Preparation method of silicon-based ester compound, silicon-based ester compound, electrolyte containing silicon-based ester compound and secondary battery

An amine compound and compound technology are applied in the fields of silicon-based ester compound preparation, silicon-based ester compound, electrolyte containing the same, and secondary battery, and can solve the problems of complicated operation process, difficult handling and purification, complicated operation, etc. , to achieve the effects of convenient operation in the preparation process, long reaction time and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

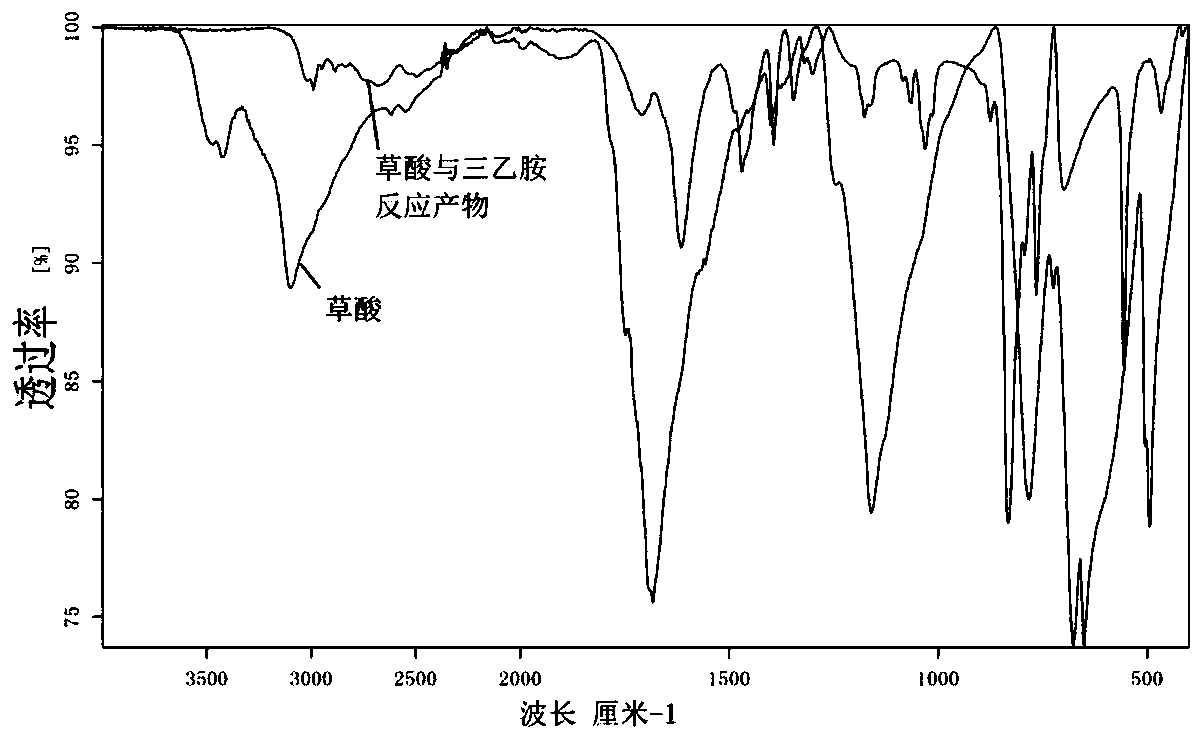

[0067] Add oxalic acid (0.2mol) and DMSO (150mL) to the flask, then add monomethylamine (0.44mol), react at room temperature for 1h overnight and let stand for 12h; then add trimethylbromosilane (0.22mol), then add DMSO (130ml) , heated at 70° C. for 8 h; after the reaction, suction filtration and vacuum distillation (20 mmHg) gave white solid bis(trimethylsilyl) oxalate with a purity of 97% and a yield of 81%.

Embodiment 2

[0069] Add oxalic acid (0.15mol) and acetonitrile (150mL) to the flask, add trimethylamine (0.05mol), and react at room temperature for 1h; then add dimethylvinylchlorosilane (0.15mol), and heat at 50°C for 2h; Suction filtration and vacuum distillation (20mmHg) after the end, to obtain a colorless liquid bis(dimethylvinylsilyl) oxalate with a purity of 97% and a yield of 85%.

Embodiment 3

[0071] Add oxalic acid (0.2mol) and carbon tetrachloride (150mL) to the flask, then add monopropylamine (0.44mol), and react at room temperature for 1h; then add dimethylisopropylbromosilane (1mol), and heat the reaction at 100°C 6h; after the reaction, suction filtration and vacuum distillation (20mmHg) gave a colorless liquid bis(dimethylisopropylsilyl) oxalate with a purity of 97% and a yield of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com