Patents

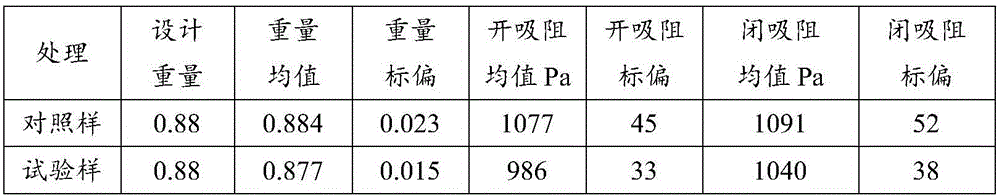

Literature

34results about How to "Single weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional resin grinding wheel and production method thereof

ActiveCN106002666AGood cutting performanceGood sharpnessBonded abrasive wheelsGrinding devicesMulti materialCeramic tiles

The invention relates to the technical field of grinding wheels and particularly relates to a multifunctional resin grinding wheel and a production method thereof. The grinding wheel comprises the following components in percentage by weight: 20-30% of silicon carbide, 20-30% of white fused alumina, 20-30% of brown fused alumina, 15-20% of a binding agent and 10-15% of cryolite, wherein the binding agent is phenolic resin liquid or powder. The grinding wheel can be used for cutting various materials and has better cutting performance; the grinding wheel has lower unit weight than a conventional product with the same specification, and every grinding wheel can save the molding material by 10-20g; and the grinding wheel is good in sharpness, incapable of generating a burn injury phenomenon when being used for cutting stone, ceramic tiles, iron, aluminum, stainless steel and the like, and meanwhile, the cutting efficiency is also greatly increased.

Owner:菊龙(天津)磨具有限公司

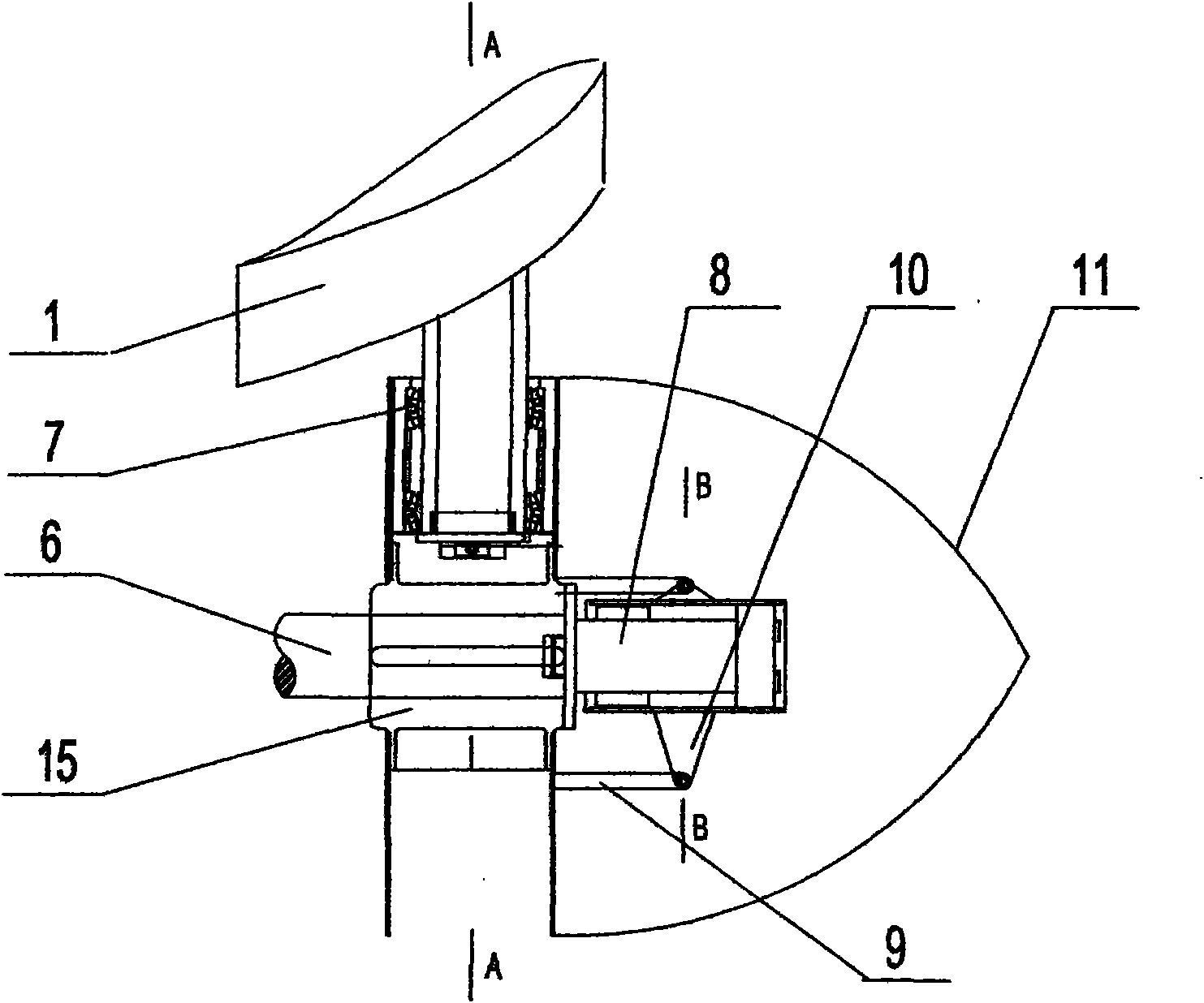

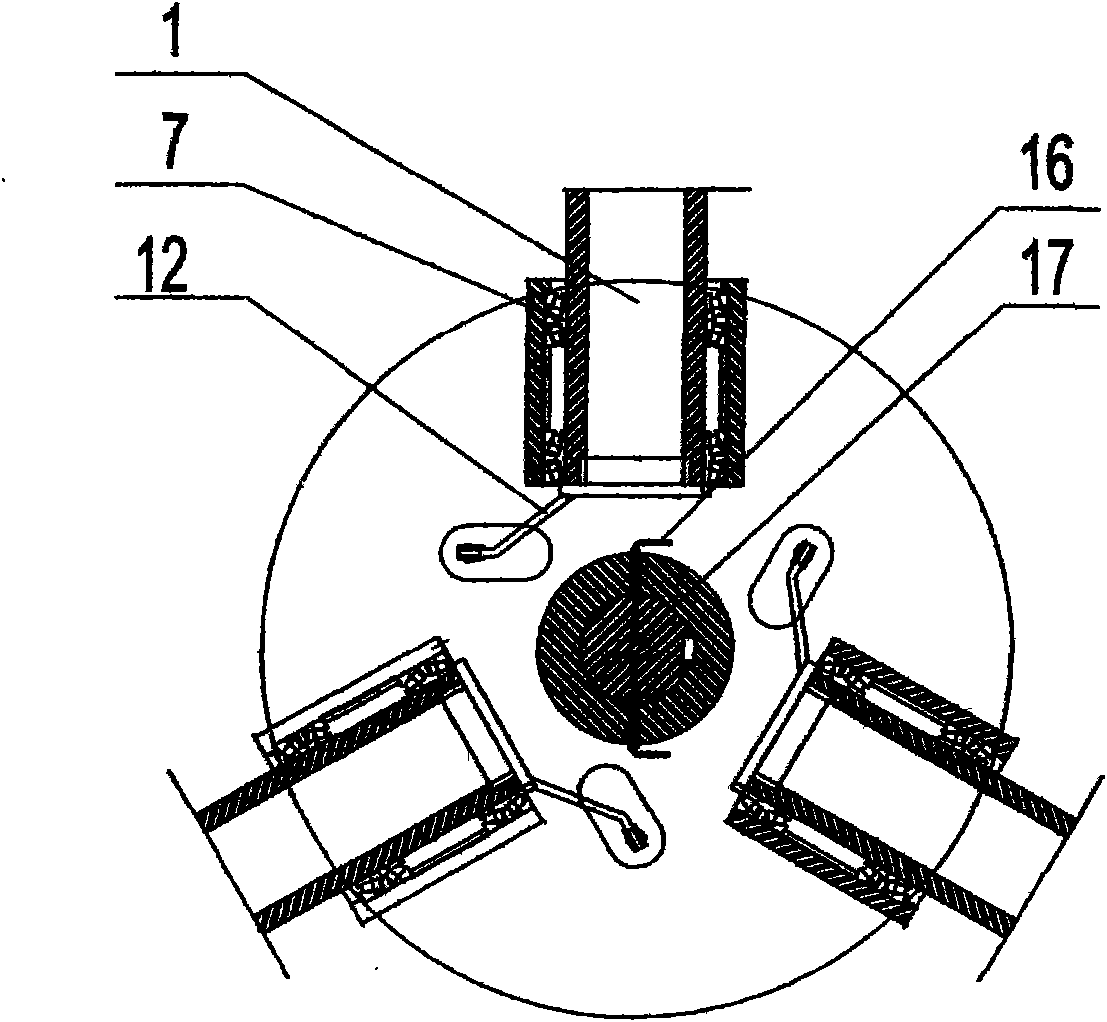

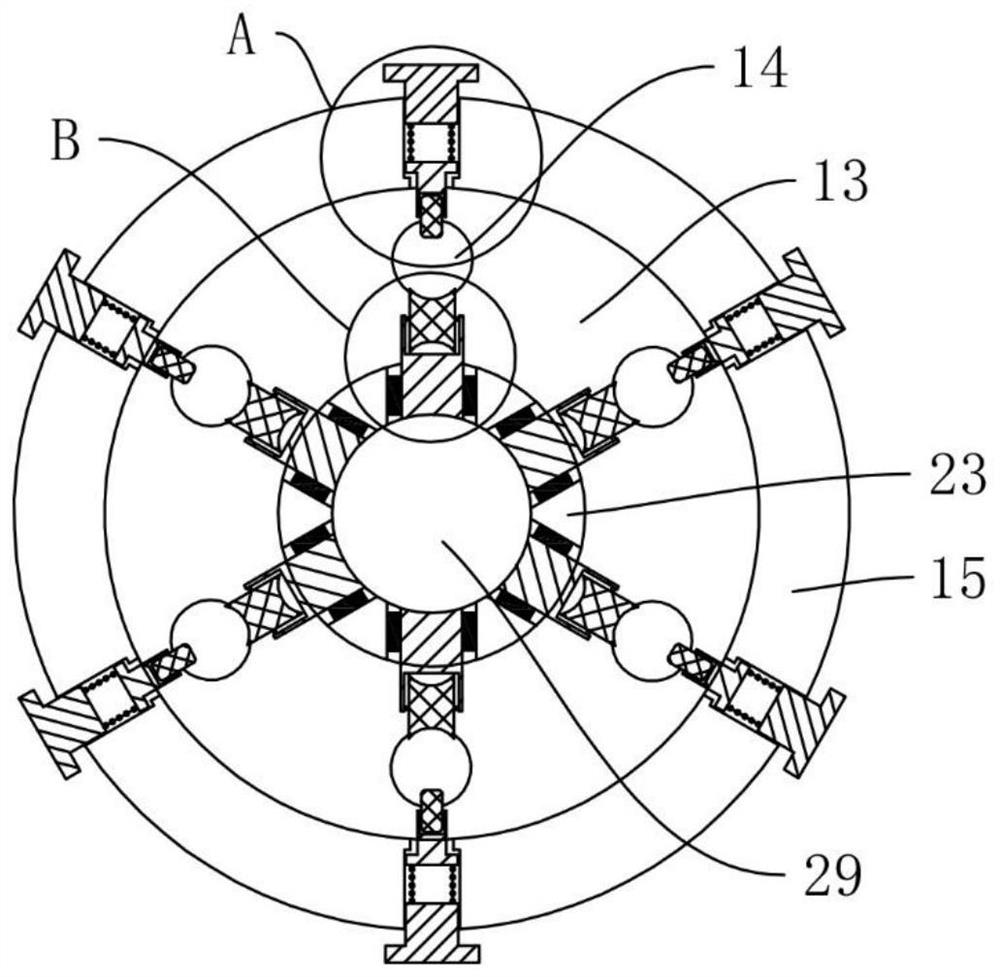

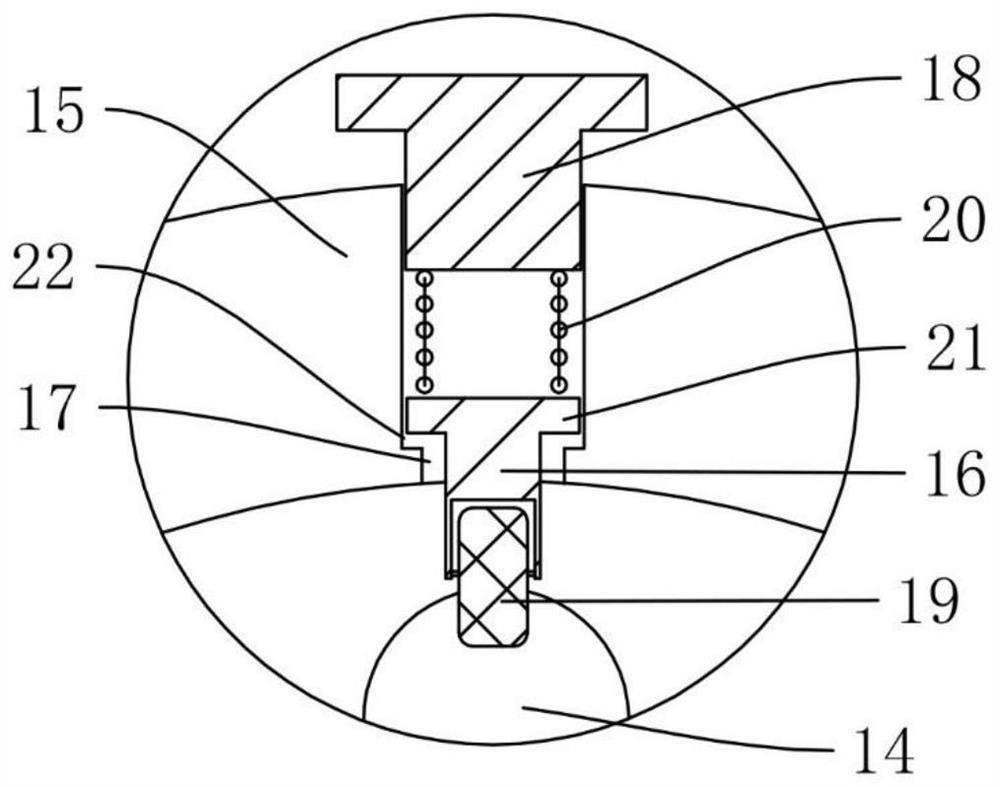

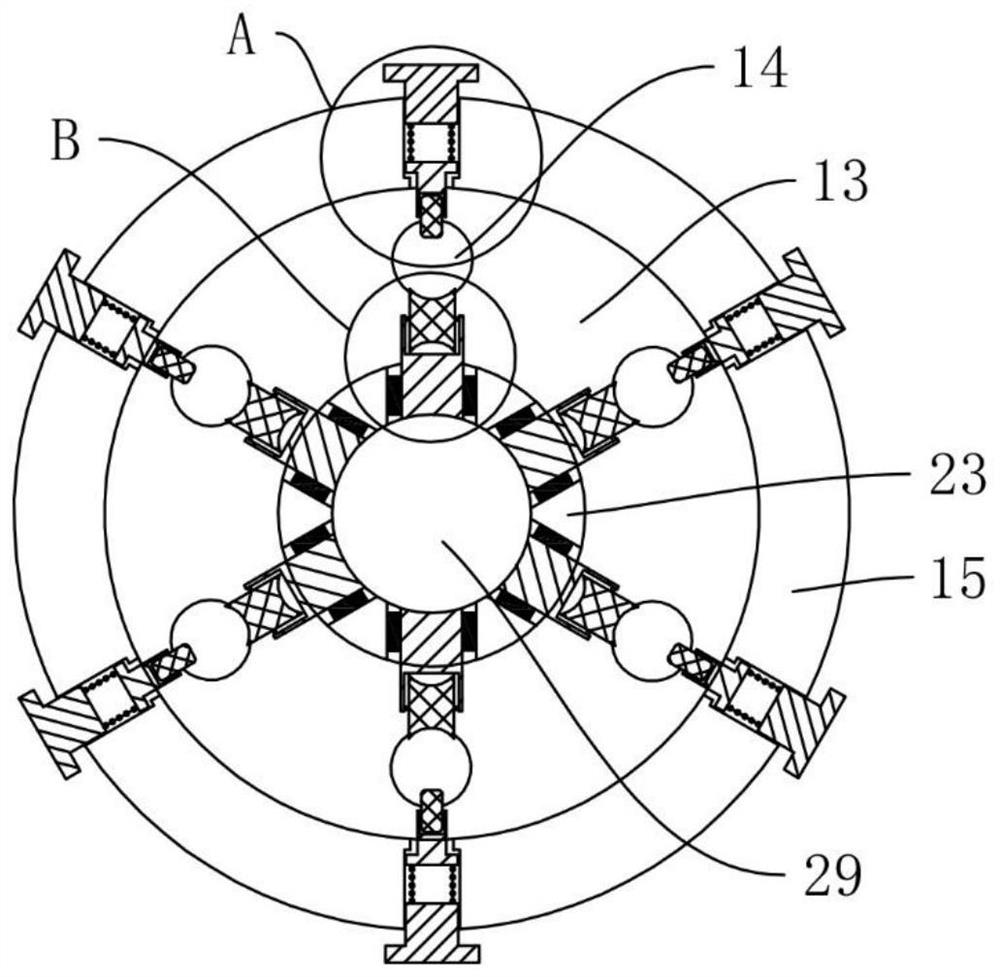

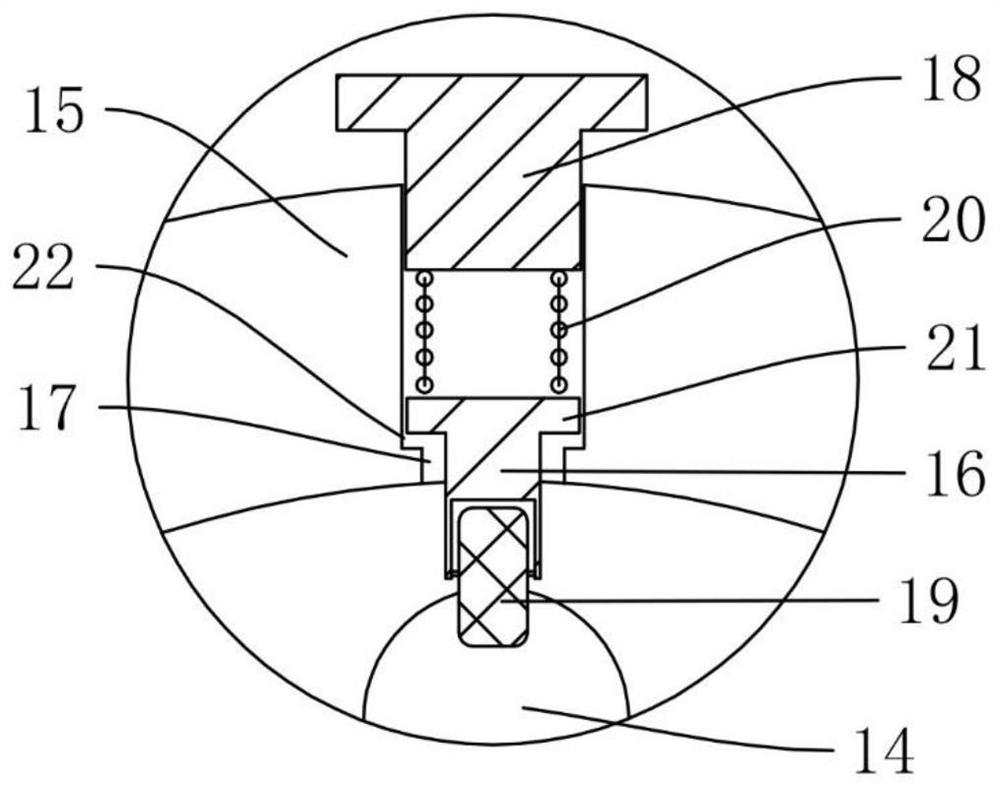

Blade pitch changing device of wind power generation device

InactiveCN101644230ALow failure rateImprove reliabilityWind motor controlMachines/enginesAngle modulationEngineering

The invention relates to the improvement of a blade pitch changing device of a wind power generation device, which is characterized in that a blade angle deflection driving mechanism consists of rocker bar members, pull rods and an axially telescopic power mechanism, wherein the rocker bar member is fixed on each blade shaft, the pull rods drive the rocker bar members to rotate, the axially telescopic power mechanism drives each pull rod to synchronously and axially move, and both ends of each pill rod are respectively connected with a rocker and a movable axially telescopic mechanism throughmovable pivots. The blade pitch changing device has the biggest characteristics that the blade pitch changing device is greatly simplified, the weight is greatly lightened, the megawatt-level weight is less than one fifth of the weight in a gear type, the reliability and the angle modulation consistency are good, and the blades are simply installed and adjusted, thereby being completely used for adjusting the blade pitch of a megawatt-level wind power generation device.

Owner:YIXING HUATAI INT GRP IND

Half-heavy refractory brick for dry-quenching furnace annular air duct and production method of half-heavy refractory brick

Disclosed is a half-heavy refractory brick for dry-quenching furnace annular air duct. The half-heavy refractory brick is produced from raw materials including, by weight, 16%-25% of mullite aggregates 5-3mm in particle size, 15%-30% of mullite aggregates smaller than 3-1mm in particle size, 5%-15% of mullite aggregates smaller than 0.074mm in particle size, 5%-15% of andalusite smaller than 1-0.074 in particle size, 10%-30% of fined mullite powder, 3%-10% of fined andalusite powder, 5%-20% of hollow spheres, 1%-8% of kaolin micro powder, 0.01%-2% of an interface treating agent and 2%-5% of a binding agent. The production method includes: firstly, mixing the hollow spheres with the interface treating agent; then adding the fined mullite powder, the fined andalusite powder and the kaolin micro powder; evenly mixing all of the mullite aggregates, the andalusite, the hollow spheres and the binding agent; pressing into a brick; drying; baking for standby use. By the arrangement, problems that the brick for the dry-quenching furnace annular air duct is prone to bloating and cracking are solved, compression strength of the brick can reach more than 60MPa, unit weight of the brick can be lowered more than 10%, and usage period is greatly prolonged.

Owner:武汉钢铁有限公司

Production method of super-strength chinlon 66 fiber

ActiveCN108441974AImprove spinnabilityUniform and stable viscosityMonocomponent copolyamides artificial filamentMelt spinning methodsFiberMaterials science

The invention discloses a production method for super-strength chinlon 66 fiber. The production method comprises the main steps of nylon 66 saline solution, concentration polymerization, spinning, cooling, oiling, drafting forming and winding. The production method is simple in technology and easy to implement, batched and continuous production of the super-strength chinlon 66 fiber can be achieved, the production efficiency is high, the yield is large, the performance of product batch pieces is uniform and stable, the breaking strength of the obtained super-strength chinlon 66 fiber reaches 10.0-10.4 g / d, the elongation at break reaches 16-22%, the elongation rate under the constant load reaches 10.5-13.5%, the dry hot shrinkage rate is 4.7-7.7%, the strength retention is larger than 90%,and the method has the advantages of being high in strength, low in unit weight, good in fatigue resistance, impact resistance, friction resistance and heat resistance and the like.

Owner:SHEN MA INDUSTRY CO LTD

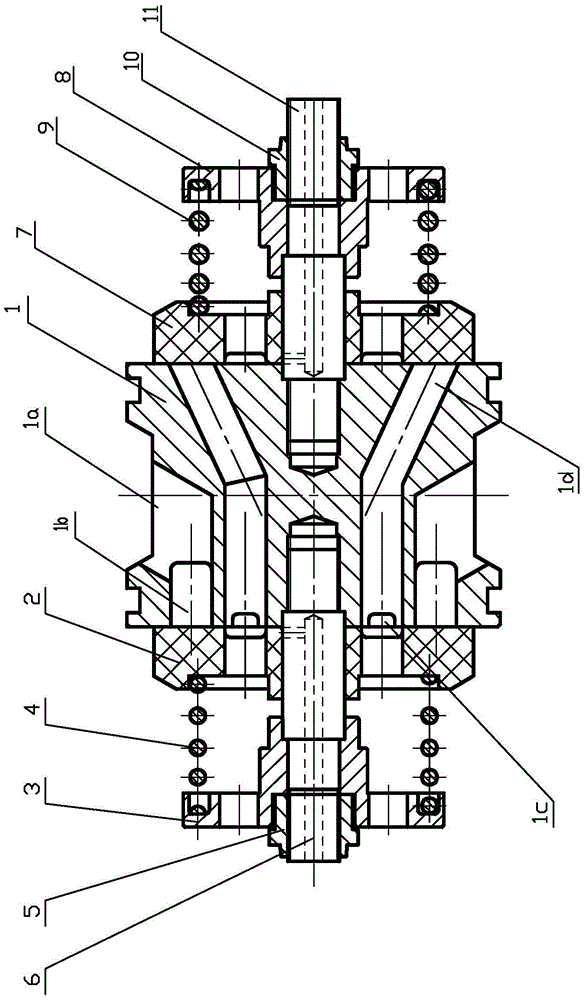

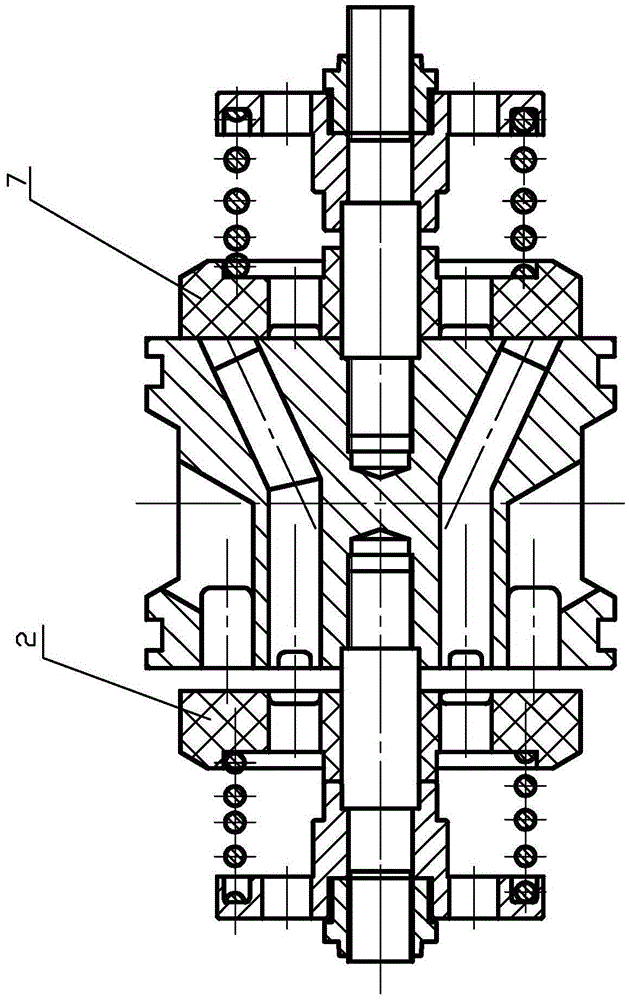

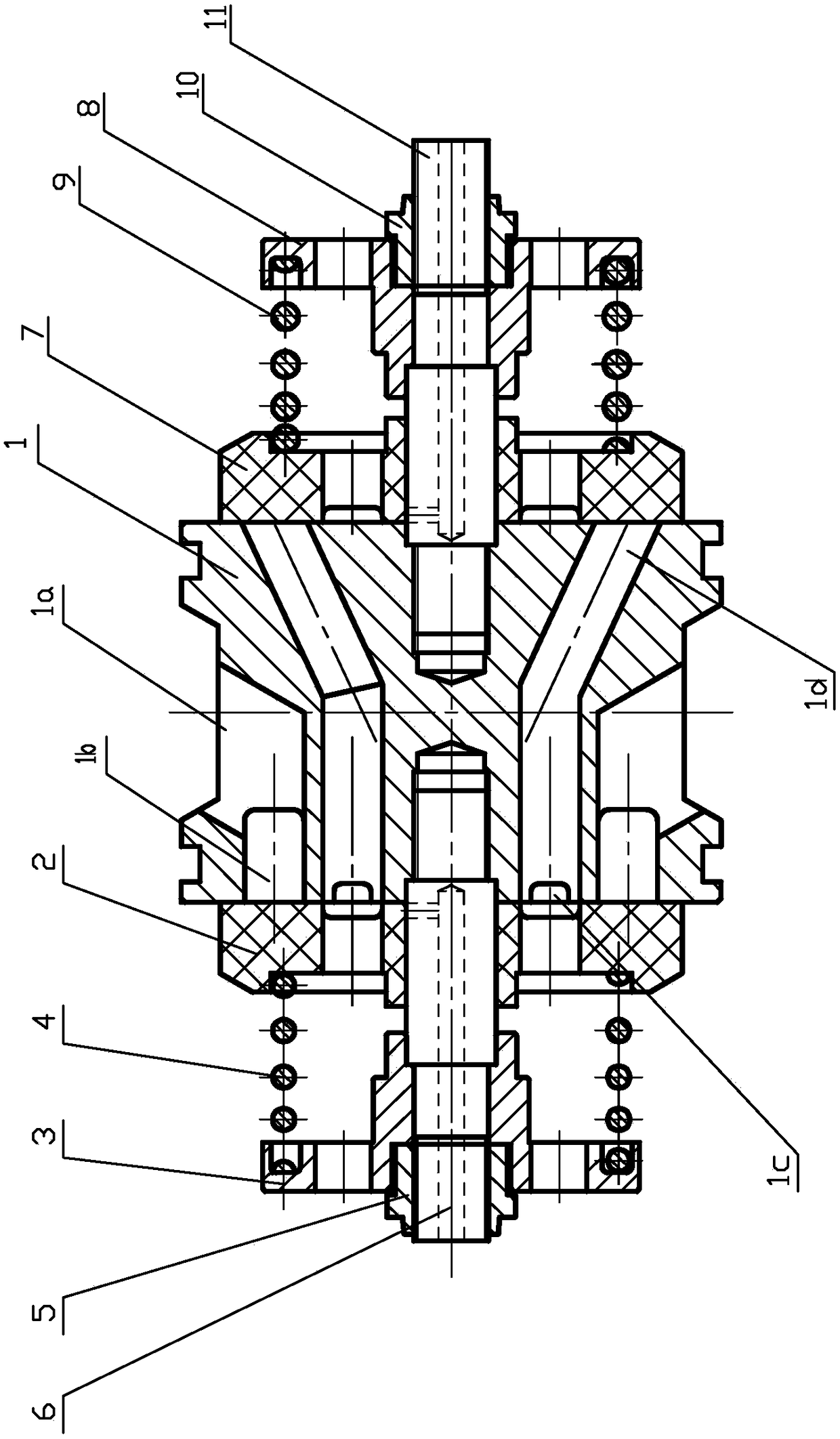

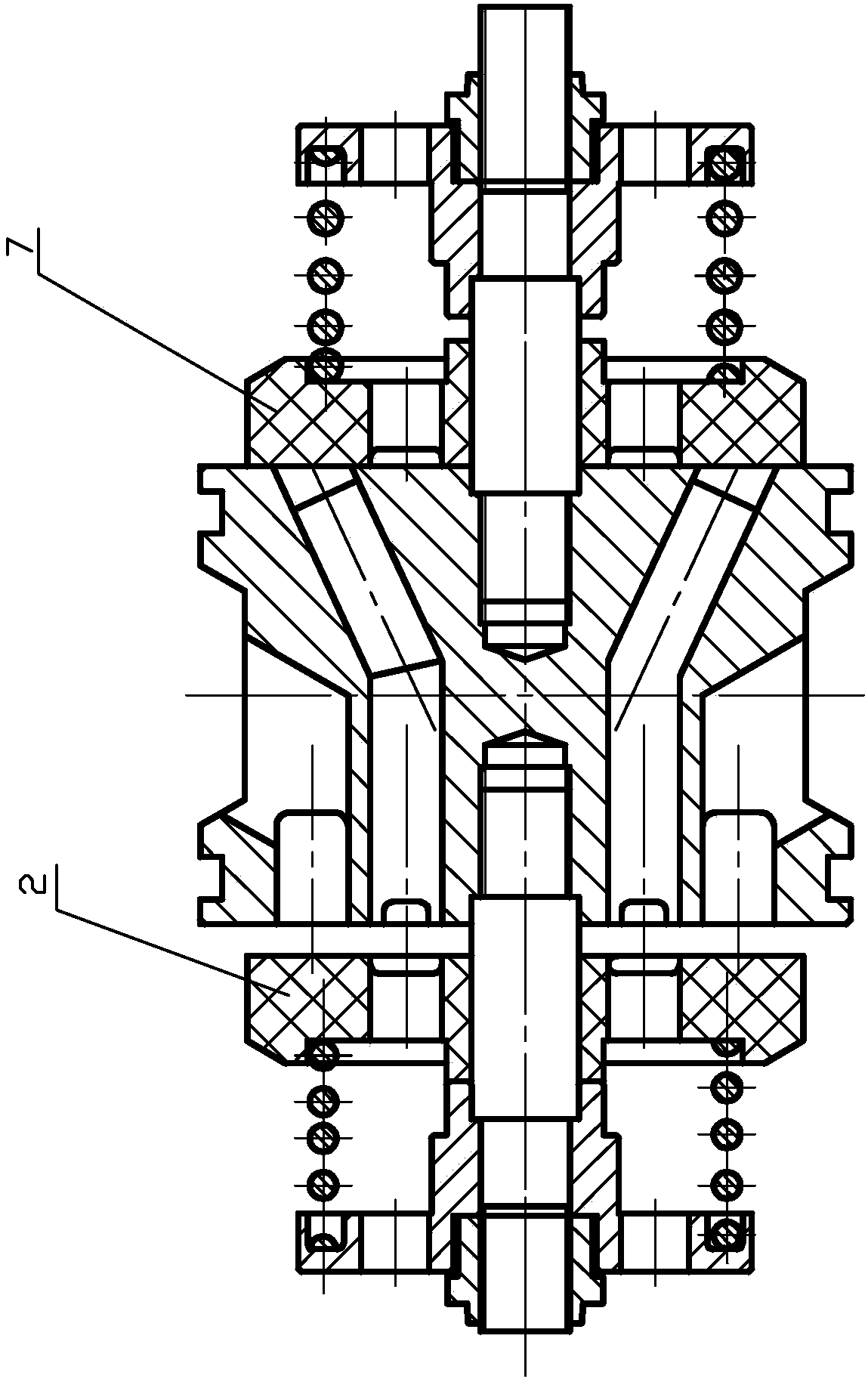

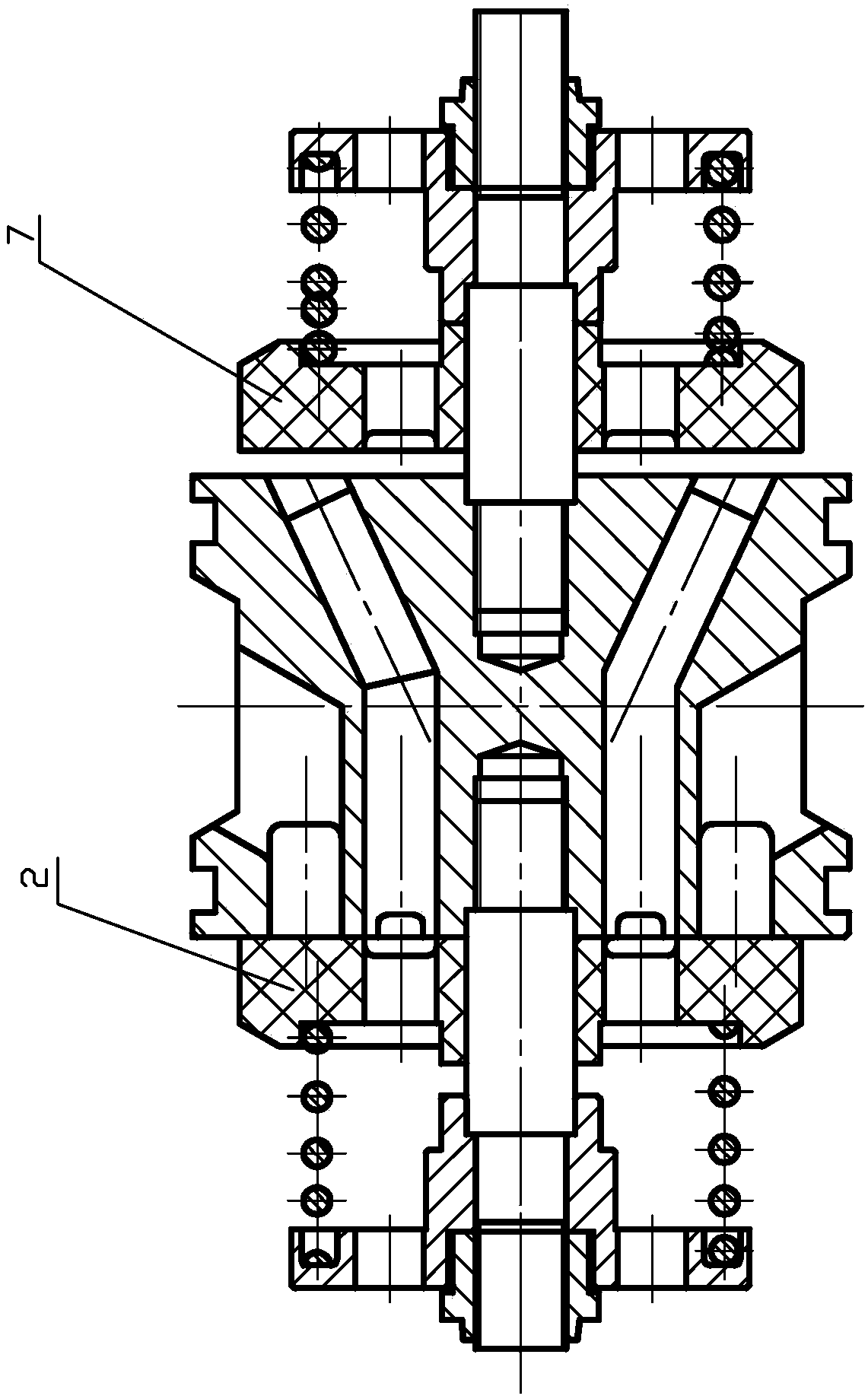

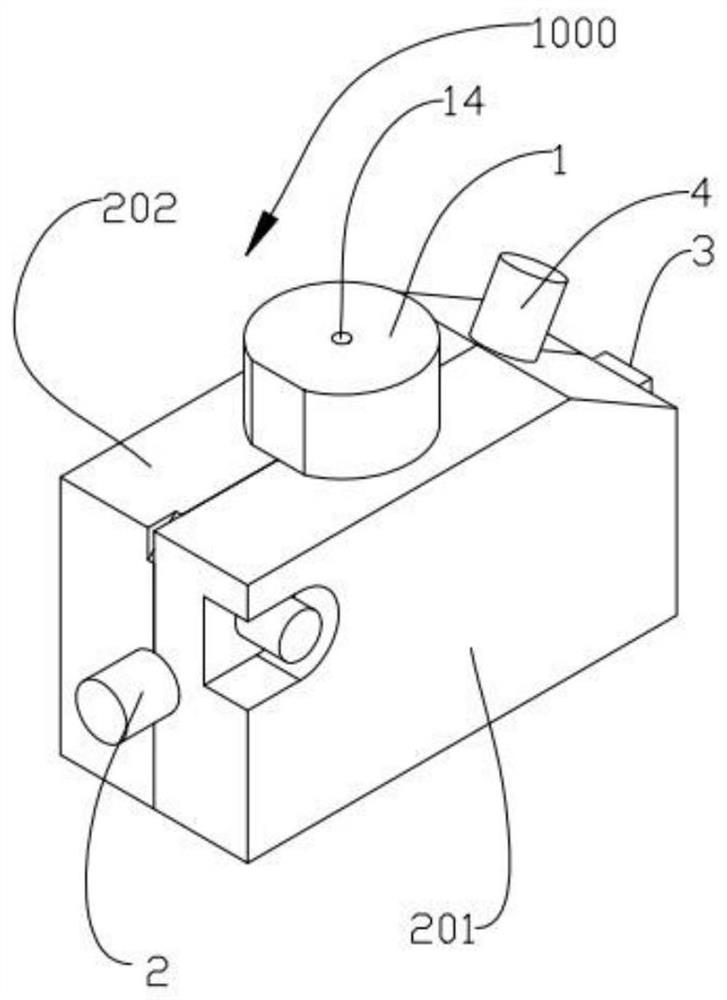

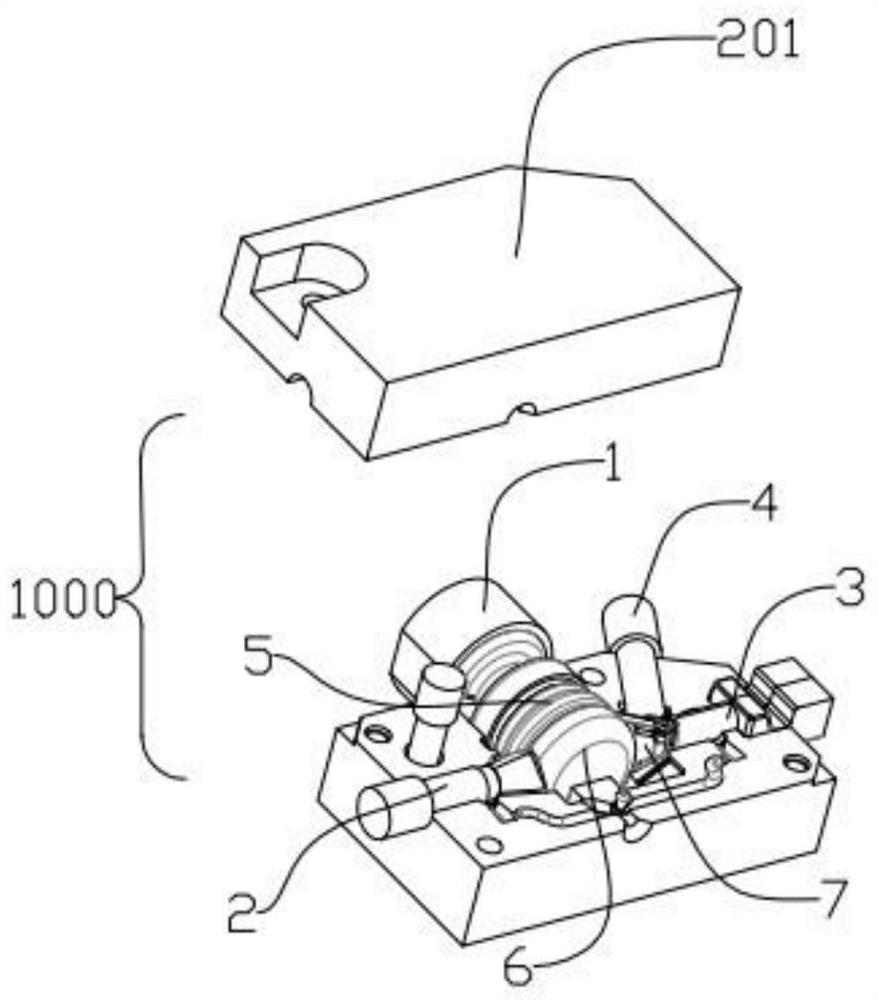

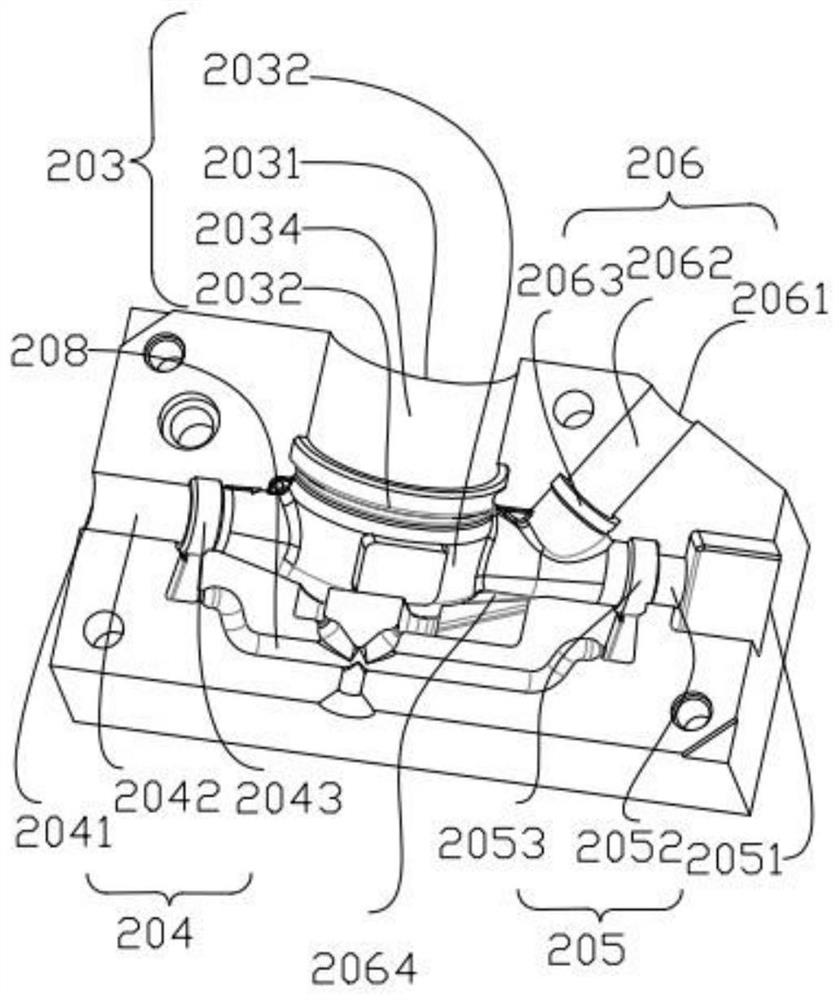

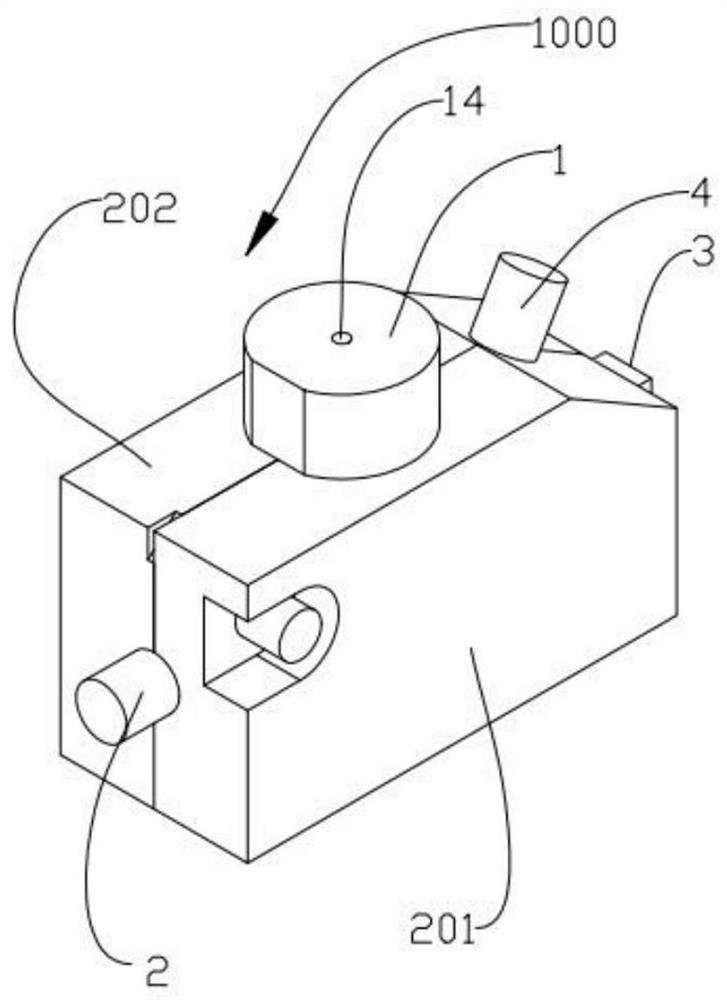

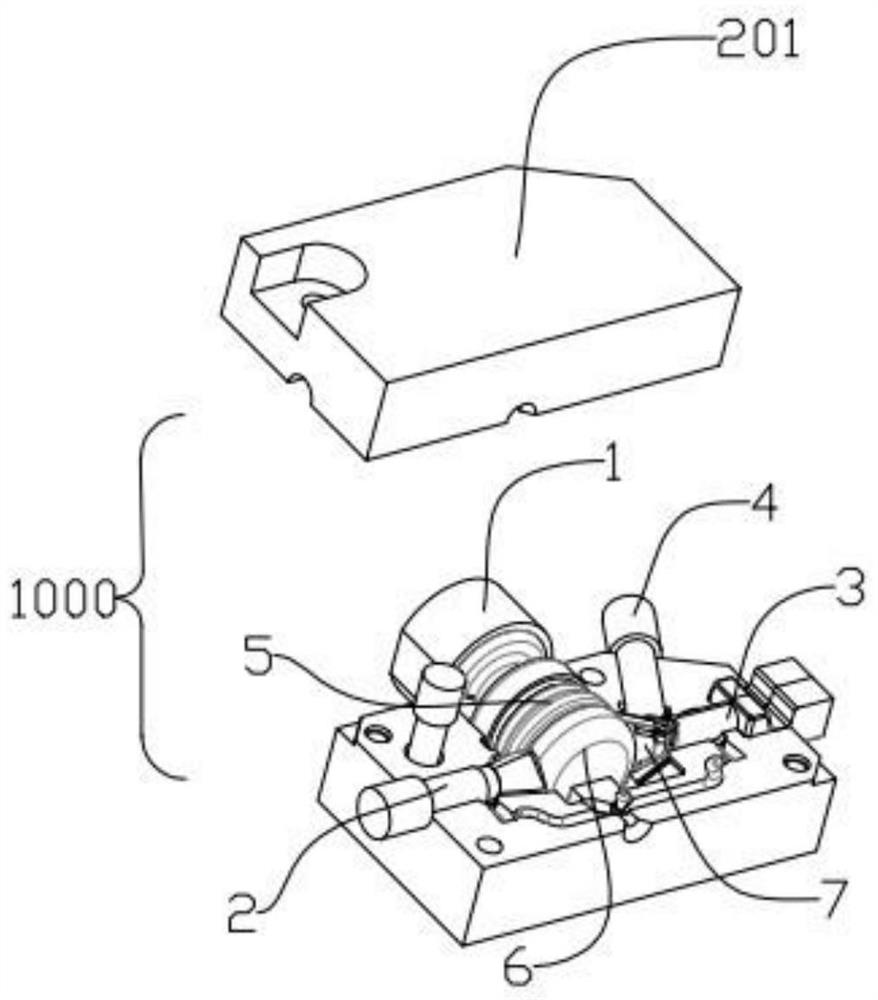

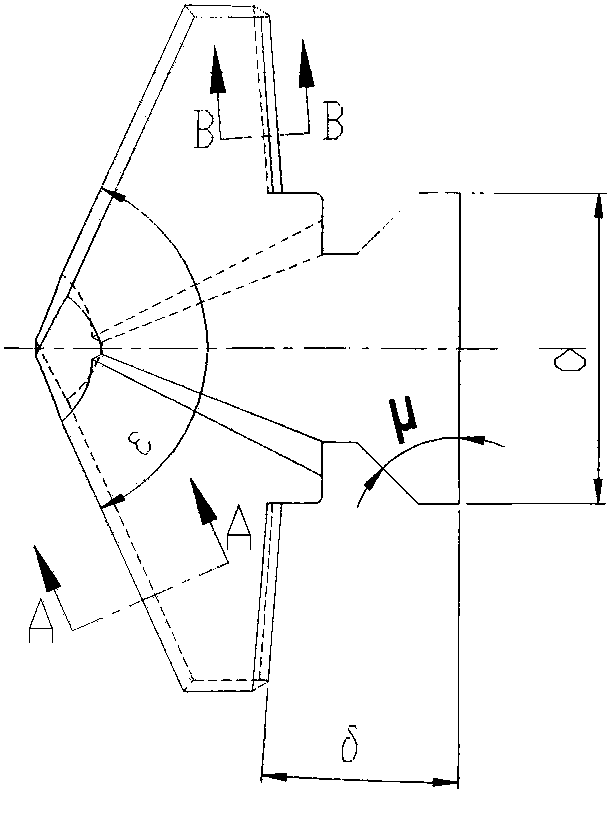

Plunger pump valve bank

ActiveCN105626509AChange directionSingle weightPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpInlet valve

The invention relates to a plunger pump valve bank which comprises a valve seat. The plunger pump valve bank is characterized in that liquid inlet cavities are formed in the outer wall of the valve seat, the two end faces of the valve seat are both planes, the plane at one end of the valve seat is the liquid inlet plane, and the plane at the other end of the valve seat is the drainage plane; the liquid inlet plane is provided with an annular groove communicating with the liquid inlet cavities; a liquid inlet valve plate is arranged outside the liquid inlet plane of the valve seat and provided with liquid inlets, and a sealing surface is located between the outer edge of the liquid inlet valve plate and the outer edge of the liquid inlet plane; the liquid inlet plane is provided with drainage cavities, and the drainage cavities and the annular groove are arranged at intervals; the drainage plane is provided with liquid outlet cavities, and drainage channels enabling the drainage cavities and the liquid outlet cavities to communicate are formed in the valve seat; a drainage valve plate is arranged outside the drainage plane of the valve seat and provided with drainage holes, and a sealing surface is located between the outer edge of the drainage valve plate and the outer edge of the drainage plane. The plunger pump valve bank provided by the invention is small in size, high in pump efficiency and capable of effectively lowering the valve play flow rate.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

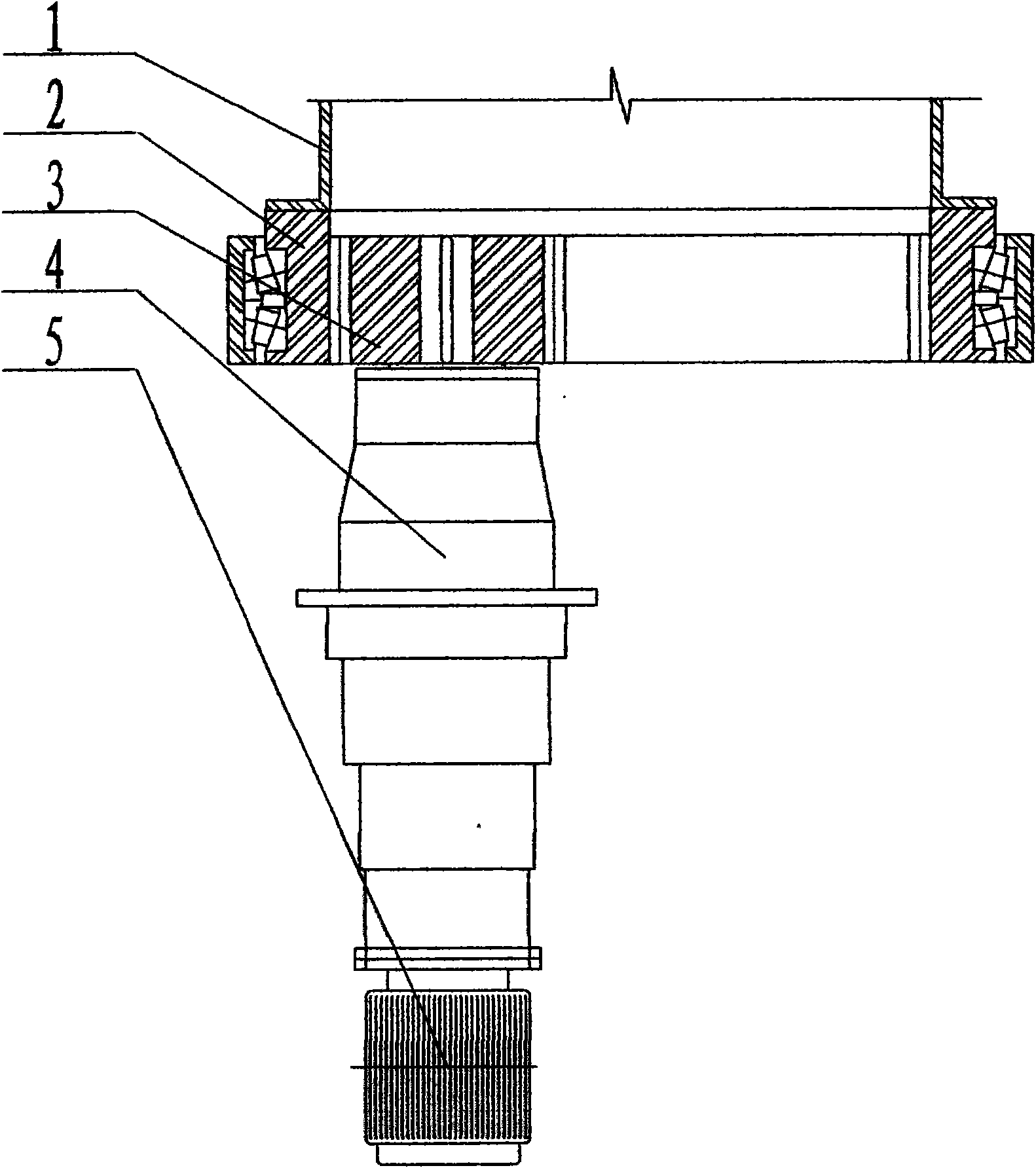

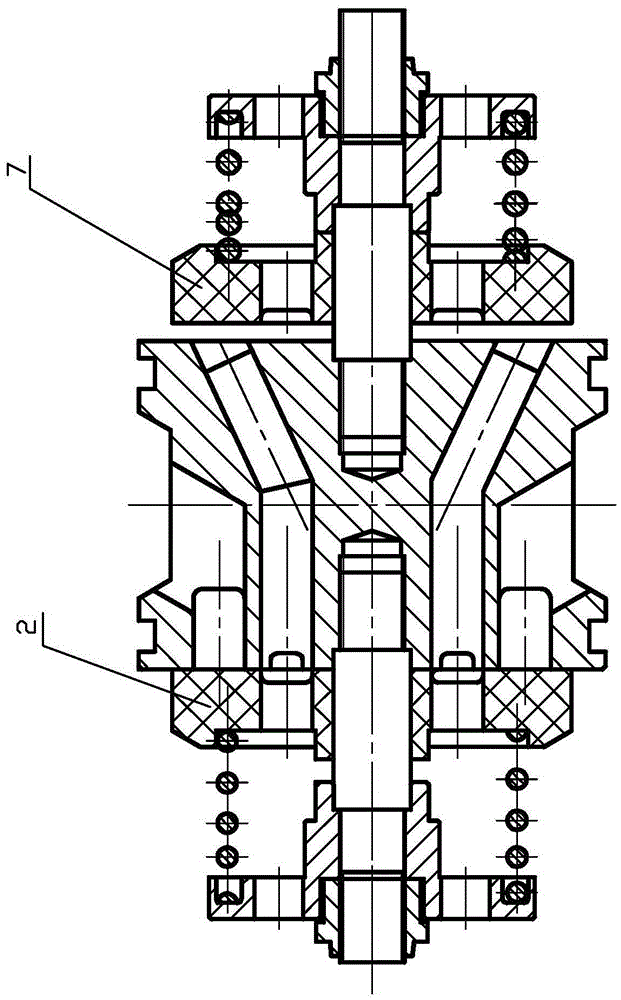

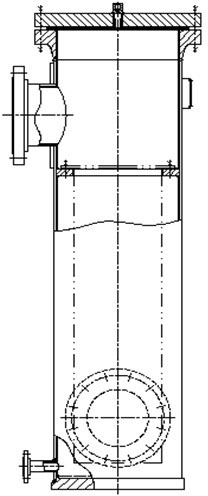

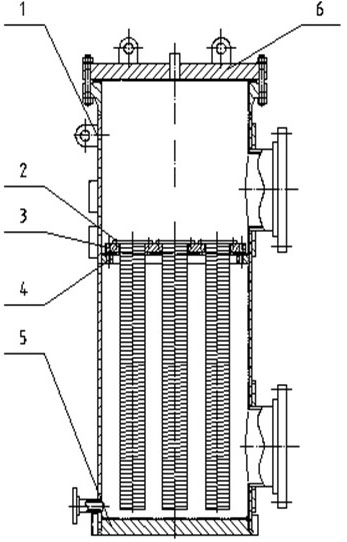

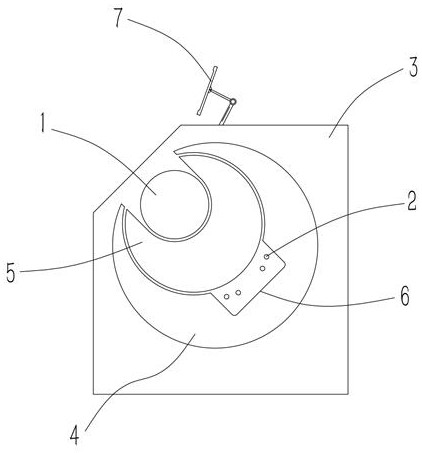

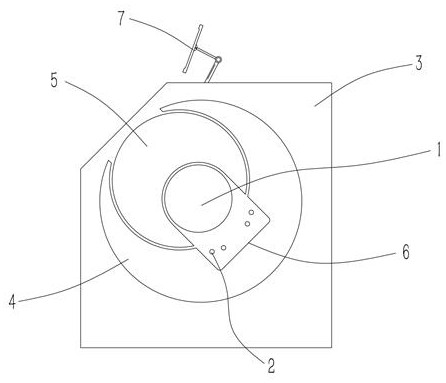

Resin catcher used in industrial water processing system

InactiveCN102423563AIncreased differential pressure toleranceSingle weightStationary filtering element filtersWater processingIndustrial water

The invention relates to a resin catcher used in an industrial water processing system comprising a cylinder body (1), filter cores (2), a filter core tube plate (3), a filter core tube plate installation ring (4), and a base plate (5). The cylinder body (1), the base plate (5), and the filter core tube plate installation ring (4) are composed into an integral whole through welding. The filter cores (2) and the filter core tube plate (3) are connected, and the connections are watertight. The filter core tube plate (3) and the filter core tube plate installation ring (4) are connected, and the connection is watertight. The number N of the filter cores arranged on the tube plate is no less then 2. The catcher provided by the invention is adopted in industrial water processing systems with high water processing capacities. With the catcher, equipment dimension and land occupation can be greatly reduced, equipment weight can be effectively reduced, and equipment manufacturing cost can be saved. A multi-core small-diameter filter core arrangement is adopted, such that the water processing filtering capacity of the equipment can be improved. With the small-diameter filter cores, reduced strength caused by increased diameter can be avoided.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

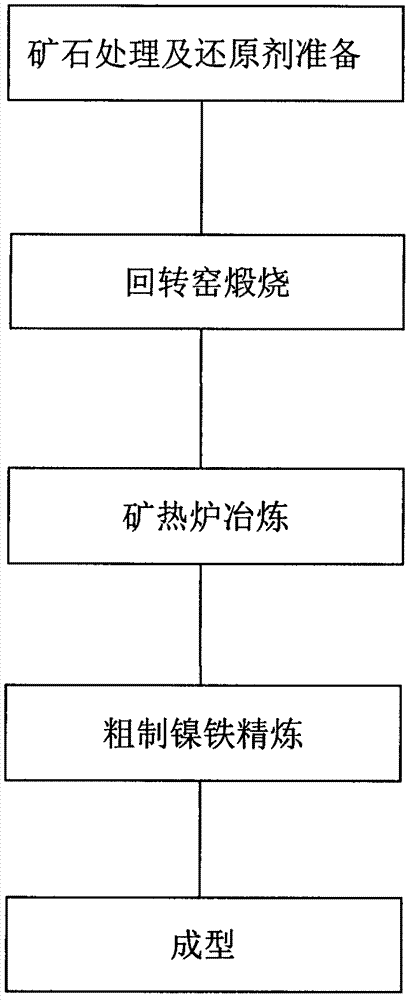

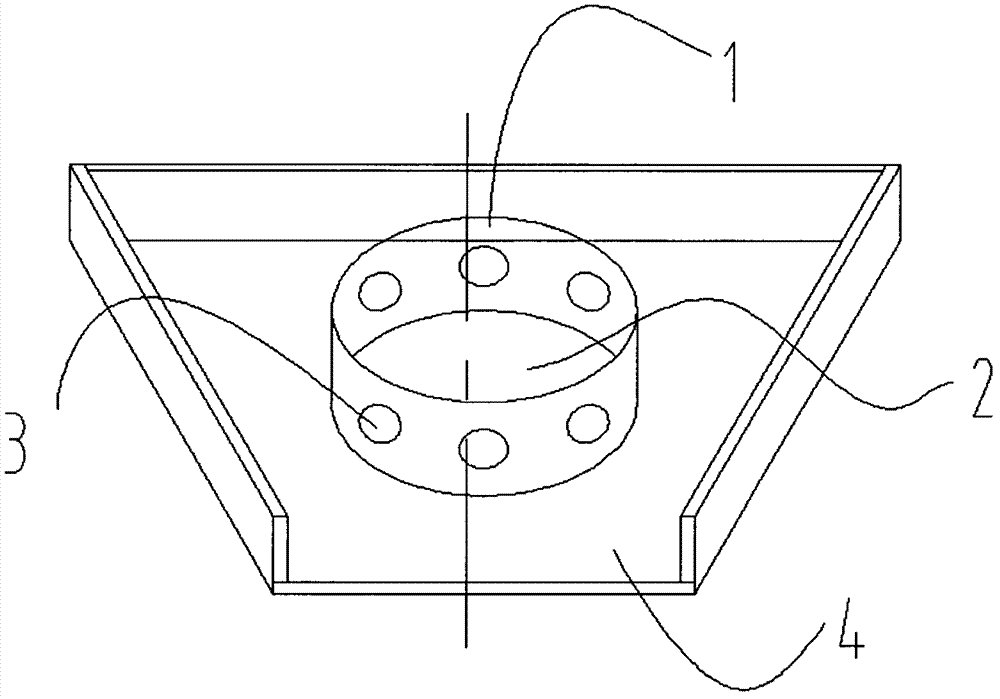

Nickel steel bean production method

InactiveCN103088254AControl ingredientControl shapeRotary drum furnacesSteelmakingChemical composition

The invention discloses a nickel steel bean production method, and belongs to the technical field of steelmaking. Chemical components of the nickel steel bean comprise: 20% of Ni, 0.15-0.3% of Si, 0.1% of C, 0.03% of S, 0.03% of P, and the balance of Fe. The nickel steel bean has an irregular bean shape. Production steps comprise: treating ore, preparing a reduction agent, carrying out calcination in a rotation kiln, smelting in a submerged arc furnace, carrying out refinement on the crudely-prepared ferronickel, forming, adopting laterite-nickel ore as a raw material, and adopting a nickel steel bean forming device and a cooling water tank to rapid form, wherein the nickel steel bean forming device can be statically fixed, and further can horizontally rotate, and a water temperature of the cooling water tank is controlled to a certain temperature range. According to the present invention, the components of the nickel steel bean can be accurately controlled, such that the Ni content is about 20%, and the Si content and the S content are low; the side surface outlet size of the nickel steel bean forming device can be adjusted so as to adjust the size of the nickel steel bean; the nickel steel bean has characteristics of small size and light weight; and the temperature of the cooling water tank is controlled so as to control the shape of the nickel steel bean shape.

Owner:SHANGHAI ZHONGHE METAL PROCESSING

A plunger pump valve group

ActiveCN105626509BChange directionSingle weightPositive displacement pump componentsLiquid fuel engine componentsInlet valveEngineering

The invention relates to a plunger pump valve bank which comprises a valve seat. The plunger pump valve bank is characterized in that liquid inlet cavities are formed in the outer wall of the valve seat, the two end faces of the valve seat are both planes, the plane at one end of the valve seat is the liquid inlet plane, and the plane at the other end of the valve seat is the drainage plane; the liquid inlet plane is provided with an annular groove communicating with the liquid inlet cavities; a liquid inlet valve plate is arranged outside the liquid inlet plane of the valve seat and provided with liquid inlets, and a sealing surface is located between the outer edge of the liquid inlet valve plate and the outer edge of the liquid inlet plane; the liquid inlet plane is provided with drainage cavities, and the drainage cavities and the annular groove are arranged at intervals; the drainage plane is provided with liquid outlet cavities, and drainage channels enabling the drainage cavities and the liquid outlet cavities to communicate are formed in the valve seat; a drainage valve plate is arranged outside the drainage plane of the valve seat and provided with drainage holes, and a sealing surface is located between the outer edge of the drainage valve plate and the outer edge of the drainage plane. The plunger pump valve bank provided by the invention is small in size, high in pump efficiency and capable of effectively lowering the valve play flow rate.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

Miniaturized blood irradiation device

PendingCN113198057AReduce system componentsReduce the failure rate of the whole machineBlood transfusionMedical physicsSurgical department

The invention discloses a miniaturized blood irradiation device which comprises a blood cup, a plurality of radioactive sources, a plurality of radioactive source pipe racks, a radiation shielding cover and a box body. According to the blood irradiation device, a thin shielding system can be selected, so that the piece weight of the device is reduced, the device has better mobility, meanwhile, the energy consumption of the device is greatly reduced, the reliability, maintainability, replaceability, combination, integration and the like of the device are greatly improved compared with those of commercially available products, and the device can be used for medical treatment and public health departments and units which need to use irradiation blood in urban blood centers, surgical hospitals and field hospitals.

Owner:CHONGQING JIANAN INSTR

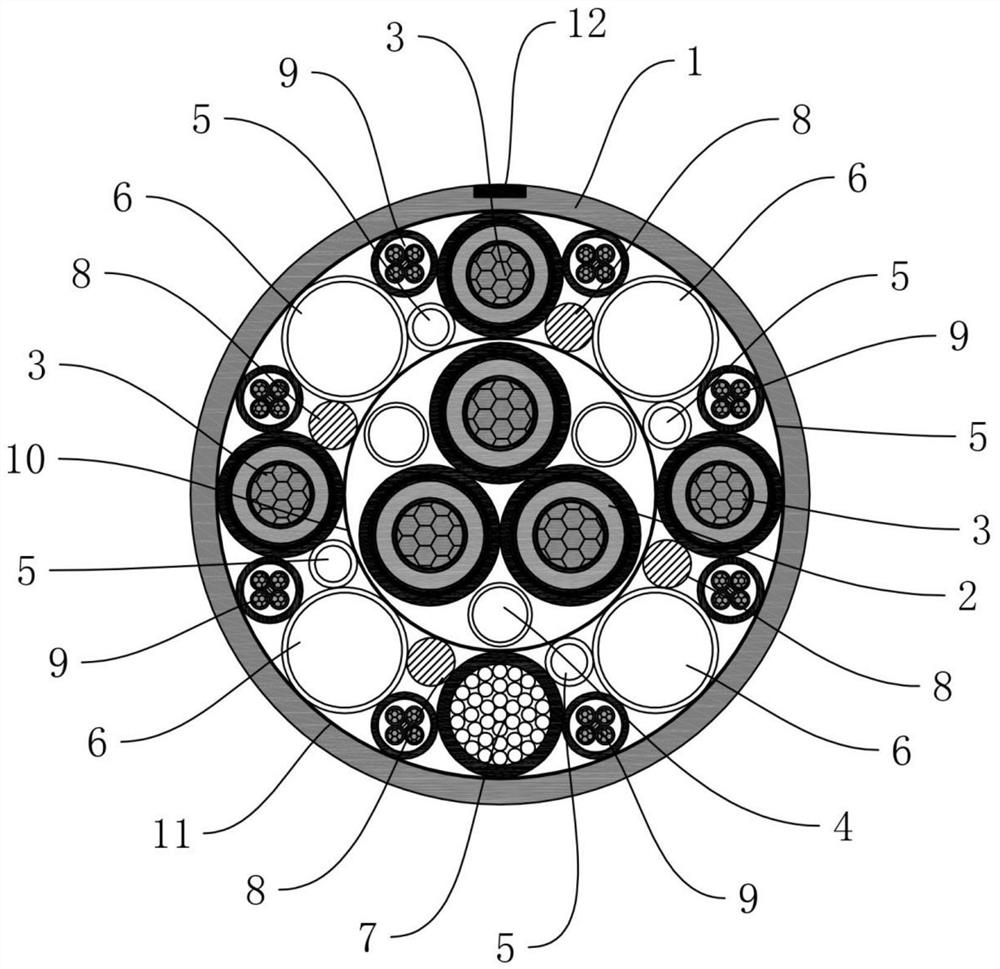

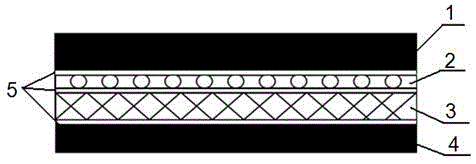

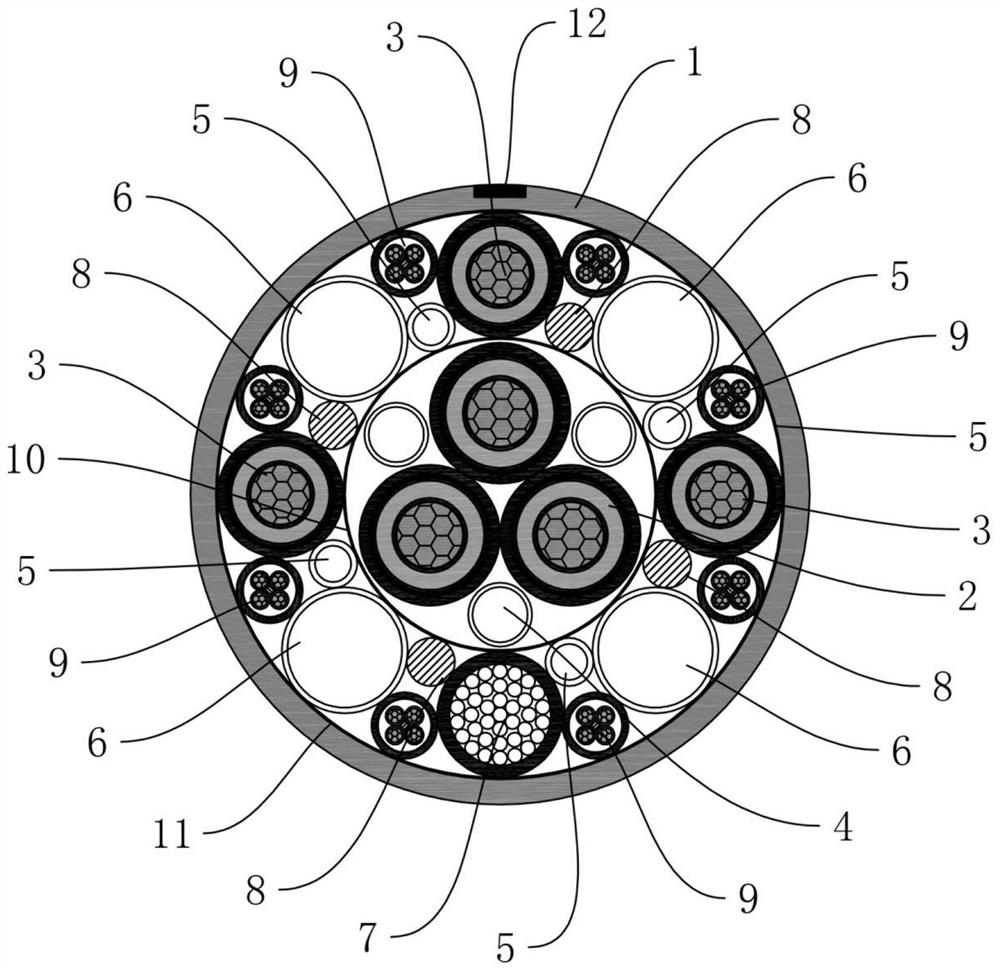

High-voltage composite umbilical cable and manufacturing process thereof

ActiveCN113539555AHigh strengthImprove stabilityInsulated cablesInsulated conductorsLow voltageEngineering

The invention discloses a high-voltage composite umbilical cable. The high-voltage composite umbilical cable comprises an inner-layer functional unit group, an outer-layer functional unit group and an outer sheath, wherein the inner-layer function unit group comprises three inner-layer medium-voltage cable units arranged in the center and an inner-layer filling steel pipe unit, and the outer-layer function unit group comprises four outer-layer steel pipe units. The four outer-layer steel pipe units divide the periphery of the outer-layer function unit into four installation areas, wherein an outer-layer medium-voltage cable unit, two low-voltage cable units, an outer-layer filling steel pipe unit and a filling body are arranged in three of the installation areas respectively. A steel strand unit, two low-voltage cable units, an outer layer filling steel pipe unit and a filling body are arranged in the other mounting area. According to the high-voltage composite umbilical cable and the manufacturing process thereof, the umbilical cable is high in tensile strength, light in weight and convenient to manufacture.

Owner:宁波东方电缆股份有限公司

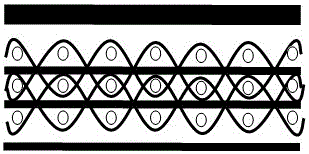

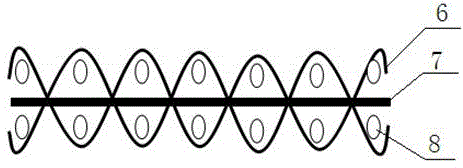

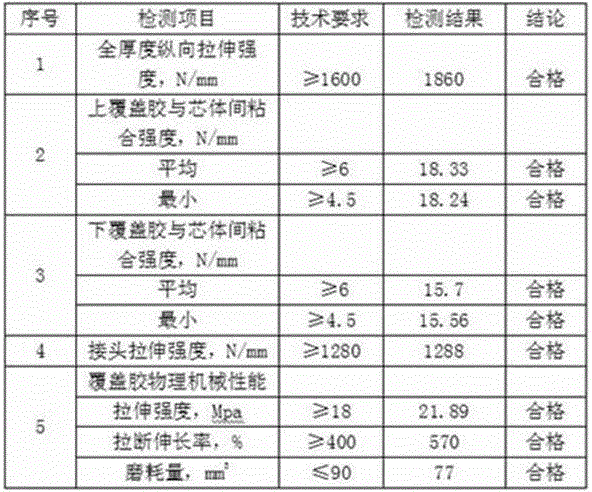

A straight warp whole core aramid flame retardant conveyor belt

InactiveCN104129595BHigh strengthImprove strength utilizationConveyorsFibre treatmentTear resistanceEngineering

The invention discloses a straight-through whole-core aramid flame-retardant conveyor belt, which combines the advantages of the whole-core conveyor belt and the steel cord conveyor belt to develop a belt body with high strength, thin belt core thickness, impact and tear resistance, A flame retardant conveyor belt with good grooving performance, not easy to run long distances, and easy joints.

Owner:YANKUANG GRP CO LTD +1

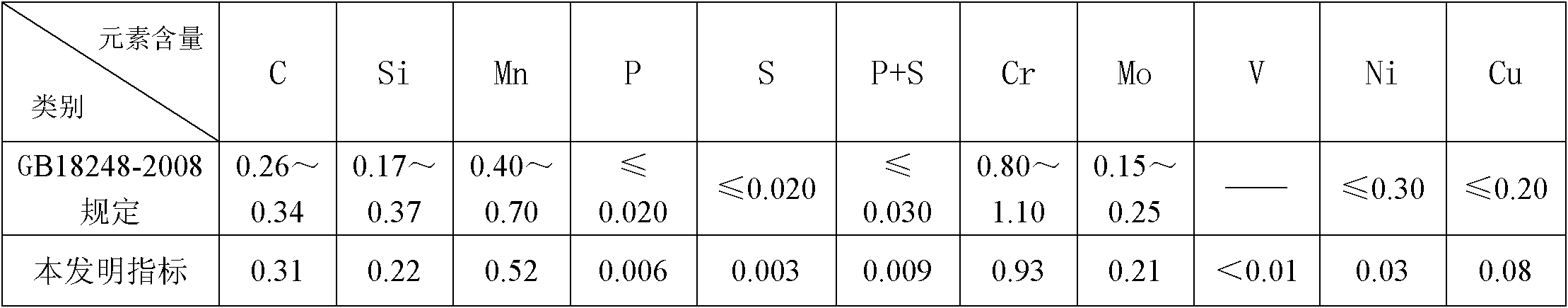

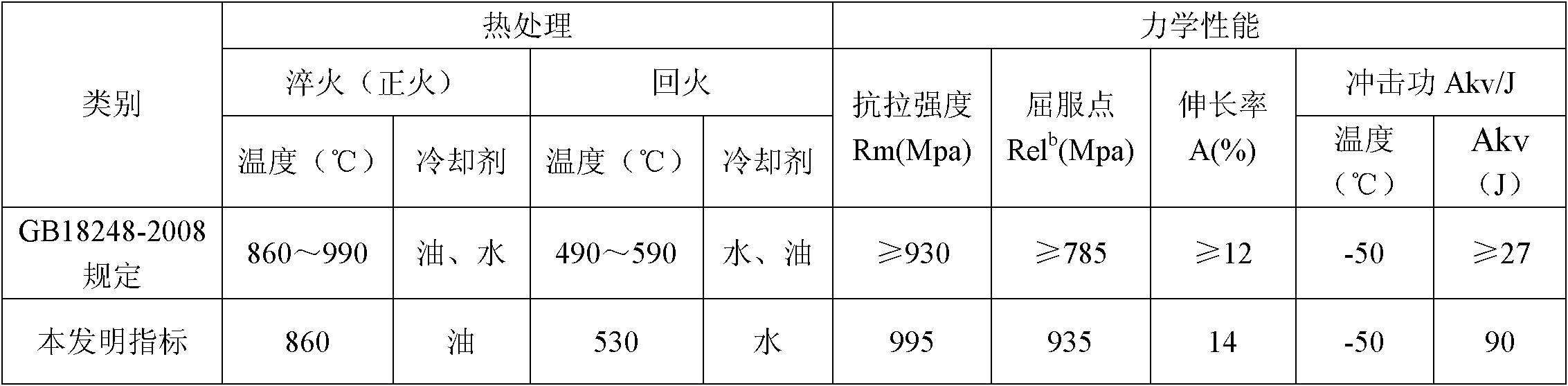

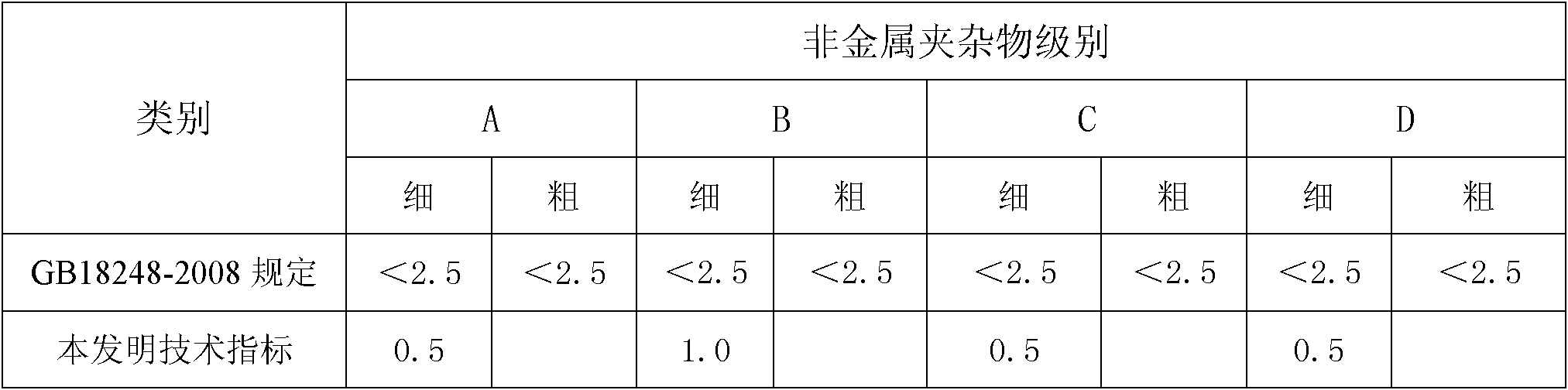

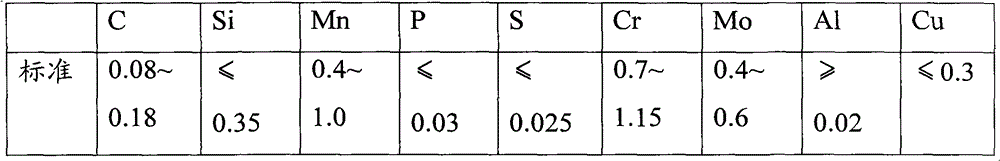

Manufacturing method of cold drawn cylinder pipe for industrial gas cylinder

InactiveCN101927276ASingle weightLarge volume-to-weight ratioSolid state diffusion coatingSteel tubeChemical composition

The invention relates to a manufacturing method of a cold drawn cylinder pipe for an industrial gas cylinder. A phi 194*5.5mm hot-rolled raw material tube of which the material is 30CrMo is washed with an acid, lubricated and drawn to a finished product of which the specification is phi 198*4.8mm at one time. In the method, the 30CrMo hot-rolled tube serves as the raw material tube. The industrial gas cylinder manufactured by cold drawing and a method of shrinking opening and bottom has the advantages of light unit weight, relatively large capacity, good comprehensive performance of the steel tube, safety and reliability. In the chemical components of the industrial gas cylinder manufactured by the method, the content of S, the content of P and the content of residual elements (Ni and Cu) are far less than the national standards, which is very favorable for guaranteeing the comprehensive performance of the gas cylinder significantly.

Owner:天津润德中天钢管有限公司

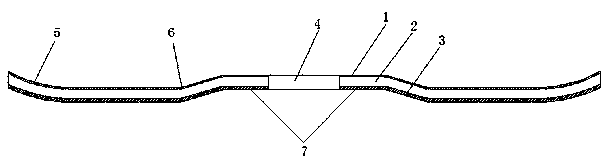

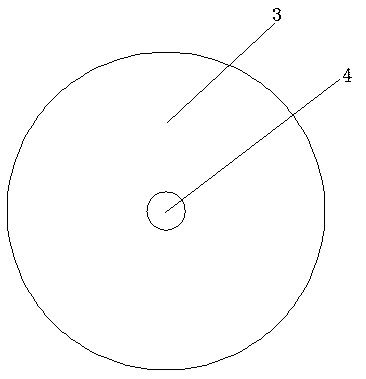

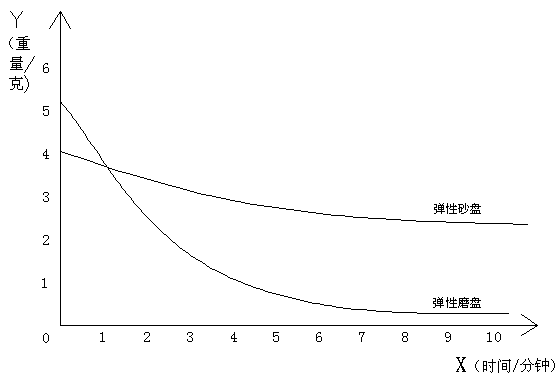

Elastic abrasive disc and manufacturing process thereof

PendingCN108818334ASimple production processIncrease productivityBonded abrasive wheelsGrinding devicesEngineeringTransportation cost

Provided are an elastic abrasive disc and a manufacturing process thereof. The elastic abrasive disc comprises a label layer, a supporting layer and a polishing layer, wherein the supporting layer islocated between the label layer and the polishing layer, the label layer, the supporting layer and the polishing layer are in the same shapes and are in circular ring shapes, mounting holes are formedin the centers of the label layer, the supporting layer and the polishing layer, and the label layer, the supporting layer and the polishing layer are solidified to be of an integrated structure by being heated in a die. The elastic abrasive disc and the manufacturing process have the beneficial effects that the manufacturing process is simple, the weight is low, the elastic abrasive disc cannotswing when being mounted on a tool, the safety performance is high, the elastic abrasive disc is degradable, high in grinding efficiency and high in self-sharpening performance, the use rate of abrasive cloth is high, the elastic abrasive disc is suitable for polishing of corners and gaps, the size is small, the package and transportation cost is low, the shape is smooth, wind resistance is small,and there is almost no noise at work.

Owner:河南圣叠磨具有限公司

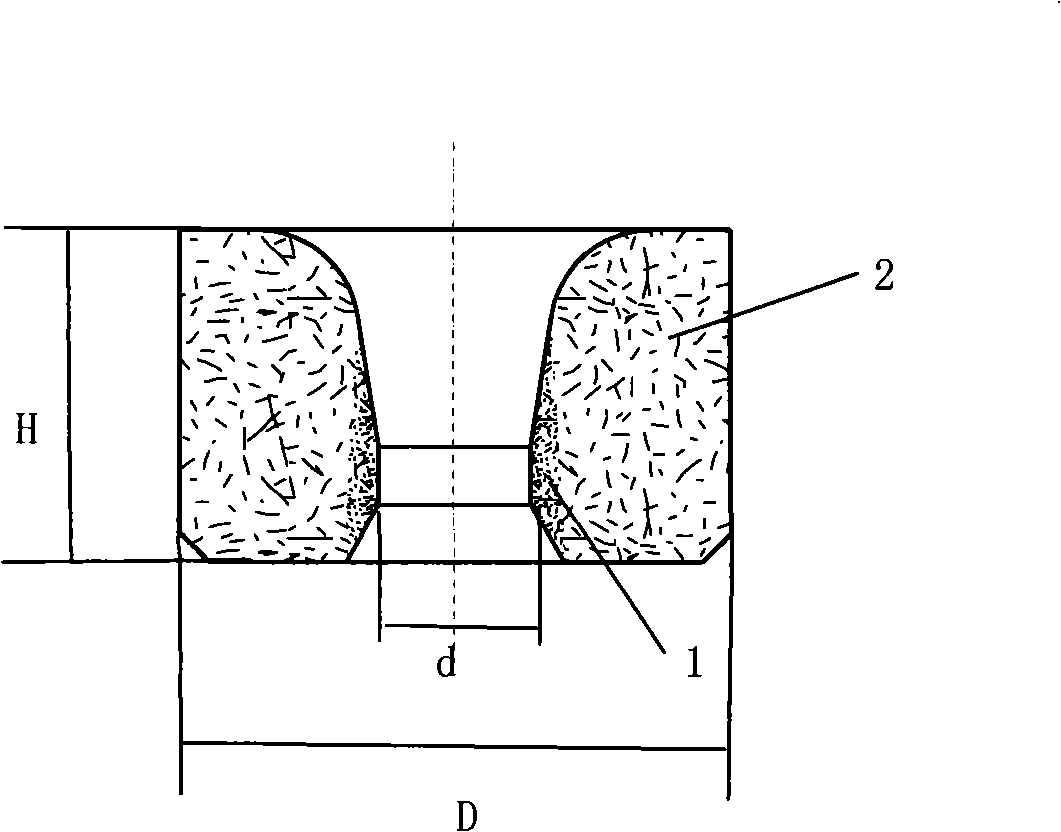

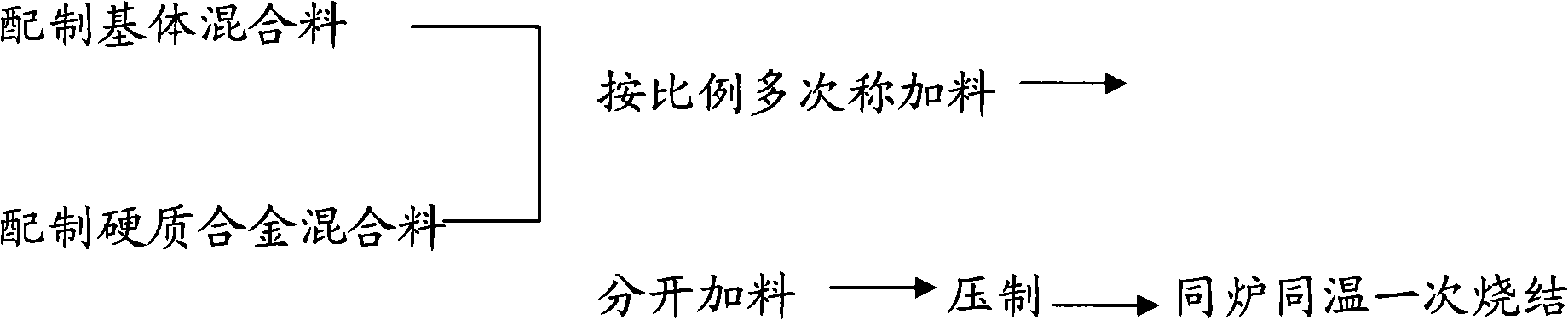

Layered composite hard metal stretching die

InactiveCN101352733ALow costComposite interface without defectsShaping toolsDrawing diesHard metalAlloy

The invention discloses a layered composite hard alloy drawing die for drawing metal wires, bars, pipes and section materials. The working area (reducing area) and sizing area of the drawing die comprise a tungsten carbide-based hard alloy layer, and the non-working area comprises a specially prepared matrix layer, the two layers are compounded by the powder metallurgic process which causes the interface between the two layers to transit continuously without defect. The use effect is the same as that of a monolayer homogeneous hard alloy drawing die, and the layered composite hard alloy drawing die can greatly save W and Co resources, reduce the cost of raw materials, and has the advantages of simple production implementation and high efficiency.

Owner:罗达成 +1

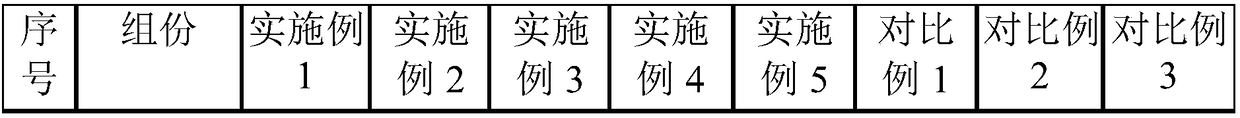

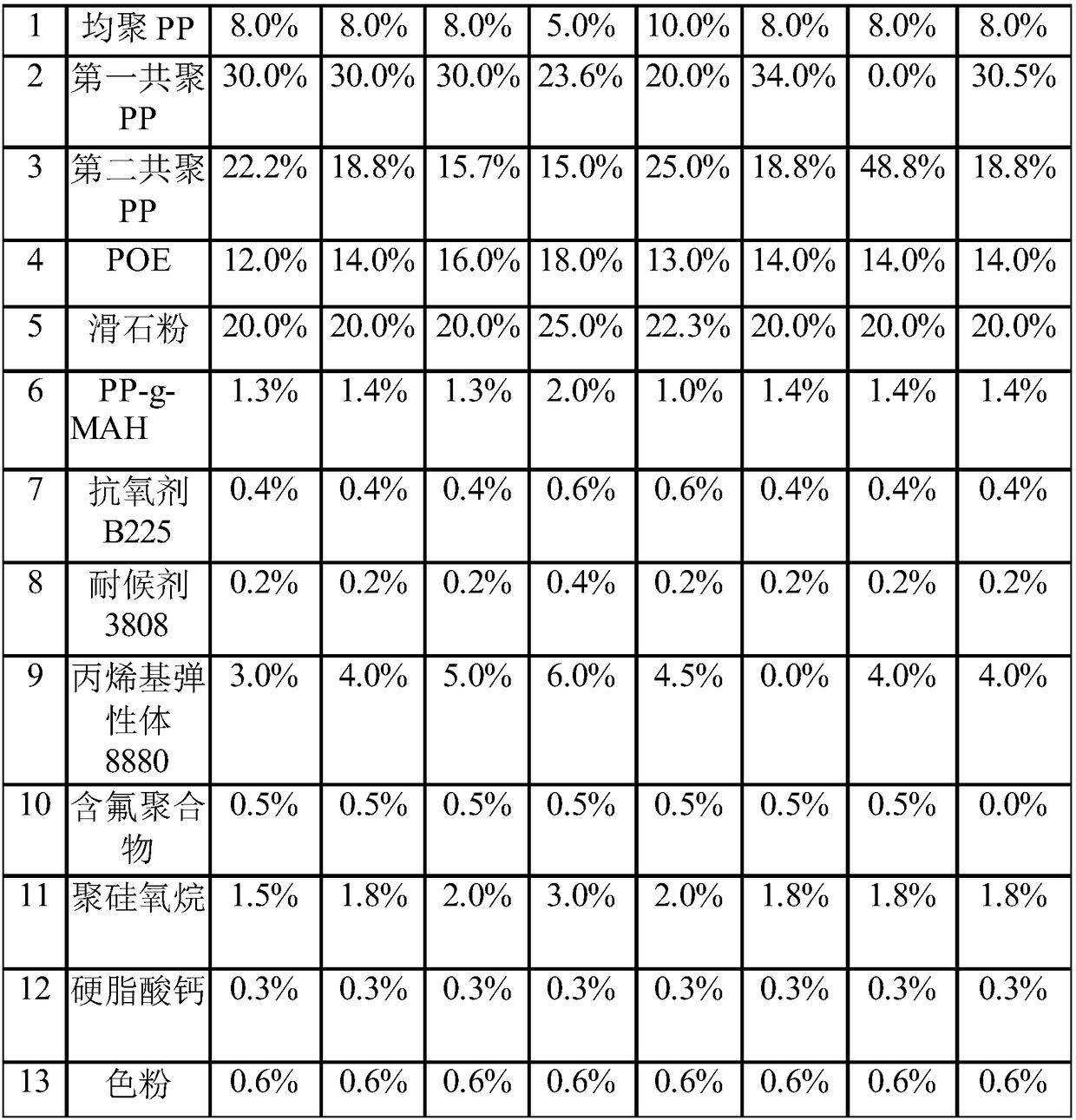

Modified polypropylene material for high-performance thin-walled automobile door panel and preparation method thereof

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

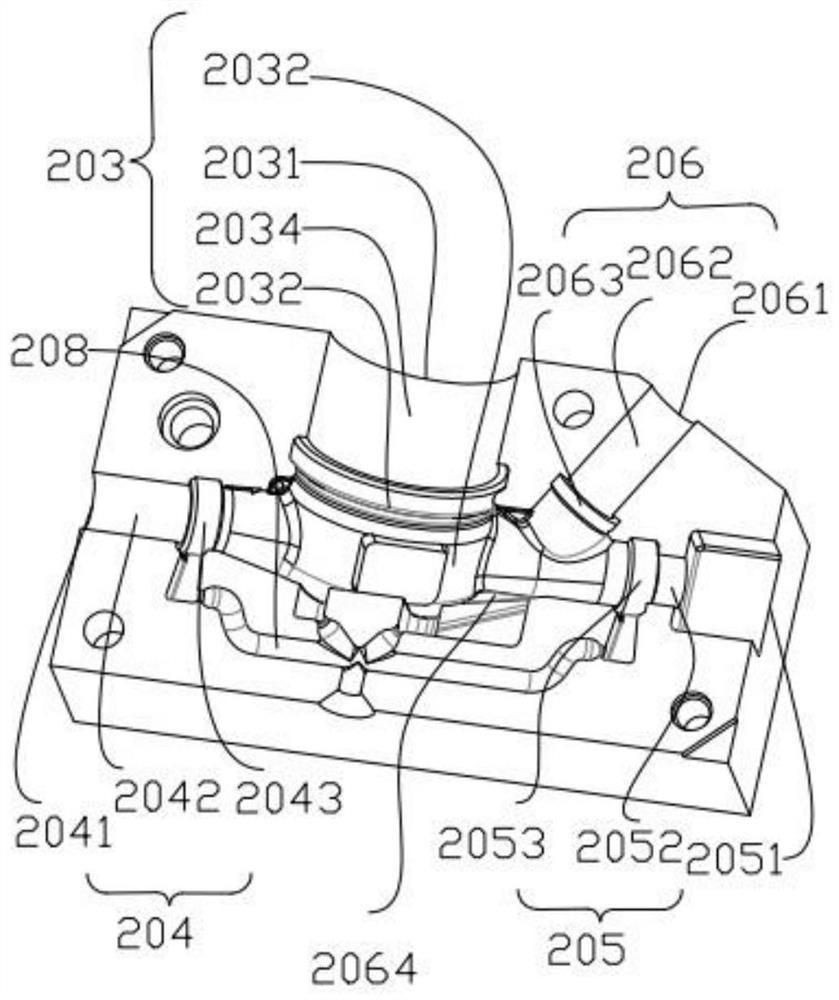

Casting mold of shell mold and mold opening and closing method thereof

PendingCN114074171AReduce preparationGuarantee product qualityFoundry mouldsFoundry coresEngineeringCasting mold

The invention discloses a casting mold of a shell mold. The independent mold core occupies the position of the casting mold of the shell mold and occupies the position of which the weight needs to be reduced so that the area cannot be filled with wax liquid in the forming process of the water meter shell mold, a cavity is formed, the weight reducing effect is achieved, and the wall thickness is uniform. According to the invention, the product quality of the water meter shell can be ensured, and the production efficiency of the wax blank and the water meter shell is improved.

Owner:苏州善鑫国际贸易有限公司

Casting mold of shell mold and mold opening and closing method thereof

PendingCN114074173AReduce preparationGuarantee product qualityFoundry moulding apparatusComposite materialEngineering

The invention relates to a casting mold of a shell mold. The casting mold comprises a main body mold plate with a combined mold cavity and a combined mold core fixedly clamped in the combined mold cavity. The combined mold cavity comprises a main mold core mold cavity, a water inlet mold cavity and a water outlet mold cavity; the main mold core mold cavity is positioned on one side of the main mold plate and extends inwards; the water inlet mold cavity is positioned on one side of the main mold core mold cavity and is communicated with the main mold core mold cavity; the water outlet mold cavity is positioned on the other side of the main mold core mold cavity, is opposite to the water inlet mold cavity and is communicated with the main mold core mold cavity; the combined mold core comprises a main mold core fixedly held in the main mold core mold cavity, a water inlet mold core fixedly held and inserted in the water inlet mold cavity and contacted with one side of the main mold core, and a water outlet mold core fixedly held and inserted in the water outlet mold cavity and contacted with the other side of the main mold core, and the combined mold cavity is an annular structure and is sealed in the main body mold plate; and the combined cavity further comprises a core groove which is arranged between the main core cavity and the water outlet cavity and is used for connecting and transitioning the main core cavity and the water outlet cavity, and the combined core further comprises an independent core arranged in the core groove.

Owner:苏州善鑫国际贸易有限公司

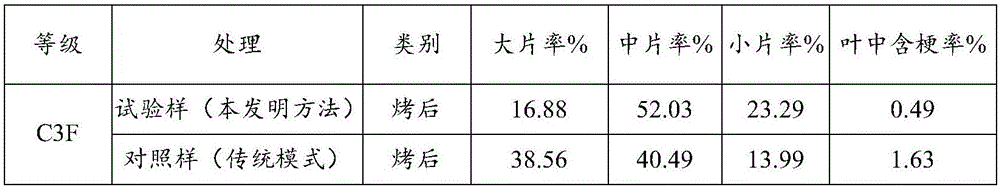

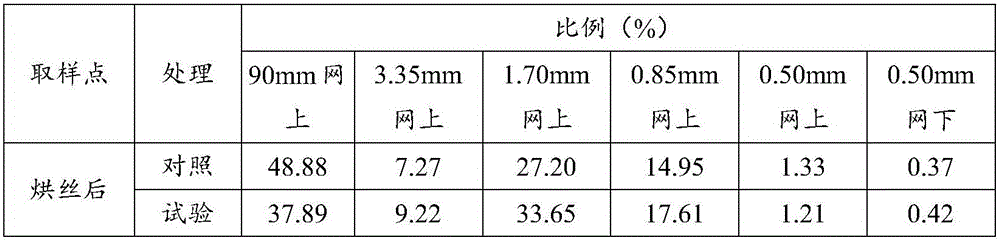

A method for optimizing the structure of shredded tobacco by improving the structure and shape of threshing and redrying blades

ActiveCN105520186BImprove the middle rateReduce quality riskTobacco preparationEngineeringShape optimization

The invention provides a method for optimizing cut tobacco structure by improving structure and shape of threshed and re-dried tobacco leaves; an orthohexagonal frame railing is adopted by the first turn of a threshing section, the dimensions of the frame railng are in the combination of 2.5''-3.5'', and corresponding rolling rate is regulated to be 40-45Hz; the 2.5'' combination of an orthohexagonal frame railing and a rhombic frame railing is adopted by the second turn, and corresponding rolling rate is regulated to be 30-35Hz; a 2.5'' rhombic frame railing is adopted by the third turn, and corresponding rolling rate is regulated to be 35-40Hz; a 2.0'' round frame railing is adopted by the fourth turn and the fifth turn, and corresponding rolling rate is regulated to be 30-40Hz; the rotation speed of a corresponding pneumatic separating fan for 1-12 pneumatic separation is regulated to be 40-50Hz; and the temperature of a corresponding re-drying section is regulated to be 60-80 DEG C, the temperature of a cooling area is regulated to be 35-40 DEG C and the temperature of a resurgence area is regulated to be 60-70 DEG C. By virtue of the method disclosed by the invention, a large-leaf rate can be effectively reduced while a medium-leaf rate and a small-leaf rate can be improved, and chip and dust rate can be controlled, so that appropriate raw material basis is provided for the optimization of cut tobacco structure.

Owner:HUBEI CHINA TOBACCO IND

Hot rolling diaphragm spring steel for automobile and production method of hot rolling diaphragm spring

ActiveCN102925812BReduce loadAvoid damageFurnace typesHeat treatment furnacesThermal insulationStrip mill

The invention discloses hot rolling diaphragm spring steel for an automobile and a production method of the hot rolling diaphragm spring steel. The hot rolling diaphragm spring steel comprises the following components by weight percentage: 0.40-0.60% of C, 0.15-0.35% of Si, 0.70-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, less than or equal to 0.050% of Alt, 0.10-0.30% of Mo, 0.70-1.20% of Cr, 0.10-0.50% of V and less than or equal to 0.005% N. The production method comprises the processing steps of desulfurating, smelting, refining, conducting vacuum treatment, continuously casting to form a blank, conducting segmented thermal insulation according to temperature, heating the casting blank, rolling, coiling, slowly cooling, shearing a steel band, annealing, molding, quenching, tempering and waiting for application. According to the hot rolling diaphragm spring steel and the production method, the production cost is low; a load of a rolling mill can be reduced; the comprehensive mechanical property is excellent; a steel coil is heated uniformly in the annealing process; the uniformity of a metallurgical structure is ensured; a tempered sorbite structure is obtained by heat treatment of the quenching and the tempering; the steel is separated out by compound precipitation of microalloys, such as Cr, Mo and V in the steel; and high strength and good wear-proof property of the steel are ensured.

Owner:武汉钢铁有限公司

Method for preventing degeneration of longya lilium

InactiveCN110959493ASolve the degradation problemSingle weightBulb cultivationHorticulture methodsBiotechnologyMedicine

The invention discloses a method for preventing degeneration of longya lilium. The method comprises the steps of seed selection, embryo stripping culture, acclimatization and transplantation and scalecutting. Fruits of native species of wild longya lilium are used as explants, excellent sexual progenies are selected by a sexual recovery method, and excellent bulbs are bred in combination with a scale cutting method, so that the problem of degeneration of longya lilium varieties is effectively solved.

Owner:HUNAN UNIV OF TECH

Wing-shaped hard alloy fixed drill bit with blade, oblique planes and jackscrews

InactiveCN103658765AHigh positioning accuracyClamp firmlyTransportation and packagingSpade drillsJackscrewAlloy

The invention provides a wing-shaped hard alloy fixed drill bit with a blade, oblique planes and jackscrews. The wing-shaped hard alloy fixed drill bit is characterized in that the front of the blade is in the shape of a combination of two wings of an airplane, the rear of the blade is in the shape of a combination of two empennages of the airplane, the blade is positioned on a cutter by the aid of two symmetrical side surfaces of the rear of the blade, the two side oblique planes are arranged at the rears of two wings of the blade and are axially symmetrically distributed, the corresponding oblique planes are arranged at the fronts of two side empennages of the blade relative to the rears of the two side empennages, a straight slot and a groove are formed in the front of the cutter and are used for positioning the blade on the cutter, and the corresponding oblique plane is arranged at the bottom of the straight slot, is meshed with the oblique planes at the rears of the two wings of the blade and is used for locking the blade and the cutter; screw holes are formed in two side surfaces perpendicular to the groove and are connected with the two fastening jackscrews; the oblique planes on two sides of the front of each empennage of the blade are jacked by the two side jackscrews, so that the oblique planes at the rears of the two wings of the blade can be firmly meshed with the cutter, and the blade and the cutter can be fastened. The wing-shaped hard alloy fixed drill bit has the advantages that the wing-shaped hard alloy fixed drill bit is light in piece weight, simple in structure, high in positioning precision, good in rigidity and long in service life, is not easy to deform and is high in stability during usage, a firm and reliable clamping effect can be realized, the blade can be replaced conveniently and quickly, and the like.

Owner:李 凤俊

Cold-rolled steel strip and production method thereof, and anode plate material for electric dust removing device

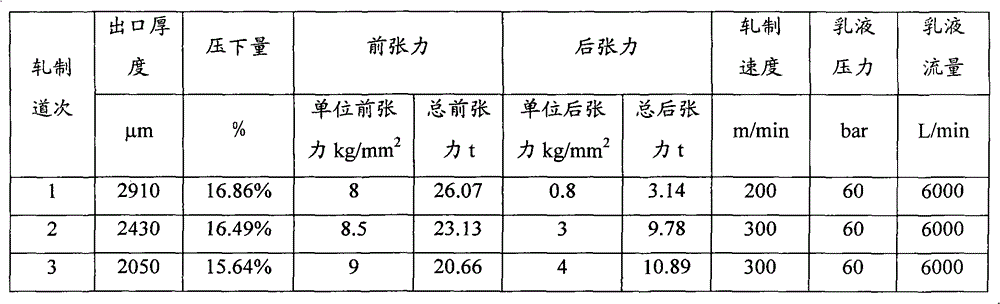

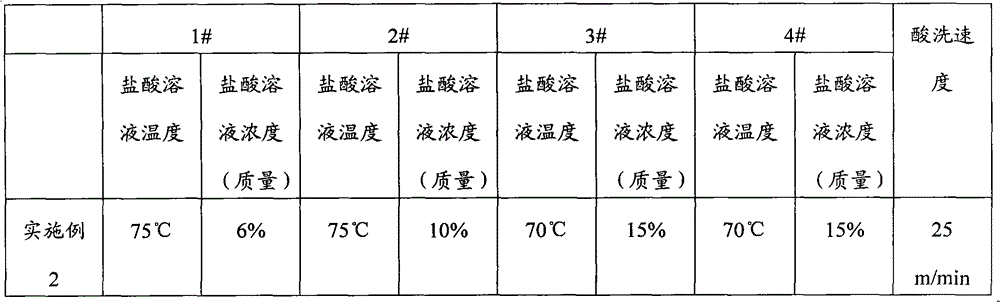

ActiveCN102489505BSimple production equipmentNo input requiredFurnace typesElectrode constructionsSteelmakingElectricity

The invention provides a cold-rolled steel strip and a production method thereof, and an anode plate material for an electric dust removing device. The method comprises the following steps of: 1, washing a hot-rolled coil blank by using an inorganic acid solution in an acid-washing tank; 2, rolling the acid-washed hot-rolled coil blank by using a rolling mill at the speed of 200 to 300m / min to obtain a steel coil of which the thickness reduction is less than or equal to 50 percent, wherein the unit front tension of a finished product pass is not less than 8kg / mm<2>; and 3, performing secondary constant-temperature annealing treatment on the rolled steel coil, heating to the temperature of between 550 and 630 DEG C, preferably 620 DEG C, at the rate of less than 20 DEG C / h, keeping the constant temperature for 3.5 to 4.5 hours, preferably 4 hours, continuously heating to the temperature of between 660 and 720 DEG C, preferably 670 DEG C, at the rate of less than 20 DEG C / h, and keeping the constant temperature for 6 to 10 hours, preferably 8 hours. By the method, the cold-rolled steel strip with the thickness deviation of less than 0.12mm and superior performance can be produced and can be used as the anode plate material for the steelmaking electric dust removing device.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A high wear-resistant and high-adhesive aramid conveyor belt

ActiveCN104071521BAvoid uneven tensionExtended flex lifeConveyorsSynthetic resin layered productsTear resistanceEngineering

The invention relates to an aramid fiber conveyor belt with high wear resistance and high adhesion, which comprises an aramid fiber skeleton layer, a buffer layer, an upper layer of covering glue and a lower layer of covering glue, the buffer layer is between the upper layer of covering glue and the aramid fiber skeleton layer, the upper layer of covering glue The buffer layer, the aramid fiber skeleton layer and the buffer layer, the aramid fiber skeleton layer and the lower cover rubber are bonded together by high-adhesion core glue. The main warp of the skeleton material in the present invention adopts high-strength aramid-impregnated canvas, and the strength level of the produced conveyor belt can reach 3150N / mm. The conveyor belt meets the performance requirements of high belt body strength, high wear resistance, high adhesive strength, impact resistance, and tear resistance. The weaving structure of the framework material of the present invention is a straight warp and straight weft structure, which has long service life, low energy consumption in operation, smaller diameter of the transmission drum, and fewer long-distance splicing times.

Owner:YANKUANG GRP CO LTD +1

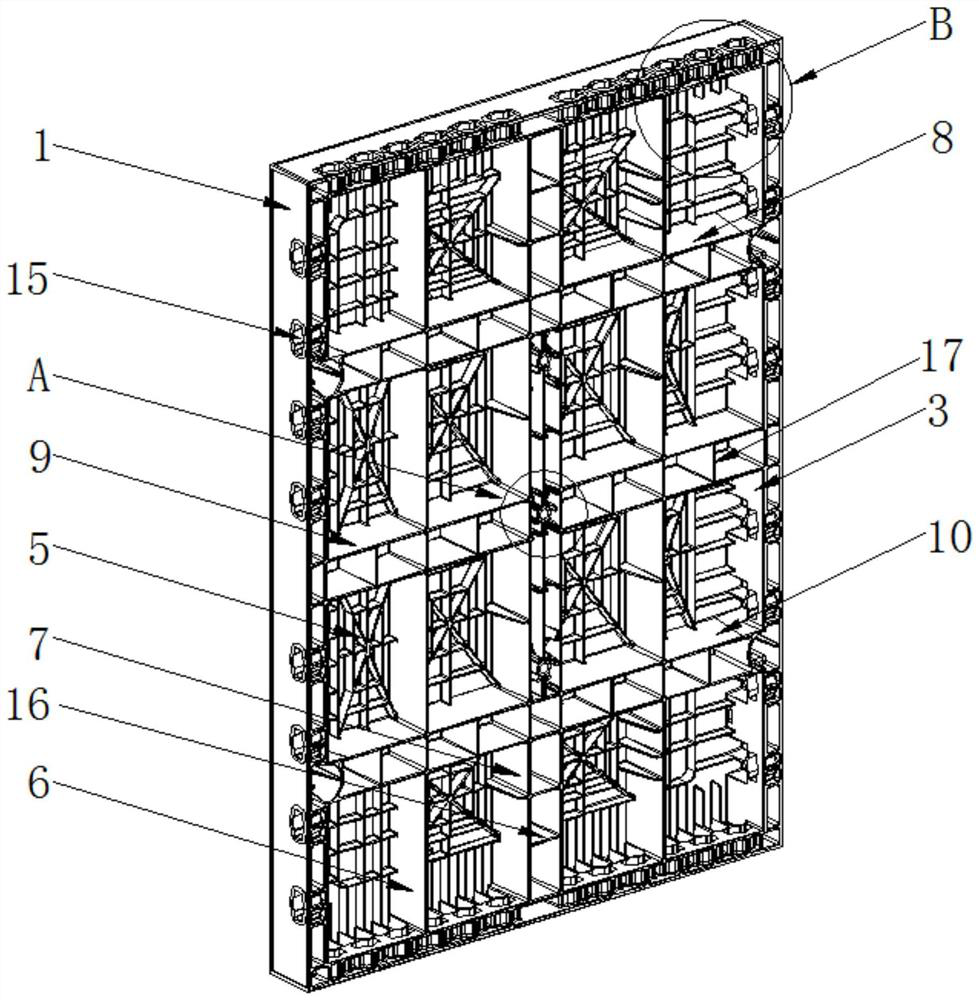

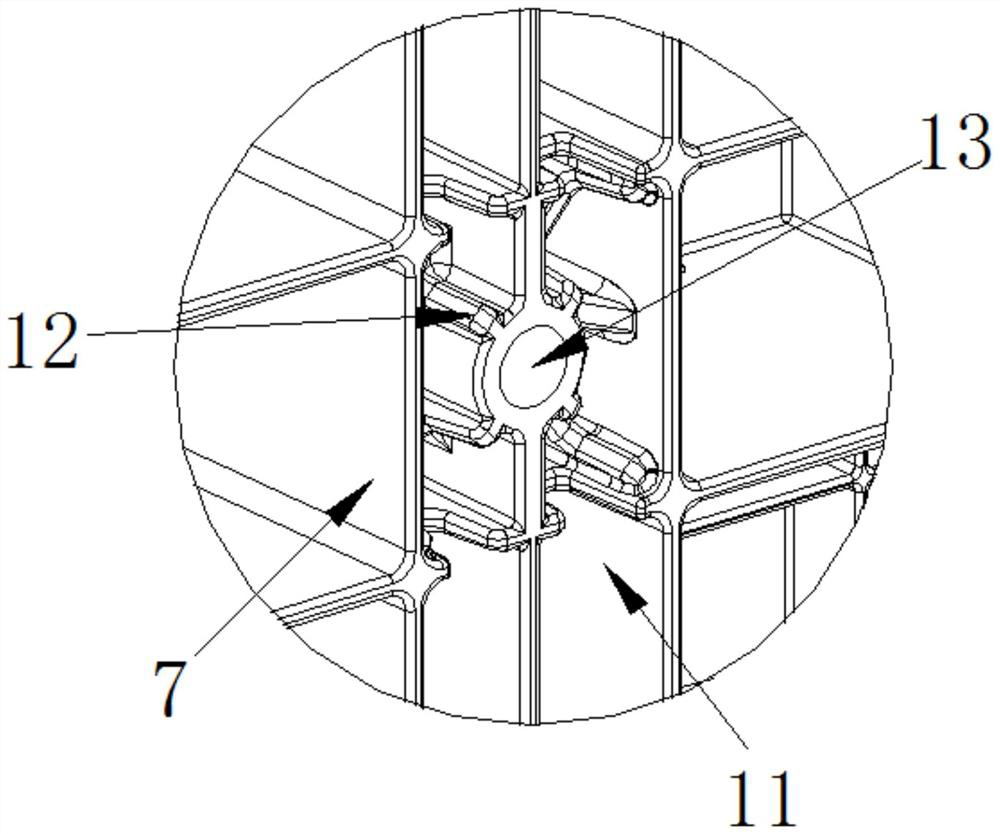

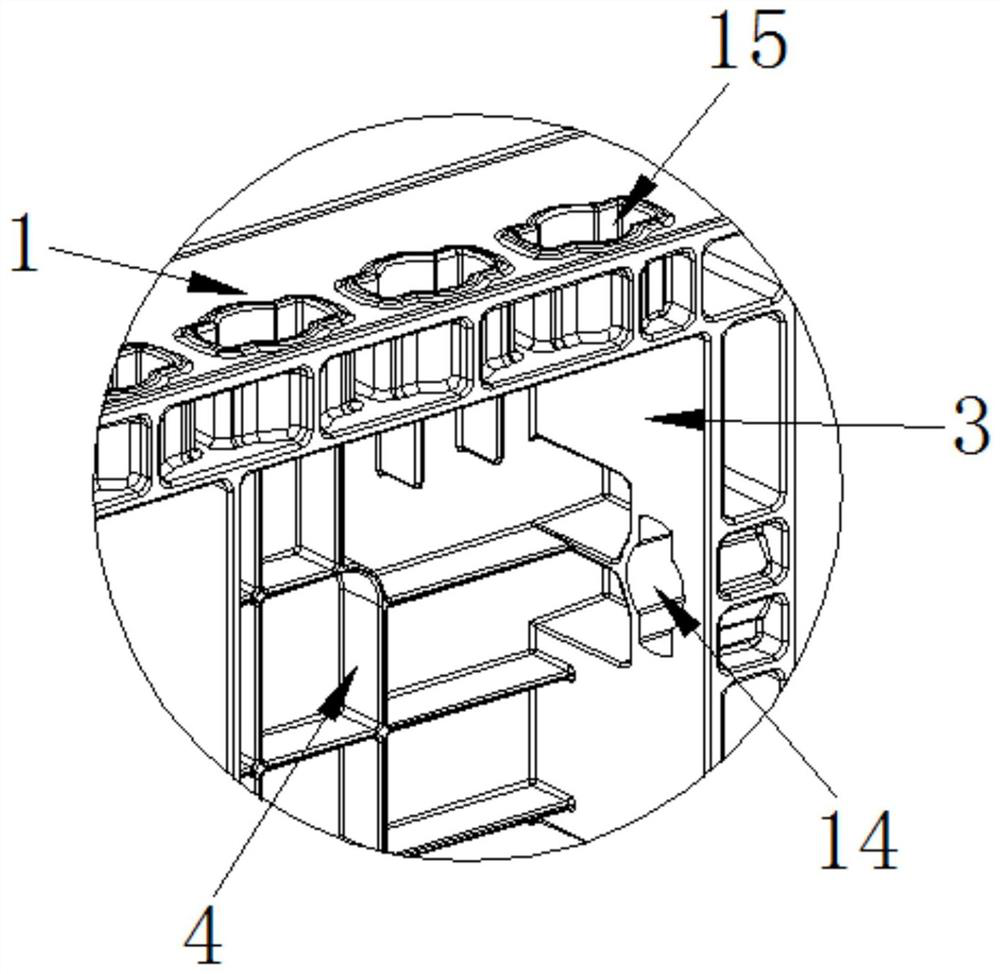

Plastic formwork structure with good impact strength

PendingCN112096051AHigh impact strengthSingle weightForming/stuttering elementsArchitectural engineeringStructural engineering

The invention discloses a plastic formwork structure with good impact strength, and relates to the technical field of plastic formworks. The plastic formwork structure comprises a frame body, a mounting hole is formed in the back surface of the frame body, an inner frame is fixedly connected to the interior of the frame body, first reinforcing ribs are fixedly connected to the inner wall of the frame body, and second reinforcing ribs are fixedly connected to the positions, located on one sides of the first reinforcing ribs, of the inner wall of the frame body. According to the plastic formworkstructure with the good impact strength, a plurality of criss-cross or checkerboard-shaped reinforcing ribs are arranged in the formwork structure, so that the impact strength of the surface of a formwork is greatly improved under the condition that the thickness of the surface of the formwork is not increased, the surface of the formwork is not prone to being damaged, and process holes are formed in the formwork; and therefore, concrete on the periphery of the side face of the formwork is effectively prevented from being blocked, the formwork cleaning difficulty is reduced, meanwhile, it isguaranteed that the boundary dimension of the formwork is not affected, the formwork splicing dimension is accurate, and the concrete quality is high.

Owner:GUANGZHOU ECHOM FORMWORK ENG CO LTD

A high-voltage composite umbilical cable and its manufacturing process

ActiveCN113539555BHigh strengthImprove stabilityInsulated cablesInsulated conductorsLow voltageElectric cables

The invention discloses a high-voltage composite umbilical cord, which comprises an inner layer functional unit group, an outer layer functional unit group and an outer sheath, and the inner layer functional unit group includes three inner layer medium voltage cable units arranged at the center And the inner layer is filled with steel pipe units, the outer layer functional unit group includes four outer layer steel pipe units, the four outer layer steel pipe units divide the outer periphery of the outer layer functional unit into four installation areas, and three installation areas are respectively equipped with The outer medium voltage cable unit, two low voltage cable units, the outer filled steel pipe unit and the filling body, and the steel strand unit, the two low voltage cable units, the outer filling steel pipe unit and the filling body in another installation area. The invention provides a high-voltage composite umbilical cord and its manufacturing process. The umbilical cord has high tensile strength, light weight and is convenient to manufacture.

Owner:宁波东方电缆股份有限公司

A kind of multifunctional resin grinding wheel and its manufacturing method

ActiveCN106002666BImprove cutting effectSingle weightBonded abrasive wheelsGrinding devicesPolymer scienceGrinding wheel

The invention relates to the technical field of grinding wheels and particularly relates to a multifunctional resin grinding wheel and a production method thereof. The grinding wheel comprises the following components in percentage by weight: 20-30% of silicon carbide, 20-30% of white fused alumina, 20-30% of brown fused alumina, 15-20% of a binding agent and 10-15% of cryolite, wherein the binding agent is phenolic resin liquid or powder. The grinding wheel can be used for cutting various materials and has better cutting performance; the grinding wheel has lower unit weight than a conventional product with the same specification, and every grinding wheel can save the molding material by 10-20g; and the grinding wheel is good in sharpness, incapable of generating a burn injury phenomenon when being used for cutting stone, ceramic tiles, iron, aluminum, stainless steel and the like, and meanwhile, the cutting efficiency is also greatly increased.

Owner:菊龙(天津)磨具有限公司

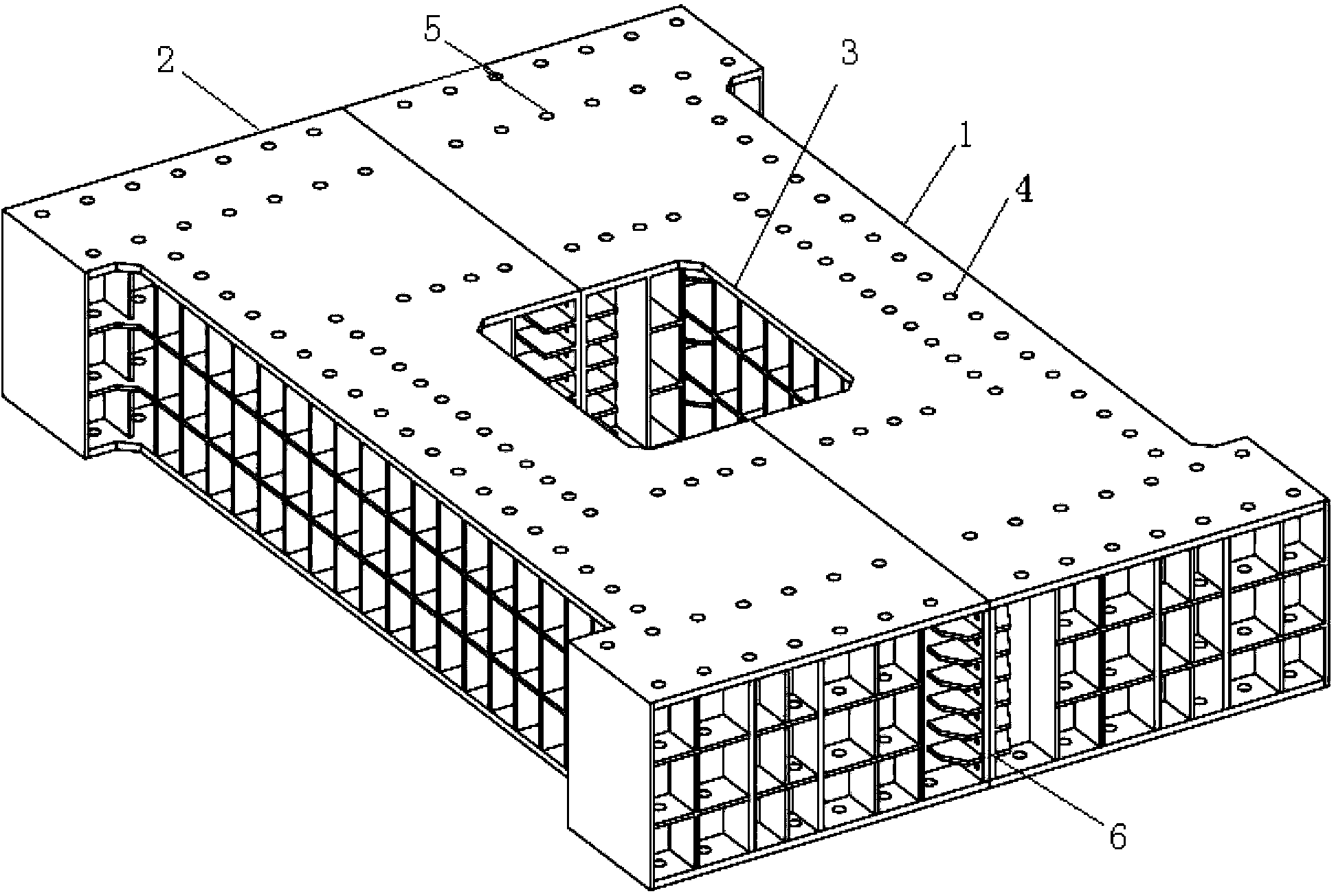

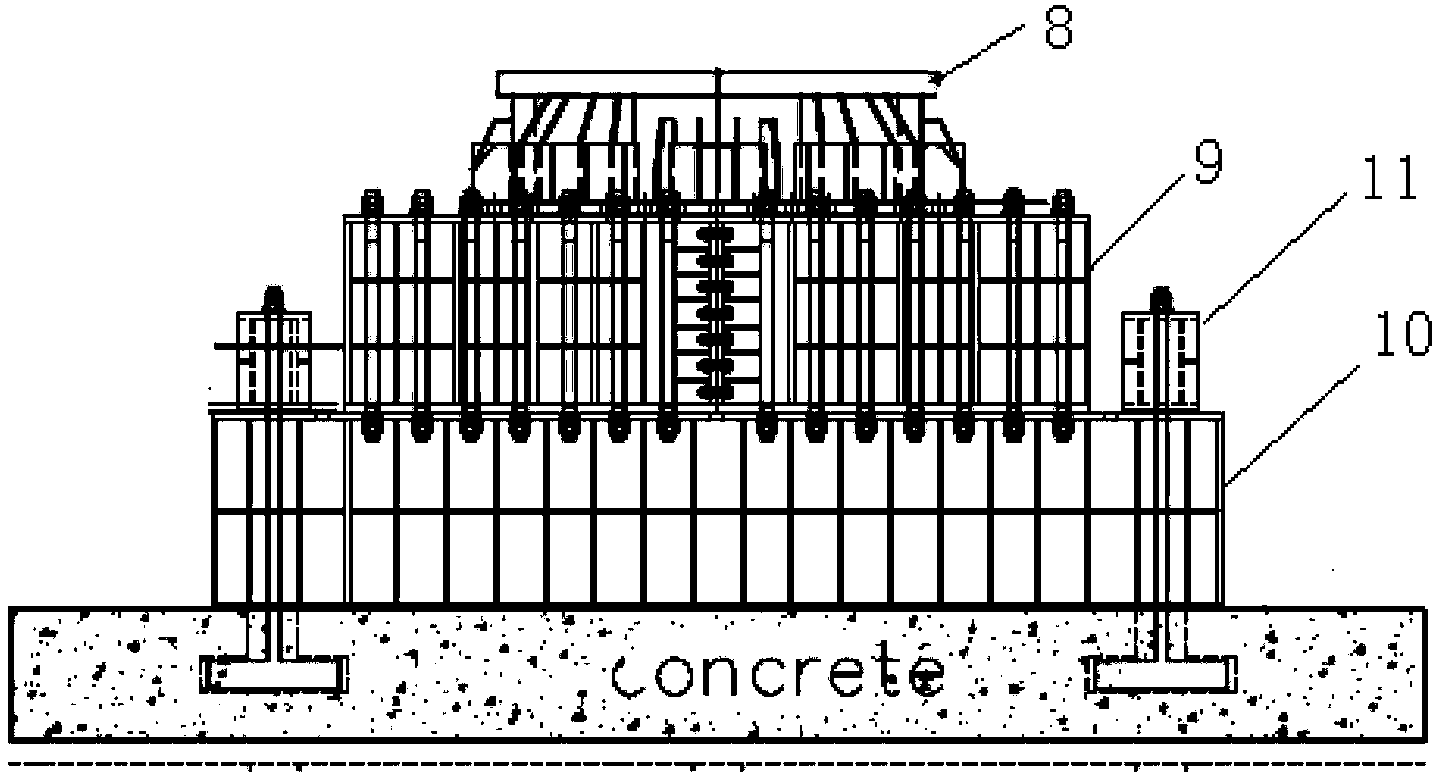

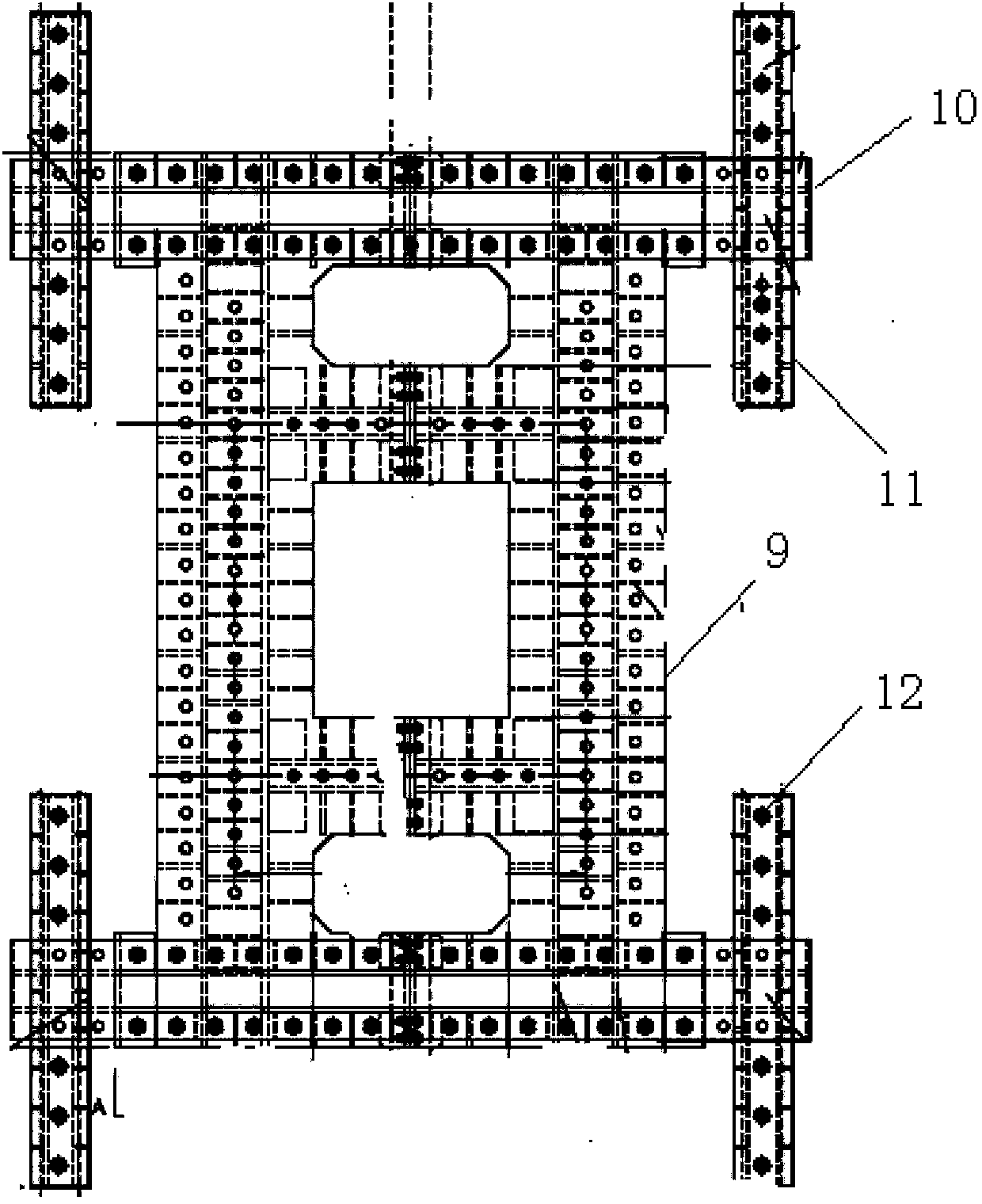

Assembled steel girder and power-transmission steel pipe pole structure assembly provided with same

ActiveCN103018021BSingle weightReduce volumeMachine part testingStructural engineeringPower transmission

The invention relates to an assembled steel girder and a power-transmission steel pipe pole structure assembly provided with the same. The assembled steel girder comprises a steel girder body, wherein an accommodating space with an upward opening is formed in the middle part of the girder body, bolt holes are formed in the circumference of the opening, and the steel girder body is formed by frame bodies connected by bolts; each frame body is a frame defined by welding steel plates, transverse plates are arranged in each frame body, each frame body is divided into a plurality of layers by the transverse plates, reinforcing plates which are arranged crisscross are vertically arranged between the transverse plates in each layer, and the reinforcing plates and the transverse plate are combined to form an independent cavity. The assembled steel girder and the power-transmission steel pipe pole structure assembly disclosed by the invention have the advantages of being detached and repeatedly used, saving the working hour, improving the working efficiency and greatly reducing the cost.

Owner:CHINA ELECTRIC POWER RES INST +2

A kind of water-resistant paper-faced gypsum board and its preparation method

The invention provides a water-repellent paper-surface plasterboard. The water-repellent paper-surface plasterboard comprises the following components in parts by weight: 100 parts of desulfurized plaster powder, 2.5-4 parts of emulsified wax, 0.3-1.0 part of starch, 0.03-0.12 parts of a foaming agent and 65-85 parts of water. The paper-surface plasterboard disclosed by the invention has the function of water repelling since emulsified wax is used as the water repellent, can be put in a plaster slurry network structure through paraffin to bloke air pores in plaster, and the function of water repelling is based on the physical action and is not influenced by plaster impurities; as the requirement of the emulsified wax for the purity of plaster is relatively low, the plasterboard disclosed by the invention has better water repellent effect, and when the mixing amount of the emulsified wax is 2.5-3 percent, the water absorption rate of the water-repellent paper-surface plasterboard soaked in water for 2 hours is lower than 10 percent; and when the mixing amount of the emulsified wax is 3.5-4 percent, the water absorption rate of the water-repellent paper-surface plasterboard soaked in water for 2 hours is lower than 5 percent.

Owner:北新建材(陕西)有限公司

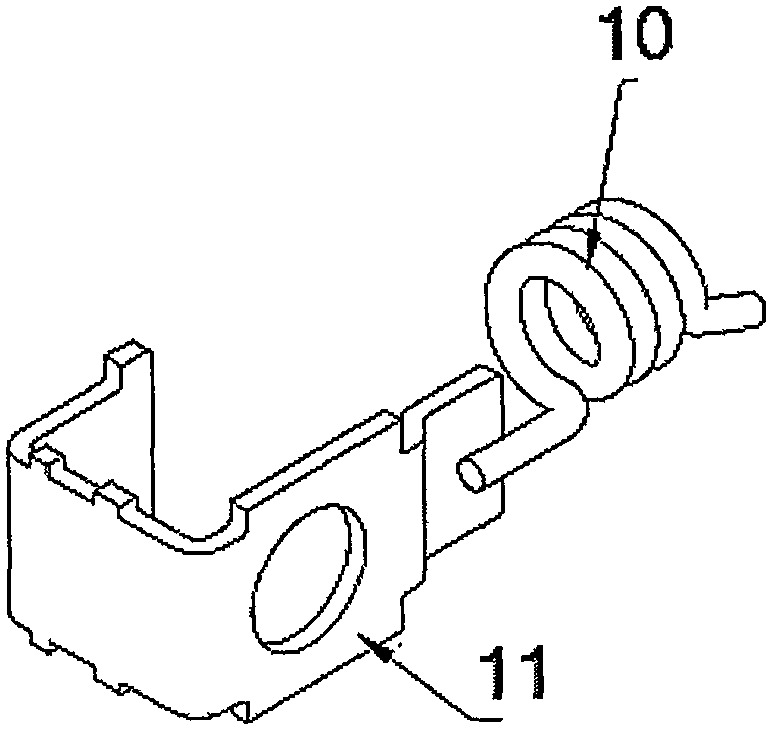

Copper-aluminum composite material, coil assembly of miniature circuit breaker and preparation method thereof

ActiveCN105489410BGuaranteed electrical conductivityResolve connectionSwitch power arrangementsEmergency protective device manufactureAluminum compositesThermal treatment

The invention discloses a Cu-Al composite material, a miniature circuit breaker coil block and a preparation method thereof. The Cu-Al composite material is a partially one-side Al-coated Cu or Cu alloy material strip which is manufactured in a compositing way through embedding an Al strip in a groove of a Cu or Cu alloy material strip. In the miniature circuit breaker coil block, a coil is formed by coiling an Al wire or Al alloy wire; a connecting plate is prepared from a Cu-Al composite material; the joint of the coil and the connecting plate is placed in an Al-coated area of the connecting plate. The preparation method of the miniature circuit breaker coil block comprises the following steps: performing thermal treatment on the Cu-Al composite material; cold rolling; striping; stamping; processing a coil ; connecting the coil and the connecting plate together. According to the preparation method, the connecting plate made of partially-Cu-embedded composite Al material is connected with the Al coil, to obtain a coil assembly; therefore, the problem of connection between the coil and the connecting plate can be solved effectively; the Cu-Al composite material has low cost reduced by 60% in comparison with the cost of the traditional material; the Cu-Al composite material has excellent processing performance and further has the advantage of high yield, good oxidation resistance and light unit weight.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

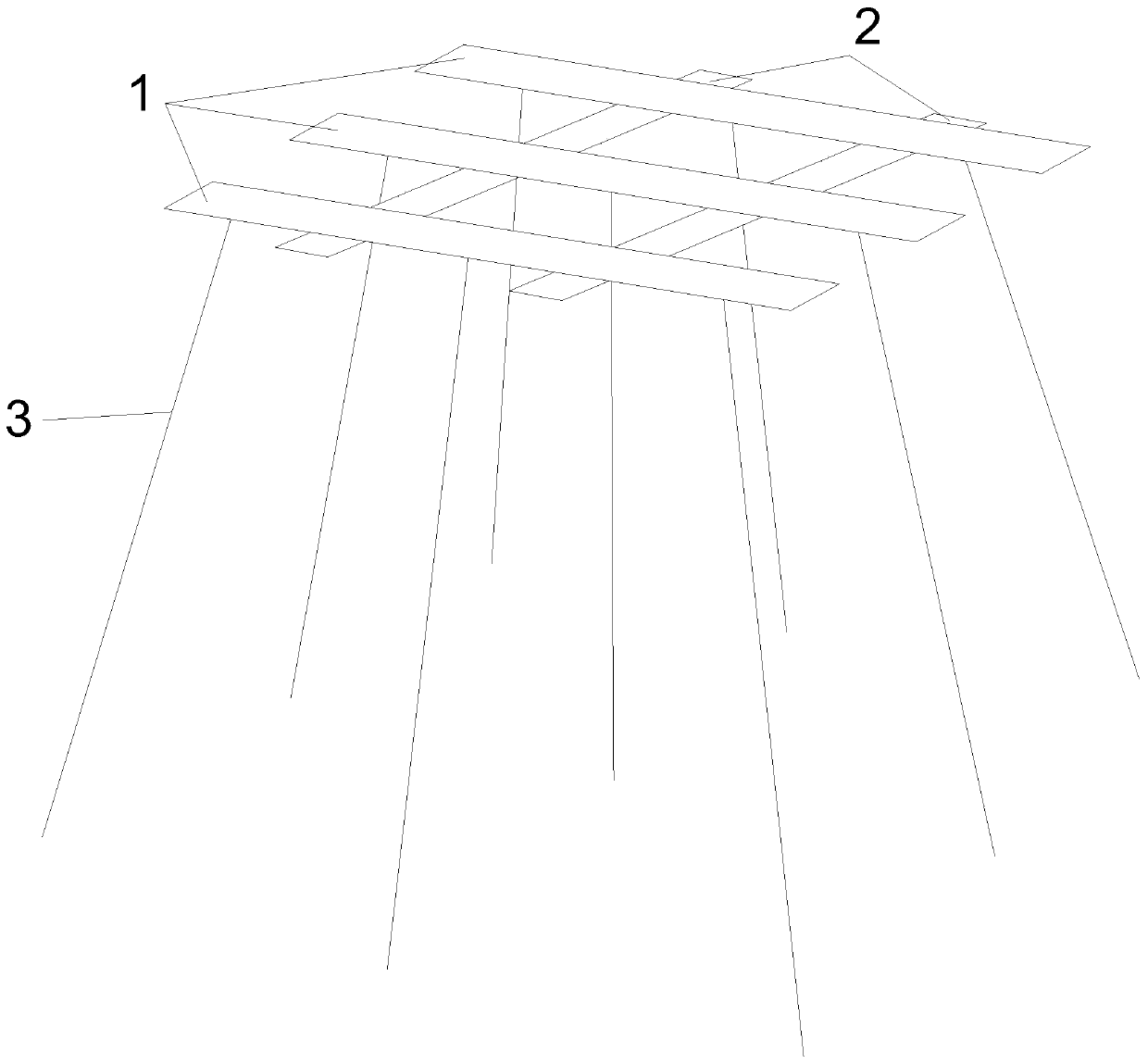

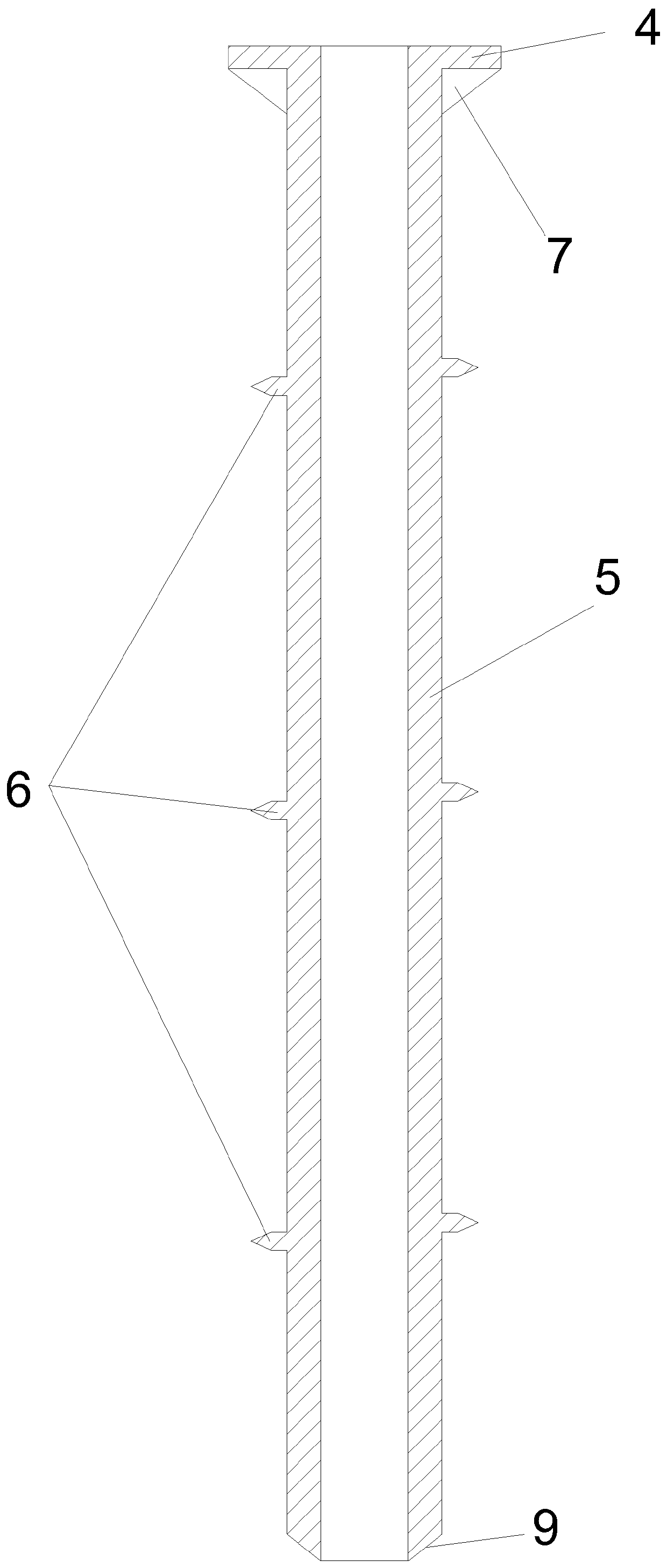

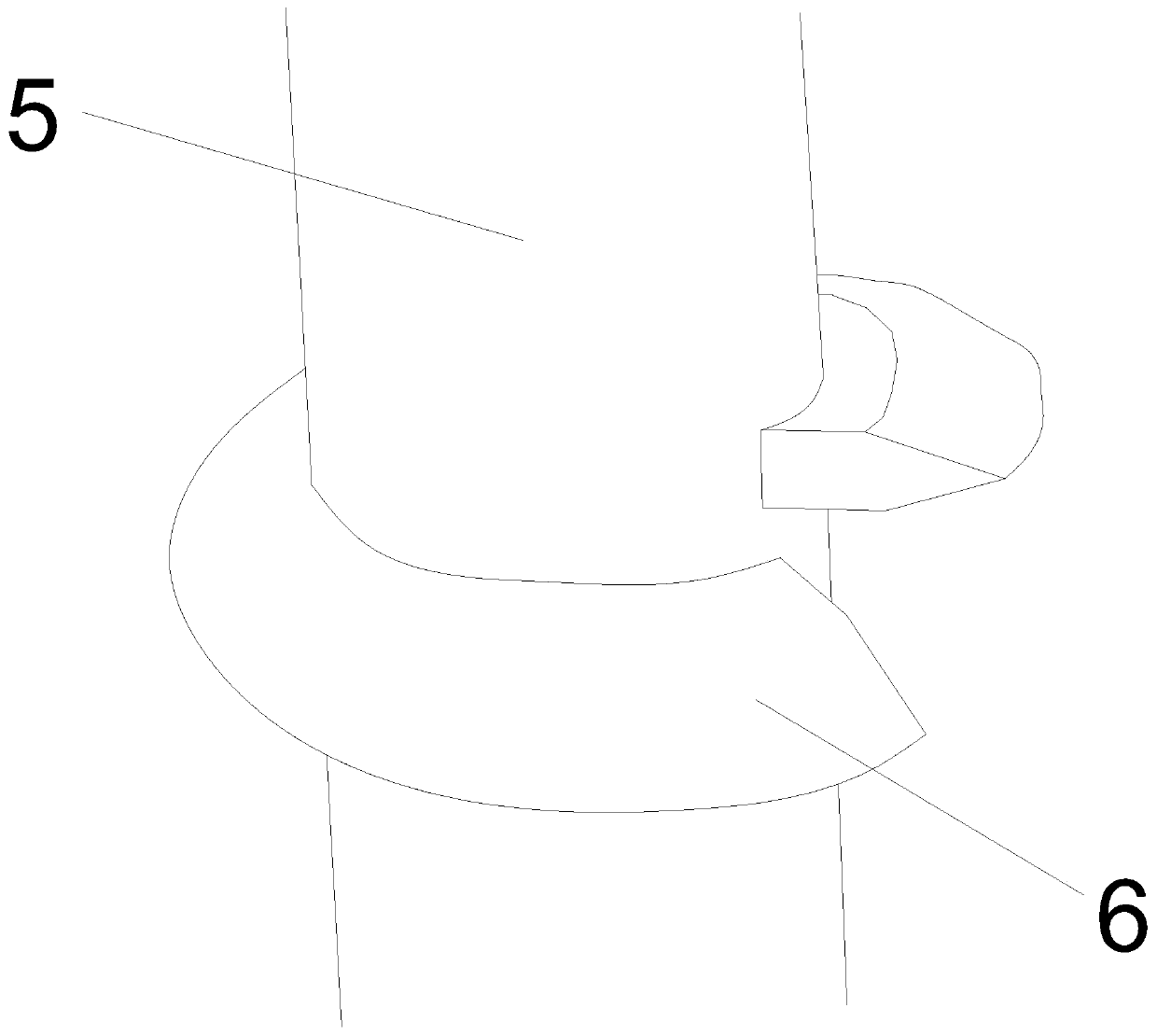

Steel pipe screw anchor pile group foundation

InactiveCN111576463AShorten the lengthImprove bearing capacityFoundation engineeringRiver networkArchitectural engineering

The invention provides a steel pipe screw anchor pile group foundation. The steel pipe screw anchor pile group foundation comprises a base, a plurality of steel pipe screw anchors perpendicular to thebase are fixed to the middle of the bottom of the base, and steel pipe screw anchors forming a certain angle from 2 degrees to 15 degrees with the steel pipe screw anchors perpendicular to the base are fixed to the periphery of the bottom of the base. Pile bodies of the steel pipe screw anchor pile group foundation are arranged in a slightly inclined manner and can bear relatively large longitudinal force and horizontal force; the steel pipe screw anchors greatly improve the bearing capacity and reduce the length of the pile bodies by 30% or above; and the manufacturing cost is reduced by about 19%-24% compared with that of steel pipe piles. The steel pipe screw anchors have a small diameter and a low piece weight, so that transportation in river network areas is facilitated.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com