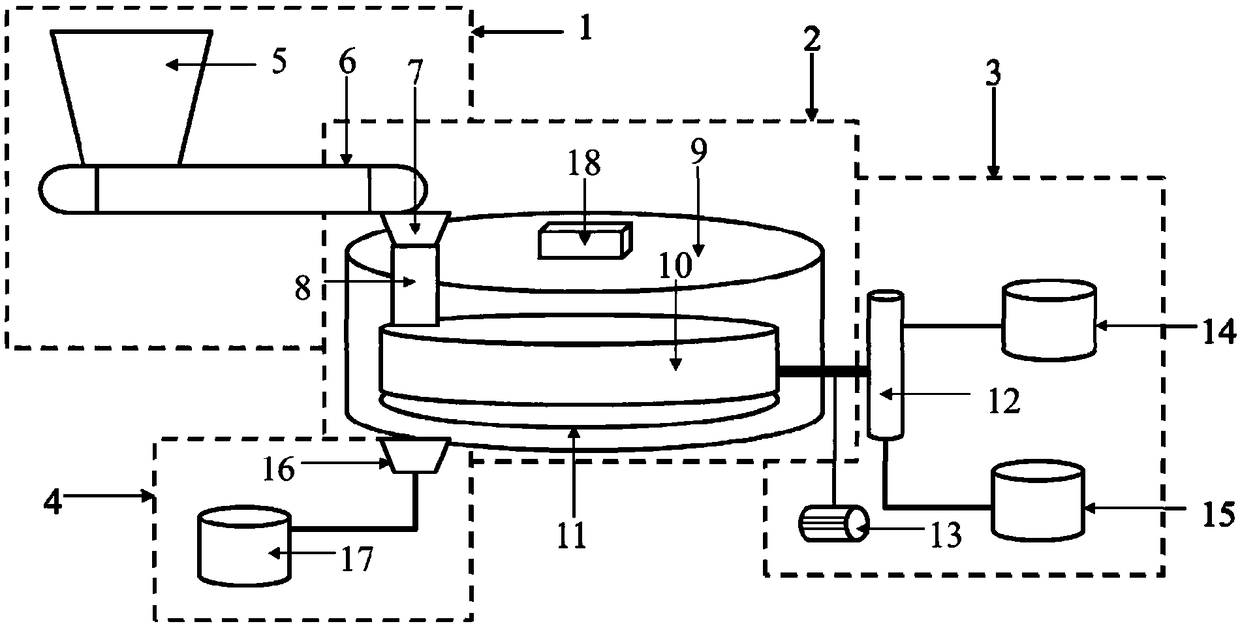

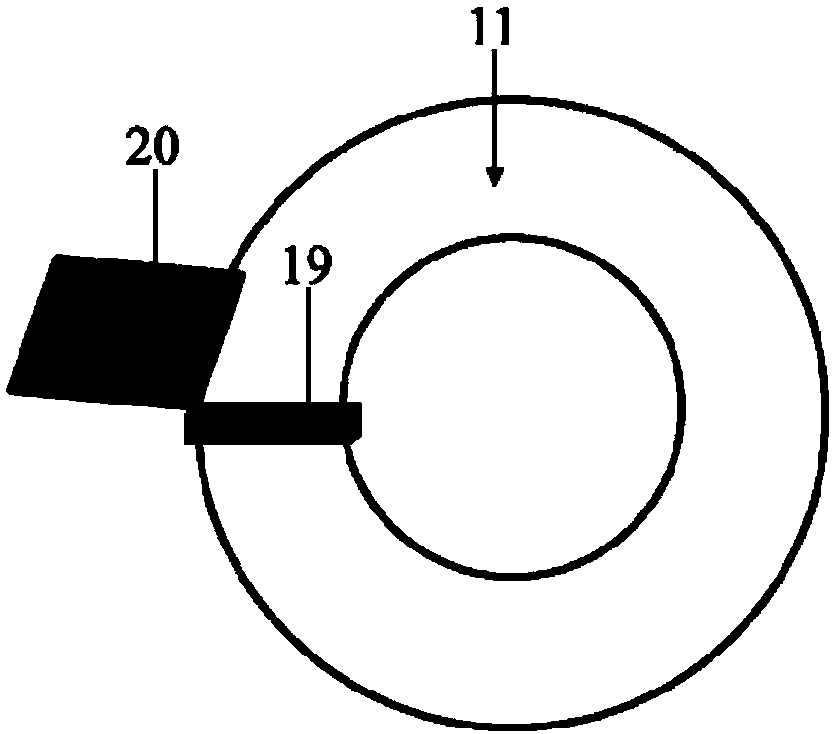

Oil-based drill cutting continuous microwave pyrolysis device and process

A technology of oil-based drill cuttings and pyrolysis, which is applied in the petroleum industry, pyrolysis treatment of sludge, and treatment of hydrocarbon oil. It can solve the problems of ineffective use of pyrolysis residue heat energy and low microwave absorption efficiency. Uniform distribution, prolonging service life and saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0045] Implementation case: Oil-based drill cuttings were dried in Zhejiang Oilfield, with a water content of 5% and an oil content of 4%.

[0046] The oil-based drill cuttings are placed in the continuous microwave pyrolysis equipment of the present invention for pyrolysis reaction. The temperature is increased for 20 min to 500° C. under 900 W power, and the temperature pyrolysis is 30 min. The oil and gas recovery rate is above 90%, and the oil content of the pyrolysis residue is It is 0.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com