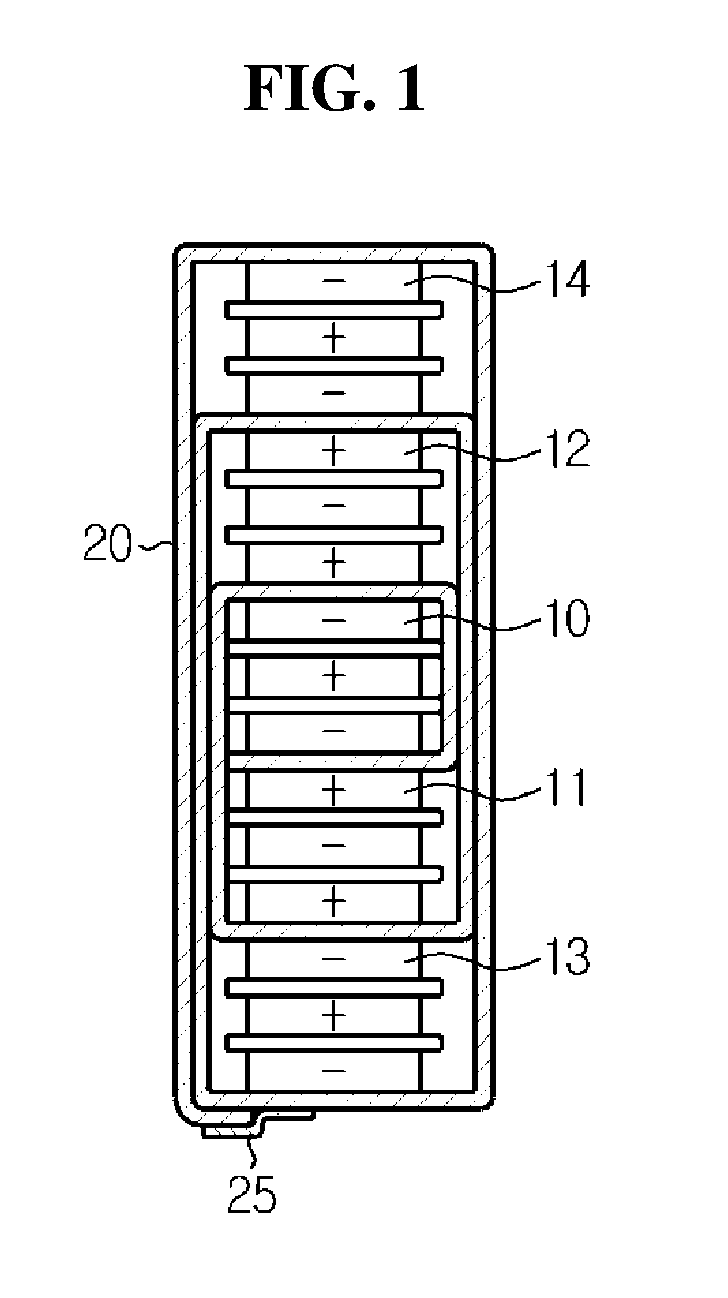

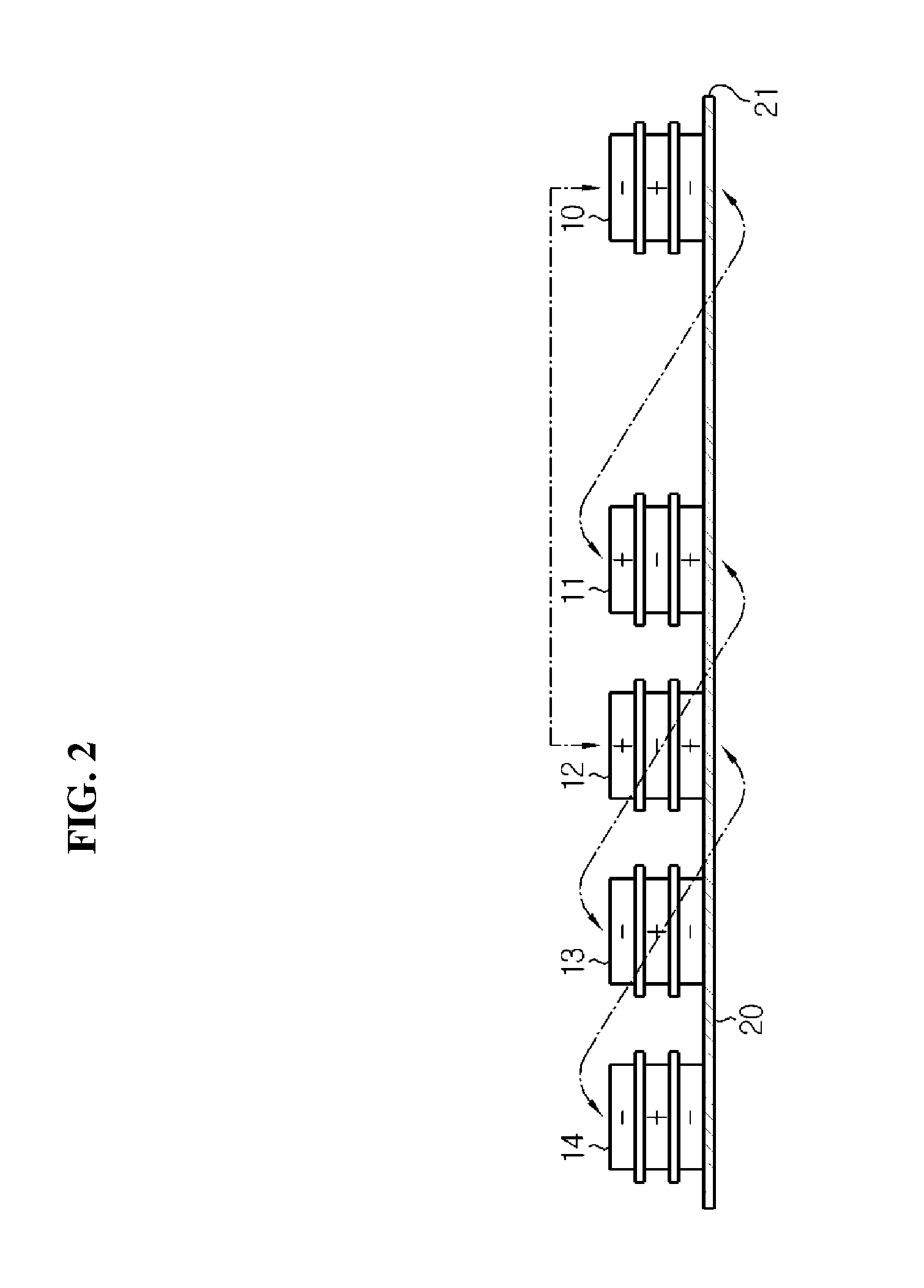

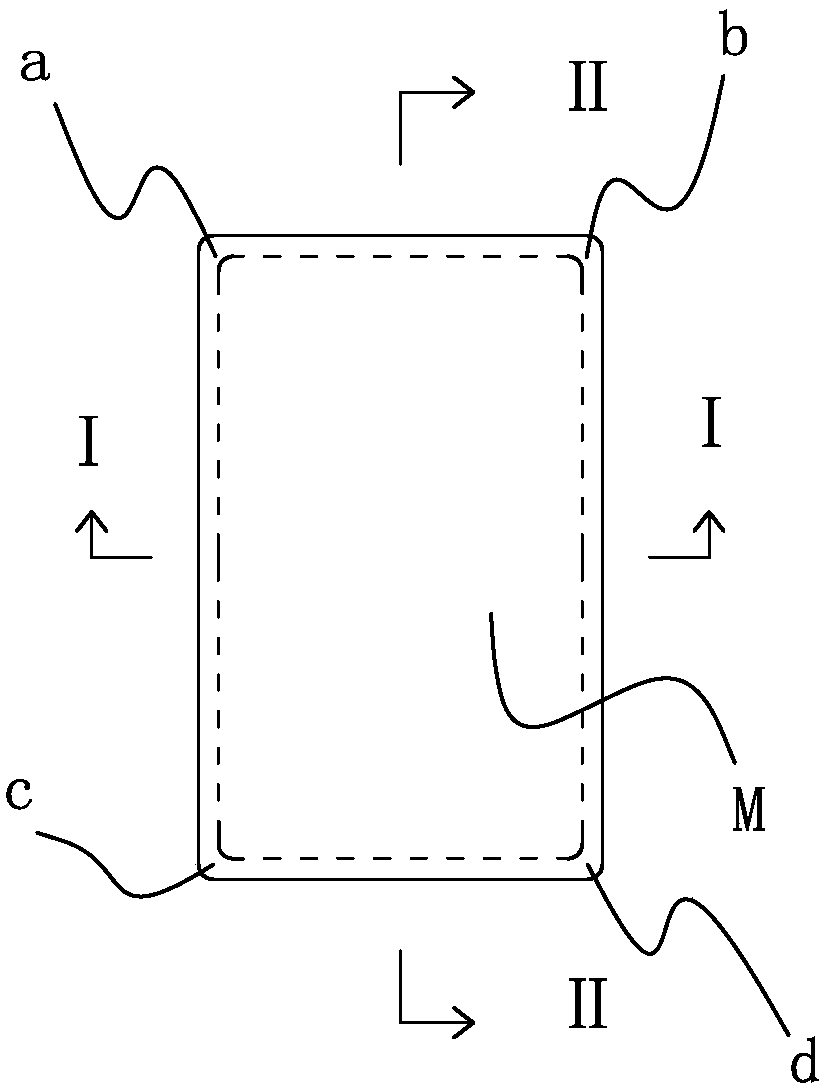

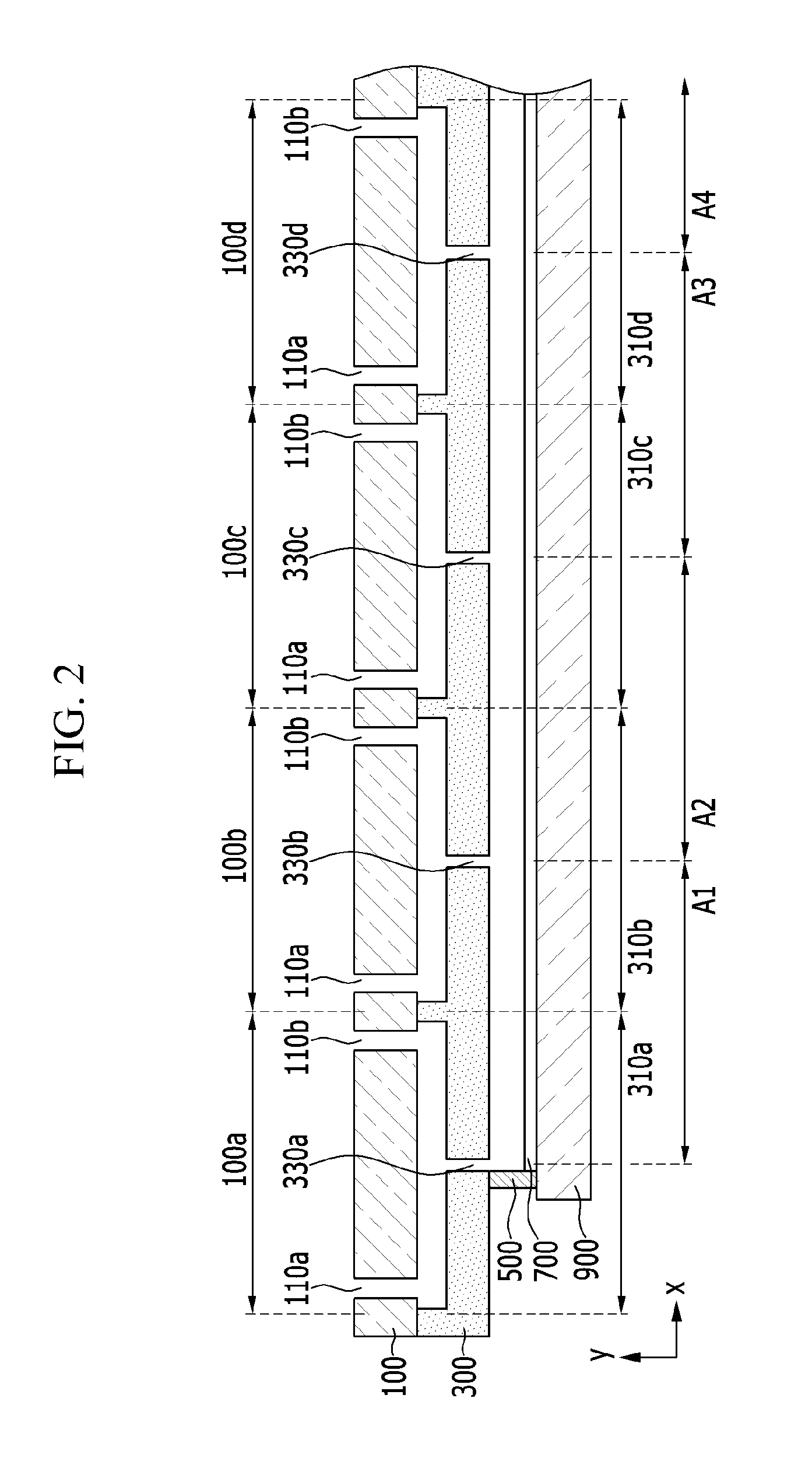

Stack-folding type electrode assembly and method of manufacturing the same

ActiveUS20160293994A1Reduce in quantityReduce defective rateLarge-sized flat cells/batteriesFinal product manufactureMechanical engineeringBattery cell

The stack-folding type electrode assembly according to the present disclosure is an electrode assembly including a plurality of stack type unit cells which is stacked on one another with a continuous folding separator sheet interposed between each of the stacked unit cells, wherein the unit cells has a combination of at least two quad cells of a positive electrode / separator / negative electrode / separator / positive electrode / separator / negative electrode structure, and one C-type bicell of a negative electrode / separator / positive electrode / separator / negative electrode structure, and unit cells disposed above and below a central part or a winding start point have an asymmetrical structure each other with the quad cell disposed at the central part, or unit cells disposed above and below a central part or a winding start point have a symmetrical structure each other with the C-type bicell disposed at the central part.

Owner:LG ENERGY SOLUTION LTD

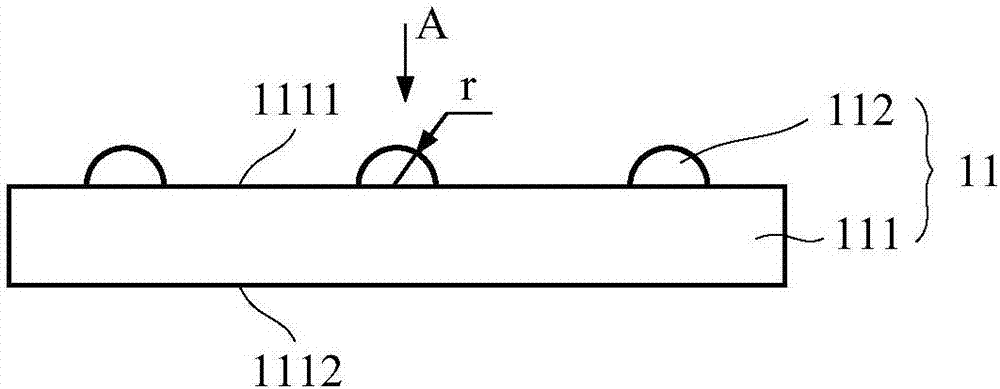

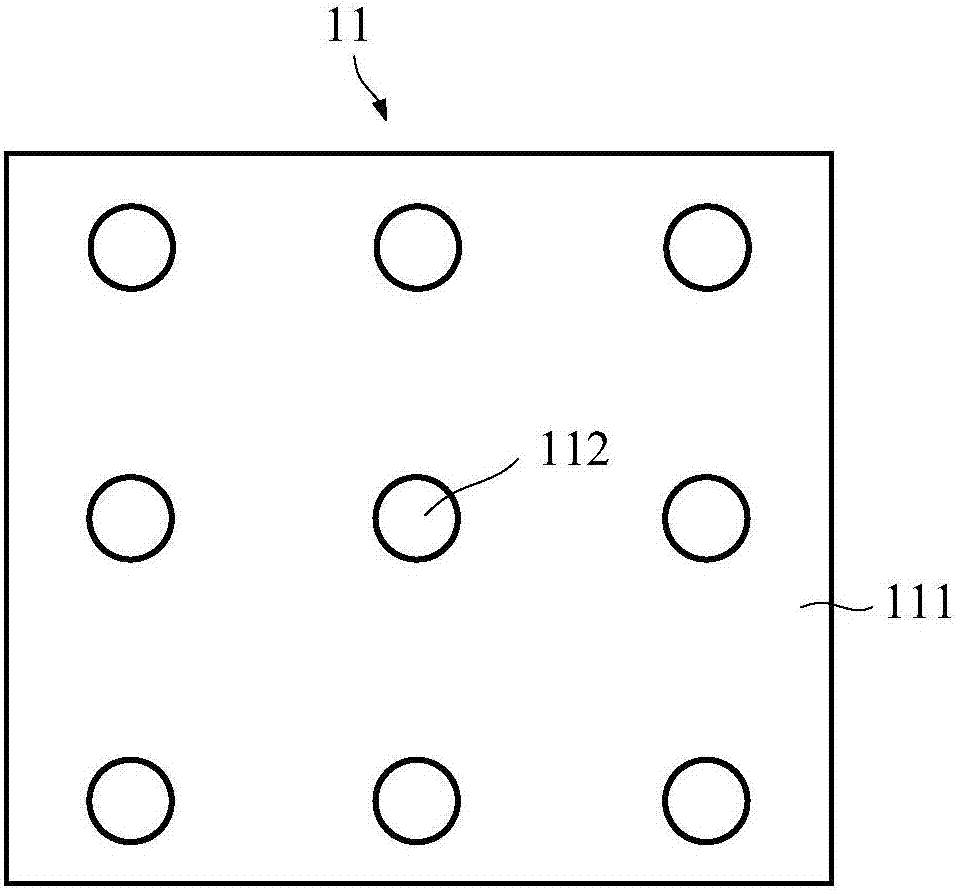

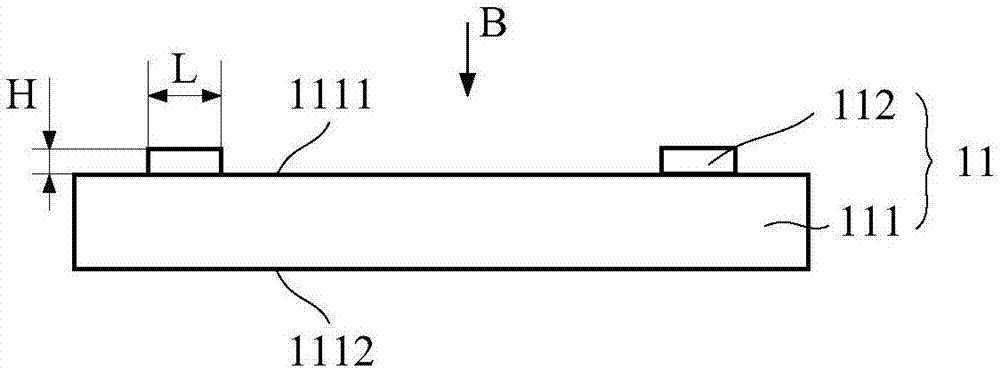

Mobile phone cover plate attachment mold and process

The invention provides a mobile phone cover plate attachment mold. The mobile phone cover plate attachment mold is used for enabling a glass cover plate to be attached to a protection film so as to form a mobile phone cover plate. The mobile phone cover plate attachment mold comprises an upper mold, a pad film and a lower mold. A groove is formed in the upper mold. The lower mold comprises a substrate, a bearing part and elastic parts. The substrate comprises a bottom plate and a side plate, and containing space is formed between the bottom plate and the side plate. The pad film is located between the upper mold and the lower mold and comprises a bearing portion. The upper surface of the bearing portion faces the upper mold and is used for containing the to-be-attached protection film. Thelower surface of the bearing portion is borne on the bearing part and the side plate of the substrate of the lower mold. The bearing part gives first supporting to the middle area of the bearing portion, and the side plate gives second supporting to the corner areas of the periphery of the bearing portion. When the upper mold and the lower mold are compounded, second supporting pressure providedfor the corners of the periphery of the bearing portion is larger than first supporting pressure of the middle area of the bearing portion. The invention further provides an attachment process for carrying out attachment of the glass cover plate and the protection film through the attachment mold. The protection film and the glass cover plate are attached closely, and the effect is better.

Owner:DONGGUAN GUANHE OPTICAL GLASS CO LTD

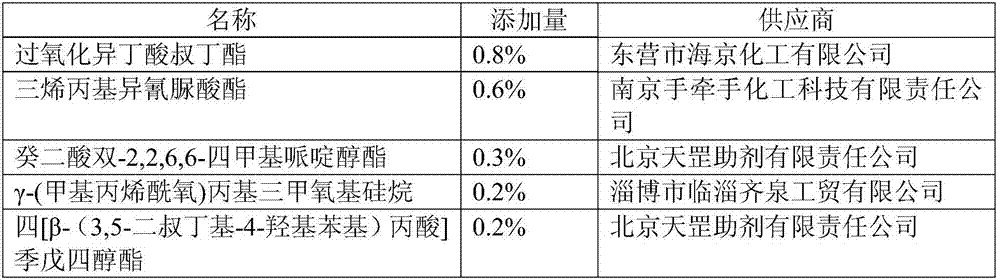

Ultra-fast solidified solar energy packaging adhesive film and preparation method thereof

InactiveCN108611025AShorten lamination timeGood lookingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveUltra fastEngineering

The invention relates to a solar energy packaging adhesive film, in particular, relates to an ultra-fast solidified solar energy packaging adhesive film and a preparation method thereof, and belongs to the field of photovoltaic packaging adhesive film, wherein the ultra-fast solidified solar energy packaging adhesive film is used for photovoltaic single-glass and double-glass assemblies. The solarenergy packaging adhesive film for reducing the lamination time is designed. The invention aims to reduce the vacuumization and lamination time of the photovoltaic assemblies in the packaging process, improve the efficiency and reduce the cost by adjusting the process, changing an auxiliary agent and improving the lamination temperature.

Owner:ZHEJIANG SINOPONT TECH +1

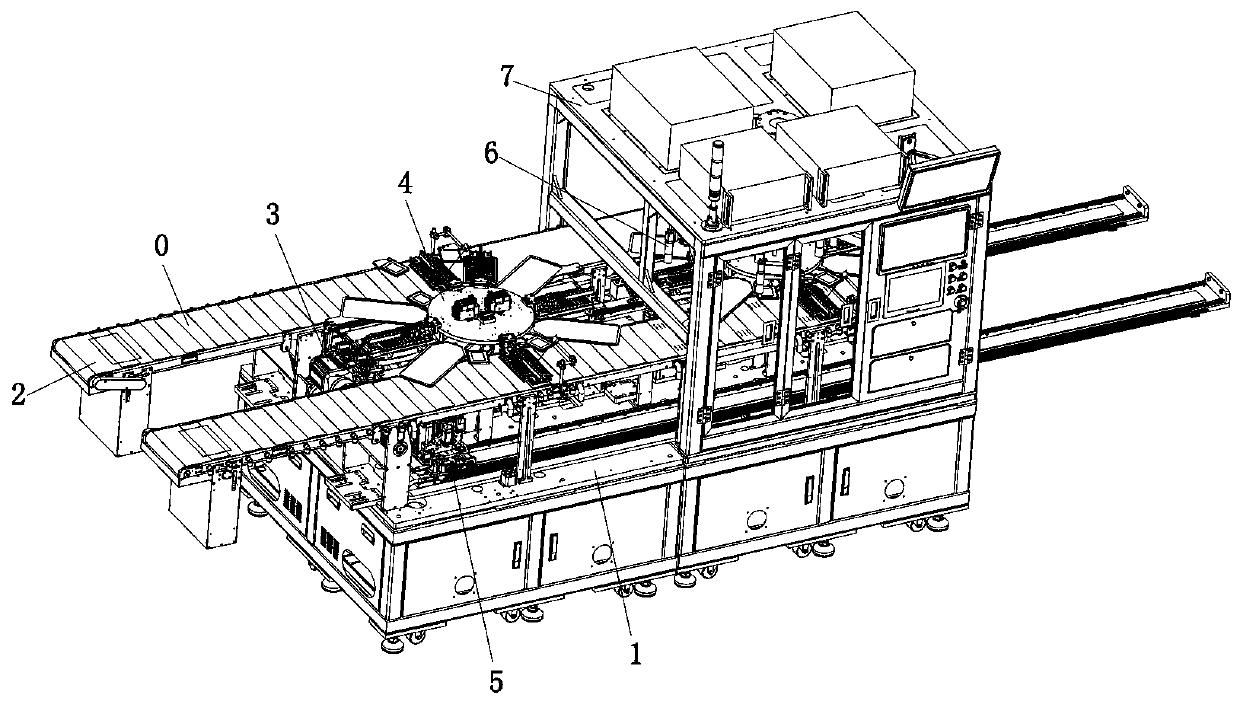

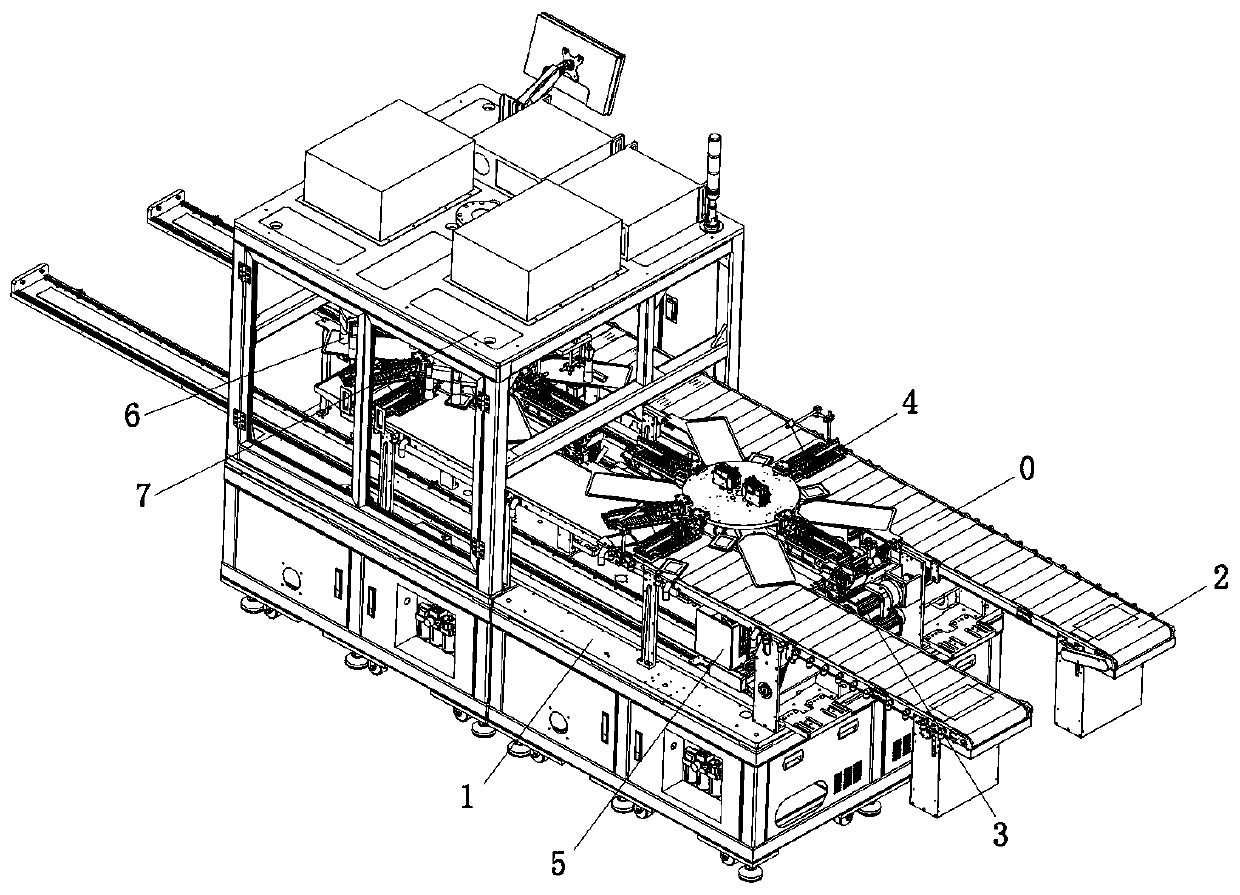

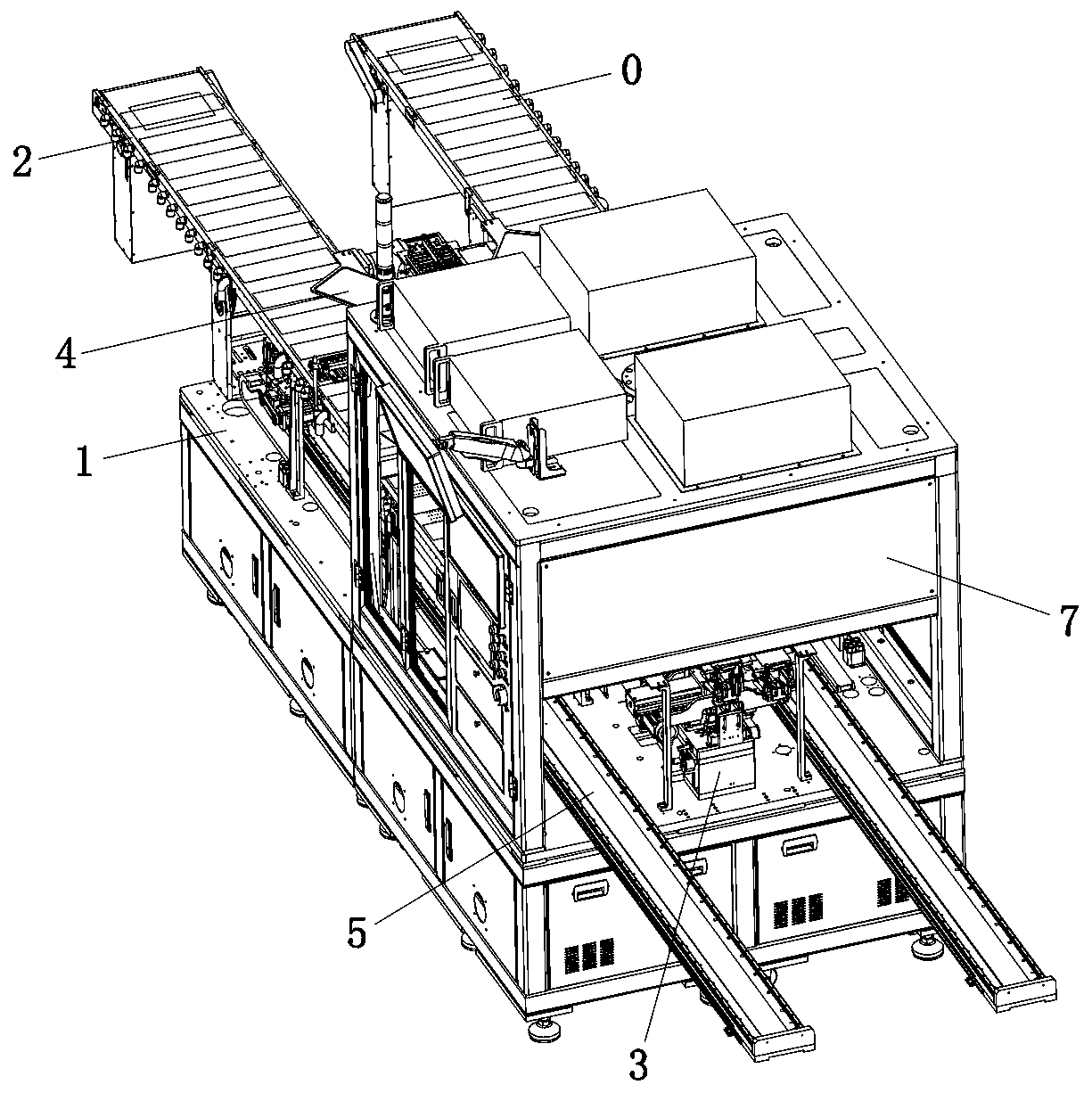

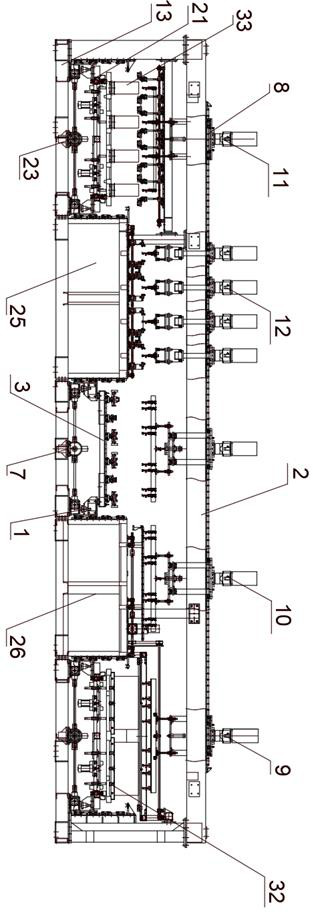

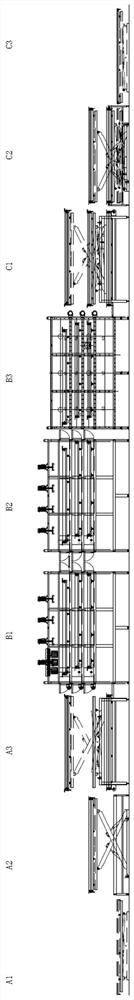

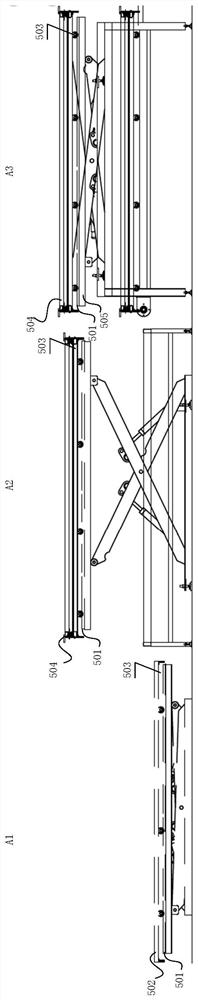

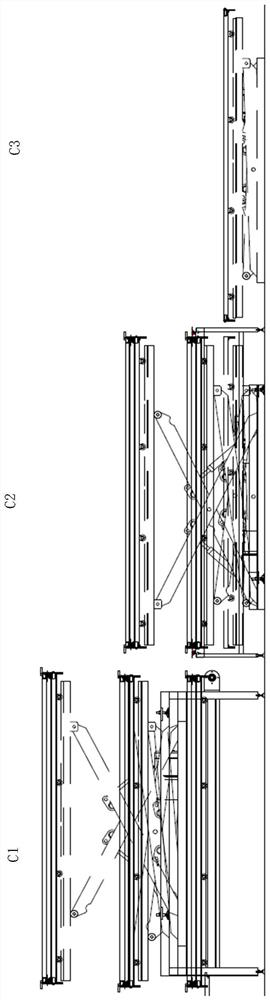

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Double-glass assembly manufacturing method

InactiveCN105895739AAvoid prone to air bubblesAvoid displacement of cells on both sidesFinal product manufacturePhotovoltaic energy generationAdhesiveEngineering

The invention discloses a double-glass assembly manufacturing method, and the method comprises the steps: double-glass assembly laying, appearance inspection, EL testing, hot melting laminating, junction box installation, secondary EL testing, power testing, and finished product examination. The double-glass assembly laying specifically comprises the steps: firstly enabling a cut EVA glue film to be laid on bottom toughened glass; secondly enabling a required number of solar cells to be laid on the EVA glue film; thirdly enabling the plurality of cells to be connected in series through a bus bar to form a body; fourthly sequentially laying the EVA glue film and surface roughened glass on the solar cell string, and forming a solar double-glass assembly; and finally carrying out edge sealing through a high-temperature adhesive tape, and drilling. According to the invention, the high-temperature adhesive tape is used for fully pasting and sealing the periphery of the laid double-glass assembly, thereby effectively controlling the overflow quantity. The method greatly shortens the laminating time, and improves the production efficiency.

Owner:JIANGSU LINYANG PHOTOVOLTAIC TECH

Expansion sleeve type cast-aluminum dummy shaft

InactiveCN101867264AImprove uniformityReduce processing stepsManufacturing stator/rotor bodiesEngineeringMetal working

The invention relates to an expansion sleeve type cast-aluminum dummy shaft. A core shaft is arranged on a shaft base; an expansion sleeve is sleeved outside the core shaft; an outer key groove is formed on an outer surface of the expansion sleeve along the axial direction; a positioning key is inserted in the key groove; and a rotor core is sleeved outside the expansion sleeve. The side wall of a rotor core mounting inner hole is provided with an inner key groove along the axial direction; an outer end of the positioning key is inserted in the inner key groove; a pressing plate which is used for pressing the rotor core is sleeved on the core shaft; and a fastening nut which makes the pressing plate tightly support the rotor core is screwed on the core shaft. The expansion sleeve type cast-aluminum dummy shaft is characterized in that: a section of core shaft which is sleeved with the expansion sleeve is a cone; a base plate which is pressed against an end face of the expansion sleeve is sleeved on the core shaft; and a wedged plate is arranged on the core shaft on the upper part of the base plate. The expansion sleeve type cast-aluminum dummy shaft can completely expand the inner diameter of the core, improve the uniformity of cast-aluminum rotor shaft hole, and reduce metal working procedures. Meanwhile, after aluminum is cast on the rotor, because the core shaft is matched with the conical surface of a trivalve sleeve, the shaft withdrawal is convenient, labor-saving, and time-saving.

Owner:WUXI ZHONGDA MOTORS

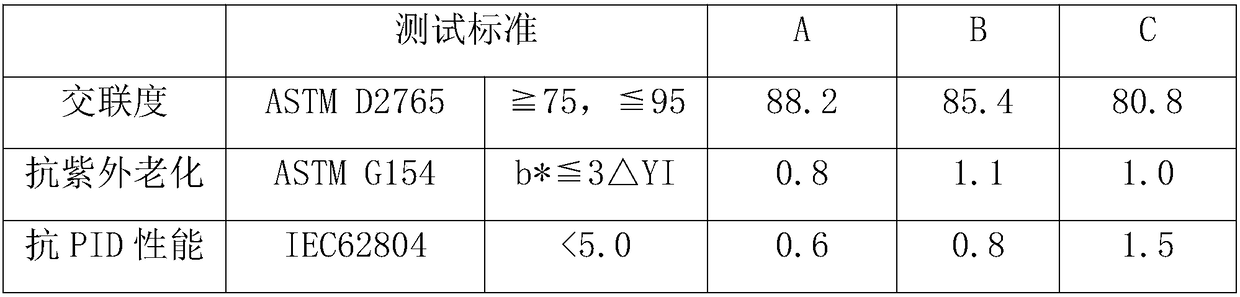

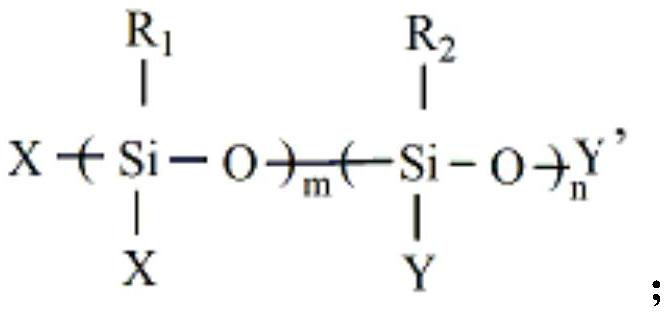

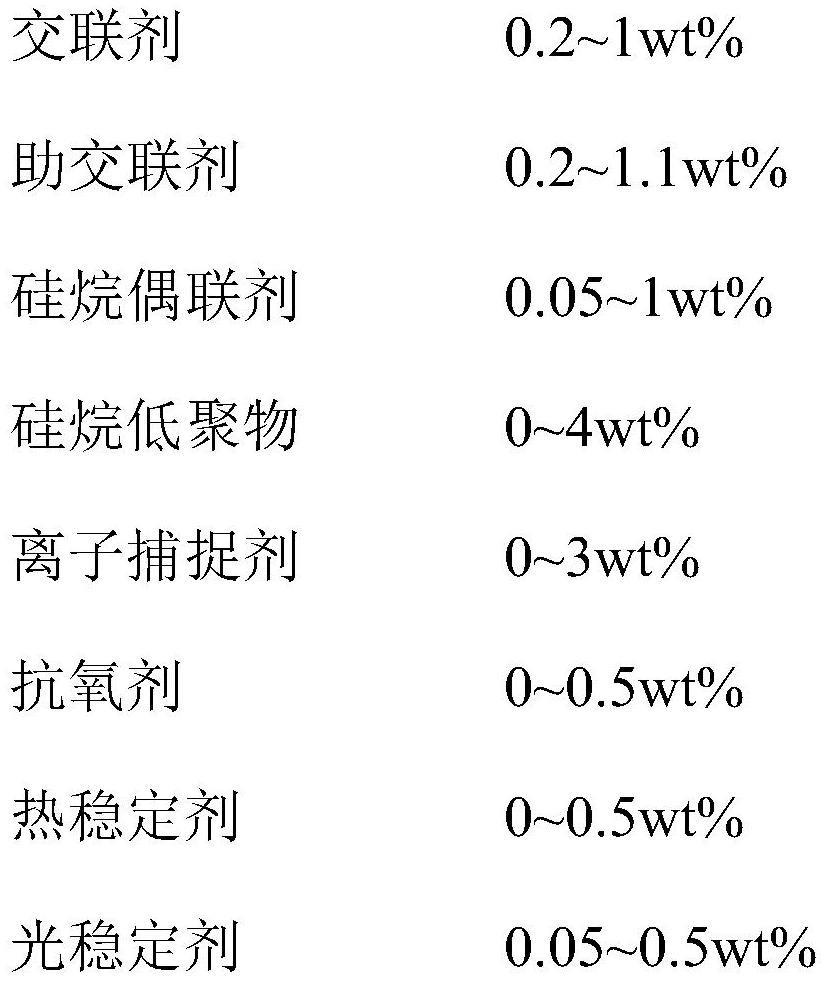

Multifunctional packaging adhesive film and preparation method thereof

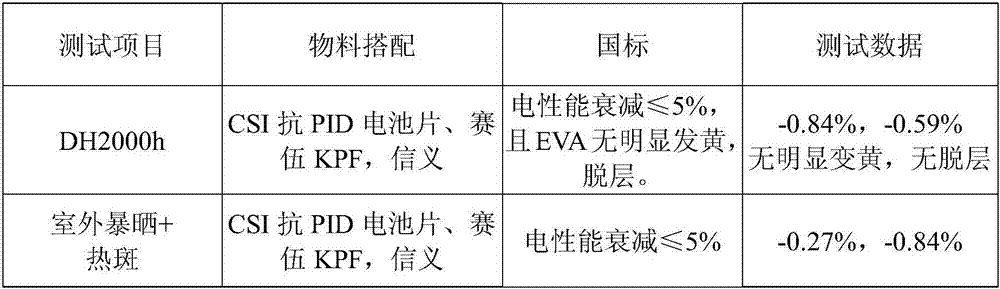

PendingCN111961422AImprove the attenuation effectExcellent anti-PID performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceOligomer

The invention provides a multifunctional packaging adhesive film and a preparation method thereof. The multifunctional packaging adhesive film comprises, by mass, 90 to 99% of a polymer and 1 to 10% of an auxiliary agent, and the auxiliary agent comprises a silane oligomer. The prepared multifunctional packaging adhesive film has excellent peeling force attenuation resistance and PID resistance, and can meet the requirements of packaging adhesive films with different functions.

Owner:CYBRID TECHNOLOGIES INC

Lightweight double-glass module

InactiveCN105489683AHigh strengthAvoid breakingPhotovoltaic energy generationSemiconductor devicesCollocationEngineering

The invention belongs to the field of solar cells, and provides a lightweight double-glass module comprising chemically toughened glass, a packaging layer, cell strings, a packaging layer and physically toughened glass which are arranged from the top to the bottom in turn. According to the lightweight double-glass module, chemically toughened glass acts as front glass and cell sheets crack if chemically toughened glass is used for supporting due to excessive flexibility of chemically toughened glass, and physically toughened glass acts as back glass and float physically toughened glass acts as a main bearing surface under the condition of wind-snow load so that the cell strings in module can be greatly protected, and the overall strength of the module can be increased through the collocation; besides, the installing method is almost the same with that of common double-glass modules so that the installing method does not need to be changed; and thinner glass is adopted on the basis of a backboard module and the double-glass module, and weight is relatively low and is only about 12KG so that weight is reduced by 40% in comparison with that of conventional double-glass.

Owner:CHANGZHOU ALMADEN

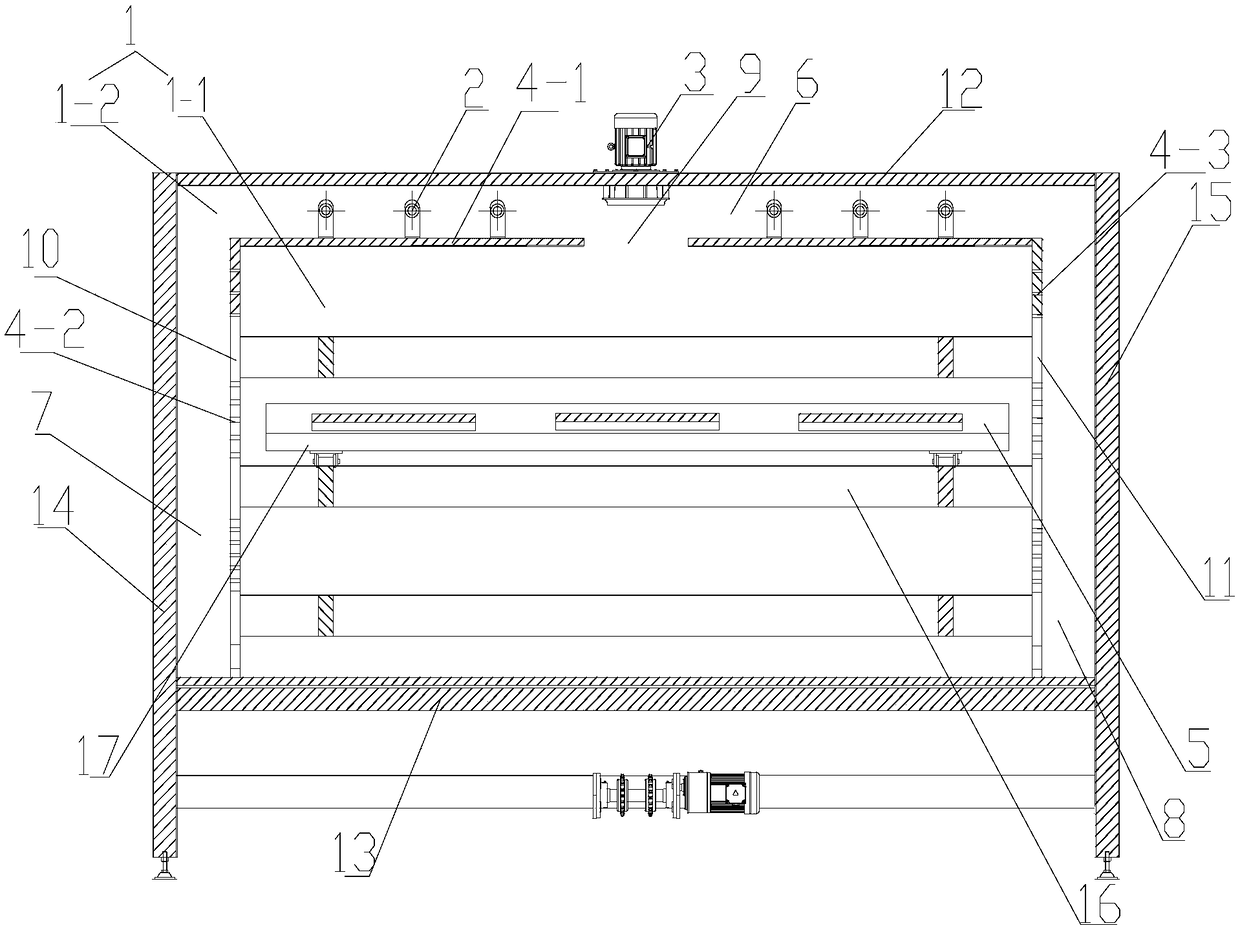

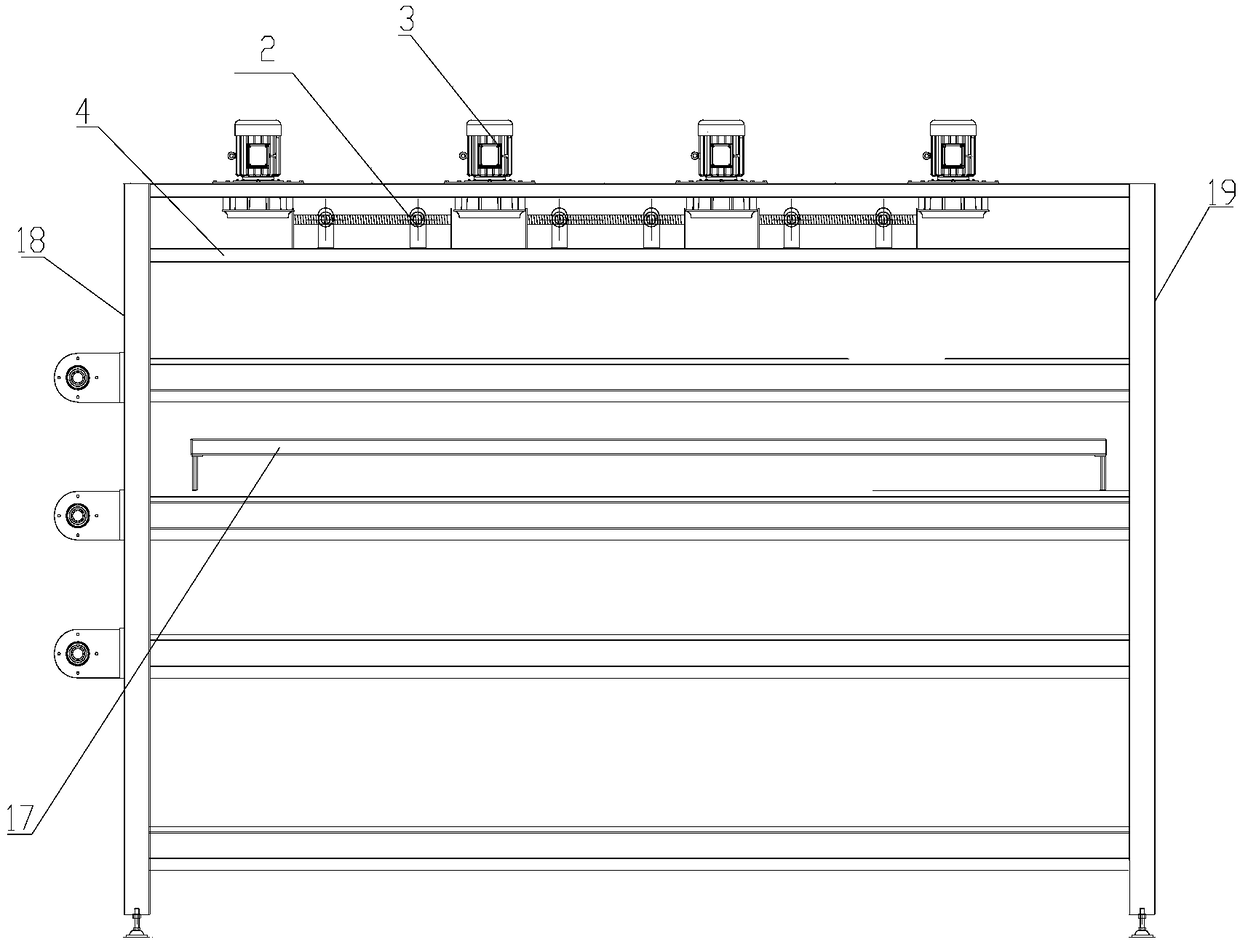

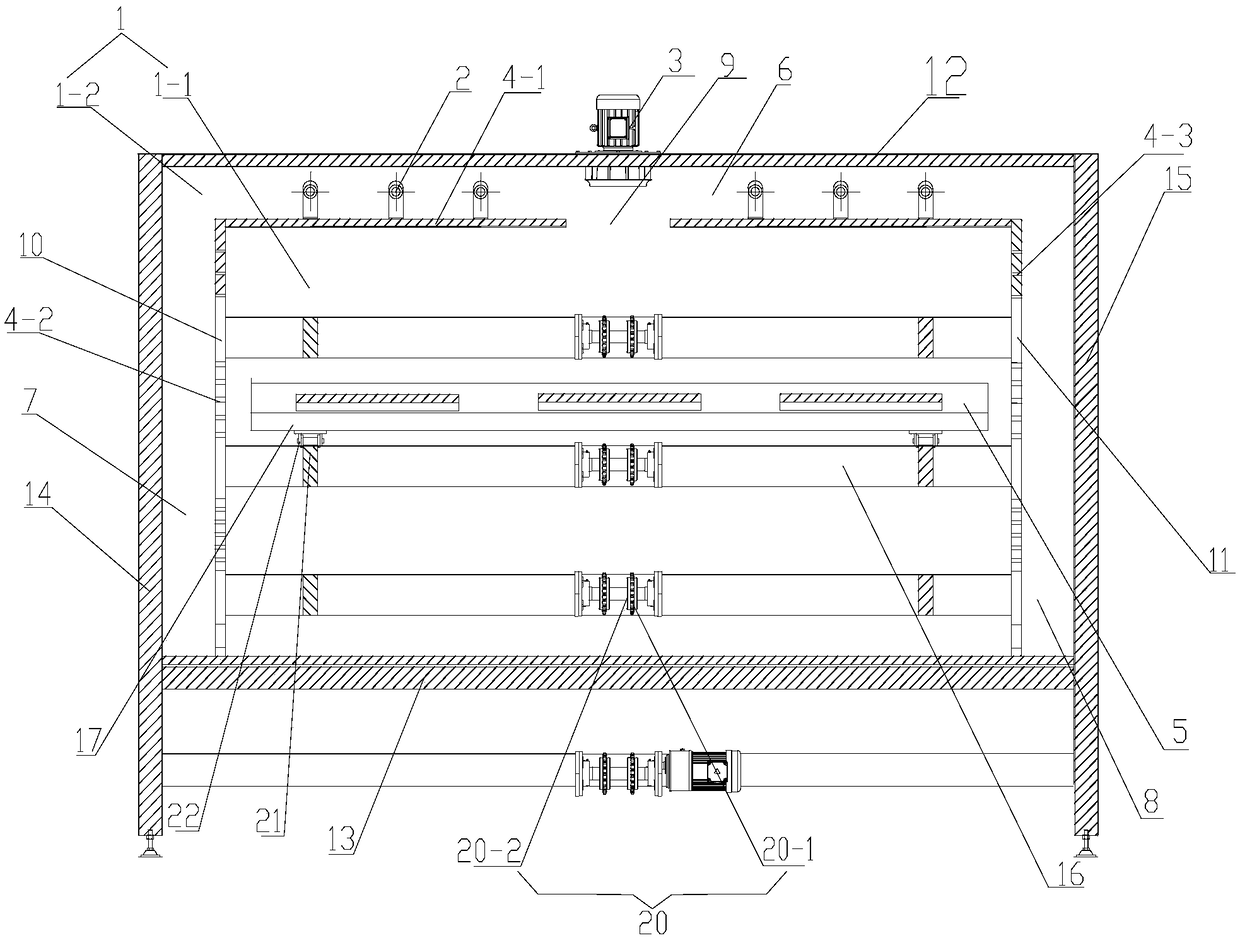

Rapid laminating machine with double-glass photovoltaic assembly

InactiveCN106541672AImprove heating uniformityShorten lamination timeLaminationLamination apparatusEngineeringSilica gel

The invention discloses a rapid laminating machine with a double-glass photovoltaic assembly. The rapid laminating machine comprises an upper layer heating module, an infrared radiating coating, a silica gel plate, a lower layer heating module and a vacuum system, wherein the infrared radiating coating is smeared on the whole lower surface of the upper layer heating module. The upper layer heating module comprises three or more heating units which can control the area temperature independently and accurately, and a first pipeline opening of the vacuum system is formed in the upper layer heating module. The lower layer heating module comprises three or more heating units which can control the area temperature independently and accurately, and a second pipeline opening of the vacuum system is formed in the lower layer heating module. In laminating, the silica gel plate, the upper layer heating module and the infrared radiating coating form an upper laminating cavity together, the silica gel plate and the lower layer heating module form a lower laminating cavity, the radiating heat from the infrared radiating coating is absorbed to heat the double-glass photovoltaic assembly in a heat conduction mode. The vacuum system is composed of a vacuum pump, a vacuum pipeline and a vacuum valve, and vacuum degrees of the upper laminating cavity and the lower laminating cavity can be controlled through the first pipeline opening and the second pipeline opening.

Owner:SHANGHAI DIANJI UNIV

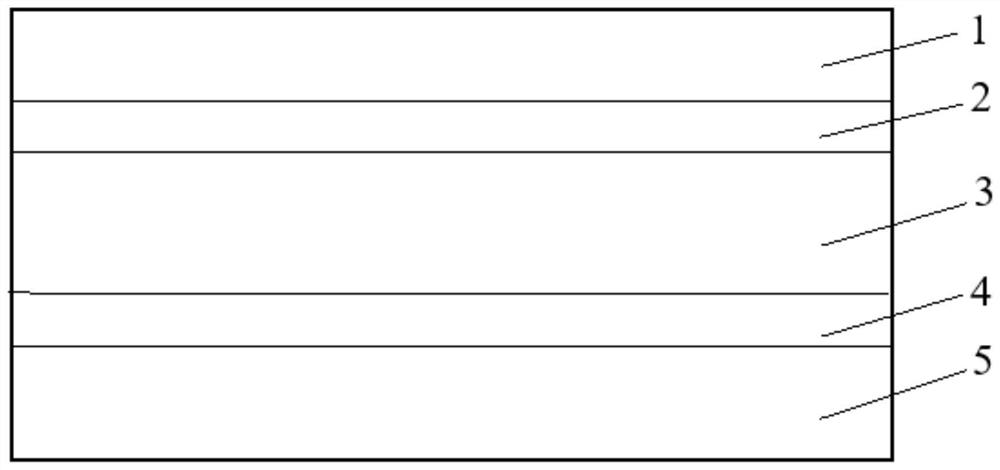

Photovoltaic module containing multilayer packaging adhesive film and preparation method thereof

PendingCN111863996AExcellent anti-PID performanceImprove production yieldNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveBattery cell

The invention provides a photovoltaic module containing a multilayer packaging adhesive film and a preparation method thereof. The photovoltaic module containing the multilayer packaging adhesive filmcomprises a front plate, an upper layer adhesive film, a battery piece, a lower layer adhesive film and a rear plate which are sequentially arranged from top to bottom, at least one layer of the upper layer adhesive film and the lower layer adhesive film is the multilayer packaging adhesive films, and the multilayer packaging adhesive film comprises at least two layers of packaging adhesive films. The photovoltaic module containing the multilayer packaging adhesive film has excellent PID resistance, and can meet the requirements for the packaging adhesive films with different functions.

Owner:CYBRID TECHNOLOGIES INC

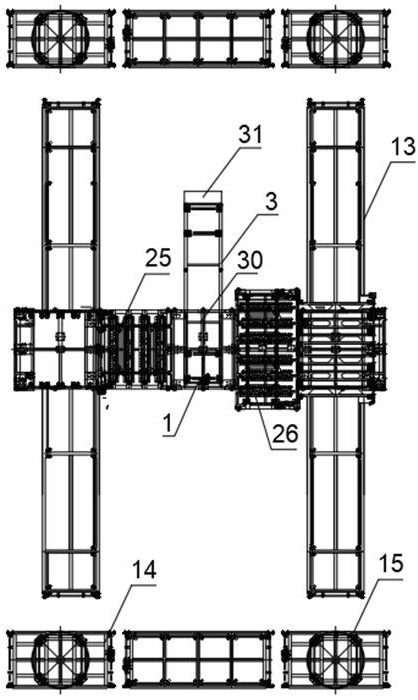

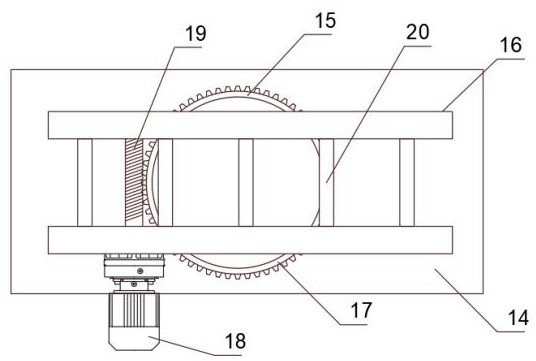

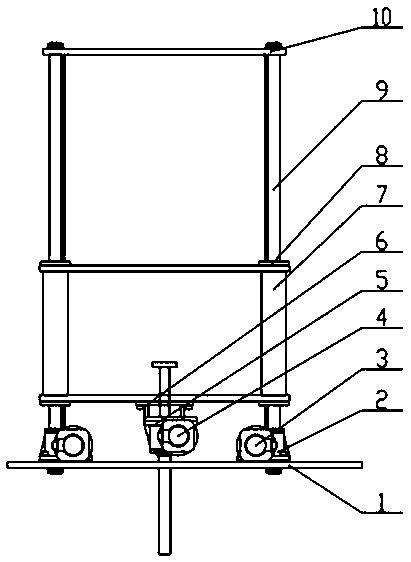

Automatic stacking equipment for stacking four iron cores at time

PendingCN112259358AReduce movement distanceShorten lamination timeInductances/transformers/magnets manufactureElectric machineGear wheel

The invention discloses automatic stacking equipment for stacking four iron cores at a time. The equipment comprises stacking mechanisms, each stacking mechanism comprises a supporting frame and a gantry support, the upper surface of the supporting frame is slidably connected with a supporting plate, the inner wall of the supporting frame is fixedly connected with a first driving motor, a tooth groove is formed in the lower surface of the supporting plate, the output end of the first driving motor is fixedly connected with a driving gear matched with the tooth groove, a first elevator is arranged on the lower end of the supporting frame. The invention belongs to the technical field of transformer production equipment. The four stacking mechanisms are matched with a circulation feeding mechanism, so that synchronous stacking of iron cores of four transformers can be realized; the circulation feeding mechanism is adopted, on one hand, the moving distance of a moving frame is reduced, thestacking time is shortened, the stacking efficiency is increased, and on the other hand, different yoke pieces are separately placed by a circulation feeding system, the stacking requirement is low,and yoke piece plate materials can be replaced or added at any time.

Owner:江苏金佳铁芯有限公司

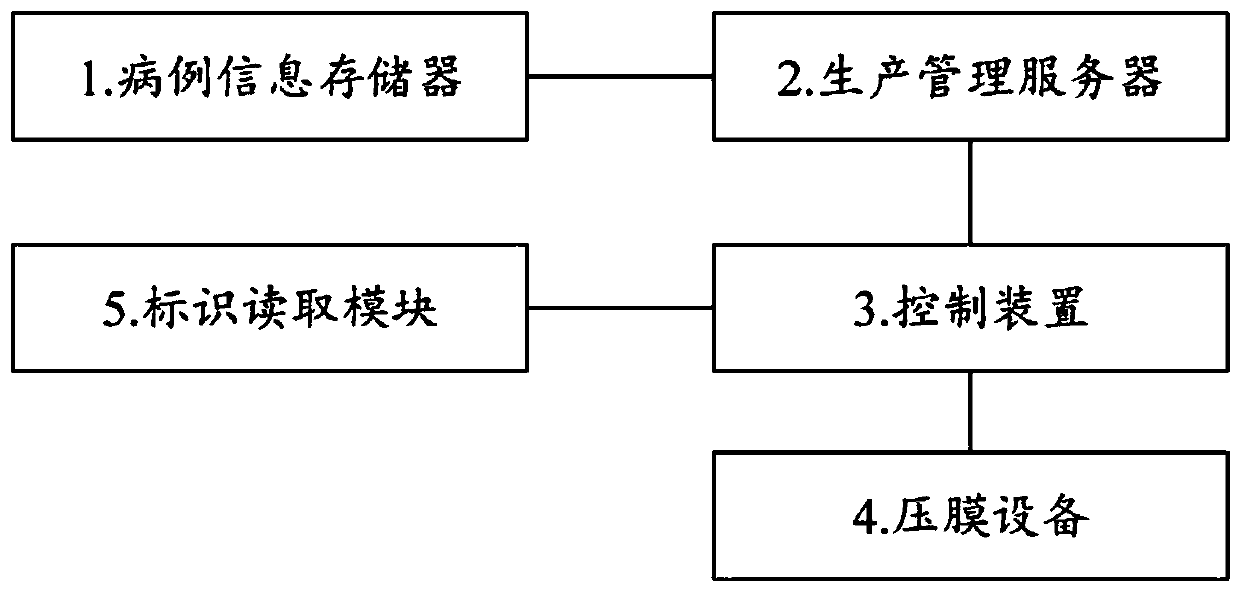

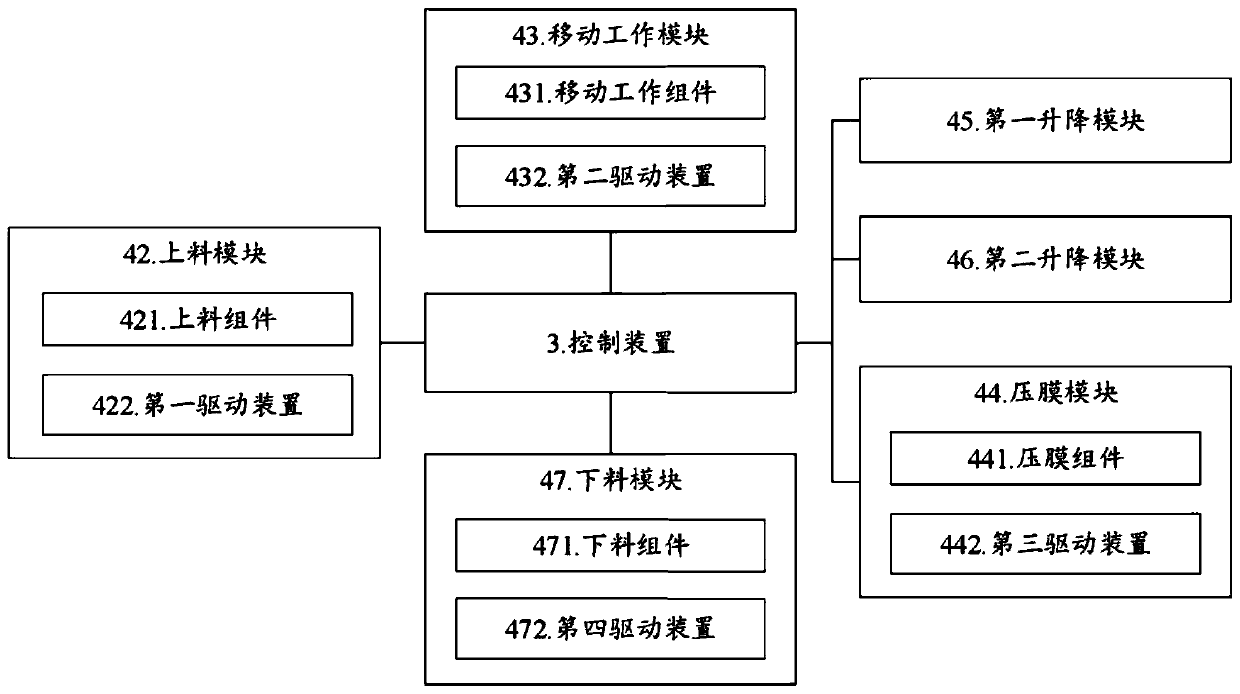

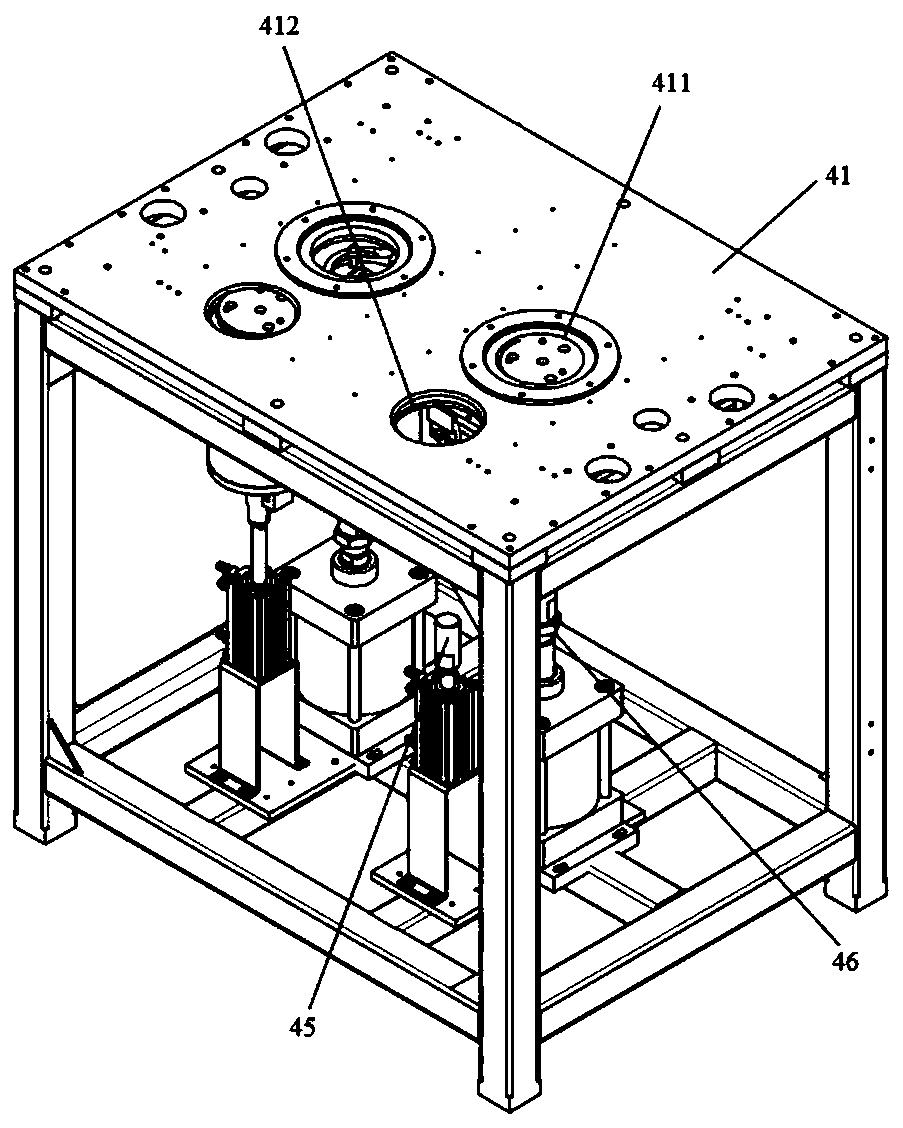

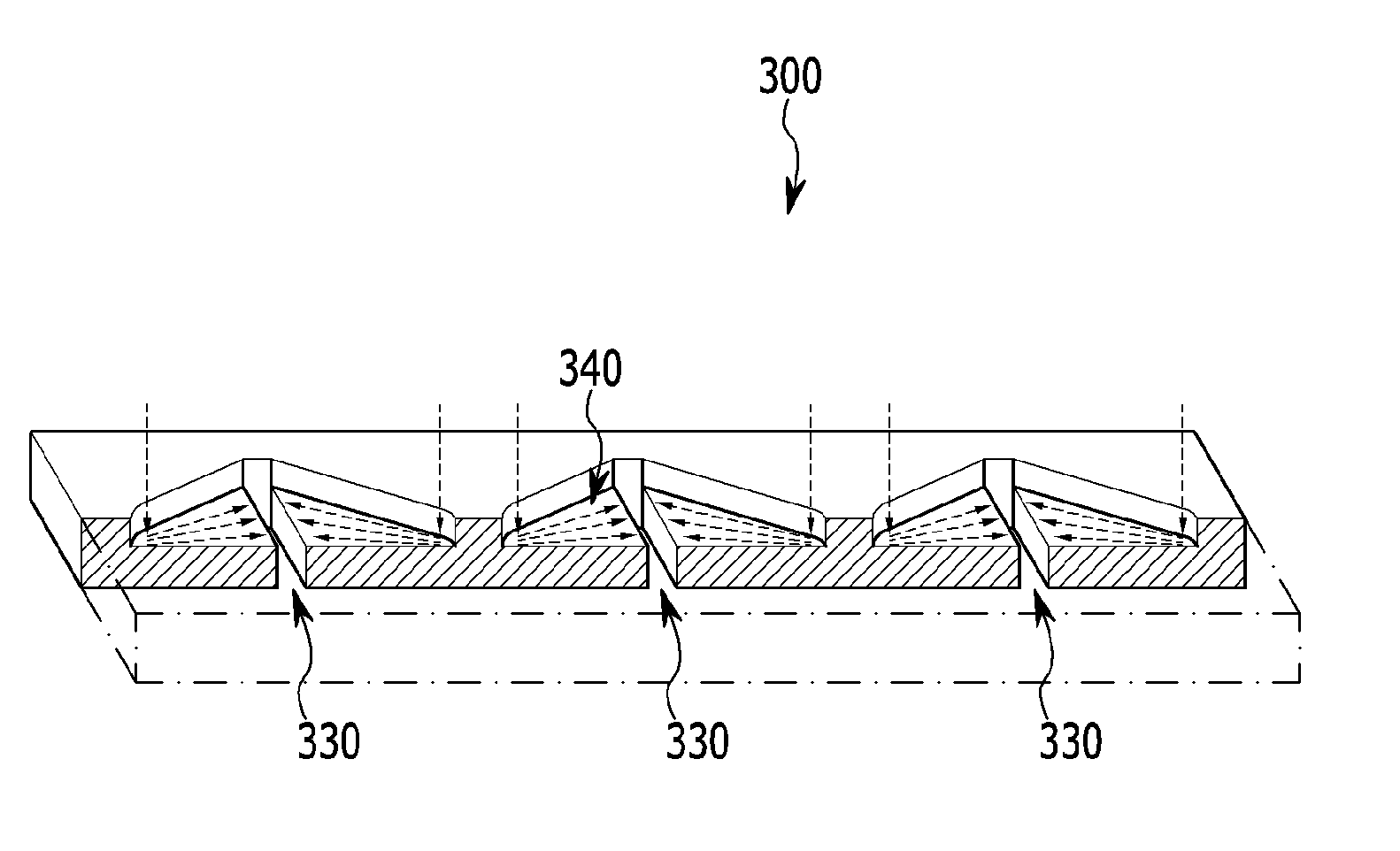

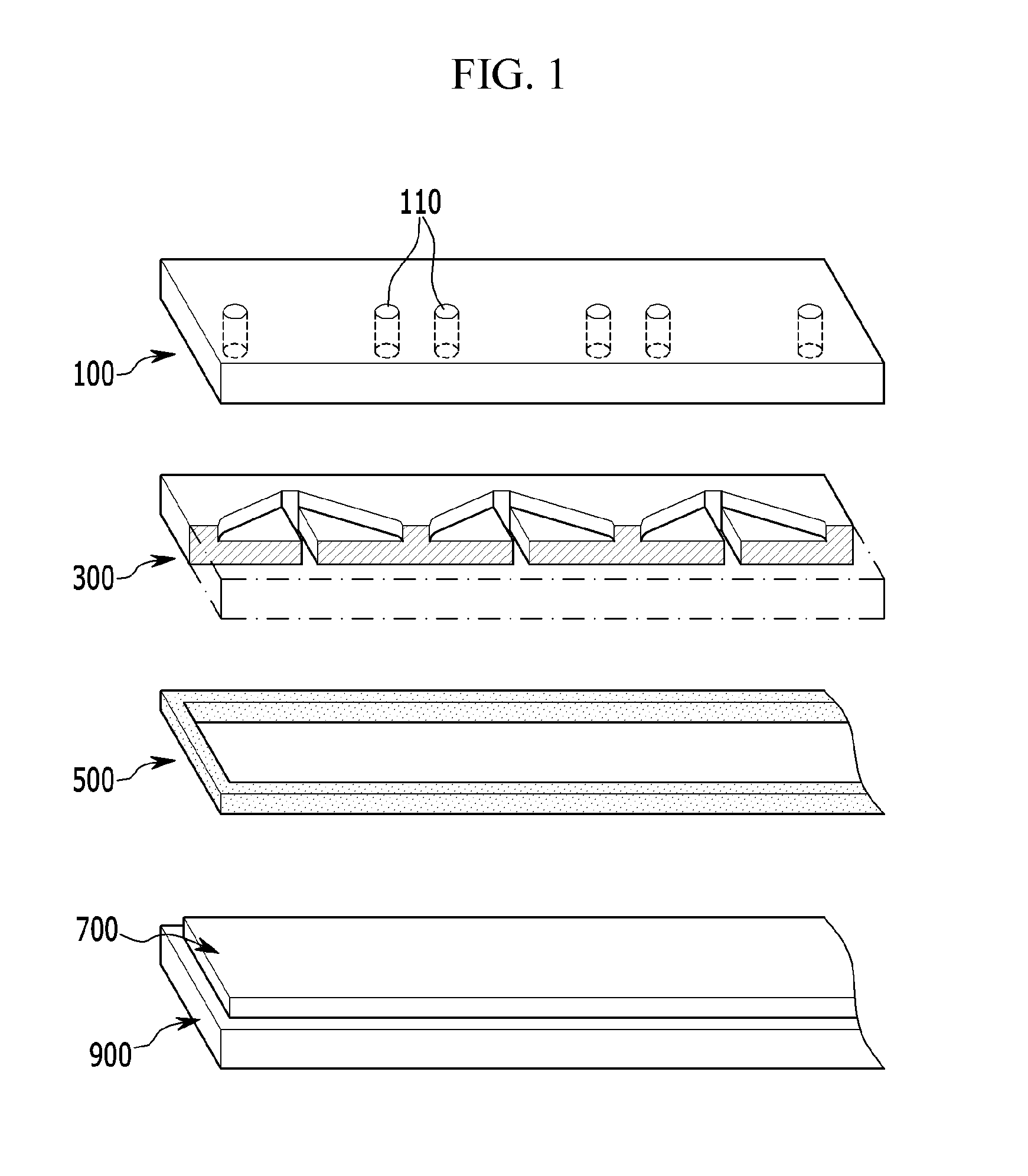

Membrane press system and method for production of shell-shaped tooth correction appliance

ActiveCN110696333AImprove processing efficiencyShorten lamination timeOthrodonticsThermodynamicsProcess engineering

The invention provides a membrane press system for production of a shell-shaped tooth correction appliance. A method comprises the steps that a production management server acquires a membrane press technology parameter of the shell-shaped tooth correction appliance from a case information storage according to user identification information and sends a membrane press command to a control device;the control device controls a feeding assembly to move and pick up a membrane and a tooth and jaw model assembly at the same time and convey the membrane and the tooth and jaw model assembly to a first station and a second station, and controls a second driving device to drive a movement work module to move, at the same time, a heating device is moved to the first station and a bearing table is moved to the second station, and the heating device is further controlled to heat the membrane according to a predetermined technology parameter; after heating is ended, the bearing table is controlledto move from the second station to the first station, and the heating device is away from the first station; a second lifting module is controlled to drive the bearing table borne with the tooth and jaw model assembly to ascend, and the membrane press assembly is controlled to press the heated membrane on the tooth and jaw model assembly according to the film press technology parameter.

Owner:浙江正雅齿科股份有限公司

Atomic layer deposition apparatus and method of atomic layer deposition using the same

ActiveUS20150275362A1Increase in sizeShorten lamination timeChemical vapor deposition coatingComputer moduleEngineering

An atomic layer deposition apparatus includes: a substrate support supporting a substrate; a first divider including a plurality of first division modules provided on the substrate support and selectively spraying a source gas, a reaction gas, and a purge gas to each of predetermined areas; and a second divider including a plurality of second division modules provided on the first divider and supplying the gases to the respective first division modules, wherein each of the plurality of second division modules is formed of a first through-hole and a second through-hole, and the gas passed through the first and second through-holes moves to the first division modules.

Owner:SAMSUNG DISPLAY CO LTD

Method for applying large bottom of shoes

The invention discloses a large sole doubling method, which comprises steps of coating a film layer on the large sole, activated in an oven (the oven is provided with UV lamps by intervals), doubled and shaped. The invention has the advantages that: in process, the large sole factory only needs to add one procedure and coats a layer of glue film on the sole surface while in process, the prior five procedures can be omitted while the same doubling effect can be obtained, the method overcomes the problems of the pollution on the environment and damages on operators in the prior procedures, saves the doubling time and labor force by about one half, and saves the doubling and shaping time by about one half. The non-doubled large soles can be used repeatedly, and the film edge materials can be recycled and added to the use of the large sole, thereby improving the production efficiency and lowering the cost.

Owner:许添华

Anti-PID packaging adhesive film for double-sided PREC battery and preparation method of anti-PID packaging adhesive film

PendingCN111635706ALight transmittance does not existReduce accumulationNon-macromolecular adhesive additivesFilm/foil adhesives without carriersAdhesiveAntioxidant

The invention relates to the technical field of packaging adhesive films, in particular to an anti-PID packaging adhesive film for a double-sided PREC battery and a preparation method of the anti-PIDpackaging adhesive film. The packaging adhesive film comprises an upper anti-polarization transparent EVA layer and a lower quick-curing high-cut-off transparent EVA layer, the anti-polarization transparent EVA layer comprises the following components in percentage by mass: the content of the ethylene-vinyl acetate copolymer resin is 80%-89%, the content of the antioxidant is 0.01%-1%, the contentof the light stabilizer is 0.01%-1%, the content of the crosslinking agent is 1%-2%, the content of the silane coupling agent is 0.1%-2%, the content of the inorganic anti-polarization material is 0.5%-2%, and the content of the organic anti-polarization material is 2%-8%; the PID-resistant packaging adhesive film for the double-sided PERC battery has a good PID-resistant effect on a double-sidedPREC battery single-package assembly and has the characteristic of good assembly reliability; meanwhile, a rapid curing cross-linking system is adopted so as to effectively shorten the assembly laminating time and greatly improve the assembly end production efficiency; in addition, the material cost of the co-extrusion adhesive film is relatively low, thereby being more beneficial to promoting photovoltaic equal-price networking.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Laminating system and laminating method

PendingCN111619190AUniform pressureShorten the timeLaminationLamination apparatusMechanical equipmentHot blast

The invention relates to the technical field of mechanical equipment, in particular to a laminating system and a laminating method. The laminating system comprises a pre-laminating device, a laminating device and a flexible chamber, wherein the flexible chamber is of a sealed structure and is used for accommodating a to-be-laminated assembly; the pre-laminating device and the laminating device each comprise a laminating machine. The laminating machine comprises a hot air circulation mechanism, an air exhaust mechanism and a butt joint mechanism. A hot air circulation mechanism is used for heating the flexible chamber; a butt joint mechanism is used for communicating the air exhaust mechanism with the flexible chamber in a butt joint manner; and the air extracting mechanism is used for extracting air from the flexible chamber. A traditional mechanical laminating mode is replaced with a vacuum laminating mode, laminating pressure borne by the laminating assembly is uniform and is not limited by whether the surface of an object to be laminated is flat or not, and the laminating effect is improved. And meanwhile, the pre-laminating device and the laminating device are matched for use,so that the laminating requirements of batch to-be-laminated assemblies can be met.

Owner:DONGJUN NEW ENERGY CO LTD

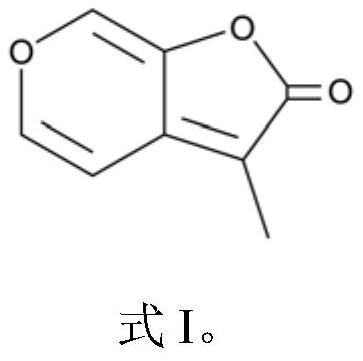

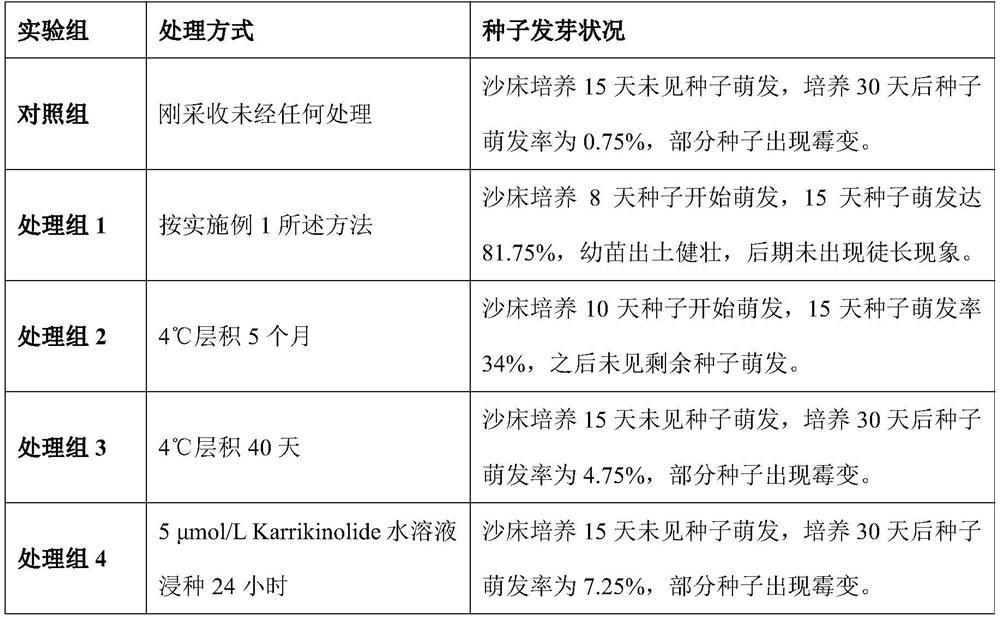

Method for breaking dormancy of rosa laevigata michx seeds and increasing germination rate

ActiveCN112868307ABreak dormancyImprove germination rateGerminating apparatusSeed dormancyAqueous solution

The invention discloses a method for breaking dormancy of rosa laevigata michx seeds and increasing germination rate. The method comprises the following steps that (1), seeds are soaked in a Karrikinolide aqueous solution with the concentration of 5-10 [mu]mol / L for 24 hours; (2), the soaked seeds are mixed with perlite, and low-temperature stratification is carried out at 4 DEG C for 30-40 days; (3), the laminated seeds are soaked in an aqueous solution containing 5-15 [mu]mol / L of sodium nitroprusside and 2.5-10 mmol / L of hydrogen peroxide for 24 hours; and (4), sowing is carried out in a sand bed. According to the method for breaking the dormancy of the rosa laevigata michx seeds and increasing germination rate, the dormancy of the rosa laevigata michx seeds is broken and the germination rate of the rosa laevigata michx seeds is increased in a 'seed soaking, lamination and seed soaking' mode, so that the germination rate of the rosa laevigata michx seeds reaches 80% or above, the lamination time in a traditional rosa laevigata michx seed dormancy breaking method is greatly shortened, and the technical bottleneck problem of large-scale production of rosa laevigata seedling plants is solved.

Owner:AGRO BIOLOGICAL GENE RES CENT GUANGDONG ACADEMY OF AGRI SCI +1

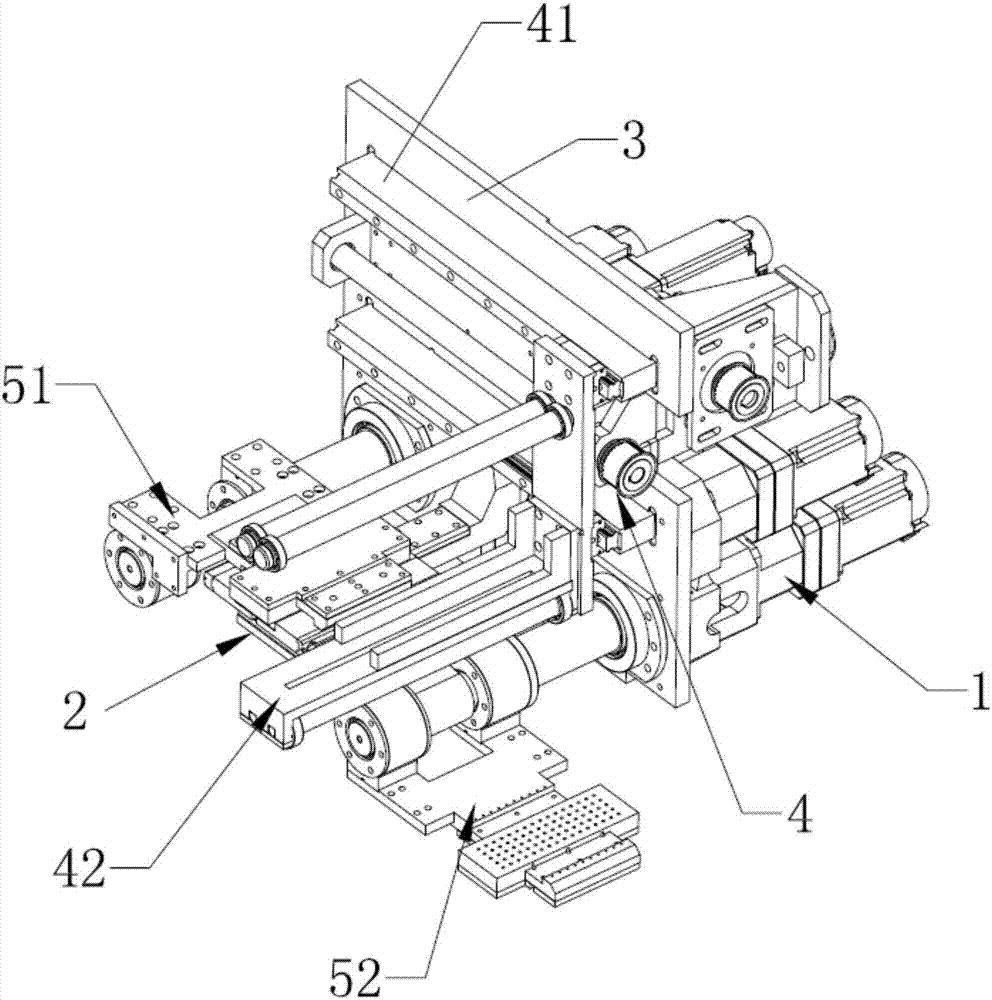

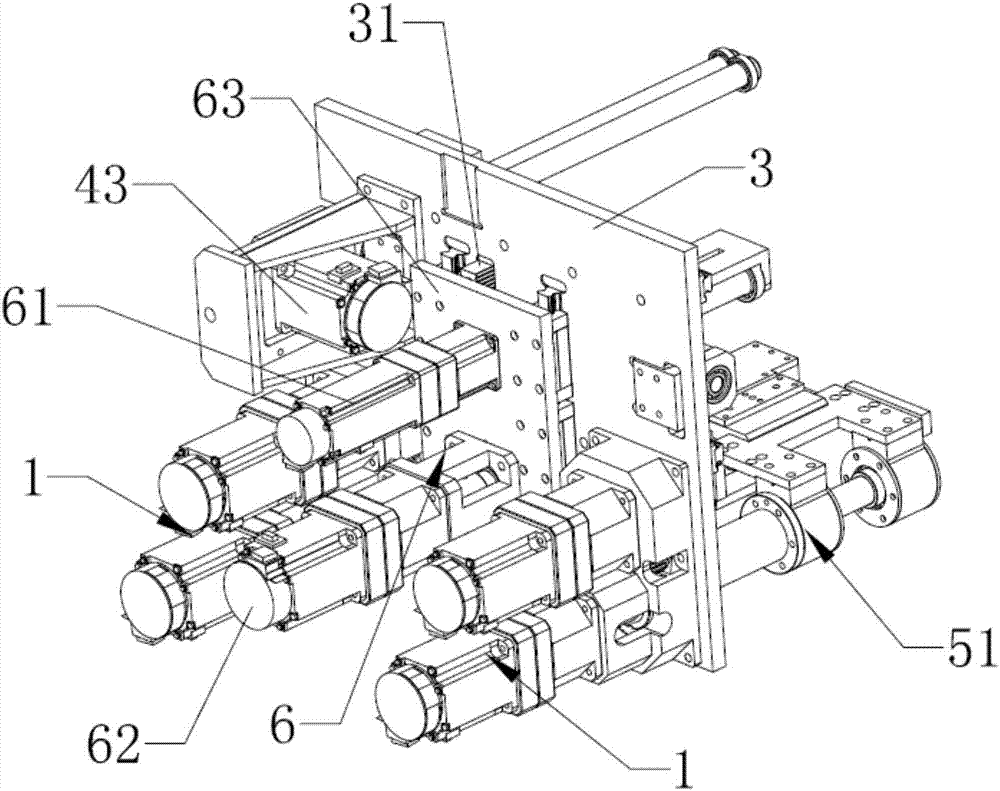

Cell high-speed lamination apparatus

ActiveCN106960983AShort lamination cycleImprove stabilityFinal product manufactureSecondary cellsPole pieceEngineering

The invention relates to the technical field of pole piece lamination, particularly to a cell high-speed lamination apparatus. The cell high-speed lamination apparatus comprises a driving mechanism, a lamination table and a mounting plate, wherein the driving mechanism is mounted on the mounting plate; the cell high-speed lamination apparatus also comprises a diaphragm moving mechanism and a rotary lamination mechanism mounted on the mounting plate; the diaphragm moving mechanism comprises a movable guiding rail and a diaphragm traction assembly; the diaphragm traction assembly is glidingly mounted on the movable guiding rail; the rotary lamination mechanism comprises a first rotary lamination assembly and a second rotary lamination assembly; the first rotary lamination assembly and the second rotary lamination assembly are in driving connection with the driving mechanism separately; and the first rotary lamination assembly and the second rotary lamination assembly are arranged on the two sides of the lamination table. The cell high-speed lamination apparatus is creative in structure, and capable of realizing uninterruptible feeding between the first rotary lamination assembly and the second rotary lamination assembly, so that lamination time can be saved, and faster and more efficient lamination and a shorter lamination period can be realized; and the lamination table is kept motionless in the lamination process, so that the lamination stability and accuracy can be improved, and the pole pieces can be stacked in a tidier manner.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

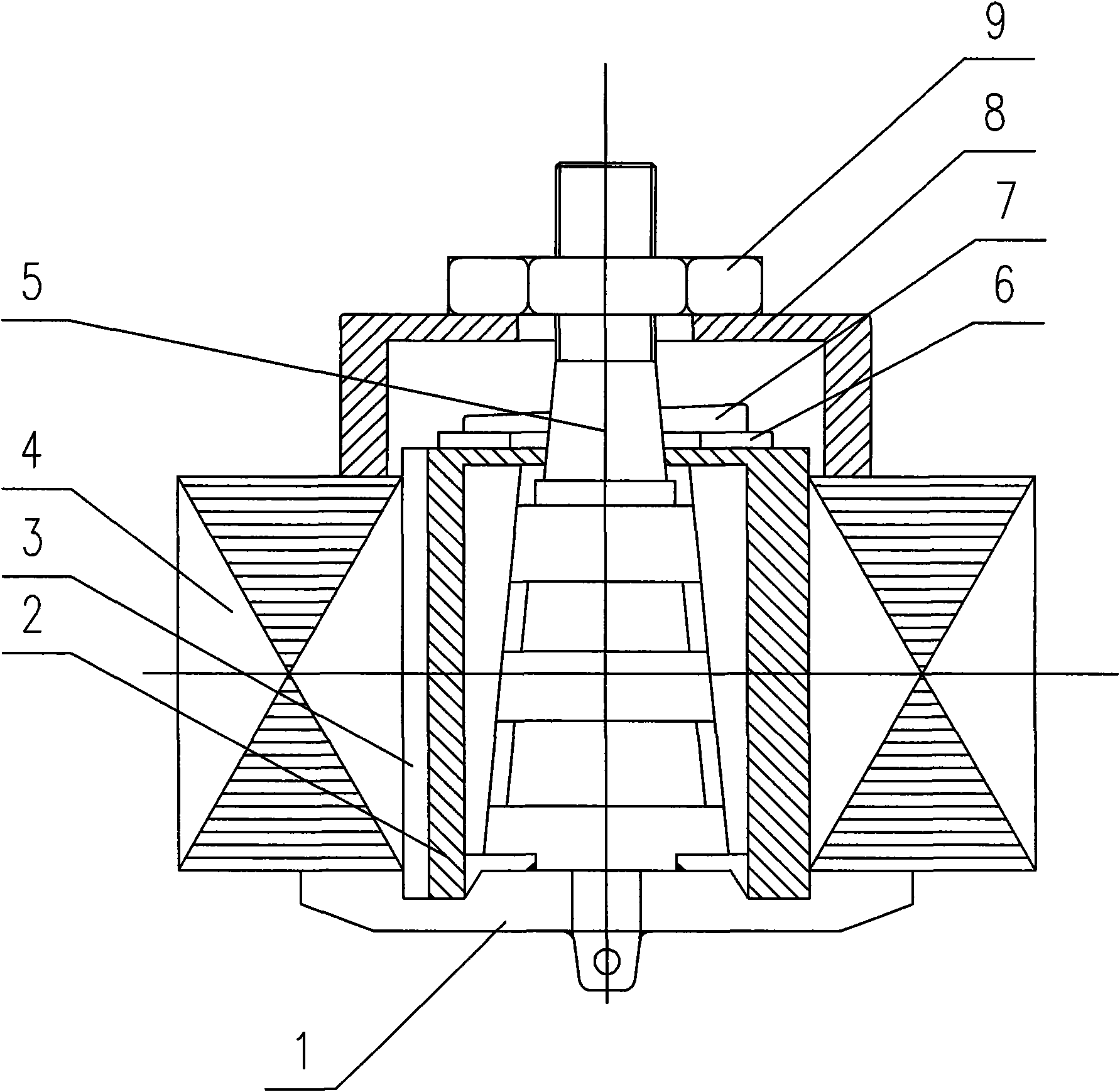

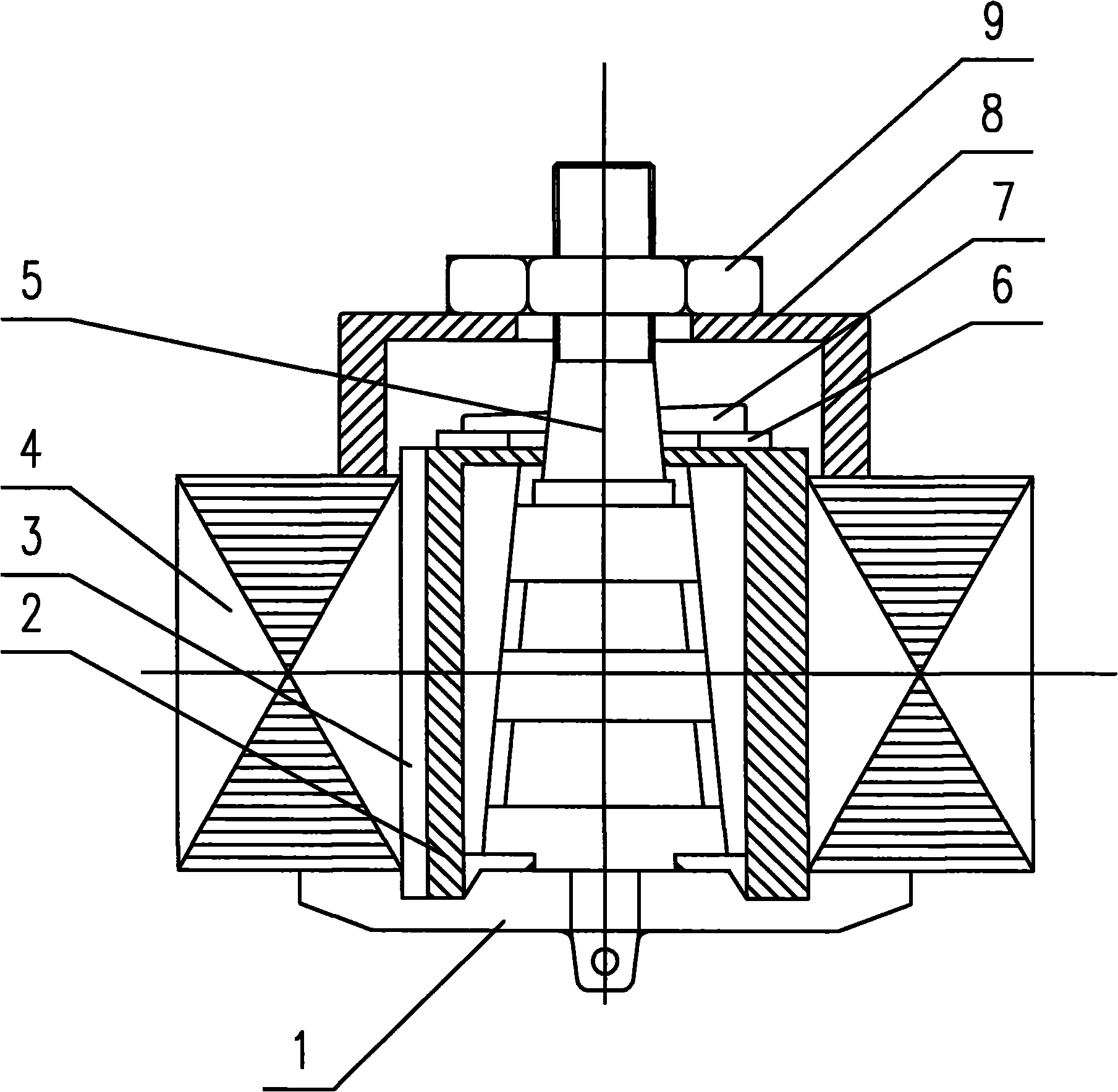

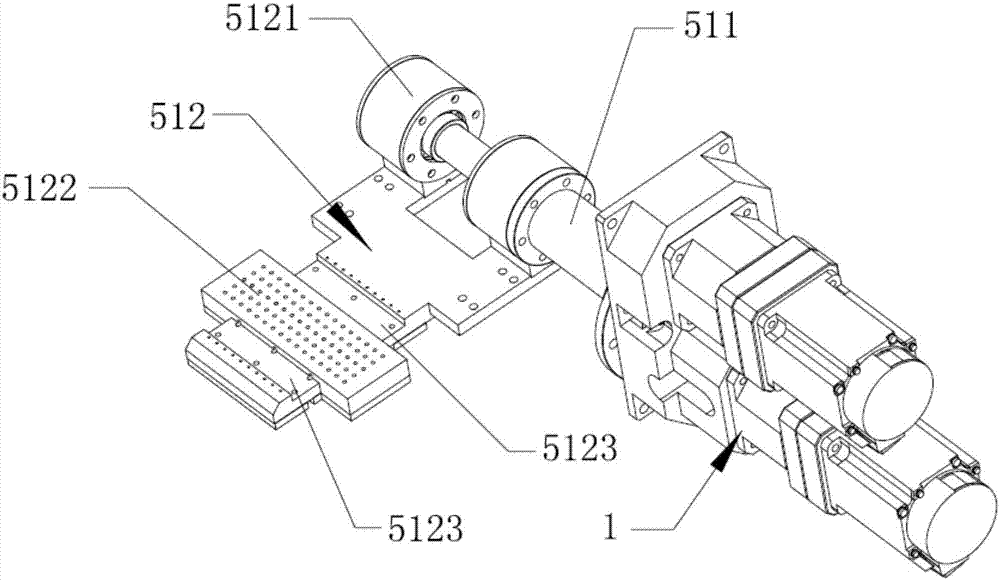

Lifting mechanism of sheet laminating device in automatic sheet laminating machine for direct-driven wind turbine stator iron core

The invention discloses a lifting mechanism of a sheet laminating device in an automatic sheet laminating machine for a direct-driven wind turbine stator iron core. The lifting mechanism comprises a Z-axis lifting unit, an S-axis lifting unit, a bottom plate (1) and a top plate (10). The Z-axis lifting unit is arranged between the bottom plate (1) and the top plate (10), the S-axis lifting unit isarranged on the Z-axis lifting unit, the Z-axis lifting unit is used for overall lifting of the sheet laminating device, and the S-axis lifting unit is used for lifting of silicon steel sheets. The lifting mechanism is provided with the two lifting units, the Z-axis lifting unit is used for overall lifting of the sheet laminating device, the S-axis lifting unit is used for lifting of the siliconsteel sheets, the two lifting units work simultaneously, and the heights of the sheet laminating device and the silicon steel sheets are adjusted according to the sheet laminating process, so that thesilicon steel sheets can be more rapidly sucked to be laminated, the sheet laminating time is shortened, and the overall production efficiency is improved.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

efficient EVA packaging adhesive film with lamination time shortened, and preparation method and application thereof

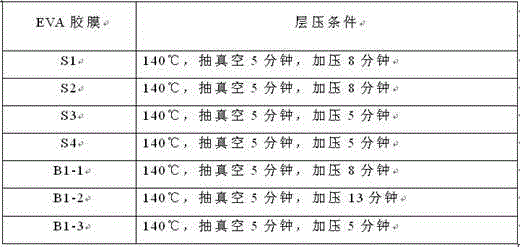

ActiveCN107984658AShorten lamination timeDoes not affect reliabilityOther domestic articlesElectron radiationChemistry

The invention provides an efficient EVA packaging adhesive film with the lamination time shortened, and a preparation method and application thereof. The preparation method of the EVA packaging adhesive film comprises the following steps of carrying out electron radiation on a transparent EVA adhesive film to obtain a pre-crosslinked transparent EVA adhesive film; carrying out electron radiation on a barrier EVA adhesive film to obtain a pre-crosslinked barrier EVA adhesive film; and carrying out lamination on the pre-crosslinked transparent EVA adhesive film and the pre-crosslinked barrier EVA adhesive film for 5 minutes to 10 minutes at the temperature of 140 DEG C to 150 DEG C to obtain the EVA packaging adhesive film. According to the efficient EVA packaging adhesive film with the lamination time shortened, and a preparation method and application thereof, under the conditions that no other additives are added, lamination is carried out after cross-linking is carried out on the transparent EVA adhesive film and the barrier EVA adhesive film through electron radiation, the time for lamination can be effectively shortened, reliability is not affected, apparent affects can be avoided, and the production cost is greatly reduced.

Owner:嘉兴优固应用材料有限公司 +3

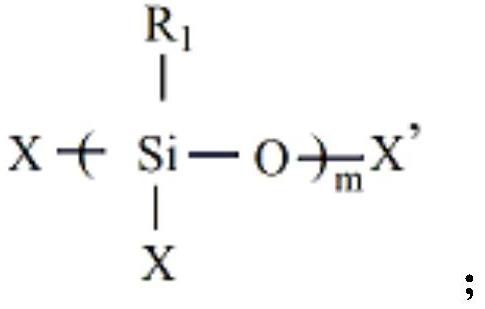

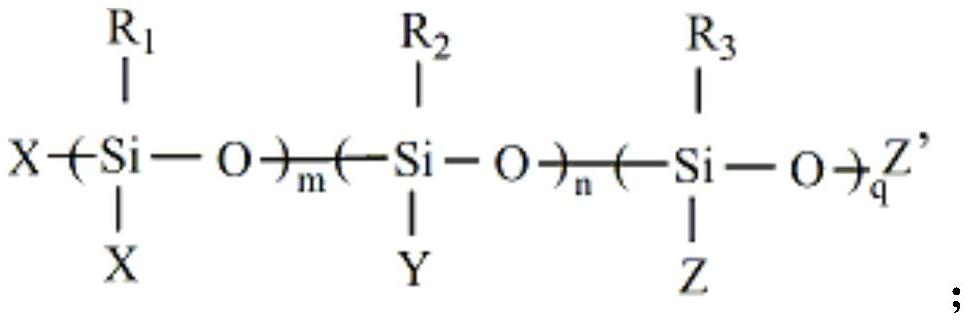

Preparation method of silane crosslinked ethylene-vinyl acetate copolymer adhesive film

ActiveCN103131336BImprove lamination efficiencyReduce manufacturing costNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSilanes

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

A kind of silane grafted poe adhesive film for photovoltaic encapsulation and preparation method

ActiveCN108753184BHigh melting temperatureSolve the problem of poor thermal creep resistance that is prone to occurNon-macromolecular adhesive additivesMacromolecular adhesive additivesUltraviolet lightsThermal creep

The invention belongs to the field of photovoltaic encapsulation adhesive film and its preparation, and particularly relates to a silane-grafted POE photovoltaic encapsulation adhesive film and a preparation method thereof; the mass parts composition of the silane-grafted POE adhesive film is as follows: ethylene-octene copolymer resin 100 parts, 0.3-3 parts of silane grafting monomer, 0.05-0.25 parts of initiator, 5-20 parts of modified resin, 0.05-0.25 parts of co-grafting monomer, 0.5-4 parts of compatibilizer, UV stabilizer 0.05-0.3 part, 0.05-0.3 part of ultraviolet light absorber, 0.1-0.6 part of antioxidant; the adhesive film for POE photovoltaic encapsulation prepared by the present invention can be applied to flexible thin-film photovoltaic modules and traditional crystalline silicon photovoltaic modules at the same time, and can solve the problem of Problems of air bubbles, unmelted and poor thermal creep resistance in the aging process, shorten the lamination time of components, reduce the packaging defective rate, improve the production efficiency of components, and reduce production costs.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

High-strength hydrophobic high-reliability packaging adhesive film and preparation method thereof

PendingCN113372831AImprove water resistanceImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolyolefin

The invention relates to the technical field of packaging materials for photovoltaic modules, and provides a high-strength hydrophobic high-reliability packaging adhesive film. The high-strength hydrophobic high-reliability packaging adhesive film comprises an EVA adhesive film layer, a high-strength hydrophobic layer, a water absorption bonding layer and a polyolefin adhesive film layer which are sequentially arranged from top to bottom. Transverse and longitudinal grooves are formed in the upper surface of the EVA adhesive film layer and the lower surface of the polyolefin adhesive film layer and form #-shaped pattern surfaces; a plurality of regular first arc structures are arranged on the lower surface of the high-strength hydrophobic layer; and a second arc structure matched with the first arc structure is arranged on the upper surface of the water absorption bonding layer. The invention further provides a preparation method of the high-strength hydrophobic high-reliability packaging adhesive film. The front surfaces of the composite high-strength hydrophobic layer and the water absorption bonding layer functional film are compounded with the transparent EVA adhesive film, the back surfaces are compounded with a transparent polyolefin film, and then the upper surface and the lower surface are subjected to #-shaped embossing and rolling. The packaging adhesive film is good in water blocking effect and high in tensile strength, the mechanical performance of a packaging assembly can be effectively improved, and the lightweight design of the packaging assembly is promoted.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

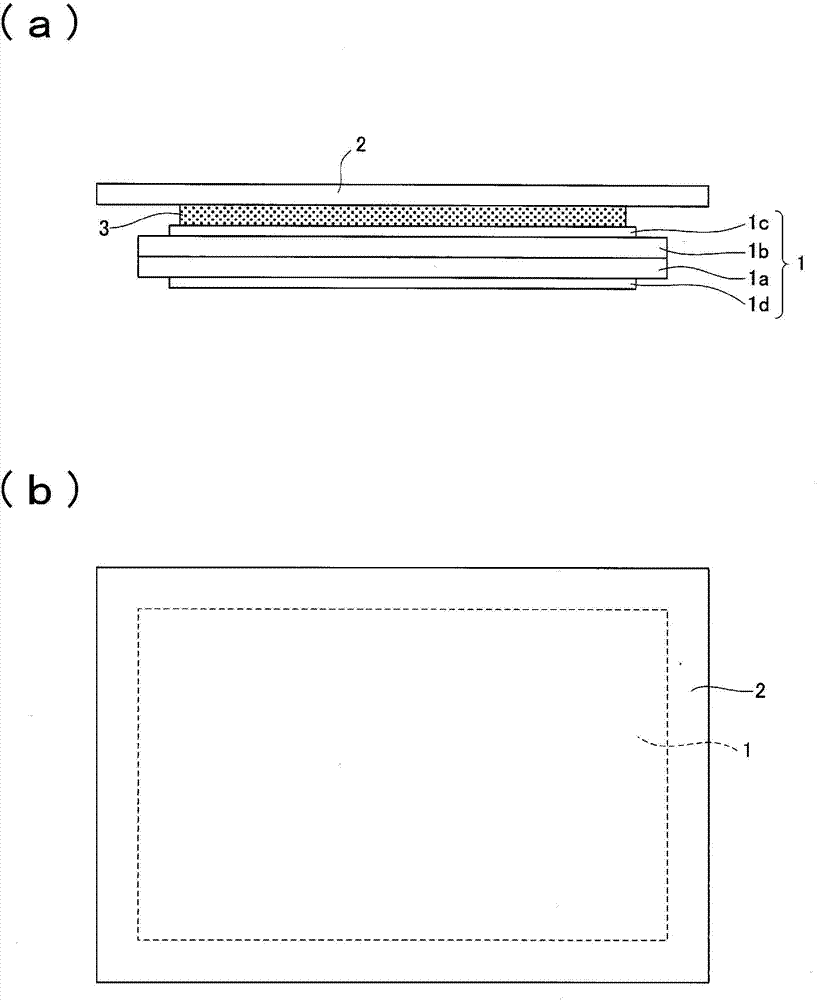

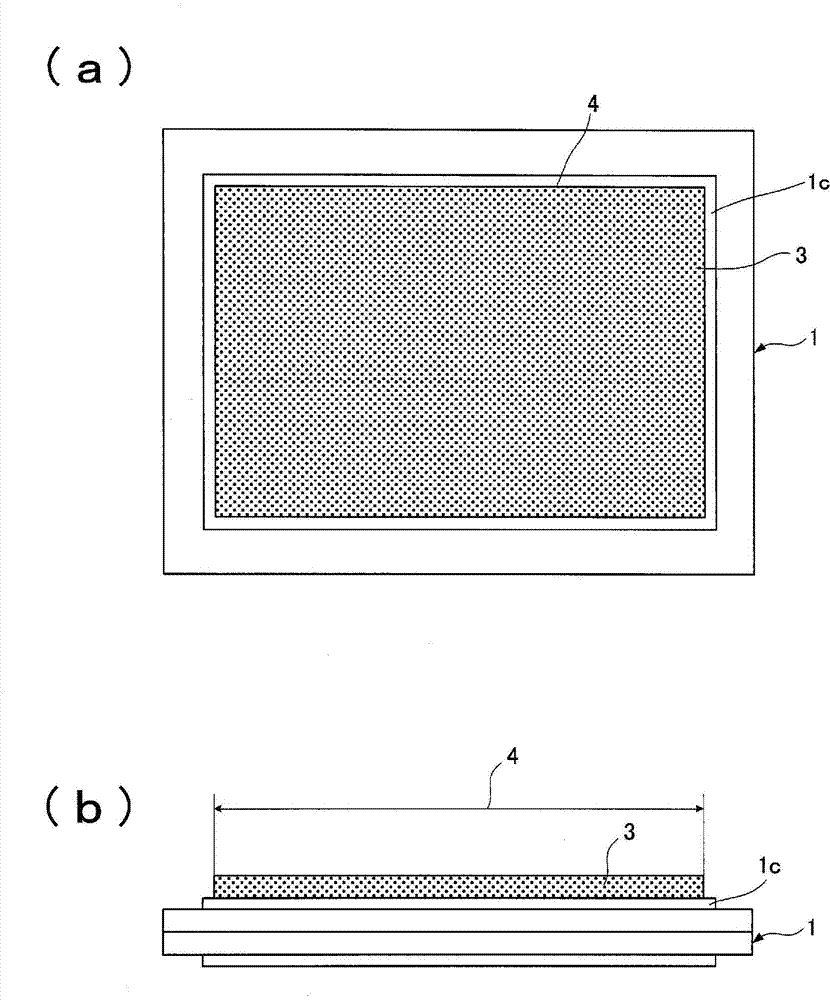

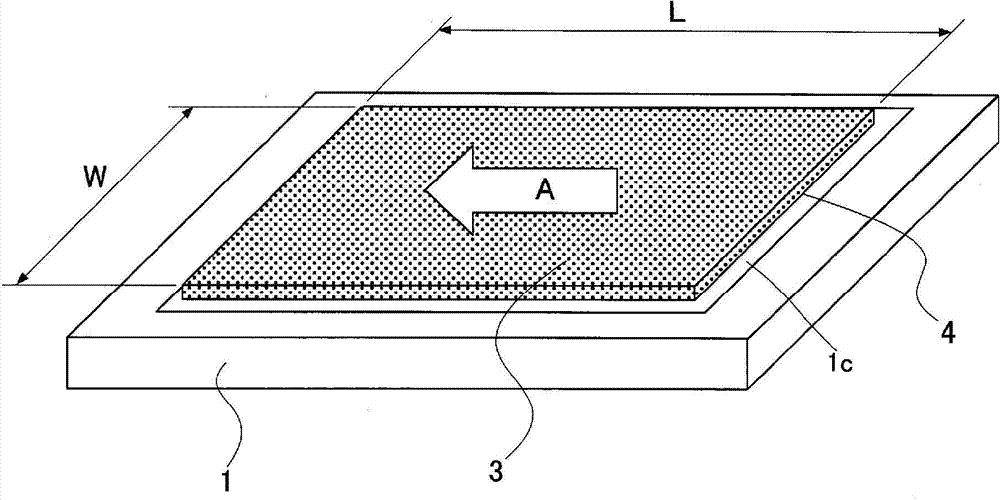

Method for attaching panel and apparatus therefor

InactiveCN103773255AWon't overflowAvoid flowAdhesive processesInput/output processes for data processingEngineeringCoating

The invention provides a method for attracting a panel and an apparatus therefor. A first panel (1) and a second panel (2) are bonded. The whole surface of the first panel (1) is coated into a rectangle with resin (3). At the same time, one pair of edges (L1 and L2) and another pair of edges (W1 and W2) relative to the periphery of the resin (3) are respectively higher than a coating surface (4a) inside the resin (3), and through coating, the heights of the edges (L1 and L2) are different from the heights of the edges (W1 and W2). The periphery of the overall-coated resin (3) is half solidified. Then, the first panel (1) and the second panel (2) are enabled to be opposite to each other, and after the first panel (1) and the second panel (2) are tightly bonded, all the resin (3) is fully solidified.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

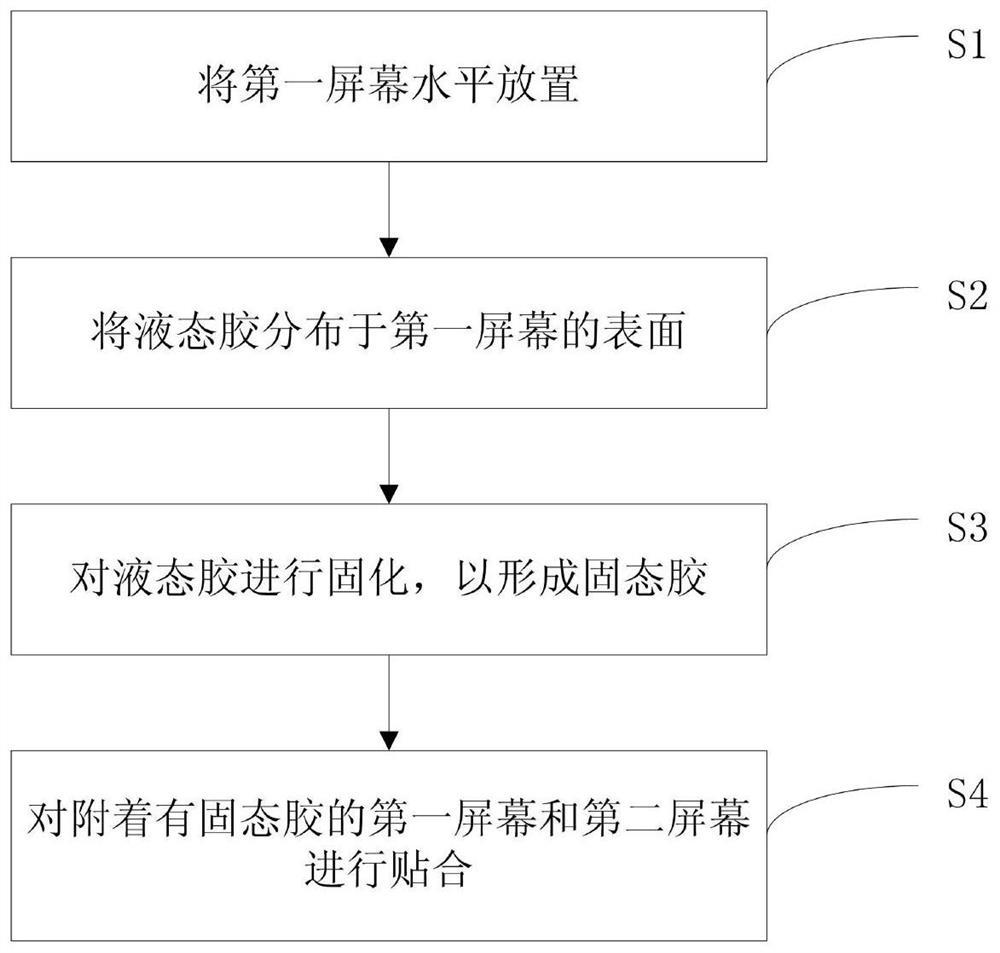

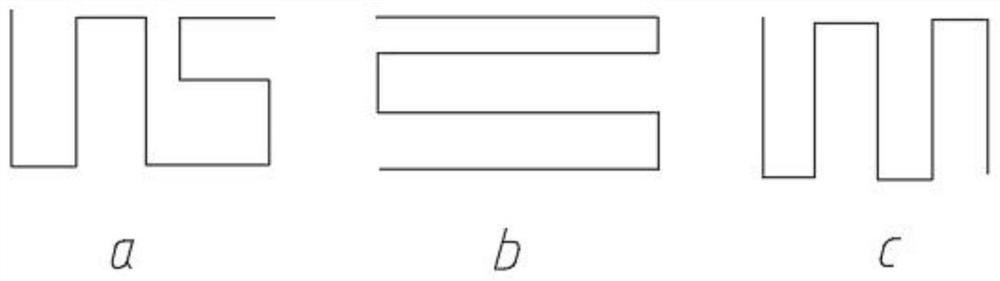

Full-lamination method, touch display module and full-lamination system

InactiveCN113653714AStable formStickyMaterial gluingAdhesive processes with adhesive heatingLiquid stateMechanical engineering

The invention relates to a full-lamination method, a touch display module and a full-lamination system, which are used for laminating a glass screen and a display screen. The full-lamination method comprises the following steps: horizontally placing a first screen; distributing liquid glue on the surface of the first screen; curing the liquid glue to form solid glue; and laminating the first screen and a second screen which are attached with the solid glue. According to the full-lamination method provided by the invention, a step of the first screen is filled and leveled up with the liquid glue by utilizing the characteristic of high fluidity of the liquid glue, the upper surface of the liquid glue is ensured to be horizontal, the liquid glue is cured to form the solid glue, the solid glue is stable in form and has viscosity, and then the first screen and the second screen attached with the solid glue are laminated, so that the laminating time is greatly saved, and the laminating stability is improved; and moreover, before lamination, abnormity (bubbles and smudginess) can be repaired in time, the lamination yield can be improved, the efficiency is high, the productivity is large, and the stability is high.

Owner:XIANGSHI ENERGY SAVING GLASS KUNSHAN CO LTD

Laminating machine heating device, laminating machine and heating method of prepackaging assembly

The invention relates to the field of laminating equipment and discloses a laminating machine heating device, a laminating machine and a heating method of a prepackaging assembly. The laminating machine heating device comprises a heating cavity, a heating assembly, a gas circulating device, a separation component and a plurality of air inlet ends, wherein the heating assembly and the gas circulating device are arranged in the heating cavity, the separation component is arranged in the heating cavity to divide the heating cavity into an inner cavity and an outer cavity, an air outlet end corresponding to the gas circulating device and a plurality of air inlet ends are arranged on the separation component, air circulates between the inner cavity and the outer cavity, and the temperature in the heating cavity is uniformly distributed. Compared with the prior art, the laminating machine heating device has the advantages that the heat loss in the heat conduction process is reduced, the prepackaging assembly in a vacuum bag can be comprehensively and uniformly heated, the laminating time is shortened, and the laminating efficiency is improved.

Owner:DONGJUN NEW ENERGY CO LTD

Reeled strip-shaped carrier

InactiveCN103738584AContinuous and stable productionShorten lamination timePackagingEngineeringMechanical engineering

Owner:SUZHOU MIDAS PRECISION ELECTRONICS

Method for improving packaging fastness of color layer and adhesive film of solar photovoltaic module

ActiveCN112701193AStable formWithout compromising qualityFinal product manufacturePhotovoltaic energy generationPhysical chemistrySolar battery

The invention belongs to the technical field of photovoltaic modules, and particularly relates to a method for improving the packaging fastness of a color layer and an adhesive film of a solar photovoltaic module. The method at least comprises the following steps: (1), spraying a bridging agent to an adhesive film layer or a color layer printed on glass, the adhesive film layer being a PVB adhesive film or an EVA adhesive film, and the bridging agent containing unsaturated double bonds; (2), carrying out hot air drying on the sprayed bridging agent; and (3), laminating the solar cell module, the adhesive film layer and the glass printed with the color layer in a laminating machine to obtain the solar cell module. According to the technical scheme, the inventor sprays the bridging agent on the adhesive film layer or the color layer printed on the glass, so that the bonding strength between the adhesive film layer and the color layer is greatly improved, the stability of the solar photovoltaic module is improved, the laminating time of the solar photovoltaic module is shortened, and the laminating cost is saved. The production efficiency of the solar photovoltaic module is improved, and the service life of the solar photovoltaic module is prolonged.

Owner:BEIJING JINWU NEW ENERGY TECH CO LTD

Release membrane and protection membrane

PendingCN107227127AShorten lamination timeIncrease productivityFilm/foil adhesivesChemistryMembrane bodies

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com