Light diffusion sheet and backlight unit using that

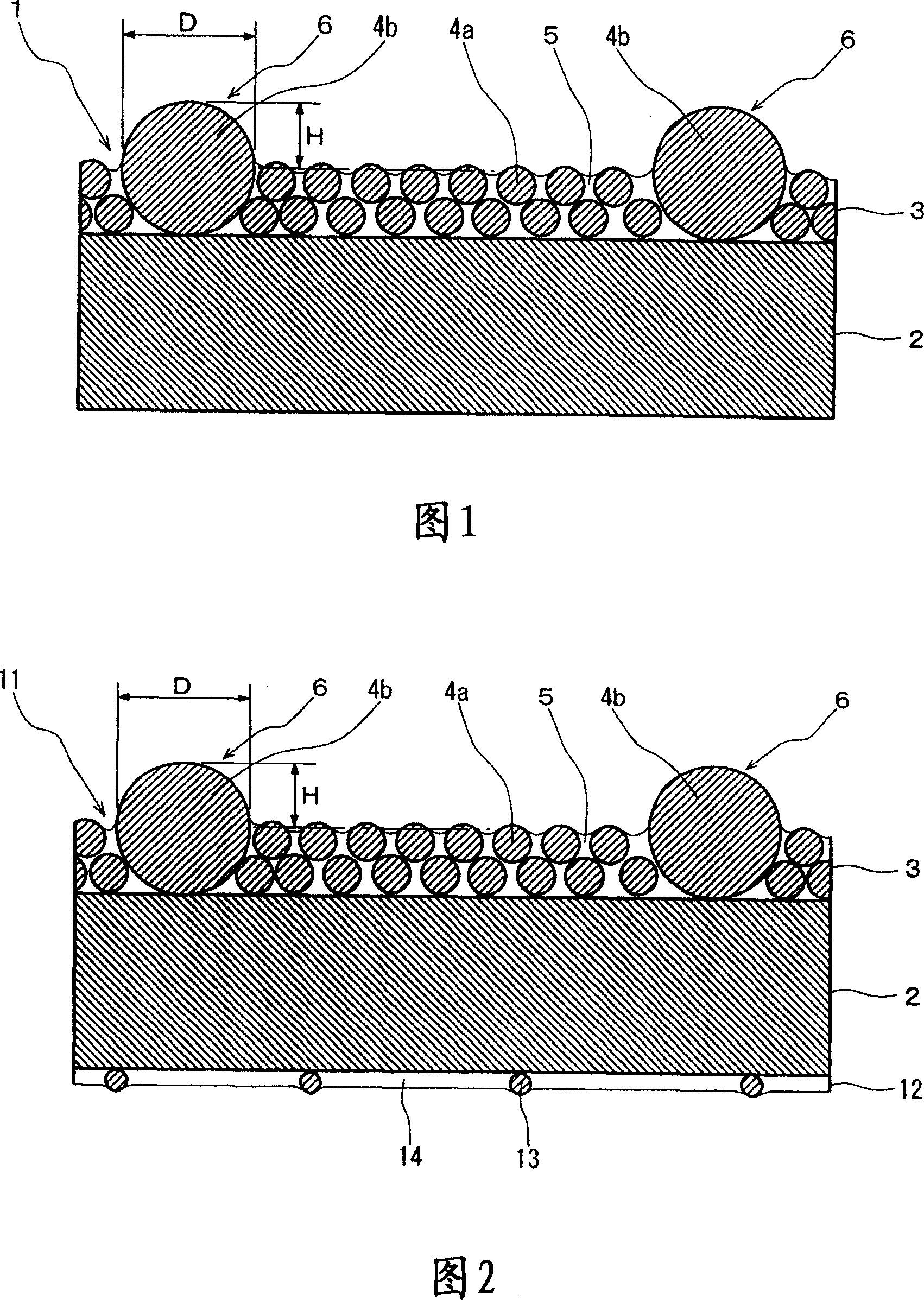

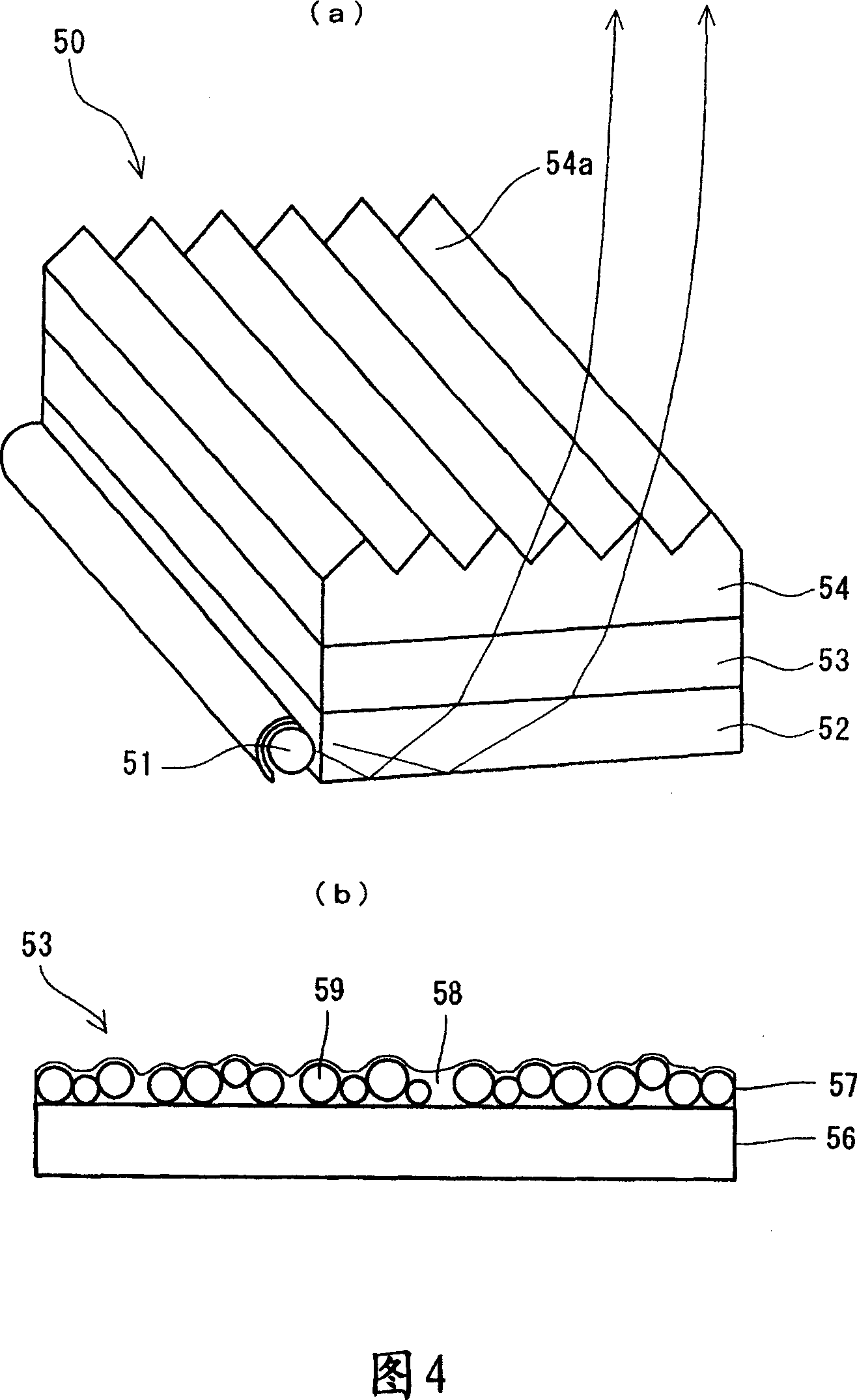

一种光扩散片、光扩散层的技术,应用在光学元件、光导、光学等方向,能够解决产品成品率降低、表面损伤等问题,达到提高辉度、低成本性、良好成本性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

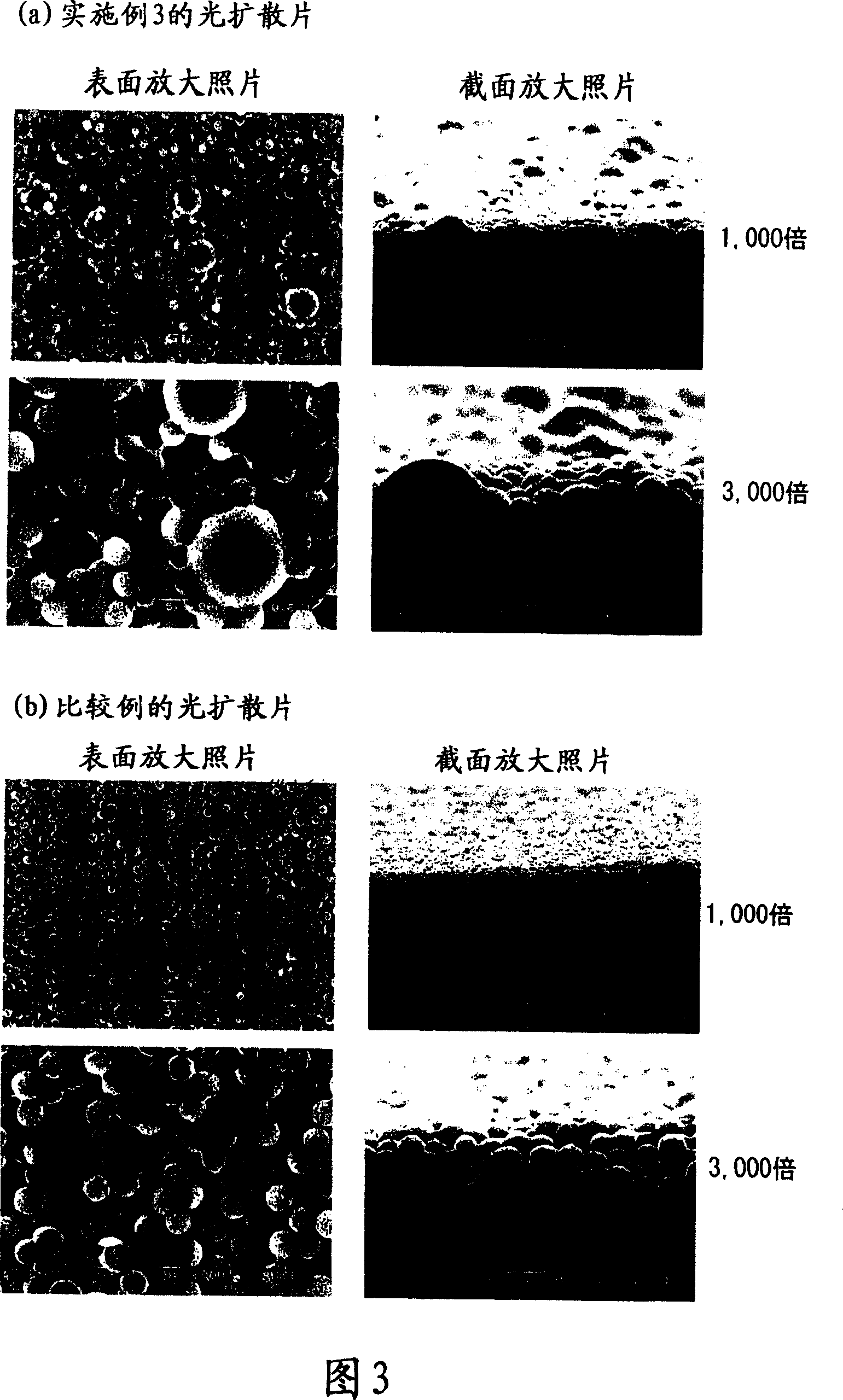

[0092] Hereinafter, the present invention will be described in detail based on examples, but the present invention is not limited to the description of the examples.

Embodiment 1

[0096] In addition to using the above-mentioned small-diameter monodisperse beads and large-diameter beads as beads, polydisperse beads with an average particle diameter of 8.6 μm, a coefficient of variation of 33.5, and a particle size distribution width of 3.2 μm or more and 23.8 μm or less are used. As the large-diameter beads, the light-diffusing sheet of Example 1 was obtained in the same manner as the above-mentioned comparative example, except that the mass ratio of the small-diameter monodisperse beads to the large-diameter beads was 95 / 5.

Embodiment 2

[0098] In addition to using the above-mentioned small-diameter monodisperse beads and large-diameter beads as beads, polydisperse beads with an average particle diameter of 8.6 μm, a coefficient of variation of 33.5, and a particle size distribution width of 3.2 μm or more and 23.8 μm or less are used. The light-diffusing sheet of Example 2 was obtained in the same manner as the comparative example above, except that the mass ratio of the small-diameter monodisperse beads to the large-diameter beads was 9 / 1 as the large-diameter beads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com