efficient EVA packaging adhesive film with lamination time shortened, and preparation method and application thereof

A technology for encapsulating adhesive film and adhesive film, applied in the field of solar cells, can solve the problems of long lamination time and high production cost, and achieve the effect of reducing production cost, shortening lamination time, and unaffected reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

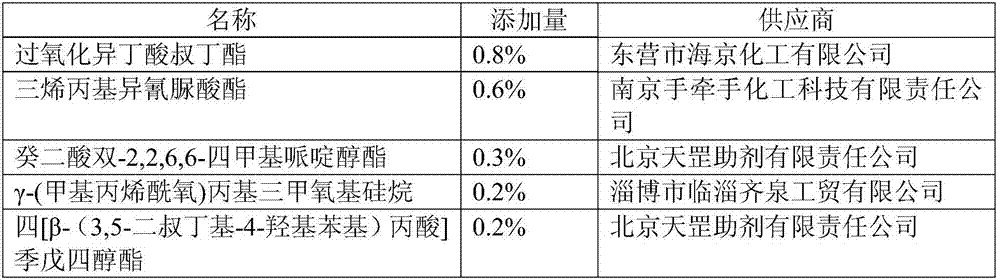

[0050] Transparent EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content and be 28% ethylene-vinyl acetate copolymer (Hanwha Total Corporation EVAE280PV) (the melt flow index (MI of described EVA resin) value) is 15g / 10min), add the components shown in the following table in terms of mass percentage of EVA resin:

[0051]

[0052] The mixture is blended and extruded in an extruder, and the temperature is controlled at 70°C. The extruded product is cast, cooled, cut, and coiled to obtain a transparent EVA film with a thickness of 0.50mm;

[0053] Then the transparent EVA film is irradiated by an electron beam accelerator to obtain a pre-crosslinked transparent EVA film. The radiation parameters are shown in the following table:

[0054]

Beam

Line speed

Transparent EVA

20mA

20m / min

[0055] Barrier EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content as 28% ethylene-vinyl acetate copolymer (Hanwha Tota...

Embodiment 2

[0068] Transparent EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content and be 28% ethylene-vinyl acetate copolymer (EVA E280PV of Hanwha Total Total Co., Ltd.) (the melt flow index of described EVA resin ( MI value) is 15g / 10min), adding the components shown in the following table in terms of mass percentage of EVA resin:

[0069]

[0070] The mixture is blended and extruded in an extruder, and the temperature is controlled at 80°C. The extruded product is cast, cooled, cut, and coiled to obtain an EVA film with a thickness of 0.50 mm.

[0071] Then the EVA film is irradiated by an electron beam accelerator to obtain a pre-crosslinked transparent EVA film. The radiation parameters are:

[0072]

Beam

Line speed

Transparent EVA

25mA

20m / min

[0073] Barrier EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content as 28% ethylene-vinyl acetate copolymer (Hanwha Total Corporation EVA E280PV) (the melt flow...

Embodiment 3

[0086] Transparent EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content as 28% ethylene-vinyl acetate copolymer (Hanwha Total Corporation EVAE282PV) (the melt flow index of the EVA resin (MI value) is 25g / 10min), add the components shown in the following table in terms of mass percentage of EVA resin:

[0087]

[0088] The mixture is blended and extruded in the extruder, the temperature is controlled at 90°C, and the extruded product is cast, cooled, cut, and coiled to obtain a transparent EVA film with a thickness of 0.80 mm;

[0089] Then the transparent EVA film is irradiated by an electron beam accelerator to obtain a pre-crosslinked transparent EVA film. The radiation parameters are shown in the following table:

[0090]

Beam

Line speed

Transparent EVA

20mA

20m / min

[0091] Barrier EVA: in parts by mass, get 100 parts of VA (vinyl acetate) mass content as 28% ethylene-vinyl acetate copolymer (Hanwha Total Corporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com