Method for attaching panel and apparatus therefor

A technology for sticking devices and panels, applied in the directions of bonding methods, adhesives, instruments, etc., can solve problems such as difficulty in overflow control and poor control, and achieve the effect of shortening the bonding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1)

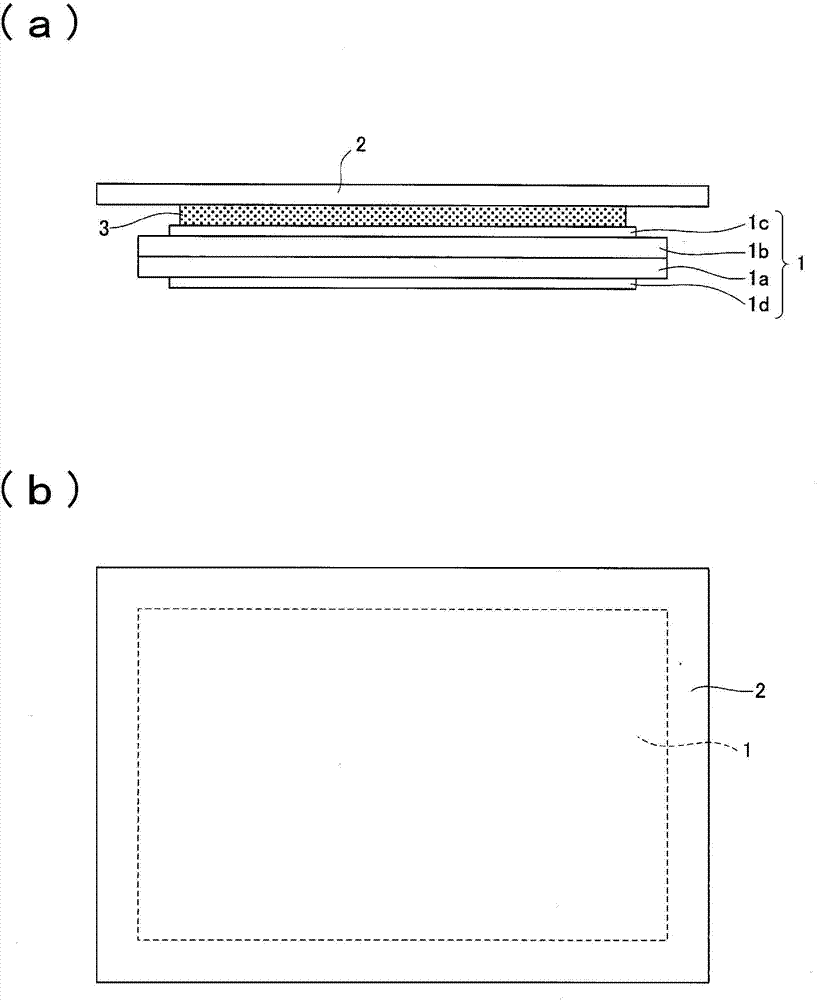

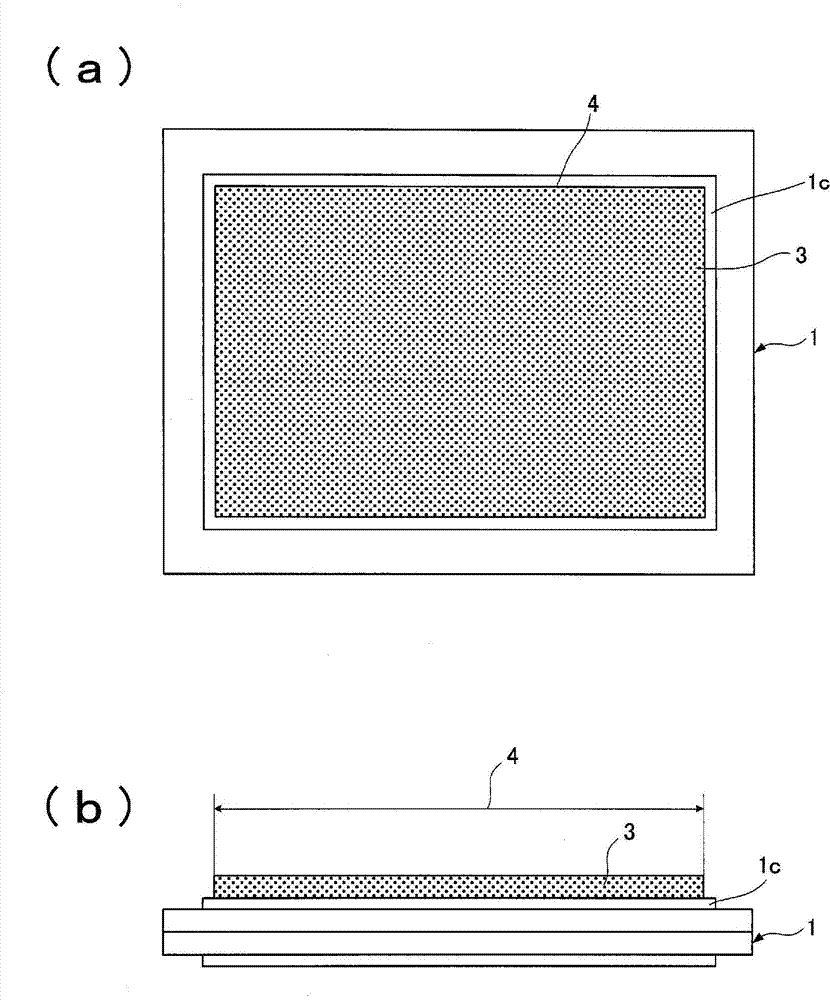

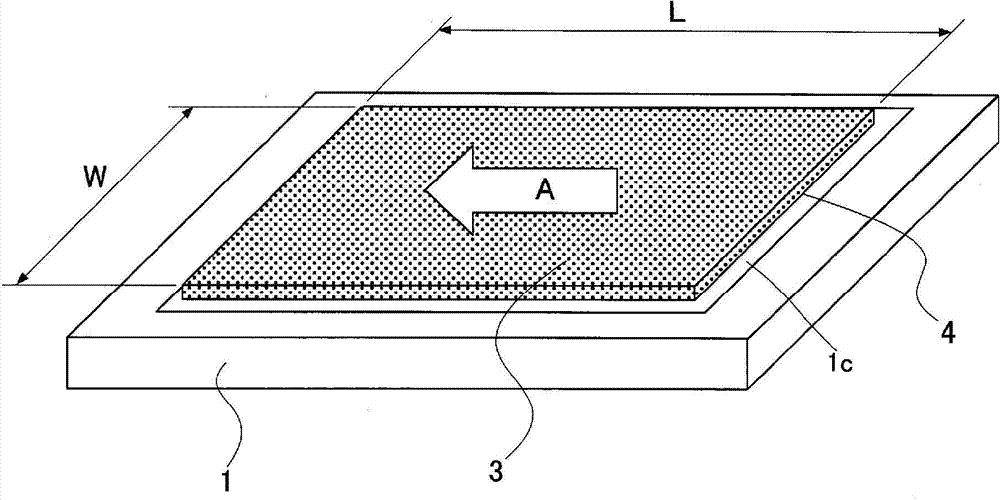

[0062] Figure 1 ~ Figure 7 This shows Embodiment 1 of the present invention.

[0063] Here, as figure 1 (A) (b) The case where the transparent touch panel (hereinafter referred to as touch panel) 2 and the liquid crystal display panel 1 are bonded with the ultraviolet curable resin 3 to manufacture a liquid crystal display module with a touch panel will be described. .

[0064] The liquid crystal display panel 1 as the first panel has a structure in which liquid crystal is enclosed between an array substrate 1a and a color filter substrate 1b, and an upper polarizing plate 1c and a lower polarizing plate 1d are attached to both surfaces, respectively. In addition, although not shown, a driver integrated circuit, a flexible substrate, etc. are mounted.

[0065] The touch panel 2 as the second panel has a structure in which a transparent electrode having conductivity is arranged on a glass substrate in order to detect a position touched by a user.

[0066] The resin 3 is a colorless ...

Embodiment approach 2)

[0111] Figure 8 ~ Figure 13 This shows Embodiment 2 of the present invention.

Embodiment approach 2

[0112] In the second embodiment, a case of bonding a protective panel to an organic EL device will be described.

[0113] Figure 8 (A) and (b) represent the monomer of the completed organic EL device.

[0114] The organic EL device 8 applies a phenomenon in which the organic substance emits light by applying a voltage to the organic substance, and has the following structure: an organic EL layer 8b is formed on the lower substrate 8a, and the organic EL layer 8b sandwiches the organic substance between two electrodes, It is formed by superimposing the film. In order to protect the organic EL layer 8b from humidity, impact, etc., it is covered with the upper substrate 8c via the resin 8d.

[0115] The lower substrate 8a uses glass with a thickness of 0.7 mm and a square with a size of 100 mm. The size of the organic EL layer 8b is 80 mm square, and the film thickness is several millimeters. Electrodes (not shown) are arranged on the lower substrate 8a. The upper substrate 8c uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com