Stretch forming-electromagnetism composite forming device and method for multi-curvature skin piece

An electromagnetic composite, multi-curvature technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the complexity of the forming process and low forming efficiency, and achieve the elimination of wrinkling, compressive stress, and improved forming. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

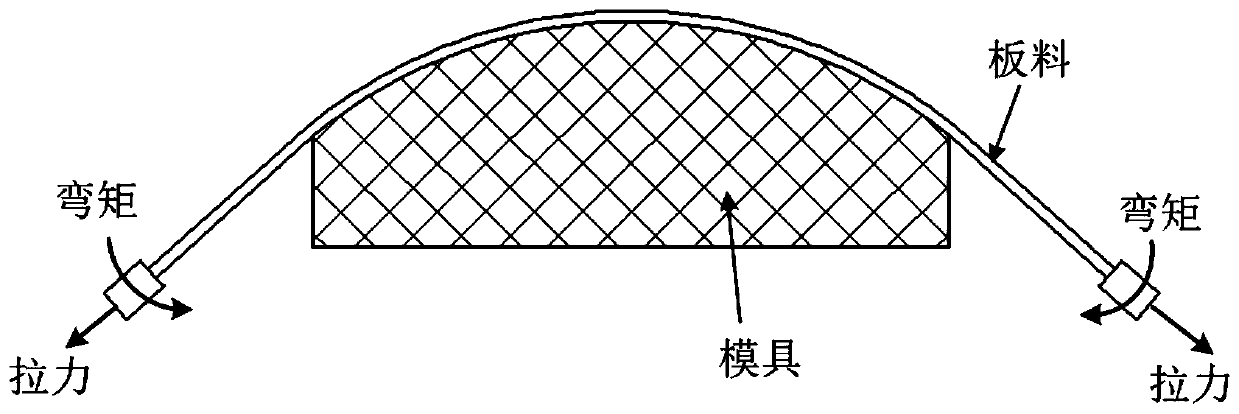

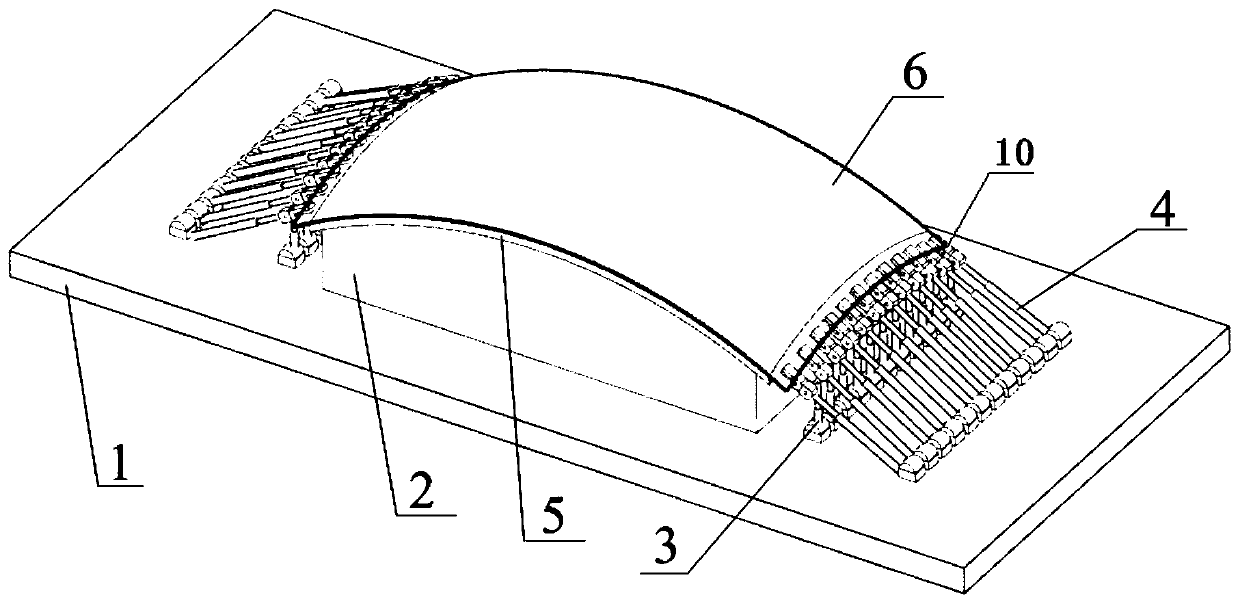

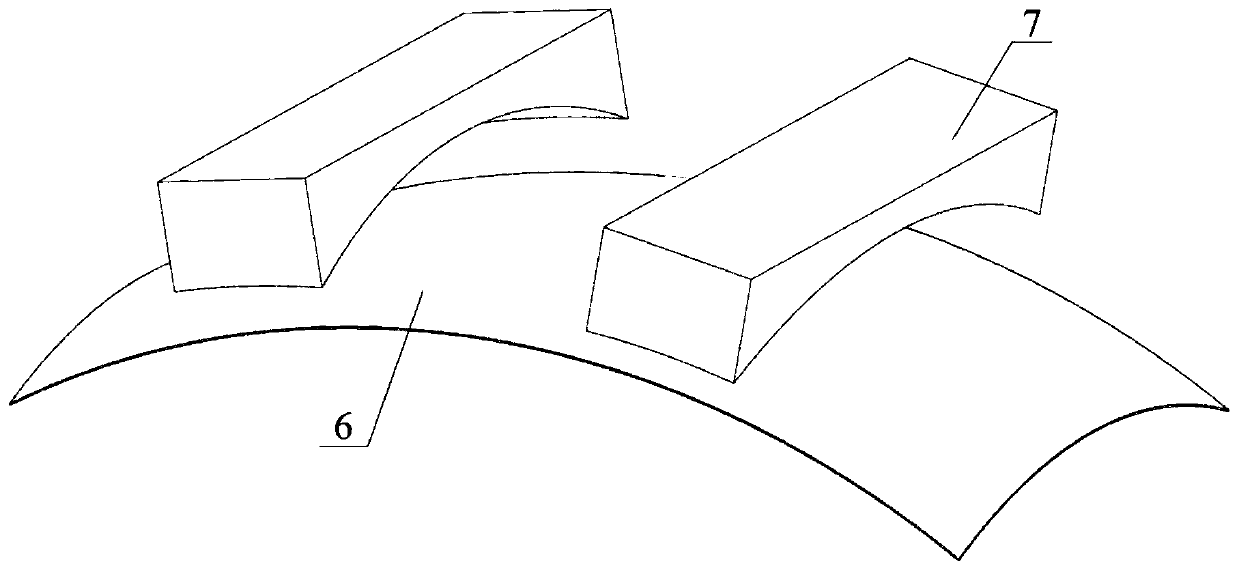

[0040] Such as figure 2 , 3 , 5 and 6, the embodiment of the present invention first discloses a tension-electromagnetic composite forming device for multi-curvature skin parts, including a base plate 1, a mold 2 and a The electromagnetic coil formed by the sheet material 6, the mold 2 is installed on the base plate 1, the electromagnetic coil is arranged above the mold 2, and also includes a vertical oil cylinder 5, a tangential oil cylinder 4 and a chuck 10 for clamping the edge of the sheet material 6. One end of the tangential oil cylinder 4 for tangentially stretching the sheet material 6 is hinged with the base plate 1, and the other end is hinged with the chuck 10, and one end of the vertical oil cylinder 5 for vertically stretching the sheet material 6 is hinged with the base plate 1, and the other end is hinged with the base plate 1. One end is hinged with the chuck 10, so that the sheet material 6 can be covered on the forming surface of the mold 2 through the vert...

Embodiment 2

[0051] In this example, if Figure 4 As shown, the composite forming device is basically the same as the embodiment, the difference is that the electromagnetic coil is composed of a plurality of discrete electromagnetic coils 8 that can be moved along the upper surface of the sheet material 6, and the lower surface of the discrete electromagnetic coils 8 is a plane or is in line with The molding surface of the mold 2 matches the curved surface structure, so that in actual use, it can be completed by discrete electromagnetic coils, thereby avoiding the current problem of manufacturing multiple sets of coils arranged according to the shape, thereby greatly reducing the cost of coil manufacturing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com