Lightweight double-glass module

A double-glass component and lightweight technology, applied in the field of solar cells, can solve the problems of reducing the power generation efficiency and life of the component, increasing the development cost of the component PID, sealing material and cell damage, etc., achieving little difference, weight reduction, sealing small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

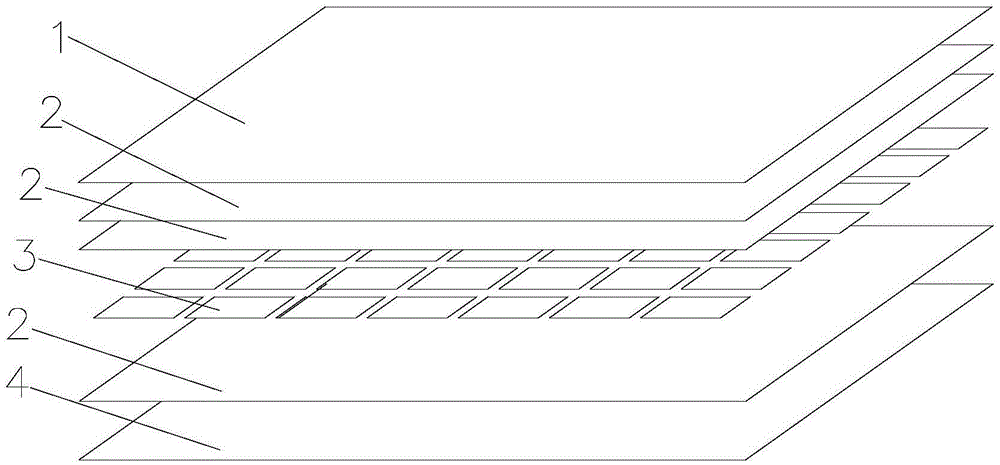

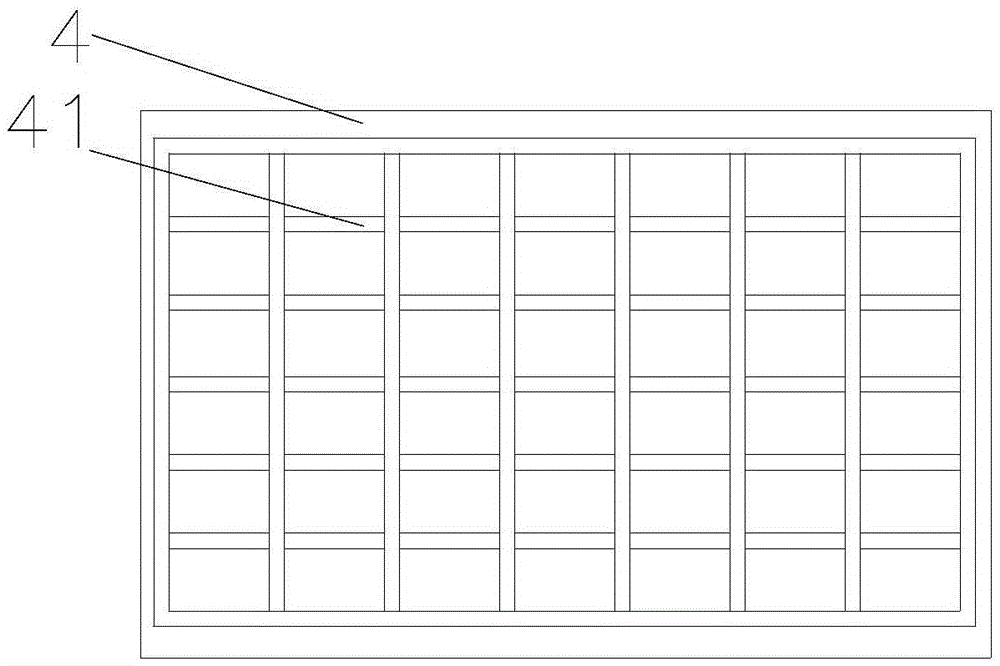

[0027] Such as figure 1 As shown, the module stacking method: use 0.85mm anti-reflective coating chemically tempered glass 1 for the positive glass, first spread two POE sheets on the positive glass, and then arrange the battery string 3 on it, after welding, then install the battery string 3 Lay a piece of POE on top of it, and cover it with 2.0mm physical toughened glass 4.

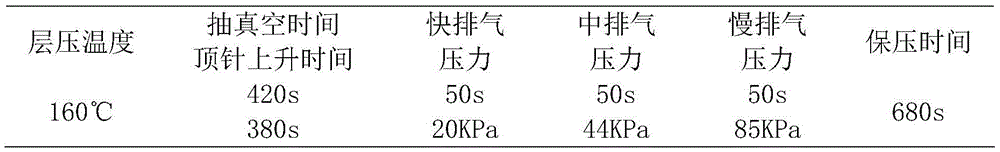

[0028] Among them, the encapsulation layer 2 POE needs to achieve a corresponding cross-linking degree of about 75%-90% and a peel strength tensile force of more than 100N, and the lamination process needs to realize that the battery string 3 does not have lamination problems such as parallel strings, string expansion, and air bubbles. The sealing material itself also needs to undergo UV aging 60kw*h / m 2 , TC200 and DH1000 tests; the chemical tempered glass 1 surface stress value is greater than 640Mpa, and in the drop ball test, a 1040g ball falls to 60cm, and its warpage, bow bend, and wave bend shou...

Embodiment 2

[0036] The chemically tempered glass 1 in Example 1 is replaced by chemically tempered glass 1 with a thickness of 0.55 mm, the physically tempered glass 4 is replaced with chemically tempered glass 1 with a thickness of 2.2 mm, and other structures are the same as in Example 1.

Embodiment 3

[0038] The chemically tempered glass 1 in Example 1 is replaced with chemically tempered glass 1 with a thickness of 0.65 mm, and the physically tempered glass 4 is replaced with physical tempered glass 4 with a thickness of 1.6 mm. The other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com