Patents

Literature

95 results about "Price reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Price reduction - the act of reducing the selling price of merchandise. discount, deduction. reduction, step-down, diminution, decrease - the act of decreasing or reducing something.

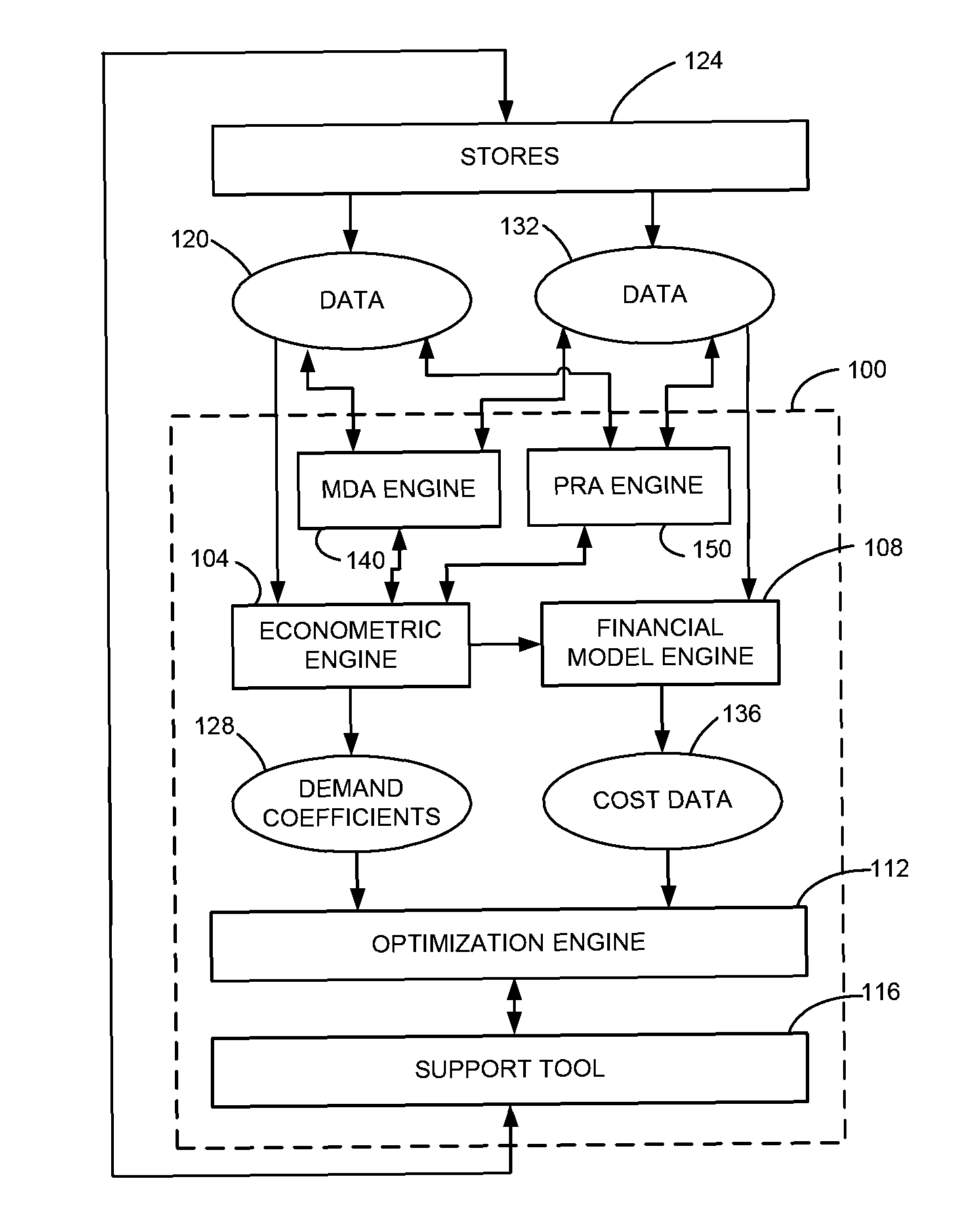

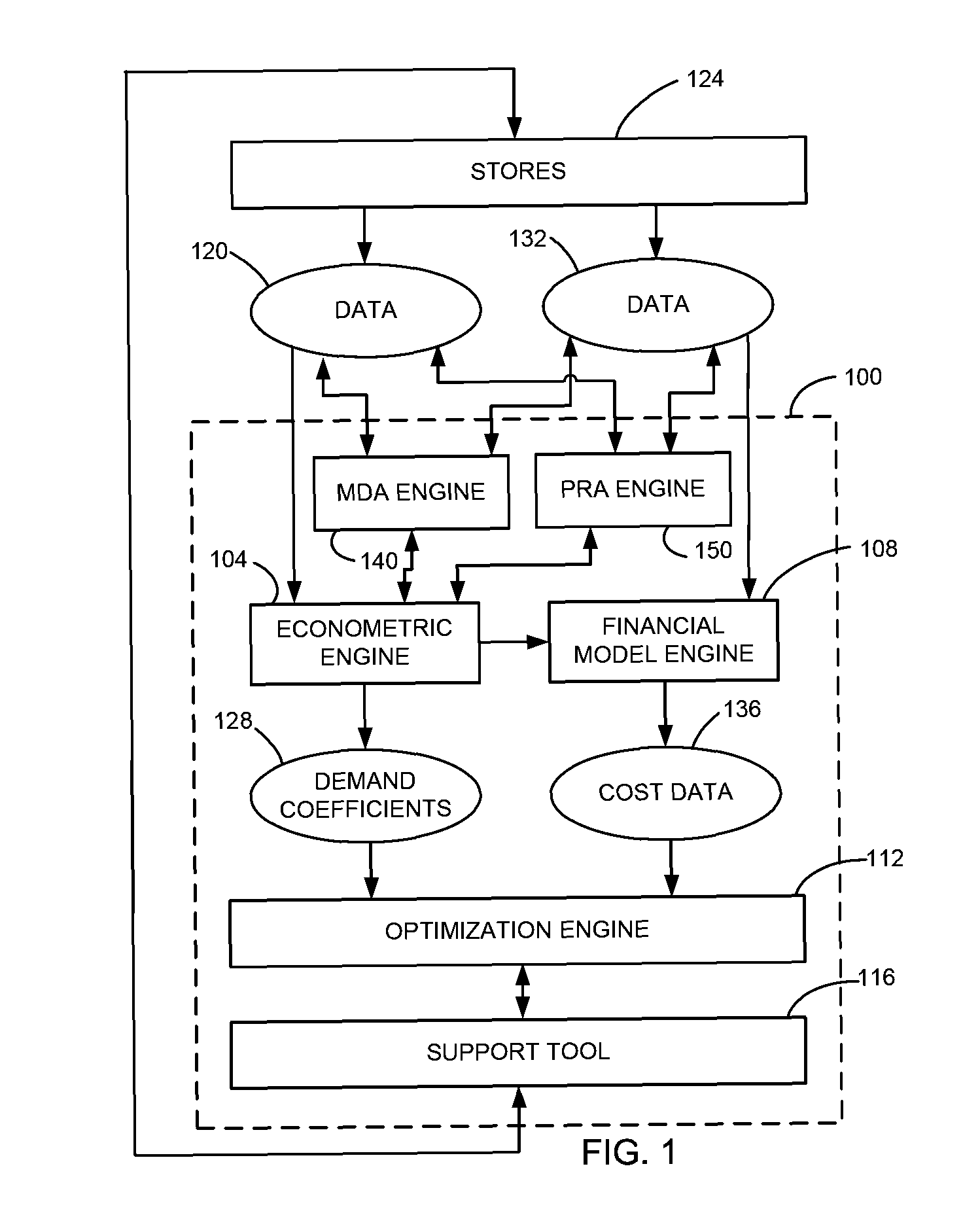

Systems and methods for price and promotion response analysis

A system and method for price and promotion response analysis is provided. Such a system is useful for a business to analyze the forecasted lifts associated with changes in price and promotion activity. The system sets the configuration of the response report, which includes price change and promotion change intervals. Promotions include temporary price reductions, displays, ads and multiples. Modeling data is received for the products. Forecasts, both non-cannibalistic and cannibalistic, are generated for the sales of the products dependent upon the price change and promotion change intervals. Forecasts include at least one of product forecasts, demand group forecasts, line level forecasts and category level forecasts. Suspect forecasts below a minimum confidence may be flagged. Confidence matrices may be generated which reflect accuracy of the forecasts. The response report may be generated by collecting the forecasts and the confidence matrices according to the configuration of the response report.

Owner:ACOUSTIC LP

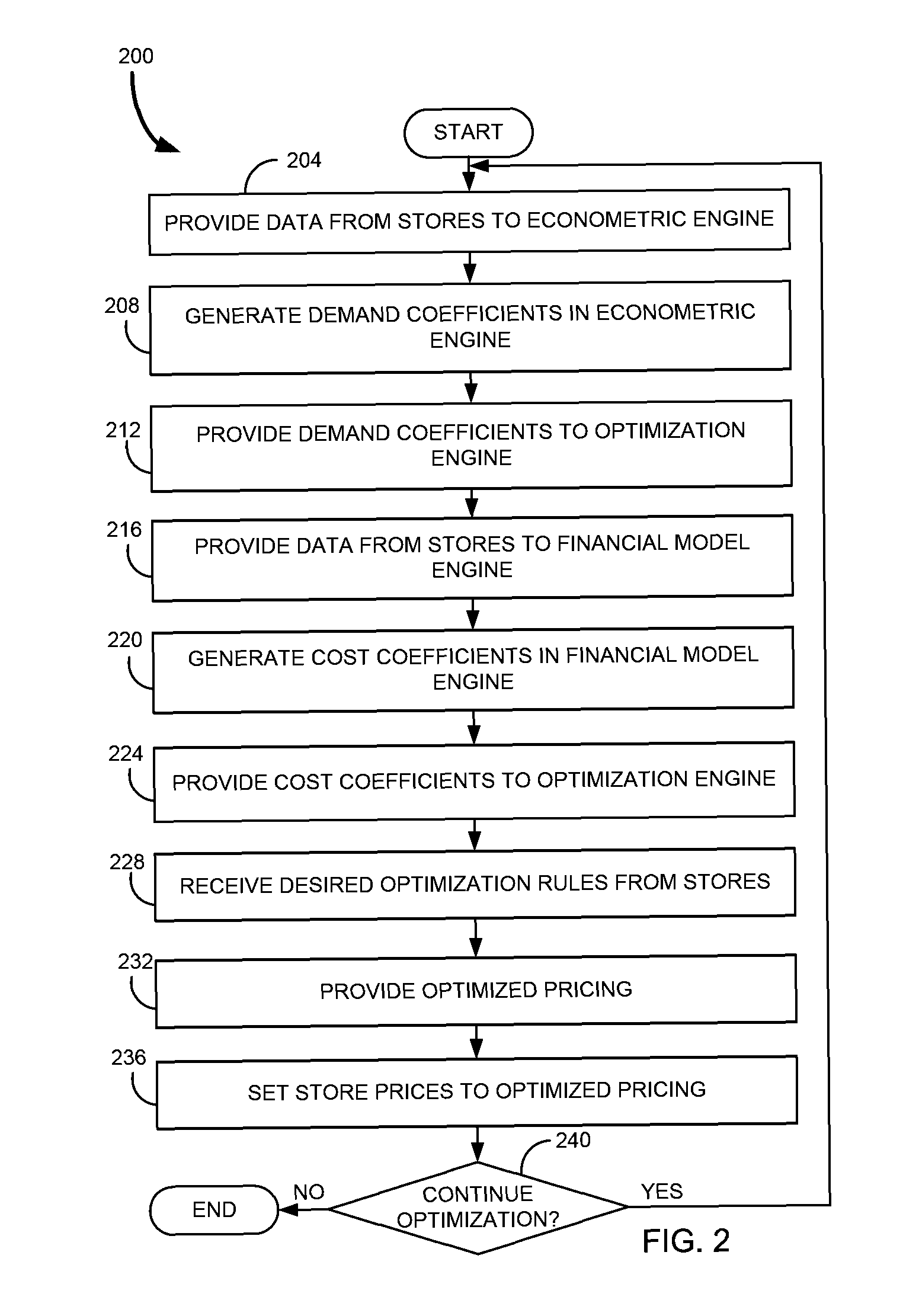

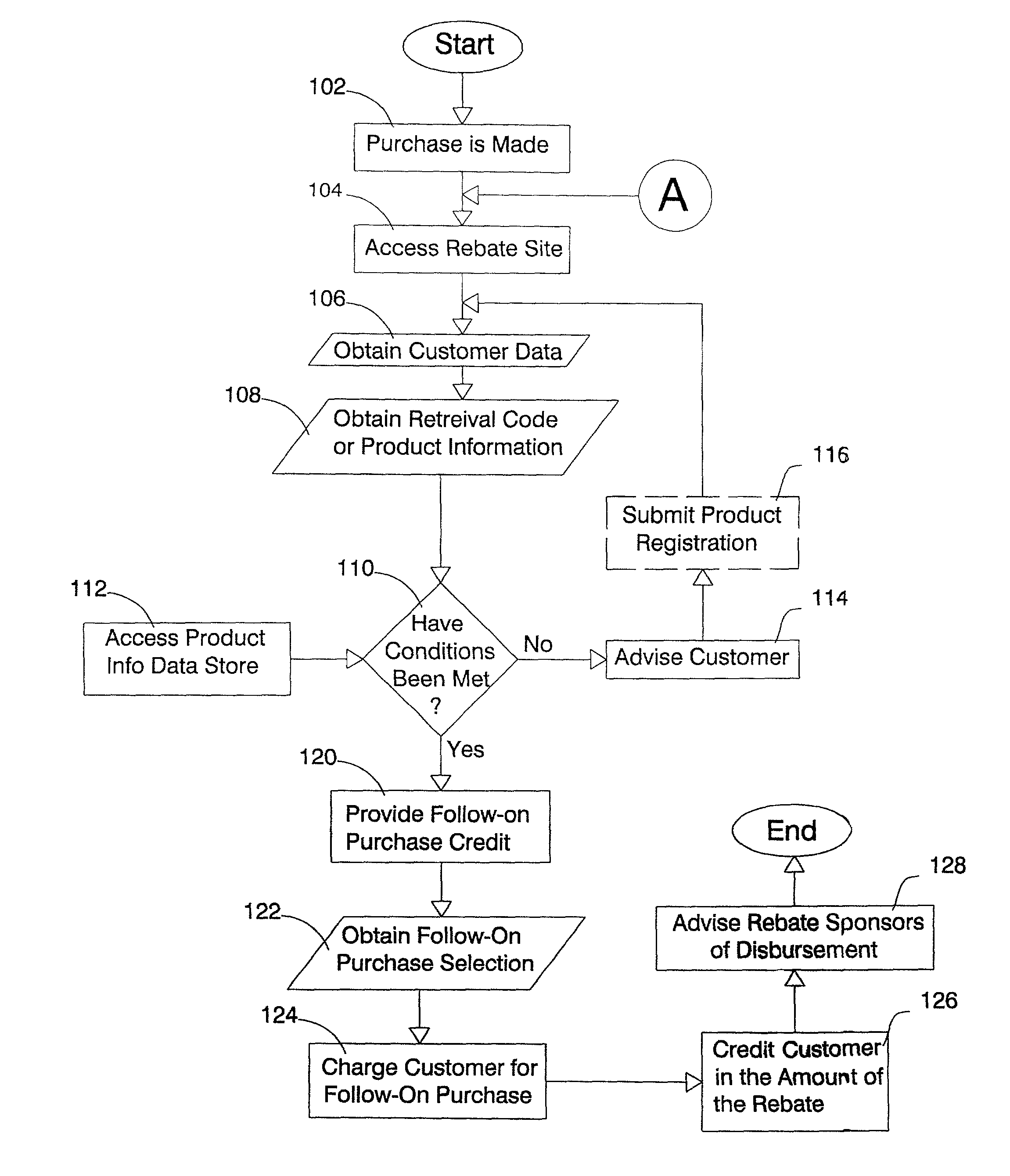

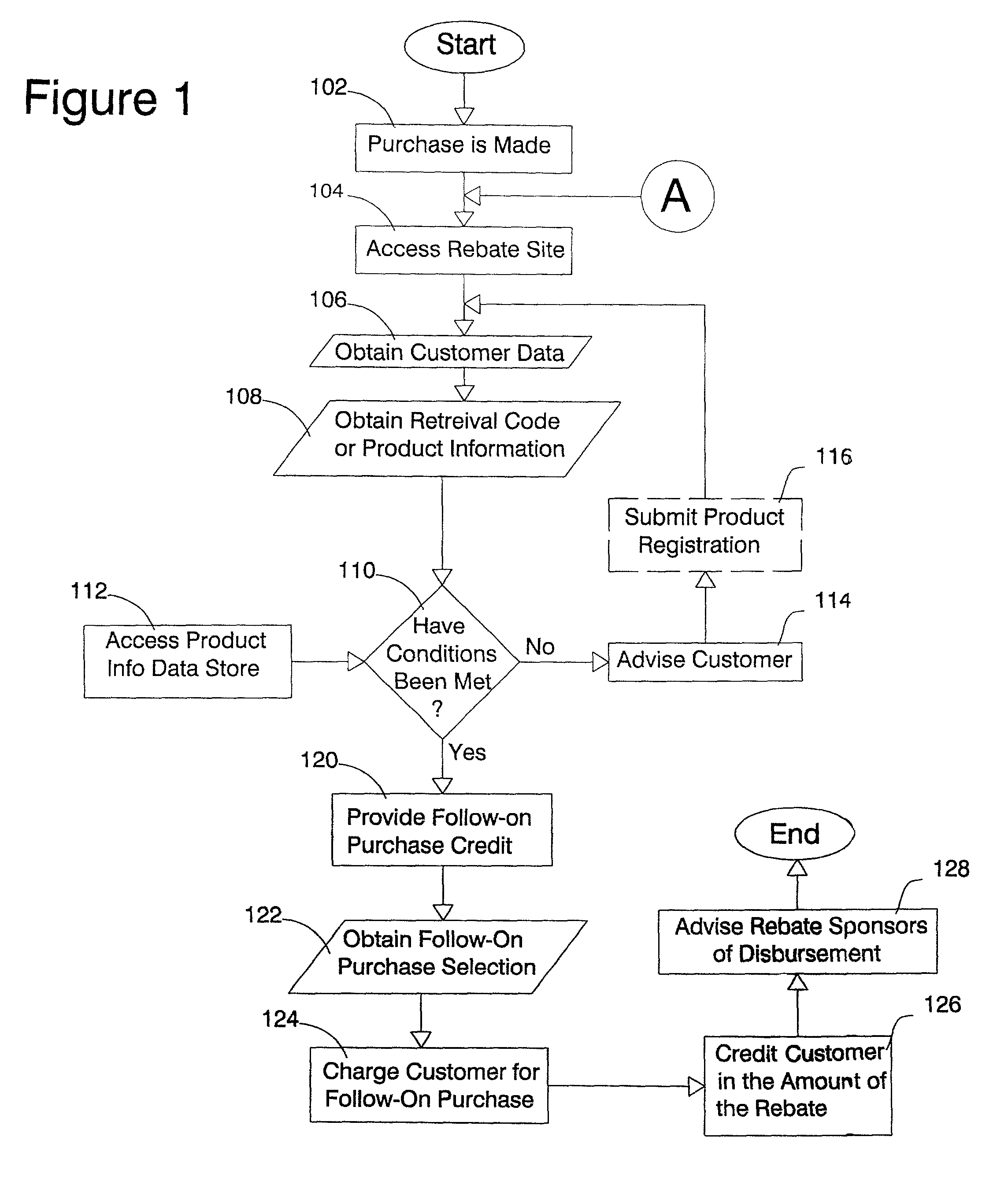

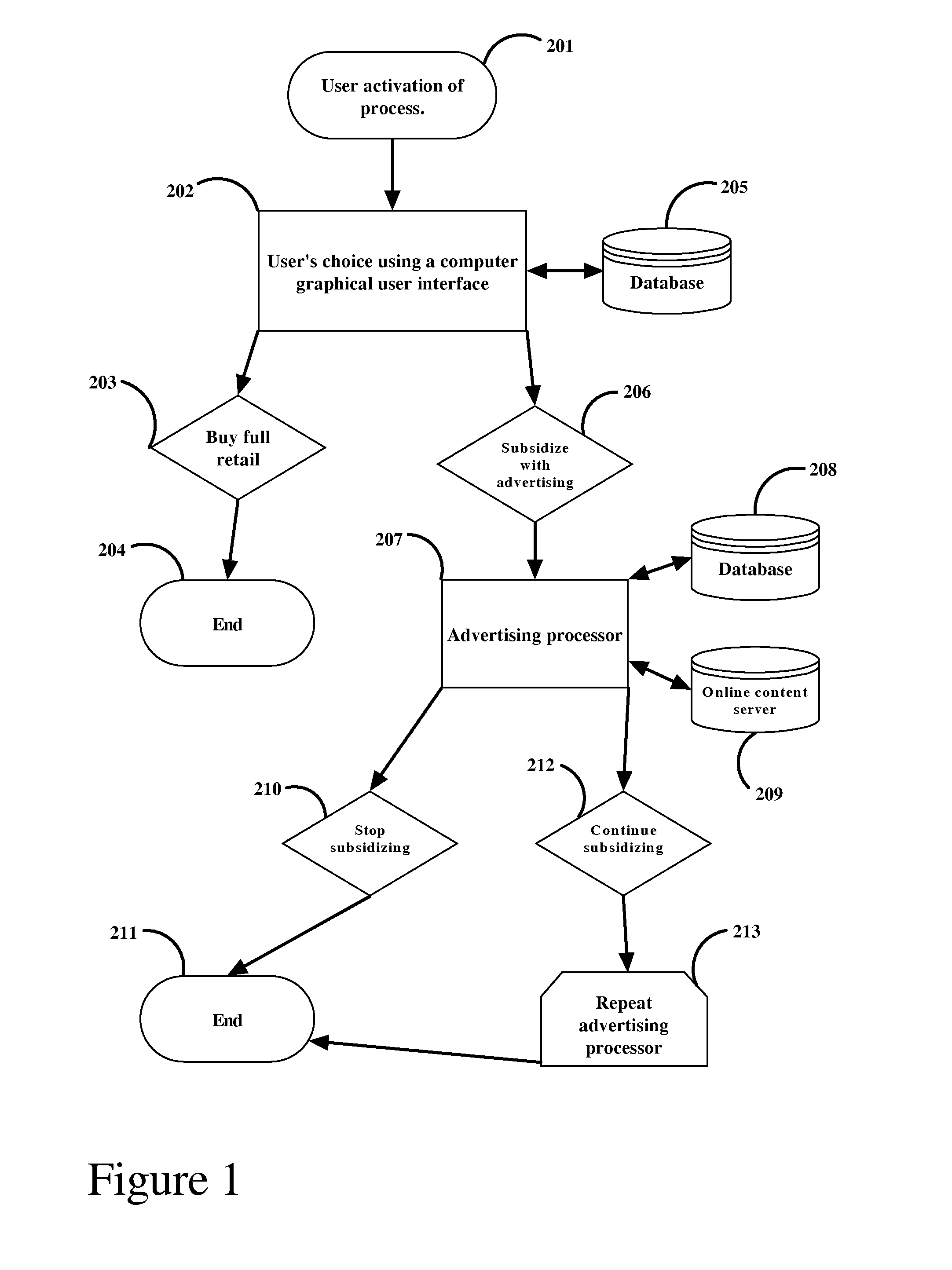

Rebate transaction system

A system and method for converting a rebate sponsor's offer into an instant credit or price reduction against a follow-on purchase. Rebate requests are obtained at a site on the Internet. The rebate request is tested to confirm that the at least one predetermined criterion has been satisfied. The person making the rebate request is enabled to make the follow-on purchase, with the rebate being converted into the instant credit or price reduction against the total price of the follow-on purchase. The follow-on purchase transaction is completed by charging that person for the purchase. The credit or price reduction can be conditioned on at least one predetermined criterion such as amount being spent on the follow-on purchase, the vendor from which the follow-on purchase is being made, and other criteria. The credit or price reduction can be redeemed in parts across a series of follow-on purchase transactions. In another aspect of the invention, consumers are advised of rebate offers. In this aspect, a server of a credit issuer receives purchase transaction details concerning an item purchase from a vendor, the item purchase is correlated with any rebate offer, and, in the event of a match, the consumer is advised by electronic mail that a rebate is available and can be converted into instant credit or price reduction on a follow-on purchase.

Owner:LEASON DAVID +1

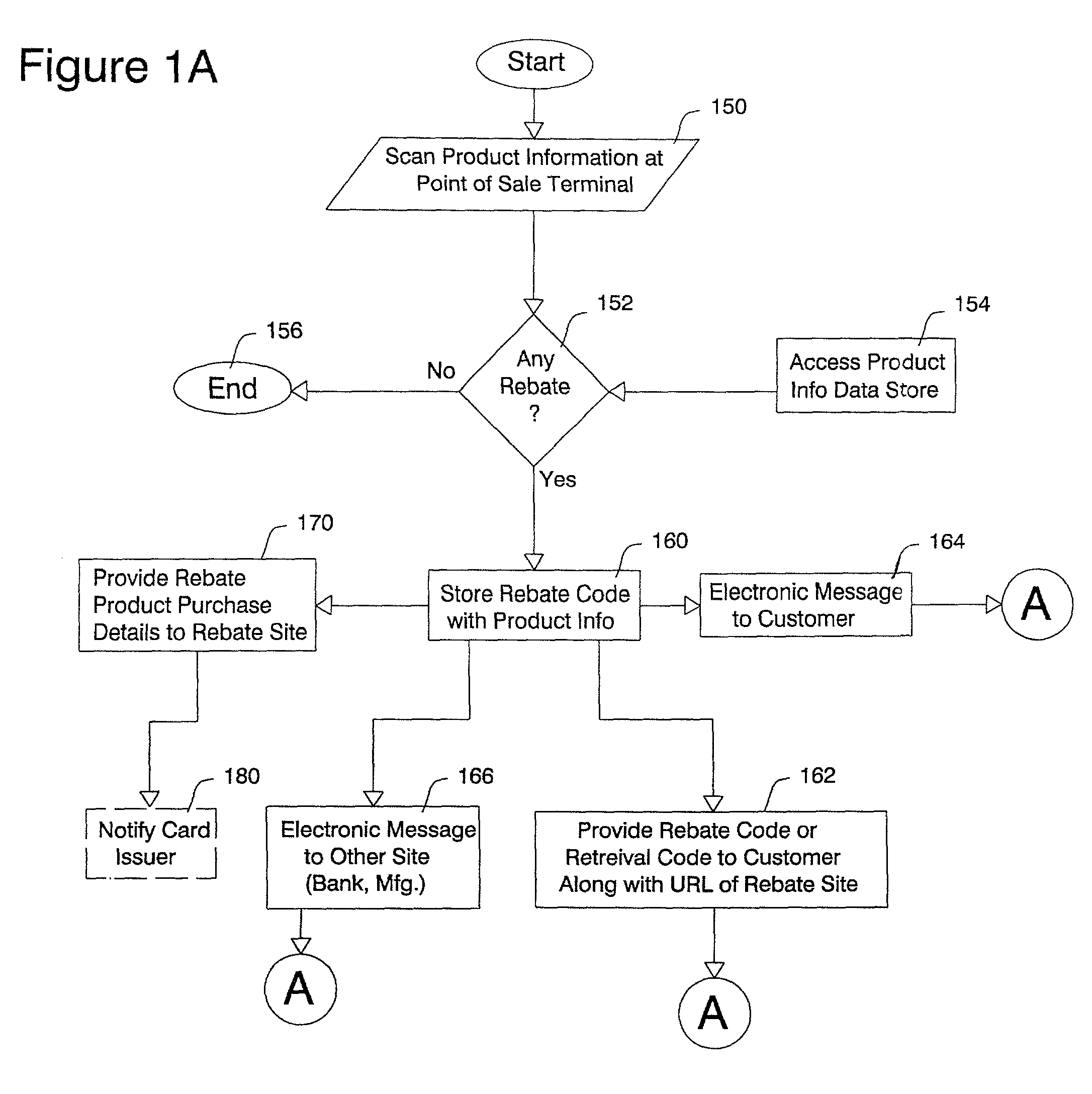

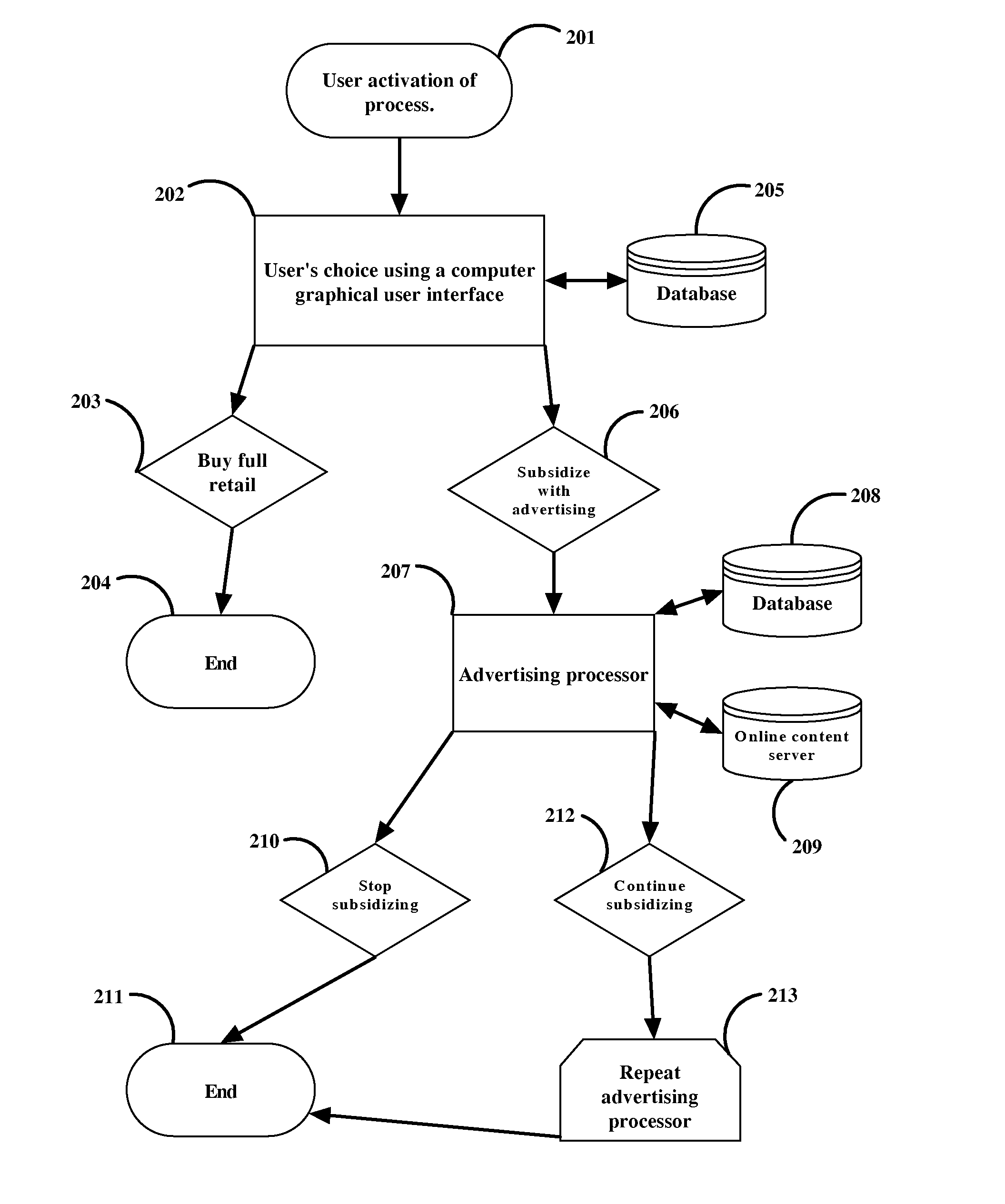

Optional progressive price reduction system using sponsorship subsidization.

InactiveUS20090018909A1Inexpensive and easy to obtainLost profitDiscounts/incentivesPaymentPurchasing

An optional progressive price reduction system using sponsorship subsidization which allows content owners to provide multiple purchasing options for consumers. The purchasing options provided by this system offers an incentive for consumers to obtain expensive internet based content delivered through a facilitator. At the point of sale of a product, consumers can choose a payment option comprising a prepaid sponsorship model which reduces the retail price according to the consumer's preference or pay the full retail price for consumers who wish to avoid advertising.

Owner:GRECIA WILLIAM

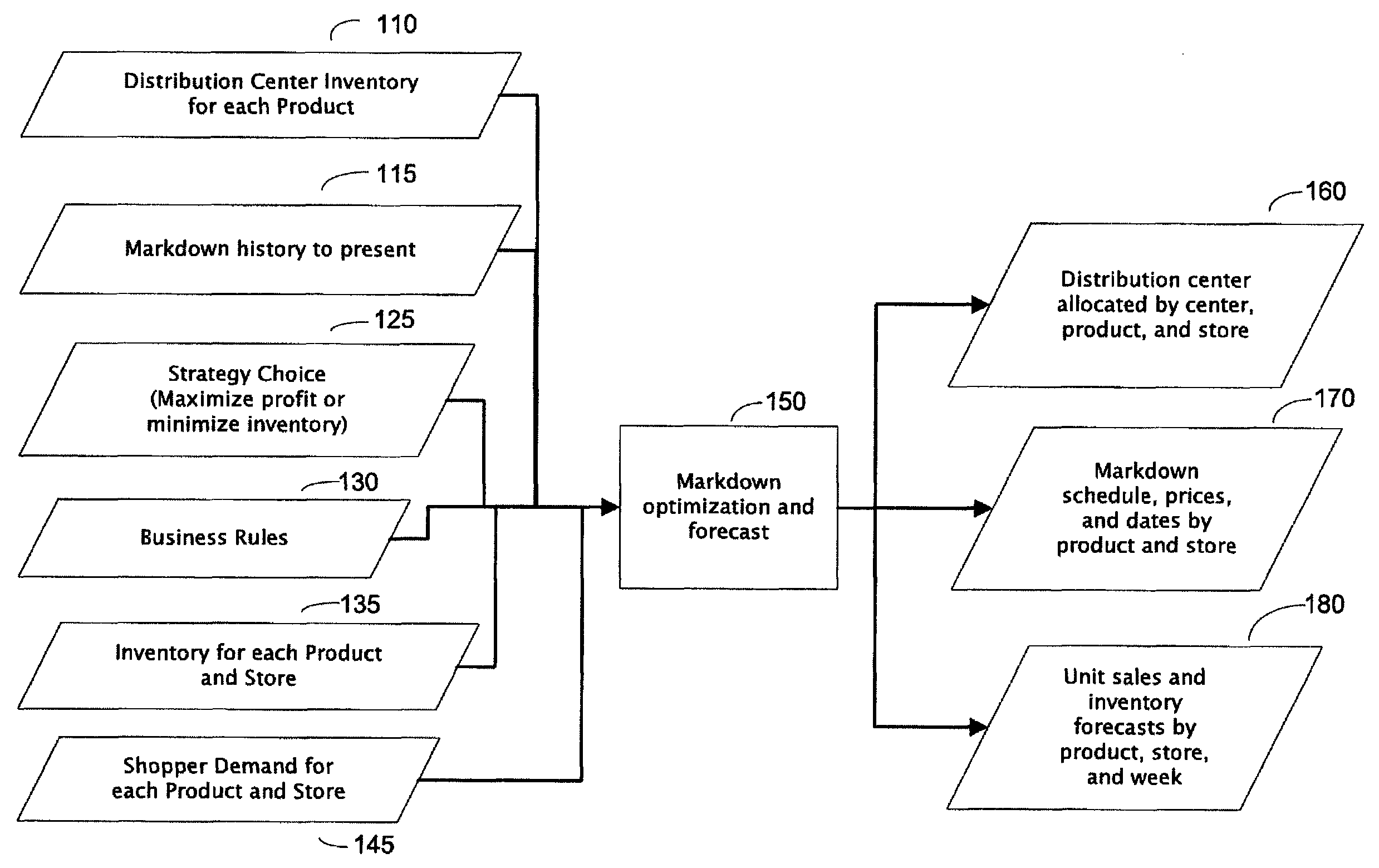

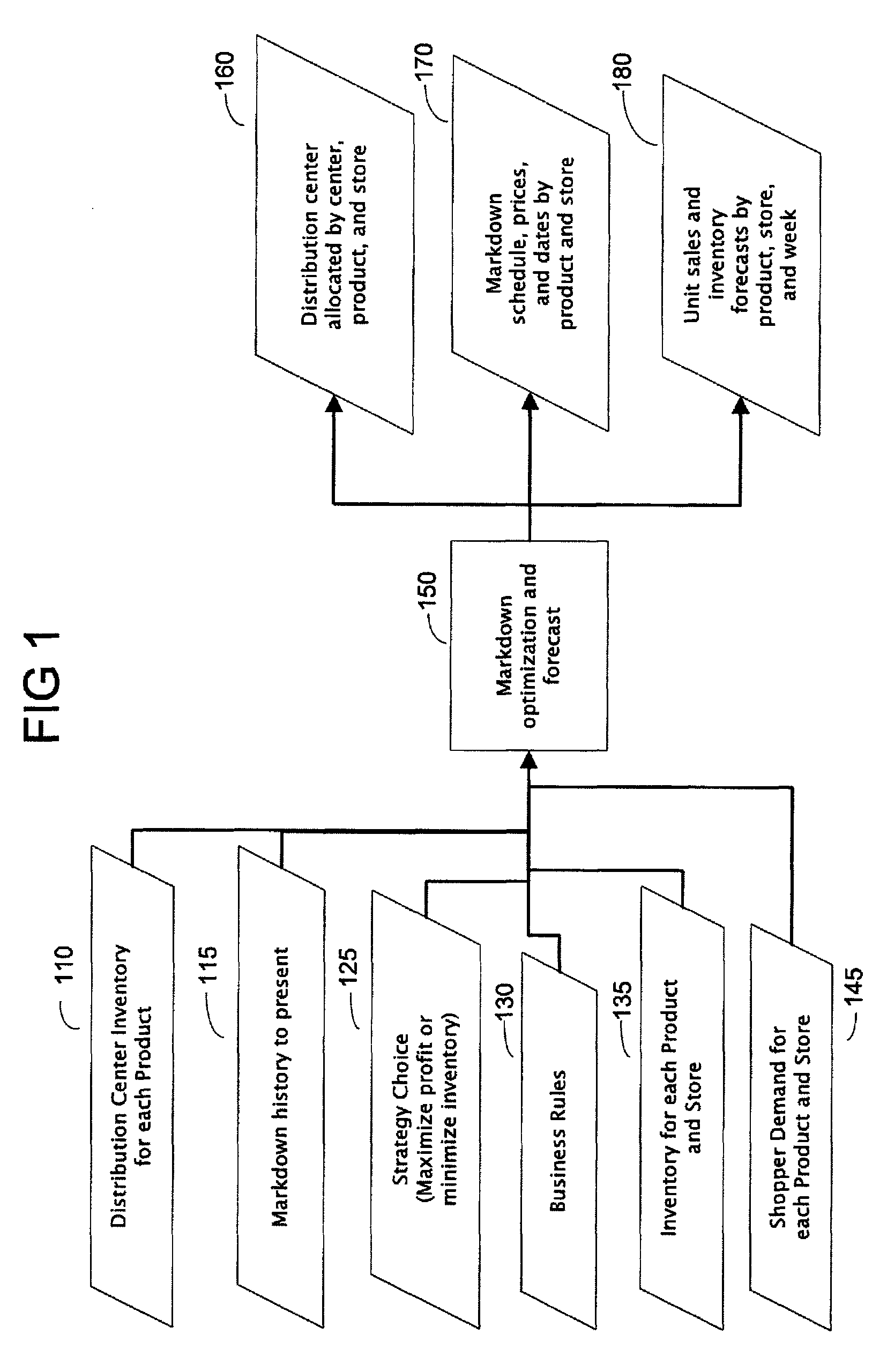

Method and system for determining price markdown schedule

ActiveUS7912748B1Increase marginDecrease stockMarket predictionsBuying/selling/leasing transactionsProgram planningComputer science

Markdown optimization may be performed using a computer system. Markdown objectives may include margin maximization or inventor minimization. Markdown schedule optimization uses an efficient, iterative, targeted combinatorial search. First, permissible discount steps are identified, then for each permissible discount step, a subspace of permissible step dates is identified. Elements from the date step subspace and price reduction subspace are combined and evaluated against the markdown objectives. If an improved markdown schedule is located, a new subspace of permissible step dates is defined to search the subregion of the solution space where the improved markdown optimization schedule was identified. Scheduling of inventory allocation from a distribution center is also disclosed.

Owner:SAP AG

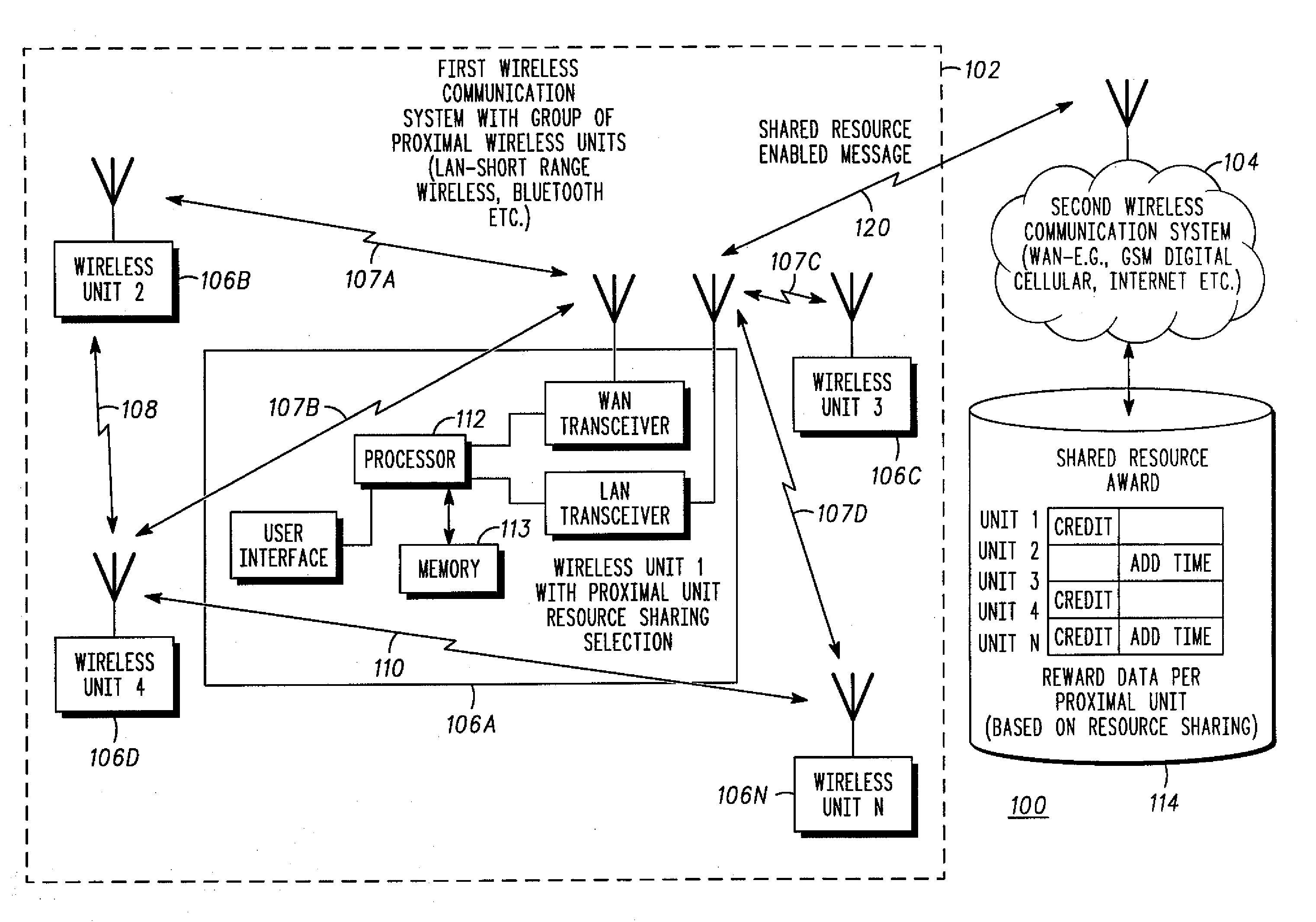

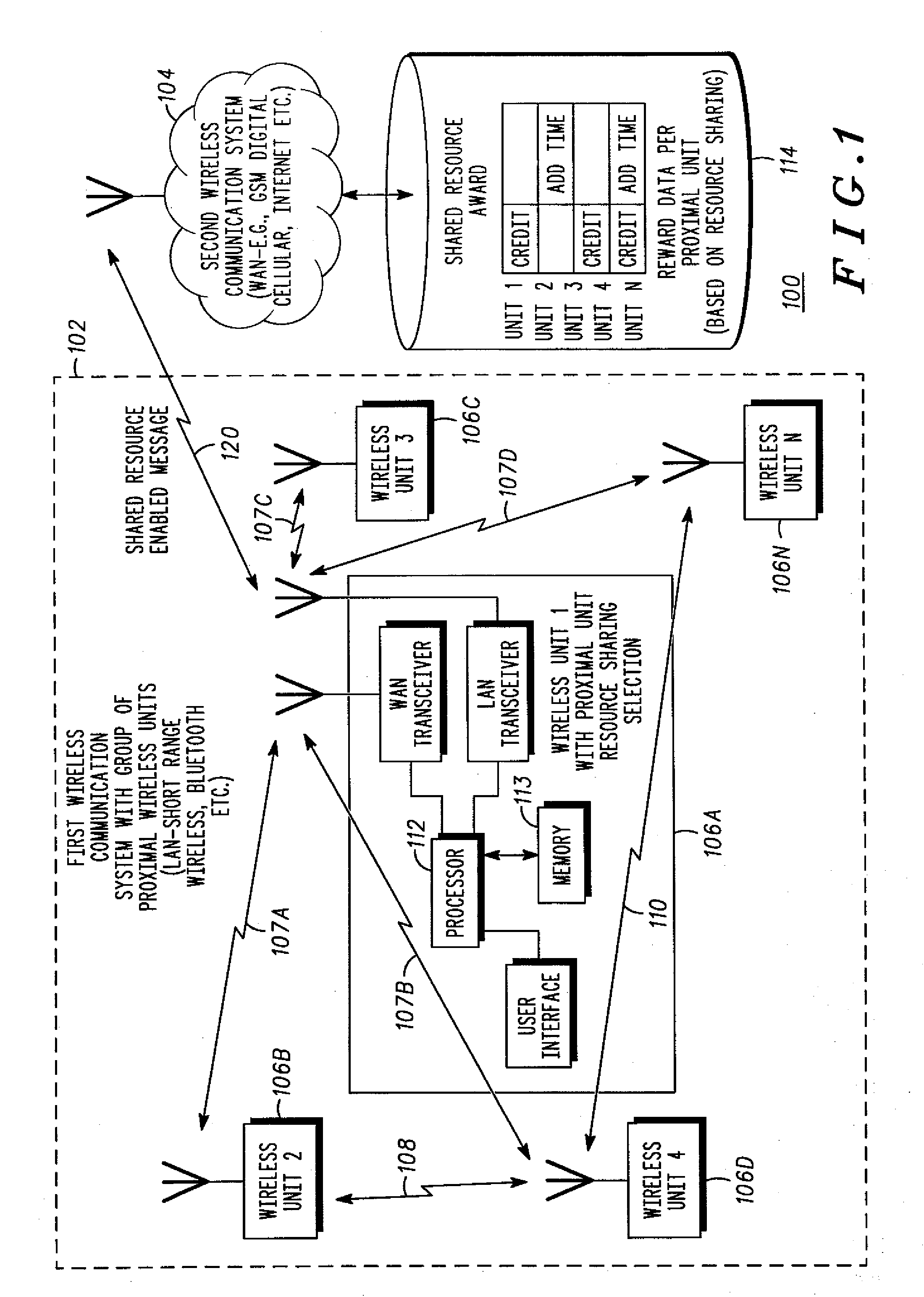

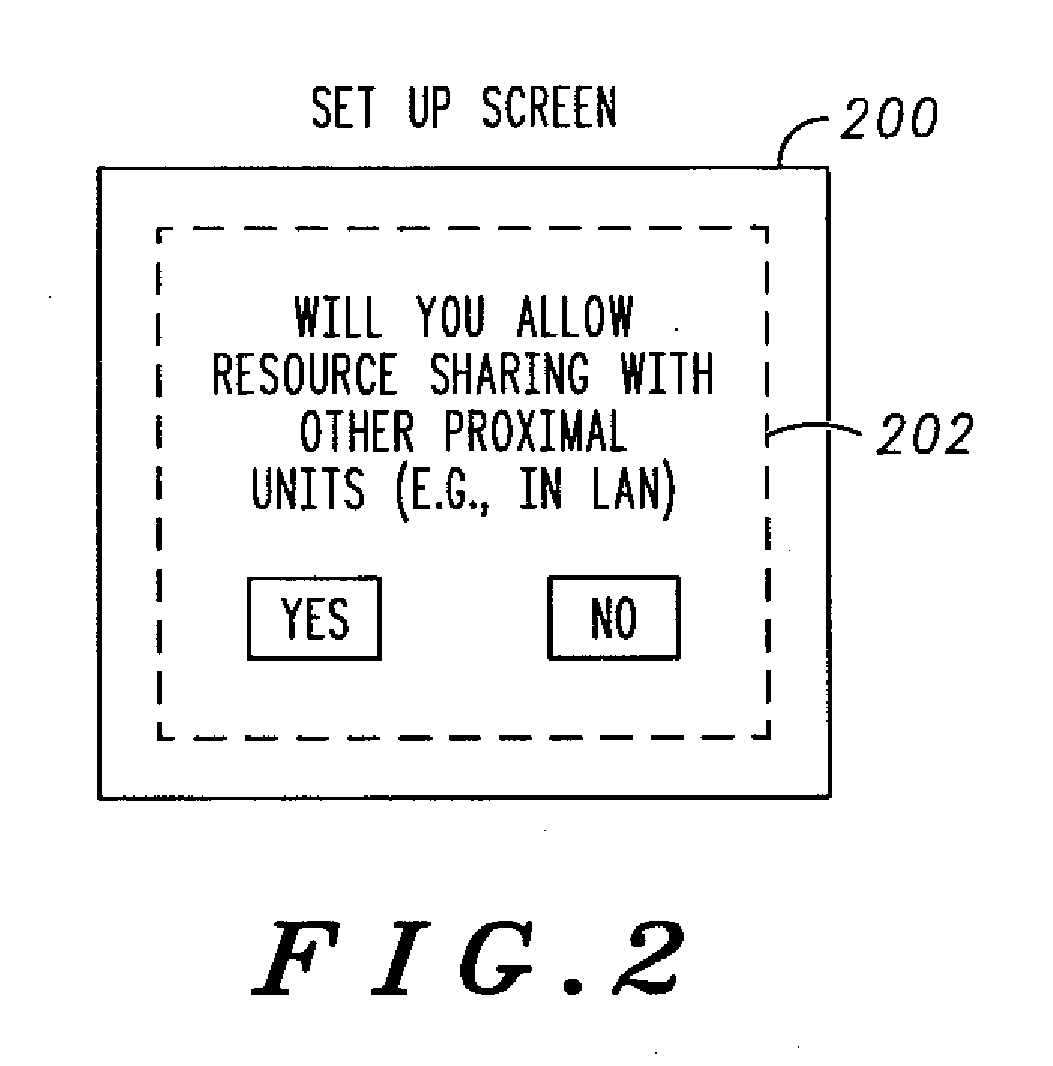

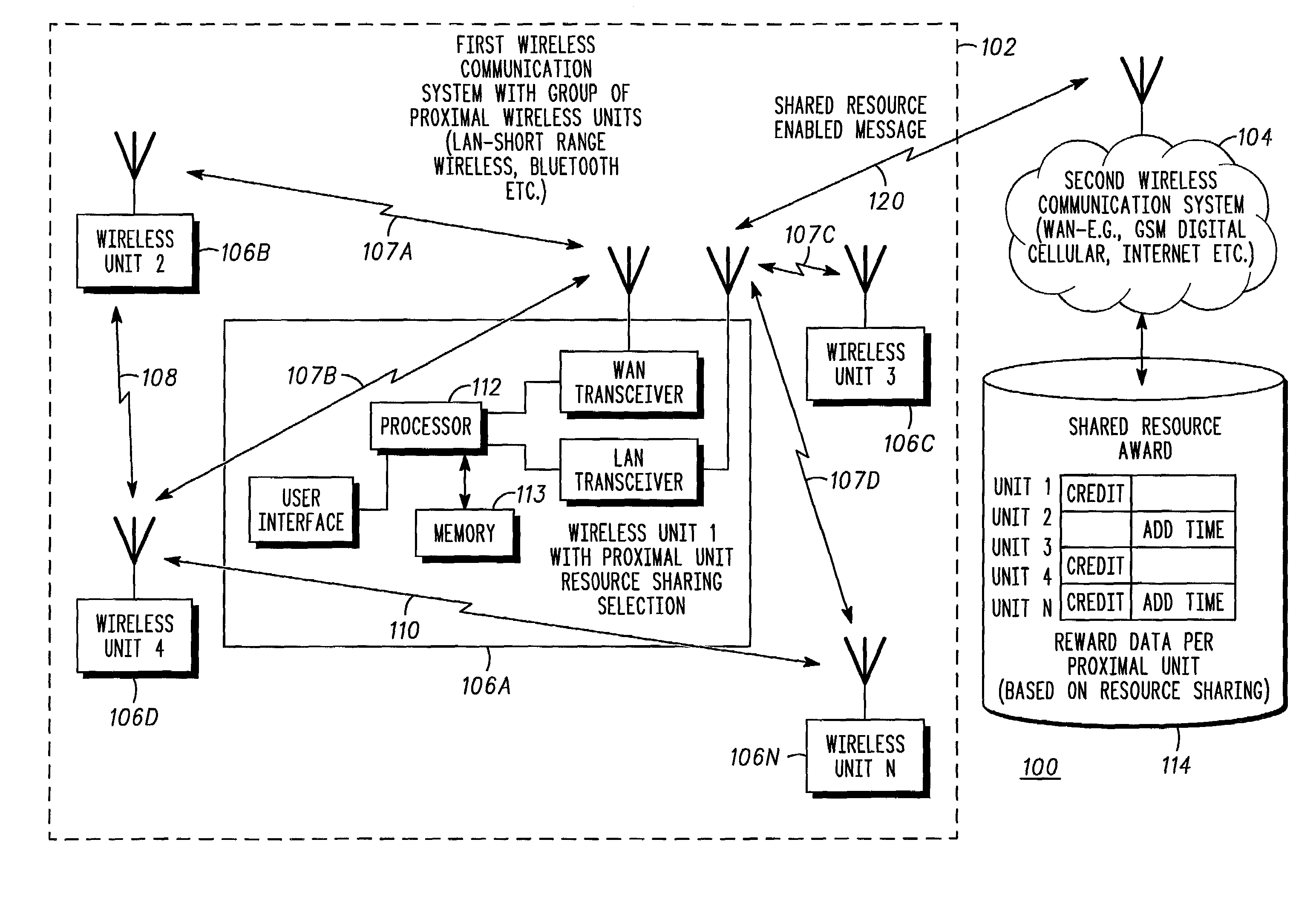

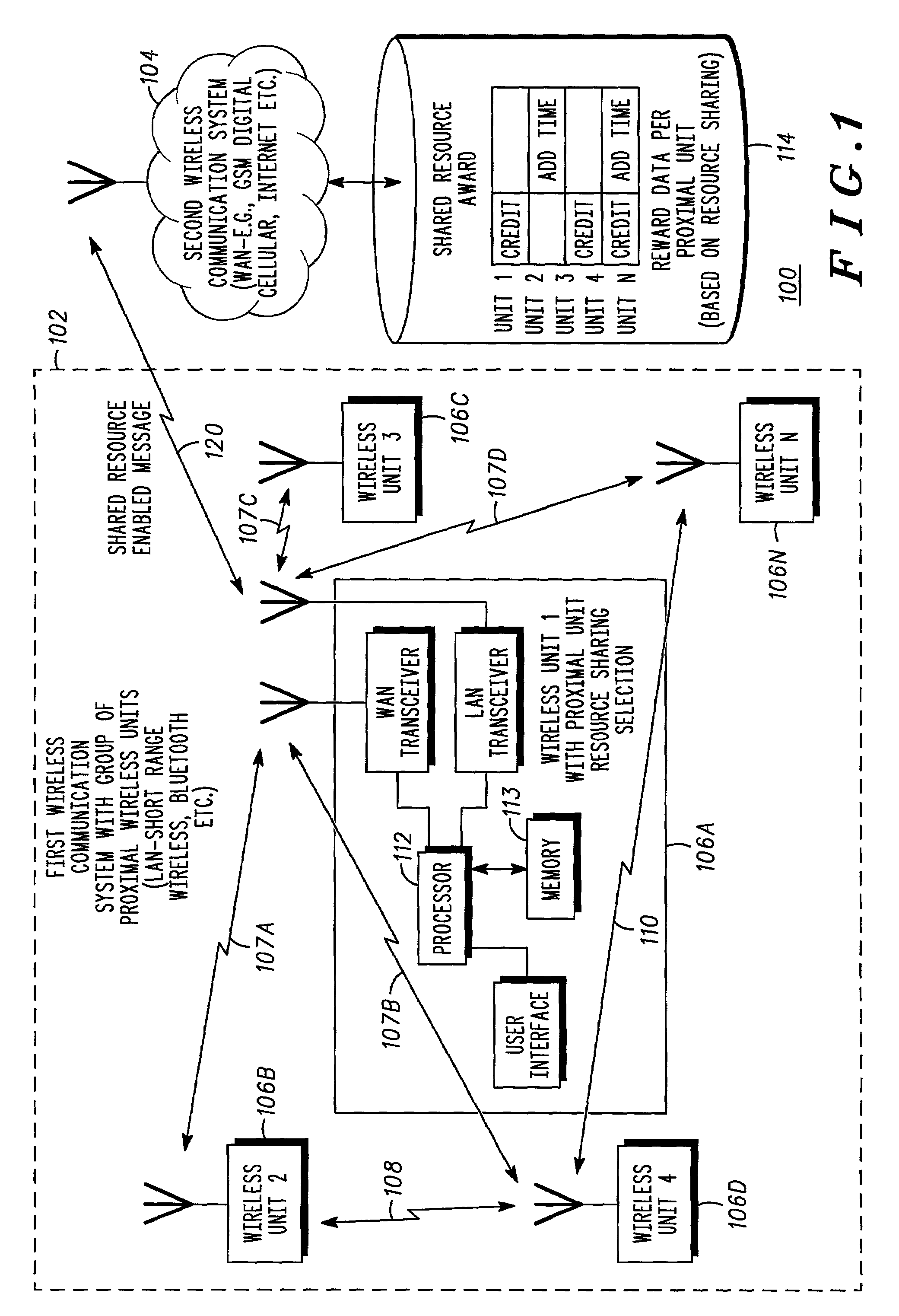

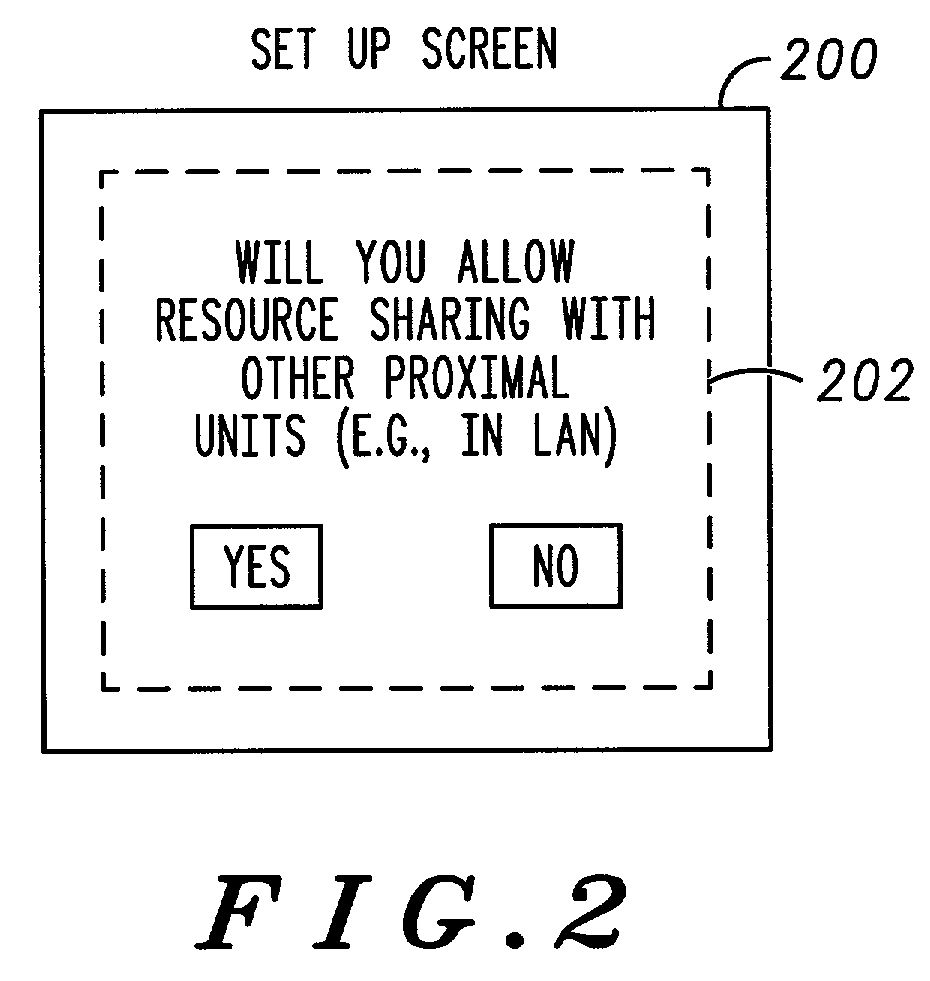

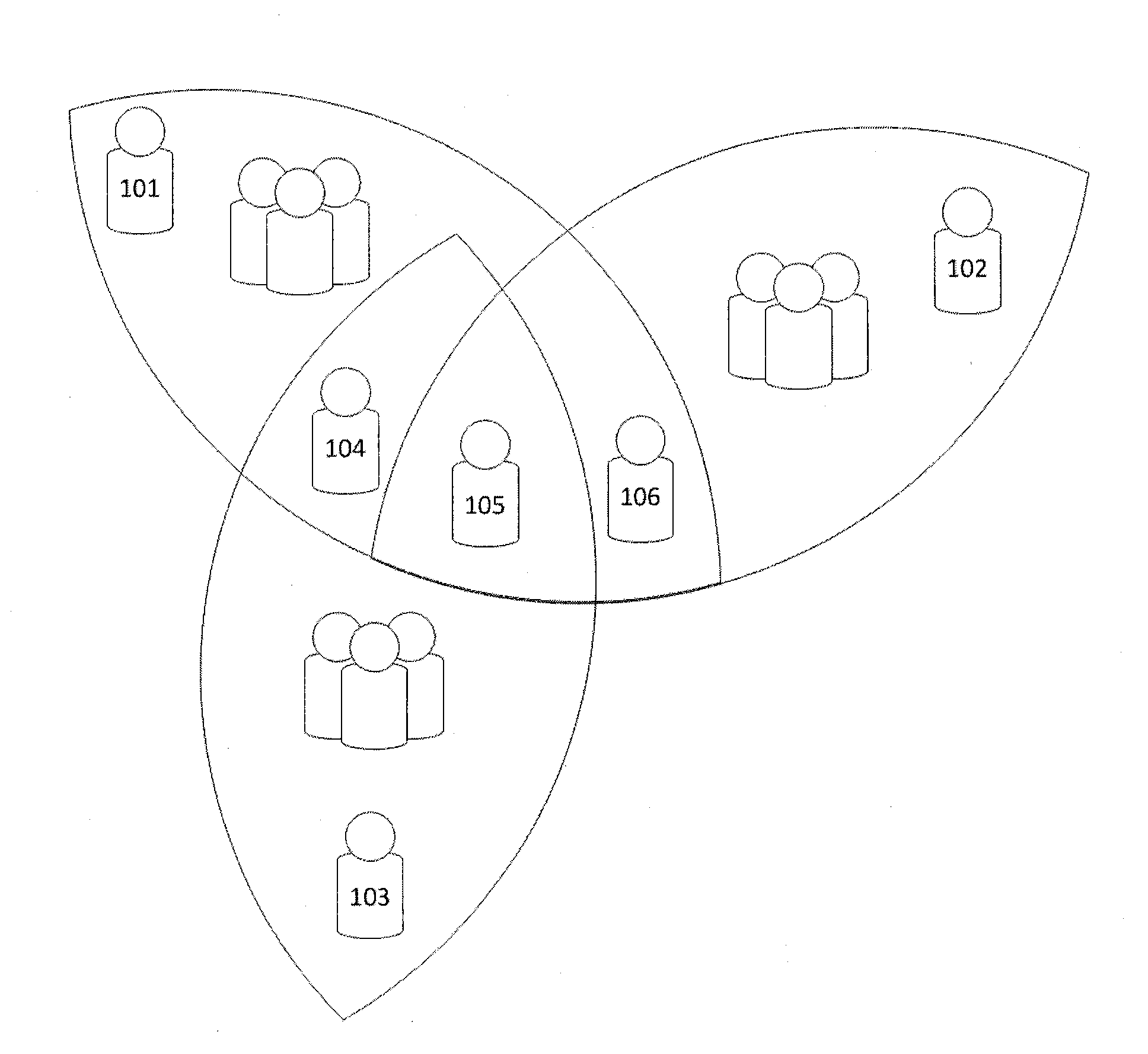

Method and apparatus for enabling and rewarding wireless resource sharing

A method and apparatus determines whether a wireless apparatus (106a) that is operative to communicate over both a wireless wide area network (104) and a wireless local area network (102), will allow shared use of its short range wireless resources, such as LAN radio frequency bandwidth, optical bandwidth or other local area wireless resources, with other proximal wireless units (106b-106n) in the wireless local area network (102). In addition, the method and apparatus generated reward data (116) to provide a reward, such as free telephone calls, account credits, price reductions, or other rewards, so that a billing system is updated when a wireless apparatus (106a-106n) has been designated as allowing shared use of its wireless resources by other proximal wireless units.

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

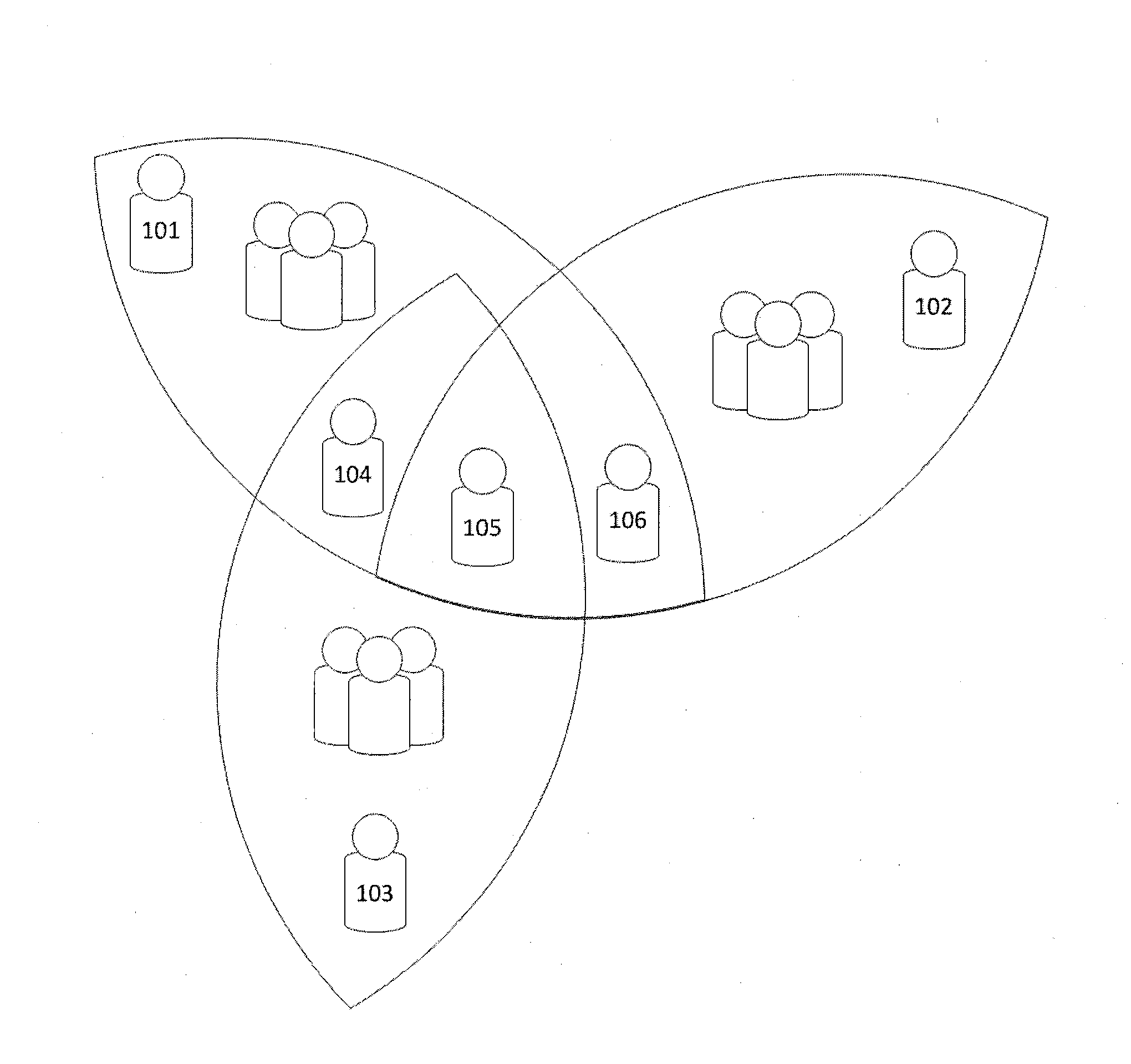

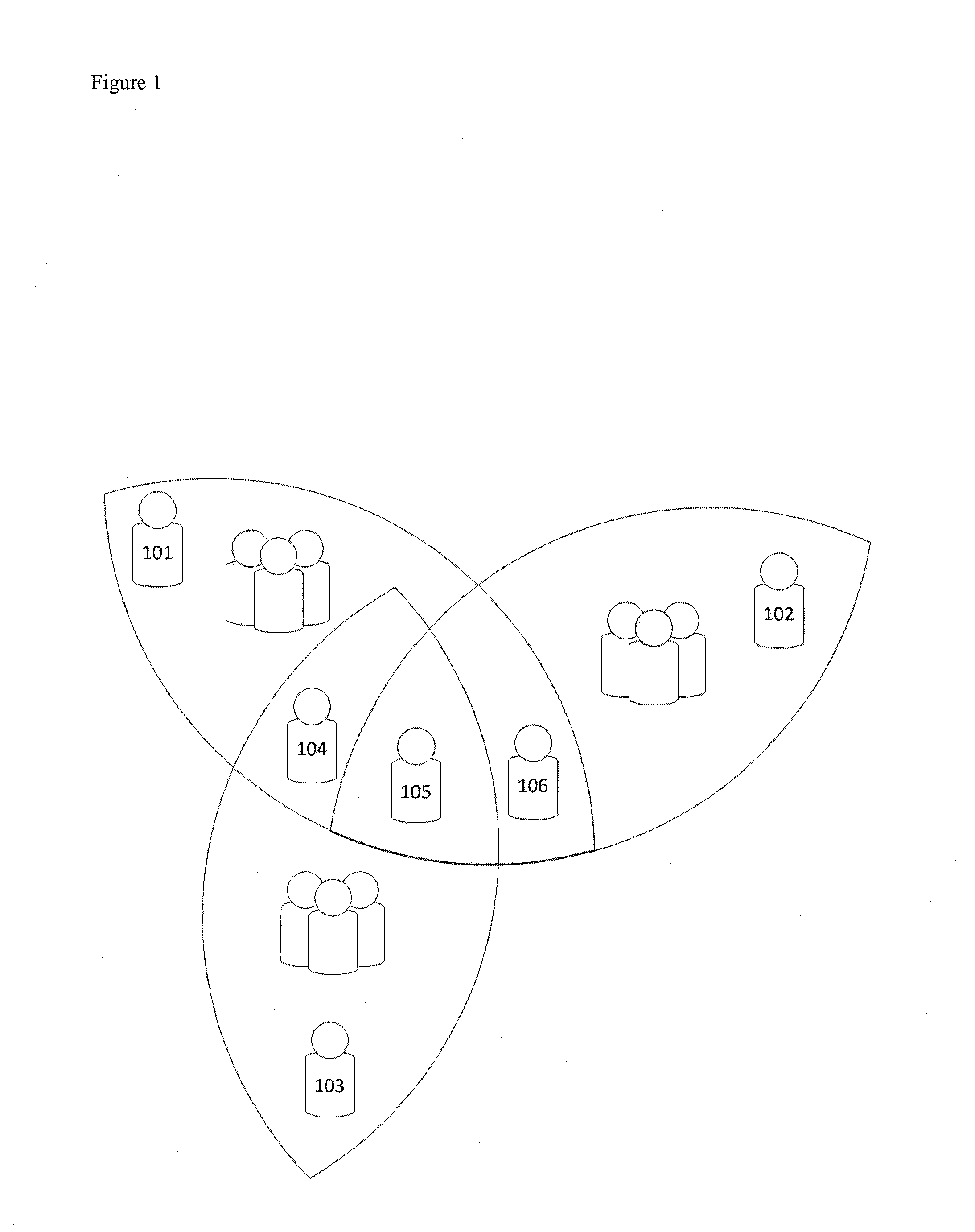

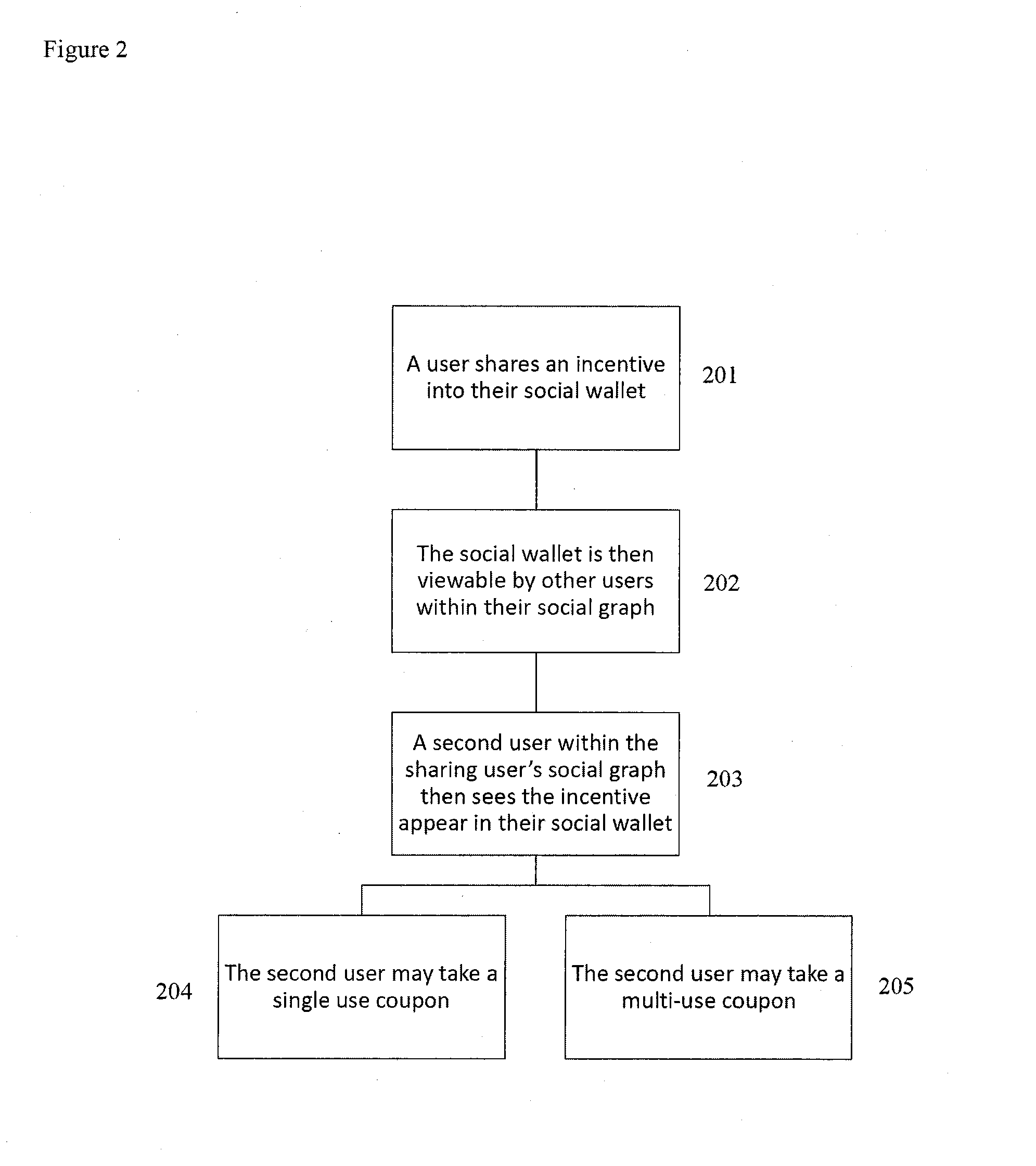

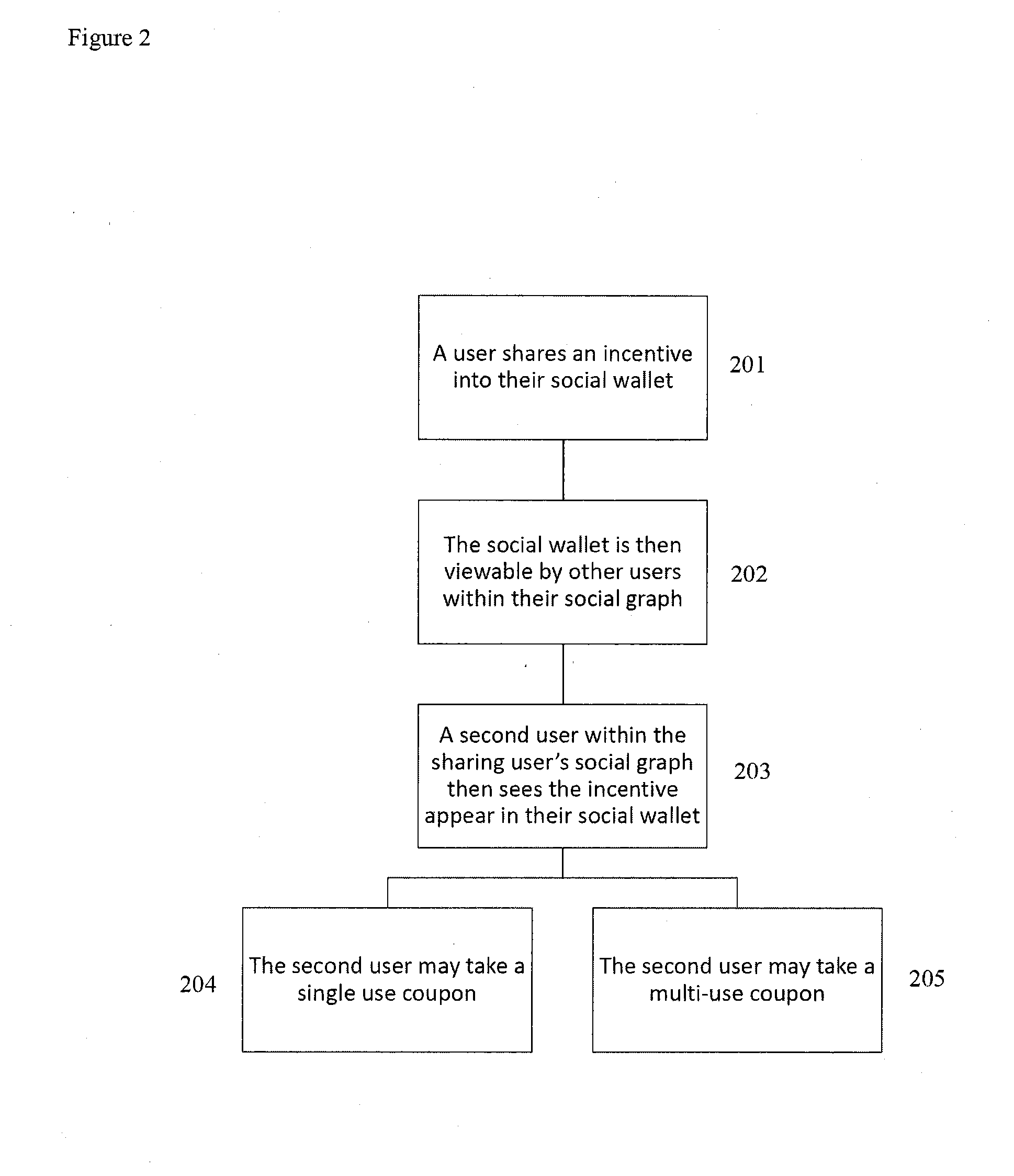

System and method for sharing incentives among groups

A system and method for sharing incentives, restricted price reductions, and stored value quantities among groups of persons, more particularly to support sharing transactions between members in a group. The system and method for sharing incentives includes receiving item information for at least one item associated with a friend, displaying the item information in a location viewable by at least one authorized friend, and receiving a request from the authorized friend to take the item, and removing from view the item information associated with the item.

Owner:SPARKBASE

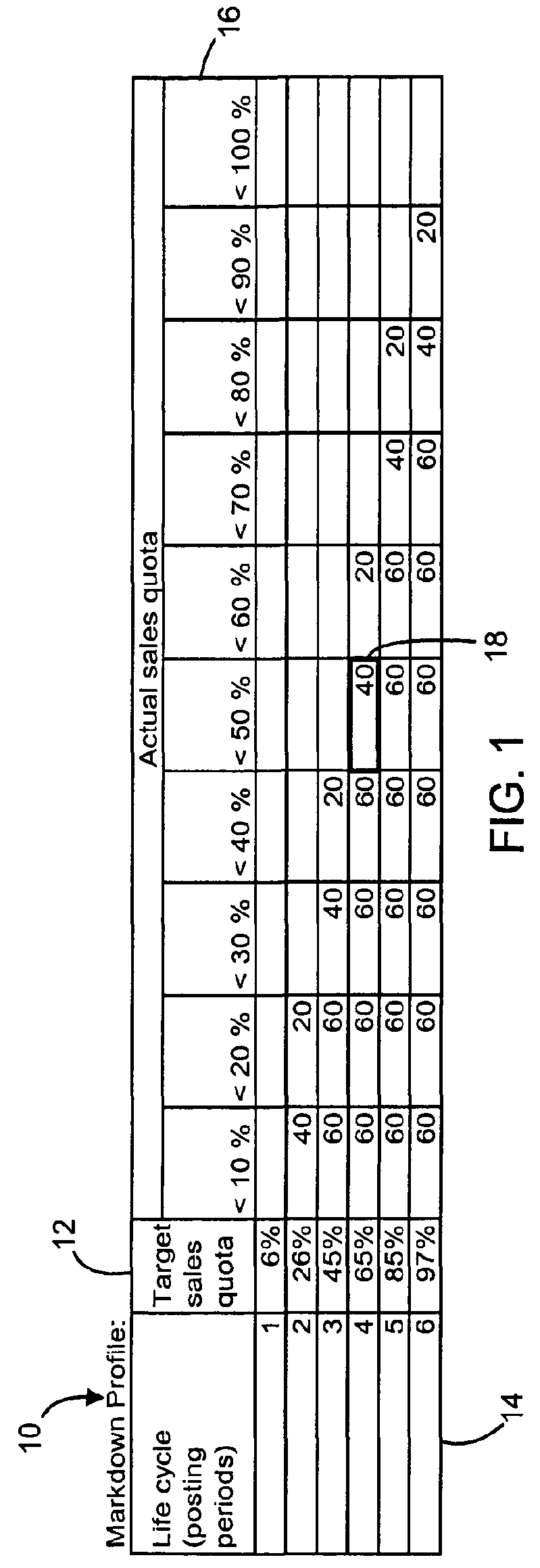

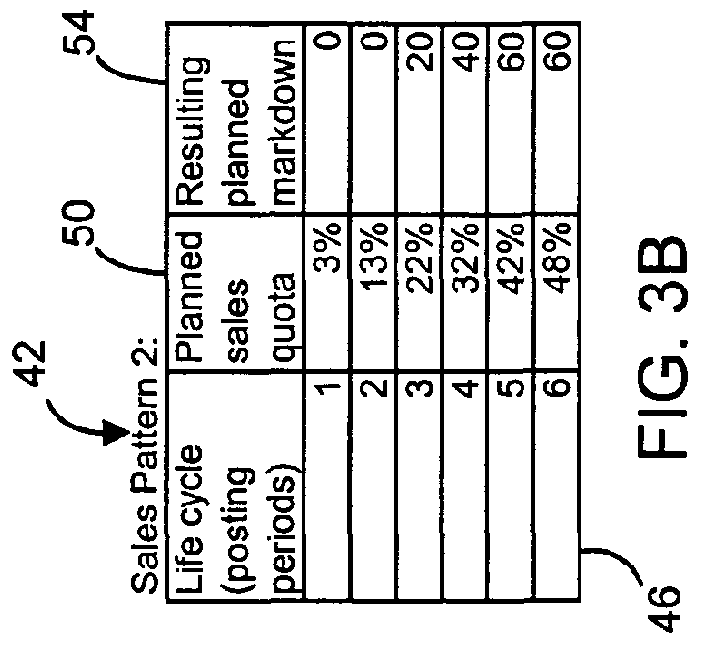

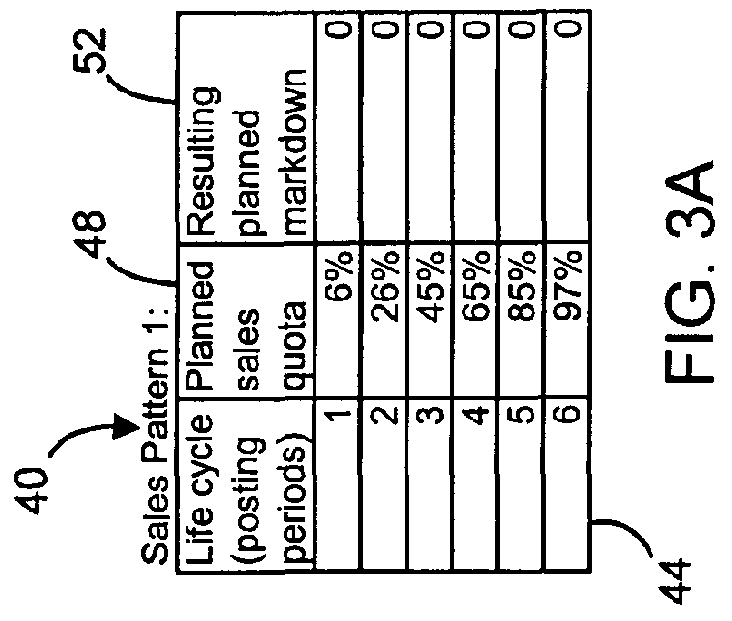

System and method for using sales patterns with markdown profiles

ActiveUS8219444B2Accurate and Efficient SimulationMarket predictionsDiscounts/incentivesEngineeringService use

A system, method and program product are provided for planning sales of one or more products or services. The method comprises selecting a markdown profile associated with the one or more products or services, selecting a sales pattern associated with the markdown profile, and distributing sales of the one or more products or services using the markdown profile and sales pattern.

Owner:SAP AG

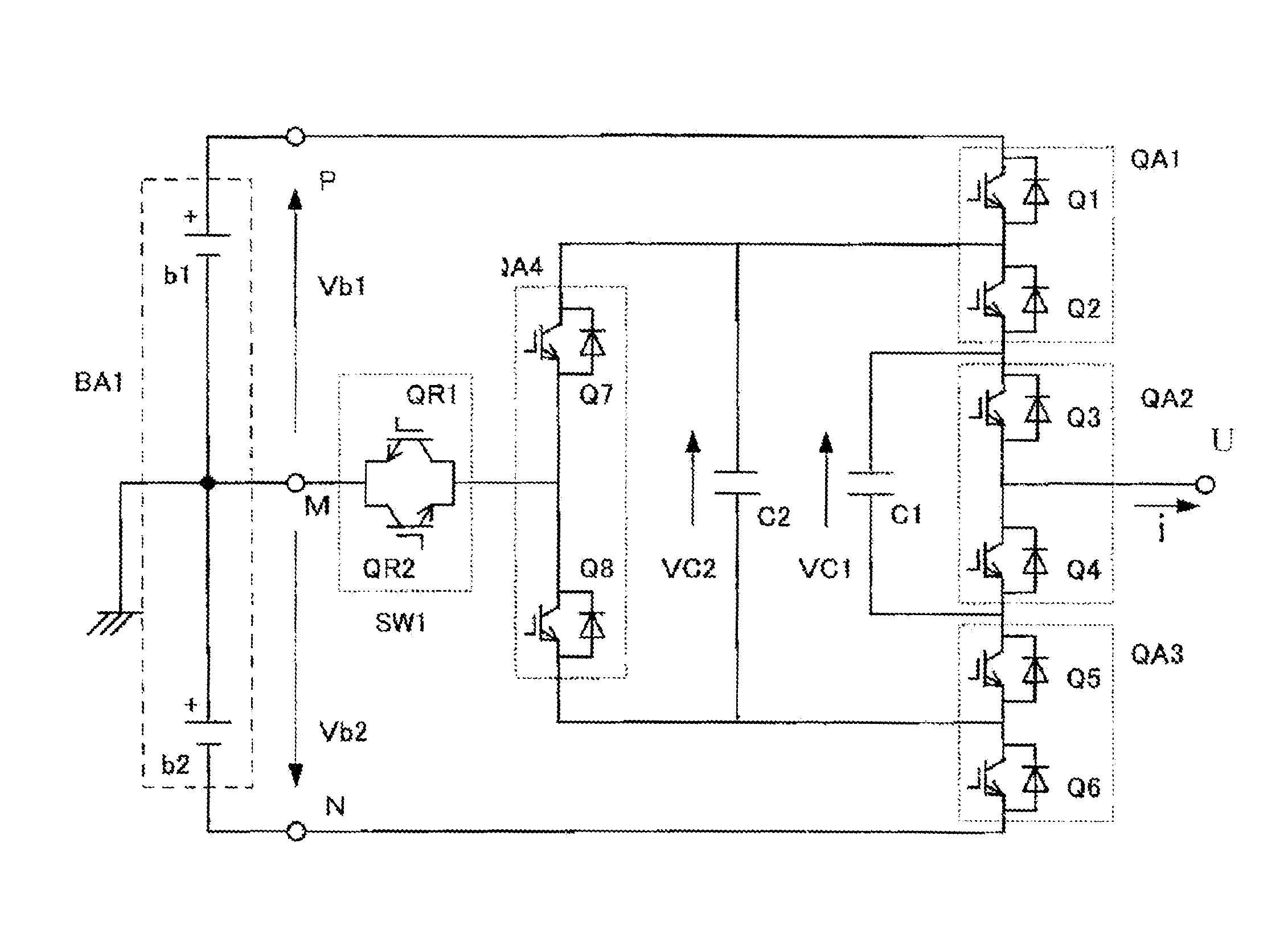

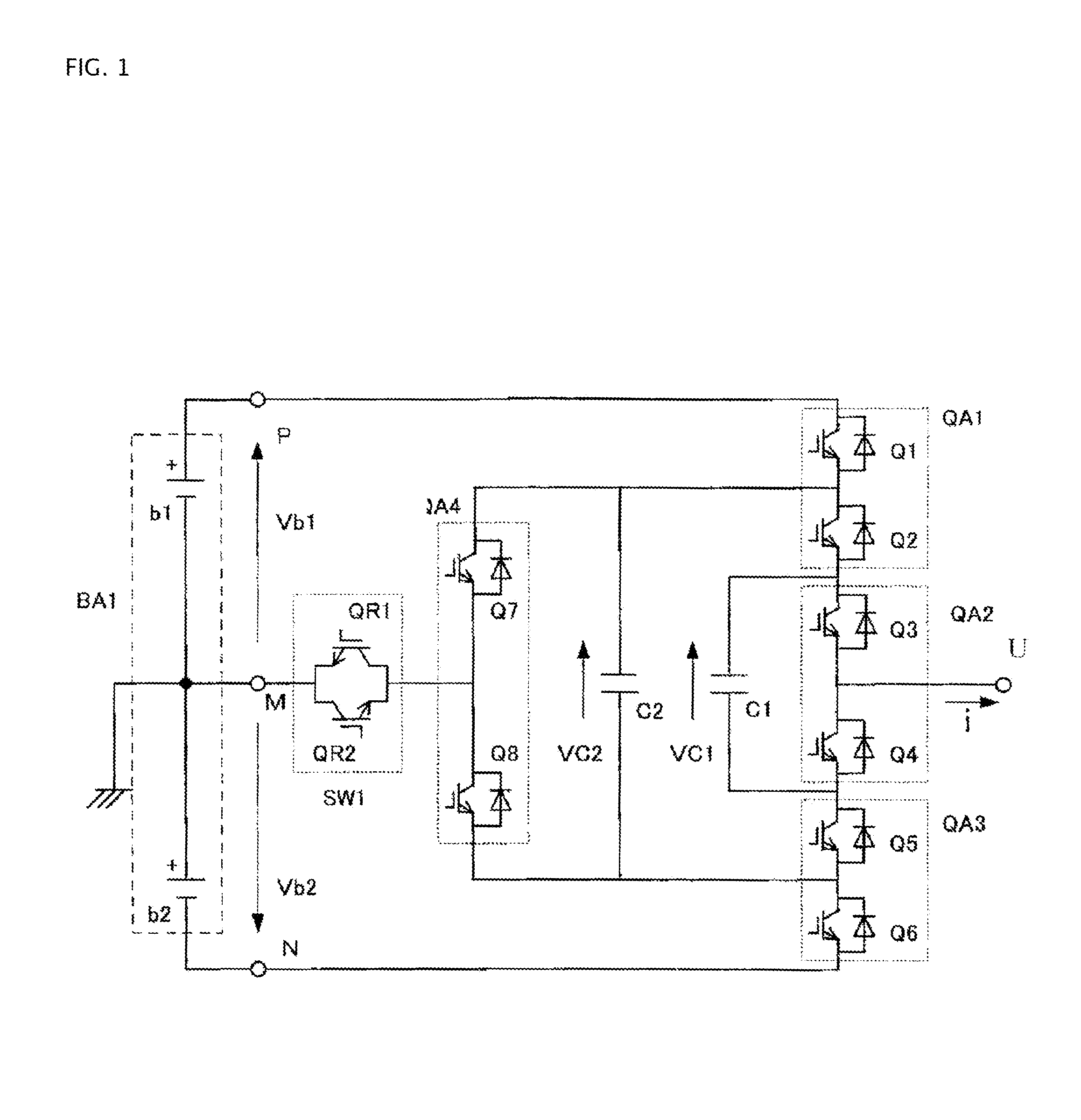

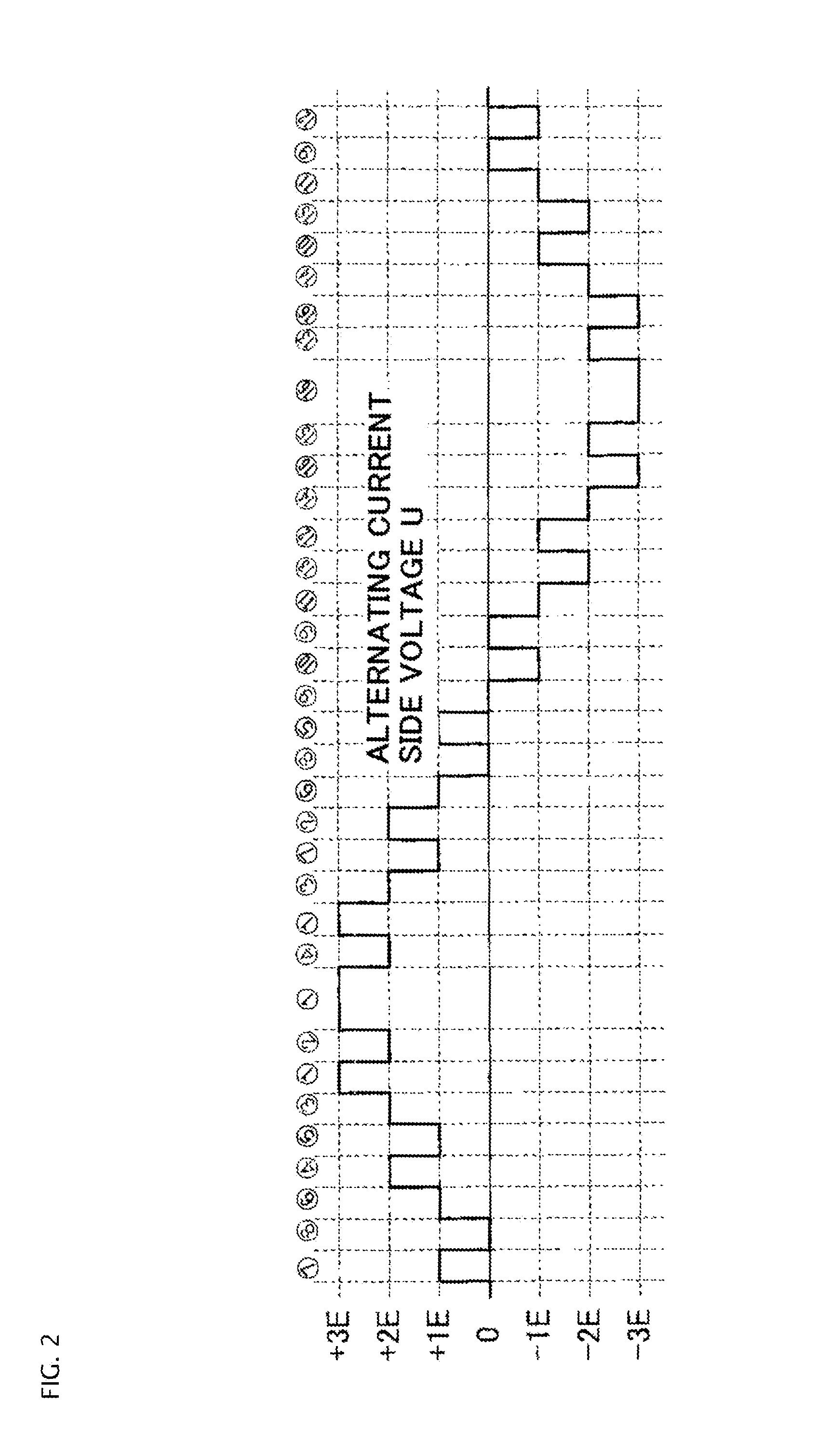

Multilevel converter circuit

ActiveUS20140098587A1Improve efficiencyMiniaturizationAc-dc conversionMiniaturizationAlternating current

In some aspects of the invention, a number of semiconductor switches through which output current passes can be reduced between a direct current power source side, which is an input, and an alternating current output, thus achieving loss reduction, and enabling higher efficiency, price reduction, and miniaturization of a device. In some aspects, a direct current power source, formed of a series connection circuit of single power sources, which has three mutually different voltage levels including zero can be provided with first, second, third, and fourth arm pairs, each configured by connecting two arms formed of semiconductor switches in series, an alternating current switch configured by combining semiconductor switches. As such, a plurality of voltage levels can be to be selected from and output by an on and off control of these switch elements.

Owner:FUJI ELECTRIC CO LTD

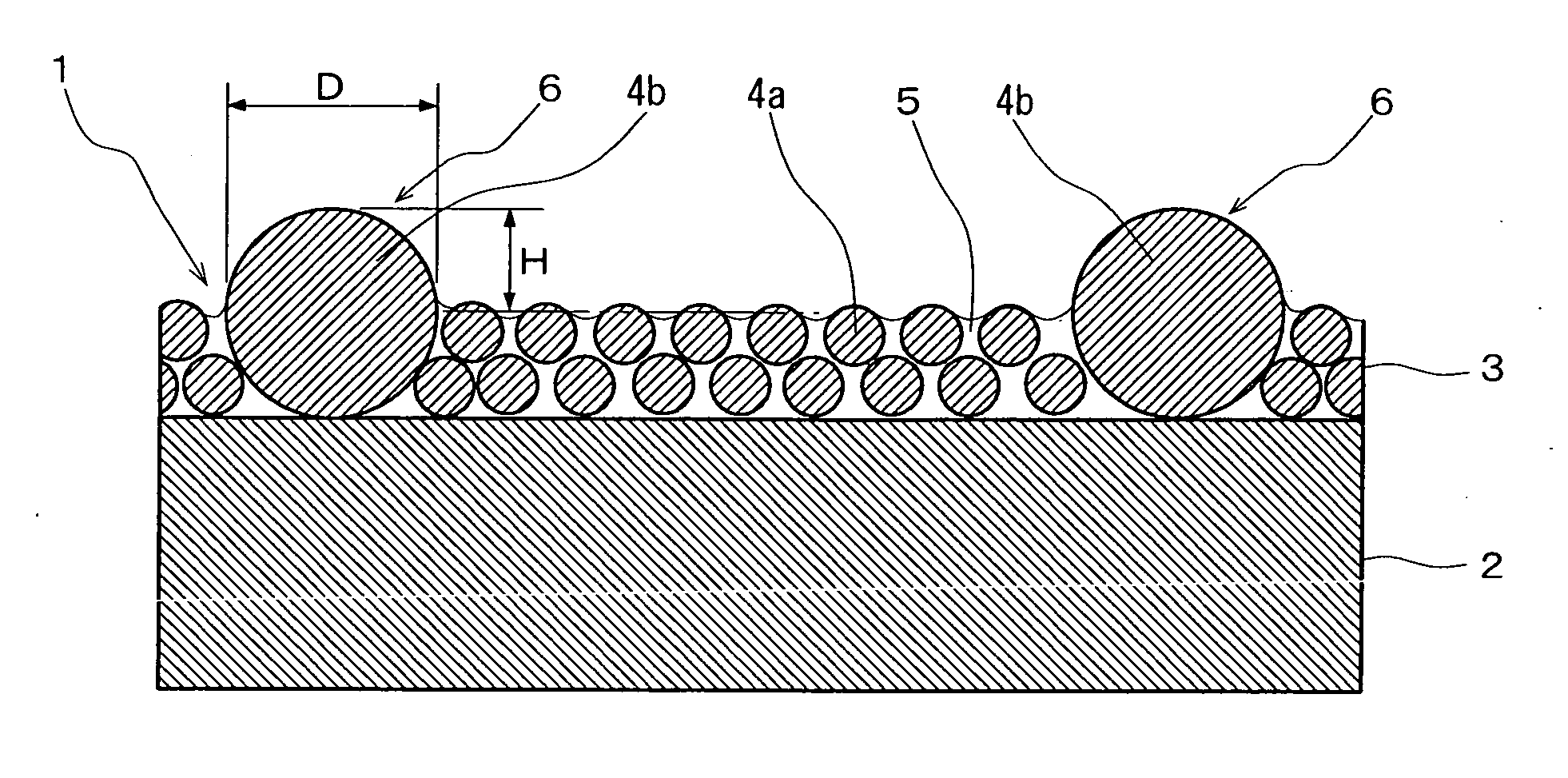

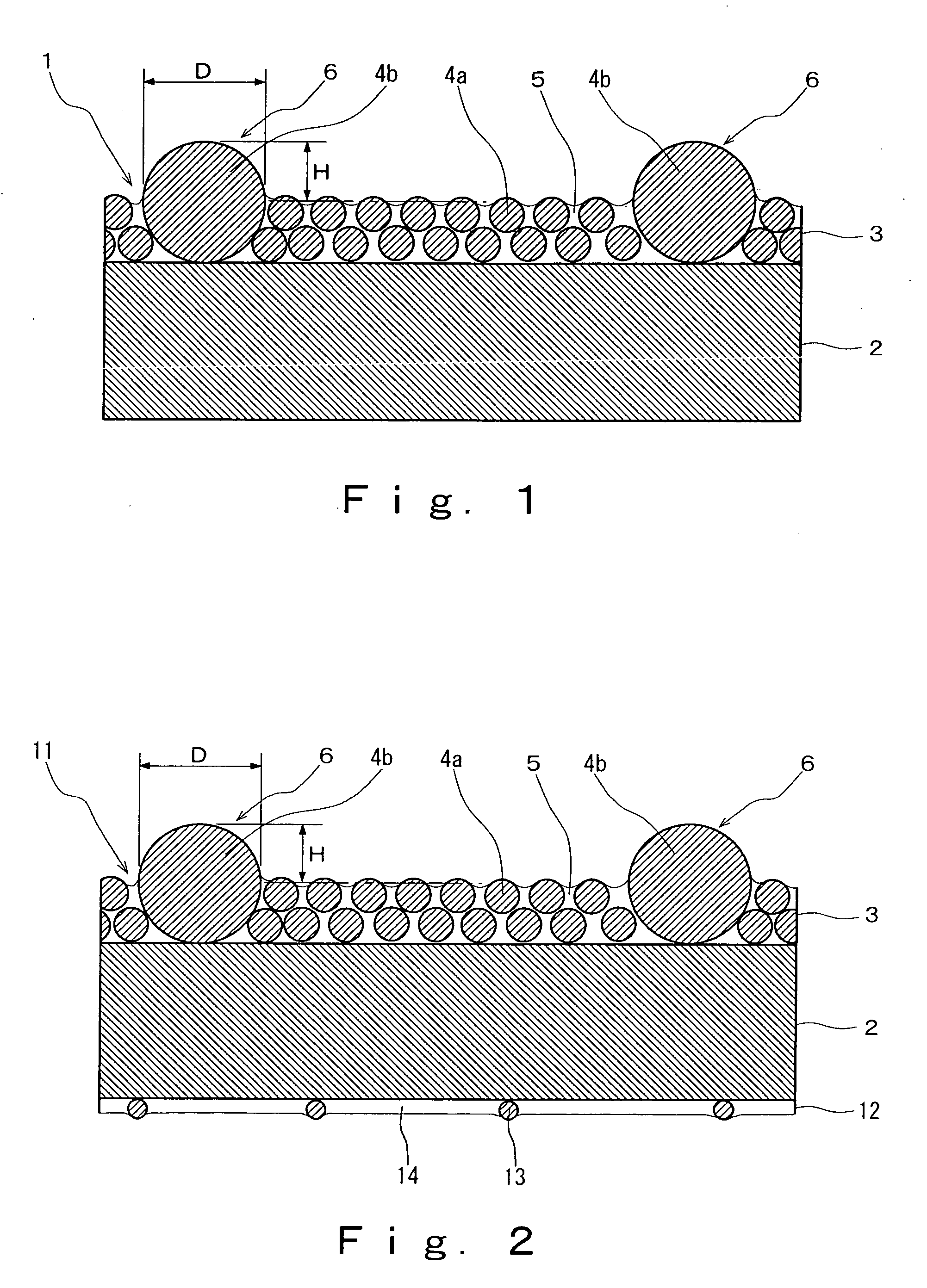

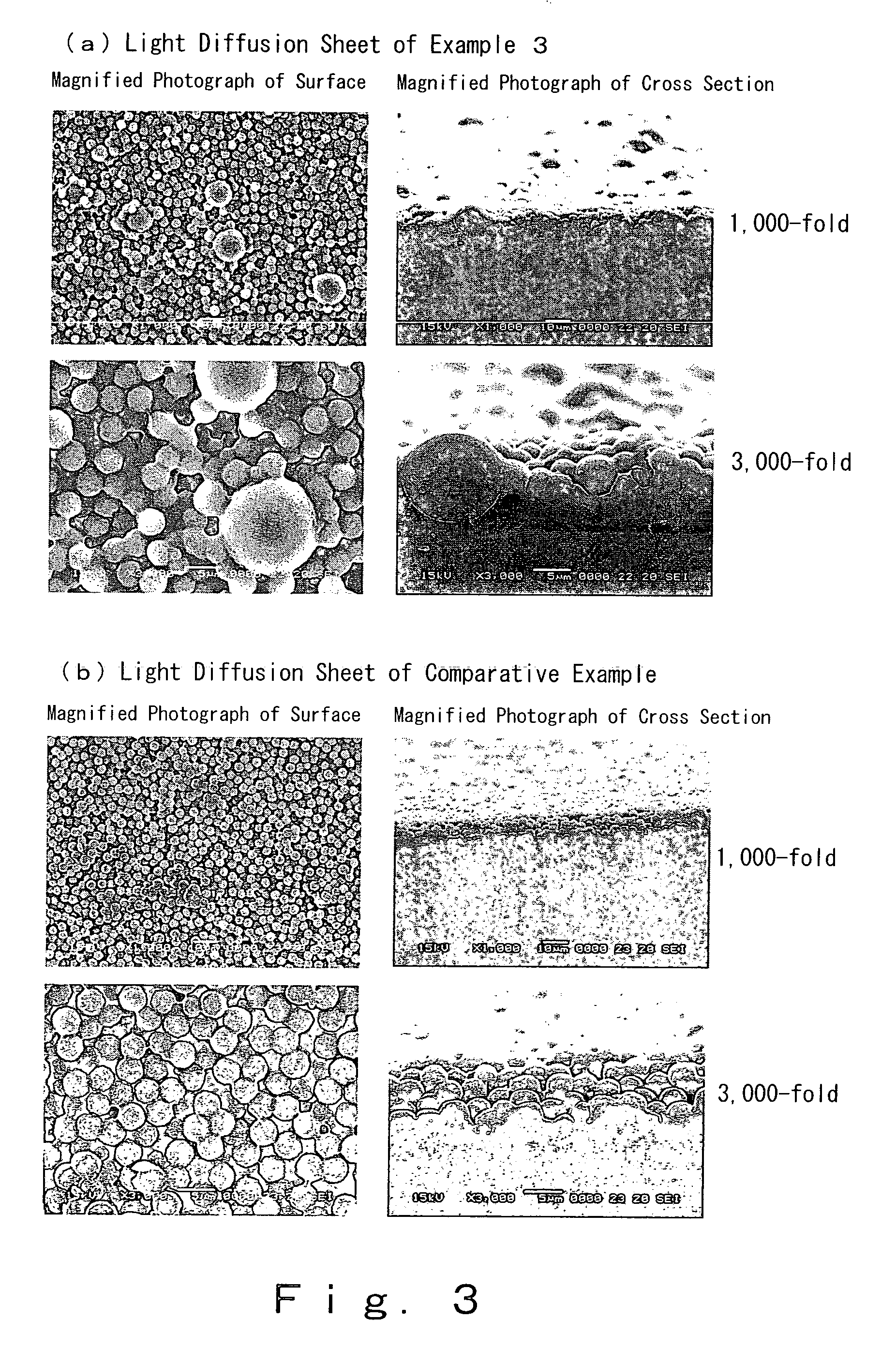

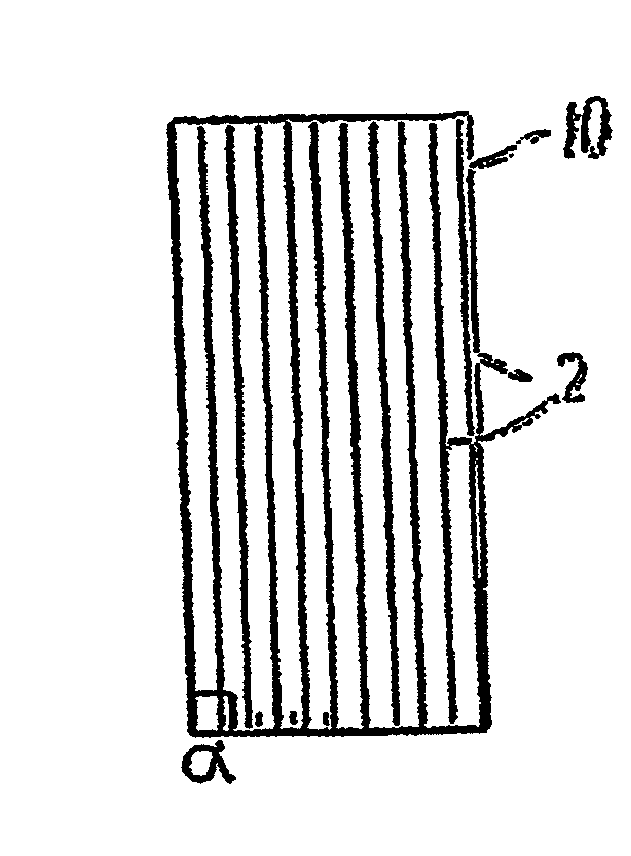

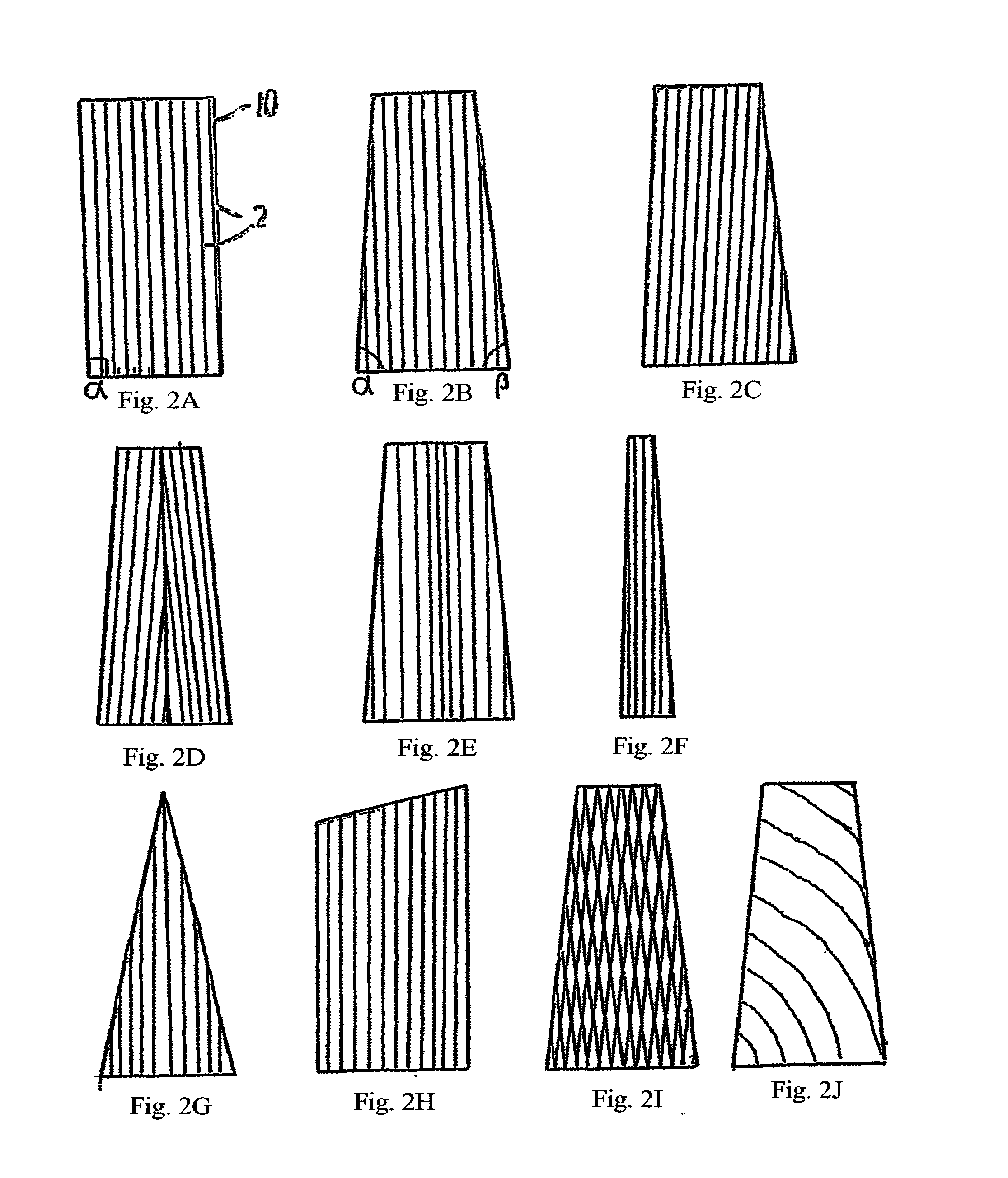

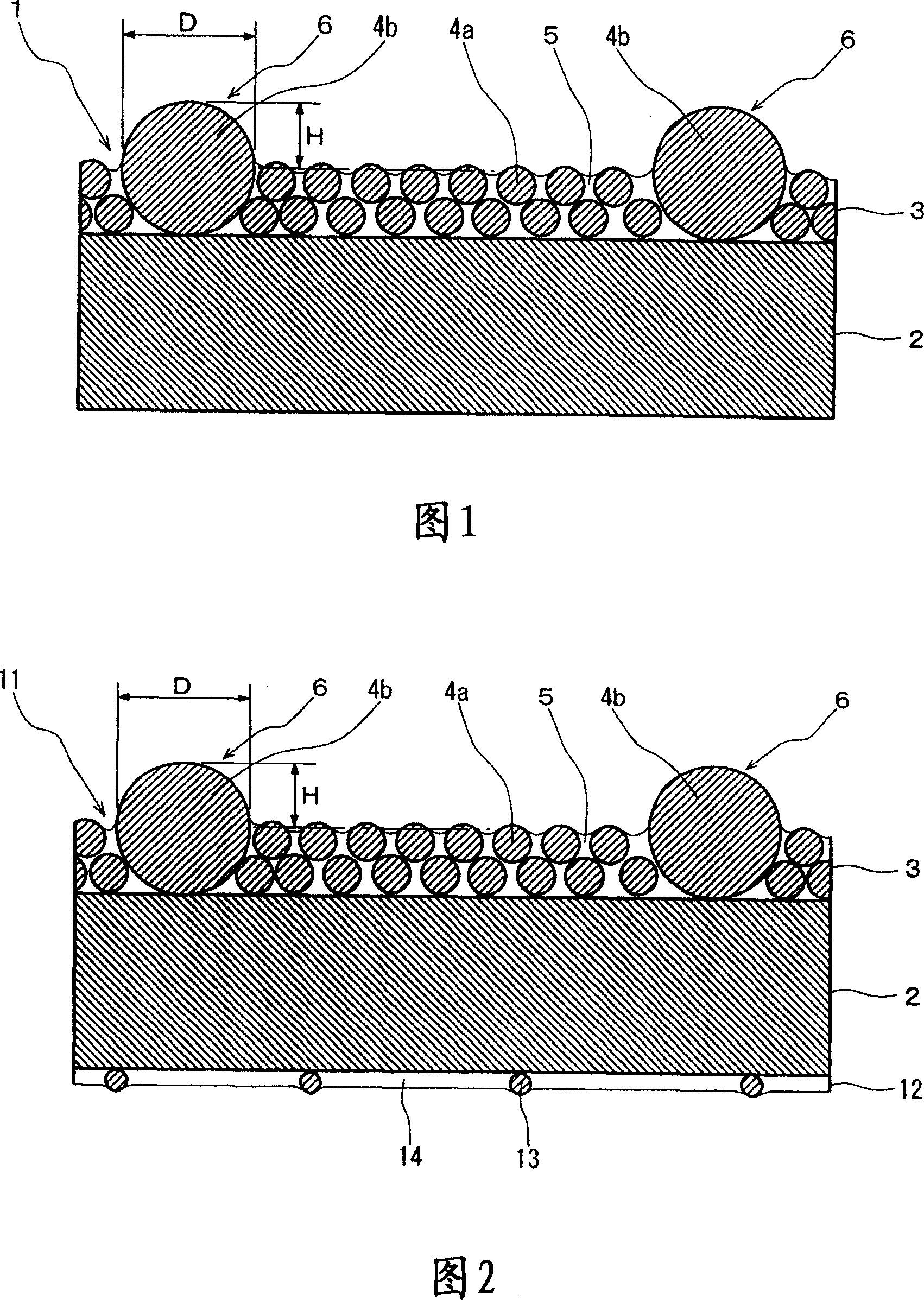

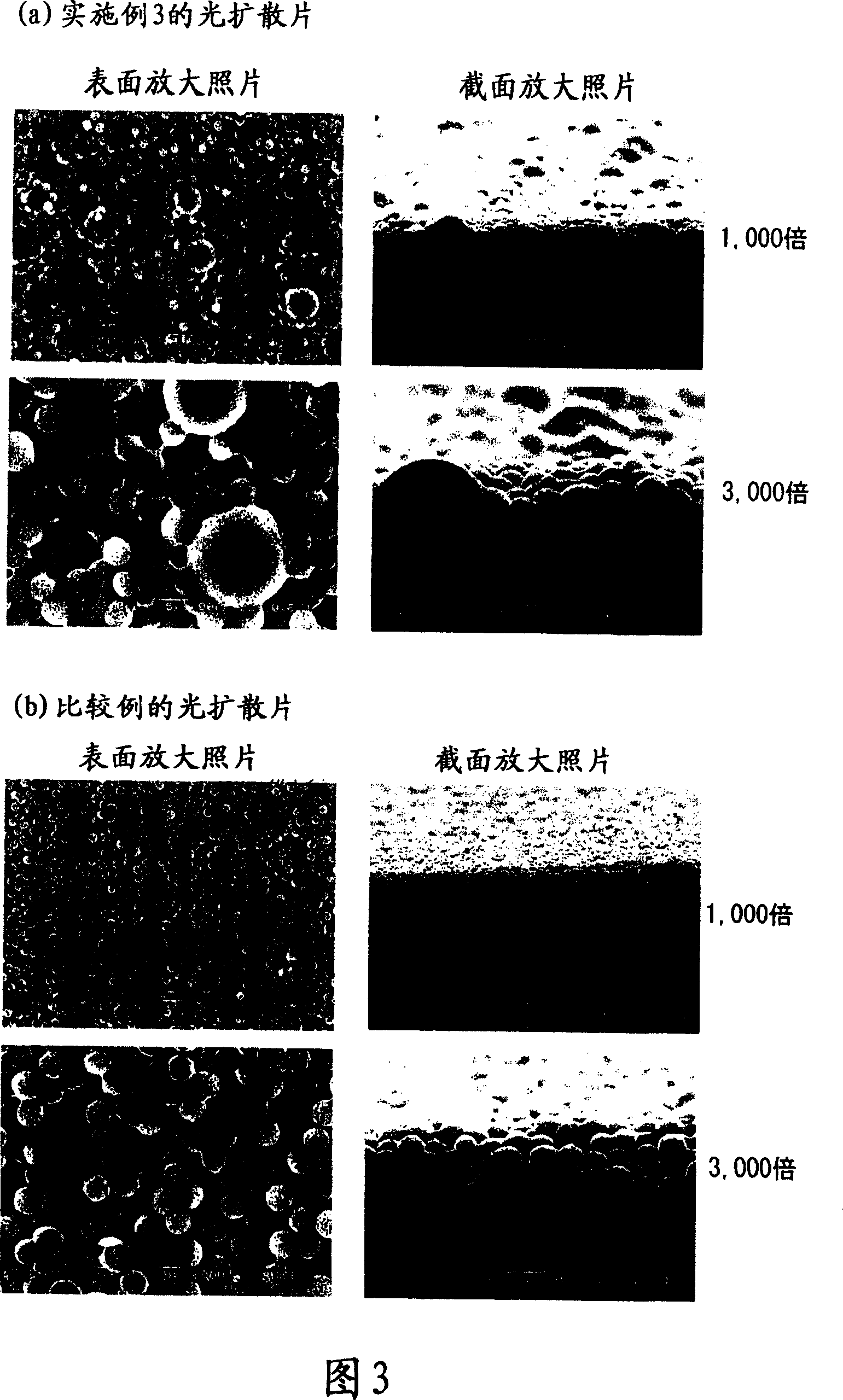

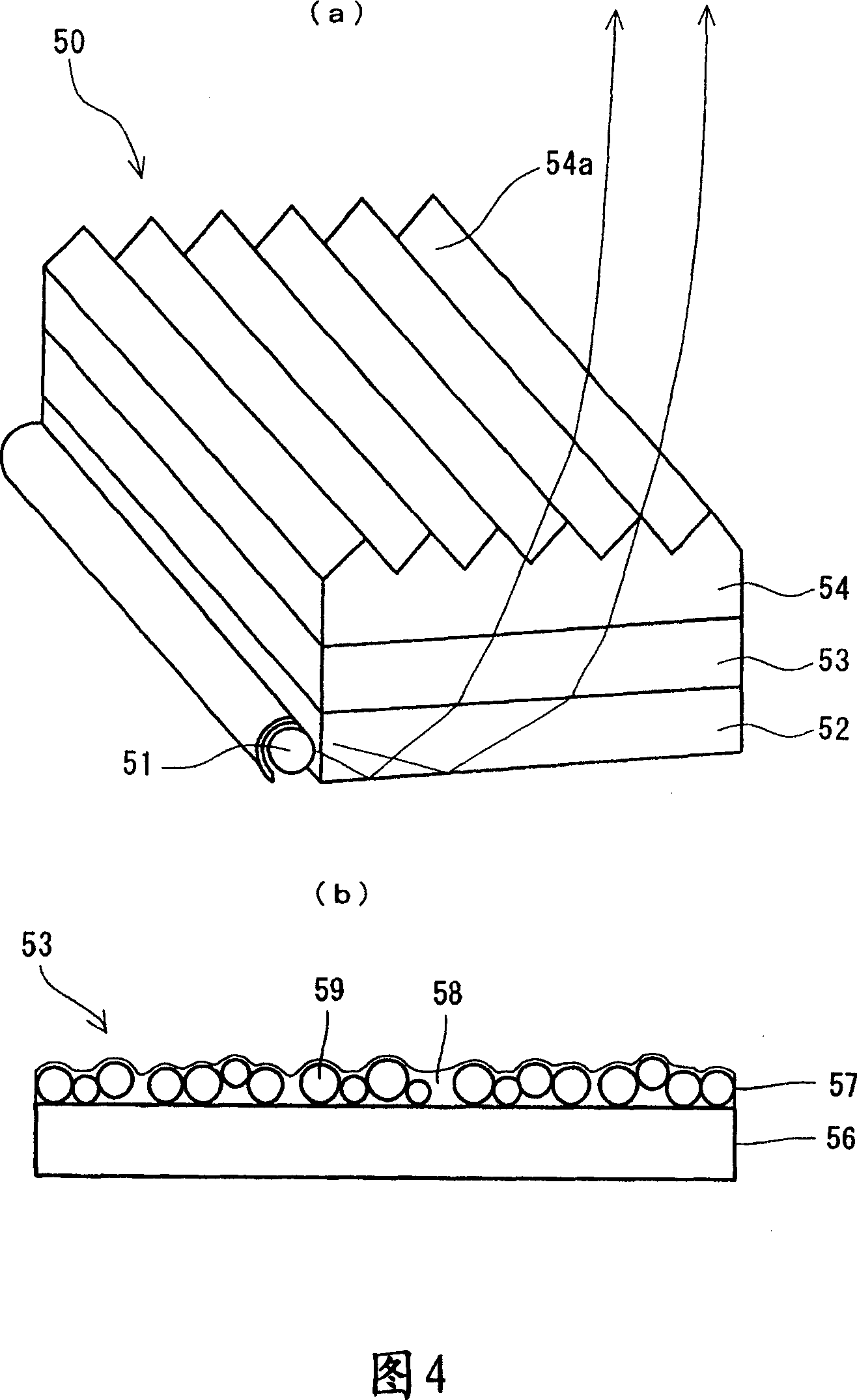

Light diffusion sheet and backlight unit using the same

ActiveUS20070087167A1Lower capability requirementsImprove scratch resistanceLayered productsRecord information storageOccupancy rateDiffusion

An object of the present invention is to provide a light diffusion sheet having a favorable cost reduction capability due to excellent scratching preventive property of the front face, and having in addition thereto, a favorable directional light diffusion function, transmittivity of rays of light, and a thin film character; and a backlight unit capable of promoting performances such as luminance as well as price reduction, and thin and light modeling capability. The light diffusion sheet of the present invention has a light diffusion sheet including a transparent substrate layer, and a light diffusion layer overlaid on the front face side of the substrate layer, wherein the light diffusion layer has resin beads and a resin binder, characterized in that the light diffusion layer has protruding parts having a shape of a partial spherical body on the front face in a scattering manner. It is preferred that mean height of the protruding parts be 1 μm or greater and 10 μm or less, mean diameter of the protruding parts be 4 μm or greater and 18 μm or less, mean occupancy rate of the protruding parts be 2% or greater and 20% or less, and surface roughness (Ra) of the light diffusion layer be 1.5 μm or greater and 10 μm or less. As the beads, small monodisperse beads as a principal component, and large beads as a sub component may be included.

Owner:KEIWA INCORPORATED

Method and apparatus for enabling and rewarding wireless resource sharing

A method and apparatus determines whether a wireless apparatus (106a) that is operative to communicate over both a wireless wide area network (104) and a wireless local area network (102), will allow shared use of its short range wireless resources, such as LAN radio frequency bandwidth, optical bandwidth or other local area wireless resources, with other proximal wireless units (106b–106n) in the wireless local area network (102). In addition, the method and apparatus generated reward data (116) to provide a reward, such as free telephone calls, account credits, price reductions, or other rewards, so that a billing system is updated when a wireless apparatus (106a–106n) has been designated as allowing shared use of its wireless resources by other proximal wireless units.

Owner:GOOGLE TECH HLDG LLC

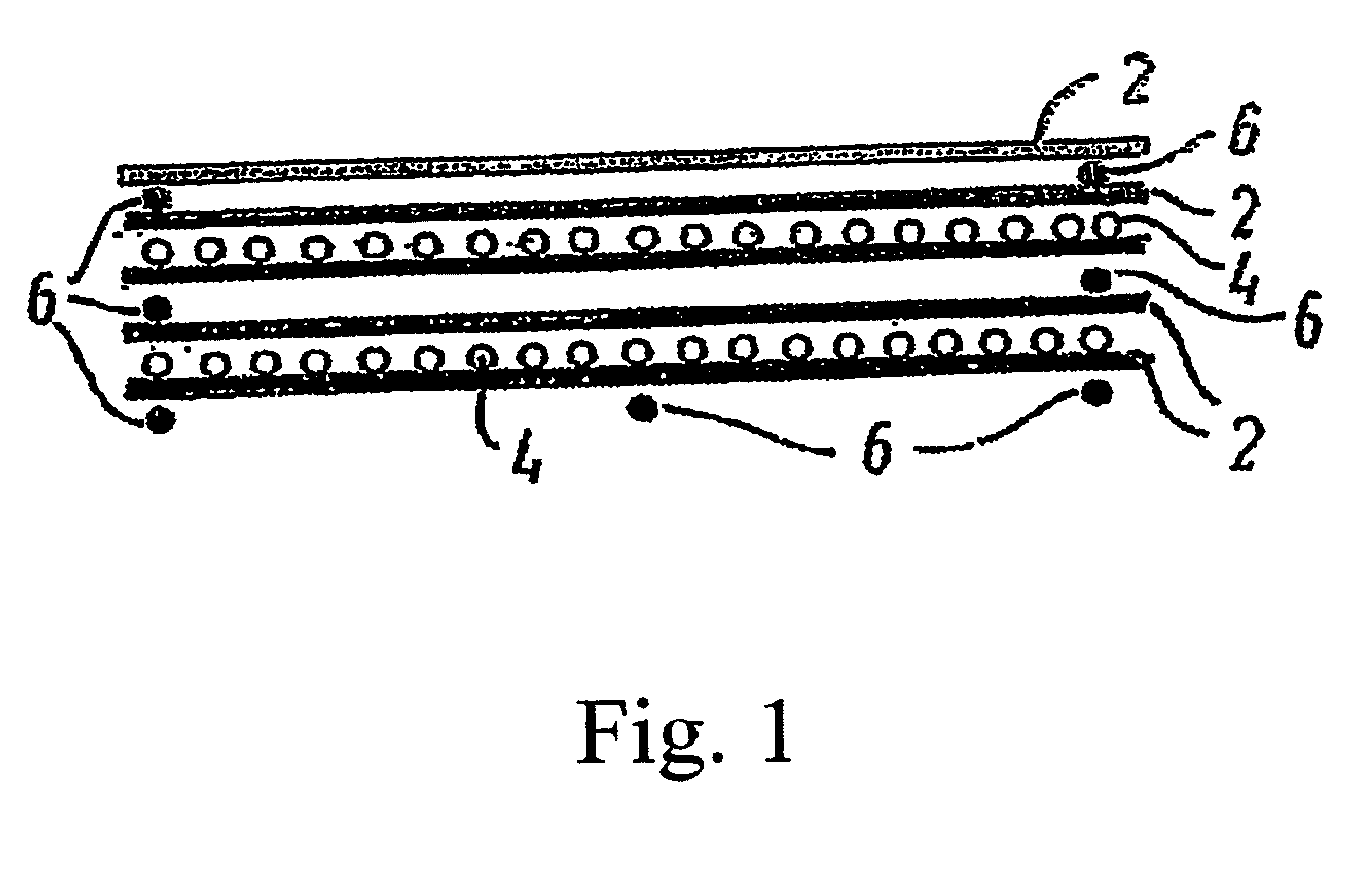

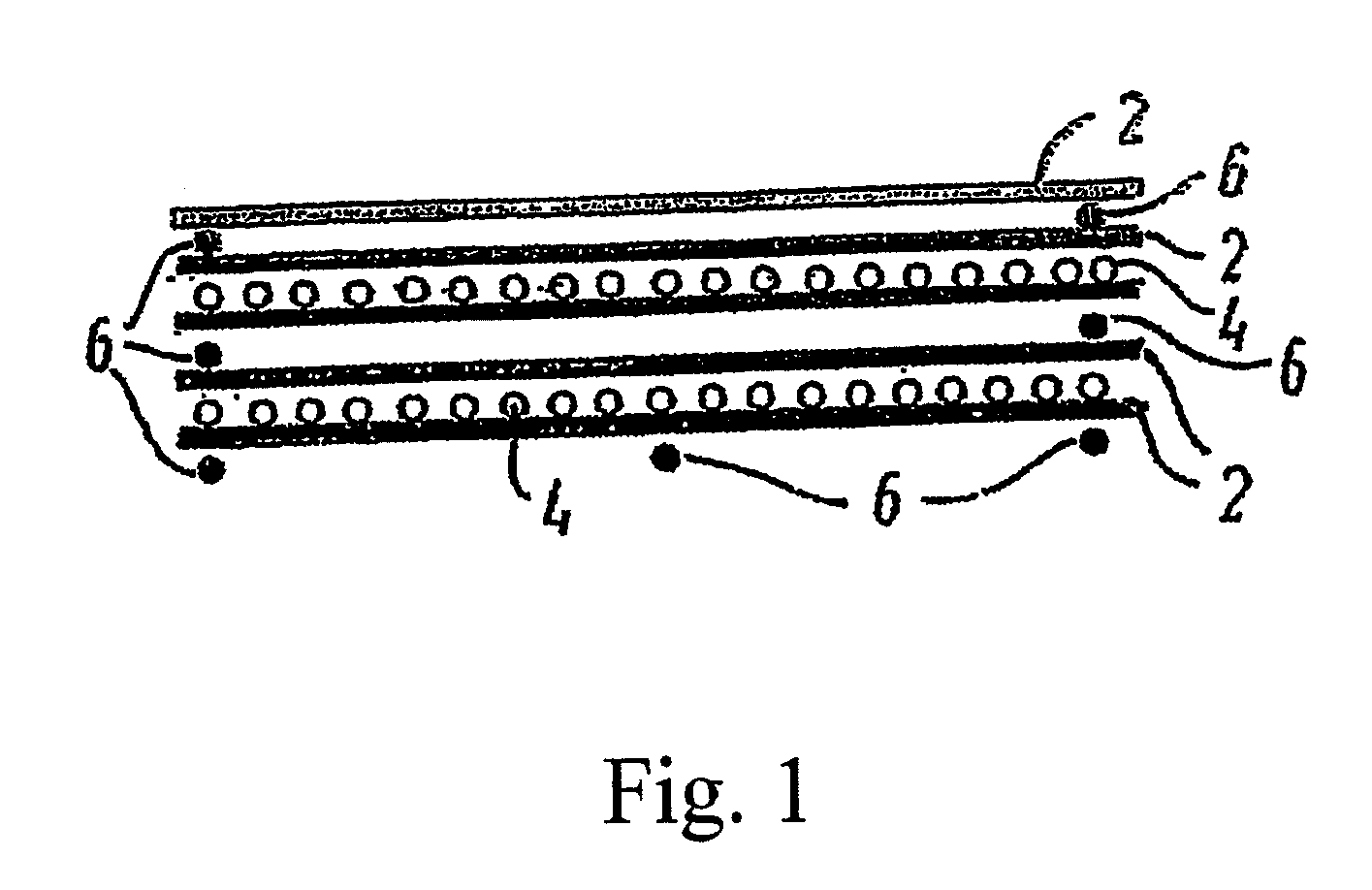

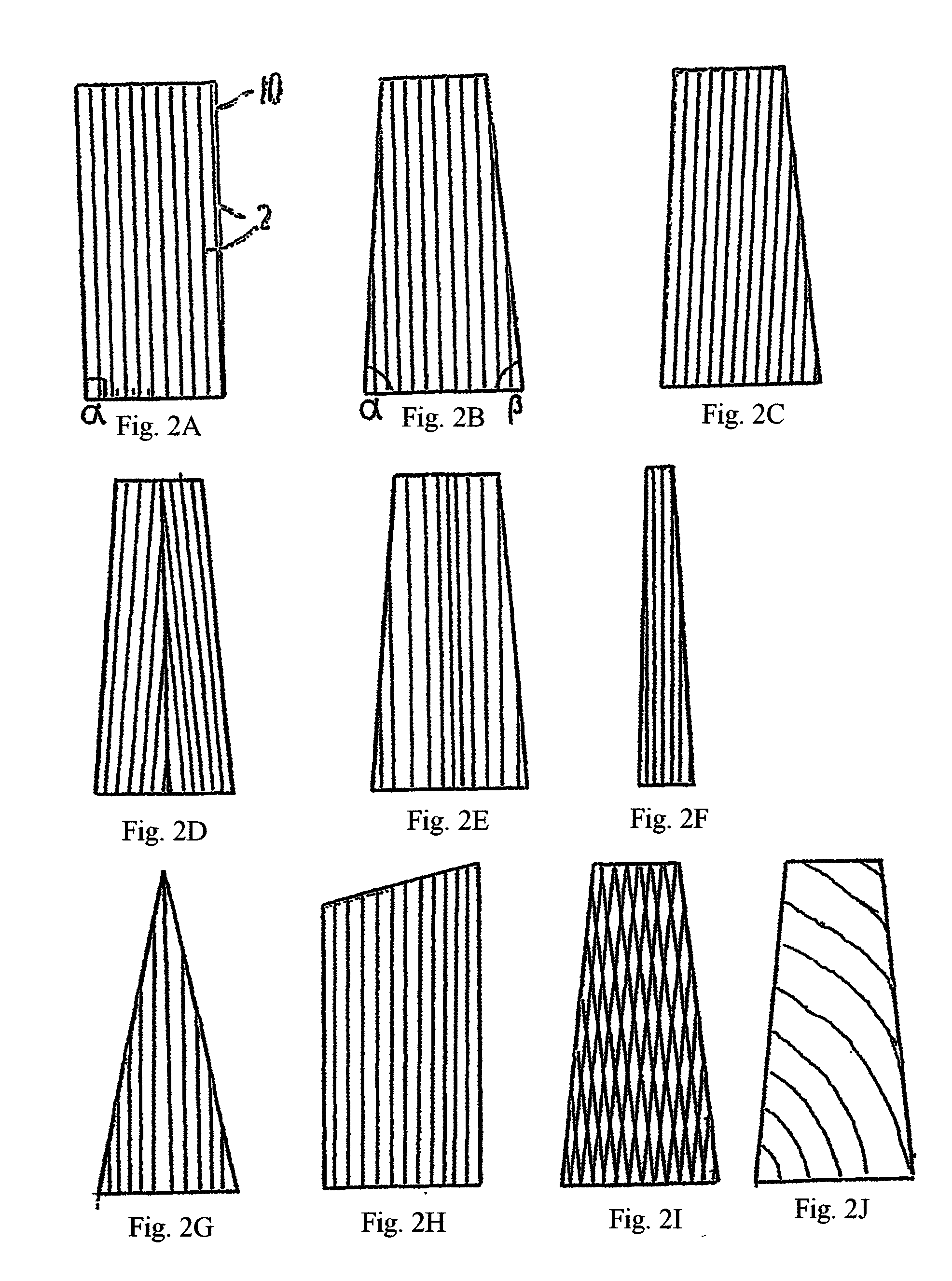

Method for preparing pre-form materials

InactiveUS20090317585A1Good reproducibilityReduce porosityLayered productsWoven fabricsTurbine bladeAdhesive

A pre-form and a method of preparing pre-forms are provided. The pre-forms comprise a resin and at least three layers of oriented fibre tows. The pre-forms comprise fibre tows instead of the traditional prepregs to enhance rearranging of resin and / or fibres during subsequent processing as well as provide greater freedom, a price reduction and / or a reduction of waste. The pre-forms may be formed three-dimensionally to enhance coupling to further pre-forms or other structures and / or to enhance shaping of the pre-form to a final three-dimensional shape. The method of preparation of pre-forms involves providing an adhesive between layers of fibres and providing a resin in contact with at least one of the layers of fibres. The resin is preferably provided in a non-continuous layer to allow for removal of gas at least partially in a direction orthogonal to the layers of resin. Advantageously, during manufacturing, the fibres are placed with an exact start and ending location, thereby avoiding waste. The pre-forms are suitable for preparation of composite structures like for example spars for wind turbine blades.

Owner:VESTAS WIND SYST AS

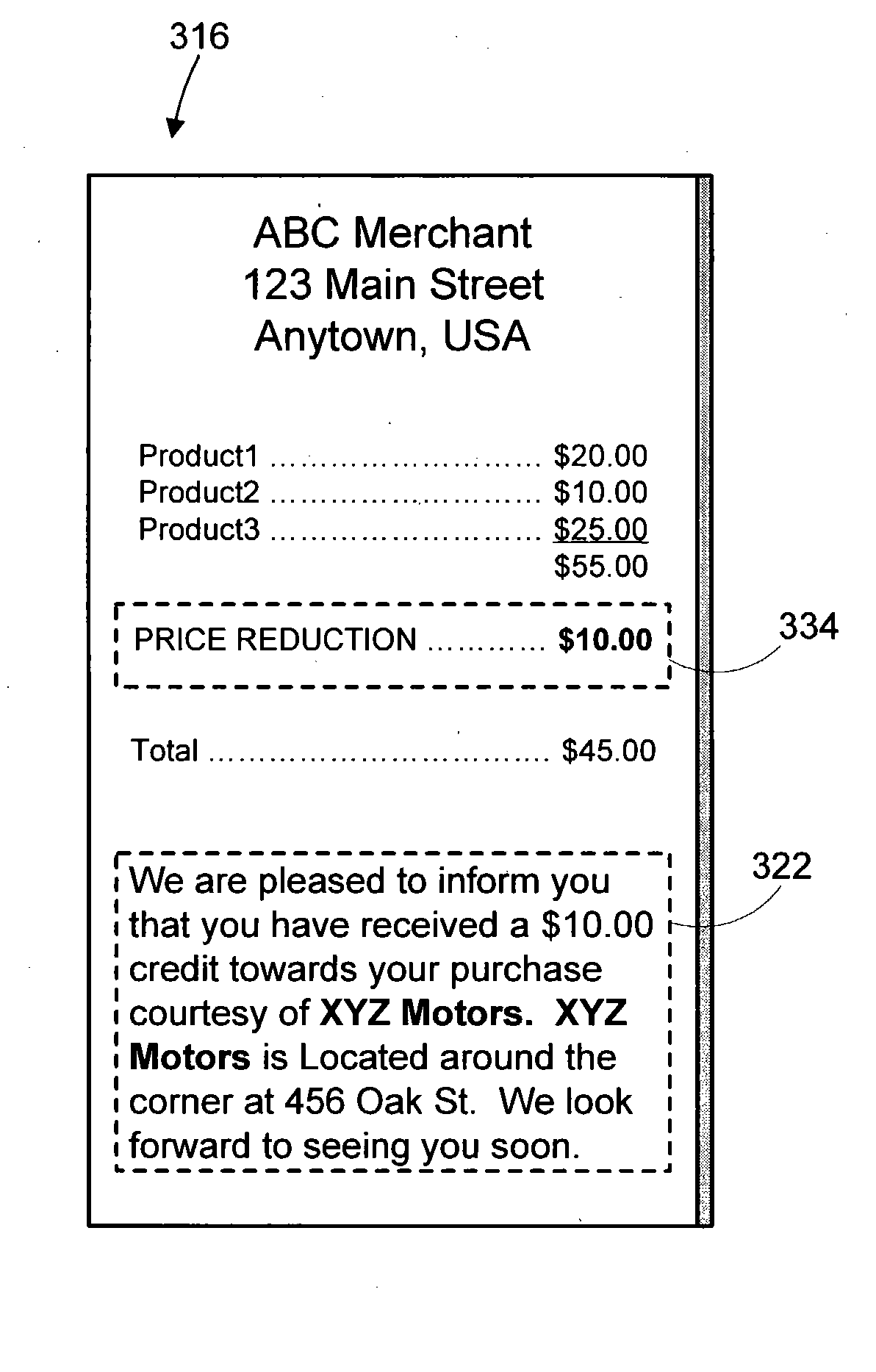

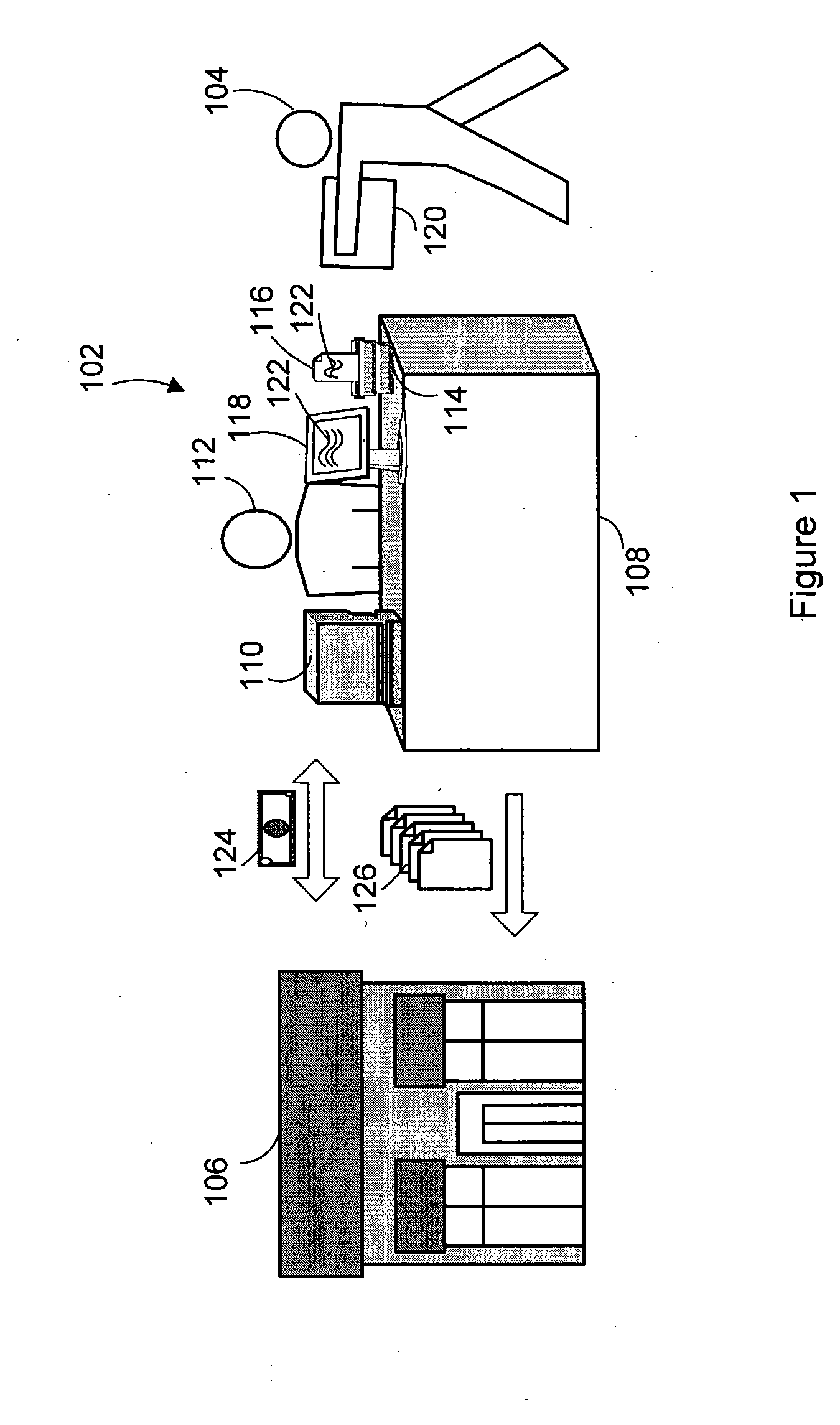

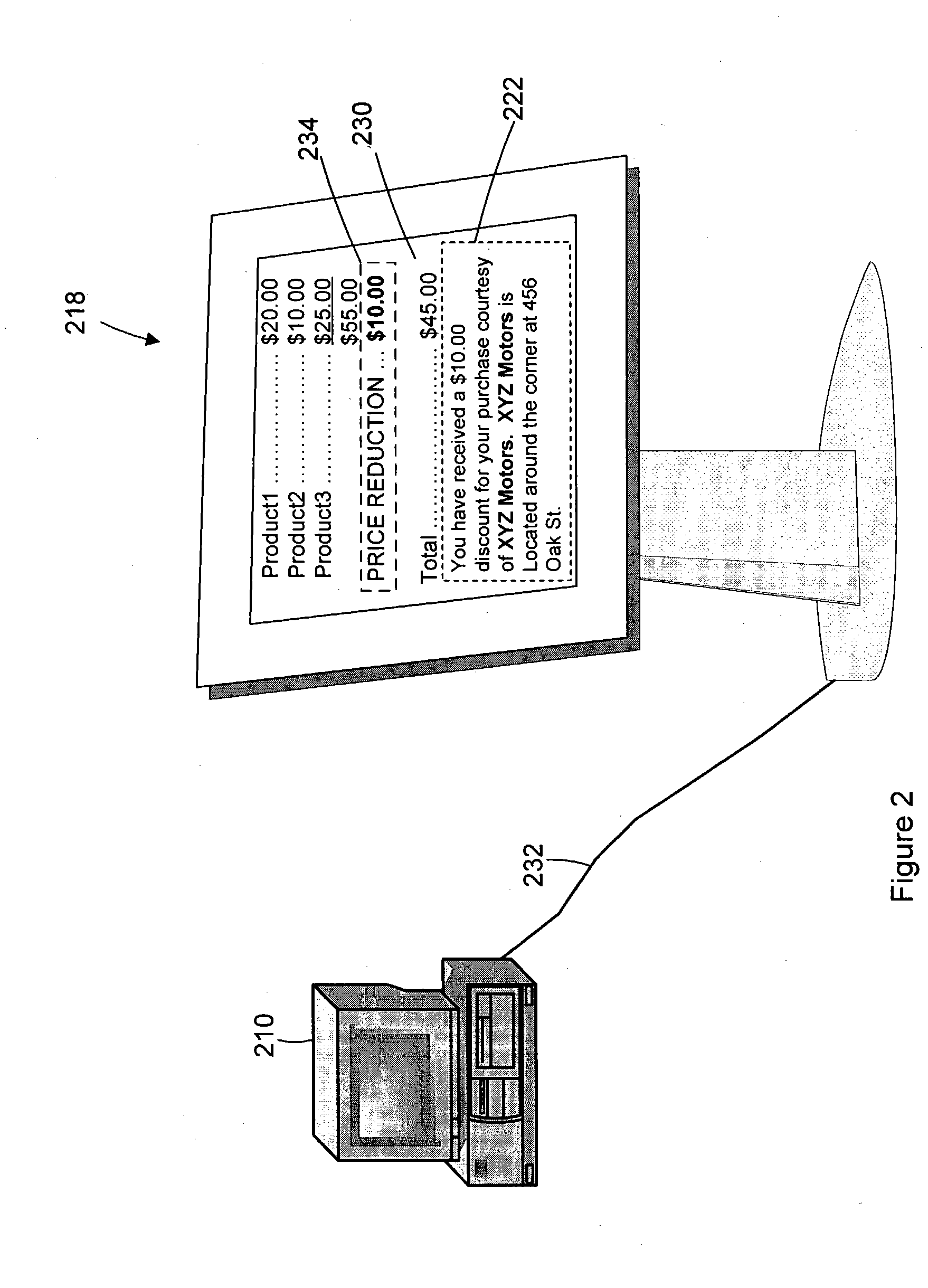

Advertising system for providing a message at point of purchase location

InactiveUS20050015299A1Surprising effectIncrease influenceAdvertisementsSpecial data processing applicationsThird partyService provision

An advertising system provides an unexpected benefit to a customer of a merchant. The benefit may take the form of an immediate price reduction for a current transaction between the customer and the merchant and is provided to the customer based on the transaction with the merchant and without customer interaction. The customer is provided a notification that the benefit is a courtesy of an advertiser. The advertiser may be a third party merchant, manufacturer, service provider, or the like. The advertiser may compensate the vendor for the amount of the price reduction or a portion thereof.

Owner:SISSERIAN VAHE

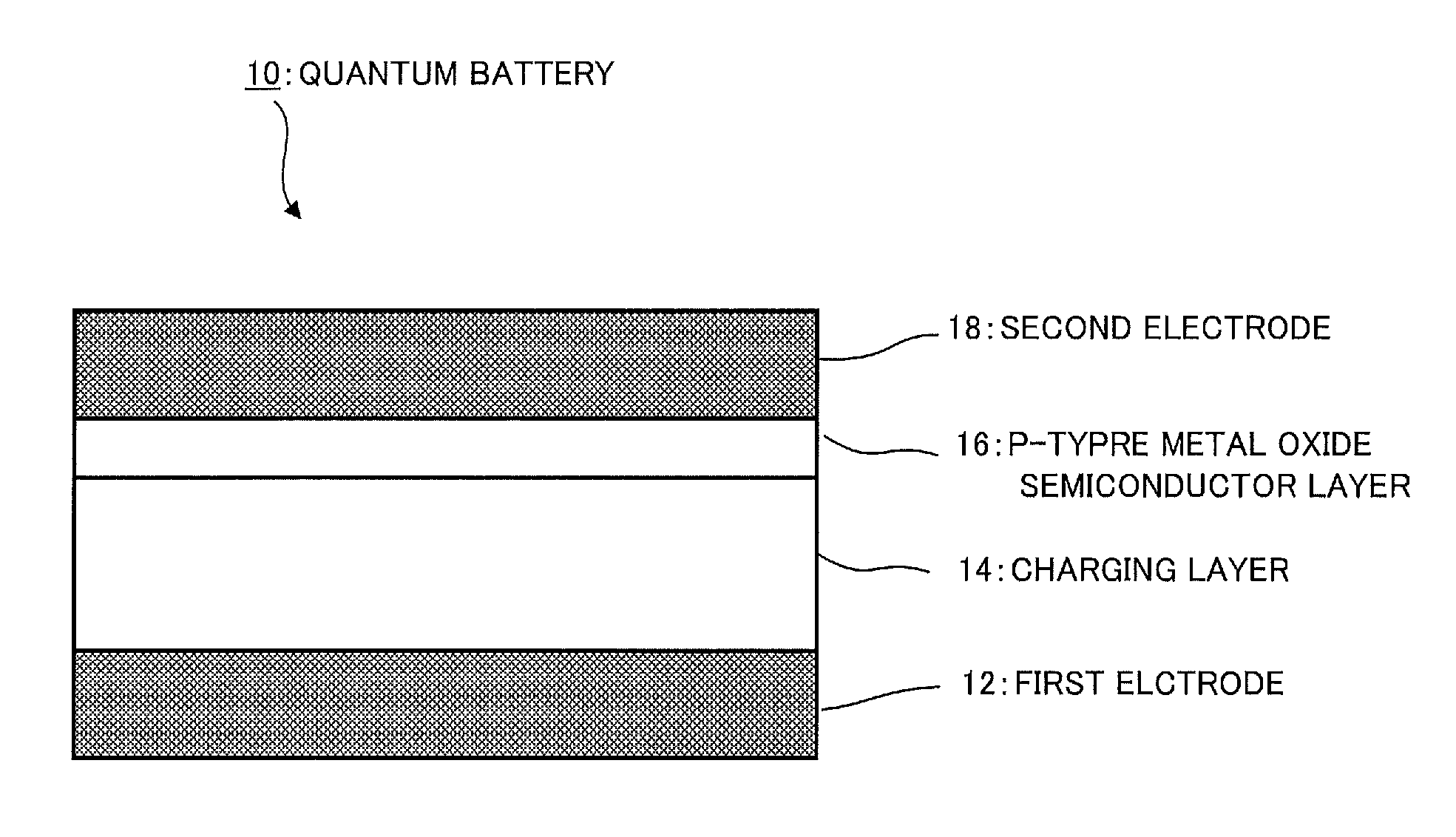

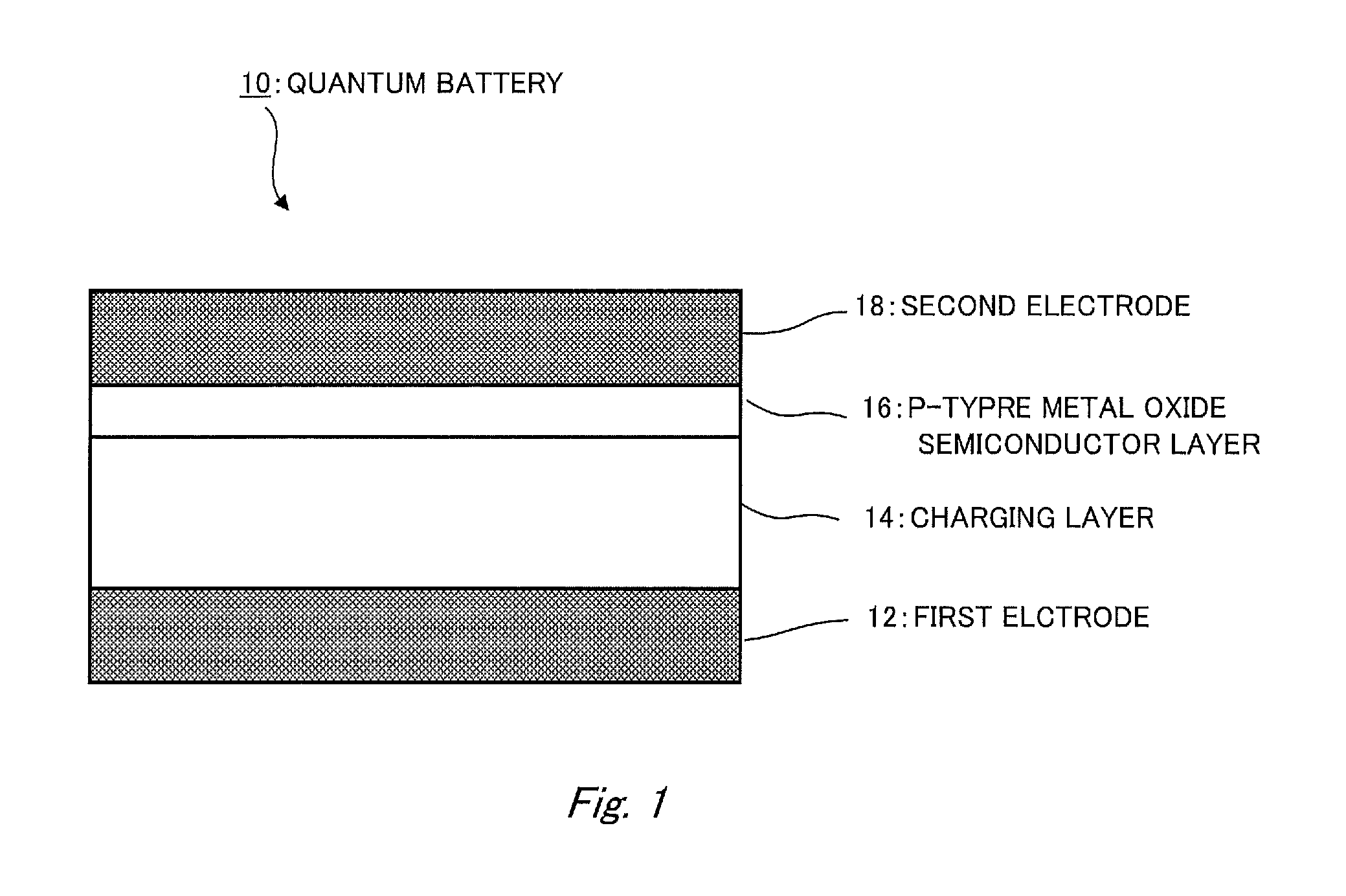

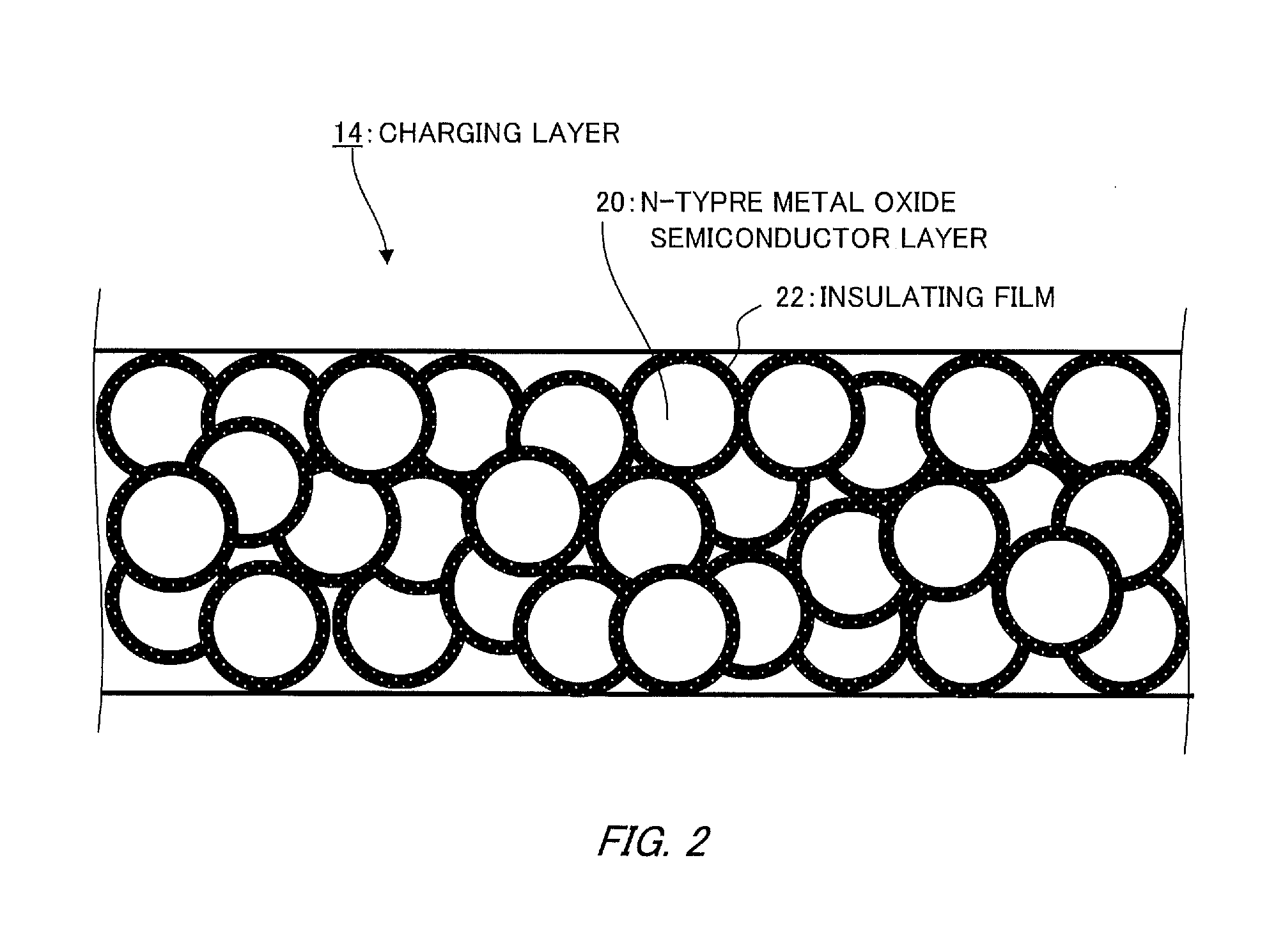

Repeatedly chargeable and dischargeable quantum battery

InactiveUS20140352775A1Avoid changePreventing deterioration and peelingBatteries circuit arrangementsSolid-state devicesCharge layerMetal electrodes

The purpose of this invention is to provide a repeatedly chargeable and dischargeable quantum battery that is available for a long period of time without an aging change. The quantum battery is charged by causing an n-type metal oxide semiconductor to have a photo-exited structural change, thereby the electrode of quantum battery is prevented from being oxide and a price reduction and stable operation are possible. The repeatedly usable quantum battery is constituted by laminating; a first metal electrode having an oxidation preventing function, charging layer in which an energy level is formed in the band gap by causing an n-type metal oxide semiconductor covered with an insulating material to have a photo-exited structure change and electrons are trapped at the energy level; p-type metal oxide semiconductor layer; and a second metal electrode having the oxidation preventing function, the electrodes are passive metal layers formed of metals having passive characteristics.

Owner:NIHON MICRONICS +1

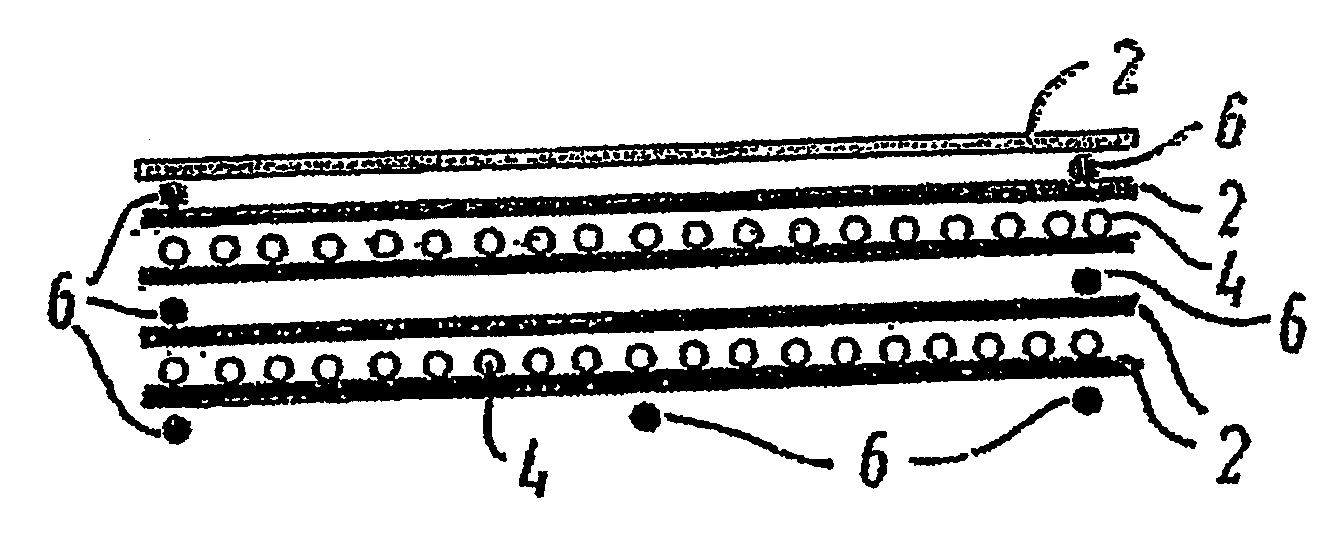

Method for preparing pre-form materials

InactiveUS20090035517A1Good reproducibilityReduce porosityLamination ancillary operationsLaminationAdhesiveTurbine blade

A pre-form and a method of preparing pre-forms are provided. The pre-forms comprise a resin and at least two layers of oriented fibre tows. The pre-forms comprise fibre tows instead of the traditional prepregs to enhance rearranging of resin and / or fibres during subsequent processing as well as provide greater freedom, a price reduction and / or a reduction of waste. The pre-forms may be formed three-dimensionally to enhance coupling to further pre-forms or other structures and / or to enhance shaping of the pre-form to a final three-dimensional shape. The method of preparation of pre-forms involves providing an adhesive between layers of fibres and providing a resin in contact with at least one of the layers of fibres. The resin is preferably provided in a non-continuous layer to allow for removal of gas at least partially in a direction orthogonal to the layers of resin. Advantageously, during manufacturing, the fibres are placed with an exact start and ending location, thereby avoiding waste. The pre-forms are suitable for preparation of composite structures like for example spars for wind turbine blades.

Owner:VESTAS WIND SYST AS

System and method for sharing incentives among groups

A system and method for sharing incentives, restricted price reductions, and stored value quantities among groups of persons, more particularly to support sharing transactions between members in a group. The system and method for sharing incentives includes receiving item information for at least one item associated with a friend, displaying the item information in a prioritized location viewable by at least one authorized friend, and receiving a request from the authorized friend to take the item, and removing from view the item information associated with the item.

Owner:SPARKBASE

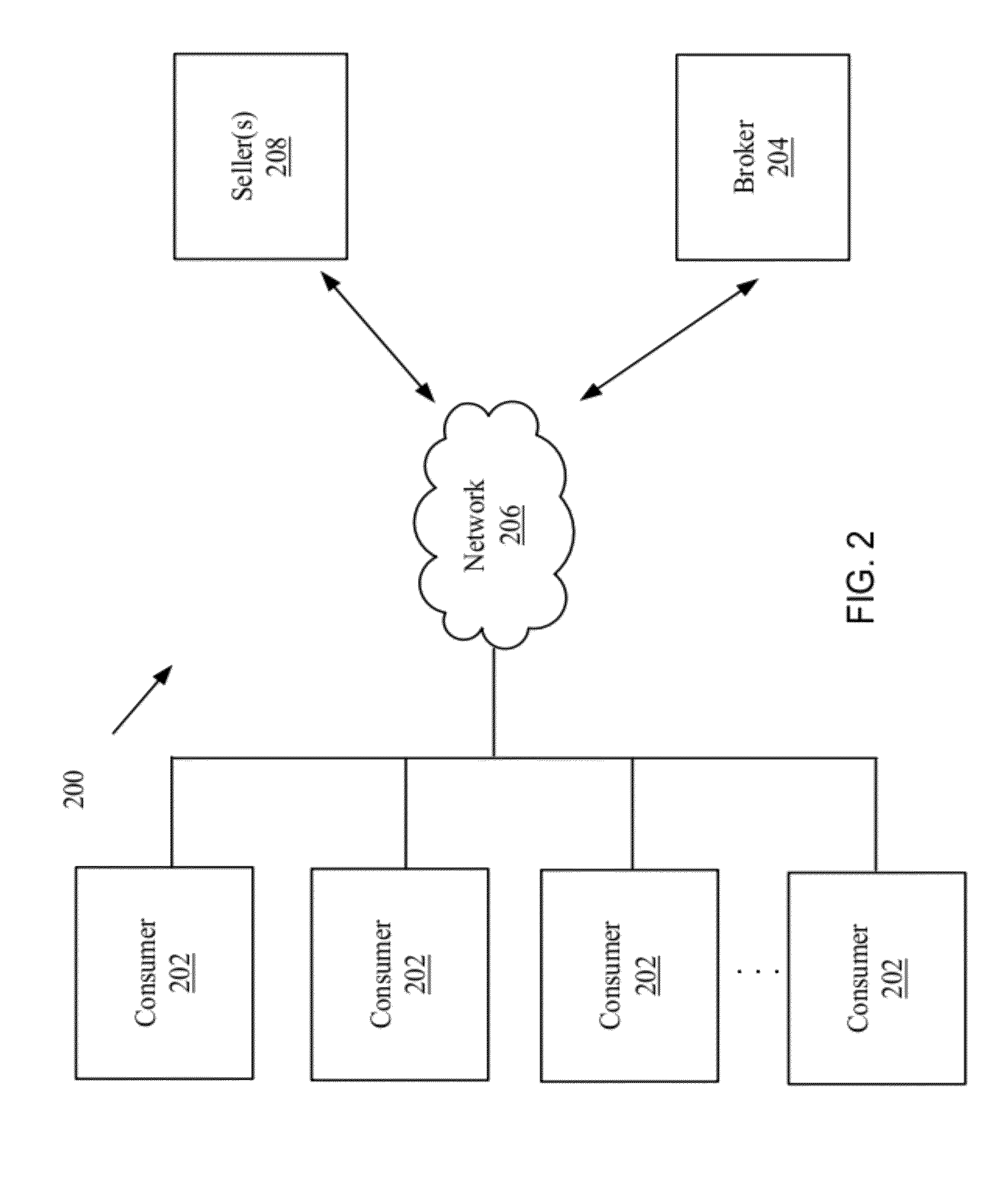

Group aggregation leveraging system

InactiveUS20120143656A1Low production costPromote aggregationDiscounts/incentivesSocial mediaEngineering

Embodiments of the invention are directed to group aggregation leveraging methods and systems for consumers to buy products from a broker. The broker offers a product to consumers for a first fixed price for a predetermined time period. Once a predetermined number of consumers commit to purchasing the product (i.e., reach a threshold), the consumers receive the same product at a second fixed price wherein the second fixed price is less than the first fixed price. Once the threshold is met, each committed consumer receives an alert from the broker that the consumer will receive the same product at the new reduced price (second fixed price). This process is repeated until the predetermined time period expires or inventory of the product is depleted. Consumers may leverage their collective group buying power by communicating to others that the product is available for the predetermined time period through social media or any other suitable means.

Owner:TRIP ALERTZ

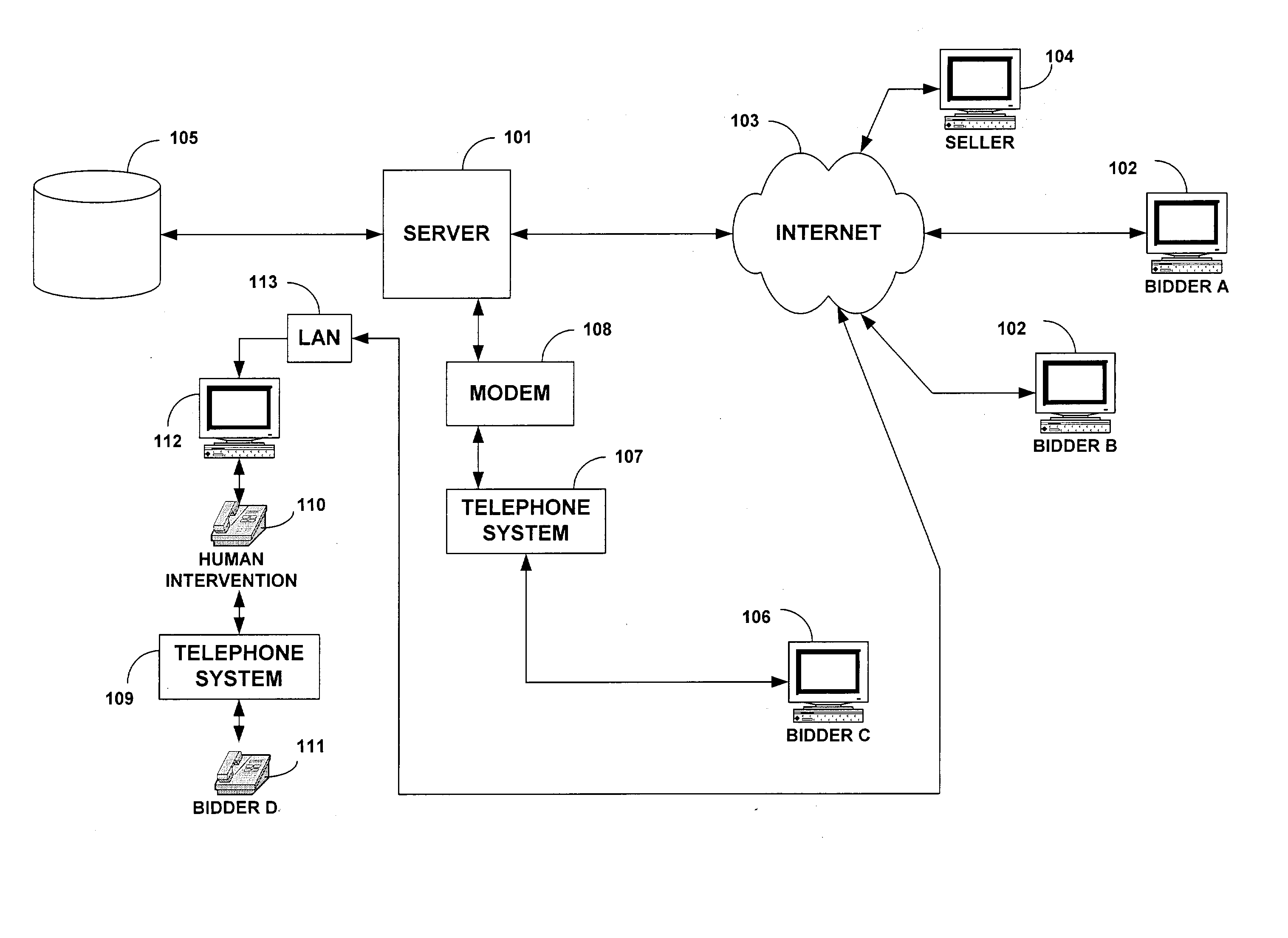

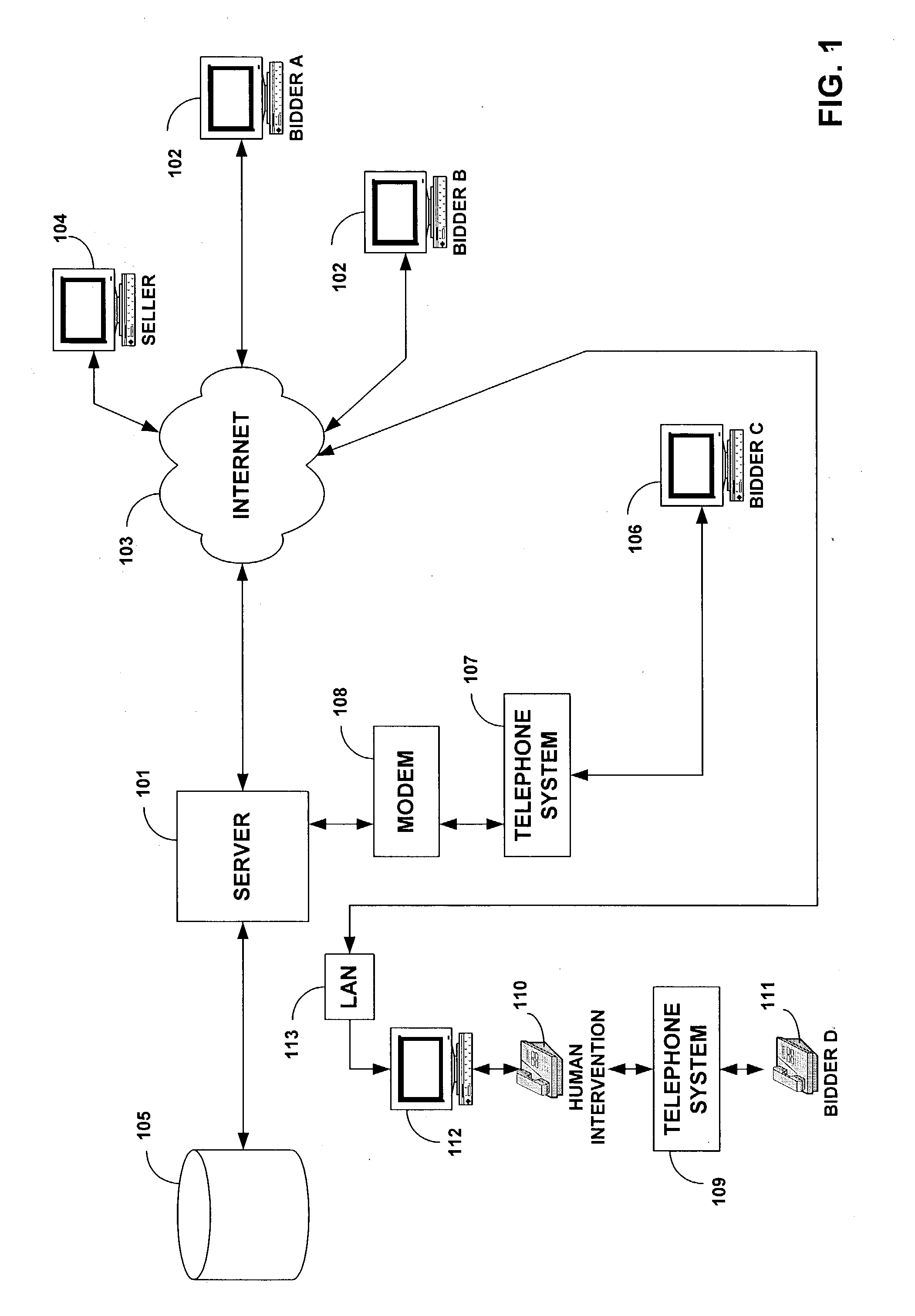

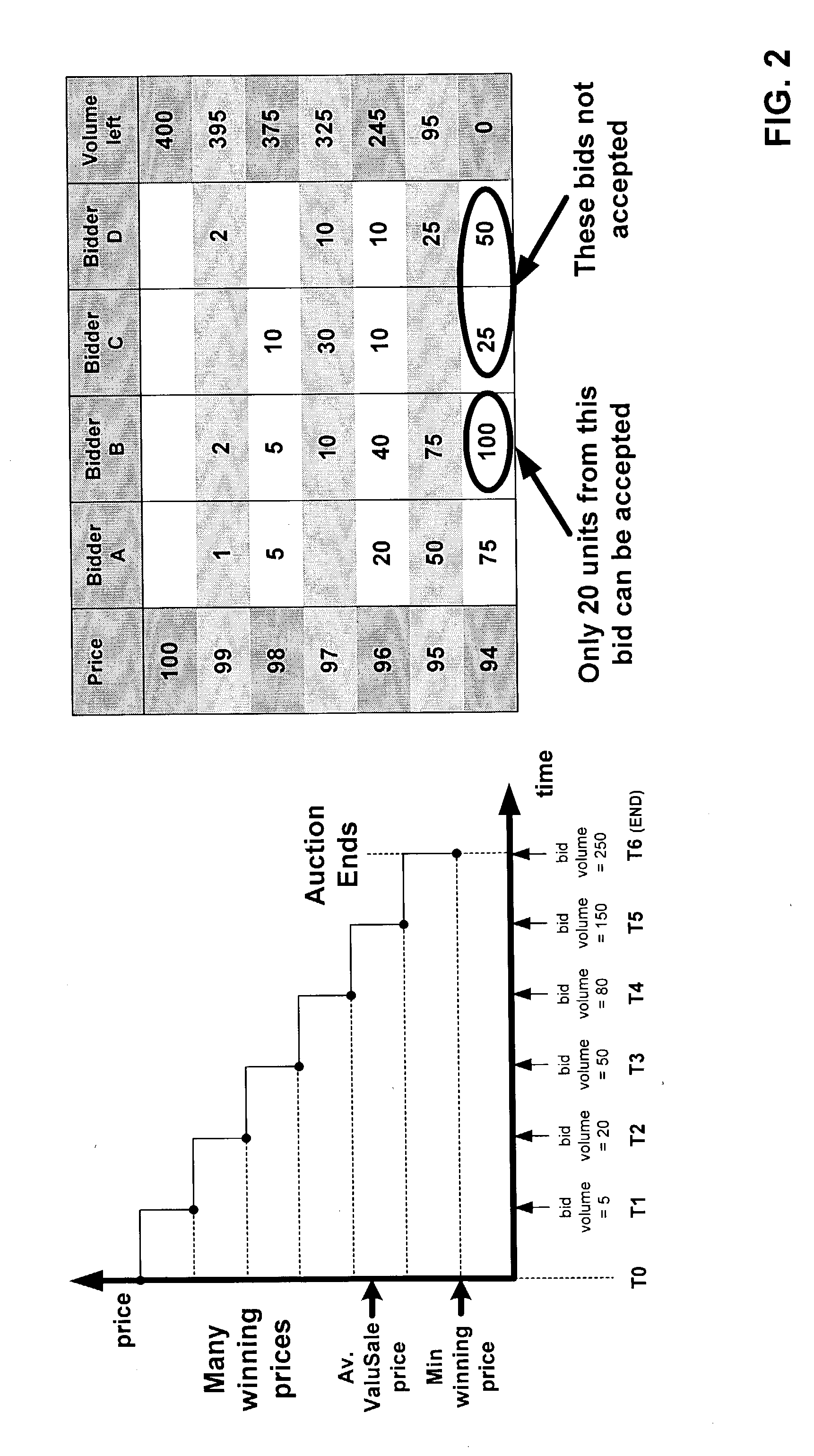

Method and apparatus for selling a plurality of units

InactiveUS20030229564A1Reduce processing stepsFinanceBuying/selling/leasing transactionsComputer scienceNumber units

Owner:TRADING PARTS LTD A BRITISH

Light diffusion sheet and backlight unit using that

ActiveCN1971316AImprove resistance to damageLow costDiffusing elementsThin material handlingOccupancy rateDiffusion

An object of the present invention is to provide a light diffusion sheet having a favorable cost reduction capability due to excellent scratching preventive property of the front face, and having in addition thereto, a favorable directional light diffusion function, transmittivity of rays of light, and a thin film character; and a backlight unit capable of promoting performances such as luminance as well as price reduction, and thin and light modeling capability. The light diffusion sheet of the present invention has a light diffusion sheet including a transparent substrate layer, and a light diffusion layer overlaid on the front face side of the substrate layer, wherein the light diffusion layer has resin beads and a resin binder, characterized in that the light diffusion layer has protruding parts having a shape of a partial spherical body on the front face in a scattering manner. It is preferred that mean height of the protruding parts be 1 mum or greater and 10 mum or less, mean diameter of the protruding parts be 4 mum or greater and 18mum or less, mean occupancy rate of the protruding parts be 2% or greater and 20% or less, and surface roughness (Ra) of the light diffusion layer be 1.5 mum or greater and 10 mum or less. As the beads, small monodisperse beads as a principal component, and large beads as a sub component may be included.

Owner:KEIWA INCORPORATED

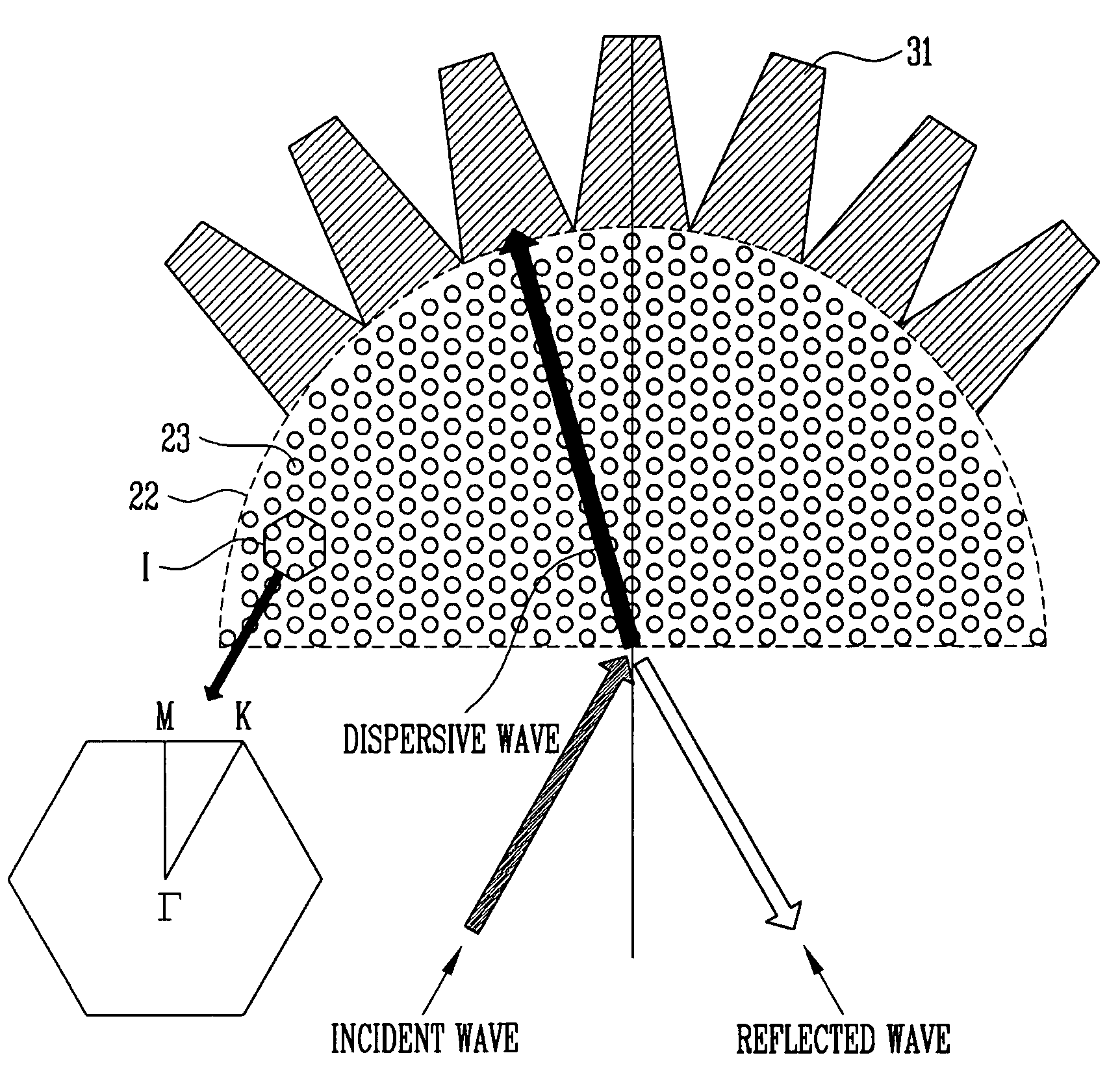

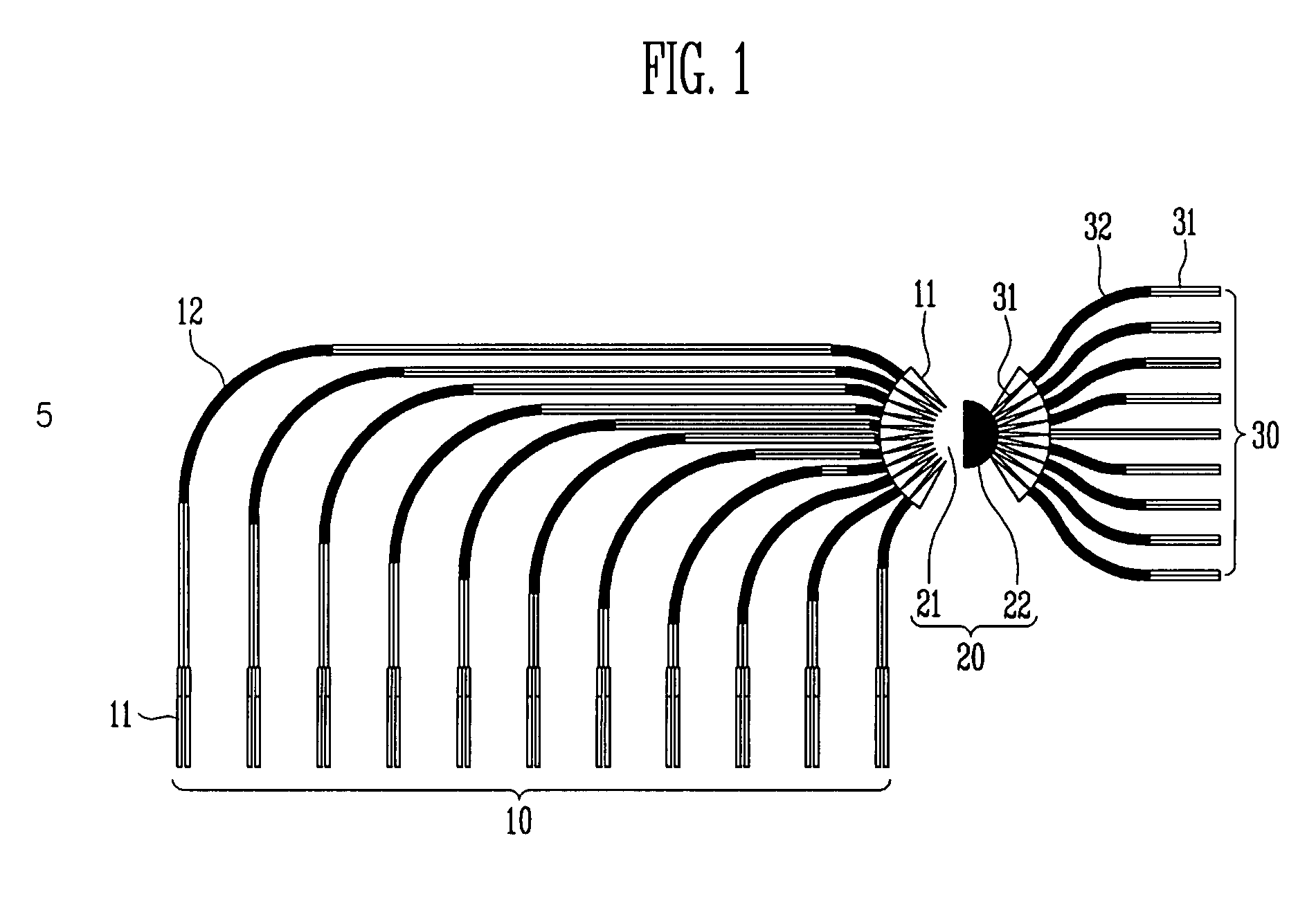

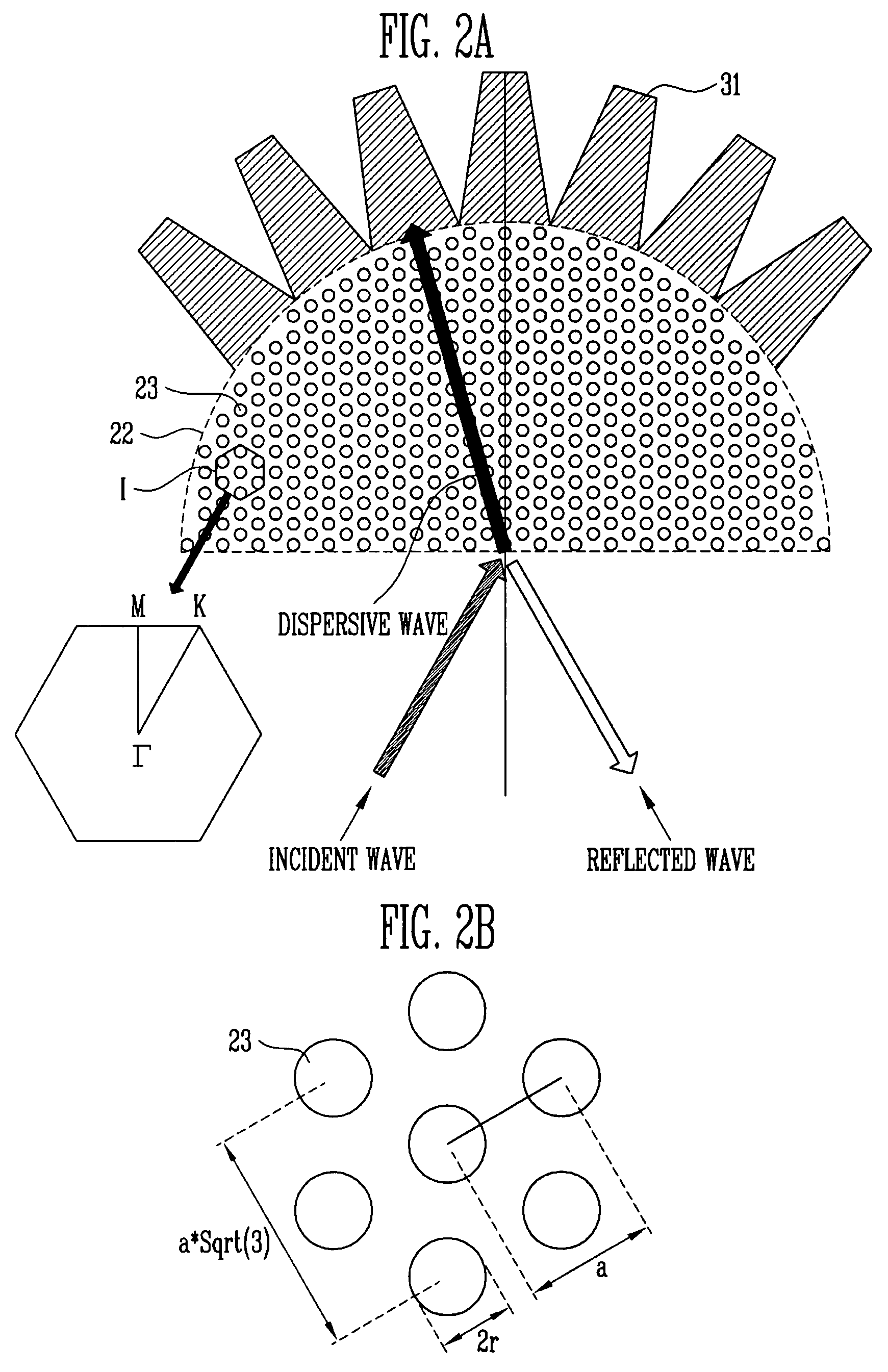

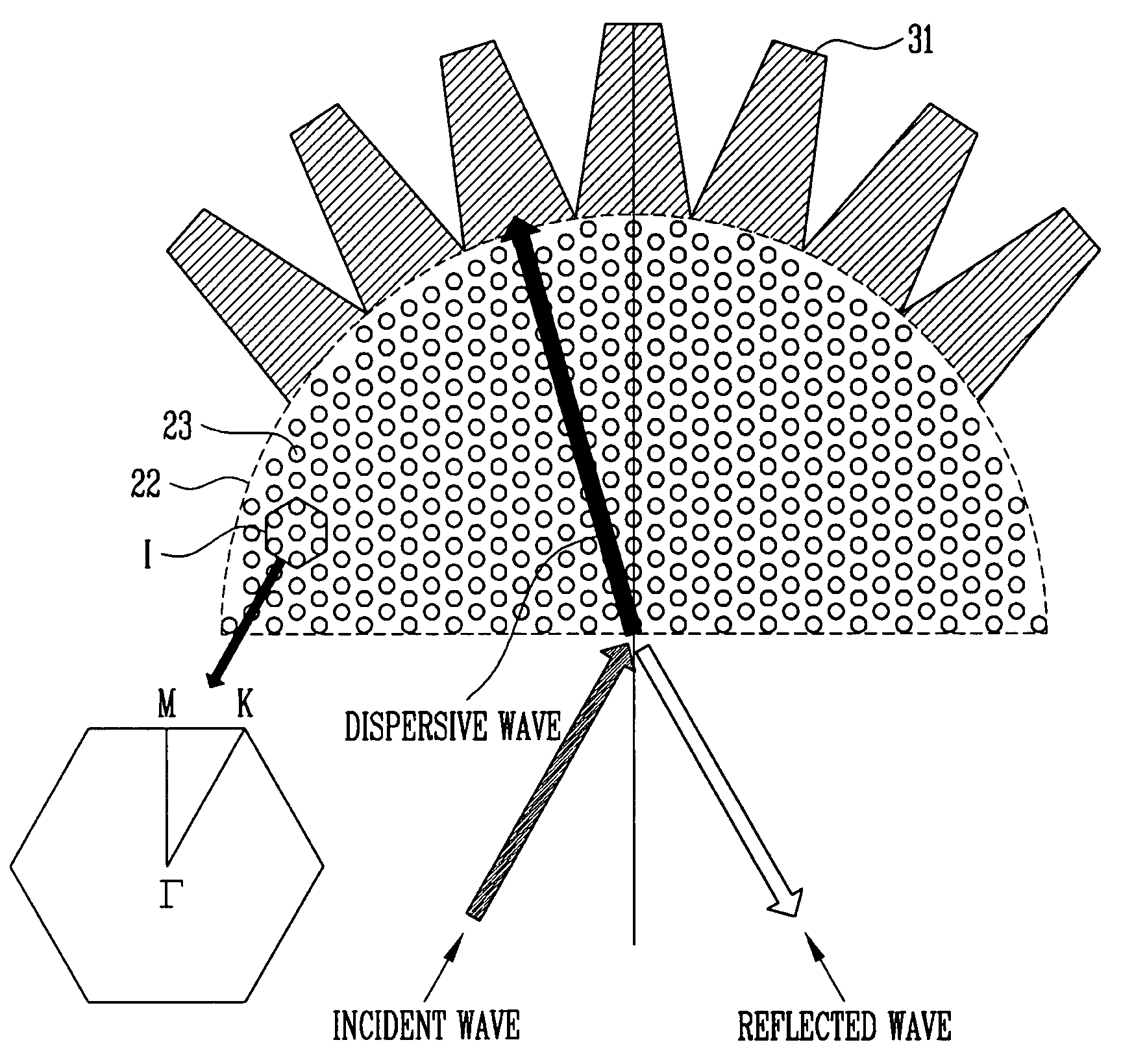

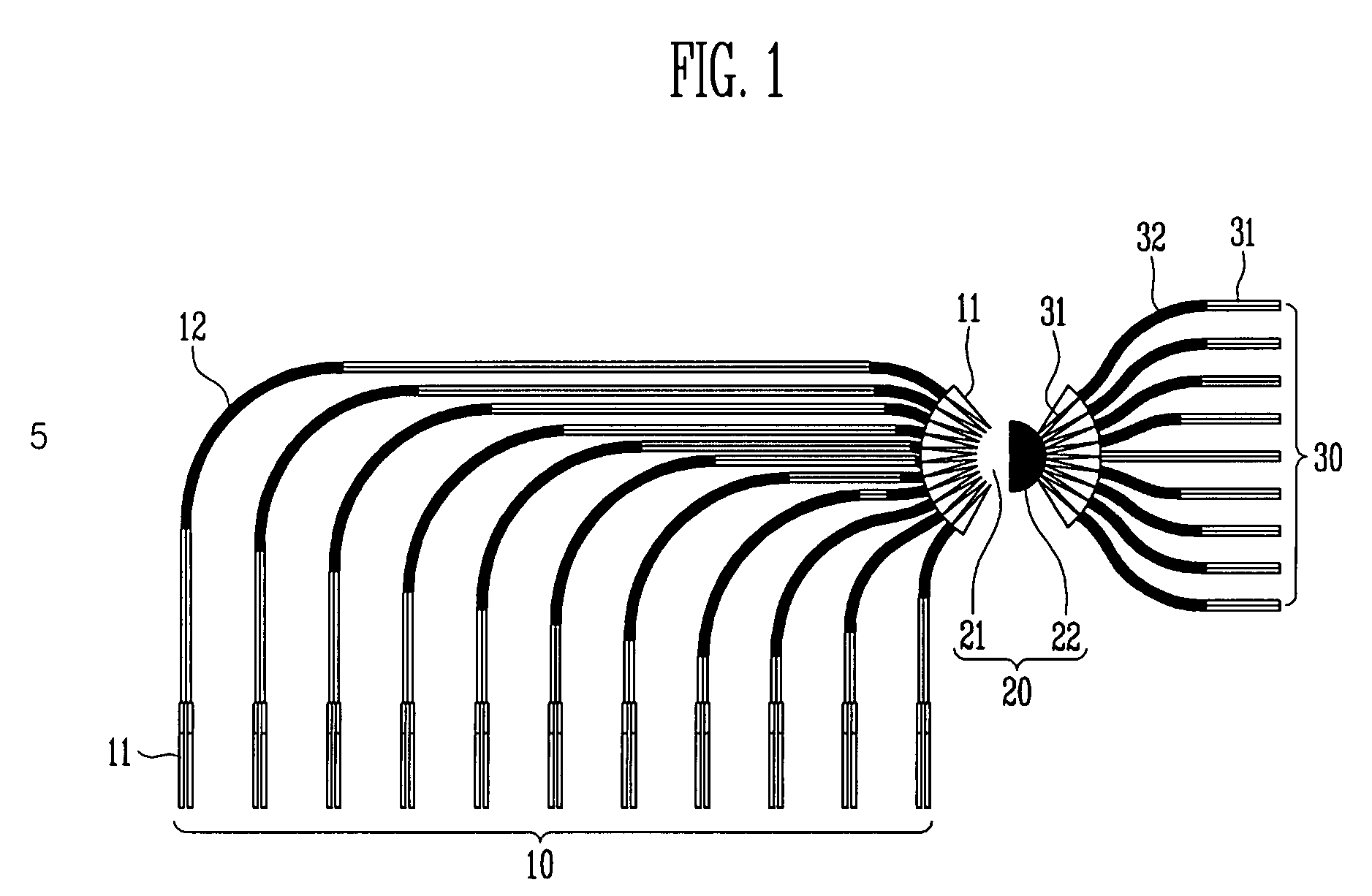

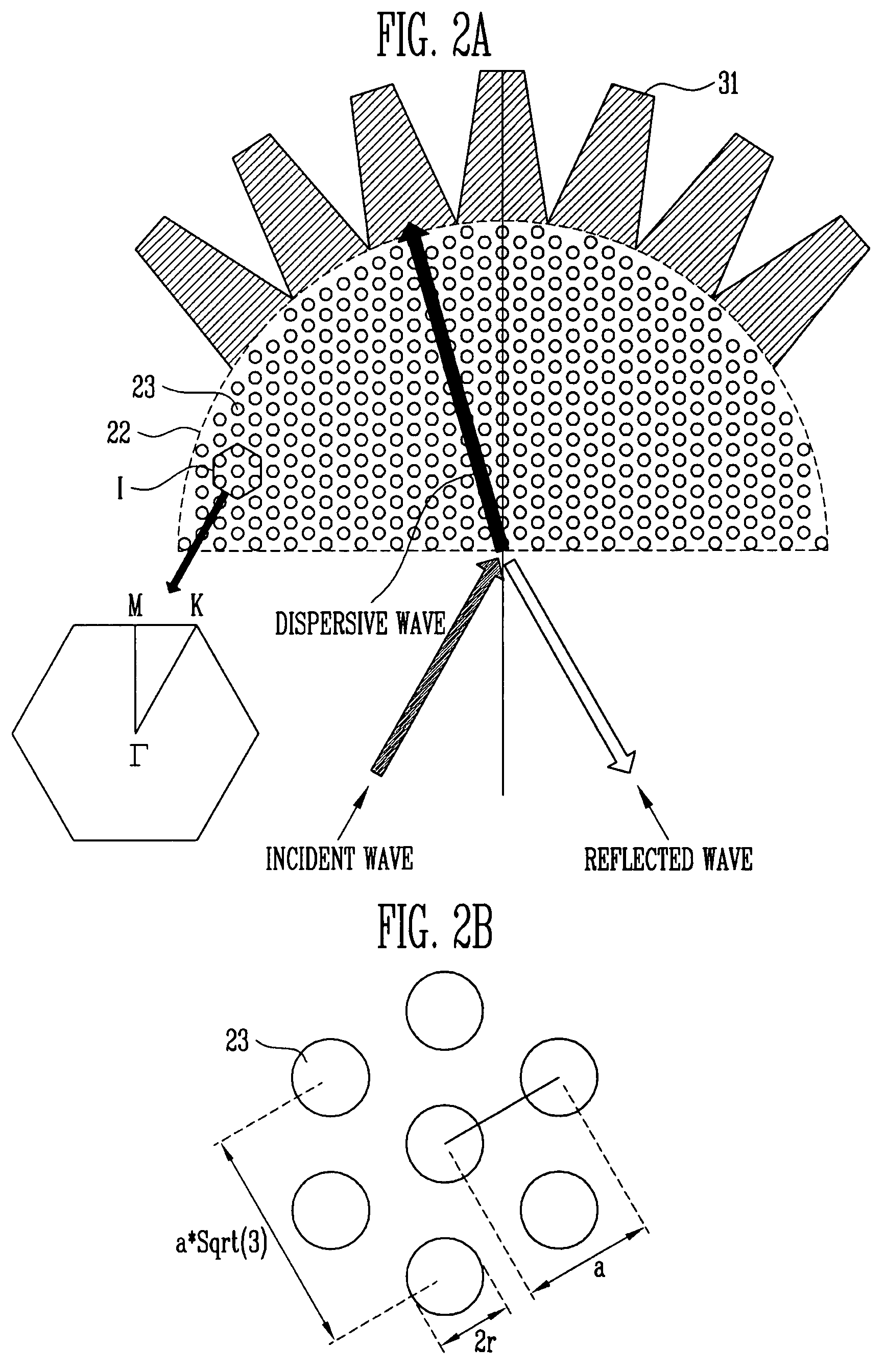

Two-dimensional Planar photonic crystal superprism device and method of manufacturing the same

InactiveUS20080112669A1Shorten the timeSimple processPrismsNanoopticsManufacturing technologyEngineering

Provided are a two-dimensional planar photonic crystal superprism device and a method of manufacturing the same, in which a manufacturing process is simplified using a nanoimprint lithography technique, and thus price-reduction and mass production are facilitated. The two-dimensional planar photonic crystal superprism device includes: a single-mode input waveguide comprising a straight waveguide having a taper structure and a bending waveguide; a superprism formed on an output end side of the single-mode input waveguide and comprising a slab and a photonic crystal superprism; and a single-mode output waveguide comprising a straight waveguide having a taper structure and a bending waveguide, and formed adjacent to the photonic crystal superprism. Using the two-dimensional planar photonic crystal superprism device, it is possible to facilitate manufacturing of nano-photonic integrated circuits, photonic crystal integrated circuits and nano-photonic systems. In addition, a wavelength-selectable photonic crystal superprism device using high dispersion of photonic crystal, which is several hundred times the dispersion of conventional glass prism, can be manufactured using thermal / hot and ultraviolet nanoimprint lithography techniques corresponding to nano-manufacturing technology.

Owner:ELECTRONICS & TELECOMM RES INST

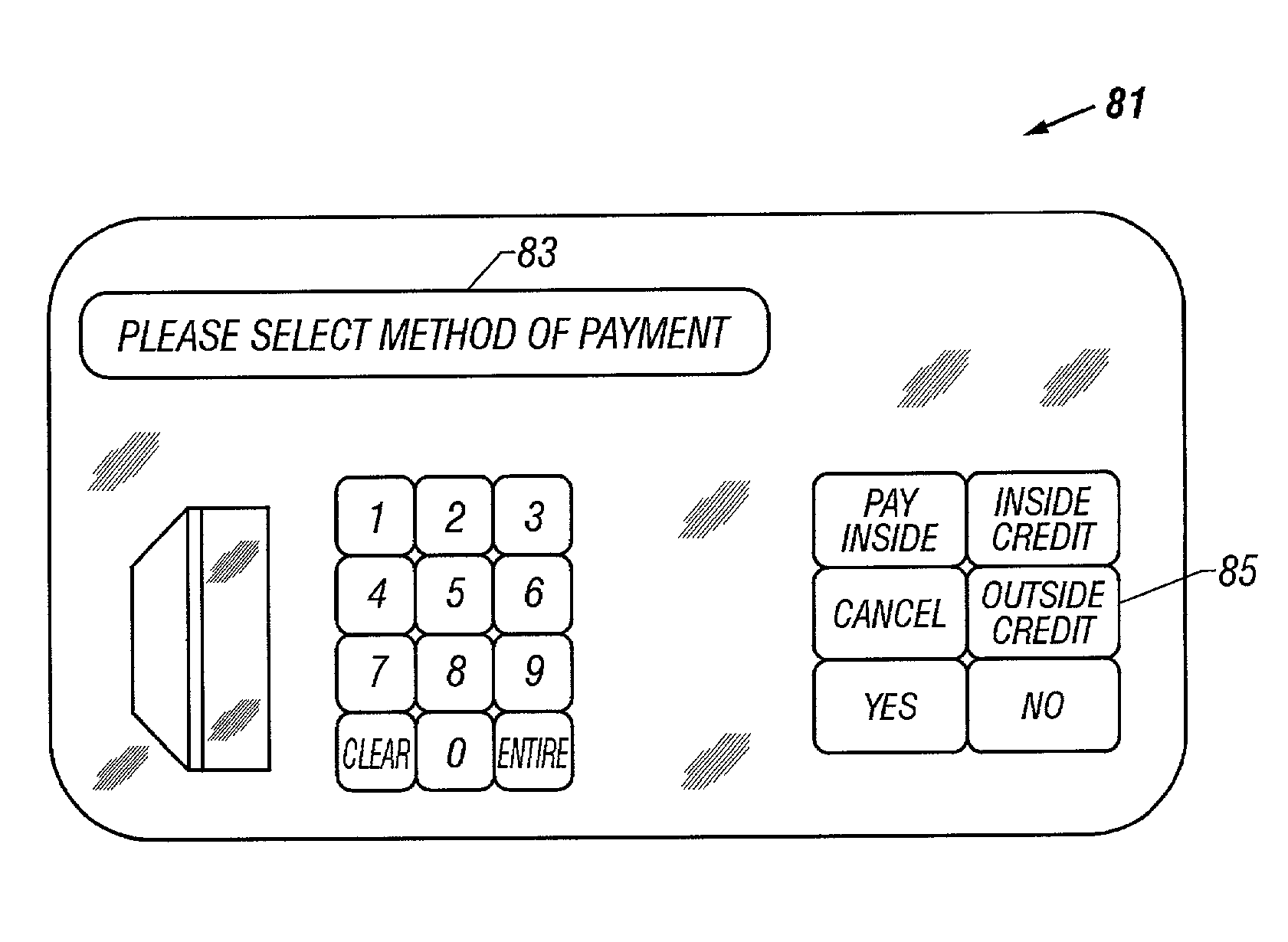

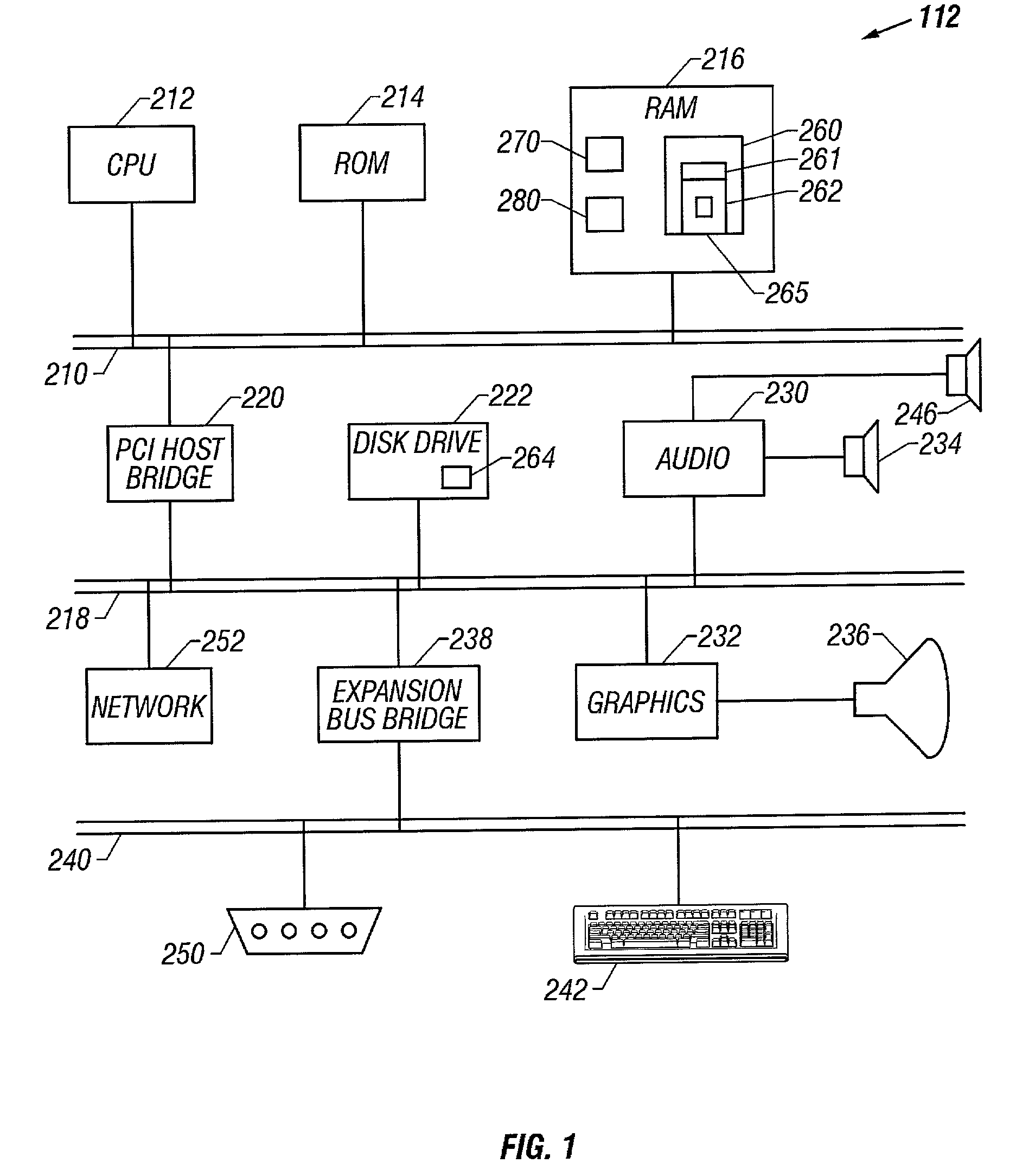

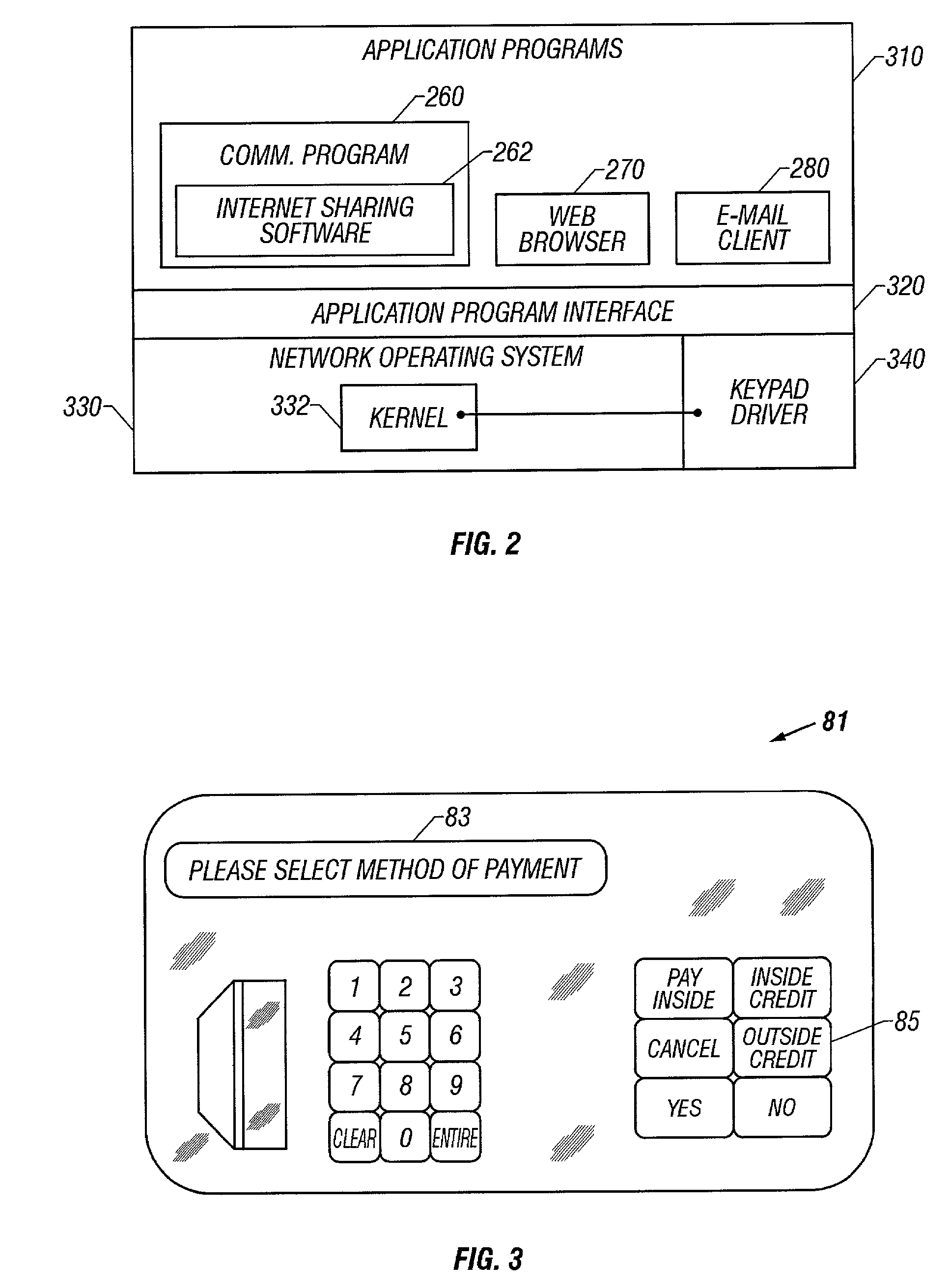

System and method for automatically adjusting merchandise pricing at a service-oriented interface terminal based upon the quantity of users present at the terminal

InactiveUS6968325B2Reduce in quantityAddress rising pricesFinanceBuying/selling/leasing transactionsCard holderPurchasing

A business method prompts users of electronic payment cards and automatically adjusts automobile fuel pricing based upon the number of passengers in a vehicle at a refueling station. When the driver stops to refuel the vehicle, the system prompts the driver to insert a payment card to pay for the fuel. If there are other passengers in the vehicle, they too are prompted to insert their cards to indicate that they are riding with the driver. The system is provided with numerous protocols for ensuring that the system is not inappropriately circumvented. For example, the system can verify that the additional cards are not from other patrons at the same service center, or that the additional cards are not from other family members of the purchasing card holder. After all cards have been read and verified, the reduced price of the fuel is displayed and the fuel is dispensed.

Owner:IBM CORP

Commodity promotion data processing method

InactiveCN103903157AMeet price reduction requirementsFlexible transactionMarketingPrice reductionData science

The invention discloses a commodity promotion data processing method at least comprising that: an intelligent device receives a command of an operator, and price request information is sent to a commodity discount strategy service system; commodity discount operation parameters are dynamically generated by the commodity discount strategy service system based on acquisition and storage purchase-sell-stock data; the commodity discount operation parameters are configured for the intelligent device by the commodity discount strategy service system; and commodity discount data are generated by the intelligent device based on the commodity discount operation parameters and the data are displayed. Based on the fact that salesmen can acquire more flexibility in adjustment of commodity price, the overall sales data can be fully utilized to meet the price reduction requirement of customers so that flexible transaction is realized and sales performance is enhanced. Besides, based on the fact that commodity operators master the overall sales situation, a network technology is fully utilized to form or adjust a price strategy timely, and sales profits and sales progress are both considered so that better operation performance is realized.

Owner:李庆成

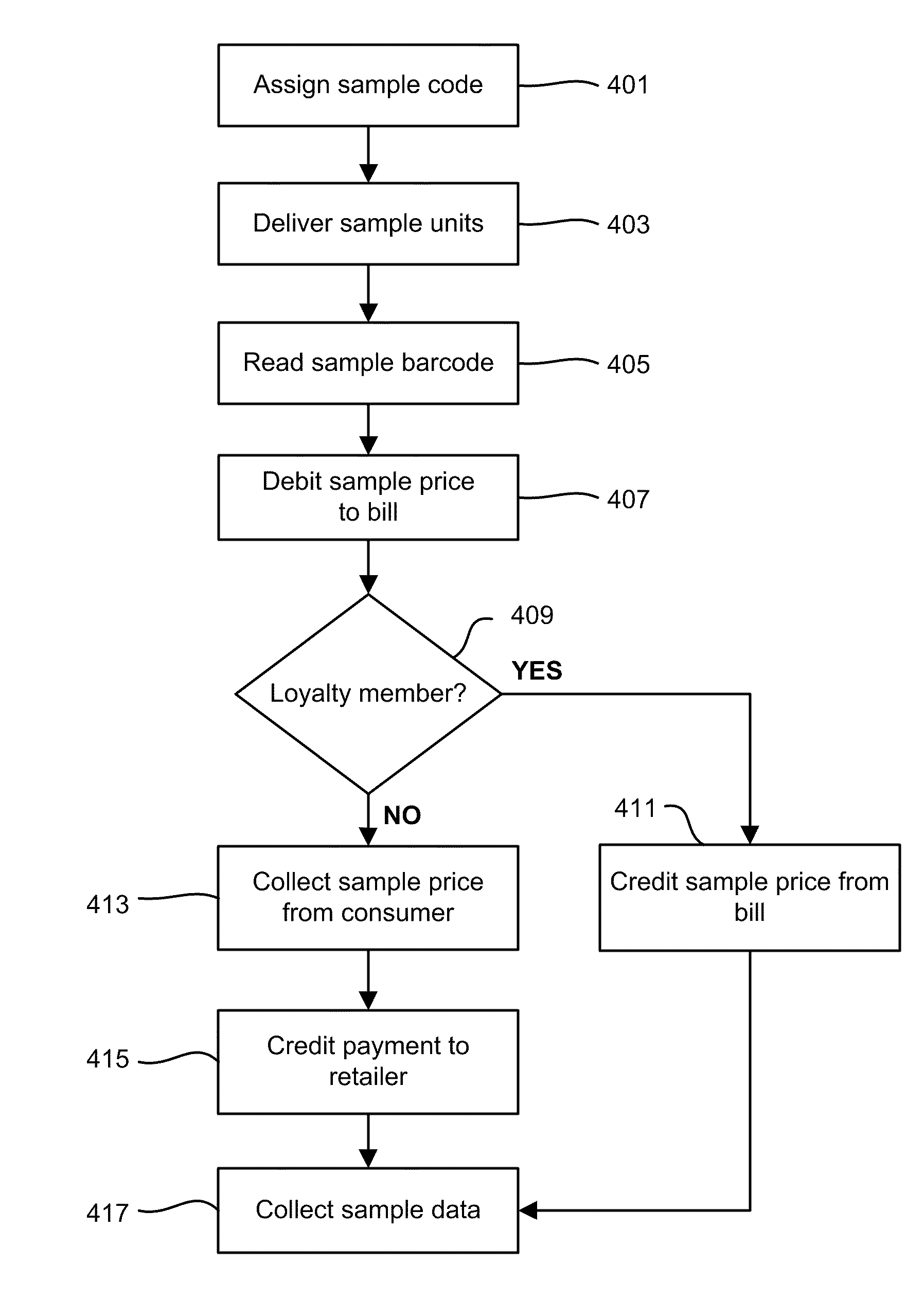

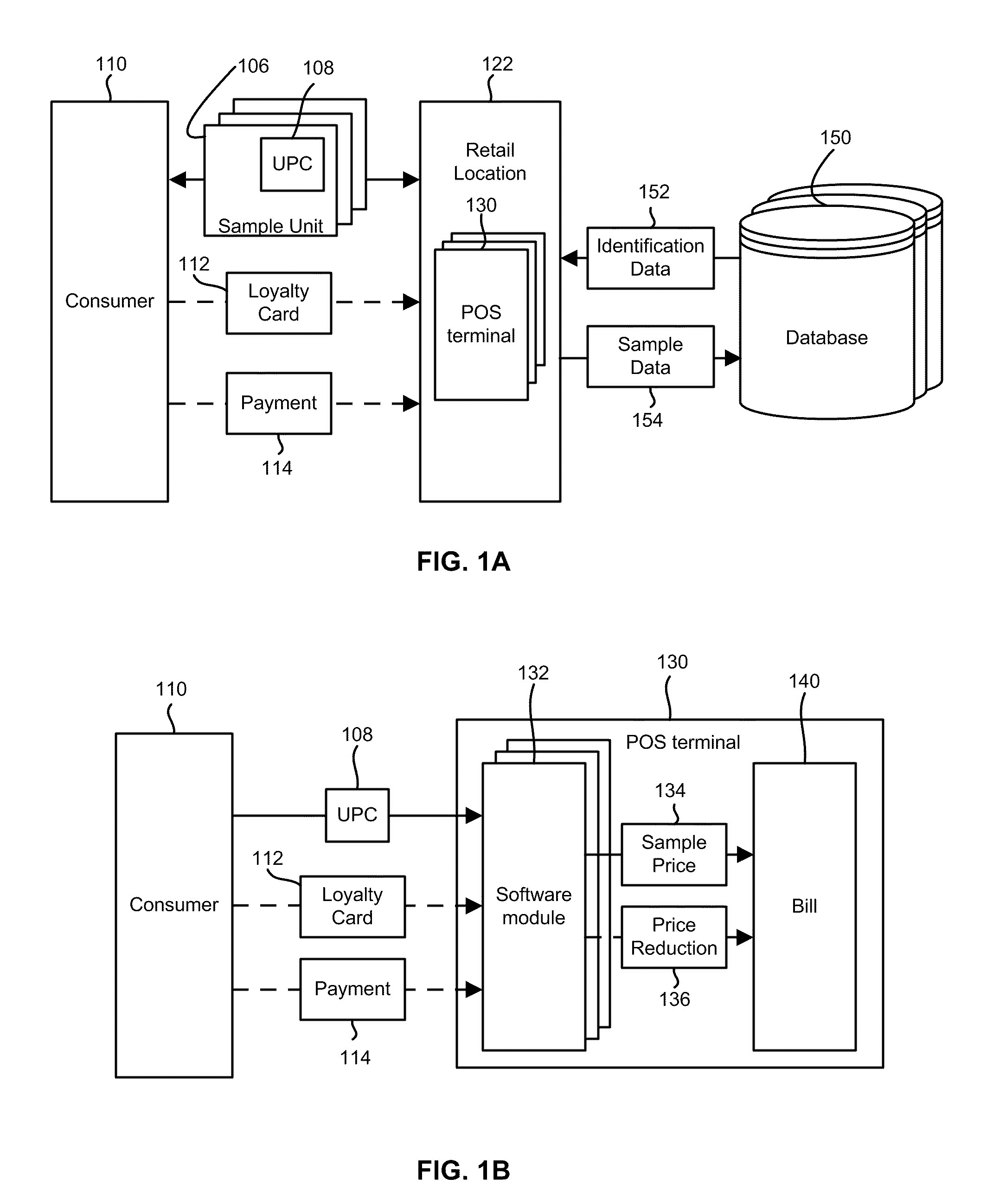

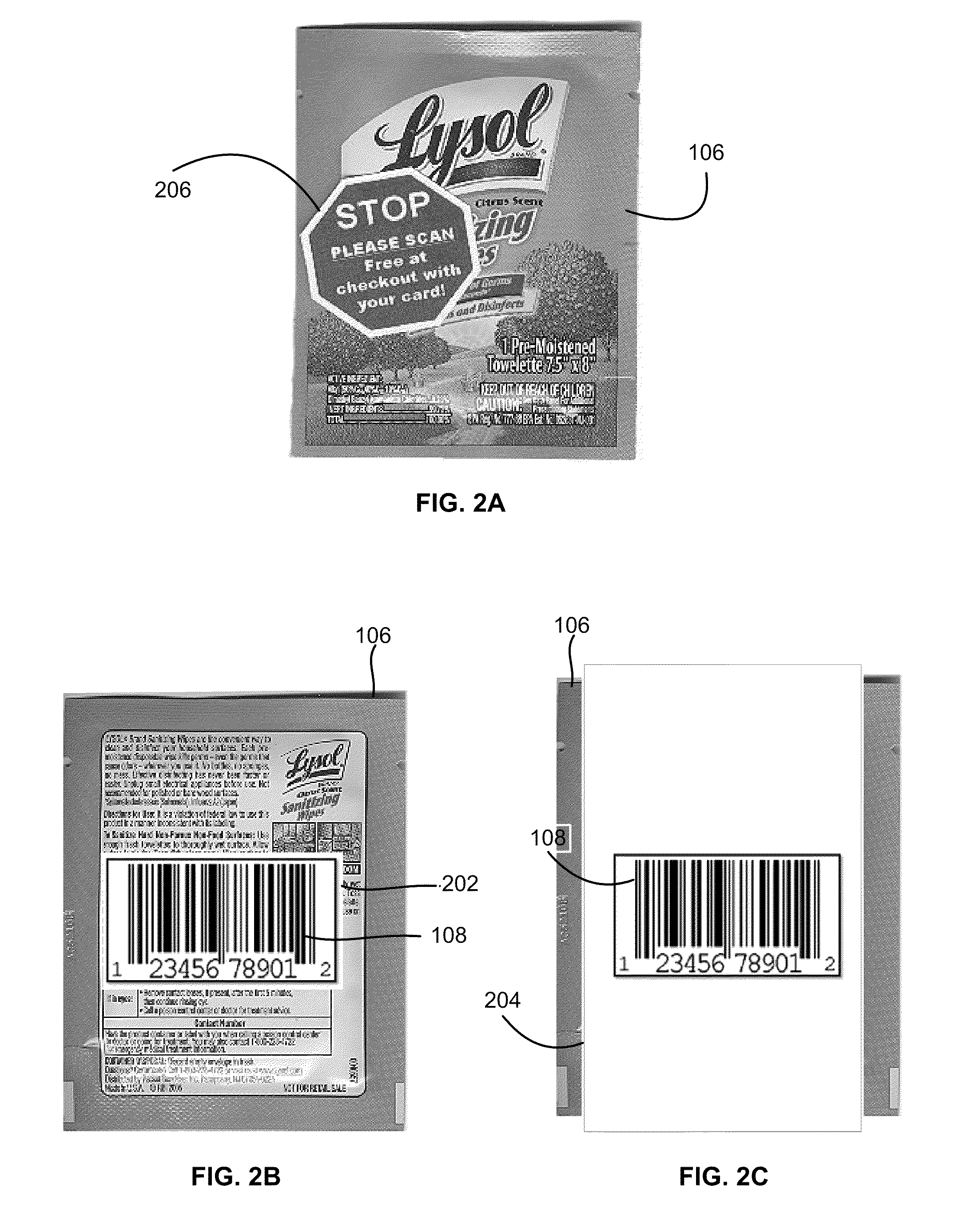

Product Sampling System And Method

InactiveUS20100257017A1Determine effectivenessComplete banking machinesShow cabinetsComputer sciencePrice reduction

A product sampling system including a sample code associated with a product sample, and a plurality of sample units provided to a retail location at no cost to the retail location, each sample unit including an indicia indicative of the sample code. The system further includes a database including identification data associated with loyalty members, software for reading the indicia from the sample units at the retail location and debiting a sample price associated with the sample units, and software for indentifying one or more consumers presenting the sample units at the retail location as being loyalty members based on the identification data. The system further includes software for crediting a price reduction equal to the sample price to each consumer identified as being a loyalty member, and for crediting the sample price to the retail location for each of the consumers not identified as being a loyalty member.

Owner:NEWS AMERICA MARKETING

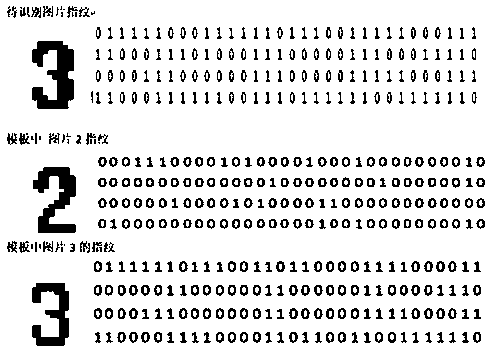

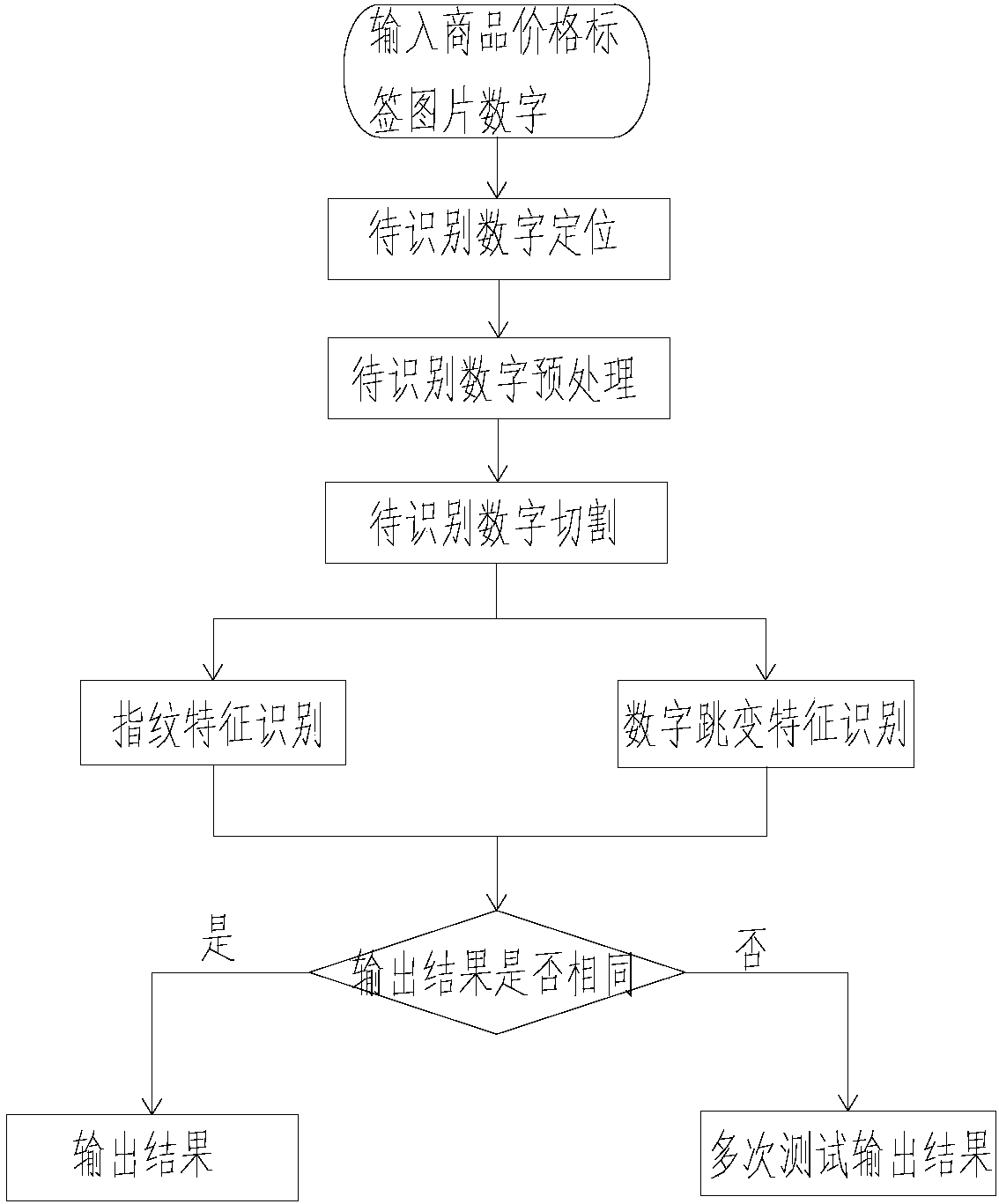

Commodity price tag number identification method

The invention discloses a commodity price tag number identification method which includes to-be-identified number positioning, to-be-identified number preprocessing, to-be-identified number cutting and pattern identification. The identification method includes the following specific steps: inputting commodity price tag image number information; to-be-identified number positioning: identifying thespecification, barcode, original price, current price and price reduction period of a commodity, and determining the position of a to-be-identified number area through template matching; to-be-identified number preprocessing: in view of uneven illumination on the price tag of the commodity, acquiring a minimum rectangle through adaptive local binarization or expansion corrosion morphological operation; to-be-identified number cutting: cutting the price tag number into single characters through a vertical projection method; and pattern identification, including fingerprint feature identification and number jump feature identification: extracting template number features, comparing the template number features with number cutting features, outputting the result if the output results are thesame, otherwise, outputting the result after multiple tests.

Owner:CHENGDU BIZ UNITED INFORMATION TECH

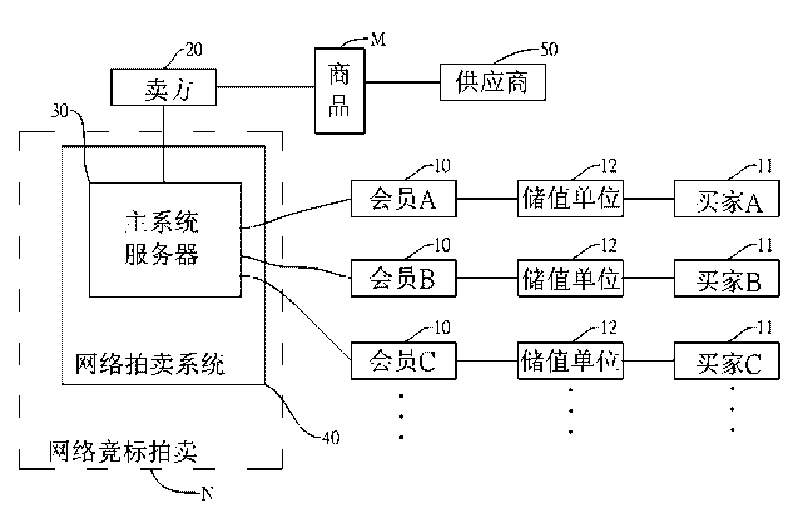

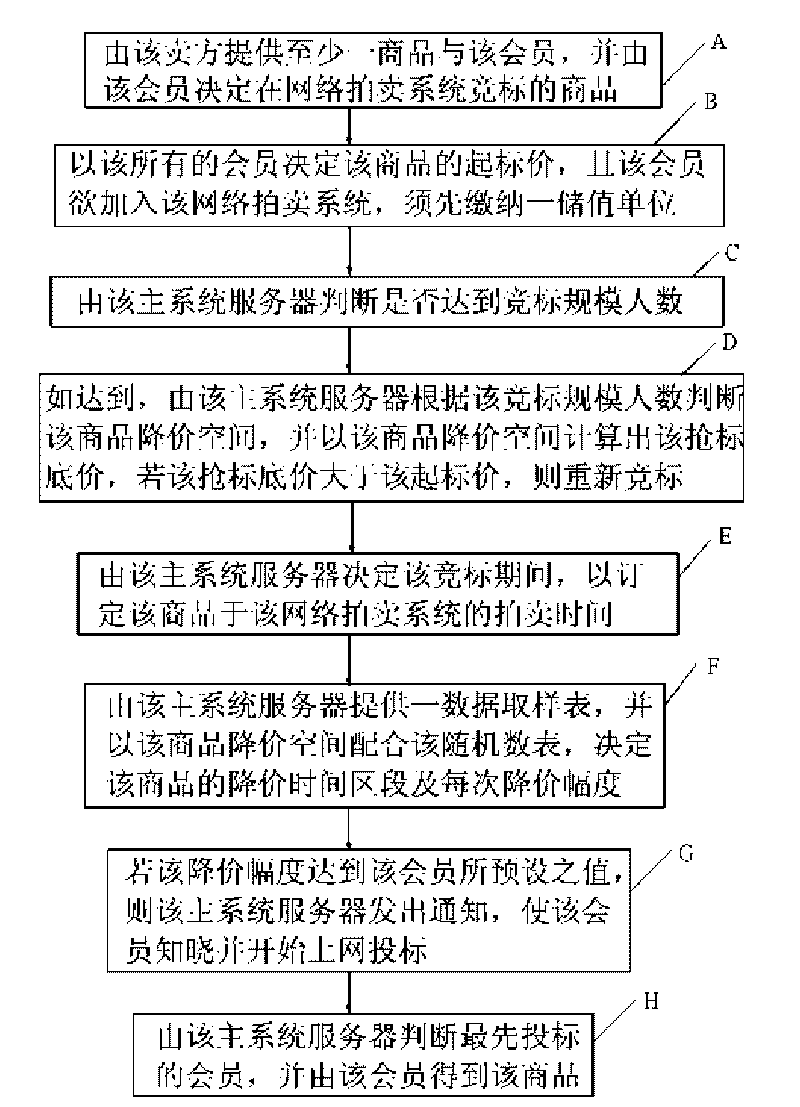

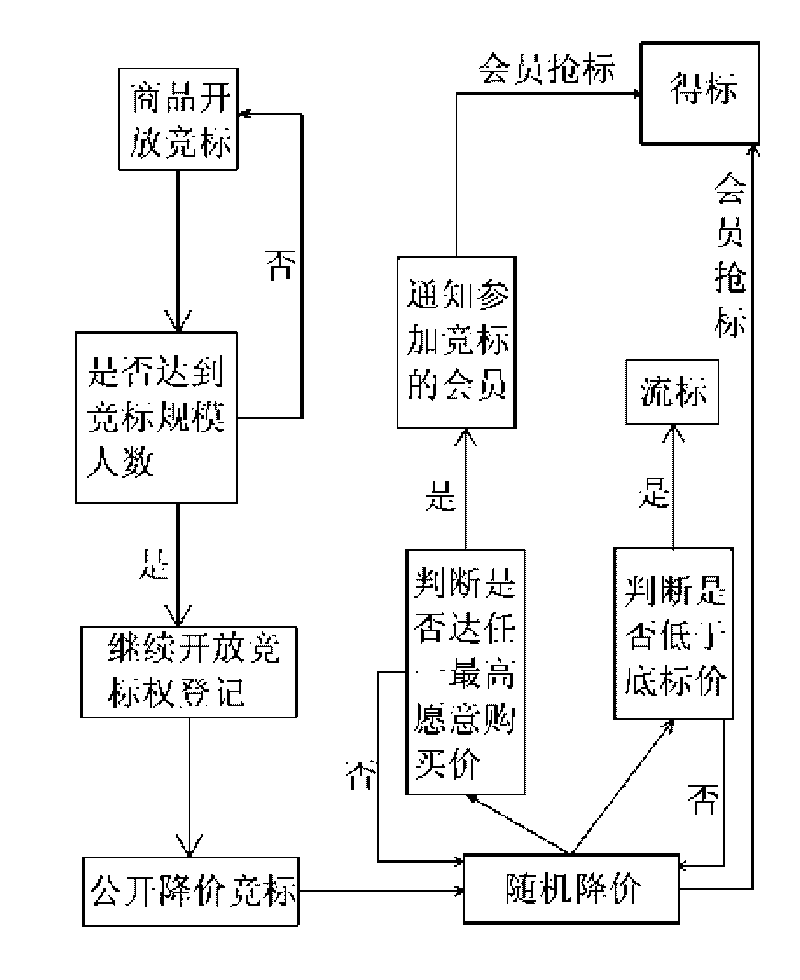

Network bidding and auction system for random price reduction

InactiveCN101751646AAchieving the purpose of price reduction auctionCommerceComputer sciencePrice reduction

The invention relates to a network bidding and auction system for random price reduction, which is characterized in that a main system server provides a data sampling table to determine a time period for price reduction and a price reducing range in one time period. The data sampling table provides a random data table or a fixed parameter table and matching data for multiplication, so that members can not predict the time period for price reduction during each bidding and auction process and the price reducing range in the time period. Moreover, the network bidding and auction system adopts the price reduction for bidding, the member is only required to bid through the network auction system, the main system server can decide the bidder (successful bidder), and the determining factors are that the bidding price of the member is closest to the price of the commodity after price reduction during the bidding period provided by the main system server, and only the member bidding earliest can win the bid. In the traditional auction system, since the bidding price is calculated based on a fixed formula, the successful bidder is decided according to the element the luck dominates, and the fairness of the auction is influenced.

Owner:曾亦青

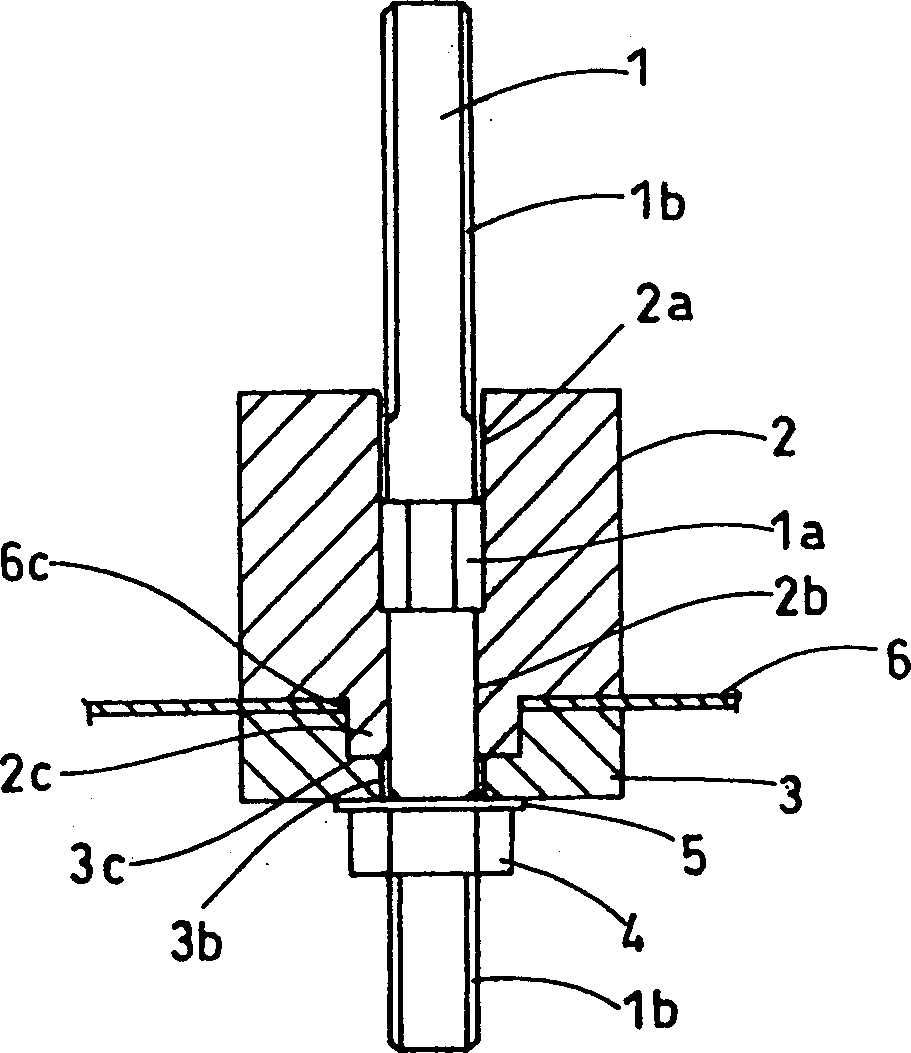

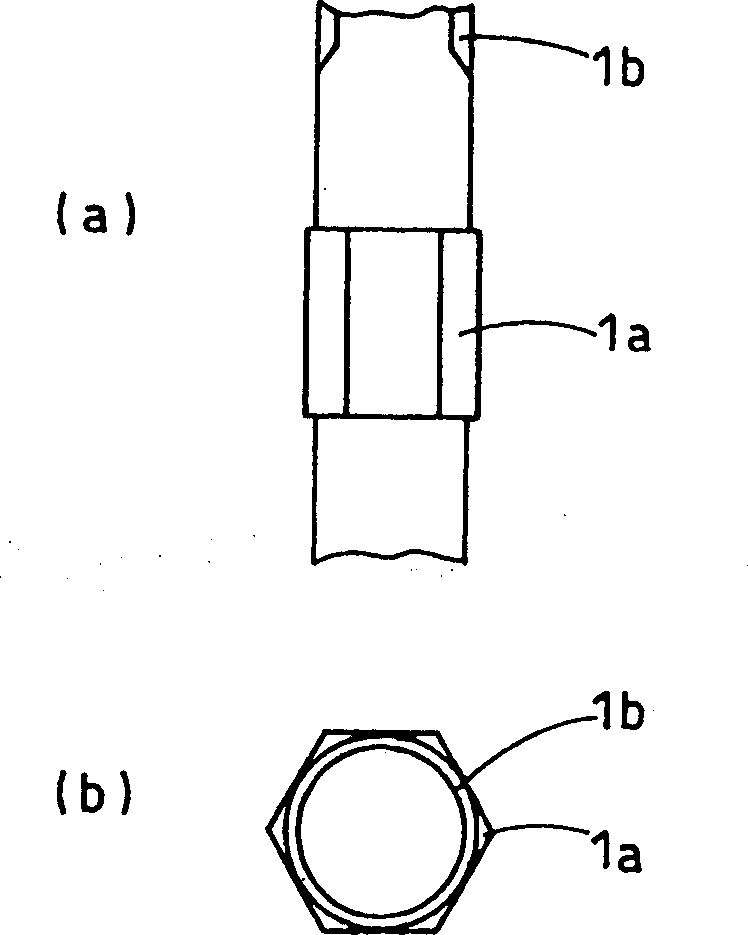

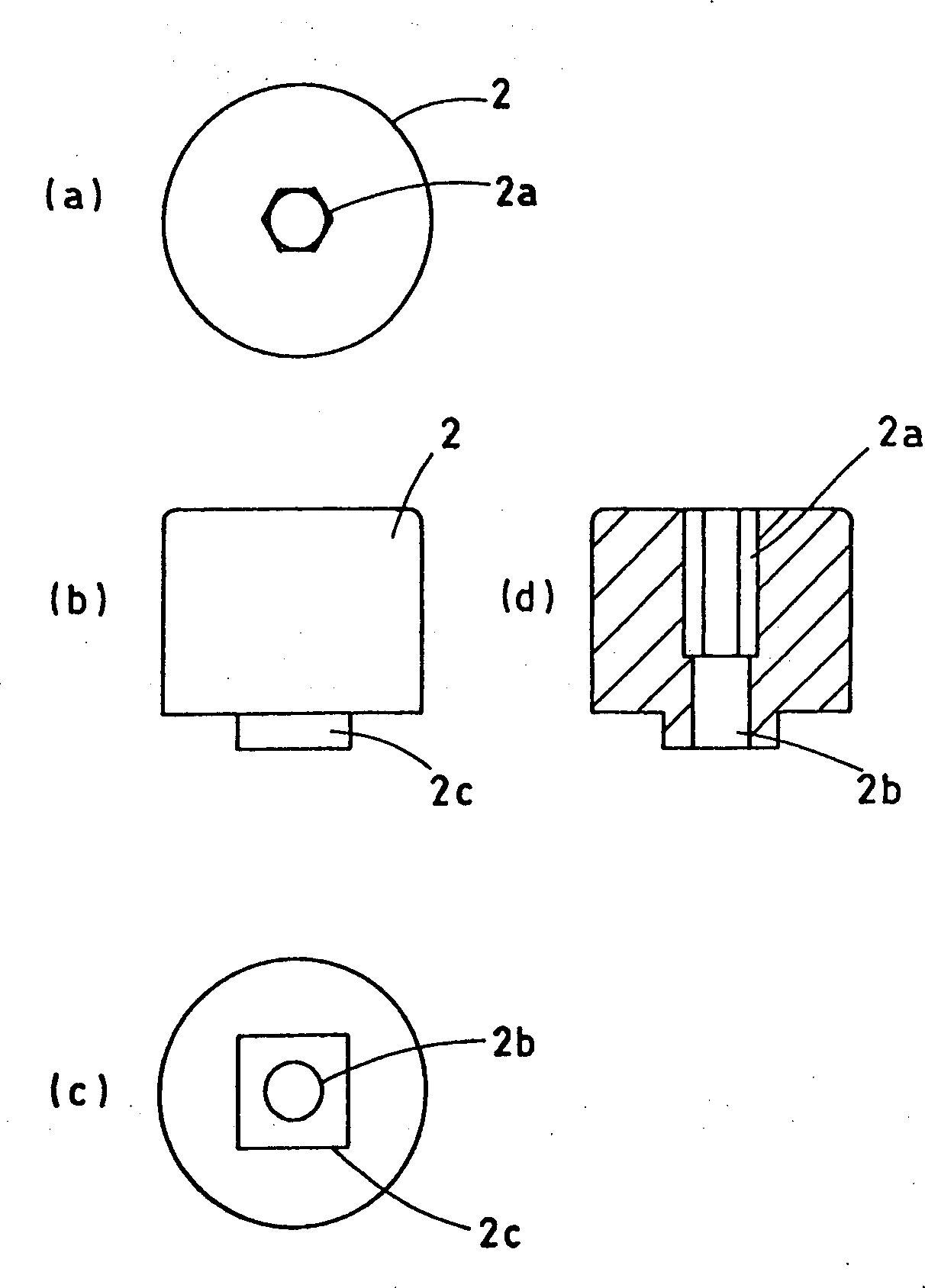

Terminal equipment of electric appliance

InactiveCN1360321APrevent rotationAvoid damageElectrically conductive connectionsFixed capacitor housing/encapsulationTerminal equipmentConvex side

The present invention relates to a terminal device for an electronic apparatus, which includes an external lead out rod having a convex side part on the center; an insulation terminal seat consists of an outer insulation terminal seat and an inner insulation terminal seat, wherein one has a concave part and the other has a convex part and the two parts forms a concavo-convex part, and a counter boring for preventing the external lead out rod from rotating is formed on the outer insulation terminal seat; a casing of a through hole that the convex part of the insulation terminal seat goes into the outer terminal seat to prevent rotating; a fixing mechanism for fixing the external lead out rod on the casing through said insulation terminal seat; a concavo-convex part sets an inner terminal seat and an outer terminal seat in and out of the through hole of the casing. The terminal device is satisfactory in rotation preventing function to the rotational torque at a terminal part and is satisfactory in setup work by preventing deterioration of the functions of the terminal part, caused by human error and by making it into a structurally simple constitution, and is high in operability, and is capable of price reduction, too.

Owner:PANASONIC CORP

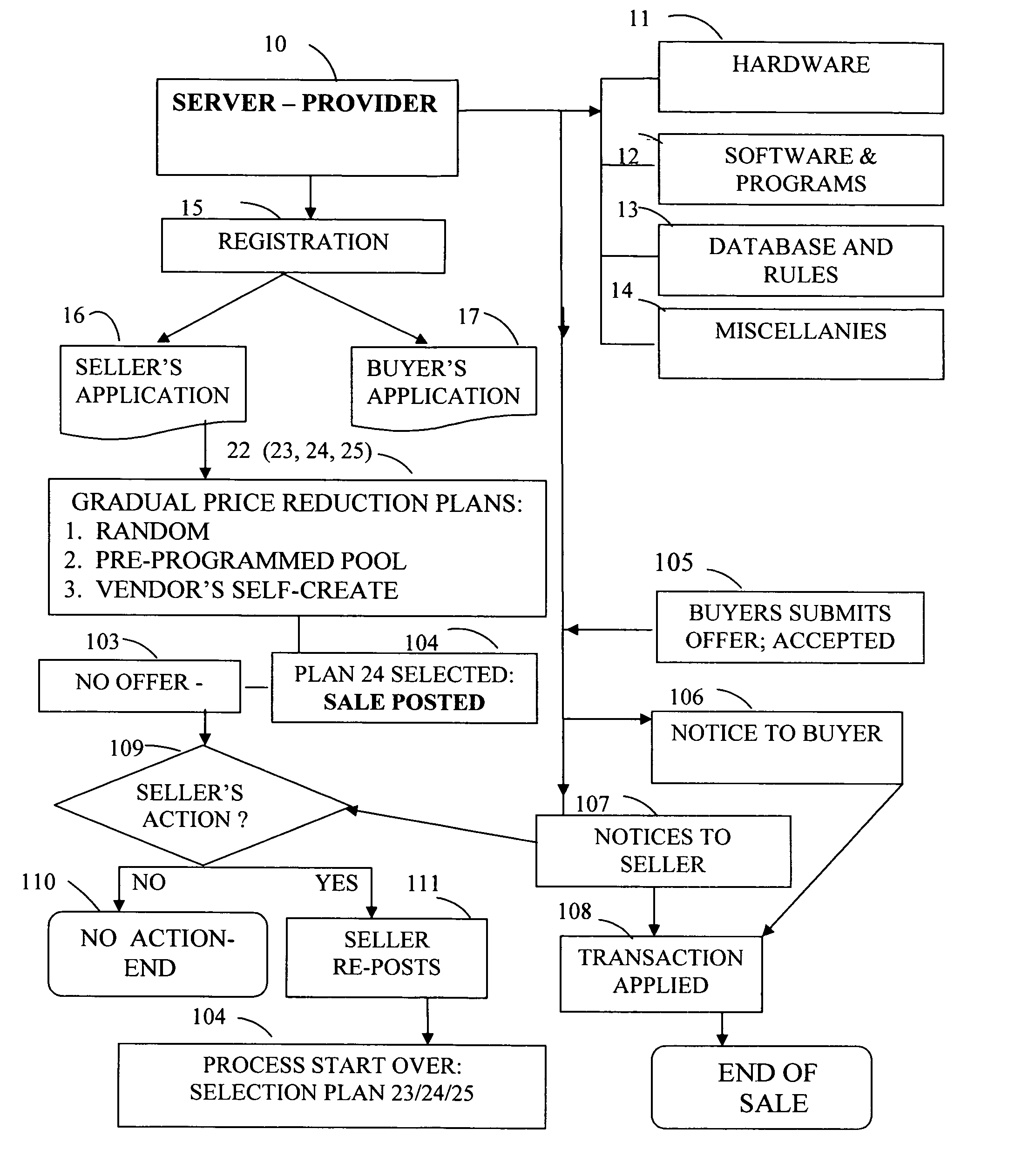

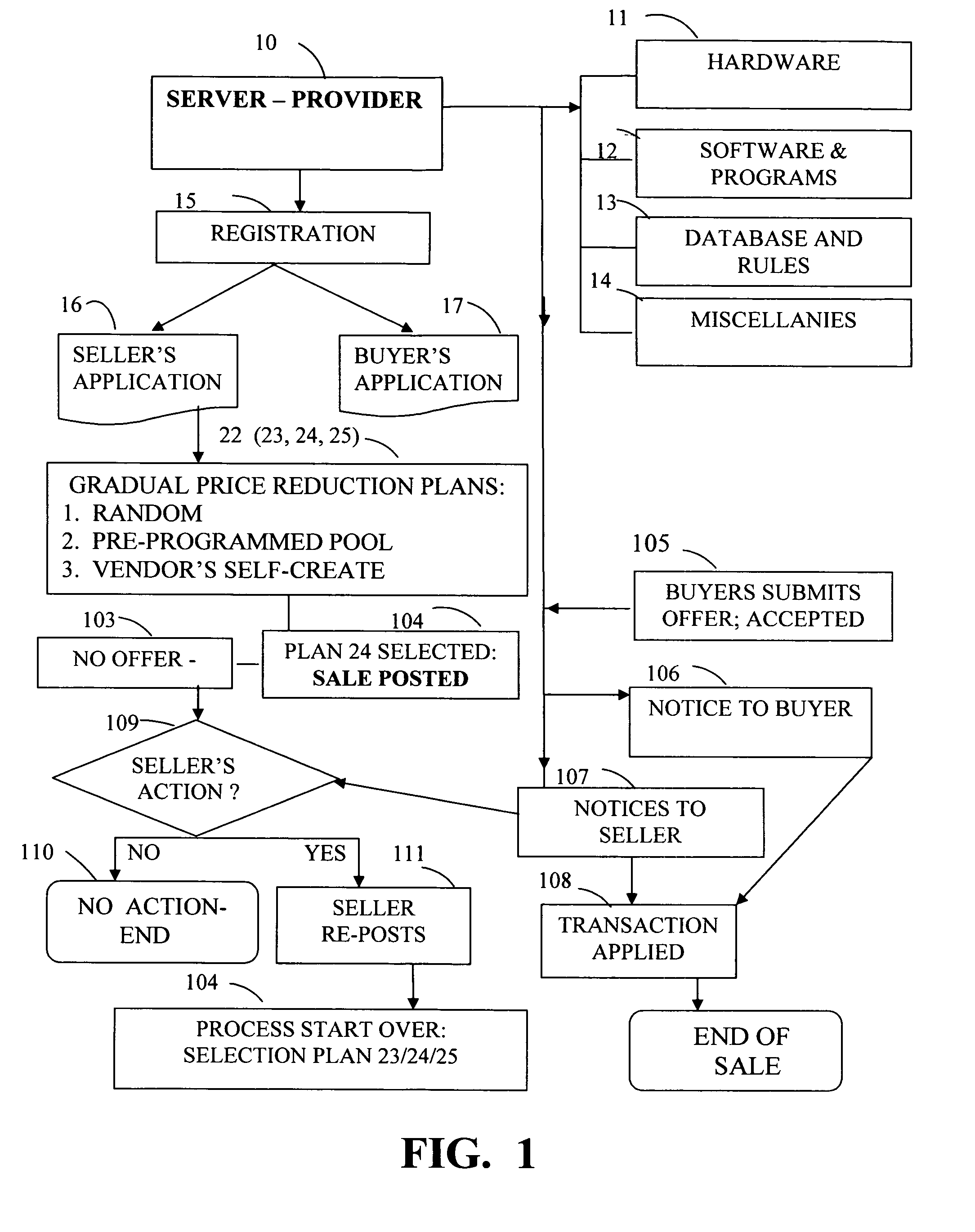

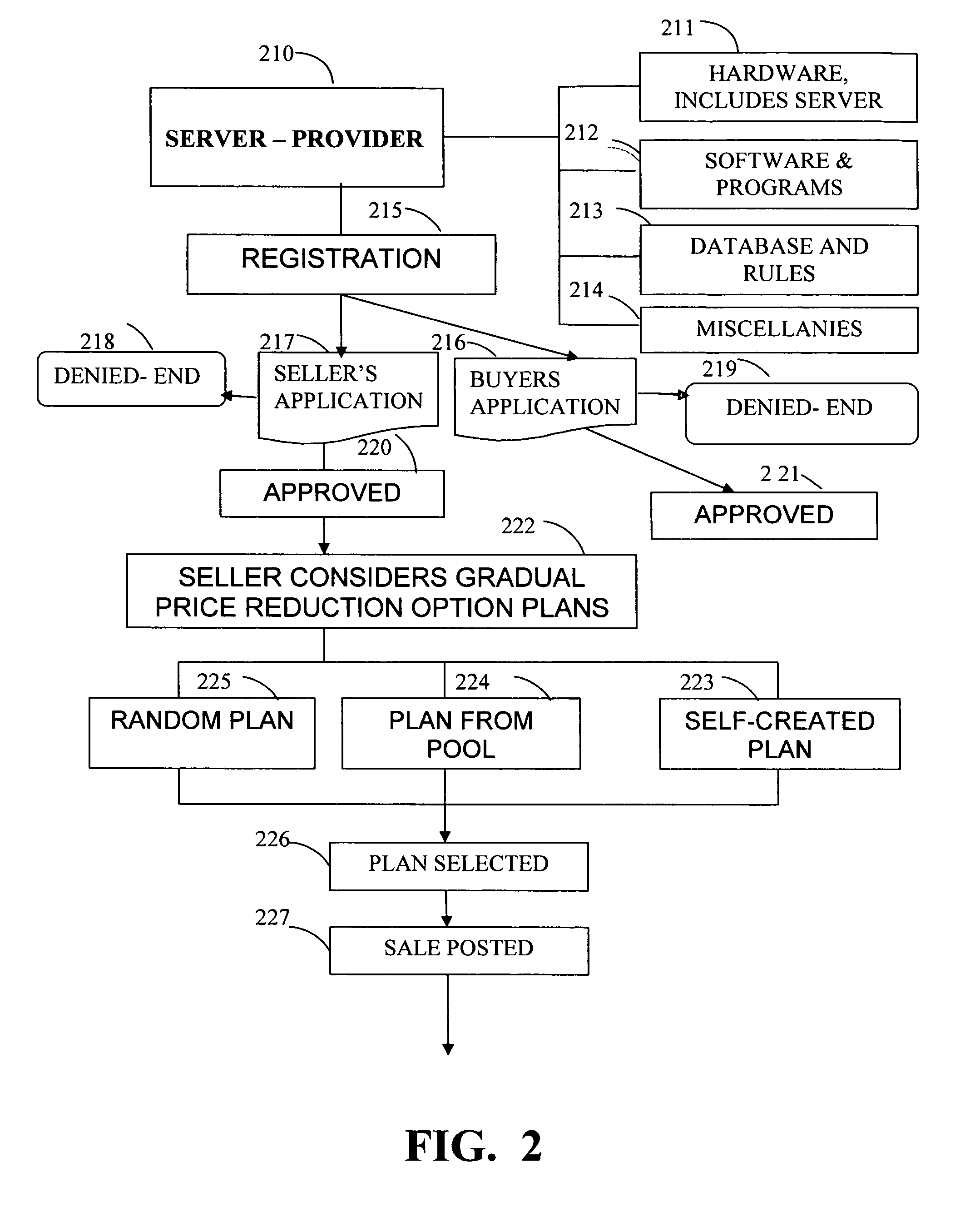

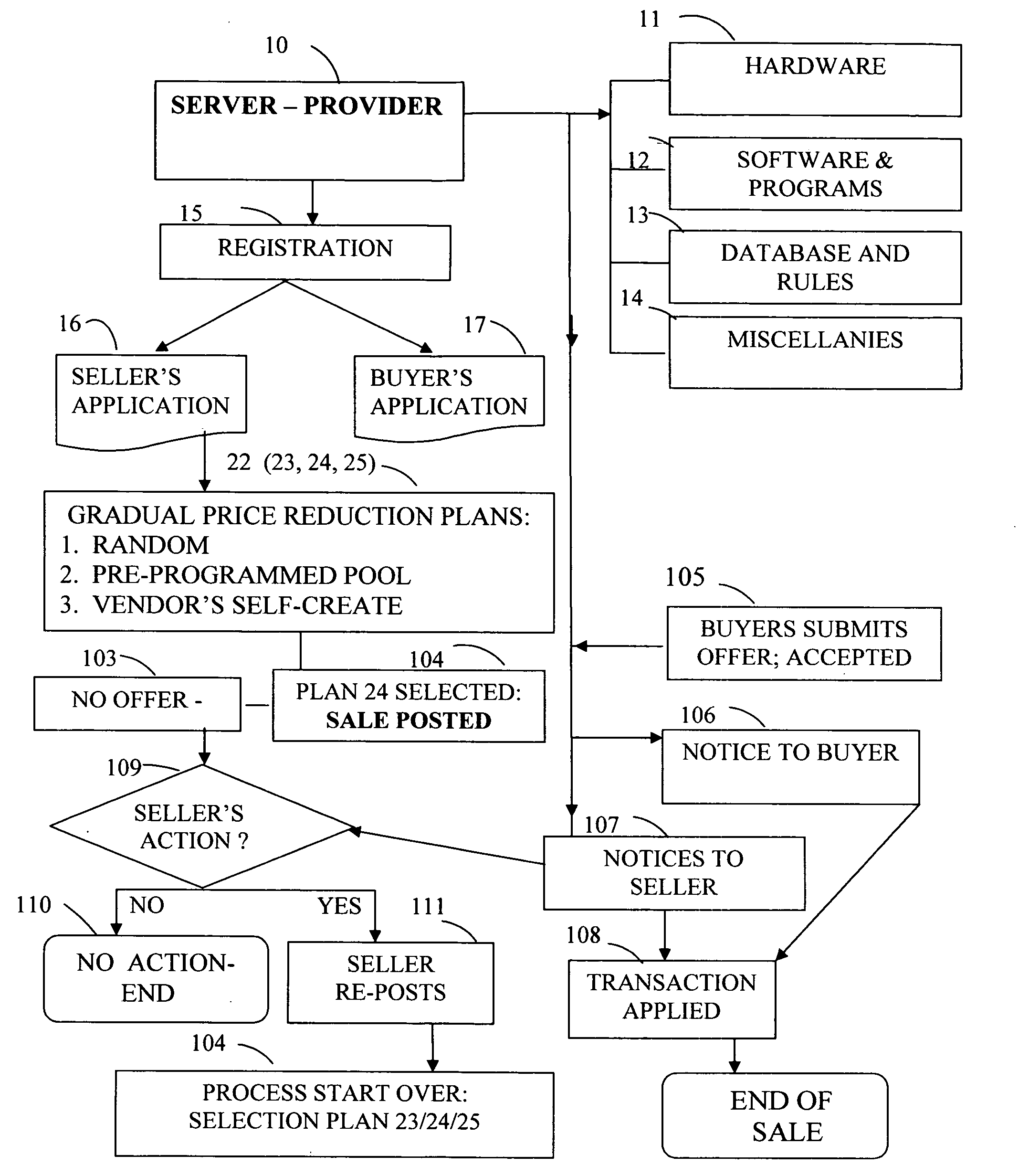

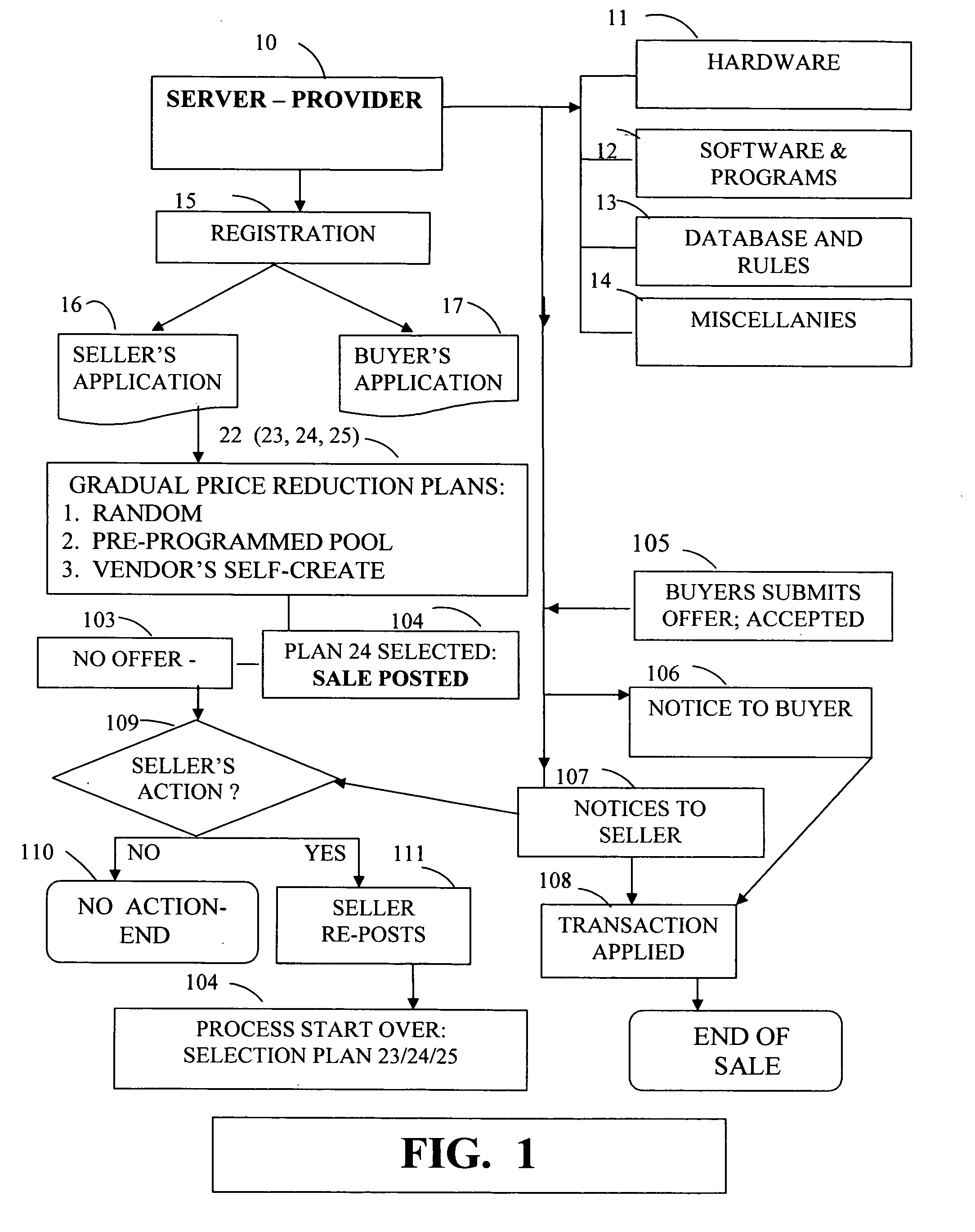

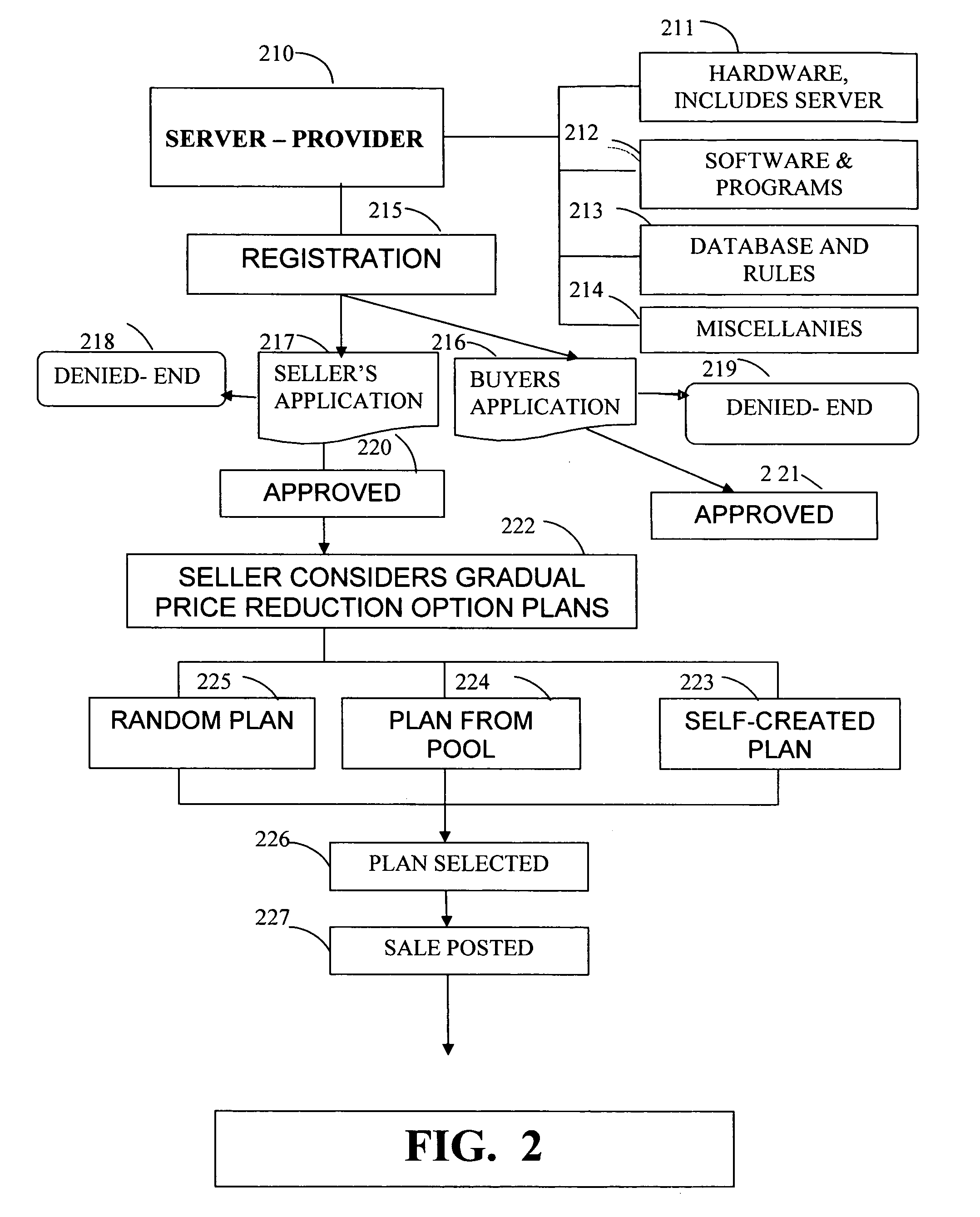

Internet trading

A new internet trading method, concept and process is introduced, enabling users to post goods and services for sale and purchasing, whereby the posted price begins at its maximum, and thereafter is gradually reduced to a minimum, pre-selected price, based on pre-programmed methods and programs, according to a pre-selected schedule of price reduction based on frequencies and sequences of amounts of time, money and percentage, respectively.The new process provides sets of pre-programmed price reduction schedules which may be prepared by the seller, or selected from a pool of sets, or randomly selected from the system, thereby, at every certain amount of pre-selected times, the maximum price of such goods or services is reduced by certain amount of money, or percentage, respectively to the maximum price initially posted during the duration of the sale, enabling a prospective buyer to ‘grab’ (purchase) the item by placing an offer at any given time, for the posted price at that time, thereby instantly purchasing the product or service, thus also, instantly, ending the sale.

Owner:TSIYONI JOSEPH

Two-dimensional planar photonic crystal superprism device and method of manufacturing the same

InactiveUS7515790B2Shorten the timeSimple processPrismsNanoopticsManufacturing technologyEngineering

Provided are a two-dimensional planar photonic crystal superprism device and a method of manufacturing the same, in which a manufacturing process is simplified using a nanoimprint lithography technique, and thus price-reduction and mass production are facilitated. The two-dimensional planar photonic crystal superprism device includes: a single-mode input waveguide comprising a straight waveguide having a taper structure and a bending waveguide; a superprism formed on an output end side of the single-mode input waveguide and comprising a slab and a photonic crystal superprism; and a single-mode output waveguide comprising a straight waveguide having a taper structure and a bending waveguide, and formed adjacent to the photonic crystal superprism. Using the two-dimensional planar photonic crystal superprism device, it is possible to facilitate manufacturing of nano-photonic integrated circuits, photonic crystal integrated circuits and nano-photonic systems. In addition, a wavelength-selectable photonic crystal superprism device using high dispersion of photonic crystal, which is several hundred times the dispersion of conventional glass prism, can be manufactured using thermal / hot and ultraviolet nanoimprint lithography techniques corresponding to nano-manufacturing technology.

Owner:ELECTRONICS & TELECOMM RES INST

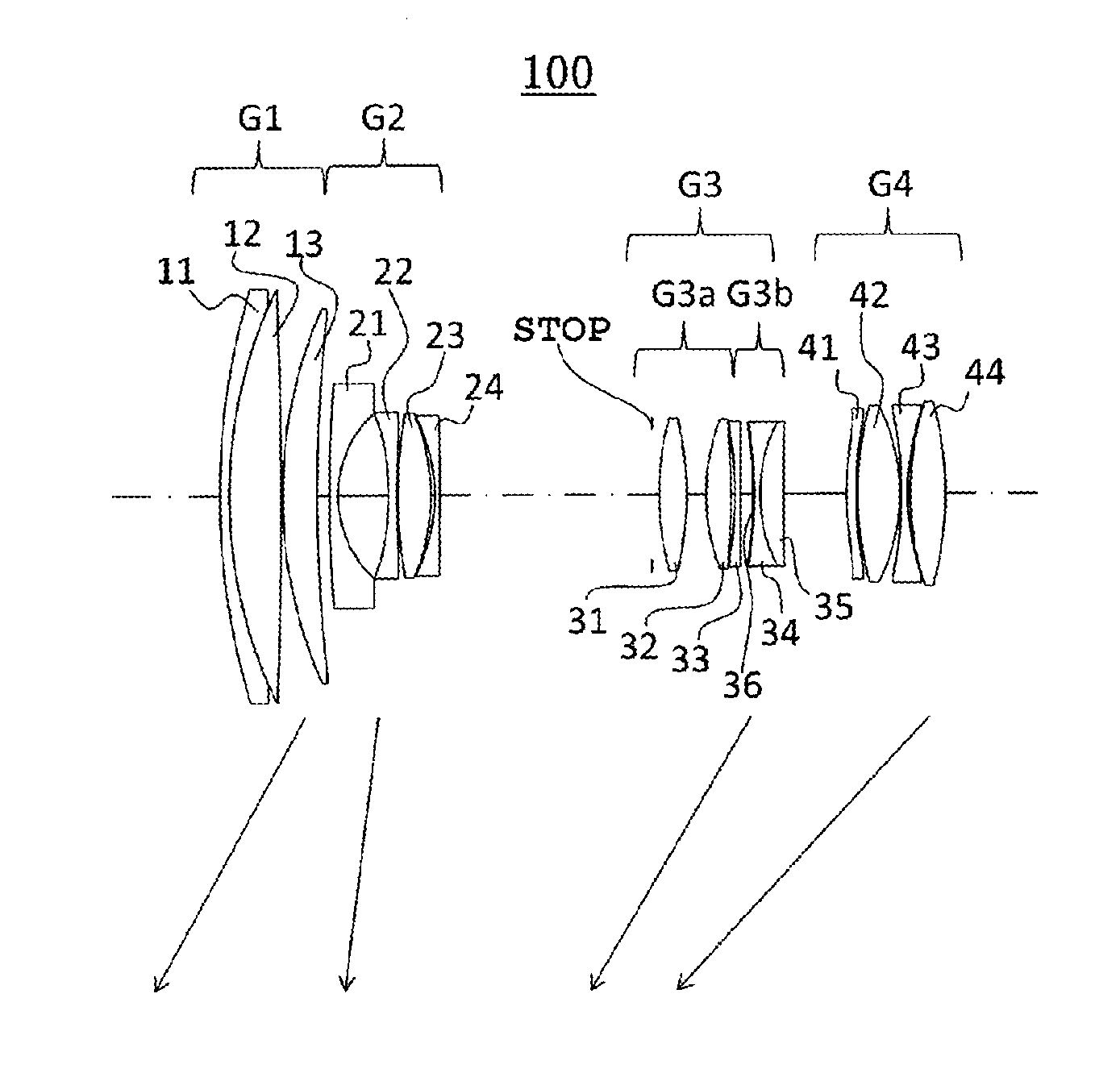

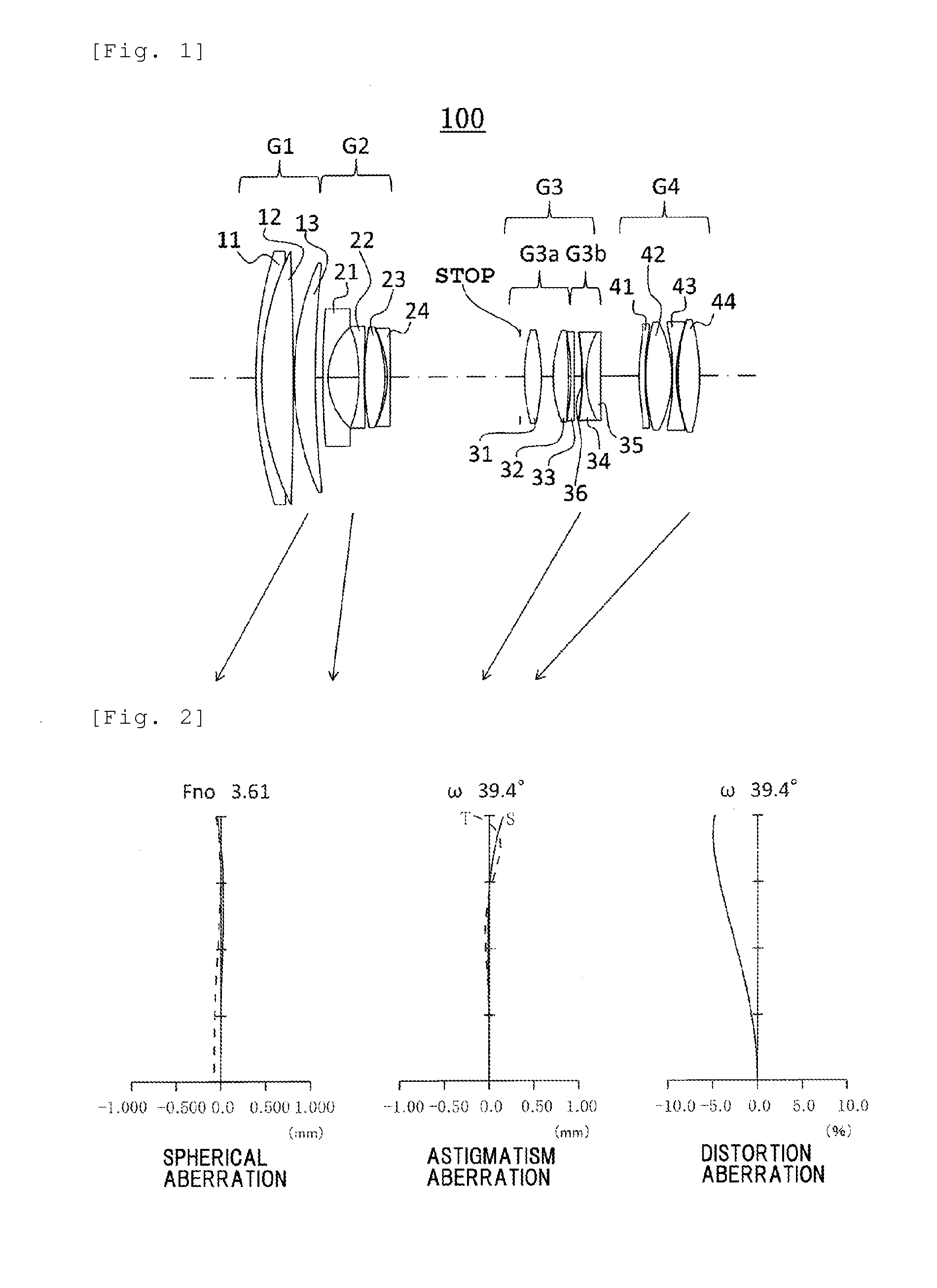

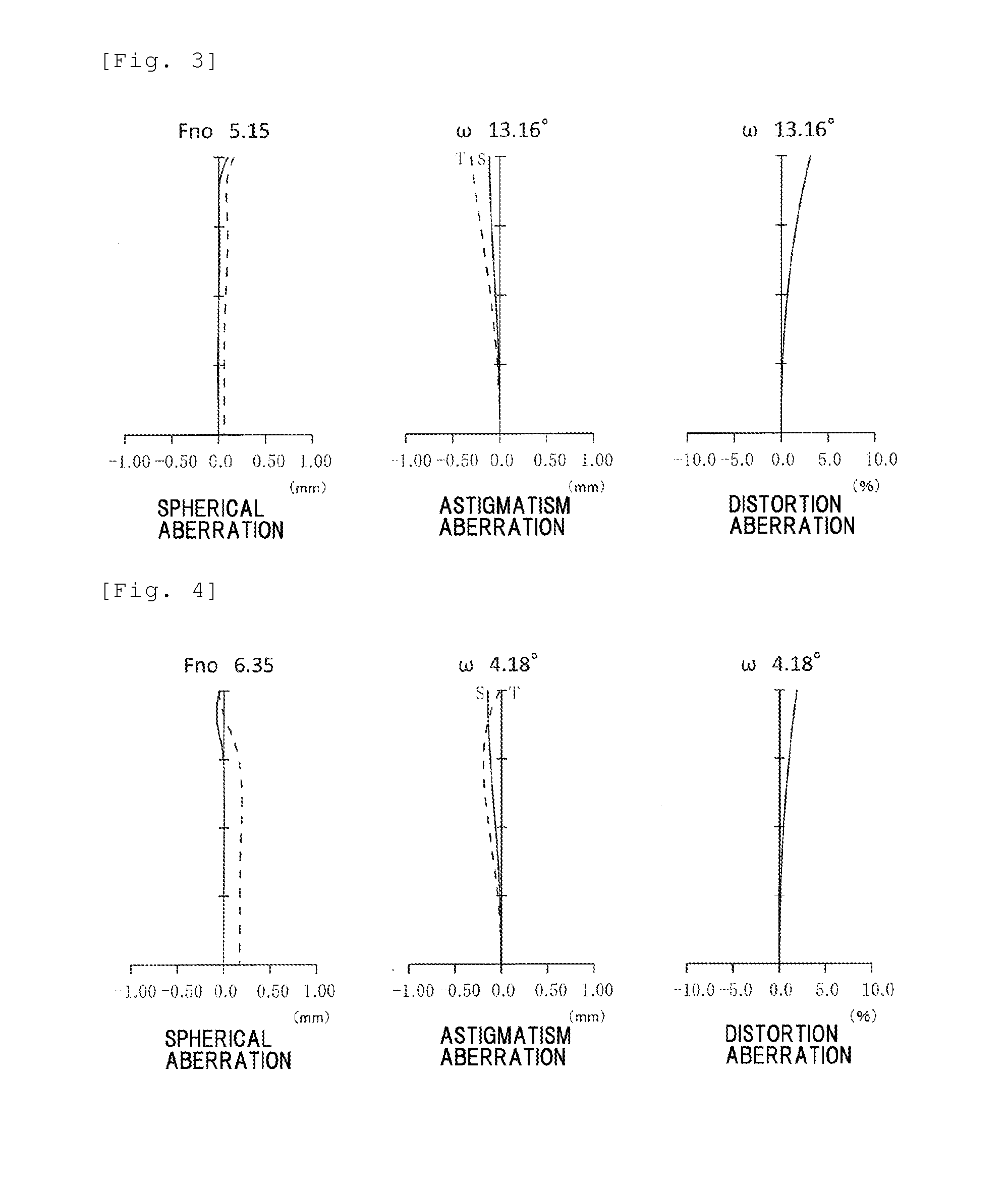

Zoom Lens

InactiveUS20140177065A1Address rising pricesHigh-quality imaging effectOptical elementsOptical axisConvex side

A high-power zoom lens that achieves size and price reduction, and at the same time provides high-quality imaging. This lens includes at least four lens groups arranged along an optical axis, which are moveable along the axis in order to achieve changes in magnification. The first, third, and fourth lens groups have positive refractive powers, and the second group has a negative refractive power. The second lens group includes a negative meniscus lens arranged closest to the object, provided with a convex surface at the object side. A negative lens is arranged next to the negative meniscus lens, and a negative lens provided with a concave surface at the object side is arranged closest to the image. The fourth lens group includes at least two positive lenses and one negative lens.

Owner:TAMRON

Internet trading

A new internet trading method, concept and process is introduced, enabling users to post goods and services for sale and purchasing, whereby the posted price begins at its maximum, and thereafter is gradually reduced to a minimum, pre-selected price, based on pre-programmed methods and programs, according to a pre-selected schedule of price reduction based on frequencies and sequences of amounts of time, money and percentage, respectively.The new process provides sets of pre-programmed price reduction schedules which may be prepared by the seller, or selected from a pool of sets, or randomly selected from the system, thereby, at every certain amount of pre-selected times, the maximum price of such goods or services is reduced by certain amount of money, or percentage, respectively to the maximum price initially posted during the duration of the sale, enabling a prospective buyer to ‘grab’ (purchase) the item by placing an offer at any given time, for the posted price at that time, thereby instantly purchasing the product or service, thus also, instantly, ending the sale.

Owner:TSIYONI JOSEPH

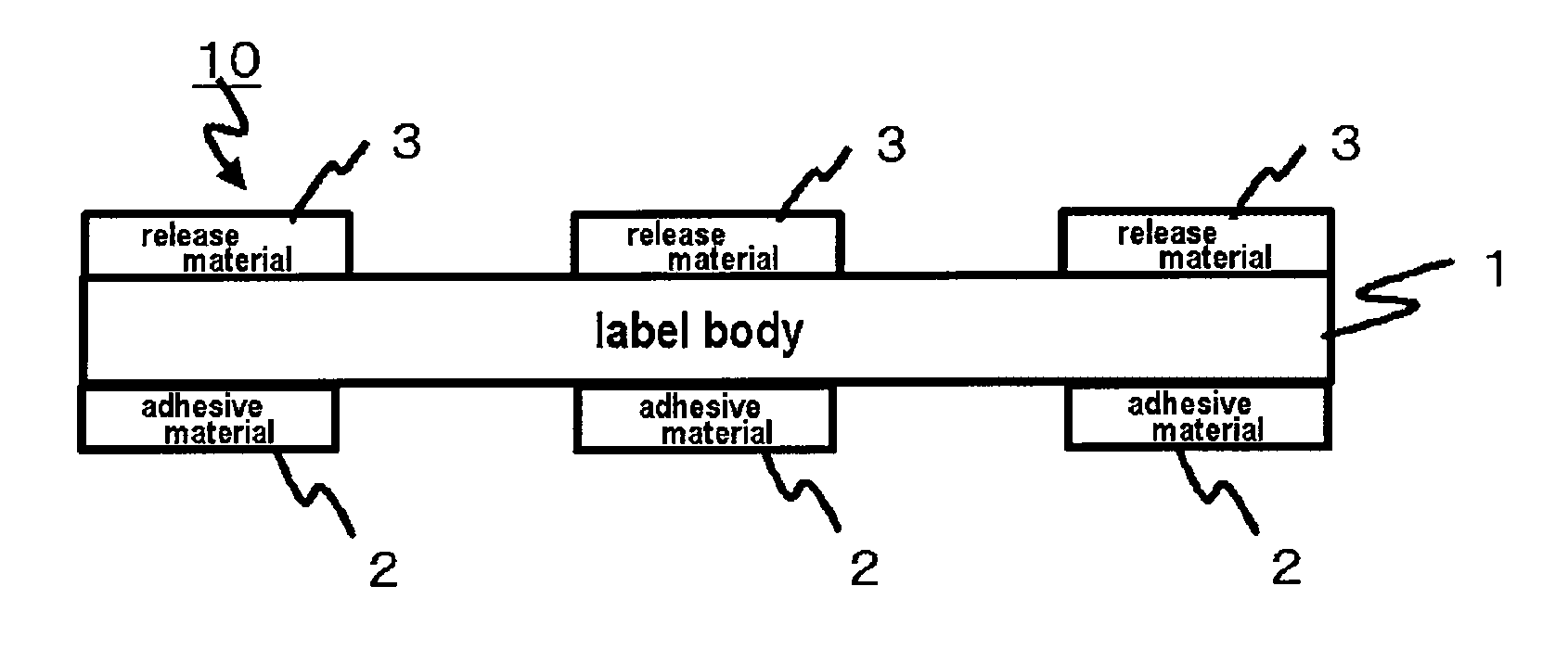

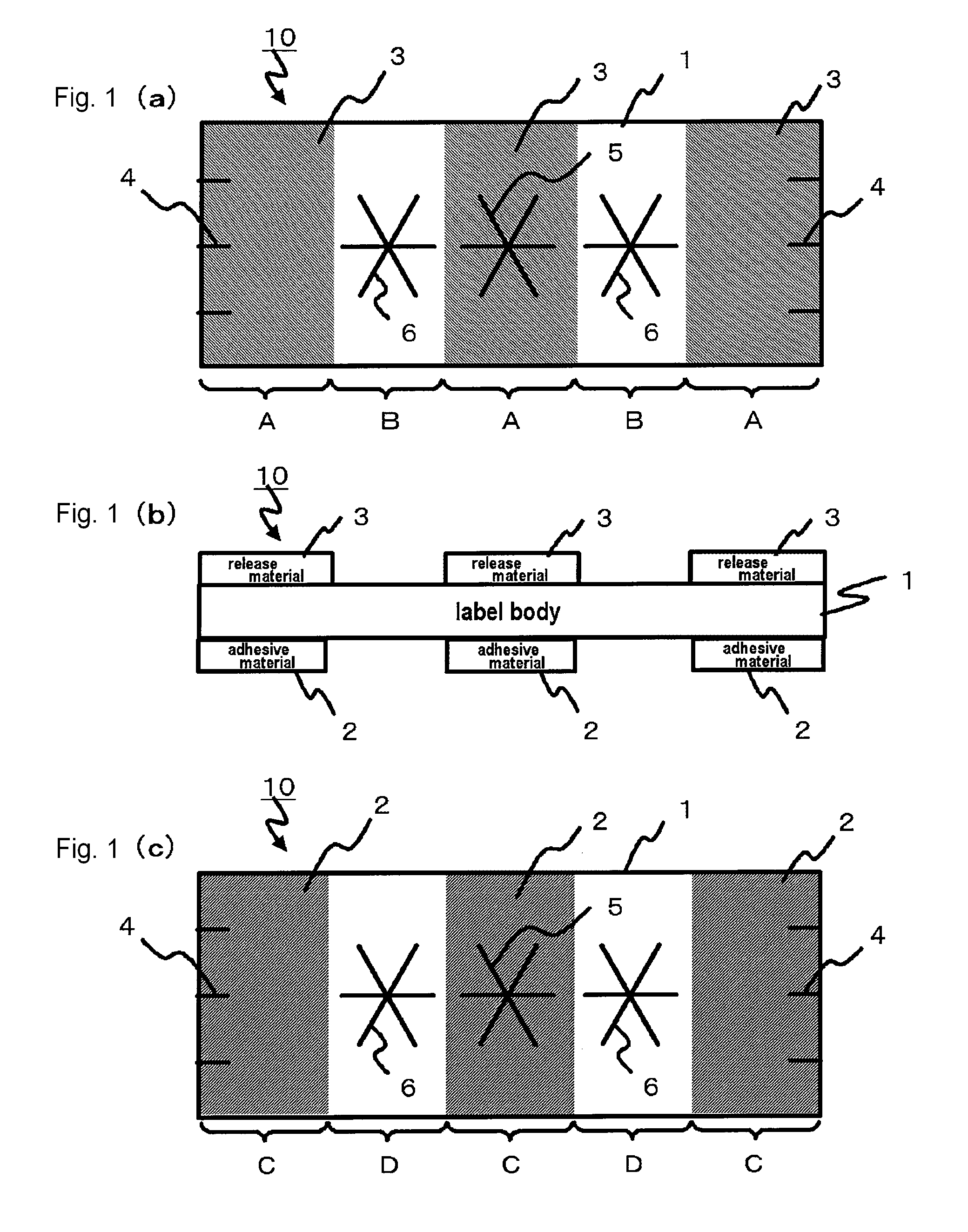

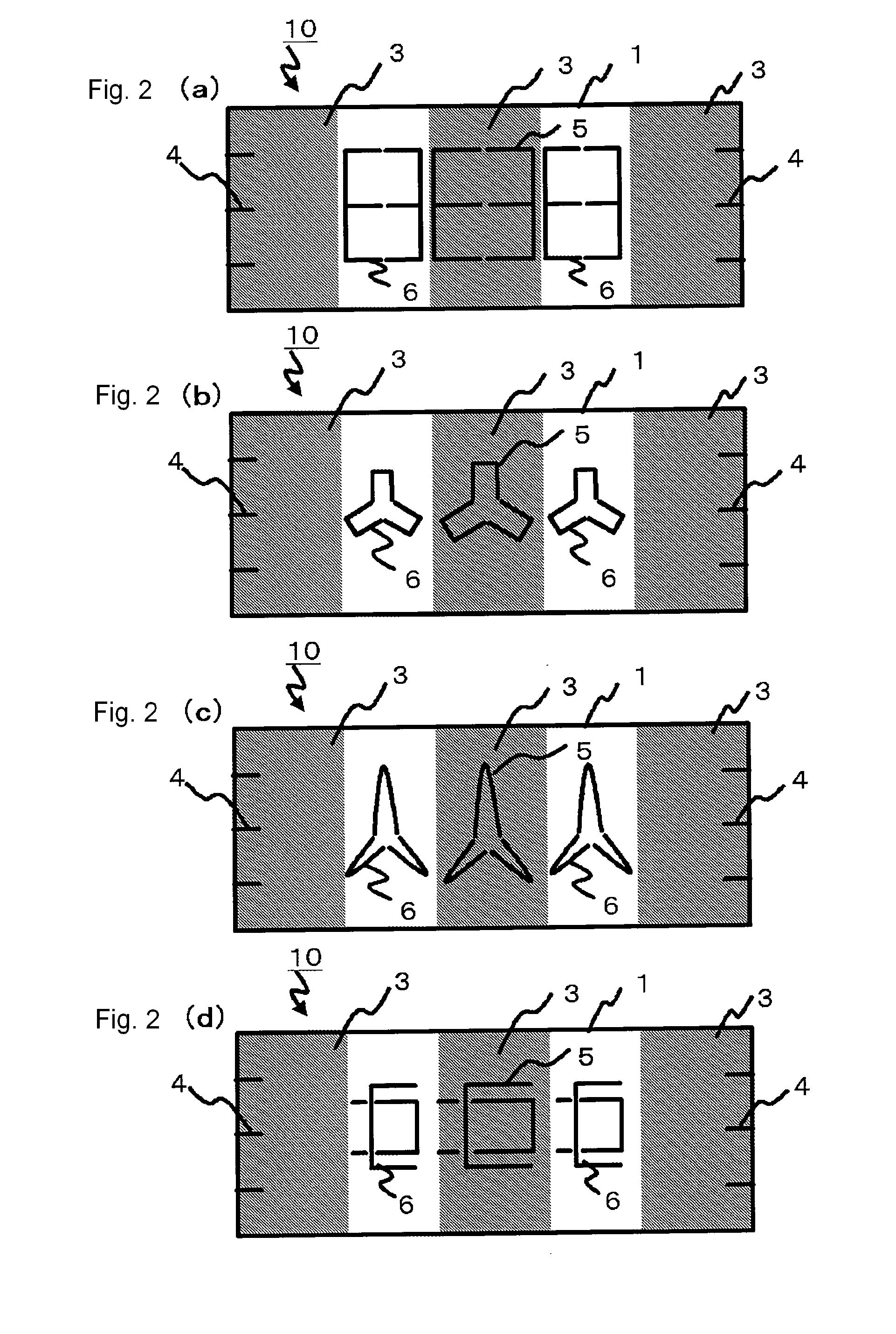

Price reduction label and price reduction label applying method

InactiveUS20110244162A1Prevent reuseEasy to understandStampsLayered productsAdhesive materialsPrice reduction

A price reduction label includes: a label body, an adhesive material coated on the back surface of the label body in spaced and strip-shape plural rows, a release material coated on the upper surface of the label body in opposing region of the adhesive material, an adhesive region coated with the adhesive material and a non-adhesive region without the adhesive material formed alternately in the width direction perpendicular to the strip direction of the strip of adhesive material on the back surface of the label body, and a release region A coated with release material and a non-release region without the release material formed alternately in the width direction of the upper surface of the label body, and the first tamper-resistant slits and the second tamper-resistant slits formed on the adhesive region of the label body.

Owner:SATO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com