Ultra-fast solidified solar energy packaging adhesive film and preparation method thereof

A solar energy encapsulation, ultra-fast technology, applied in the direction of adhesive, film/sheet adhesive, film/sheet without carrier, etc., can solve problems such as debonding and cracking, decrease in photoelectric conversion efficiency of battery components, and rupture of battery components , to achieve no wrinkle and glue overflow, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

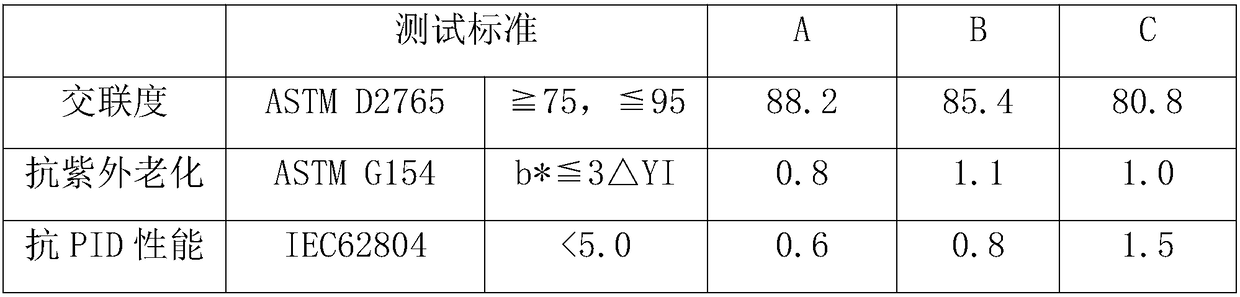

[0018] Example 1: In parts by mass, to 100 parts of ethylene-vinyl acetate copolymer (the mass content of vinyl acetate VA is 26-30%), 0.6 parts of crosslinking agent peroxy-2-ethylhexyl are added Tert-butyl carbonate, 0.7 parts of auxiliary crosslinking agent tripropenyl isocyanurate, 0.4 parts of ultraviolet light absorber 2-(2H-benzotriazol-2-yl) p-cresol, 0.5 parts of coupling agent 3-(Trimethoxysilyl)propyl-2-methyl-2-acrylate, uniformly mixed and extruded by a single-screw extruder, the extrudate is cast into a film, and after cooling, it is rolled to obtain a width of 990mm , A film with a thickness of 0.5mm is marked as A.

Embodiment 2

[0019] Example 2: In parts by mass, to 100 parts of metallocene ethylene octene copolymer, 0.65 parts of crosslinking agent peroxy (2-ethylhexyl) tert-amyl carbonate and 0.6 parts of auxiliary crosslinking agent peroxide are added 3,3,5-Trimethyl hexanoic acid tert-butyl ester, 0.45 parts of ultraviolet light absorber 2-(2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-benzene Ethyl) phenol, 0.6 parts of coupling agent aniline methyl triethoxy silane, uniformly mixed and extruded by a single screw extruder, the extrudate is cast into a film, and after cooling, it is wound up to obtain a width of 990 mm and a thickness of 0.5mm film is marked as B.

Embodiment 3

[0020] Example 3: In parts by mass, to 100 parts of ethylene-vinyl acetate copolymer (the mass content of vinyl acetate VA is 26-30%), 0.45 parts of crosslinking agent 2-ethylhexyl peroxide are added Tert-butyl ester, 0.5 part of auxiliary crosslinking agent benzoyl peroxide, 0.5 part of ultraviolet light absorber 2-(3,5-di-tert-butyl-2-hydroxyphenyl)benzotriazole, 0.4 part of coupling Vinyl tris (2-methoxyethoxy) silane, mixed uniformly and extruded by a single screw extruder, the extrudate is cast into a film, and after cooling, it is wound to obtain a glue with a width of 990mm and a thickness of 0.5mm Film, denoted as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com