Rapid laminating machine with double-glass photovoltaic assembly

A double-glass photovoltaic and laminator technology, applied in the directions of lamination, photovoltaic power generation, lamination devices, etc., can solve the problems of long lamination cycle time, improve product quality and production efficiency, and improve the consistency of cross-linking degree , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

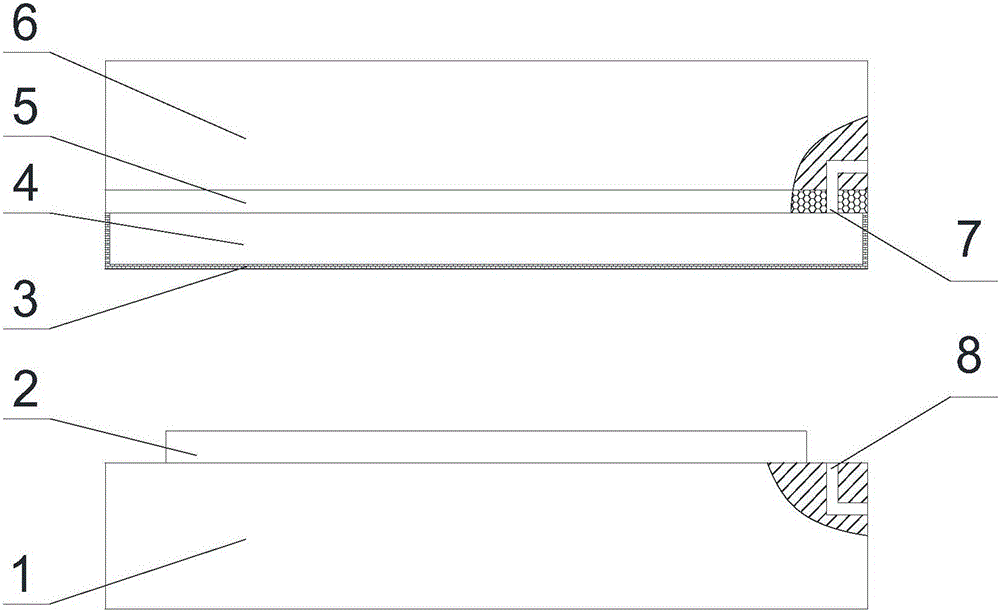

[0017] Such as figure 1 Shown: A rapid lamination machine for double-glass photovoltaic modules is provided, including an upper layer heating module 6, an infrared radiation coating 5, a silica gel plate 3, a lower layer heating module 1, and a vacuum system.

[0018] The upper heating module 6 refers to including at least three heating units capable of independently and accurately controlling the temperature of the area, so as to ensure the heating uniformity and temperature rise consistency of the module, and is provided with a pipeline port 7 of a vacuum system. Heating methods include but are not limited to heat conduction oil heating, electric heating, oil-electric hybrid heating, infrared heating, etc.

[0019] The lower heating module 1 refers to including at least three heating units capable of independently and accurately controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com