Patents

Literature

119results about How to "Reduce thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

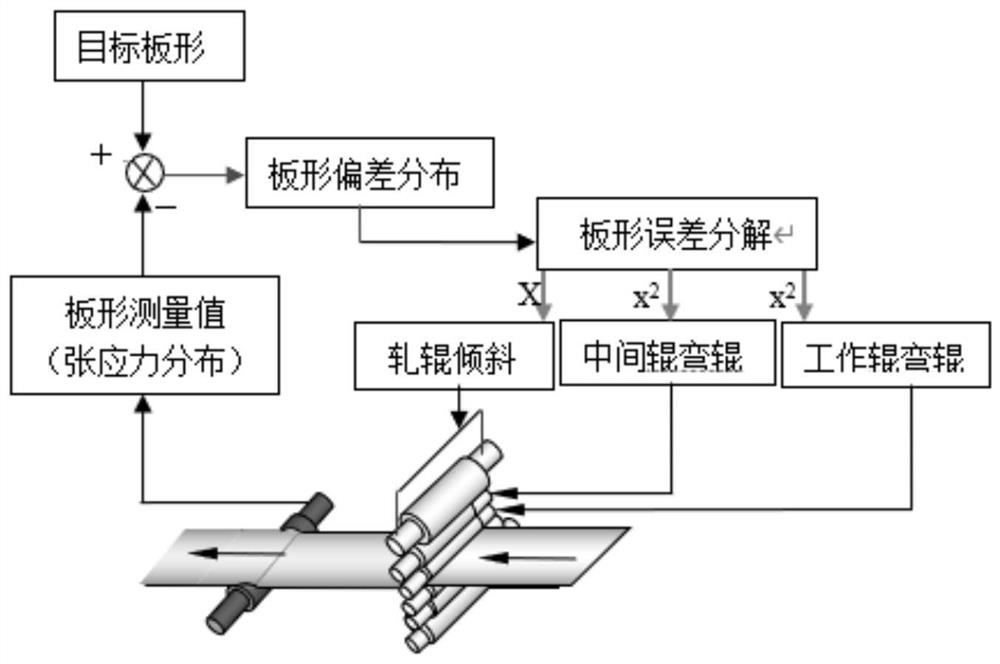

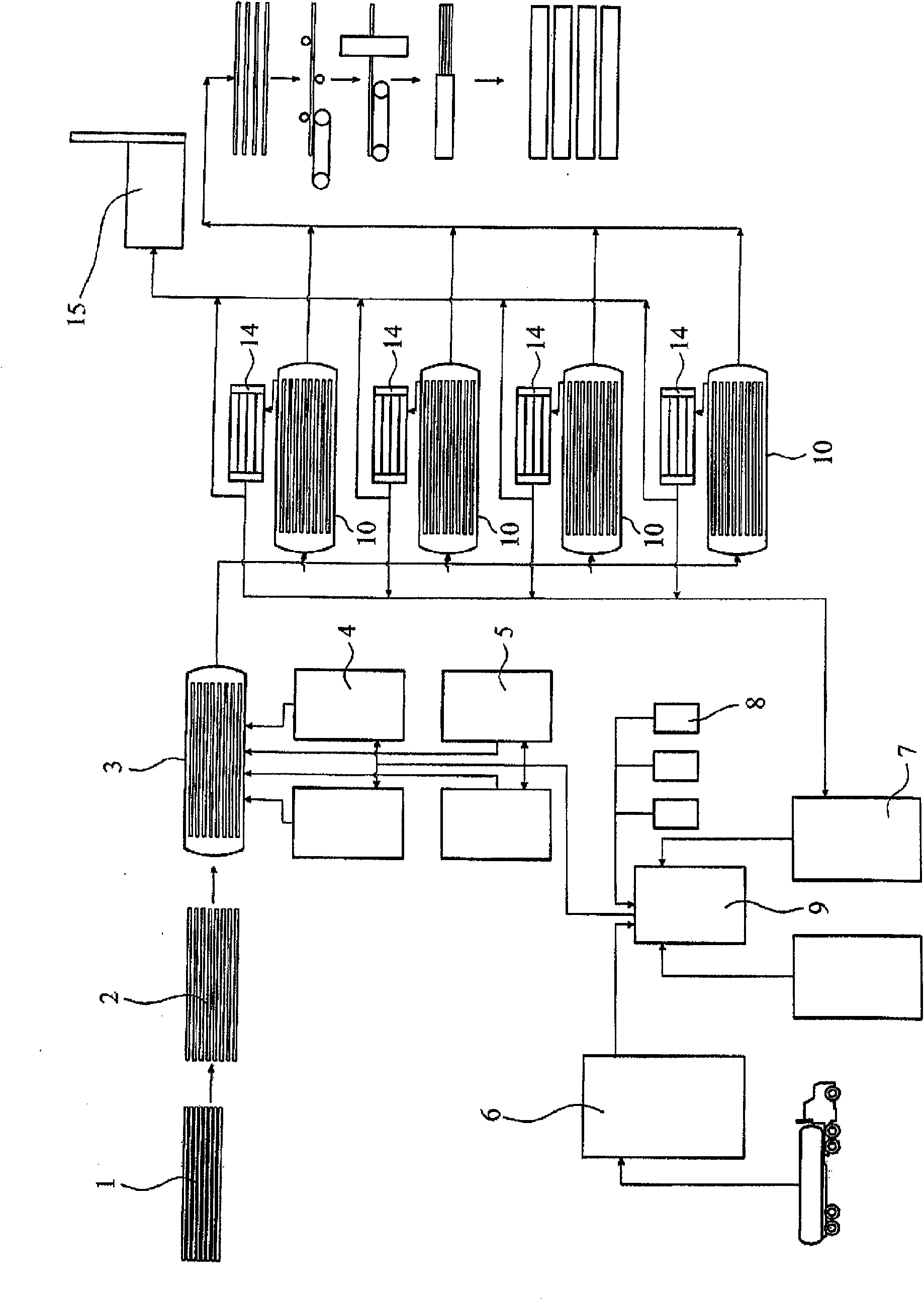

Edge drop control method of cold-rolled non-oriented silicon steel

ActiveCN103464469ARealize closed-loop controlHigh control precisionRoll mill control devicesMetal rolling arrangementsEffect functionEngineering

The invention provides an edge drop control method of cold-rolled non-oriented silicon steel. The edge drop control method includes that a cold rolling five frame and all six roller rolling mill is utilized as an object; an objective function is that the horizontal thickness difference of the non-oriented silicon steel is minimum; the complete set of working roller forecast and feedback and working roller bending compensation control method for edge thinning control of the non-oriented silicon steel is established through introduction of an efficiency effected function array. According to the edge drop control method of the cold-rolled non-oriented silicon steel, the original control device is fully utilized; the maintenance is easy; the technology import capital investment is saved; meanwhile the influence on the flatness control accuracy can be effectively reduced and the horizontal thickness control accuracy of the non-oriented silicon steel can be improved to enable the horizontal thickness difference to decrease from 25 microns to 8 microns below and accordingly the laminated rate of the non-oriented silicon steel finished product and the qualified rate of the quality of the finished product are improved and a new solution is provided to adapt to the edge drop control presetting and feedback of industrial application.

Owner:ANGANG STEEL CO LTD

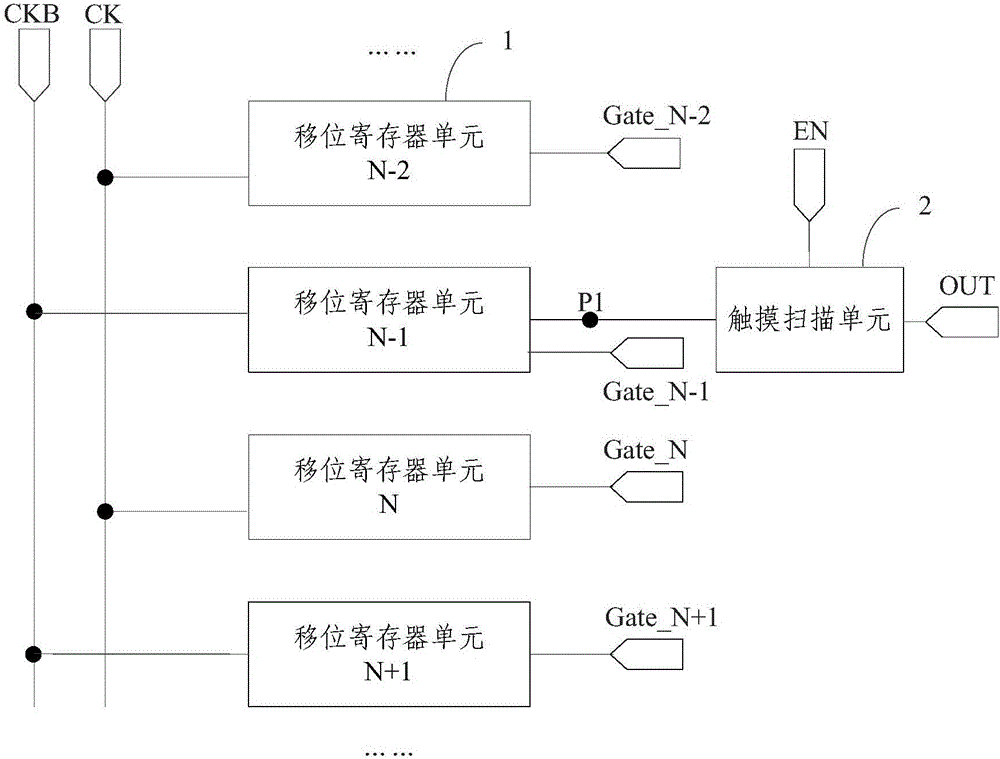

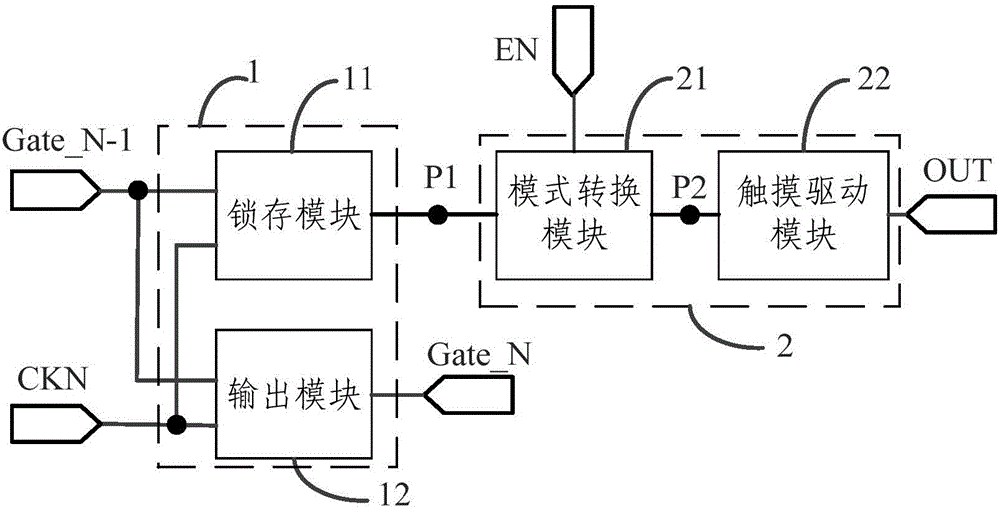

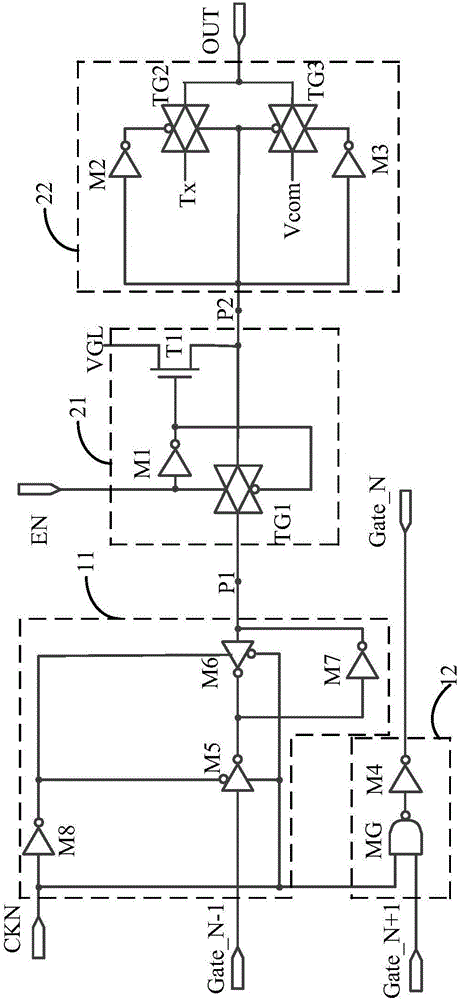

Gate drive circuit and display device

ActiveCN105741739AReduce settingsReduce outputStatic indicating devicesInput/output processes for data processingElectricityShift register

The invention relates to a gate drive circuit and a display device. The gate drive circuit comprises plurality stages of shift register units which output gate driving signals stage by stage when driven by clock signals, and each shift register unit has a first node. Each shift register unit comprises a latching module which remains the first node at active level within a preset time corresponding to the time for outputting gate driving signals. The first nodes of at least two stages of the shift register units are each connected with a touch scan unit, and the touch scan units are connected with touch control enabling ends to output touch scan signals when the first nodes are at active level and the touch control enabling ends are at active level. The display device is realized based on the gate drive circuit. The circuit is simplified, signal wires are effectively reduced, and narrow frame design of a display device can be realized.

Owner:BOE TECH GRP CO LTD +1

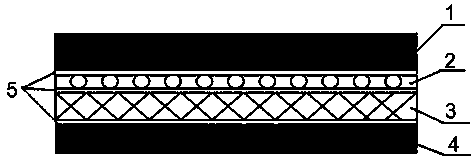

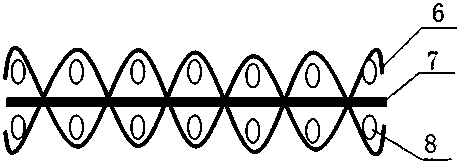

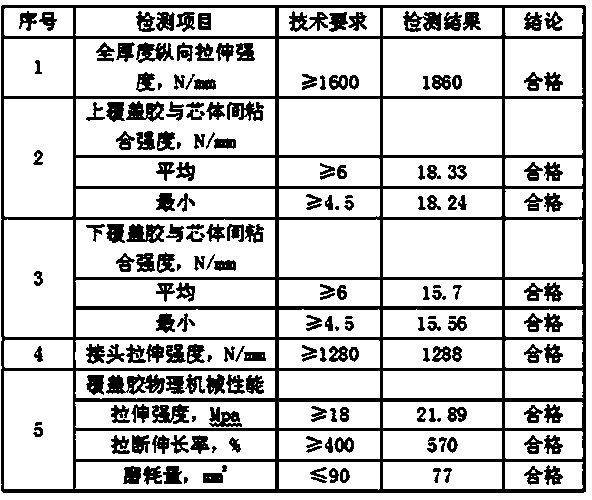

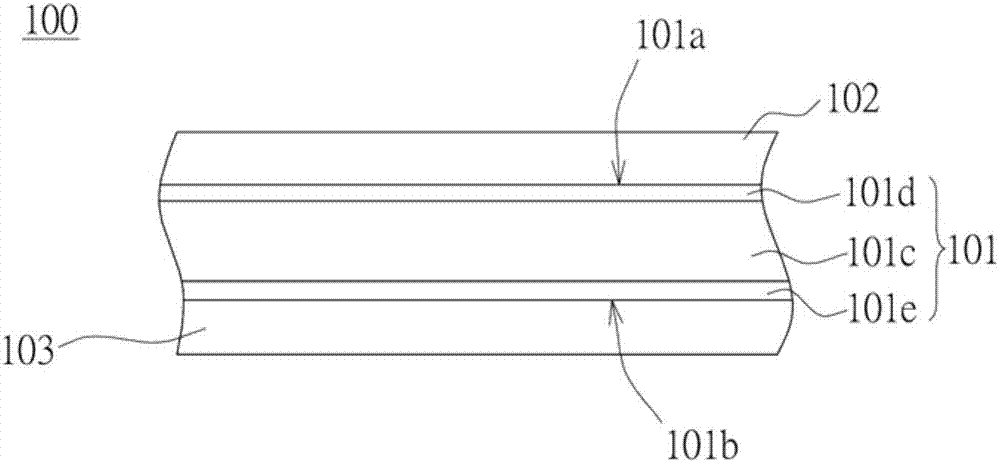

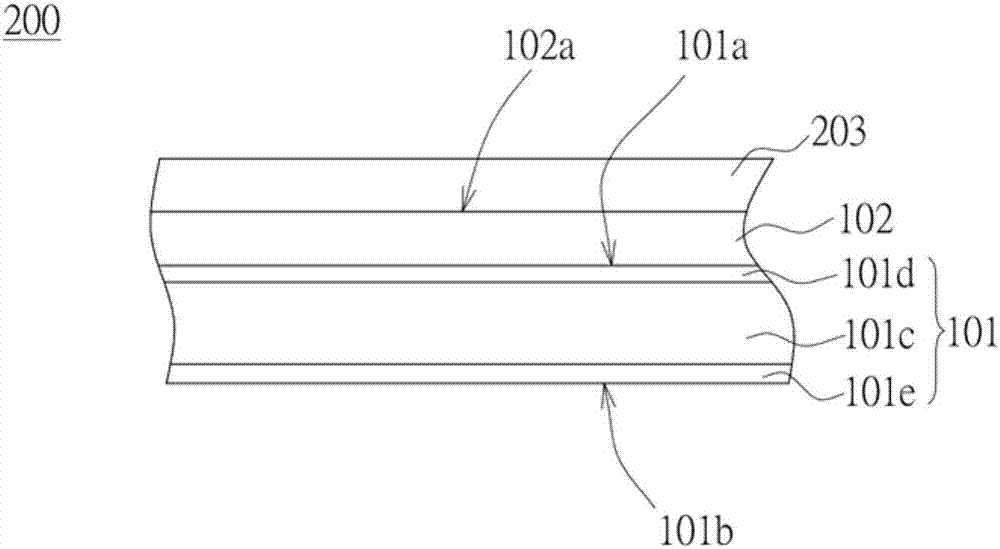

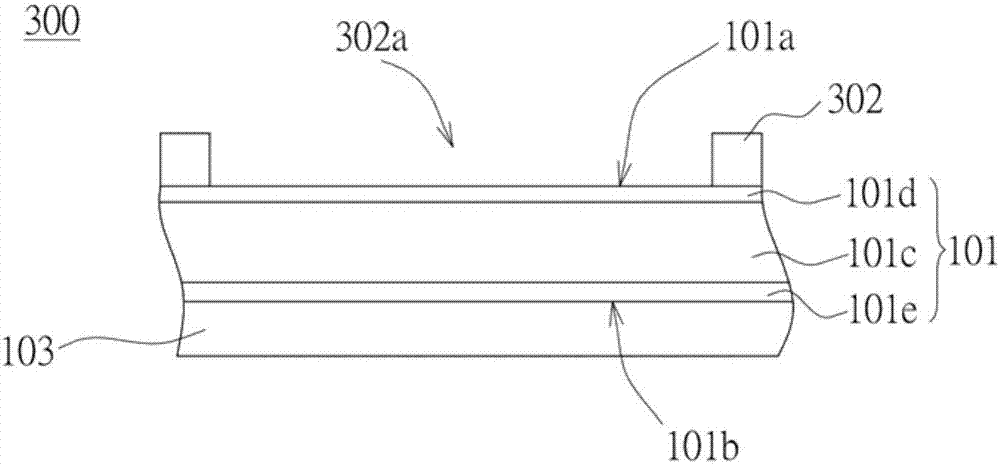

Conveying belt of aramid fiber high in wear resistance and high in bond strength

ActiveCN104071521AExtended flex lifeReduced canvas layersNatural rubber adhesivesConveyorsRettingMaterials science

The invention relates to a conveying belt of aramid fiber high in wear resistance and high in bond strength. The conveying belt of the aramid fiber high in wear resistance and high in bond strength comprises an aramid fiber skeleton layer, a buffer layer, upper layer cover gum and lower layer cover gum, wherein the buffer layer is arranged between the upper layer cover gum and the aramid fiber skeleton layer, and the upper layer cover gum and the buffer layer, the aramid fiber skeleton layer and the buffer layer, and the aramid fiber skeleton layer and the lower layer cover gum are respectively bonded together through core gum high in bond strength. Main warp threads of skeleton material of the conveying belt of the aramid fiber high in wear resistance and high in bond strength are made of aramid fiber gum dipping canvas high in strength, and the strength level of the conveying belt which is produced can reach 3150N / mm. The conveying belt of the aramid fiber high in wear resistance and high in bond strength can meet the performance requirements that the belt body of the conveying belt is high in strength, high in wear resistance and high in bond strength, resists impact, resists tearing and the like. The braided structure of the skeleton material of the conveying belt of the aramid fiber high in wear resistance and high in bond strength is a straight warp and straight weft structure, and the conveying belt of the aramid fiber high in wear resistance and high in bond strength is long in use life, low in running energy consumption, reduces the diameter of a transmission drum, and decreases the number of long distance connecting times of ends.

Owner:YANKUANG GRP CO LTD +1

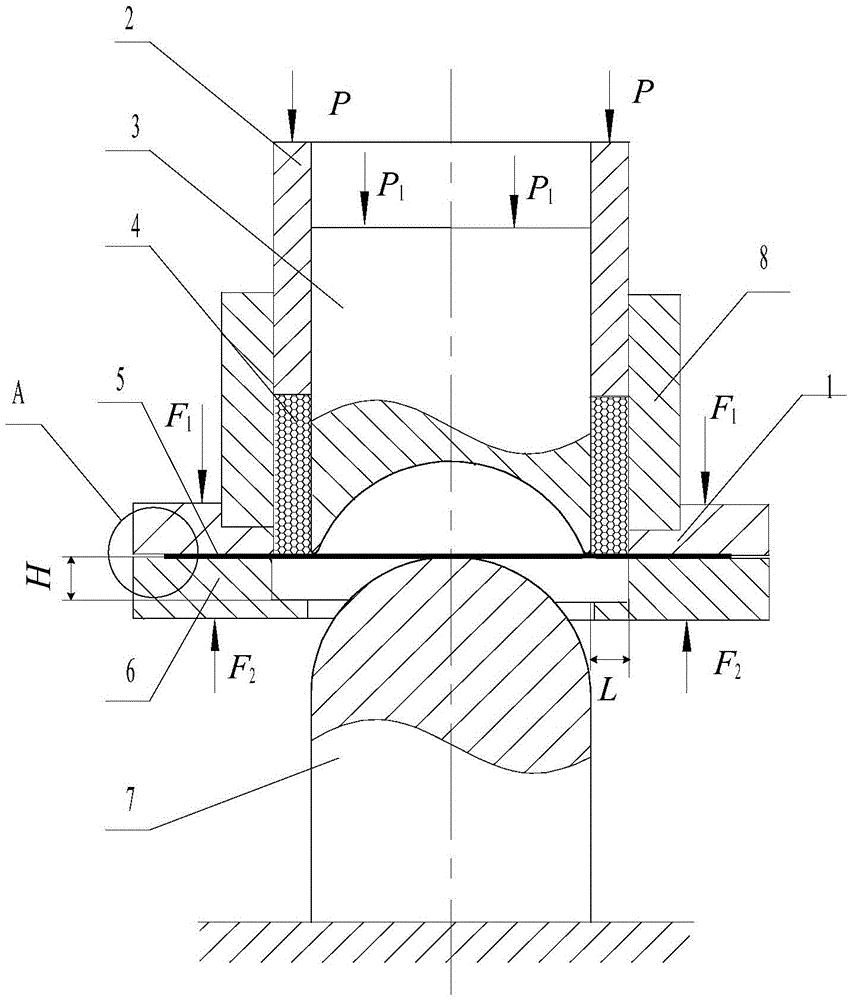

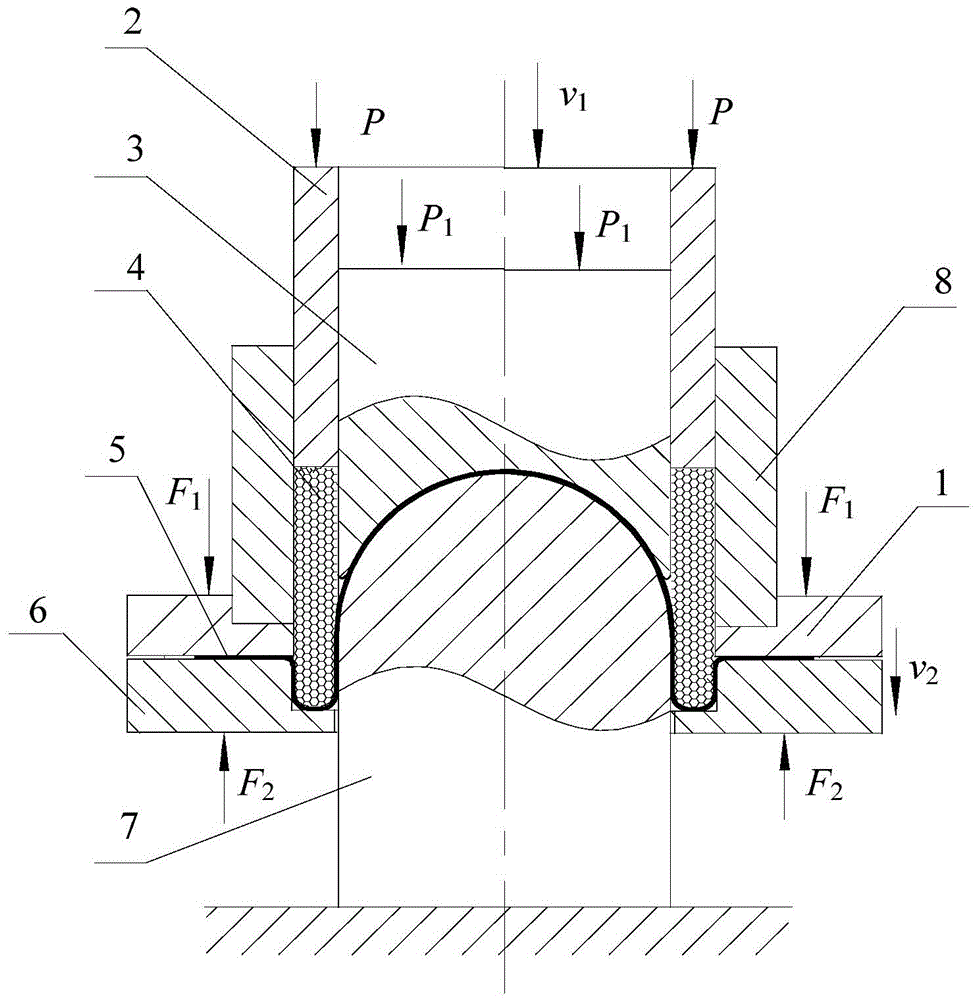

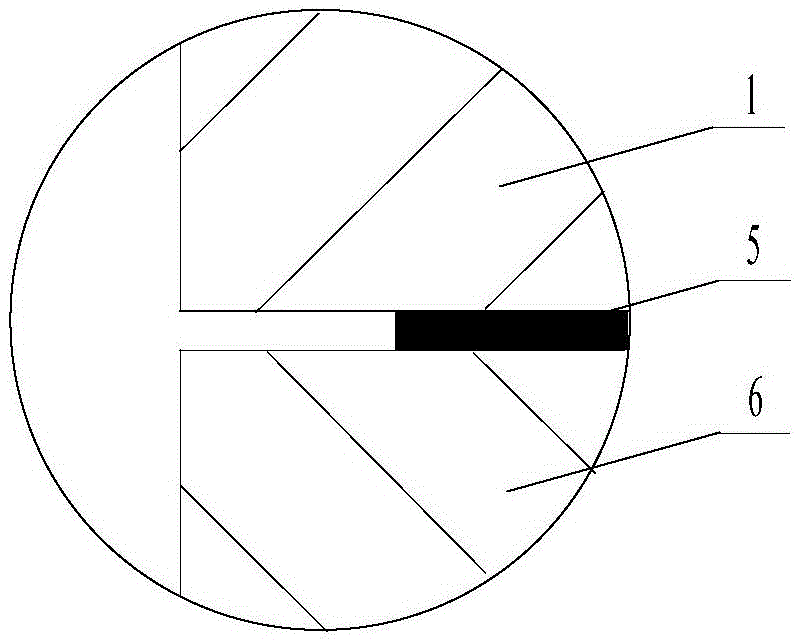

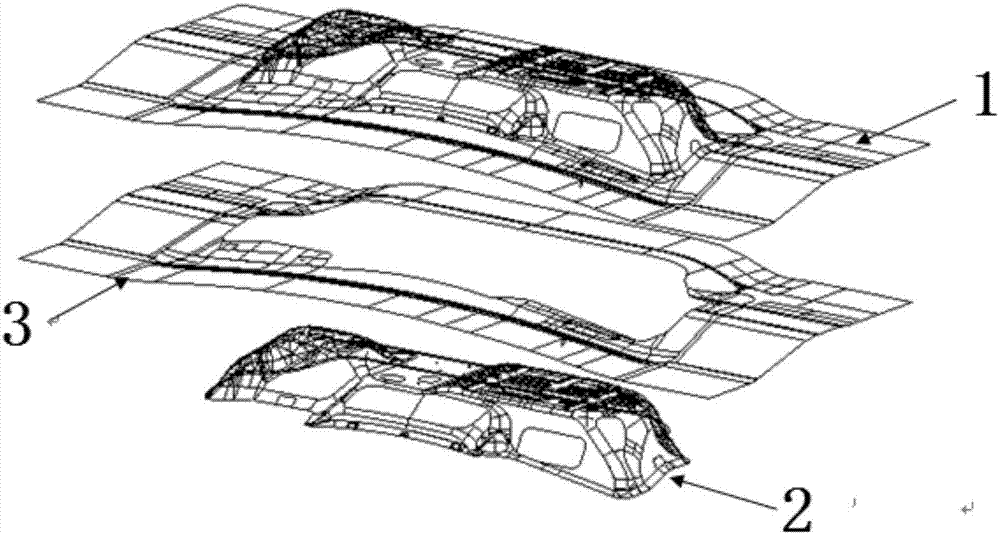

Forward-backward drawing and forming method for metal plate soft mould

ActiveCN105537360AInhibit entryEffective anti-wrinkle blank holder forceShaping toolsForward backwardSolid particle

The invention discloses a forward-backward drawing and forming method for a metal plate soft mould. A lower drawing ring is arranged on the outer surface of a male mould of a mould device in a sleeving mode; a drawing slot is formed in the lower drawing ring; an upper drawing ring is arranged on the upper surface of the lower drawing ring; a charging barrel is arranged on the upper drawing ring; a force-reducing column is arranged in the charging barrel; a pressure head is arranged between the force-reducing column and the charging barrel; and the lower end of the force-reducing column is a concave surface which corresponds to the male mould. The forming method is mainly characterized in that the upper and the lower drawing rings are oppositely pressed by external force; a solid particle medium is put into a ring-shaped cavity, the pressure head descends at a speed of v1, and the particle medium is compressed to carry out forward drawing deformation on the plate; meanwhile, under the action of back pressure P1, the force-reducing column is always in a contact state with the plate, the pressure head continuously descends, and the upper and the lower drawing rings float along with the pressing of the pressure head, wherein a flotation speed is smaller than a pressing speed of the pressure head. According to the invention, by combining solid particle medium soft mould forming and backward drawing into one set of mould, the invention provides the forward-backward drawing and forming method for the metal plate soft mould which is simple in structure, is energy-saving and environmentally-friendly, and is formed once.

Owner:YANSHAN UNIV

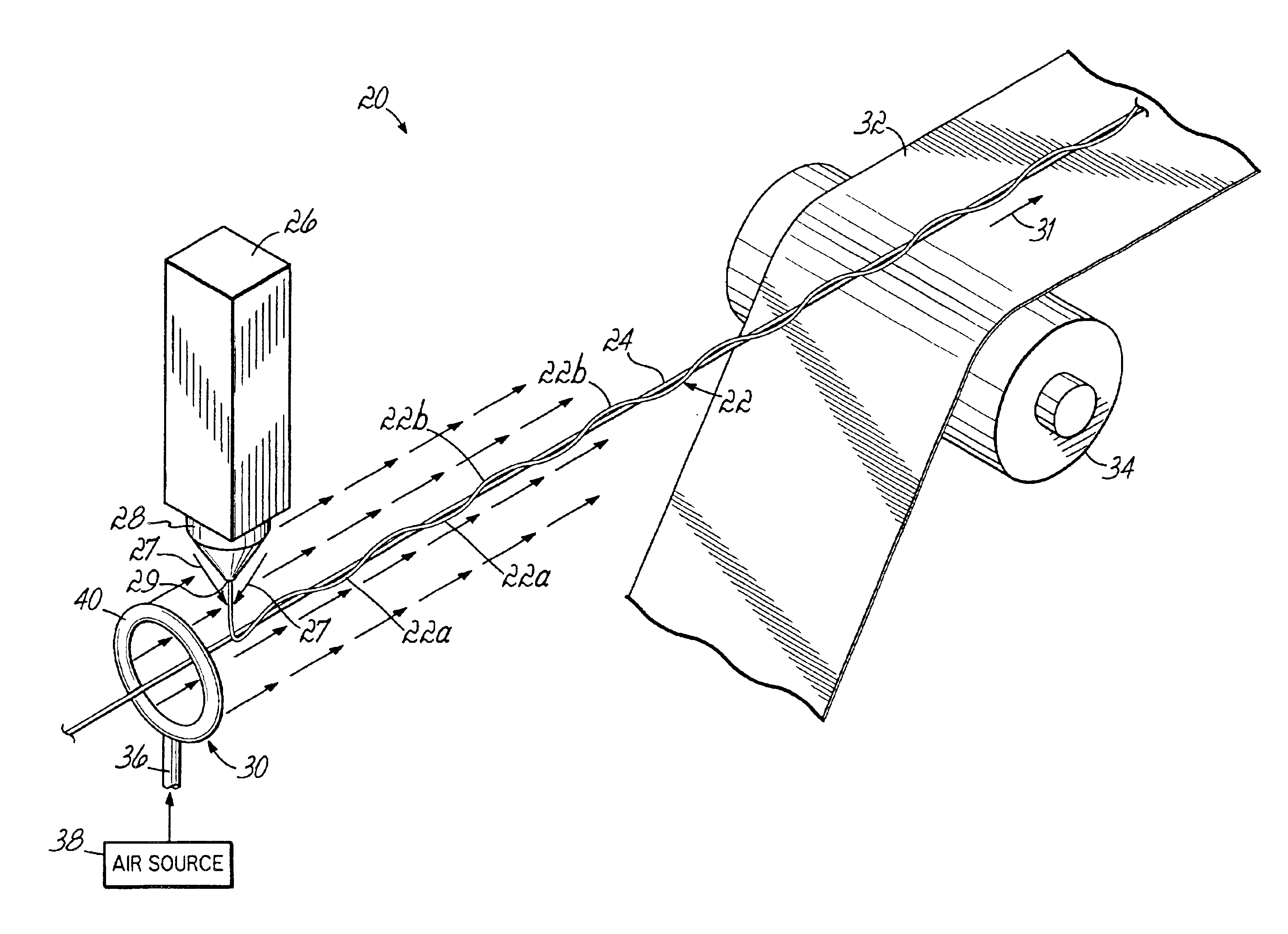

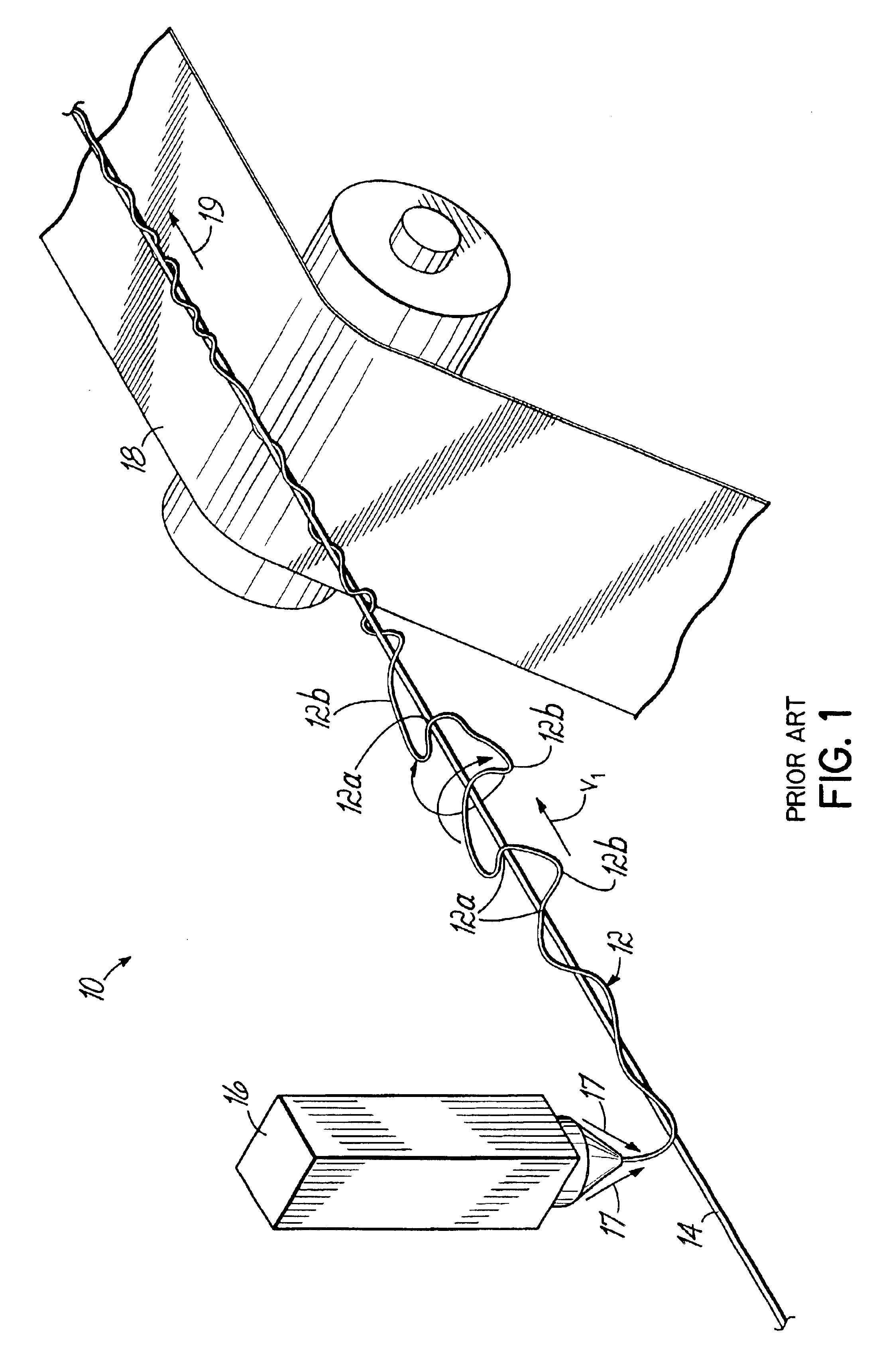

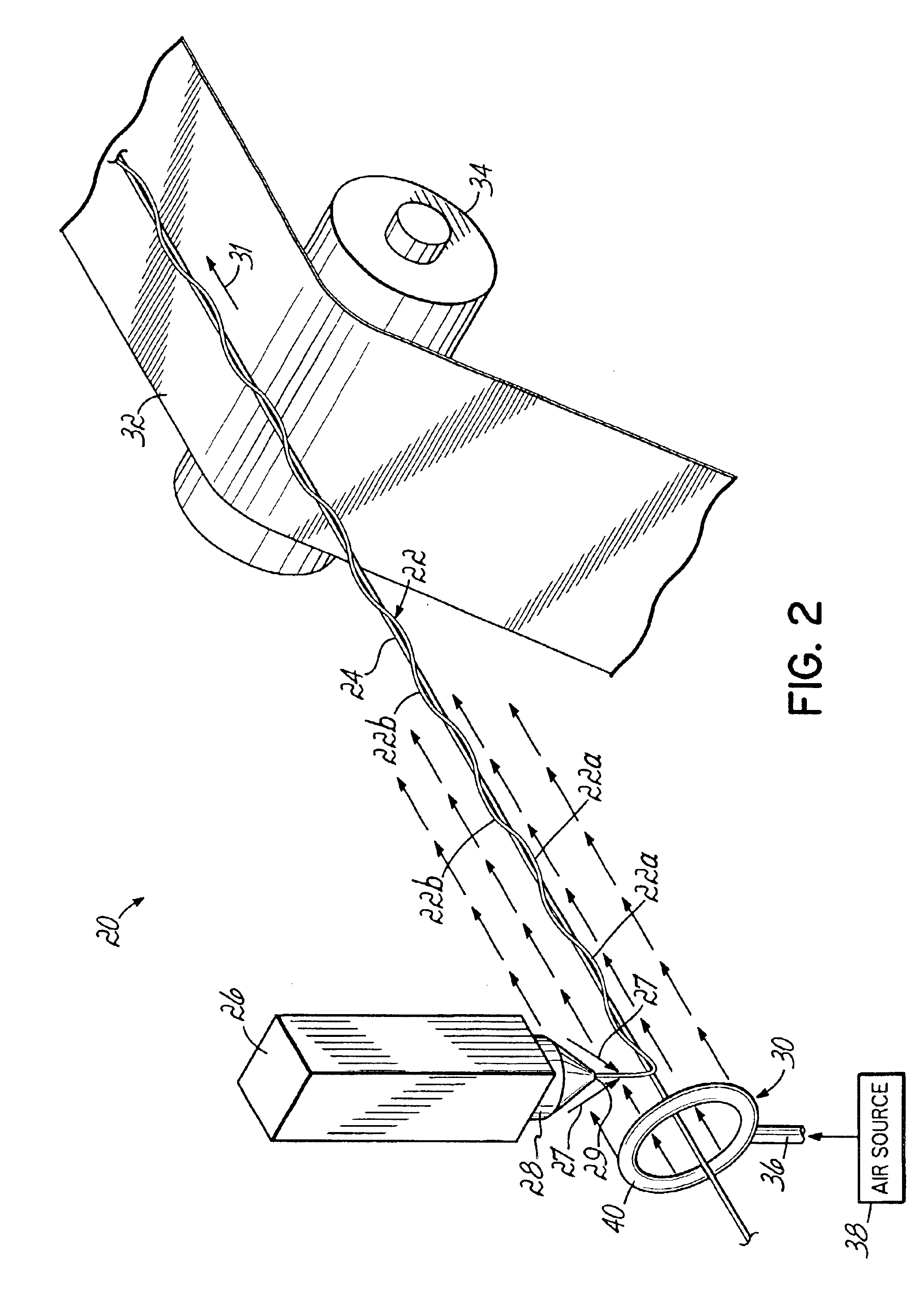

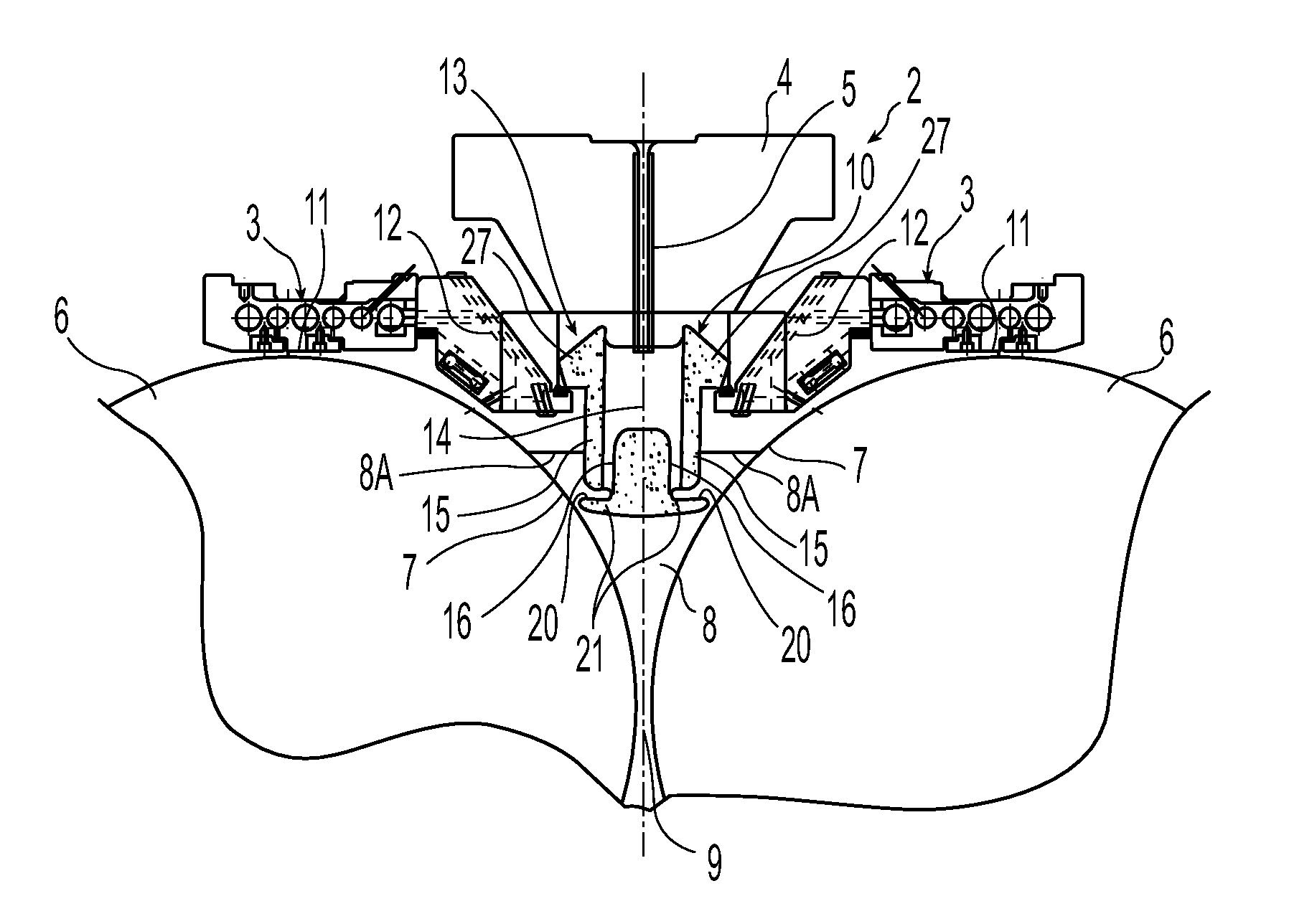

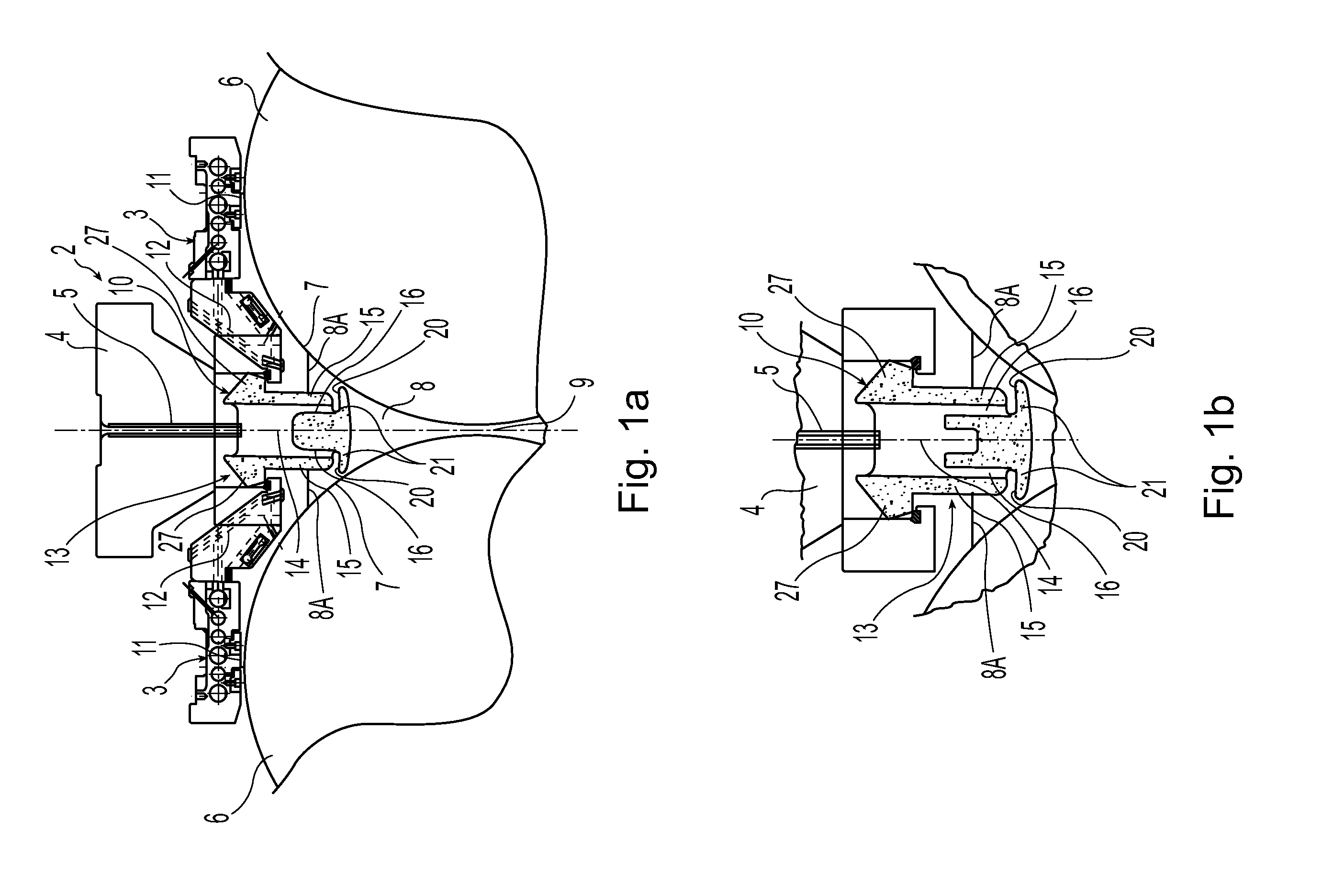

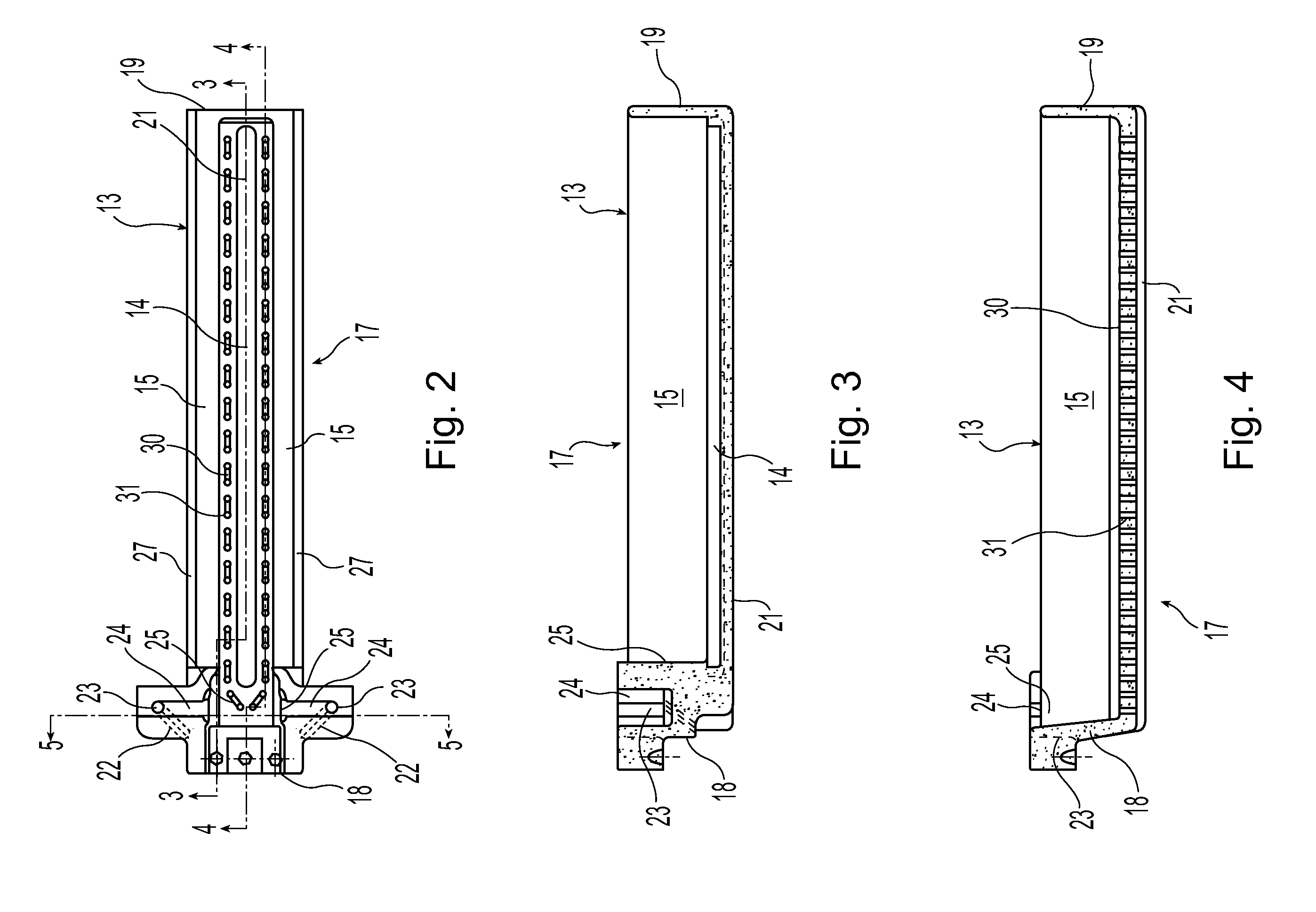

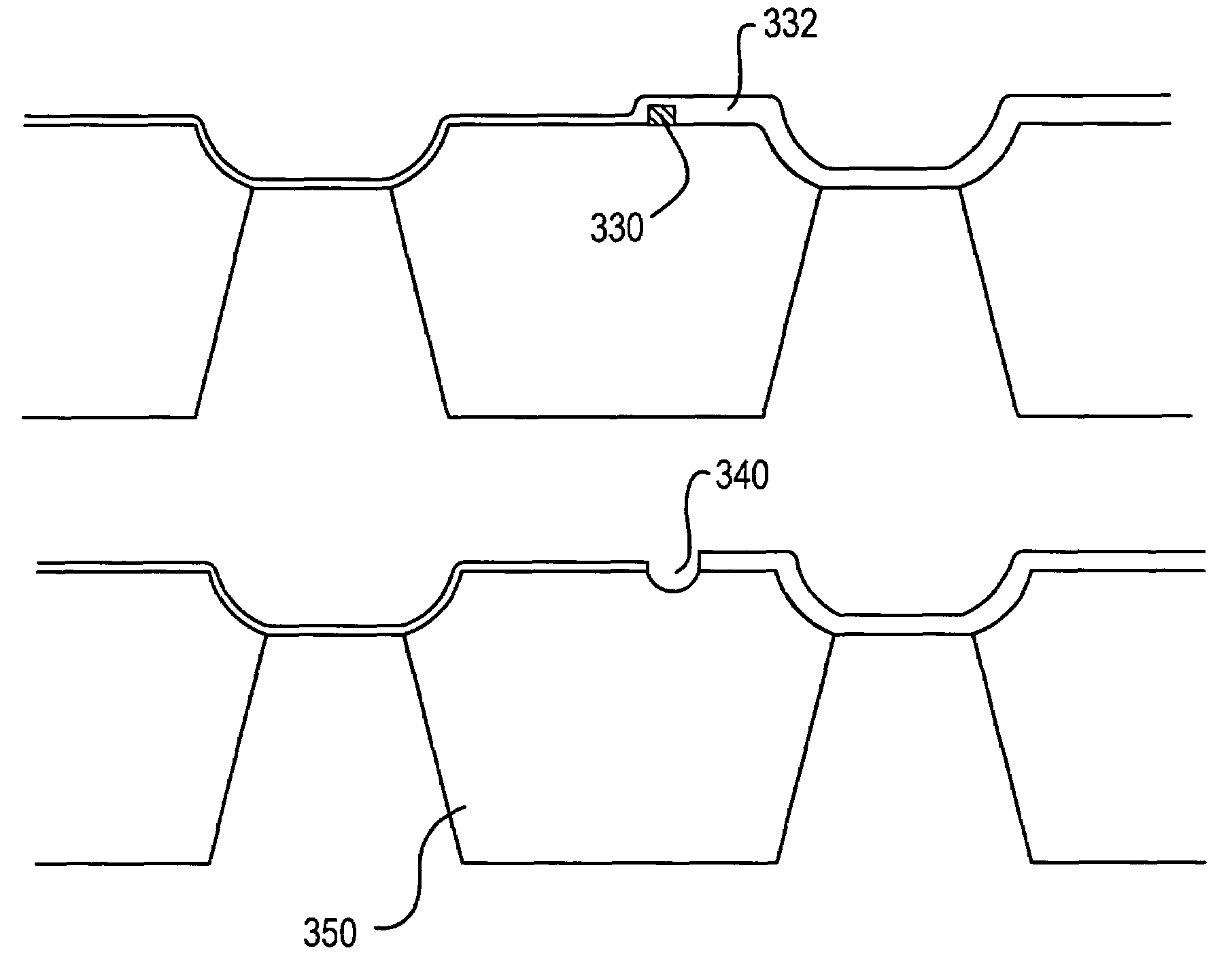

Apparatus and methods for applying adhesive filaments onto one or more moving narrow substrates

InactiveUS6905081B2Improve coating uniformityImprove uniformityLiquid surface applicatorsSpray nozzlesAdhesiveEngineering

Apparatus and methods for applying adhesive to one or more narrow substrates, such as elastic strands, that are in motion. The apparatus includes a coating applicator and an air moving device mounted adjacent to the coating applicator. The coating applicator is capable of applying adhesive in the form of an adhesive filament in a pattern onto each narrow substrate. The air moving device includes one or more air discharge passages capable of directing a flow of air toward the narrow substrate. The flow of air transfers momentum to airborne sections of the adhesive filament for promoting coating uniformity on the narrow substrate.

Owner:NORDSON CORP

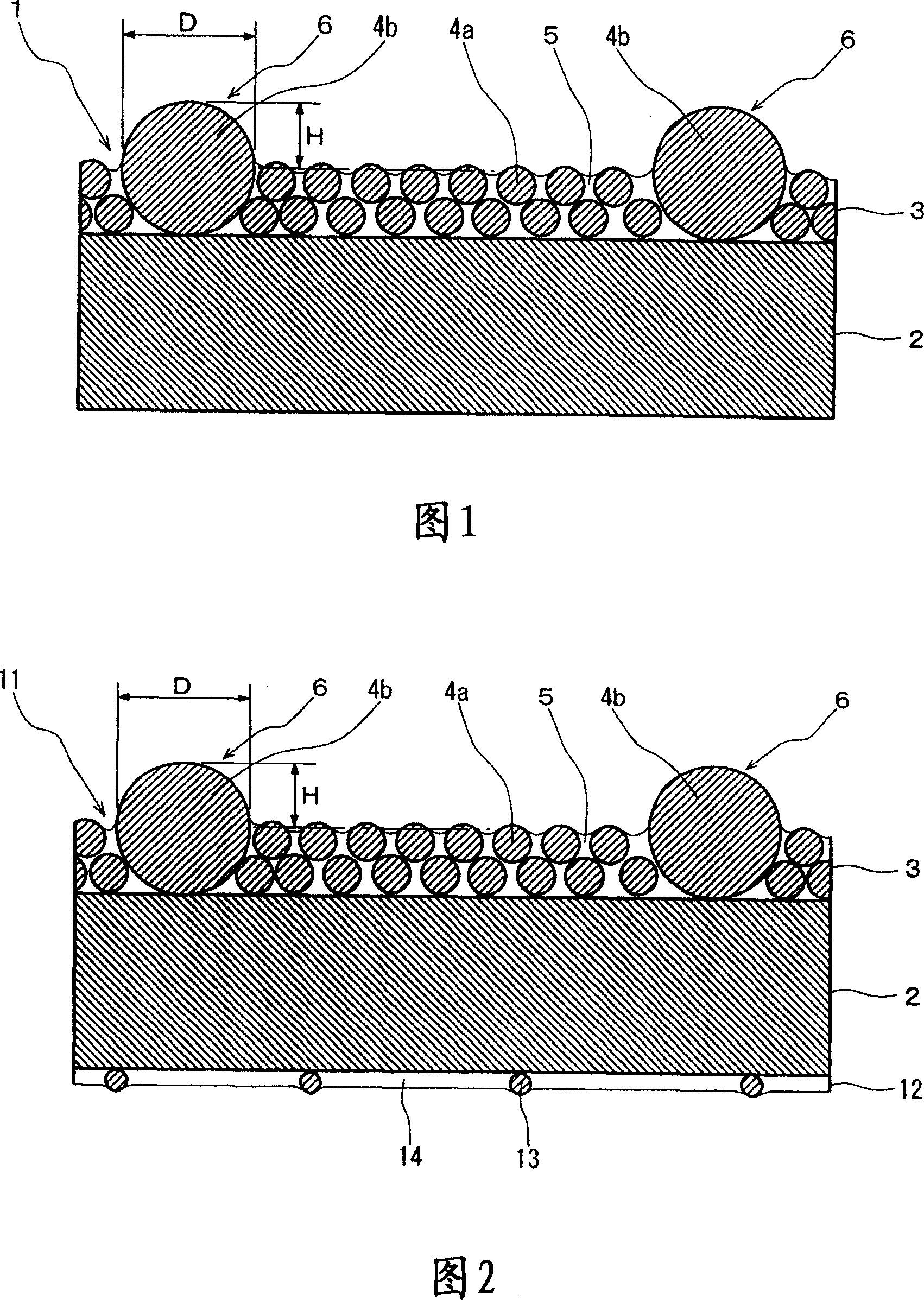

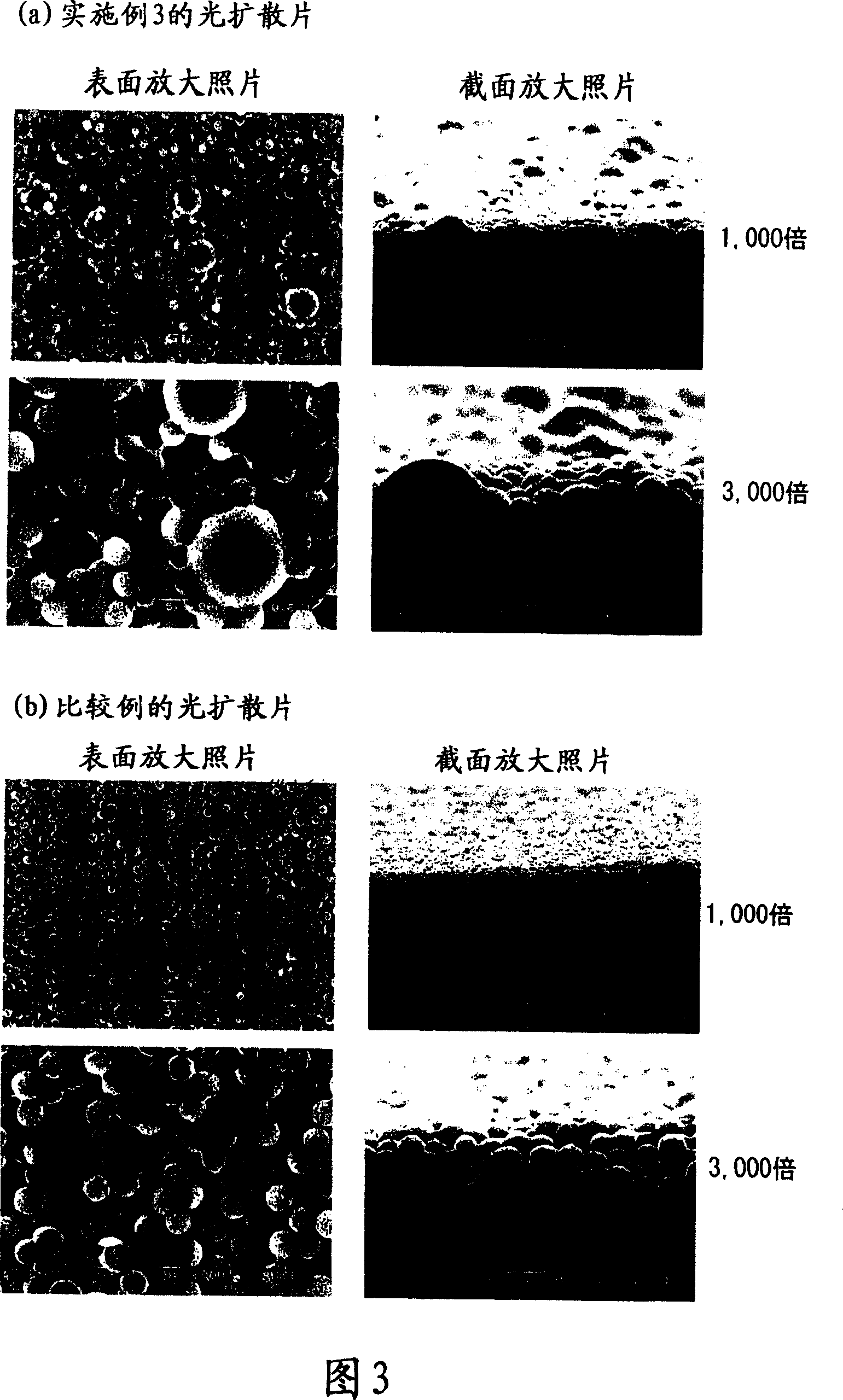

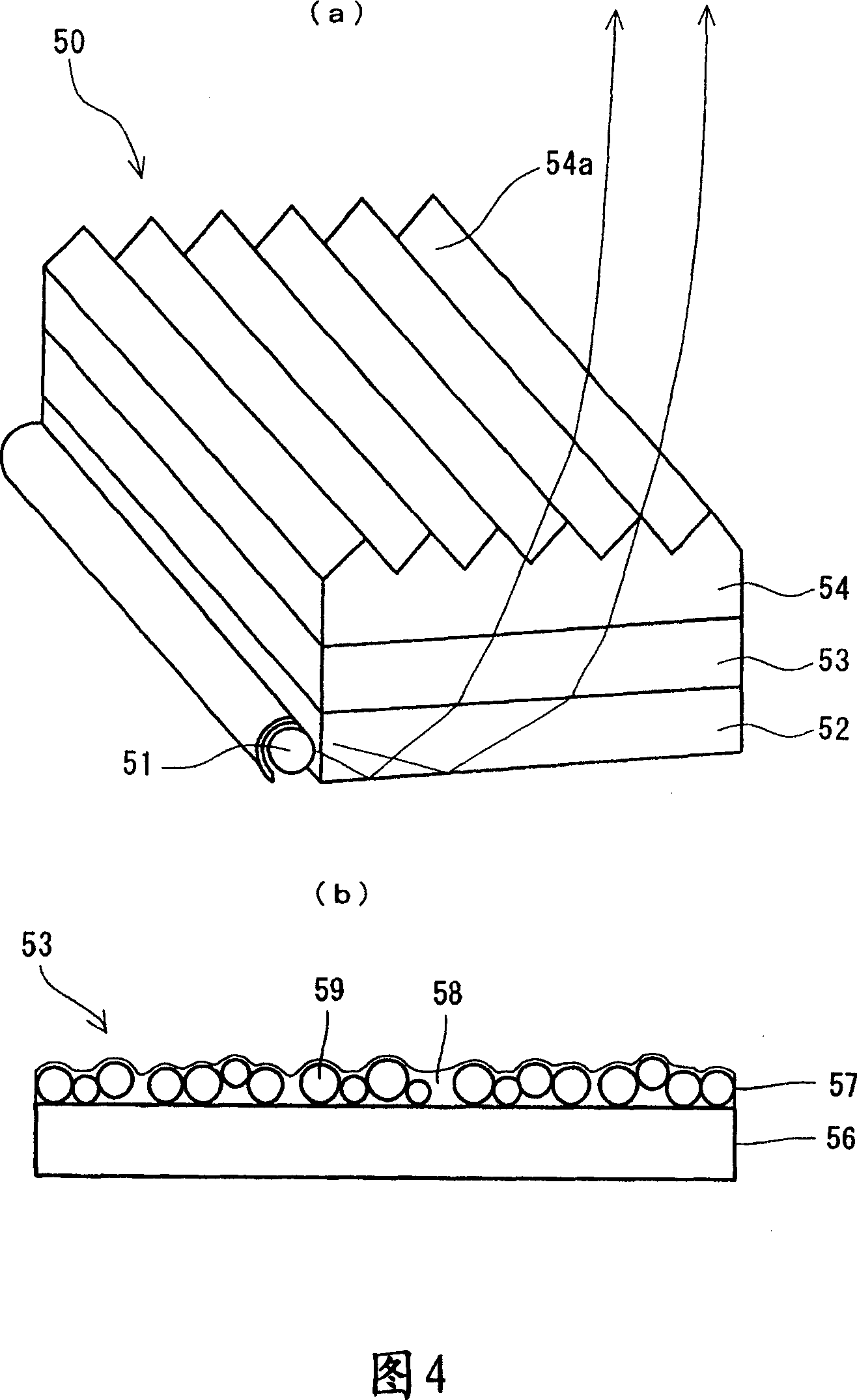

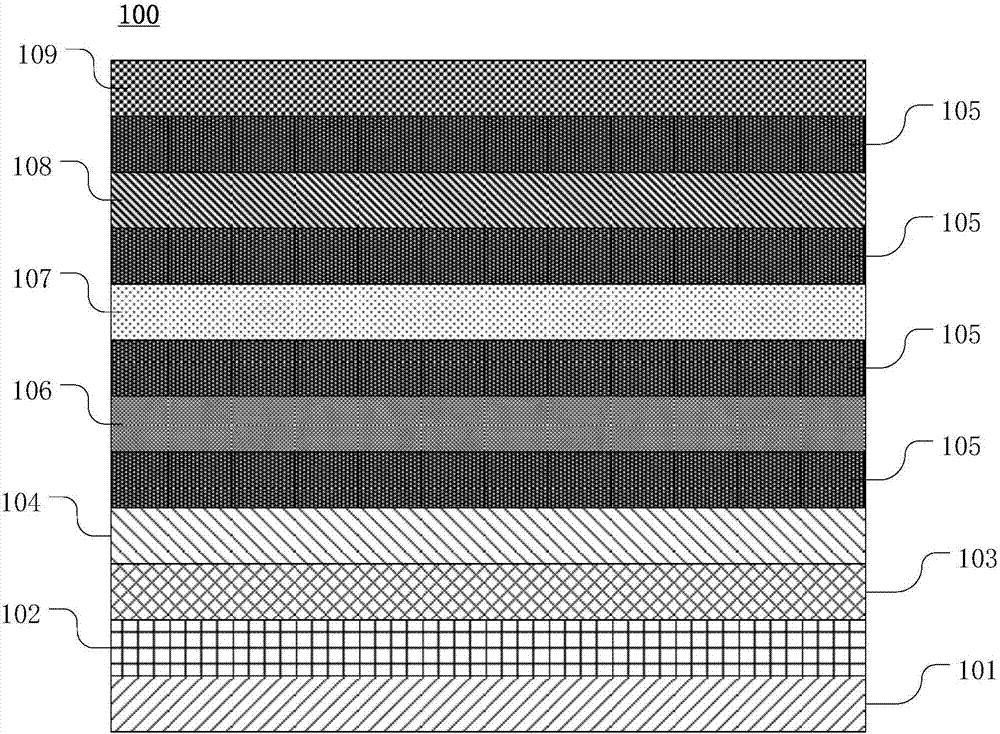

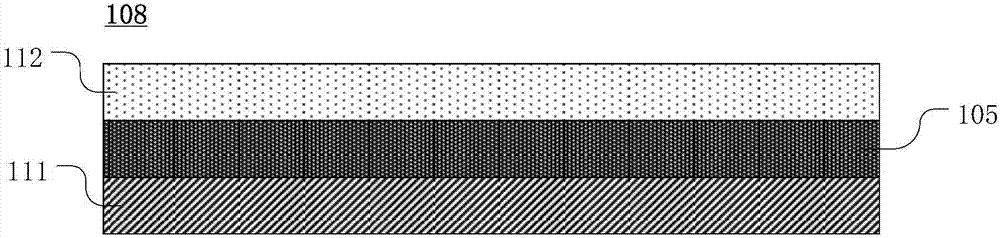

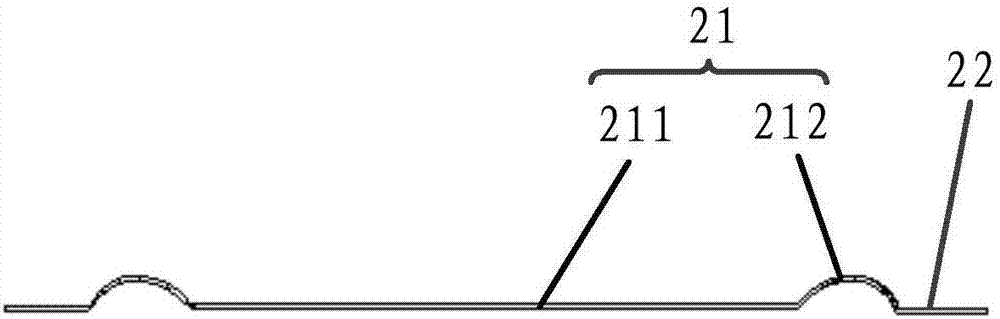

Light diffusion sheet and backlight unit using that

ActiveCN1971316AImprove resistance to damageLow costDiffusing elementsThin material handlingOccupancy rateDiffusion

An object of the present invention is to provide a light diffusion sheet having a favorable cost reduction capability due to excellent scratching preventive property of the front face, and having in addition thereto, a favorable directional light diffusion function, transmittivity of rays of light, and a thin film character; and a backlight unit capable of promoting performances such as luminance as well as price reduction, and thin and light modeling capability. The light diffusion sheet of the present invention has a light diffusion sheet including a transparent substrate layer, and a light diffusion layer overlaid on the front face side of the substrate layer, wherein the light diffusion layer has resin beads and a resin binder, characterized in that the light diffusion layer has protruding parts having a shape of a partial spherical body on the front face in a scattering manner. It is preferred that mean height of the protruding parts be 1 mum or greater and 10 mum or less, mean diameter of the protruding parts be 4 mum or greater and 18mum or less, mean occupancy rate of the protruding parts be 2% or greater and 20% or less, and surface roughness (Ra) of the light diffusion layer be 1.5 mum or greater and 10 mum or less. As the beads, small monodisperse beads as a principal component, and large beads as a sub component may be included.

Owner:KEIWA INCORPORATED

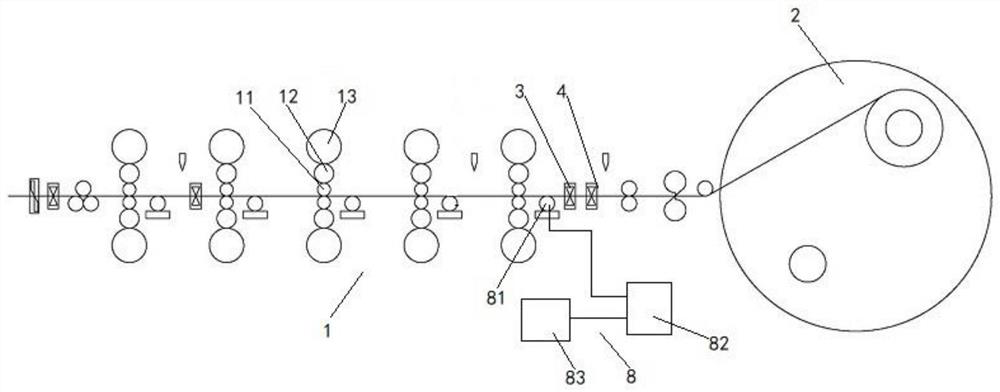

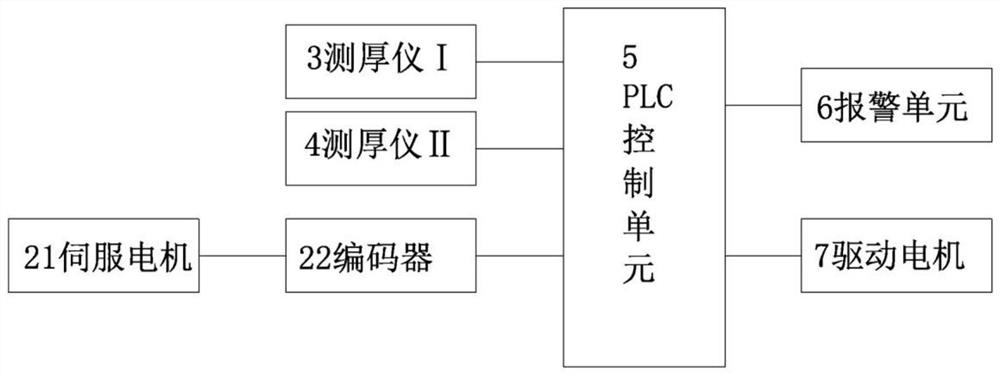

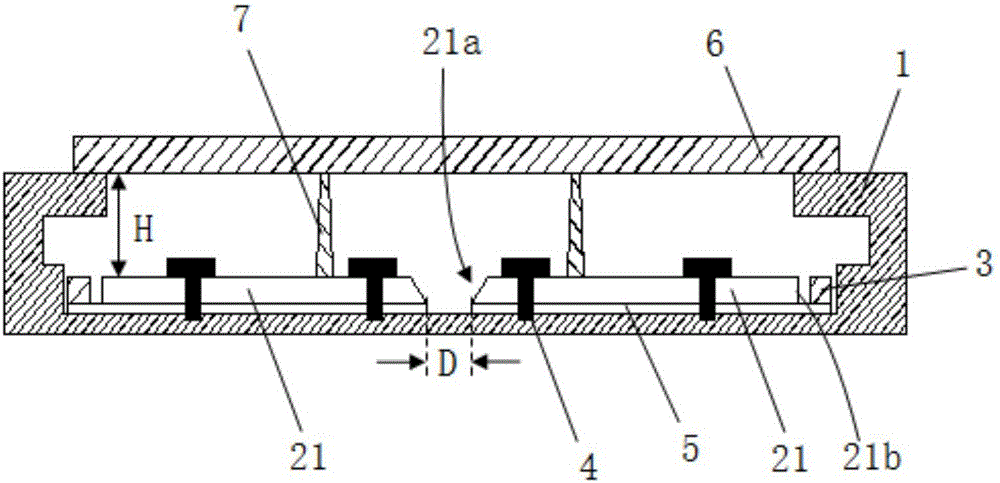

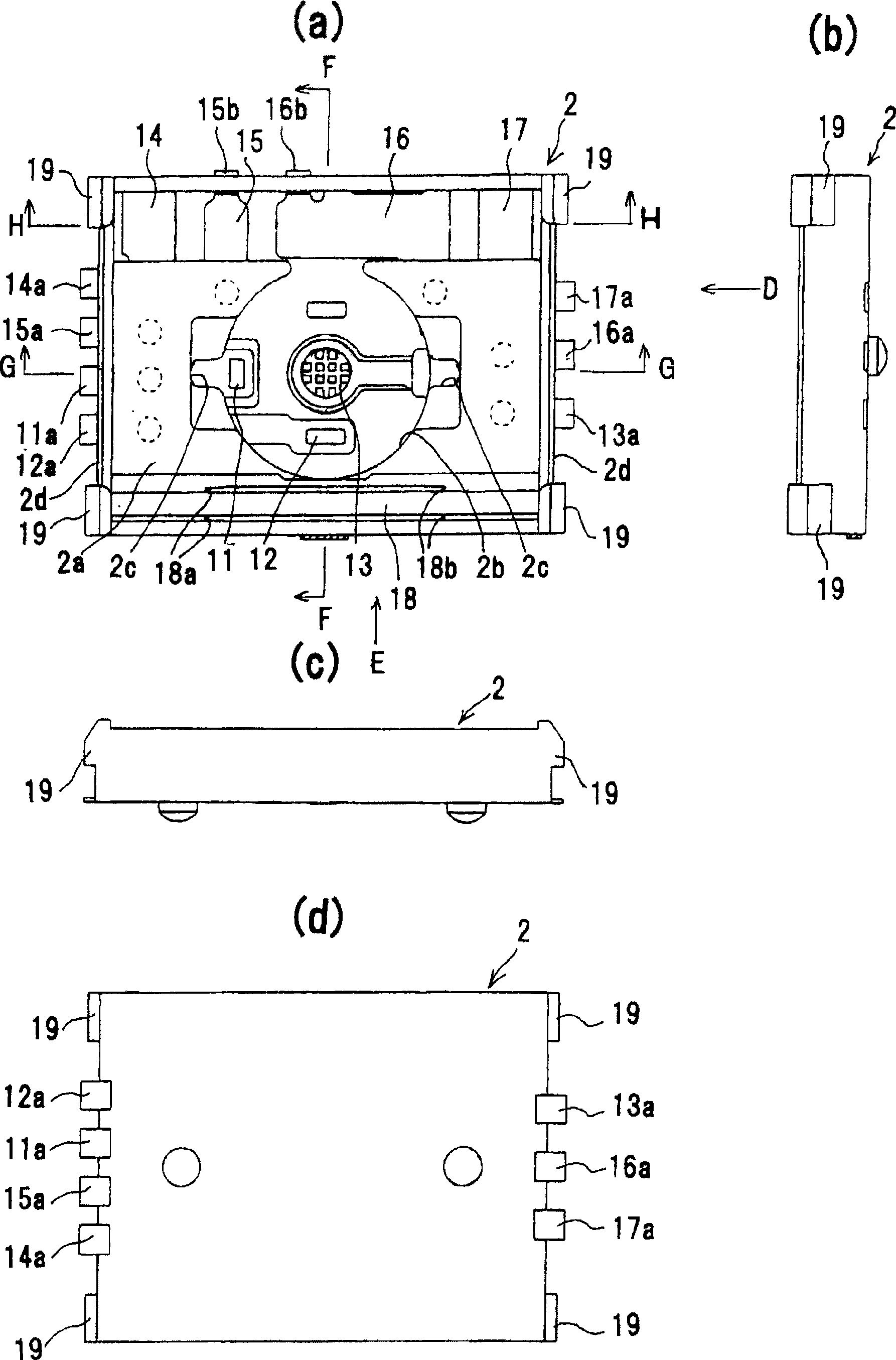

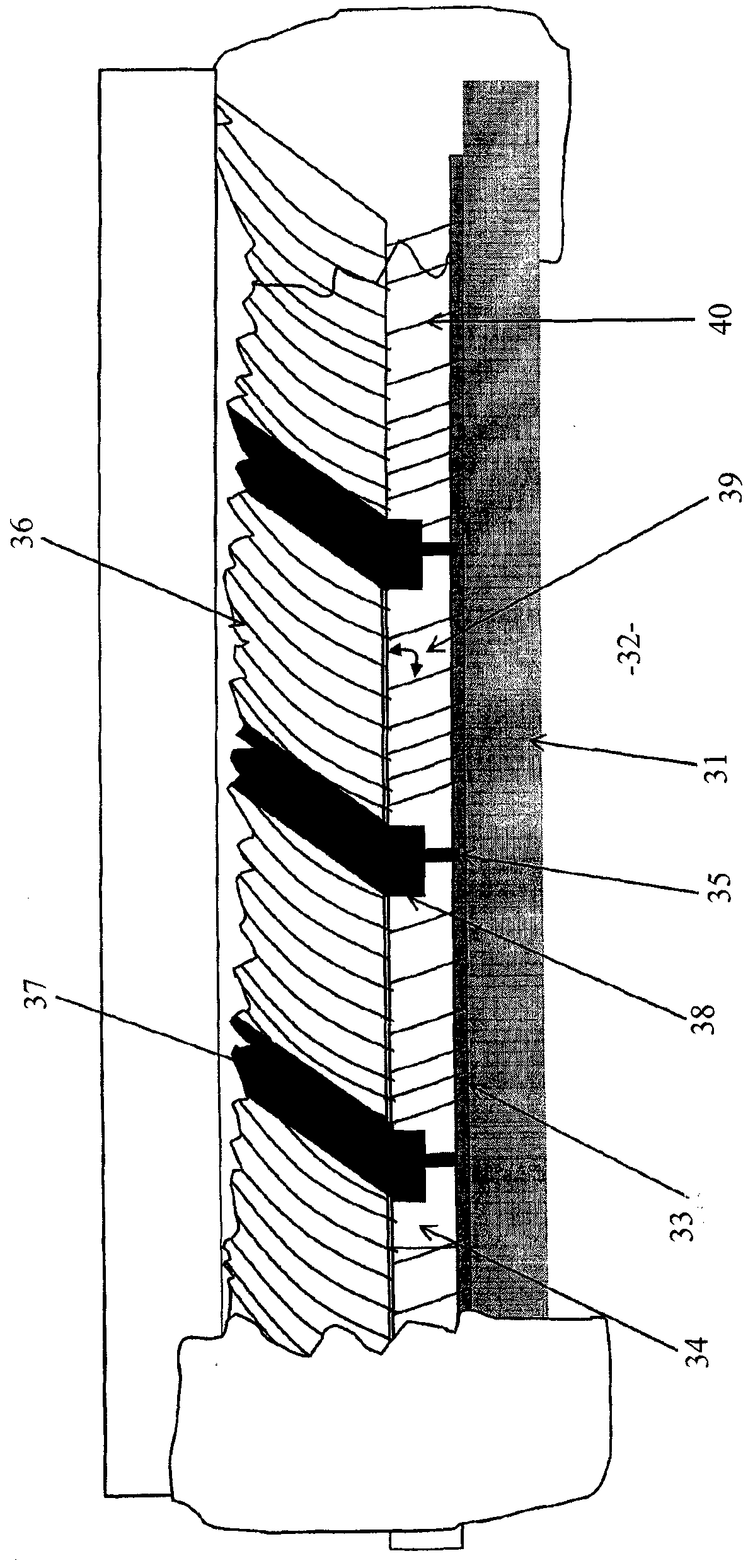

Non-oriented silicon steel cold continuous rolling device and thickness control method

PendingCN111604372AReduce contact pressureSmall amount of depressionMetal rolling stand detailsMeasuring devicesStrip steelMachine

The invention discloses a non-oriented silicon steel cold continuous rolling device and a thickness control method, and belongs to the technical field of non-oriented silicon steel cold rolling and forming. The non-oriented silicon steel cold continuous rolling device comprises a five-rack six-roller cold continuous rolling mill and a double-drum coiling machine, chamfers are correspondingly arranged at the end parts of intermediate rollers on each cold rolling unit of the five-rack six-roller cold continuous rolling mill, chamfers are correspondingly arranged at the end parts of working rollers of first, second and third cold rolling units of the five-rack six-roller cold continuous rolling mill, and the chamfering heights of the working rollers of the first cold rolling unit and the second cold rolling unit are correspondingly greater than the chamfering height of the working roller of the third cold rolling unit. The non-oriented silicon steel cold continuous rolling device has thebeneficial effects that the structure of the cold continuous rolling device and the process of cold continuous rolling are improved and optimized, the measuring accuracy of the longitudinal thicknessof strip steel is ensured, the control force of the transverse thickness of a non-oriented silicon steel strip is improved, the length of out of tolerance thickness of the steel strip head and tail isreduced, the edge thinning of the non-oriented silicon steel strip is reduced, and the qualification rate of longitudinal thickness and transverse thickness of the steel strip is increased.

Owner:新余钢铁股份有限公司

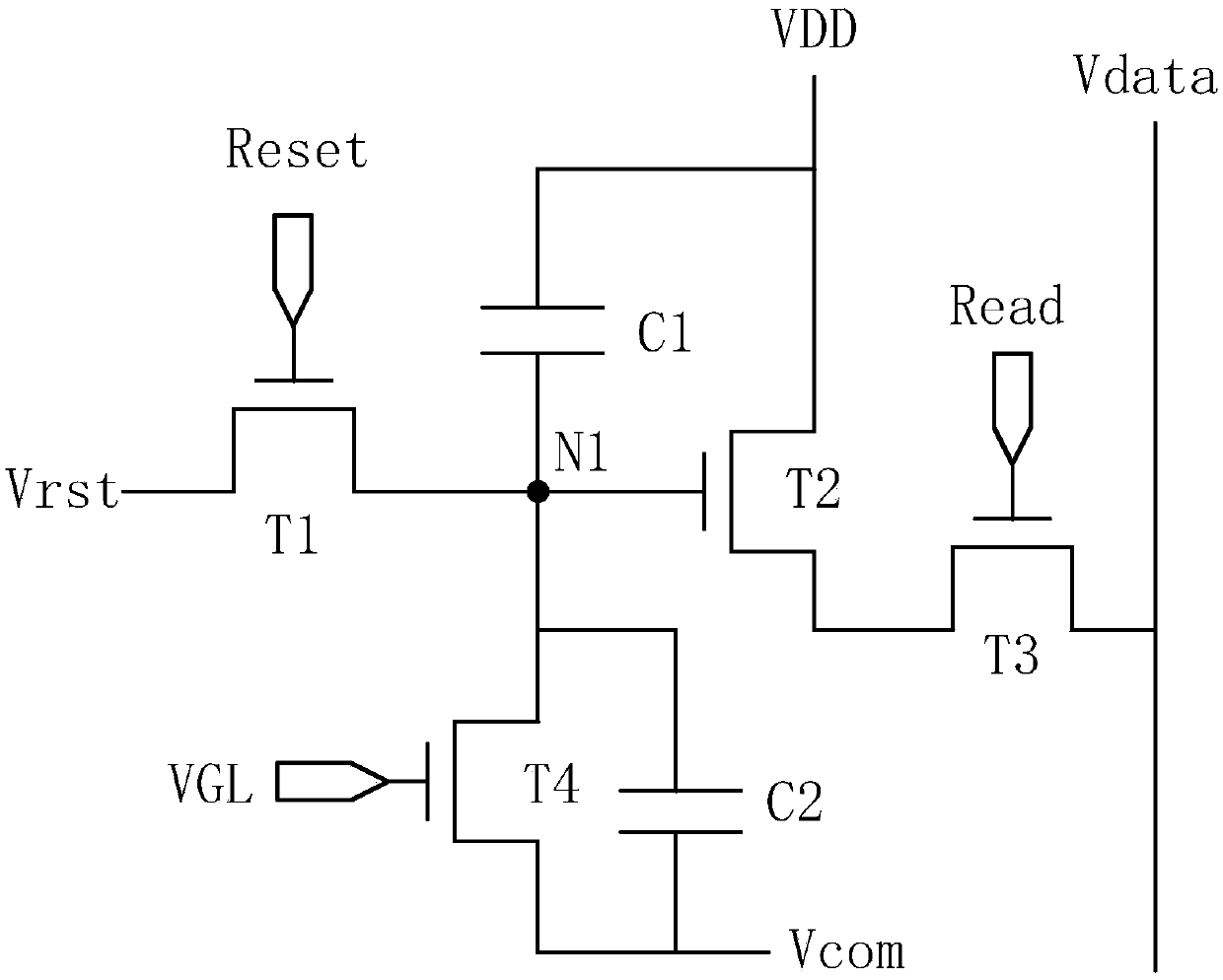

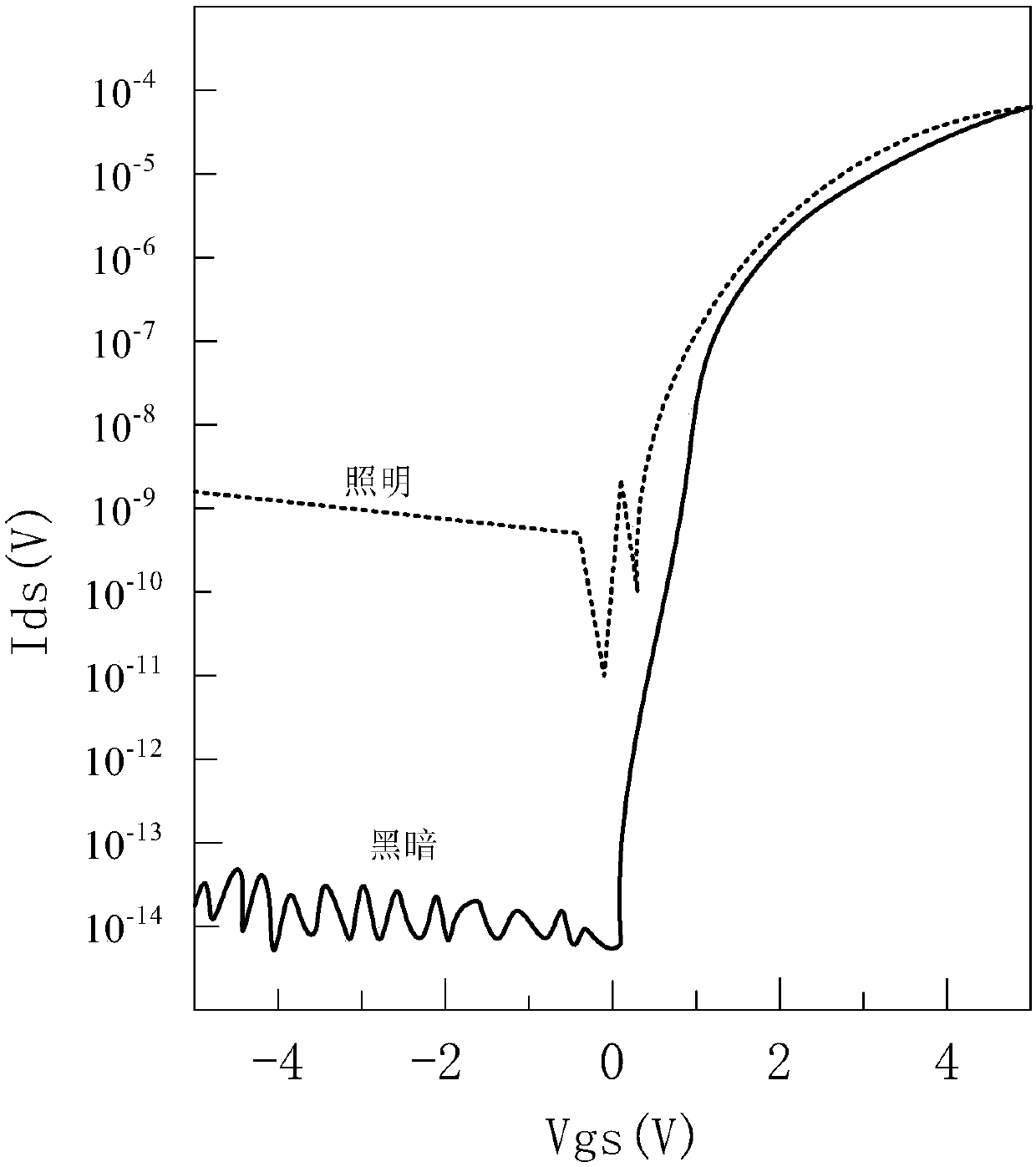

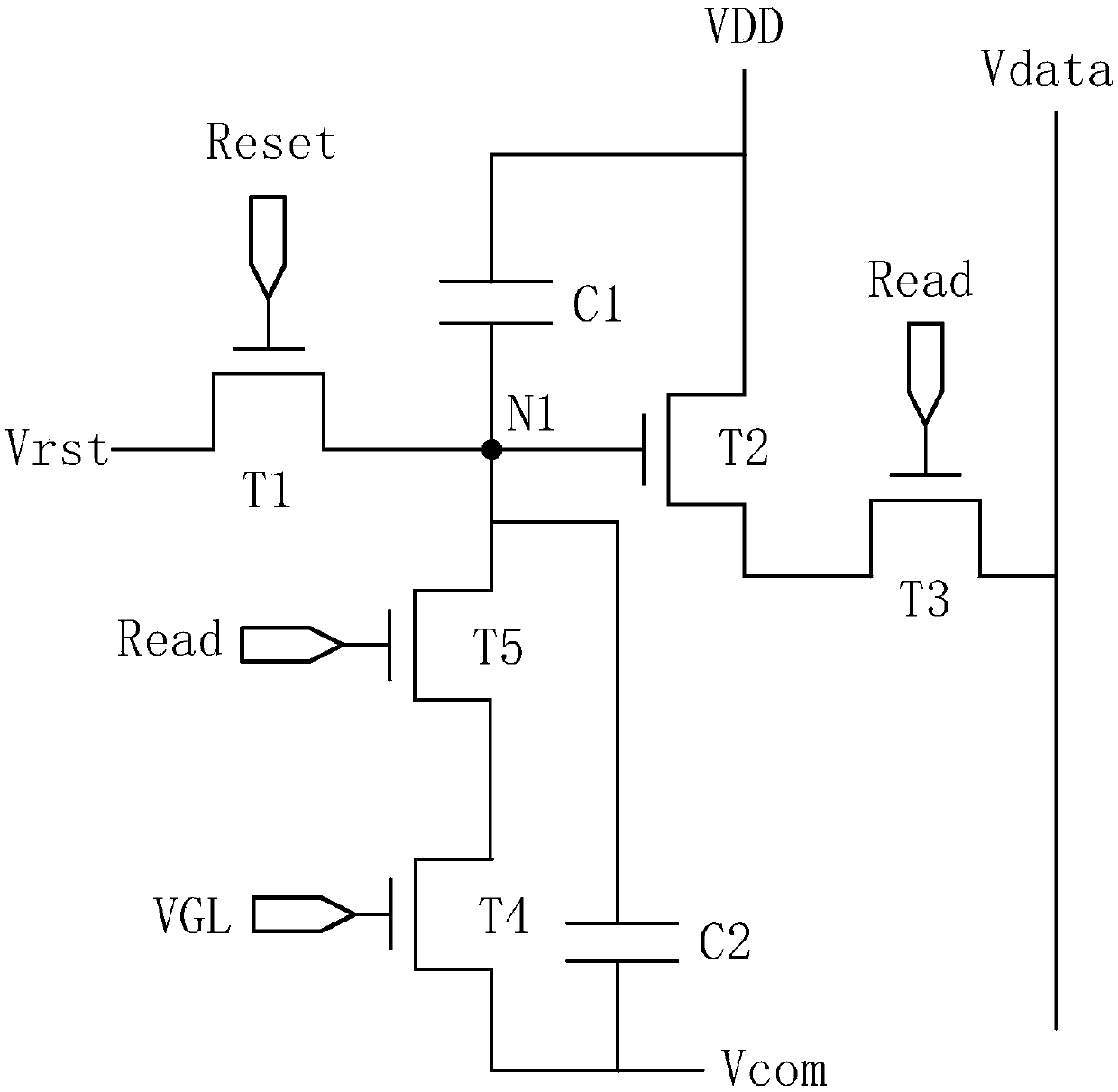

Light sensing circuit and driving method thereof, display panel and display device

ActiveCN109686301AFacilitate thinningSensitive to lightStatic indicating devicesElectricityLight sensing

The invention discloses a light sensing circuit and a driving method thereof, a display panel and a display device, belonging to the technical field of display. The light sensing circuit comprises that: the gate of a first transistor is electrically connected to a first control terminal, the first pole is electrically connected to a first voltage terminal, and the second pole is electrically connected to a first node; the gate of a second transistor is electrically connected to the first node, the first pole is electrically connected to a second voltage terminal, and the second pole is electrically connected to the first pole of a third transistor; the gate of the third transistor is electrically connected to a second control terminal, and the second pole is electrically connected to a data line; the gate of a fourth transistor is electrically connected to a third control terminal, the first pole is coupled to the first node, and the second pole is electrically connected to a third voltage terminal; the first transistor and the fourth transistor comprise active layers formed of metal oxide, and the fourth transistor is multiplexed into a light sensing element; and the second transistor and the third transistor comprise active layers formed of polysilicon. Compared with the prior art, the invention is advantageous to reduce the process steps and thin the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

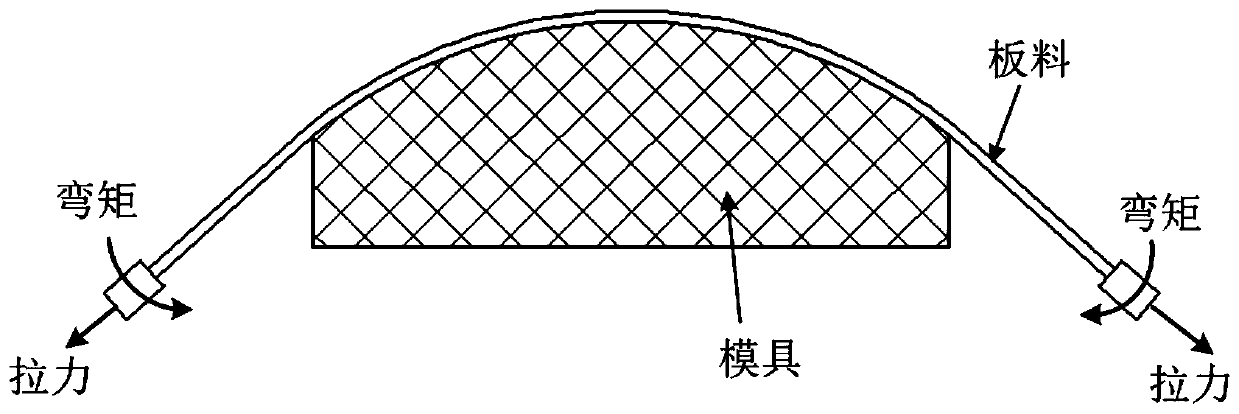

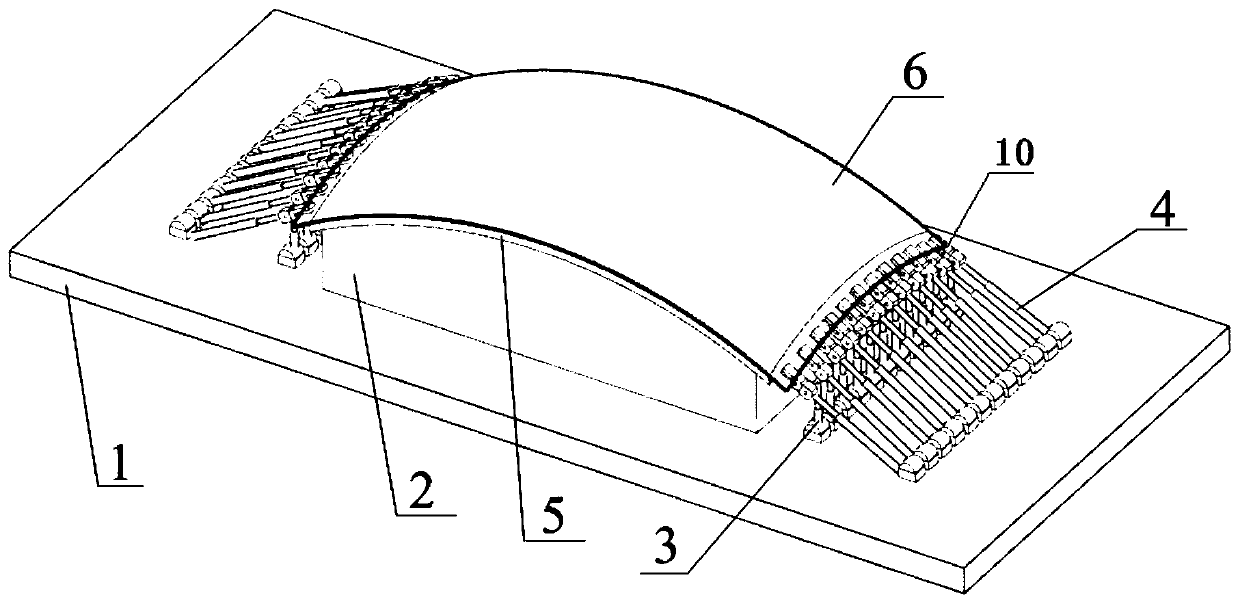

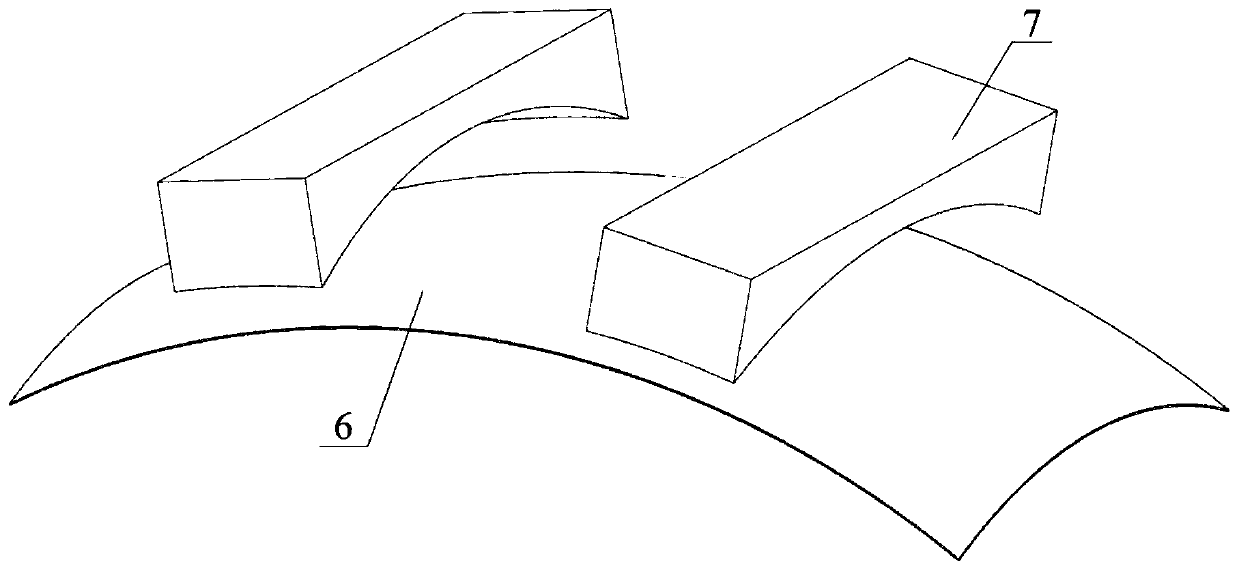

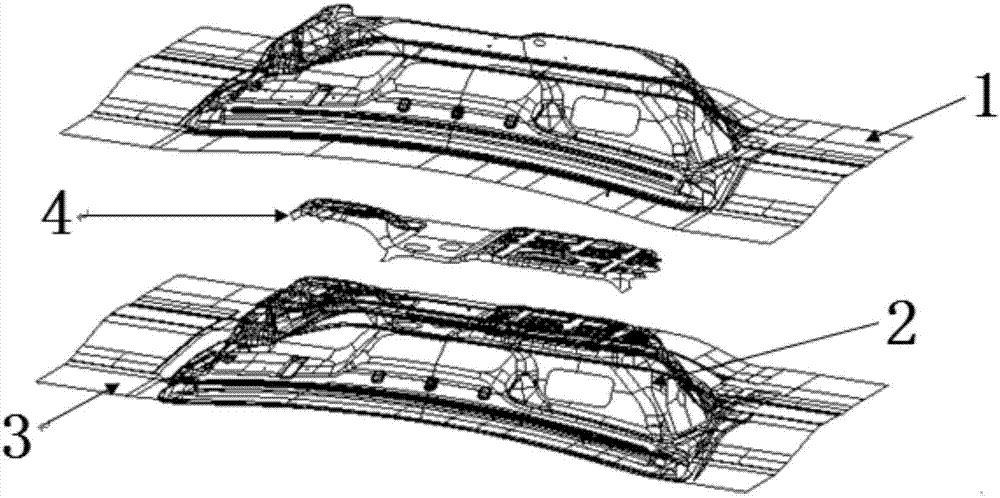

Stretch forming-electromagnetism composite forming device and method for multi-curvature skin piece

ActiveCN111167919ARaise the forming limitIncrease the tensile stressShaping toolsEngineeringElectromagnetic forming

The invention discloses a stretch forming-electromagnetism composite forming device and method for a multi-curvature skin piece. The stretch forming-electromagnetism composite forming device comprisesa bottom plate, a mold and an electromagnetic coil used for forming a plate on the mold, the mold is mounted on the bottom plate, and the electromagnetic coil is arranged above the mold. The stretchforming-electromagnetism composite forming device is characterized in that the stretch forming-electromagnetism composite forming device further comprises a vertical oil cylinder, a tangential oil cylinder, and a chuck used for clamping the edge of the plate, one end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the bottom plate, and the other end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the chuck. A stretch forming and discharging composite process is adopted, stretch forming is conducted to solve a certainspringback problem, then remaining springback is eliminated through electromagnetic force, in this way, the thickness reduction of the plate can meet the design requirement, and meanwhile the requirement for electromagnetic forming energy can also be greatly lowered.

Owner:CENT SOUTH UNIV

Touch display panel and touch display device

ActiveCN107037906AReduce reflectionIncreased anti-reflection performanceInput/output processes for data processingDisplay deviceOptical film

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

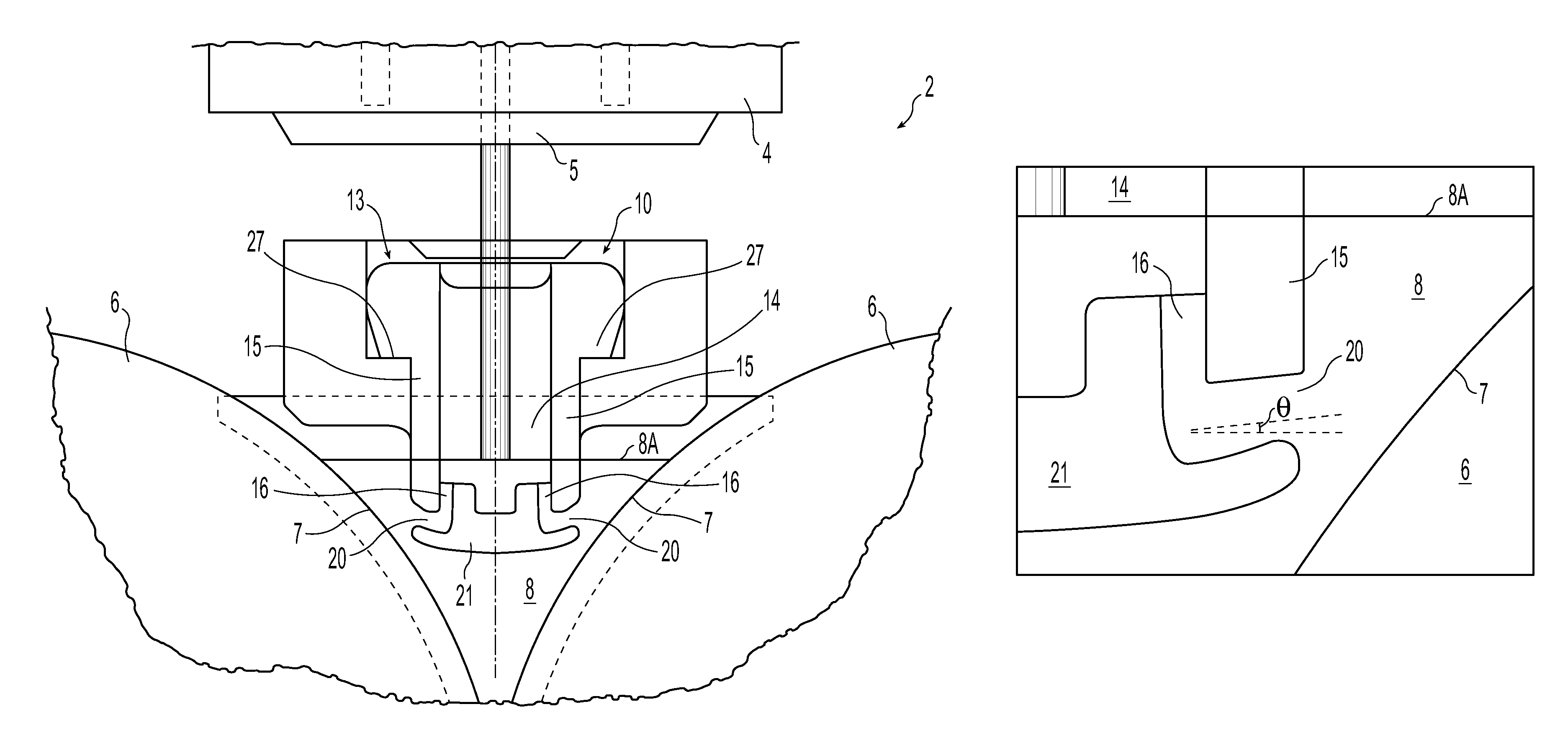

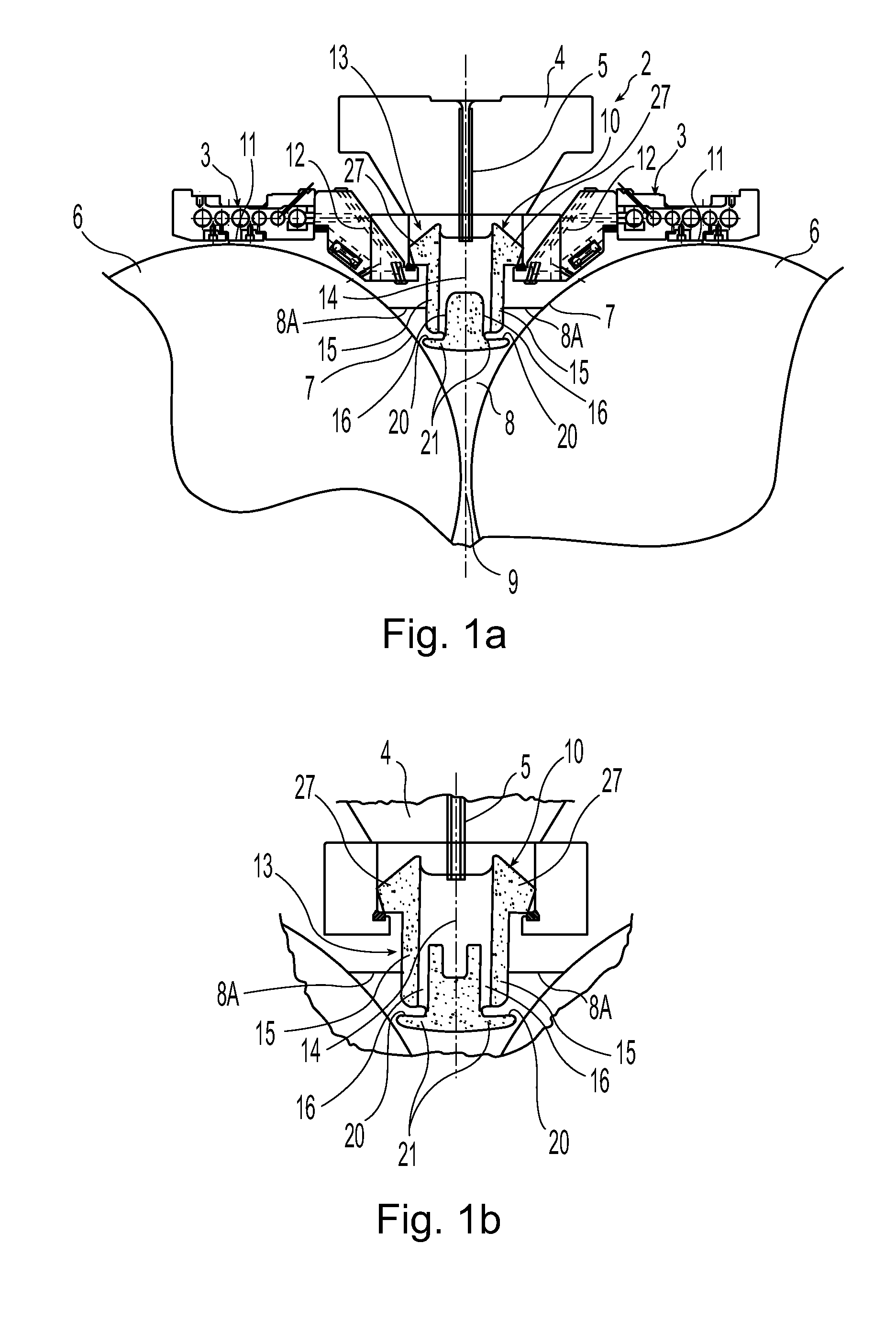

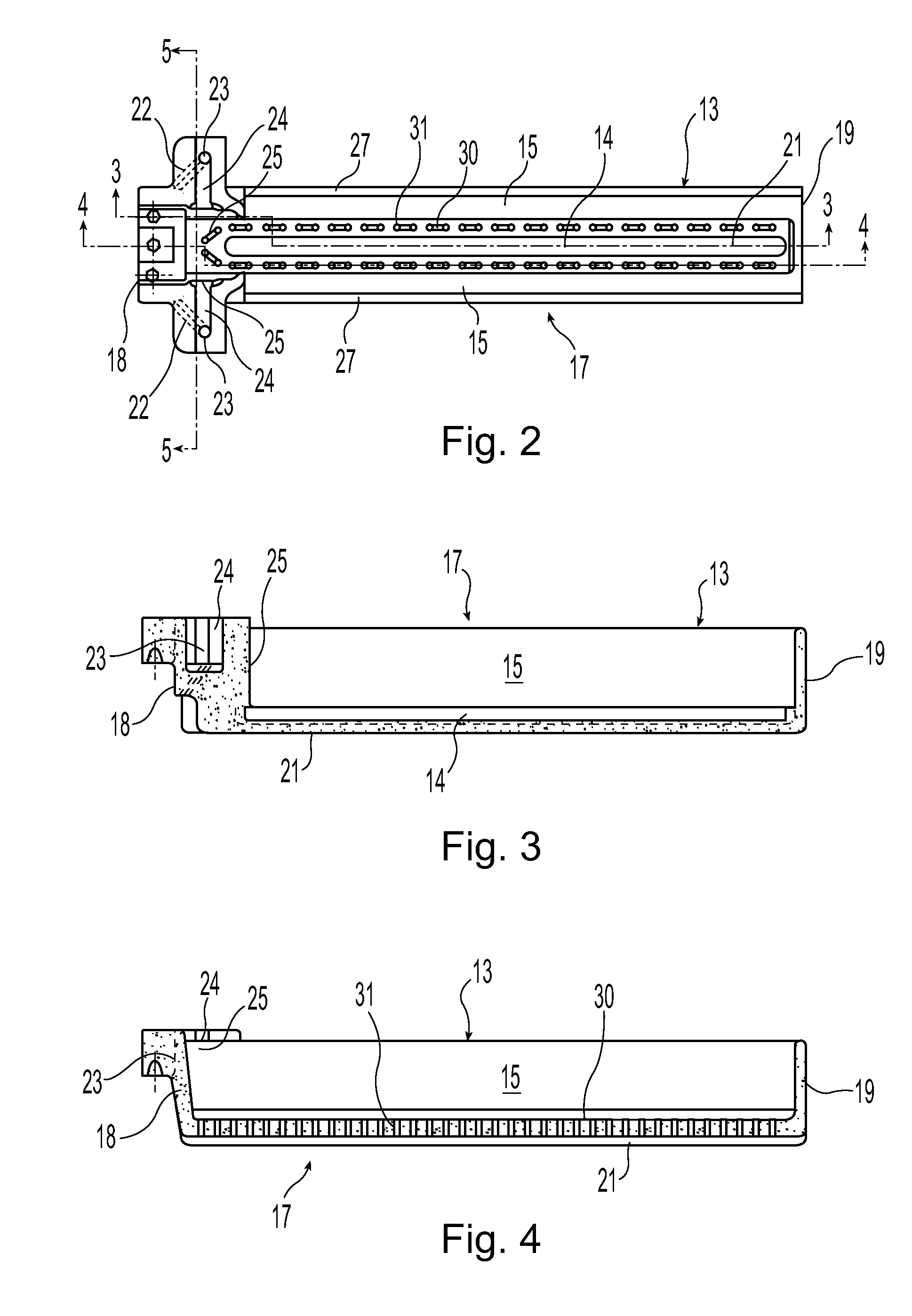

Casting delivery nozzle

A metal delivery apparatus for casting metal strip includes at least one elongated segment having a main portion extending longitudinally through the main portion with end walls at opposite ends thereof, the main portion communicating with outlets along opposite sides of each segment adapted to upwardly discharge flow of molten metal into a casting pool.

Owner:NUCOR CORP

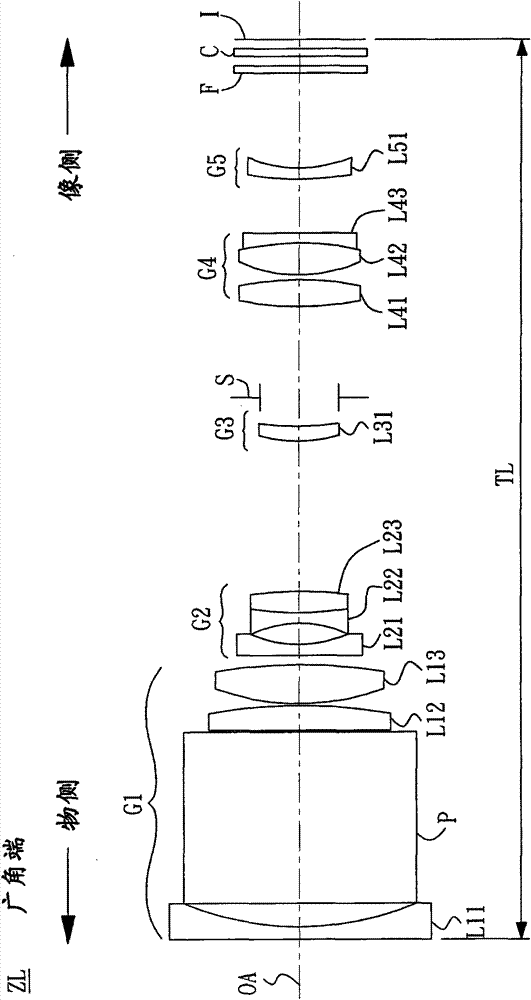

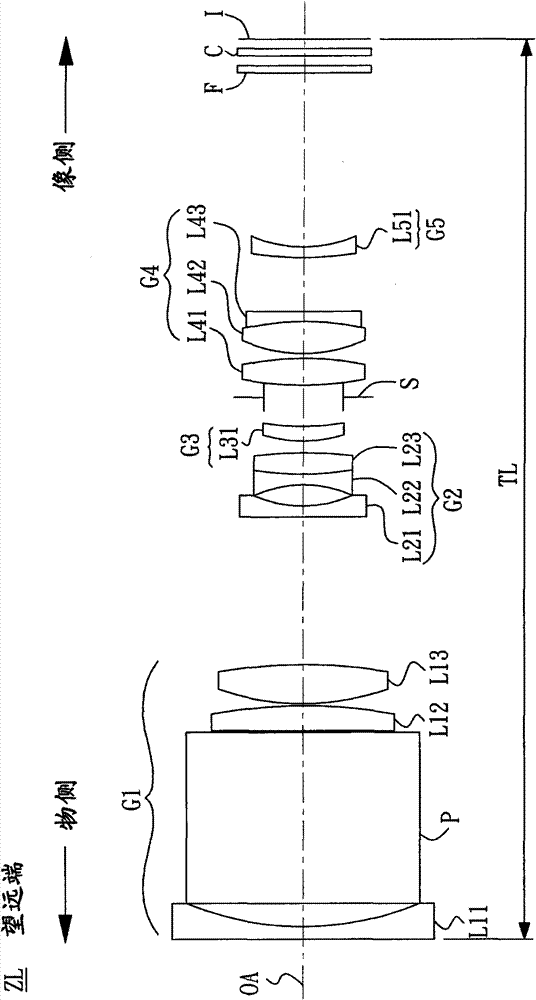

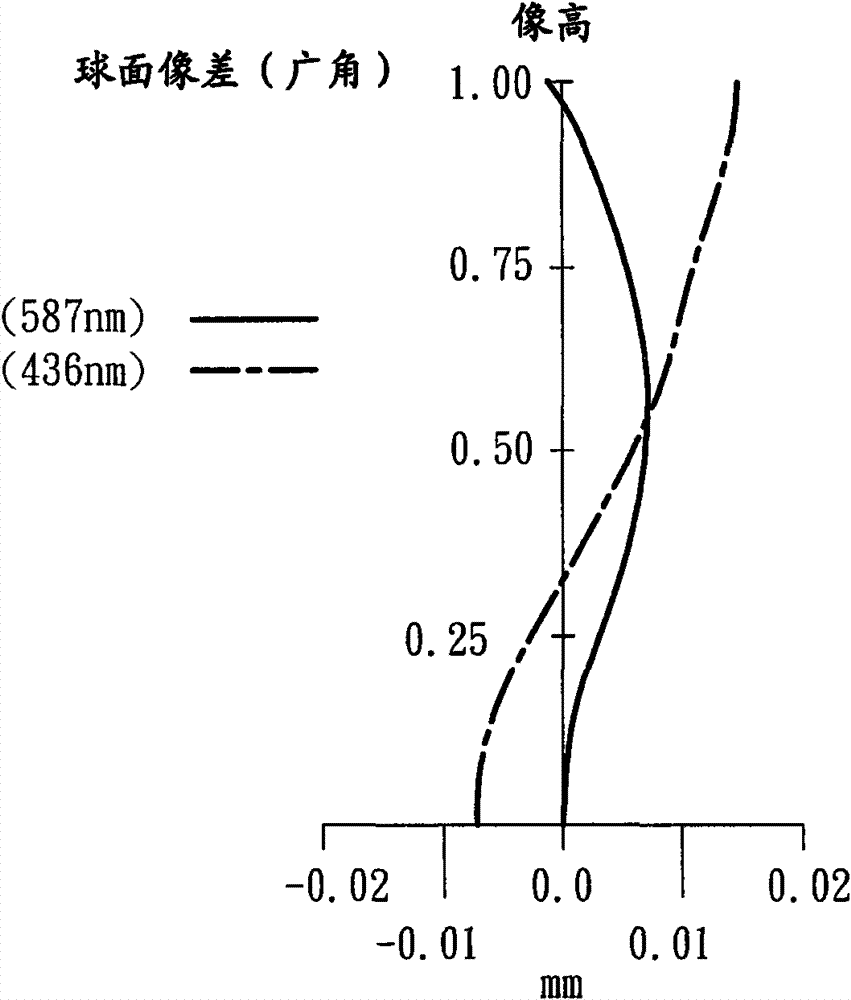

Zoom lens

The invention relates to a zoom lens. From an object side to an image-forming side, the zoom lens mainly comprises a first lens group with a positive diopter, a second lens group with a negative diopter, a third lens group with the positive diopter, a fourth lens group with the positive diopter, and a fifth lens group with the negative diopter, wherein the second lens group, the fourth lens group and the fifth lens group move relative to each other to make the zoom lens focusing between a wide-angle end and a telephoto end.

Owner:ABILITY ENTERPRISE CO LTD

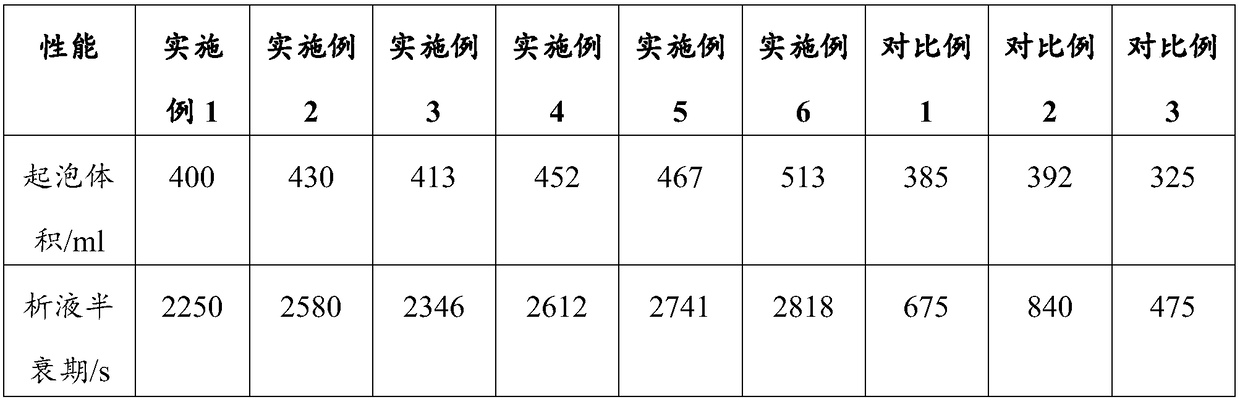

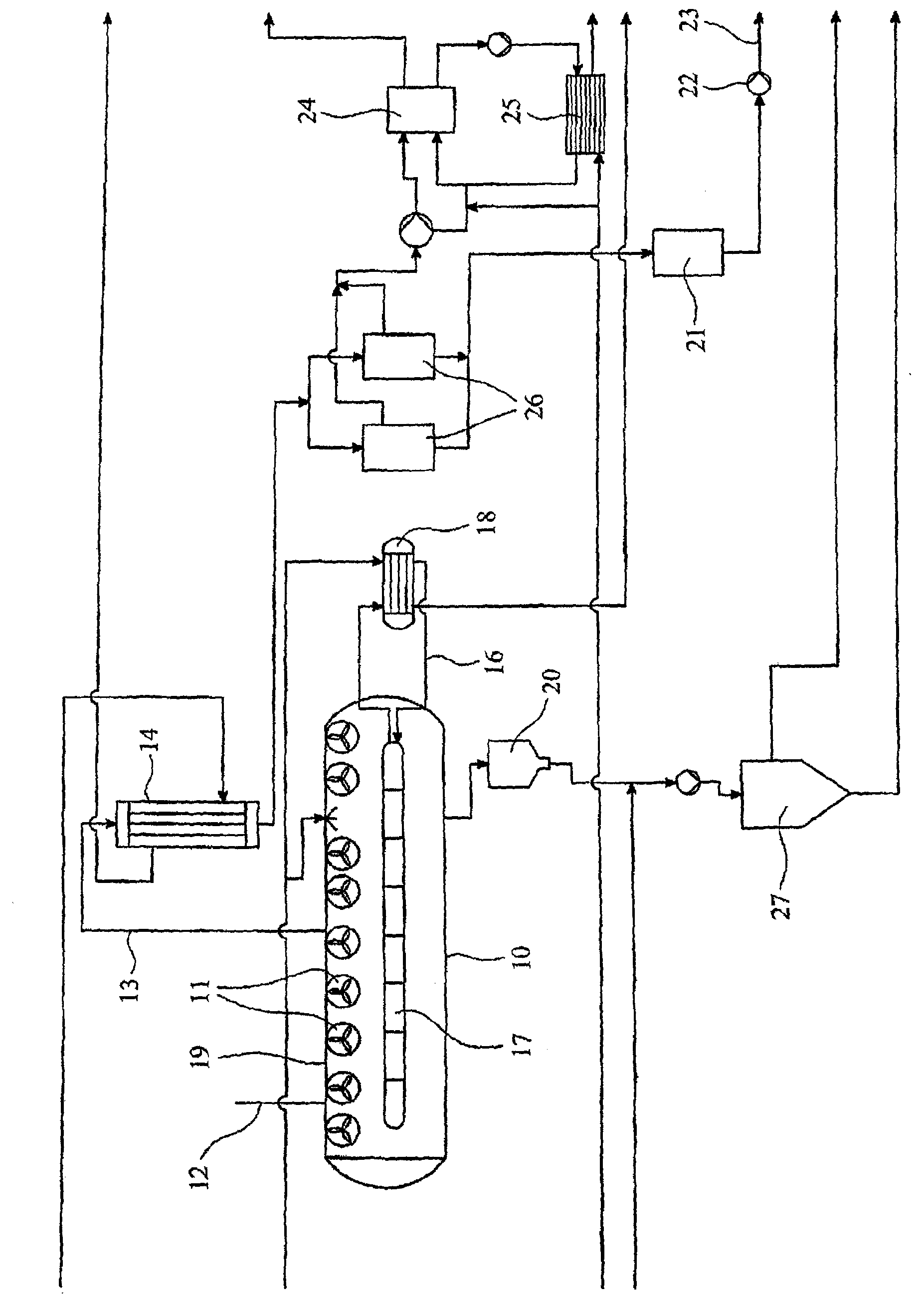

Enhanced foam system based on graphite particle synergistic stability, and preparation method thereof

ActiveCN108165248AHigh mechanical strengthReduce thinningDrilling compositionSurface-active agentsSolvent

The invention discloses an enhanced foam system based on the graphite particle synergistic stability, and a preparation method thereof, which belong to the technical field of oil-gas field developmentengineering. The enhanced foam system based on the graphite particle synergistic stability is prepared from the following components in percentage by mass concentration: 0.3 to 1 percent of anionic surface active agent, 0.2 to 1 percent of cationic surface active agent, 0.5 to 1 percent of graphite particle, and the balance of solvent supplementing to 100 percent. The anionic surface active agentis hexadecyl trimethyl ammonium bromide. The enhanced foam system provided by the invention is simple in preparation process, can be quickly prepared in a large scale, and is suitable for a foam system applied to an oil and gas well, is capable of remarkably improving the recovery ratio, and is environmentally friendly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

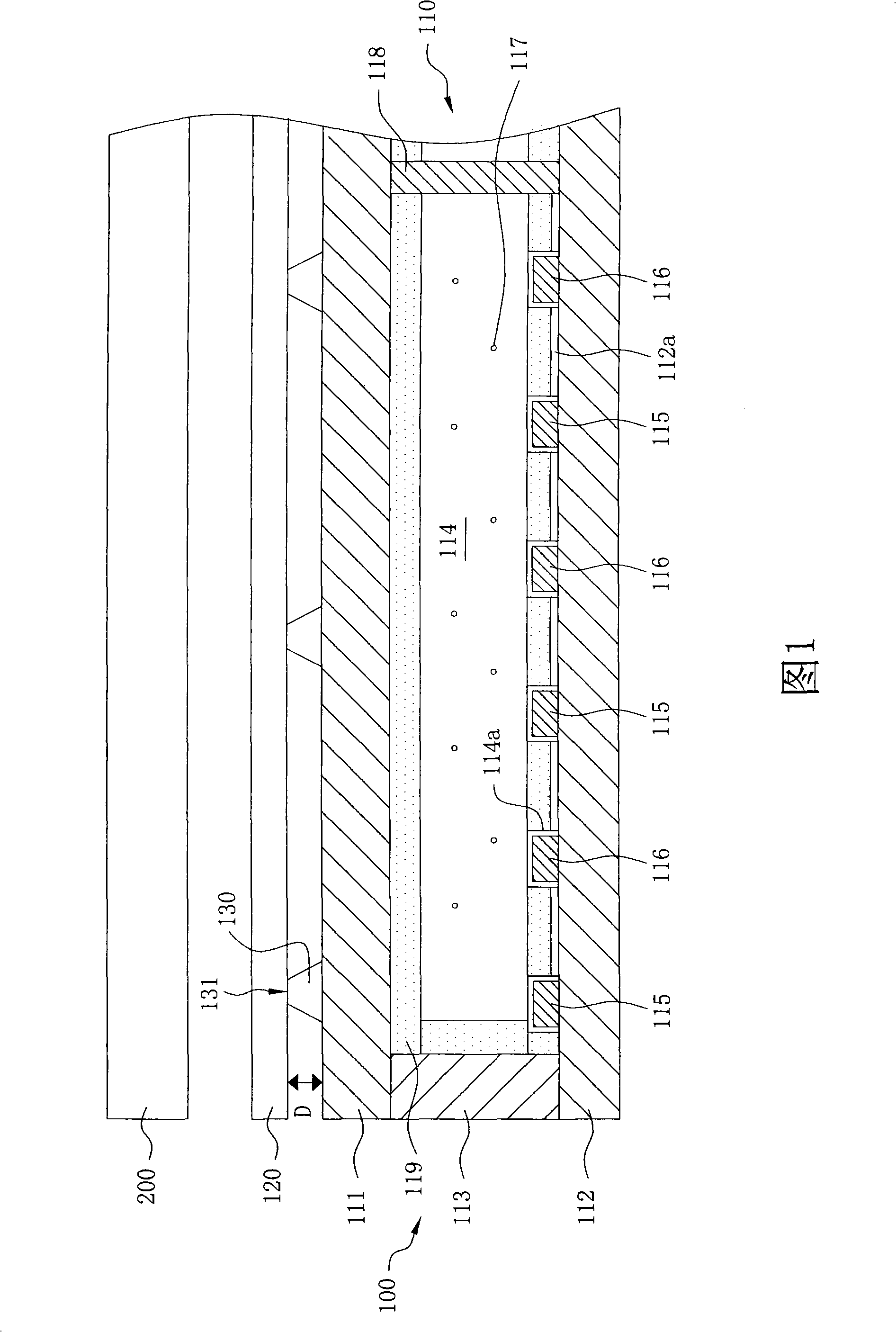

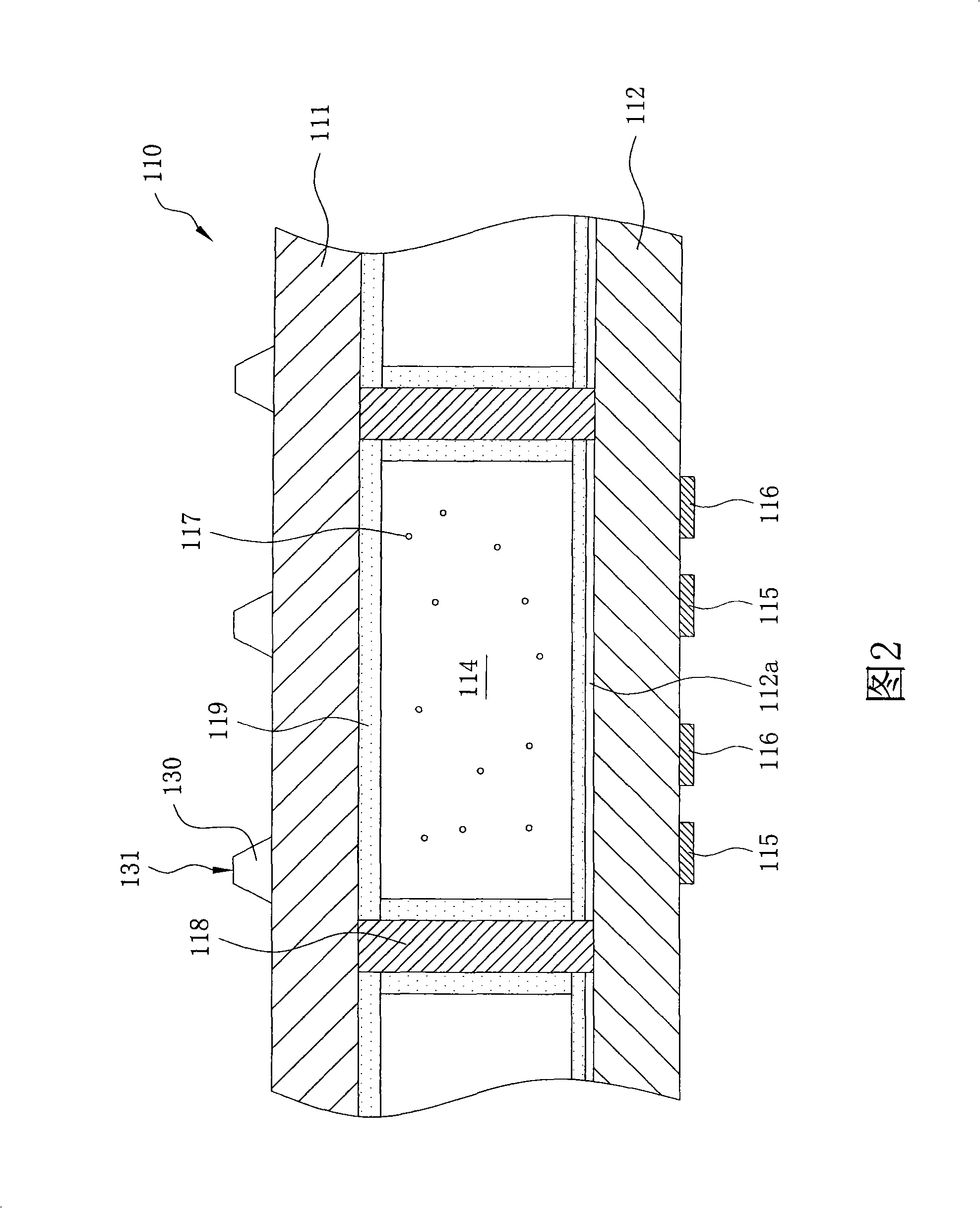

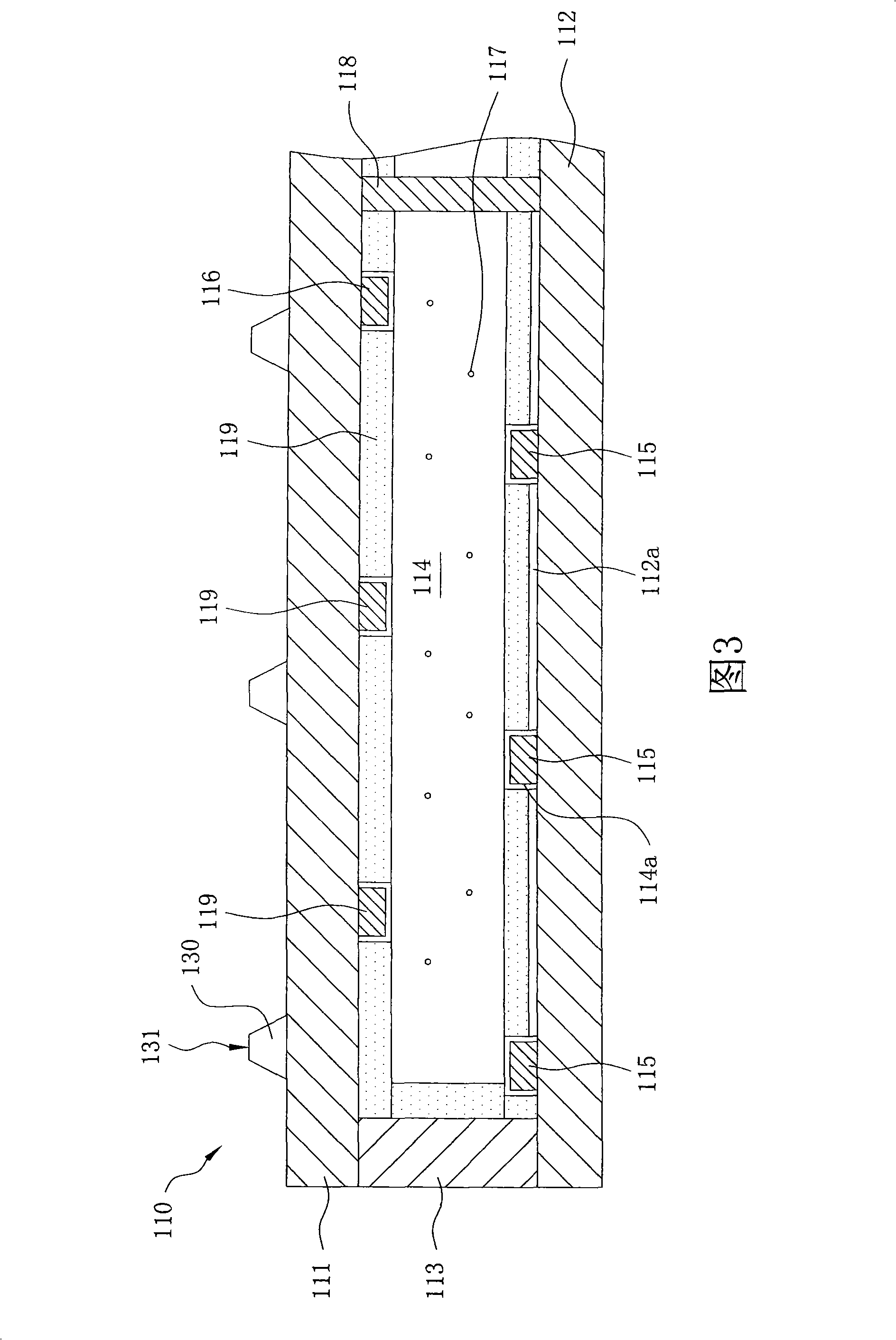

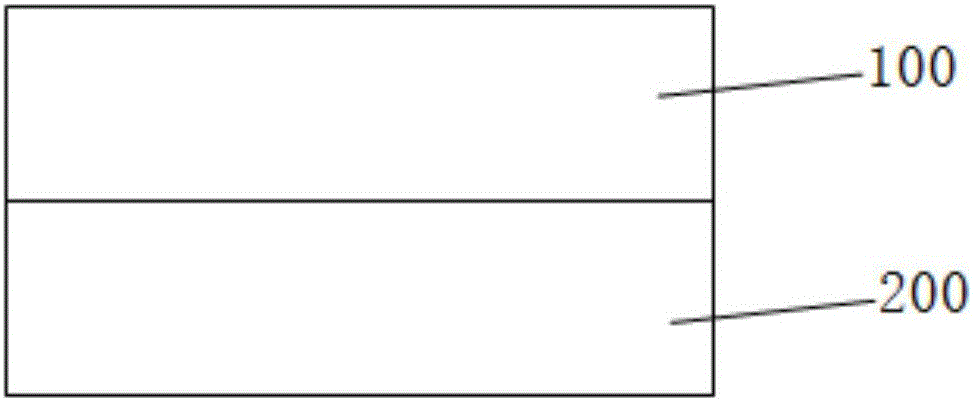

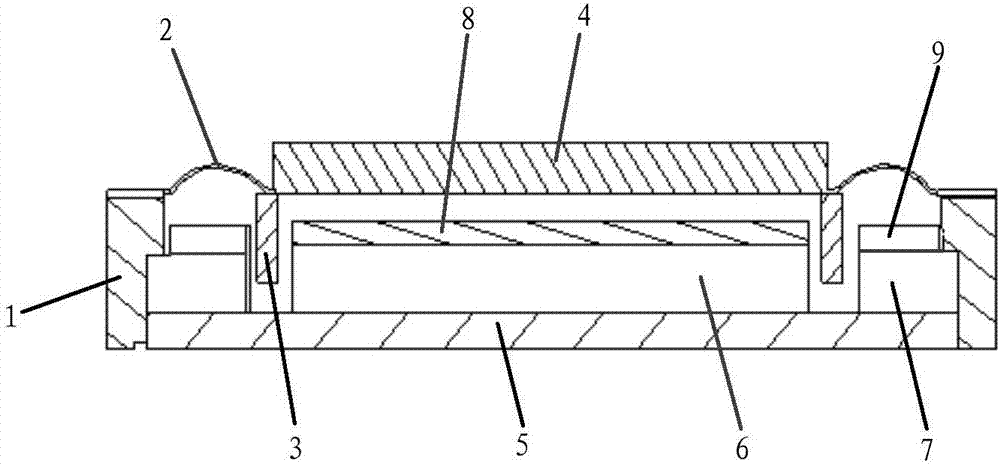

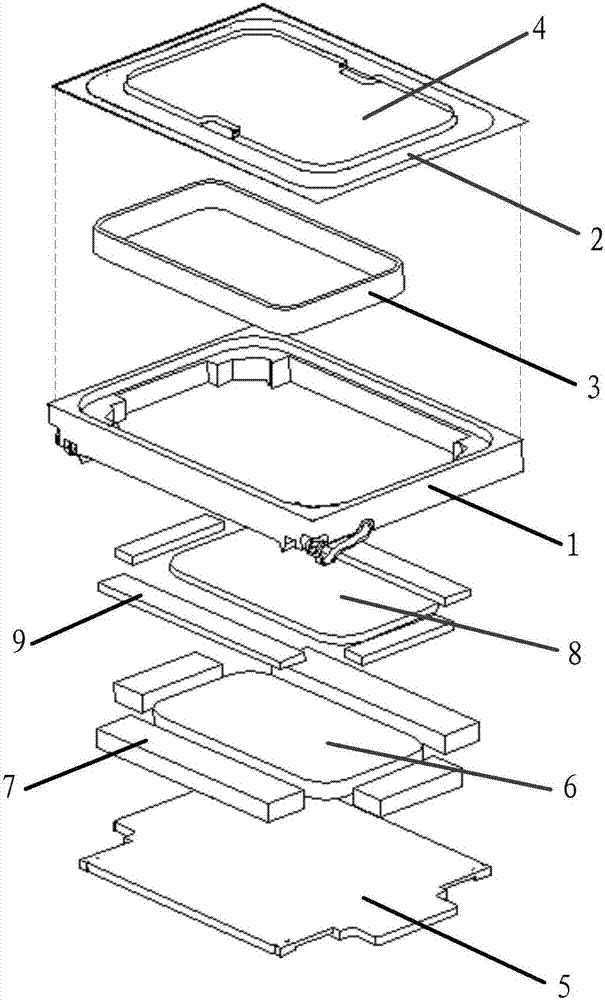

Backlight module and uses thereof

InactiveCN101349832AAvoid deflectionEnsuring Optical ImprovementNon-linear opticsLiquid-crystal displayComputer science

The invention relates to a backlight module and an application thereof, wherein the backlight module at least comprises a backlight source, at least one optical film and at least one support structure, wherein the optical film is provided above the backlight source, the support structure is provided on the backlight source for supporting the optical film on the backlight source. The backlight module can be applied in liquid crystal display devices.

Owner:CHI MEI LIGHTING TECH

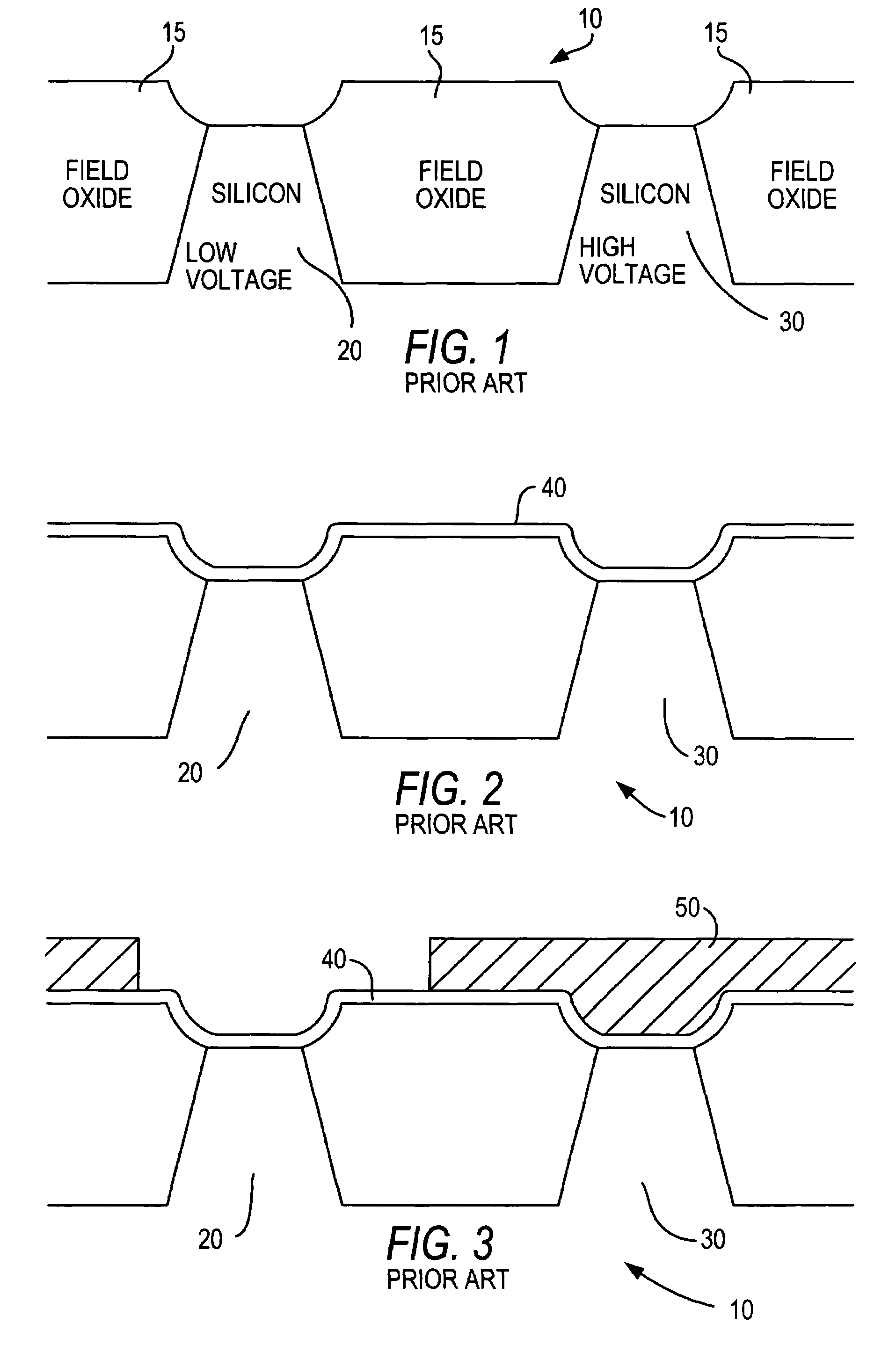

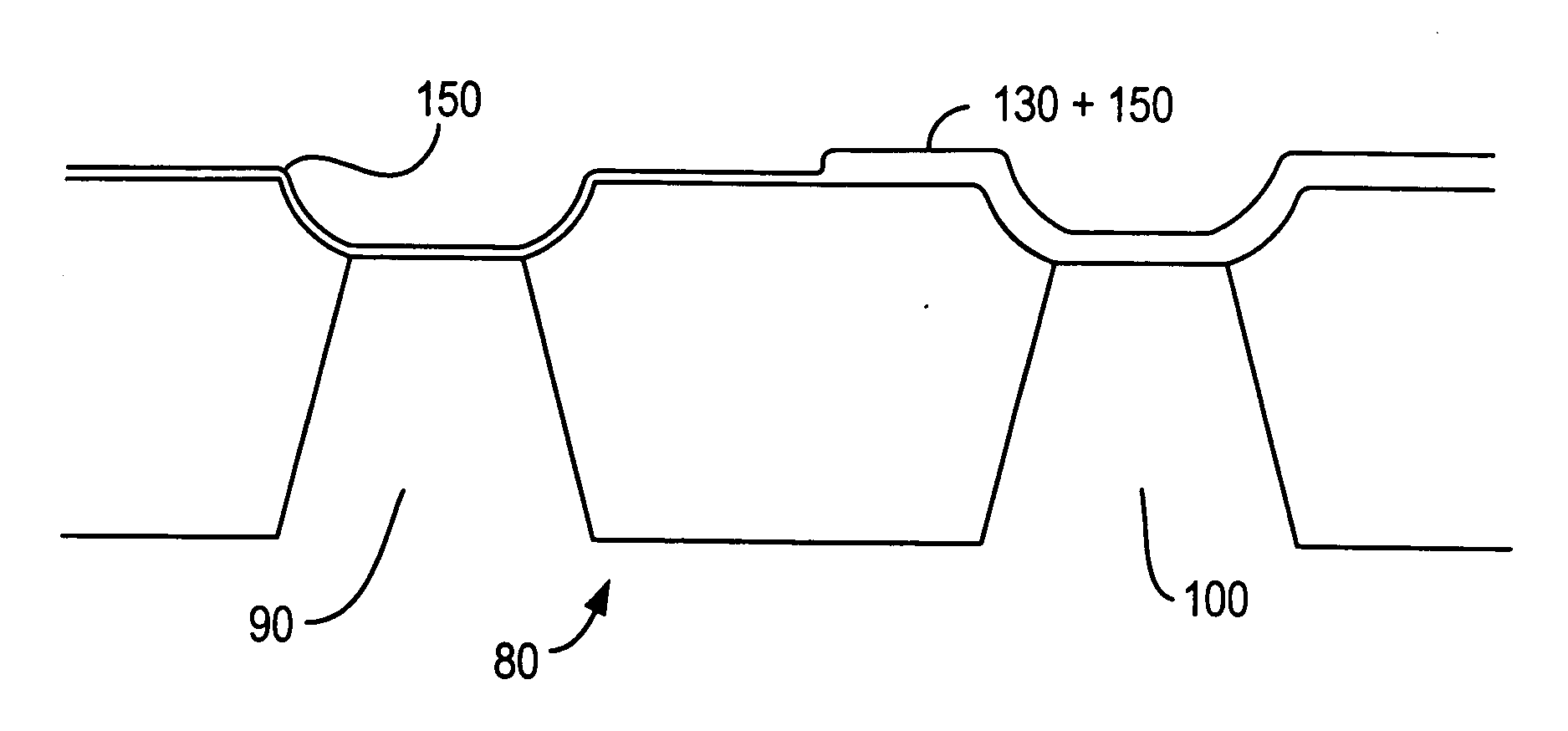

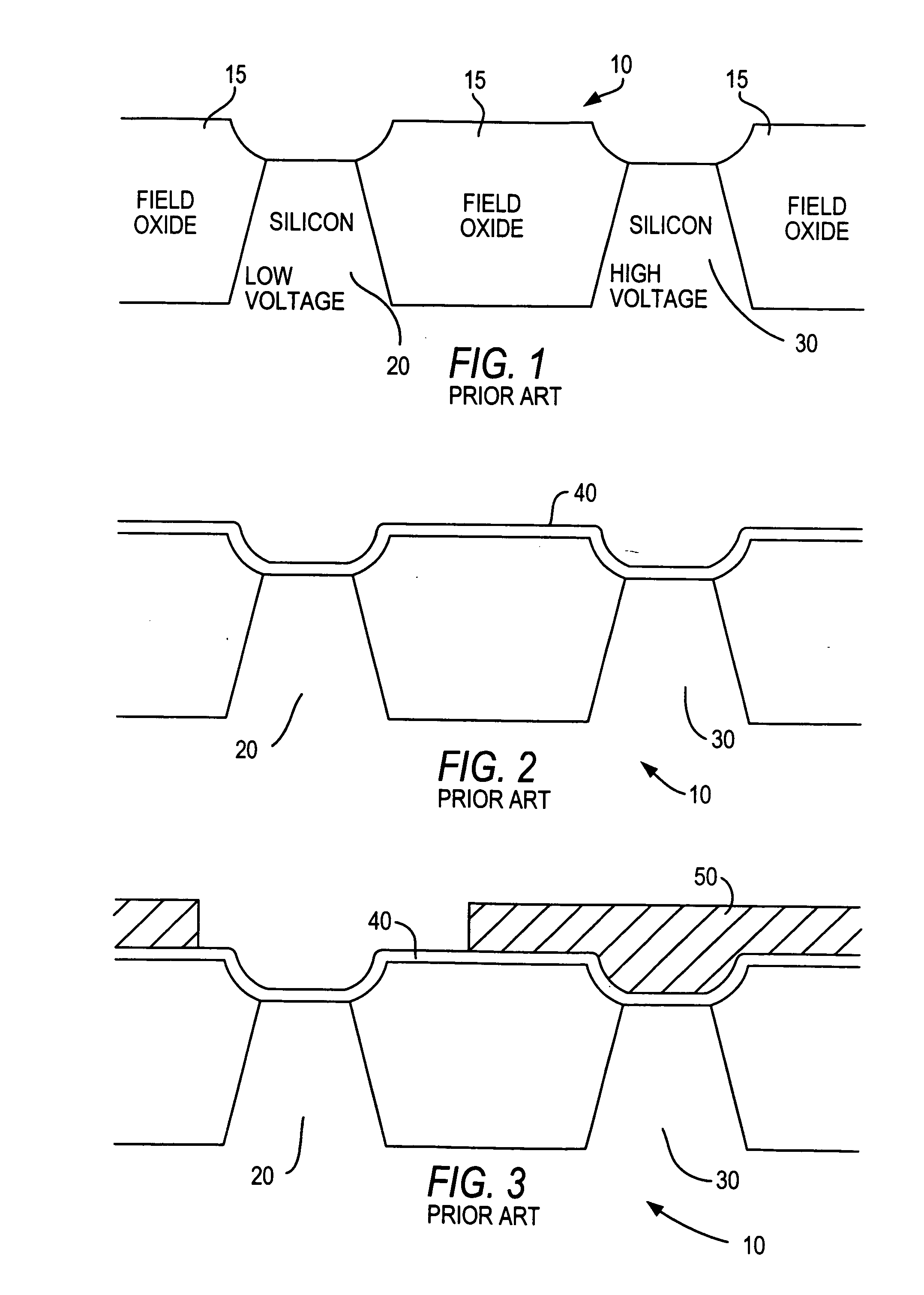

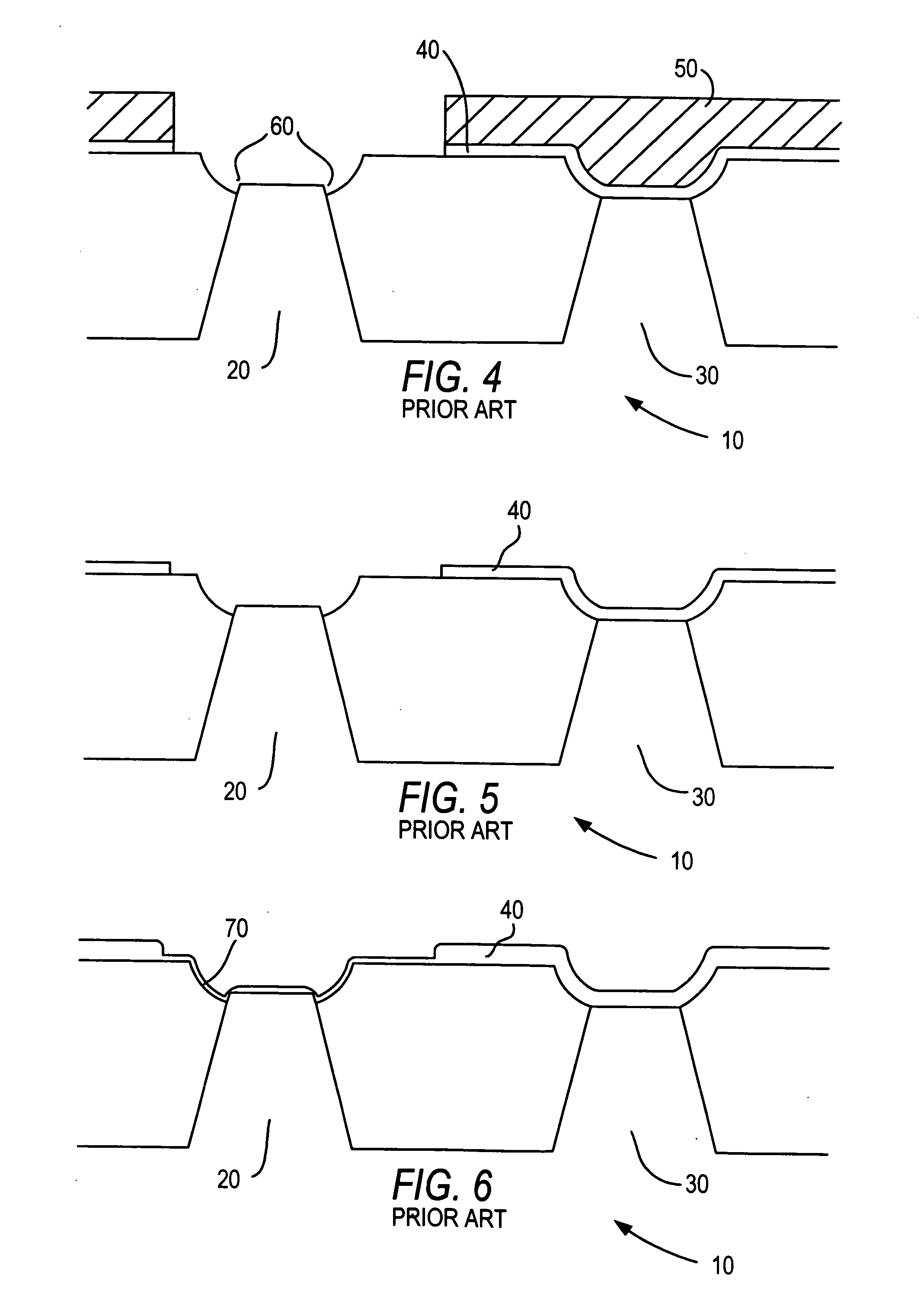

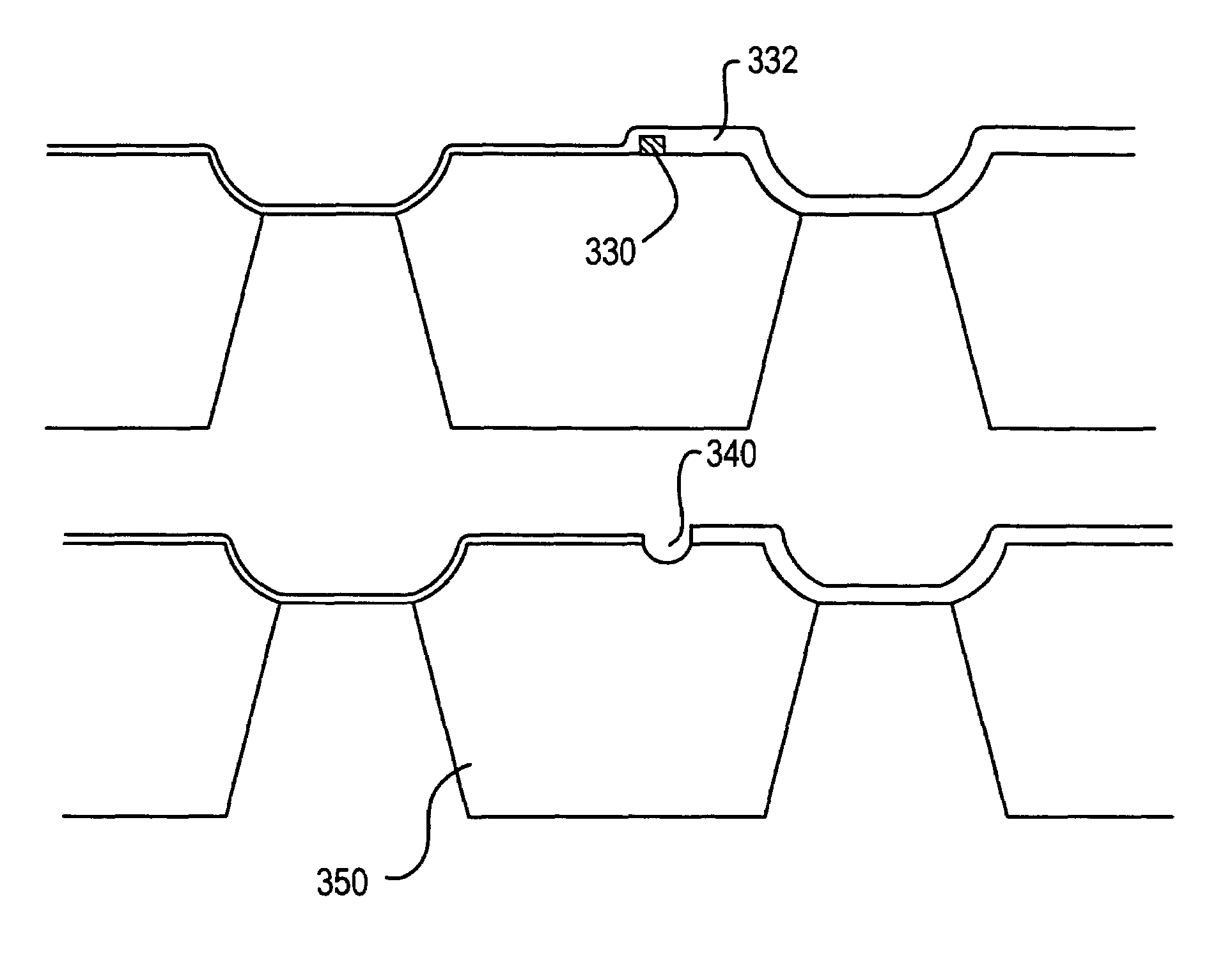

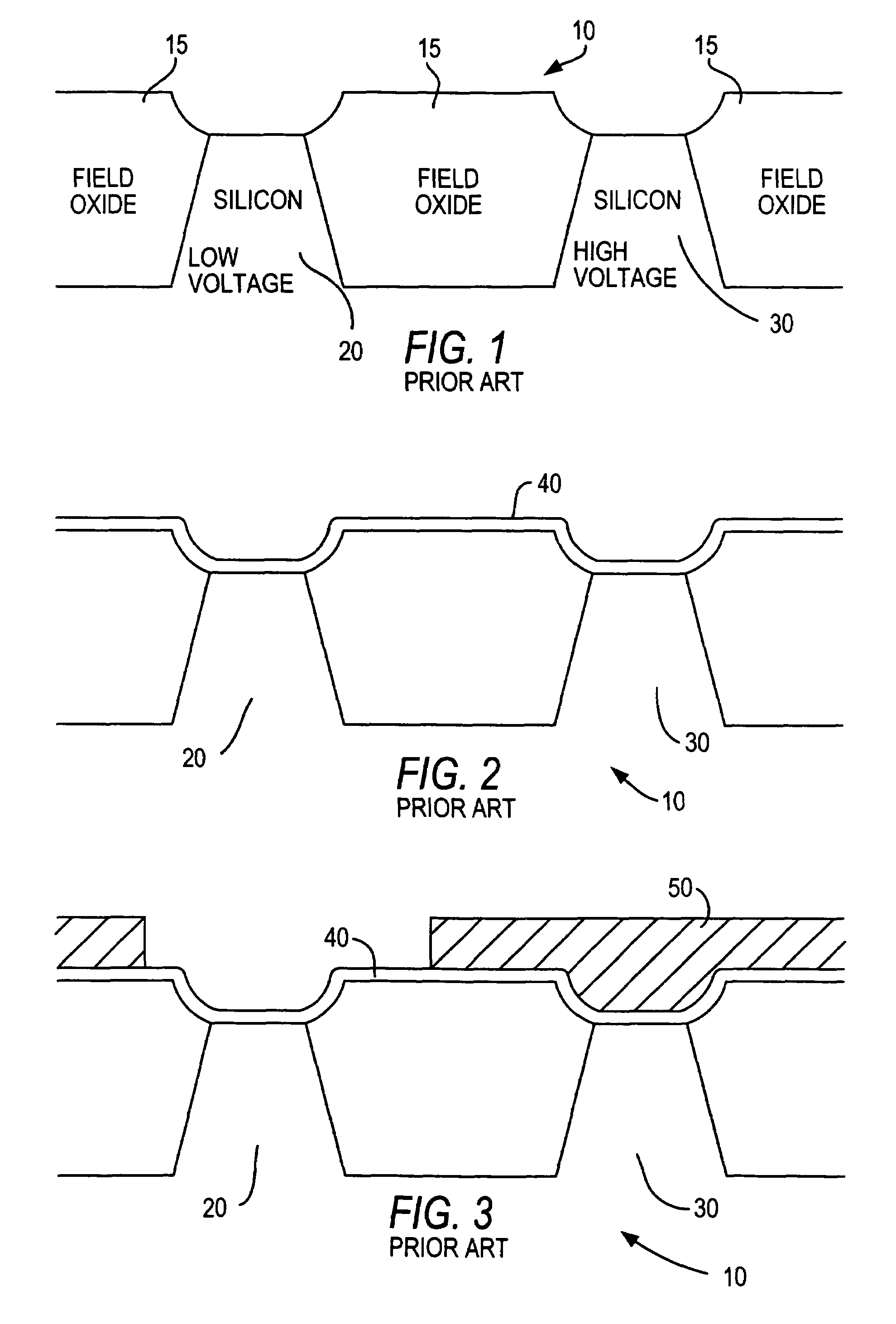

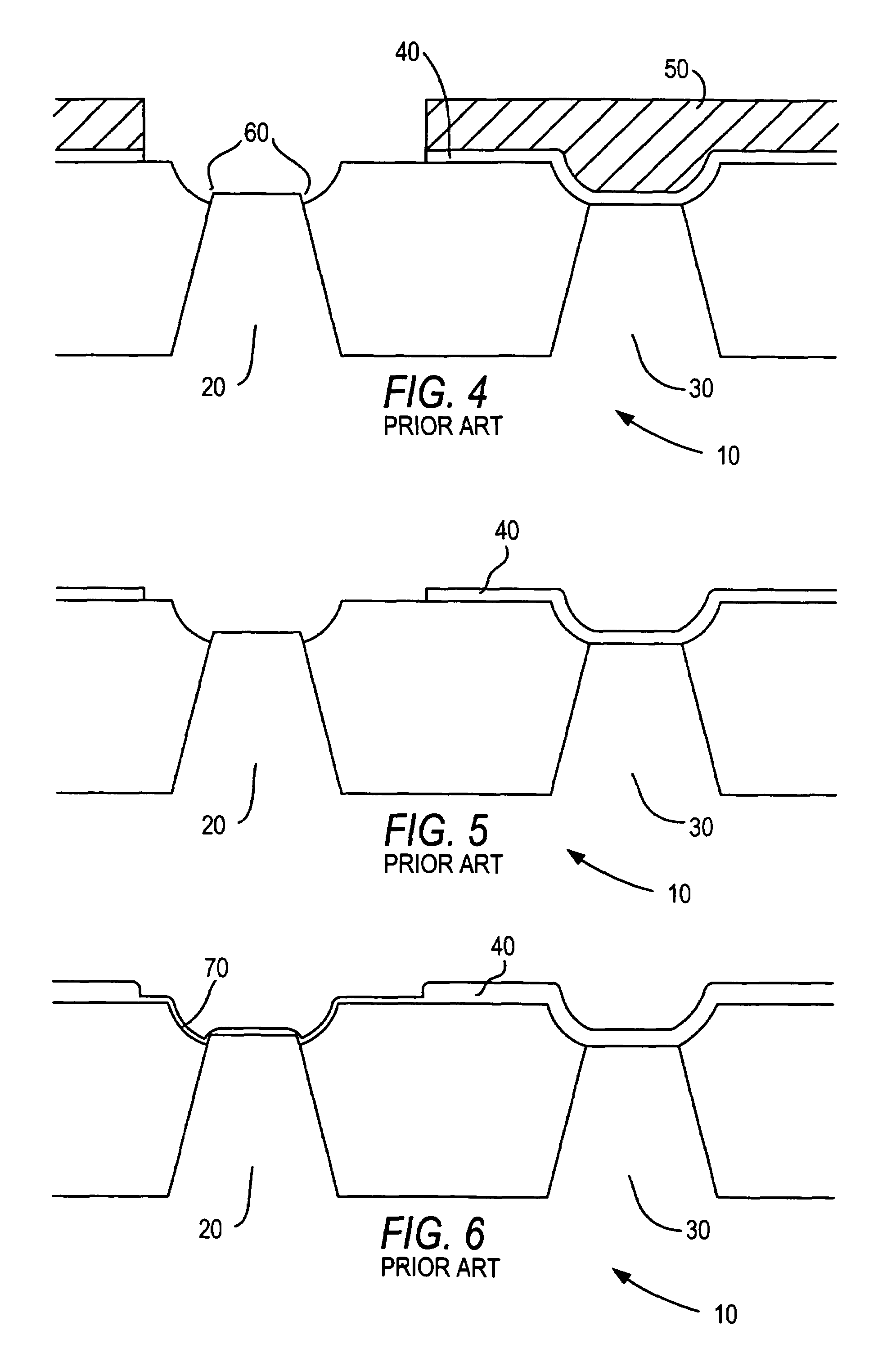

Reduction of field edge thinning in peripheral devices

InactiveUS7241662B2Reduce field edge thinningReduce exposureTransistorSolid-state devicesThinningHigh pressure

A dielectric layer (e.g., an interpoly dielectric layer) is deposited over low and high voltage devices of a peripheral memory device. The dielectric behaves as an oxidation and wet oxide etch barrier. The dielectric prevents the devices from being stripped by a wet oxide etch that can result in the exposure of the silicon corners. The exposure of a silicon corner may increase thinning of a gate oxide at the field edge. This causes variability and unreliability in the device. The dielectric is not removed from a device until the device is ready for processing. That is, the dielectric remains on a device until the growing of a gate oxide on that device has begun. This reduces the exposure of the silicon corner. Hedges that result may be removed by exposing a trench in the field oxide at the hedge.

Owner:MICRON TECH INC

Backlight module and liquid crystal display device

ActiveCN104989994ALow costReduce the height of mixed lightMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

The invention discloses a backlight module. The backlight module comprises a back board as well as a light guide plate structure and a light source component which are arranged on the back board, wherein the light guide plate structure is mainly formed by splicing a plurality of light guide plate blocks; each light guide plate block comprises a splicing end surface and at least one light inlet end surface; and the light source component is arranged on at least one light inlet end surface of each light guide plate block. The invention further discloses a liquid crystal display device comprising the backlight module. The light guide plate structure in the backlight module provided by the invention can reduce light mixing height of the backlight module, and is beneficial to thinning a product. Besides, the light guide plate structure is simple, liable to realize and beneficial to reducing the cost of the product.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Reduction of field edge thinning in peripheral devices

InactiveUS20060019449A1Reduces gate oxide thinningReduce field edge thinningTransistorSolid-state devicesThinningHigh pressure

A dielectric layer (e.g., an interpoly dielectric layer) is deposited over low and high voltage devices of a peripheral memory device. The dielectric behaves as an oxidation and wet oxide etch barrier. The dielectric prevents the devices from being stripped by a wet oxide etch that can result in the exposure of the silicon corners. The exposure of a silicon corner may increase thinning of a gate oxide at the field edge. This causes variability and unreliability in the device. The dielectric is not removed from a device until the device is ready for processing. That is, the dielectric remains on a device until the growing of a gate oxide on that device has begun. This reduces the exposure of the silicon corner. Hedges that result may be removed by exposing a trench in the field oxide at the hedge.

Owner:MICRON TECH INC

Reduction of field edge thinning in peripheral devices

InactiveUS7262102B2Reduce field edge thinningReduce exposureTransistorSolid-state devicesHigh pressureThinning

A dielectric layer (e.g., an interpoly dielectric layer) is deposited over low and high voltage devices of a peripheral memory device. The dielectric behaves as an oxidation and wet oxide etch barrier. The dielectric prevents the devices from being stripped by a wet oxide etch that can result in the exposure of the silicon corners. The exposure of a silicon corner may increase thinning of a gate oxide at the field edge. This causes variability and unreliability in the device. The dielectric is not removed from a device until the device is ready for processing. That is, the dielectric remains on a device until the growing of a gate oxide on that device has begun. This reduces the exposure of the silicon corner. Hedges that result may be removed by exposing a trench in the field oxide at the hedge.

Owner:MICRON TECH INC

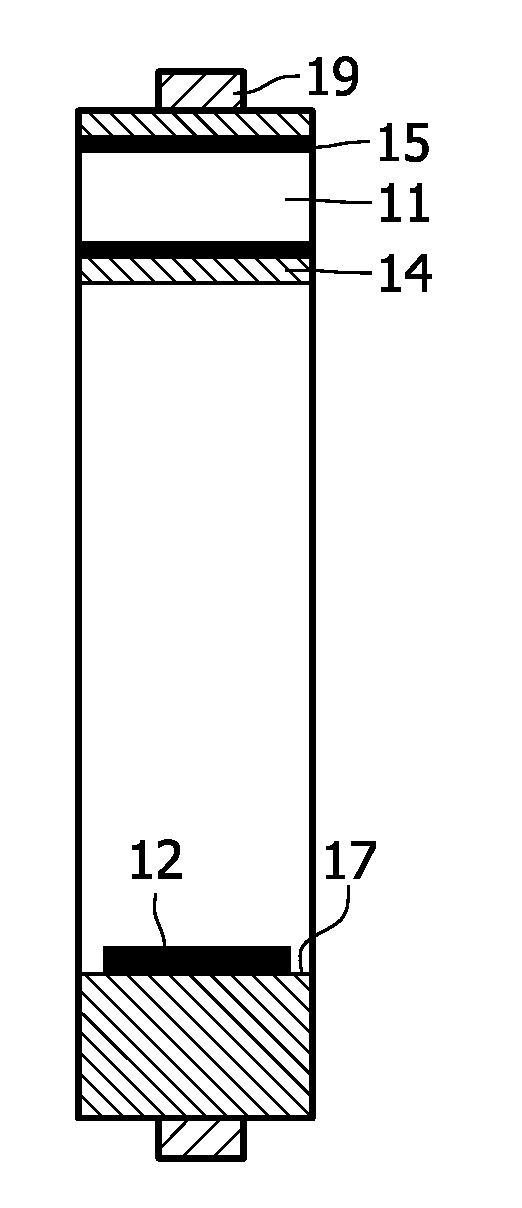

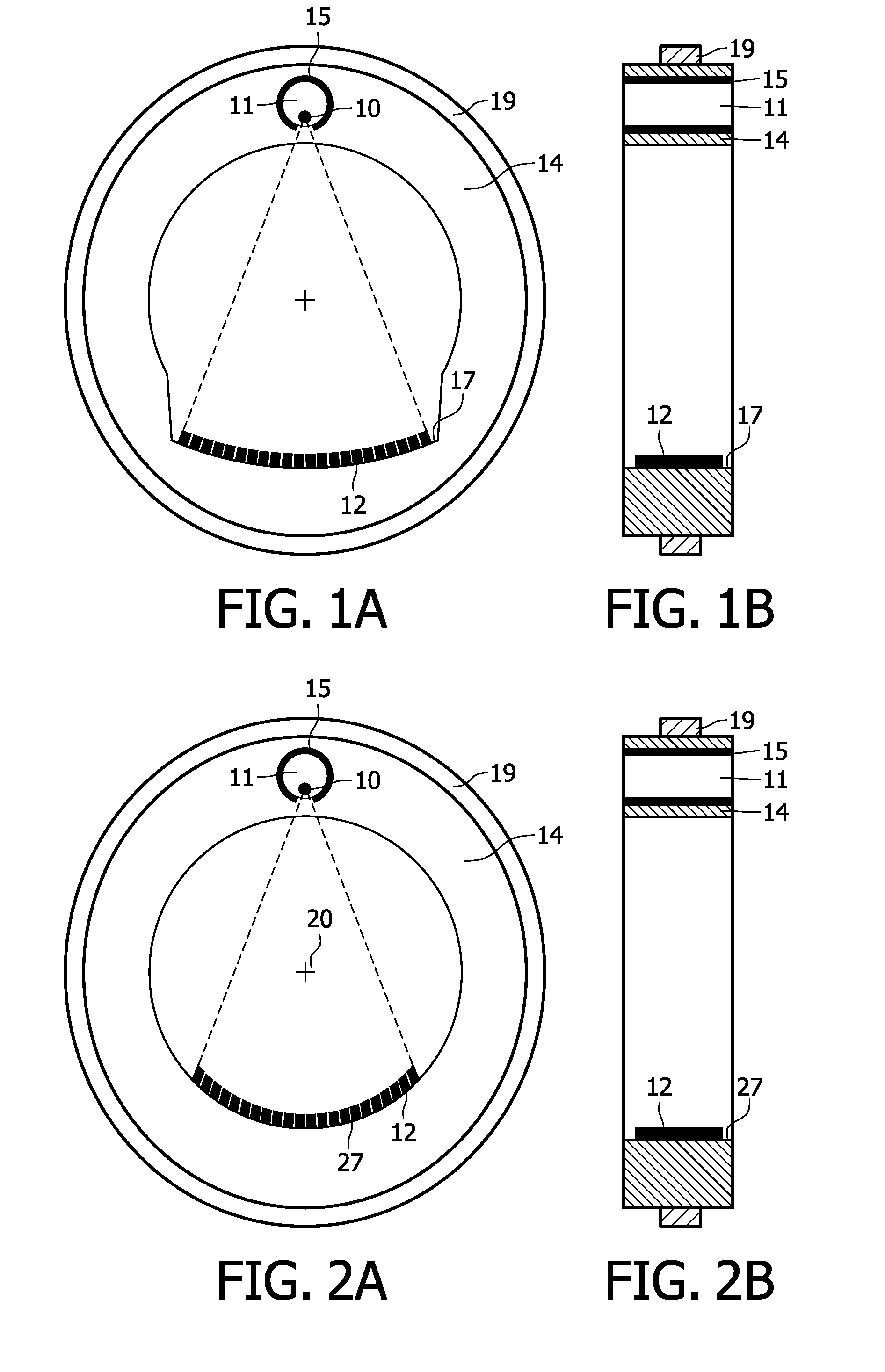

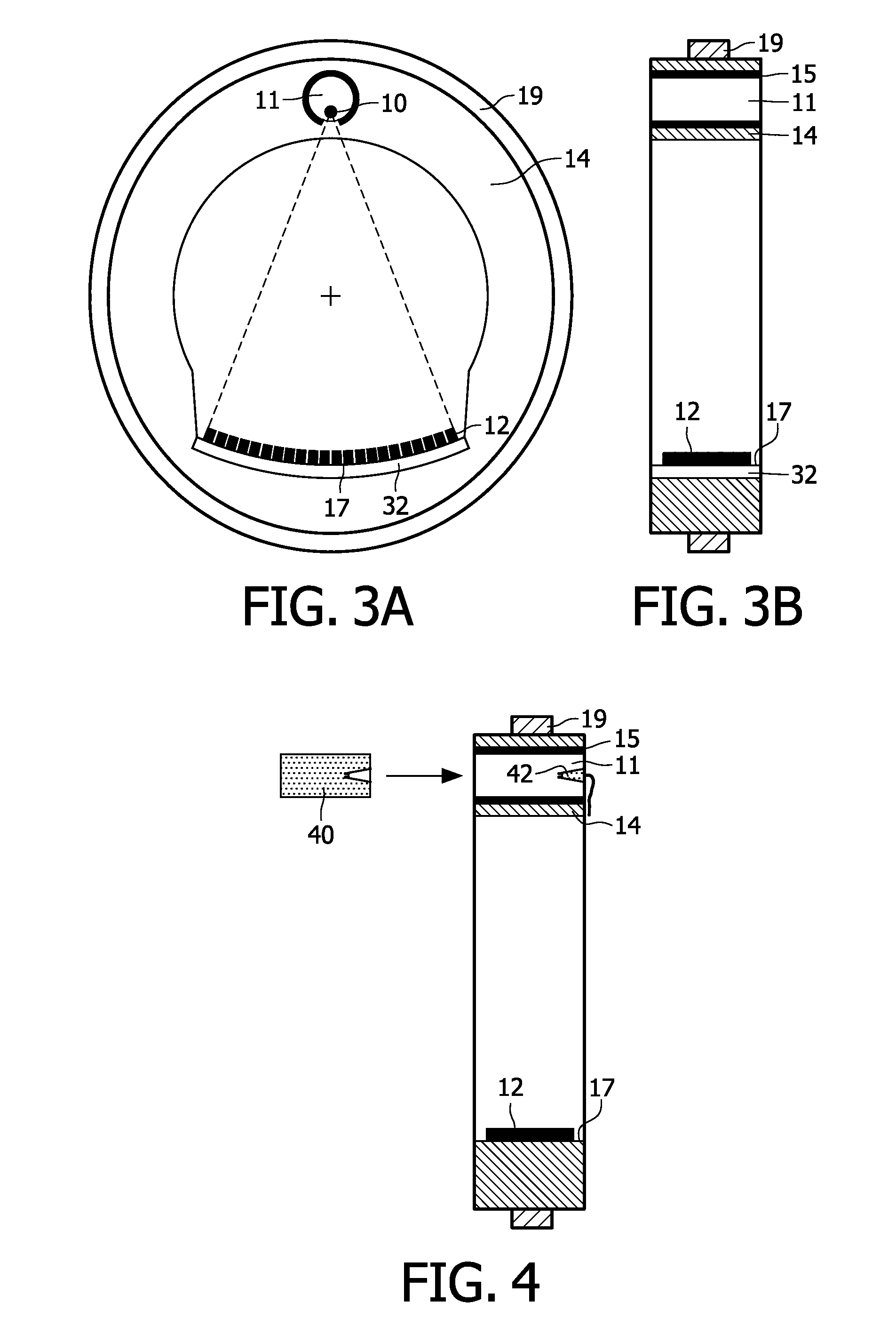

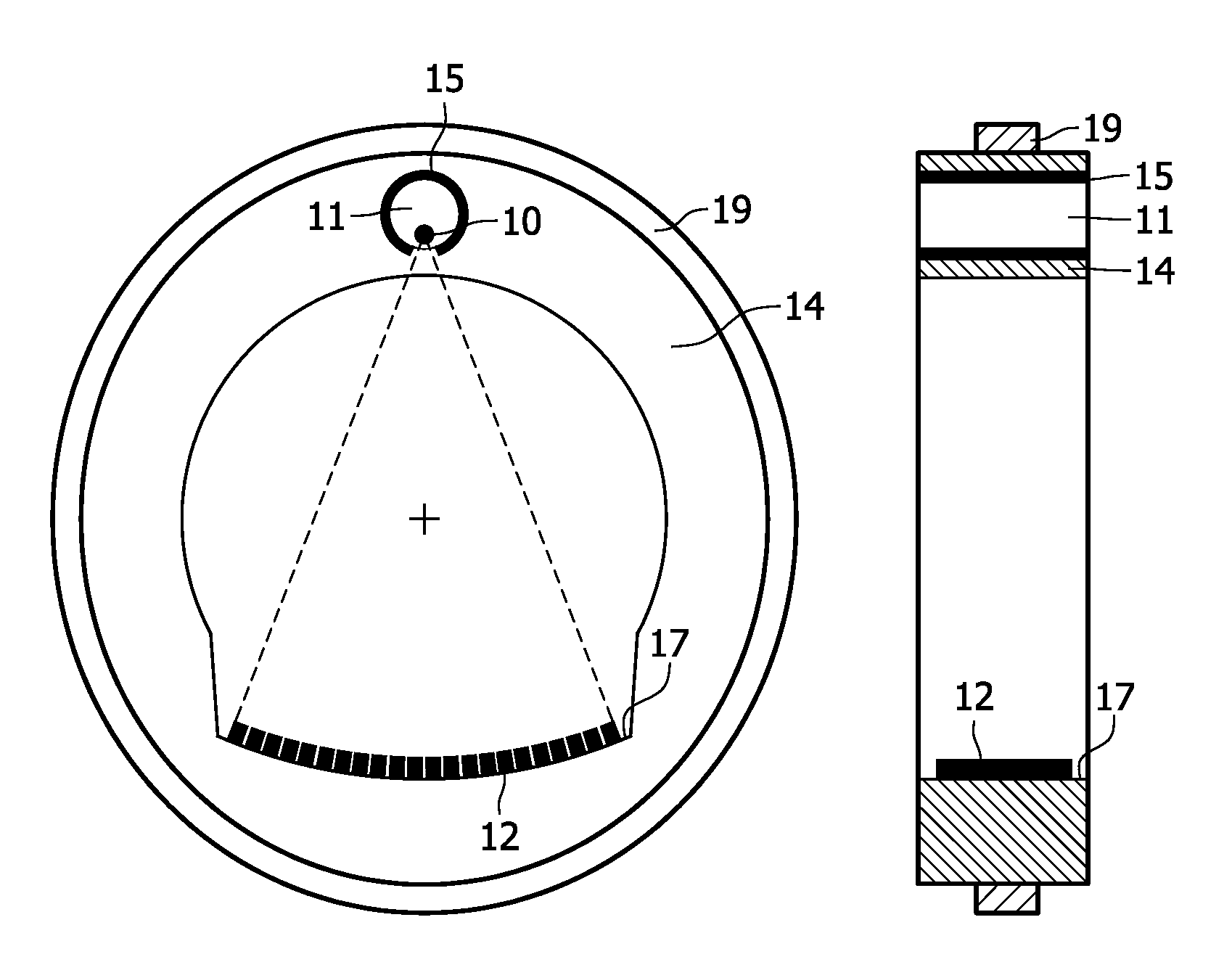

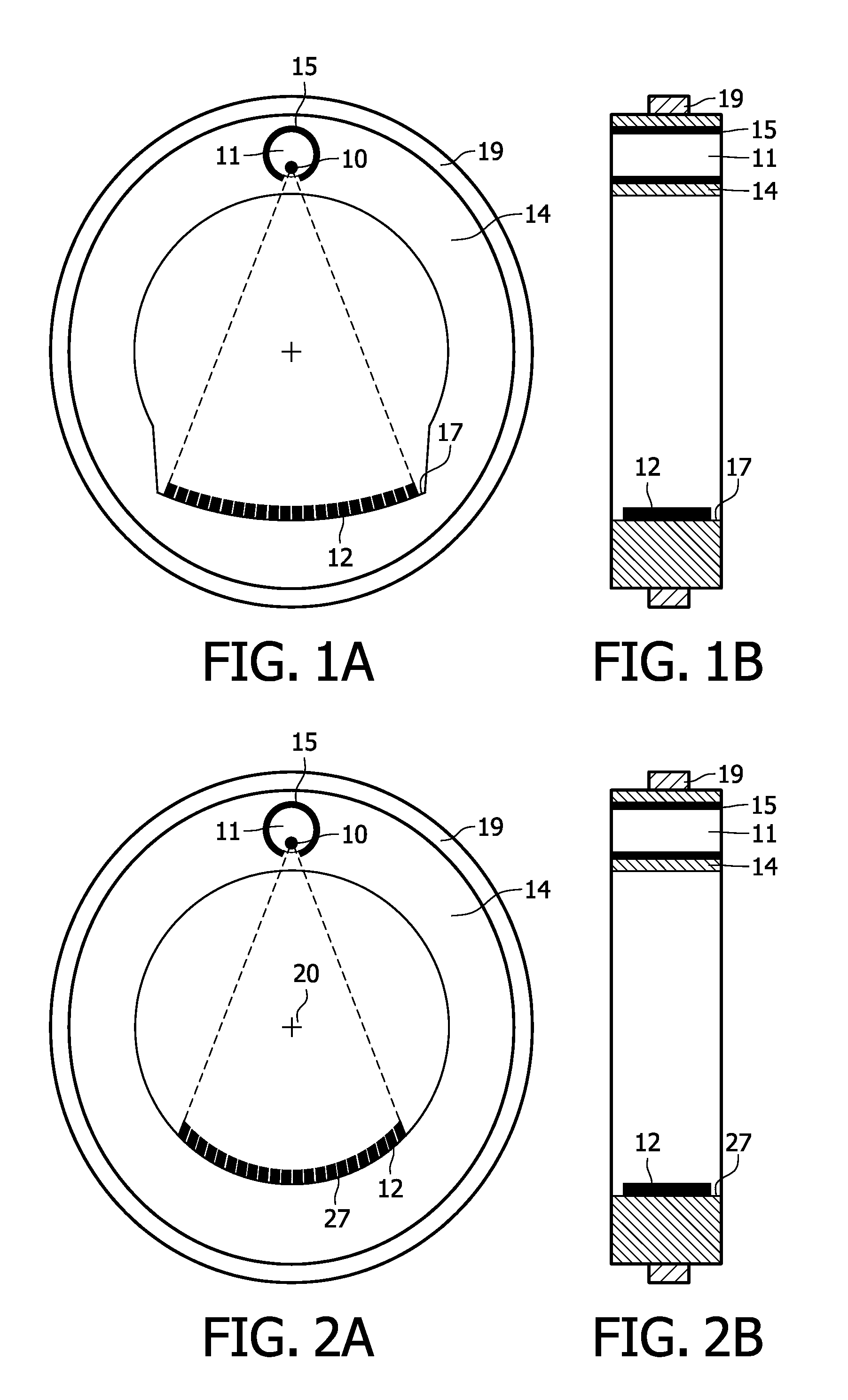

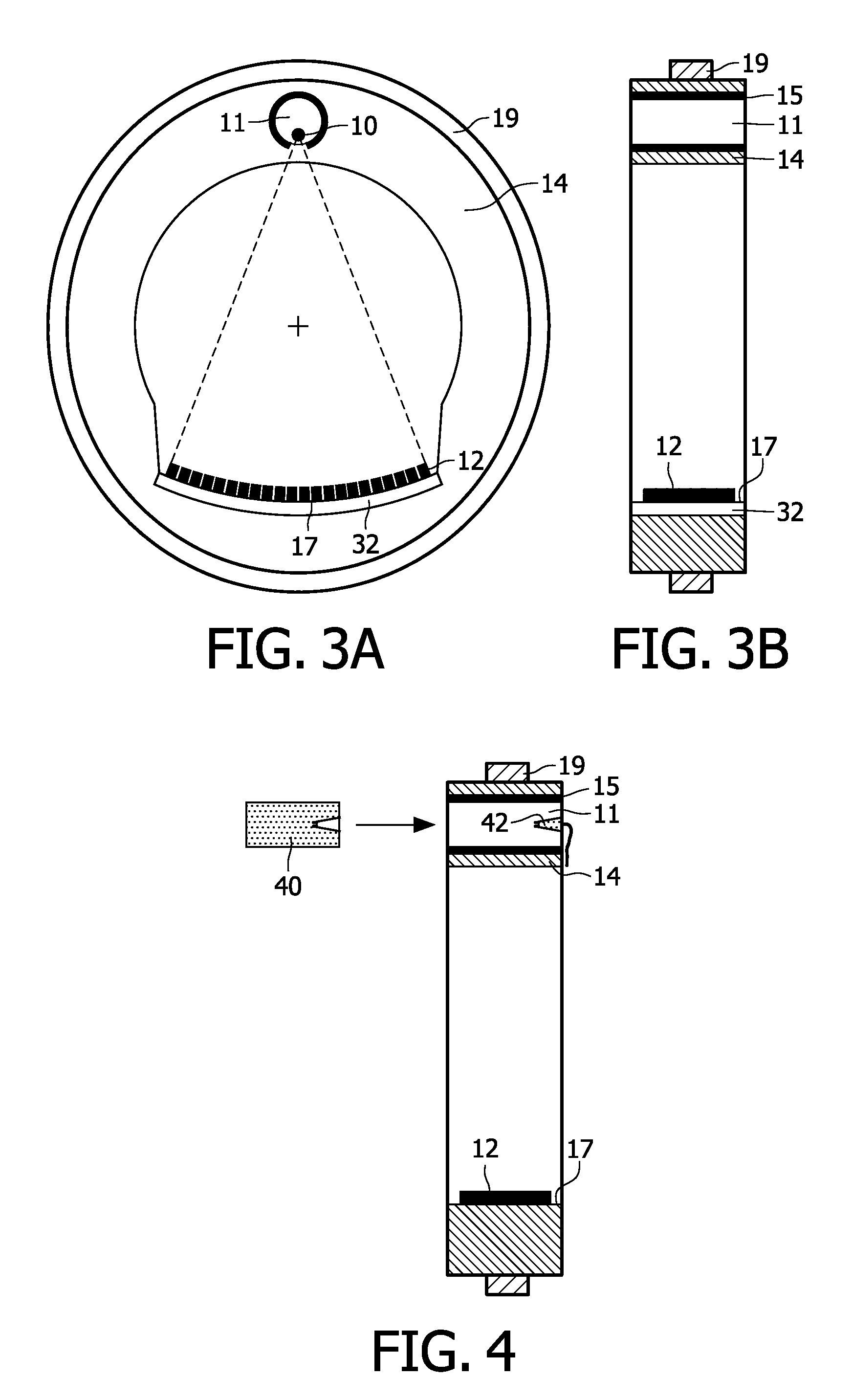

Rotor and x-ray ct scanners

ActiveUS20100303209A1Reduce relative motionReduce Image ArtifactsRadiation diagnosis data transmissionTomographyUltrasound attenuationSurface mounting

The invention relates to a rotor comprising a radiation source having a focal spot for radiating beam towards a subject, detection means for generating signals responsive to energy attenuation of said beam and a circular body having a cavity for housing the radiation source, and a circle arc-shaped surface on which the detection means are mounted. The circle arc-shaped surface is placed opposite to the cavity with respect to the subject, said cavity comprising an inside surface mounted with a shield for shielding the radiation not towards the subject. In this way, the conventional housing for radiation source and shielding are removed, resulting in reduction of focal spot motion caused by motion of the conventional housing. Furthermore, this invention proposes to mount the detection means directly on the circular body without an intermediate structural housing that reduces the detector modules motion relative to the focal spot.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Rotor and X-ray CT scanners

ActiveUS9314220B2Reduce relative motionReduce Image ArtifactsRadiation diagnosis data transmissionComputerised tomographsUltrasound attenuationSurface mounting

The invention relates to a rotor comprising a radiation source having a focal spot for radiating beam towards a subject, detection means for generating signals responsive to energy attenuation of said beam and a circular body having a cavity for housing the radiation source, and a circle arc-shaped surface on which the detection means are mounted. The circle arc-shaped surface is placed opposite to the cavity with respect to the subject, said cavity comprising an inside surface mounted with a shield for shielding the radiation not towards the subject. In this way, the conventional housing for radiation source and shielding are removed, resulting in reduction of focal spot motion caused by motion of the conventional housing. Furthermore, this invention proposes to mount the detection means directly on the circular body without an intermediate structural housing that reduces the detector modules motion relative to the focal spot.

Owner:KONINK PHILIPS ELECTRONICS NV

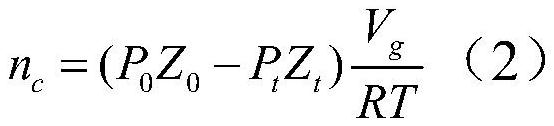

Composition capable of improving stability of hydrate and storage and transportation method based on solid hydrate

The invention relates to the technical field of safe storage and transportation of gas, and discloses a composition capable of improving the stability of a hydrate and a storage and transportation method based on a solid hydrate. The composition contains a hydrate accelerant and a supporting material; wherein foam holes are distributed in the supporting material, the compressive strength of the supporting material is 1-8 MPa, the average diameter of the foam holes is 100-150 microns, the specific surface area is 500-1000 m < 2 > / g, and the density is 0.05-0.4 g / cm < 3 >. The composition capable of improving the stability of the hydrate can improve the stability of the hydrate under a low-temperature self-protection condition, reduces gas waste and pressure-bearing requirements on storage and transportation equipment, and also can improve the gas recovery rate of the hydrate.

Owner:CHINA PETROLEUM & CHEM CORP +1

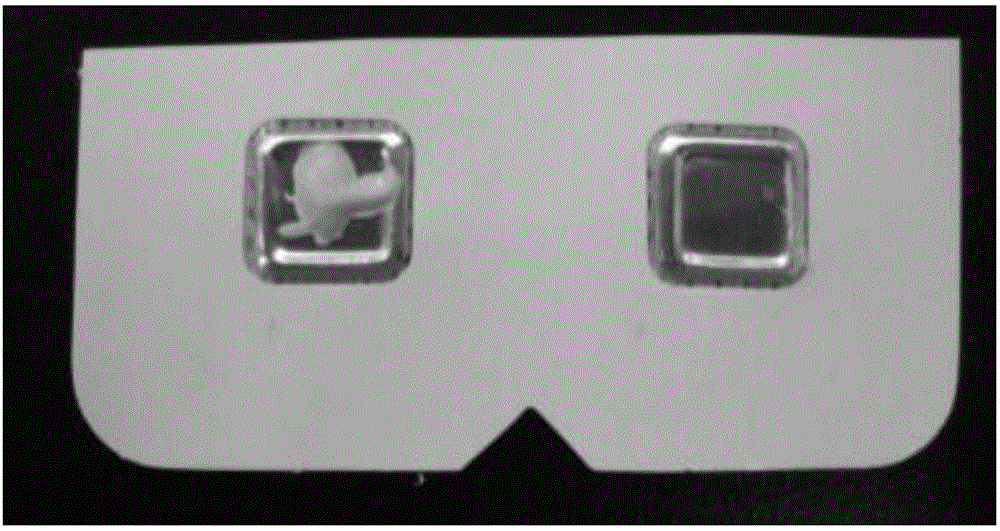

Loudspeaker, assembling method and electronic equipment

ActiveCN107124686ALight in massReduce thicknessElectrical transducersLoudspeakersMembrane bodiesEffect light

The invention discloses a loudspeaker, an assembling method and electronic equipment. The loudspeaker comprises a basin stand, a magnetic circuit assembly, a membrane, a voice coil and a globe-roof, wherein the basin stand is of a frame body structure; a containing space is formed by the inner part of the frame body structure; a first opening which is communicated with the containing space is formed in one side of the frame body structure; the magnetic circuit assembly is arranged in the containing space and is fixedly connected with the basin stand; the membrane covers the basin stand, and the first opening is sealed by the membrane; the membrane comprises a membrane body and a fixing part which is arranged around the membrane body; a first surface of the fixing part is fitted with the basin stand; the voice coil is arranged in the containing space and is fixed to the first surface of the membrane body; the globe-proof is fixed to a second surface of the membrane body. The loudspeaker disclosed by the invention is arranged in a voice cavity structure of the electronic equipment, enough sound emitting passages can be formed in a voice cavity, successful sound transmission is ensured, and lighting and thinning of a whole machine are facilitated.

Owner:VIVO MOBILE COMM CO LTD

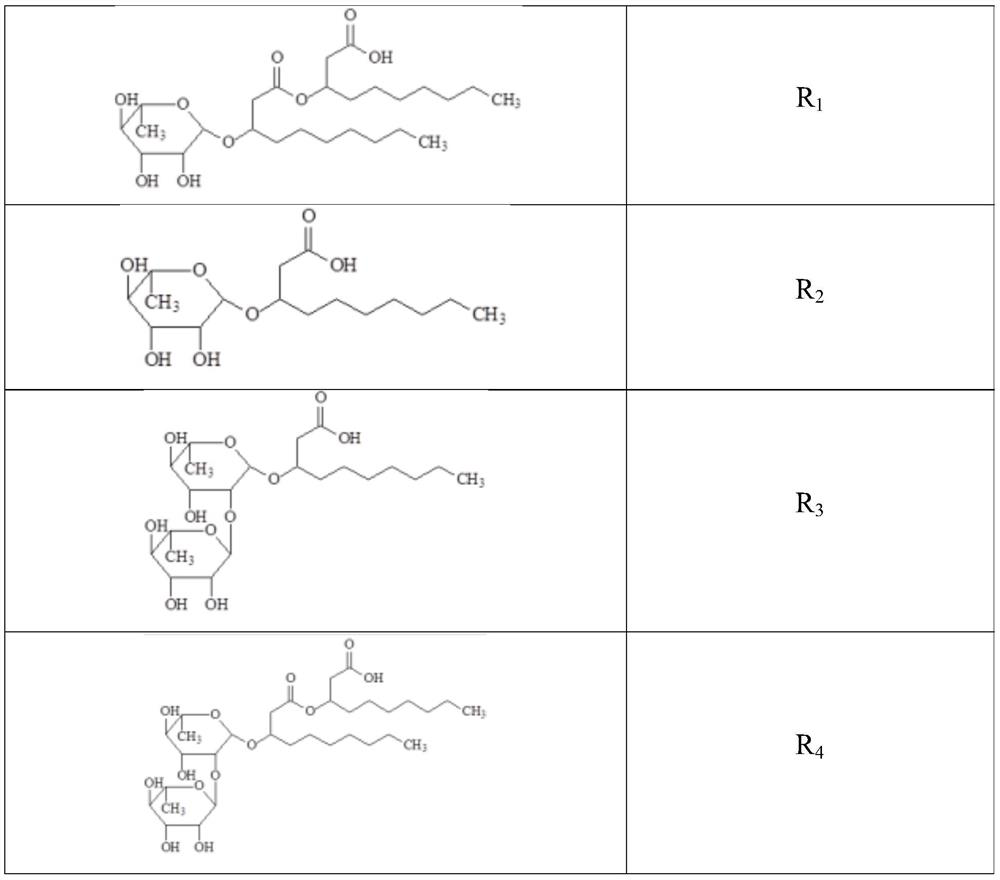

Composition for repairing skin surface lipid film and preparation method and application thereof

InactiveCN106619304AFix fixesGood restorativeCosmetic preparationsToilet preparationsZINC LACTATELipid film

The invention discloses a composition for repairing a skin surface lipid film and a preparation method and application thereof. The composition comprises, by weight percentage, 34-74% of water, 10-20% of mirabilis jalapa extract, 5-15% of anthemis nobilis flower extract, 5-15% of selaginella tamariscina extract, 1-6% of zinc lactate and 5-10% of 1,2-hexanediol. The weight percentage content of the ingredients is 100%. The product does not contain oily ingredients, has a more remarkable effect on sebum repair and is favorable for improvement of the repair effect of the oily ingredients.

Owner:广州品爵生物科技有限公司

Casting delivery nozzle

InactiveUS8225845B2Reducing and inhibiting such defectCosts in thinMelt-holding vesselsMetal stripsMetallurgy

A metal delivery apparatus for casting metal strip includes at least one elongated segment having a main portion extending longitudinally through the main portion with end walls at opposite ends thereof, the main portion communicating with outlets along opposite sides of each segment adapted to upwardly discharge flow of molten metal into a casting pool.

Owner:NUCOR CORP

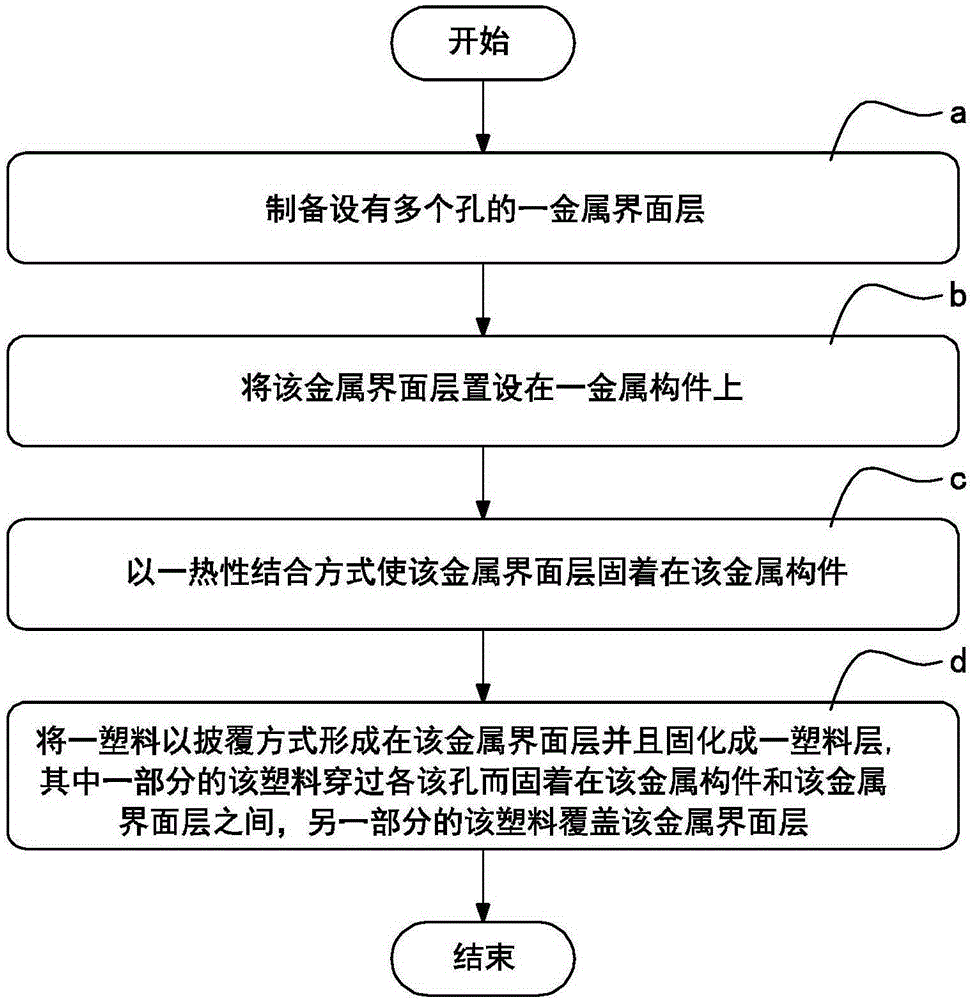

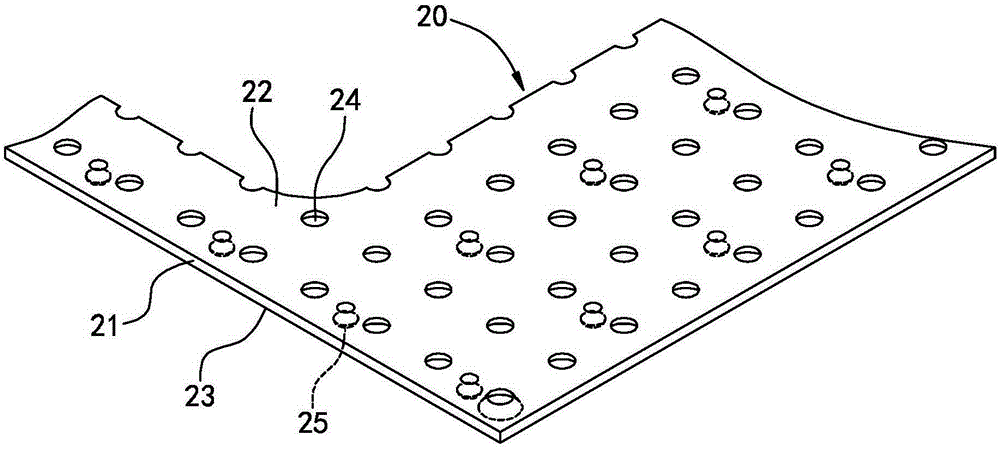

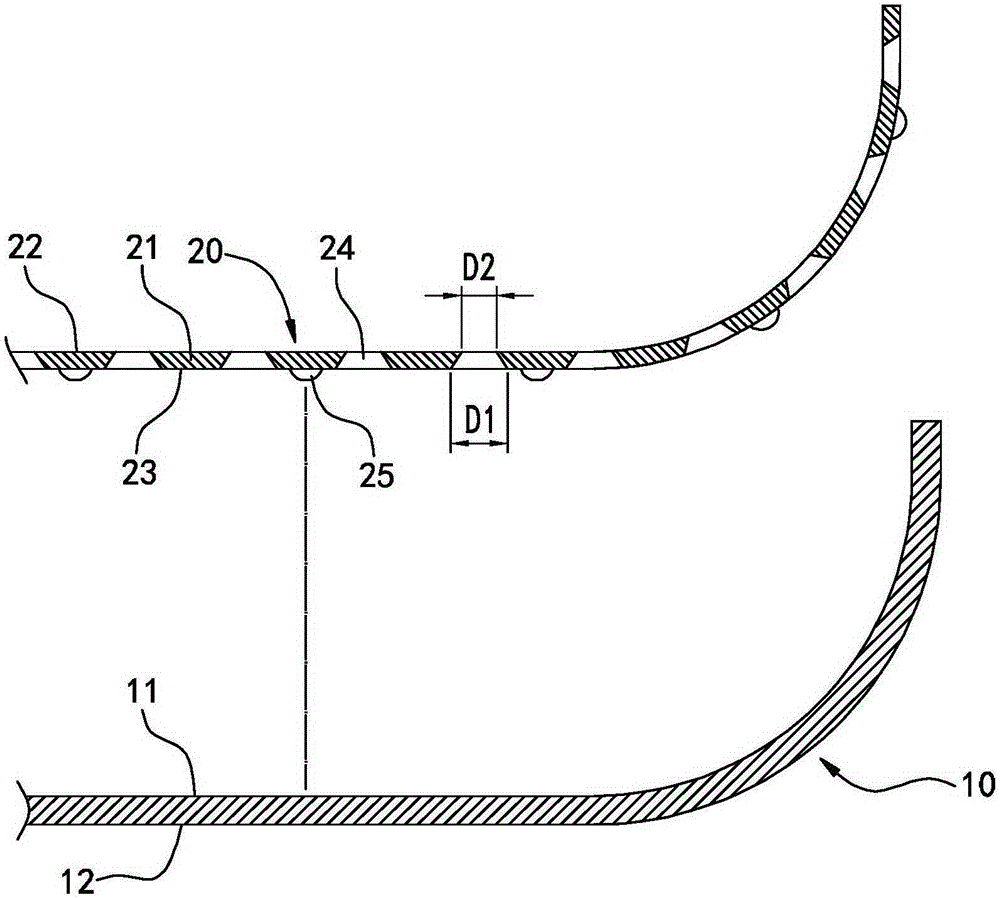

Metal member and plastic jointing method and structure

InactiveCN106363911AHigh bonding strengthMaintain strength and integrityMetal layered productsMetalMaterials science

The invention discloses a metal member and plastic jointing method and structure. The jointing structure comprises a metal member, a metal interface layer and a plastic layer, and the metal member has a first surface; the metal interface layer has an upper surface and a lower surface formed on the back of the upper surface, the lower surface is arranged corresponding to the first surface, the metal interface layer is provided with a plurality of holes, and all the holes are mutually connected at one side of the lower surface; and the plastic layer is laid corresponding to the metal interface layer, one part of the plastic layer traverses through the holes and is anchored between the first surface and the lower surface, and the other part of the plastic covers the upper surface of the metal interface layer. The method and the structure have the advantages of improvement of the metal member and plastic layer jointing firmness, simplicity of the process, and shortening of the making time.

Owner:林暄智 +1

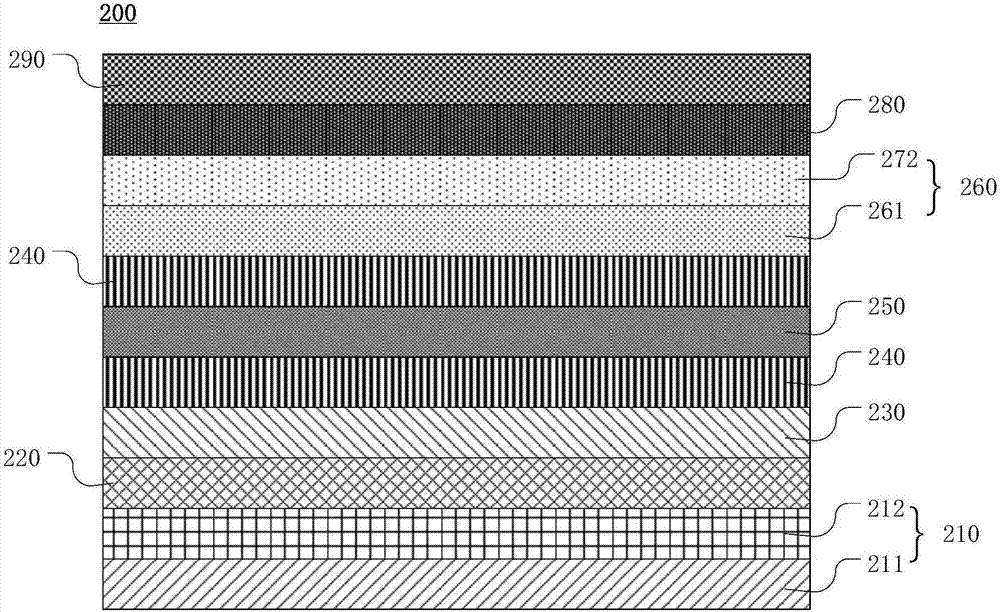

Optical film and display device

InactiveCN106896563AThe overall thickness is thinHigh hardnessNon-linear opticsDisplay devicePolarizer

The present invention discloses an optical film and a display device including a polarizer film and a conductive layer. The polarizing film has a first surface and a second surface on the opposite side of the first surface. The conductive layer is on the surface. The thickness of the conductive layer is between 2 [miu] and 10 [miu], and the sheet resistance is substantially between 10 ohm / sqr and 10 ohm / sqr.

Owner:SUMIKA TECH

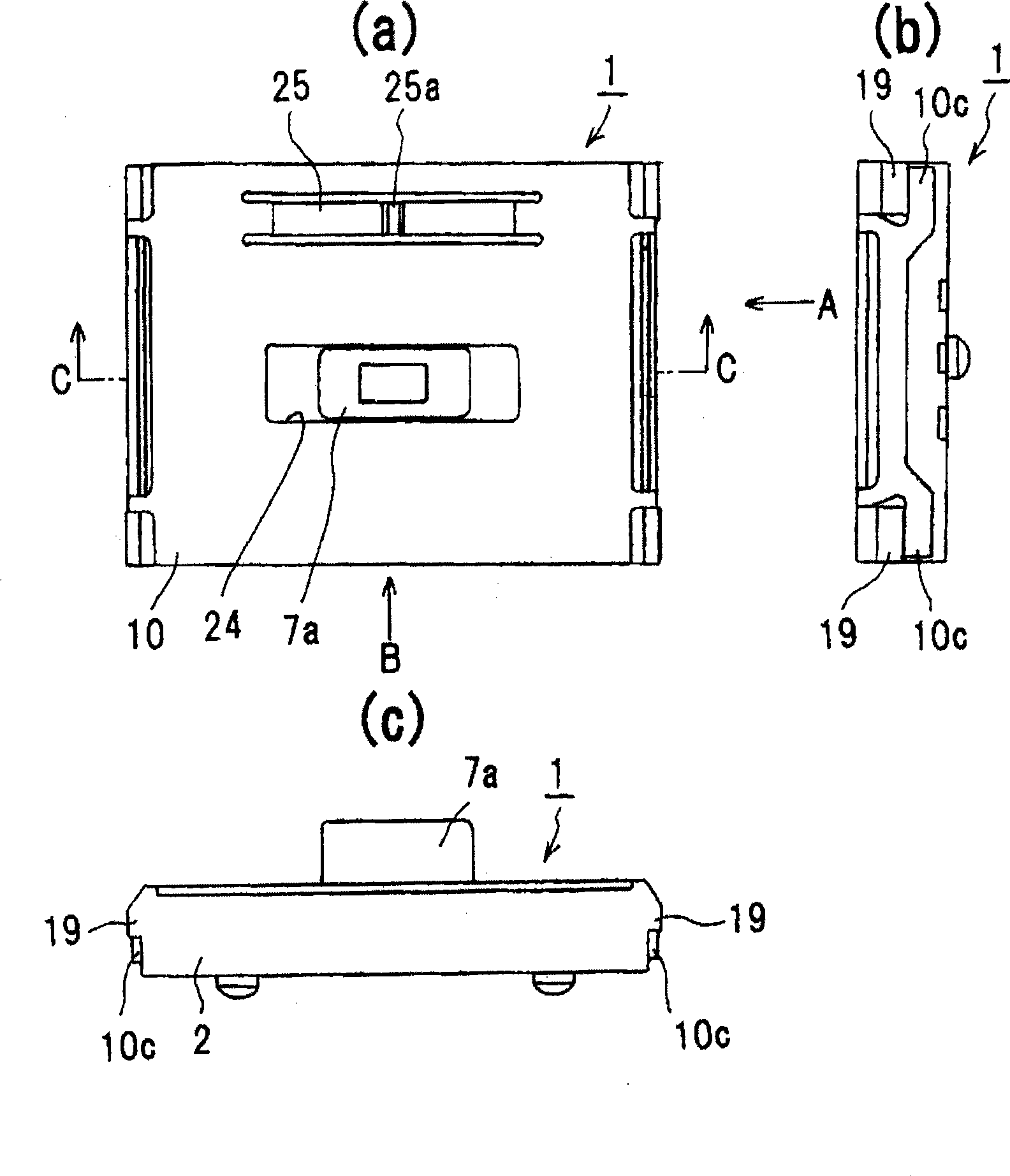

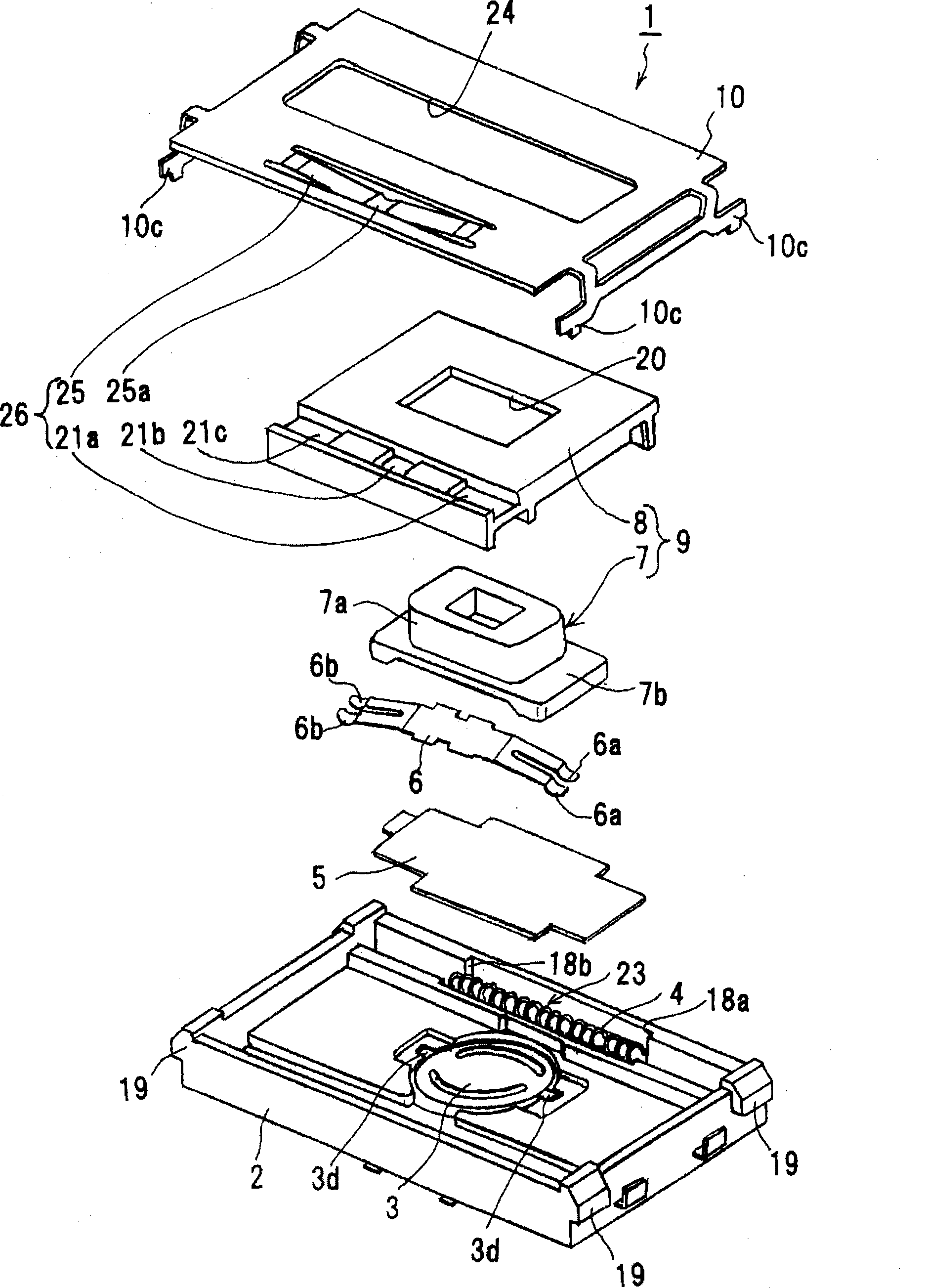

Transitional slide contact switch with twostage push-press switch

InactiveCN101447356AShorten the pressing strokeEasy to manufactureElectric switchesEngineeringSliding contact

The present invention relates to a transitional slide contact switch with a push-press switch, integrating the mechanism as follow, a slide mechanism having a plurality of slide fixed terminals and a slide contact pin for transferring the connection of the plurality of slide fixed terminals; a twostage press mechanism having a plurality of press fixed terminals and a butterfly movable contact pin facing to the press fixed terminals for transferring the connection of the plurality of press fixed terminals; an operation mechanism having a button for press operation and slide operation, and a slide block that may hold the button pressably and is equipped with a slide contact pin and drives the slide contact pin to slide on the plurality of slide fixed terminals when the button is slidely operated; a brake mechanism arranged between the slide block and the switch body side, and generating sound at each switching position between the slide fixed terminals; and a self-resetting mechanism for generating a force to reset the button to a neutral position when the button is slidely operated at least in one direction and driving the button and the slide block to reset to the neutral position together by the force when releasing the slide block.

Owner:MITSUMI ELECTRIC CO LTD

Decking

ActiveCN102481765AShow wellImprove the nature of the projectAdhesive processesWood treatment detailsEpoxyFuran

Decking comprises: a support selected from the group consisting of: polymeric materials; marine engineering polymers, fibre reinforced polymers, polymer metal composites, metal or wood sheets or marine superstructure; an array of strips of polymer treated wood secured to the support by means of an adhesive; the adhesive being selected from the group consisting of: polyurethane adhesives, modified silyl polymer adhesives and epoxy resin adhesives; wherein the polymer treated wood comprises a wood species selected from the group consisting of: maple species impregnated with a wood compatible polymerisable monomer, preferably selected from furfuryl alcohol, bis hydroxymethyl furan and mixtures thereof and subsequently dried and cured.

Owner:KEBONY

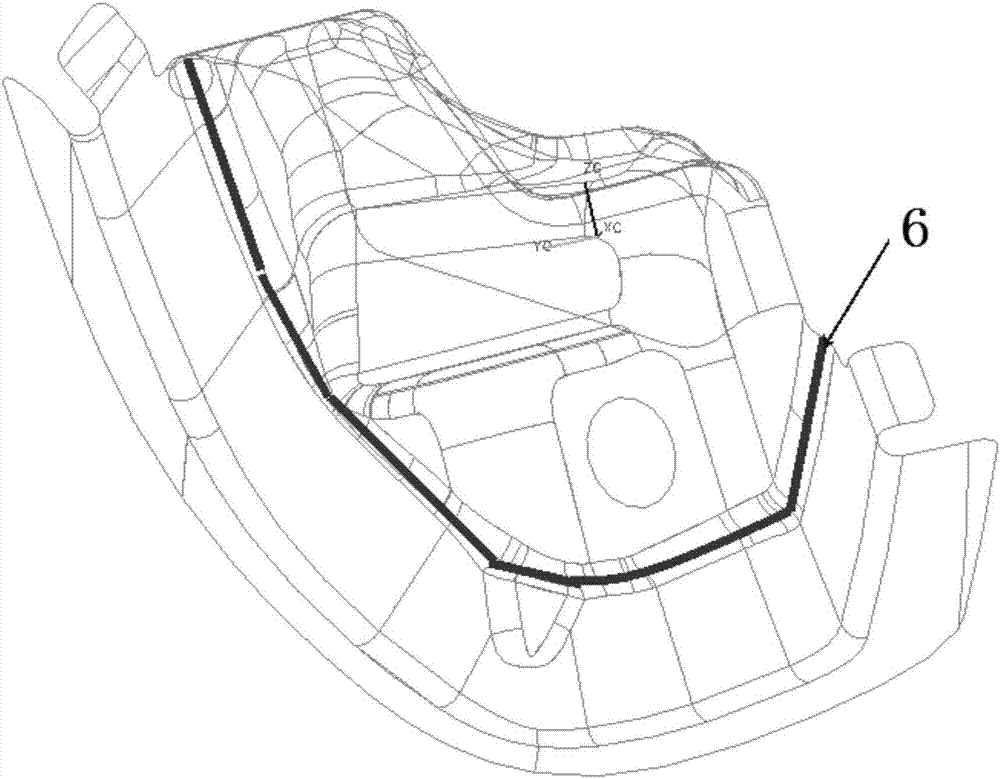

Drawing method for aluminum plate part

The invention provides a drawing method for aluminum plate parts, which belongs to the field of stamping dies for automobile panels, including the first step: dividing the first-order drawing area and the second-order drawing area; the second step: according to the material of the part Design the blank holder for drawing; the third step: place the workpiece material on the blank holder to complete the forming of the first-order drawing area of the workpiece; the fourth step: according to the first-order drawing divided in the first step Design the binder core in the area, and the binder core is fixedly connected with the upper mold; the fifth step: the material of the part drawn in one sequence is placed on the lower mold and the blank holder, and the binder core is closed with the lower mold , the formed part in the fourth step is used as the pressing area and no longer participates in the secondary molding. The upper mold moves downward to close with the blank holder first and the two move downward together until it is closed with the lower mold. Secondary drawing area forming. The present invention adopts the second-order drawing to make the molding uniform and avoid the phenomenon of wrinkling and cracking.

Owner:泊头市兴达汽车模具制造有限公司

High strength and toughness material of aluminum alloy die casting and preparation method thereof

The invention discloses a high strength and toughness material of an aluminum alloy die casting. The alloy material is prepared from the chemical components in percent by weight: 10.0-12.0% of Si, 7.0-9.0% of Zn, 1.5-2.5% of Cu, 0.8-1.1% of Mg, 0.3-0.5% of Mn, 0.3-0.5% of Fe, 0.05-0.2% of Be, 0.01-0.05% of Sr, less than or equal to 0.15% of impurity elements and the balance Al.

Owner:佛山鑫溢腾兴新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com