Laminated structure and laminating technology of solar panel component

A solar panel and solar cell technology, applied in electrical components, circuits, photovoltaic power generation and other directions, can solve the problems of low production efficiency, poor light transmittance of ordinary tempered glass, low photoelectric conversion rate, etc., to improve production efficiency, The effect of shortening the lamination heat sealing time and improving the photoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

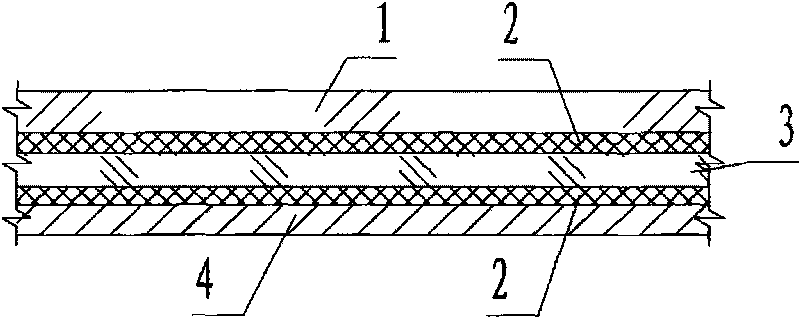

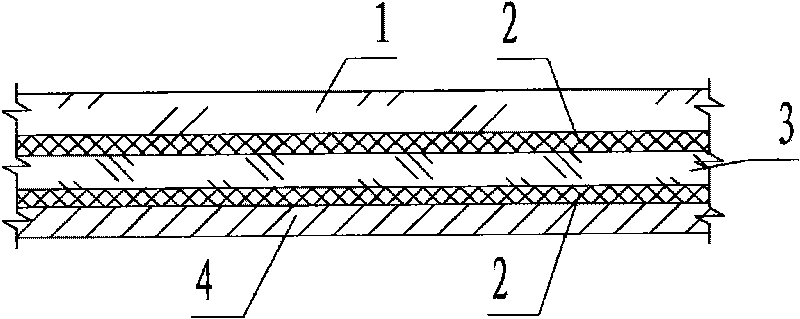

[0025] refer to figure 1 , figure 2 , a laminated structure of a solar panel assembly of the present invention, comprising a five-layer structure consisting of coated tempered glass 1, EVA2, monocrystalline silicon solar cell 3, EVA2, and BBF back film 4 from top to bottom, wherein: the The coated tempered glass 1 is a transparent tempered glass coated with an anti-reflection film on the upper surface; the EVA2 is a transparent hot-melt adhesive film of ethylene / vinyl acetate copolymer; the monocrystalline silicon solar cell 3 is a plurality of A sheet-shaped photovoltaic cell group formed by welding a single monocrystalline silicon battery sheet with a low-resistivity tin-plated busbar in series; the BBF back film 4 is a copolymer of EVA-PET-THV with a thickness of 0.4 mm film.

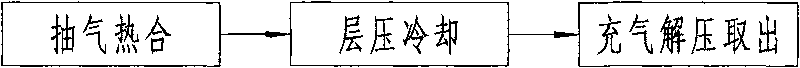

[0026] The lamination process method is as follows: pumping and heat sealing, lamination cooling, inflating and decompressing to take out;

[0027] Step 1, heat sealing

[0028] Lay the coated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com