Expansion sleeve type cast-aluminum dummy shaft

A technology of expanding sleeves and dummy shafts, which is applied in the field of dummy shafts, can solve the problems of scrapped cast aluminum rotors, difficulties in withdrawing shafts, and affecting motor vibration, and achieve the effects of saving lamination time, reducing metal processing procedures, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

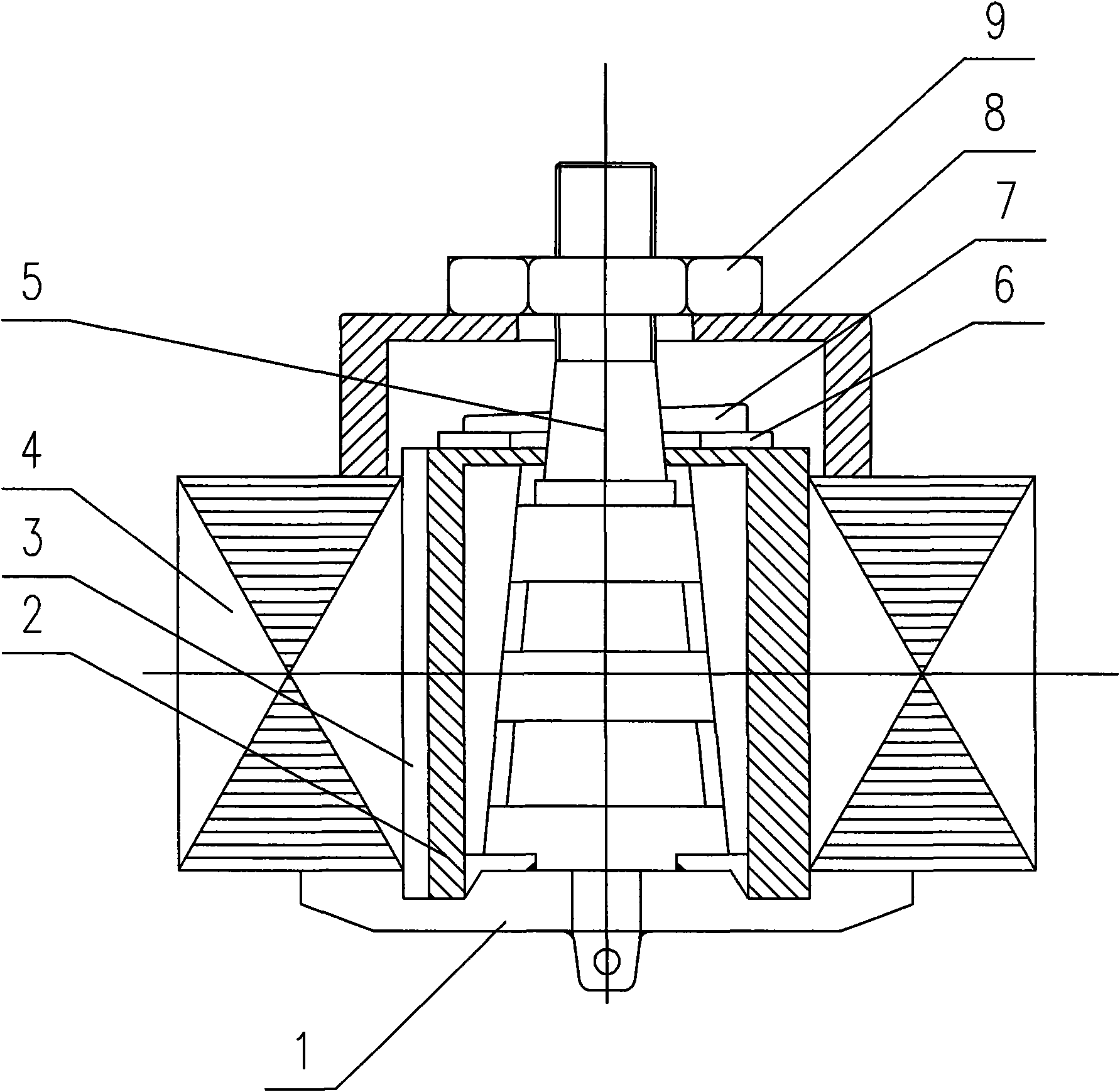

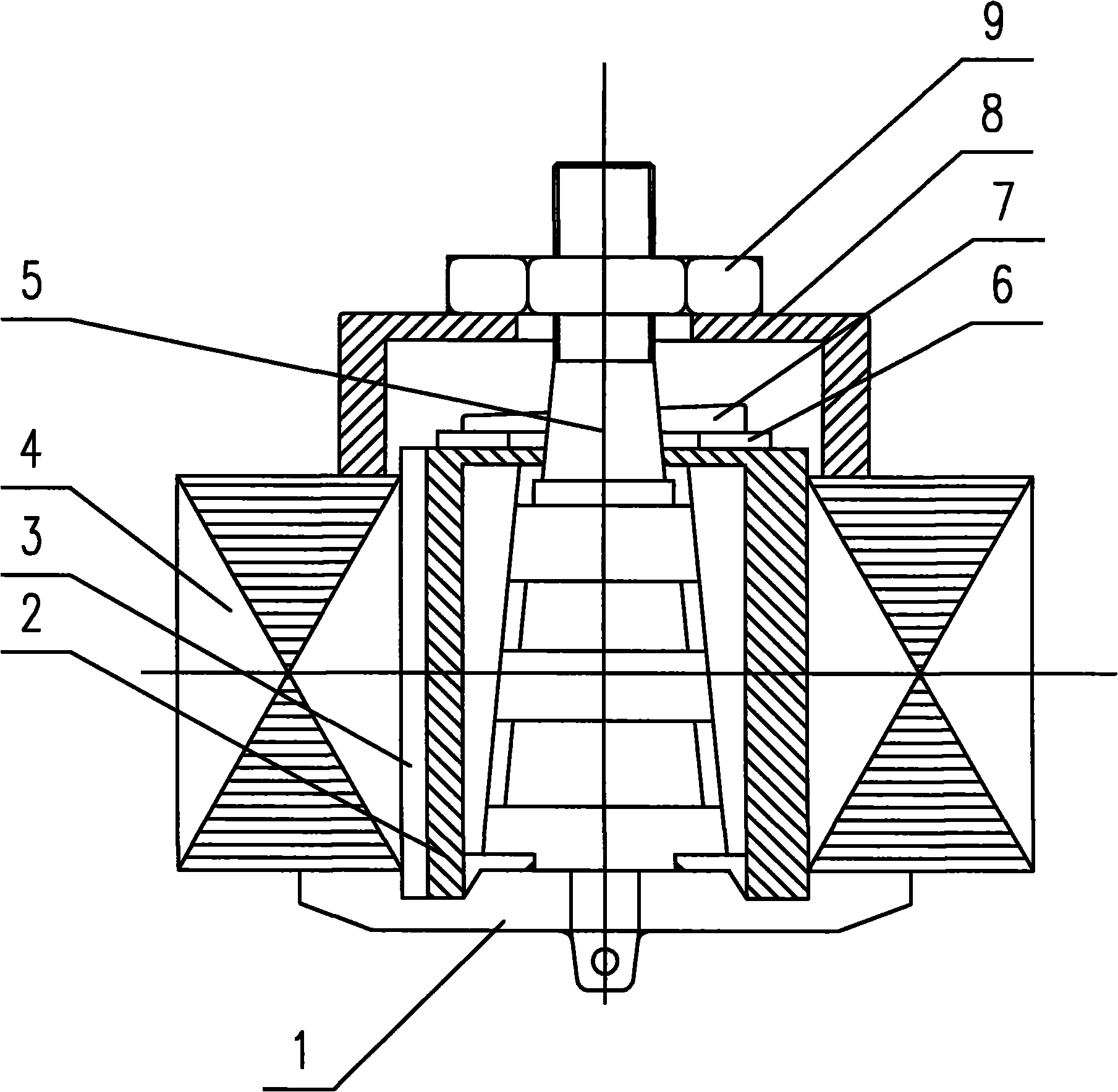

[0009] As shown in the figure: the present invention is mainly composed of shaft seat 1, expansion sleeve 2, positioning key 3, rotor core 4, mandrel 5, backing plate 6, wedge plate 7, pressure plate 8 and fastening nut 9, etc.

[0010] The expansion sleeve type cast aluminum dummy shaft includes a mandrel 5 arranged on the shaft seat 1, and an expansion sleeve 2 is set on the outer surface of the mandrel 5. The outer surface of the expansion sleeve 2 is provided with an external keyway along its axial direction, and the keyway is inserted The positioning key 3 is connected, and the rotor core 4 is set outside the expansion sleeve 2. The side wall of the inner hole of the rotor core 4 is installed with an inner keyway along its axial direction, and the outer end of the positioning key 3 is inserted into the inner keyway. , the mandrel 5 is sleeved with a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com