Wing-shaped hard alloy fixed drill bit with blade, oblique planes and jackscrews

A technology of cemented carbide inserts and bevels, which is applied in spade drilling, drill repairing, drilling tool accessories, etc., can solve the problems of cutting edge asymmetry, chip flute structure restriction, affecting the rigidity of the cutter body, etc., and achieves convenient and fast replacement. Firm and reliable clamping and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

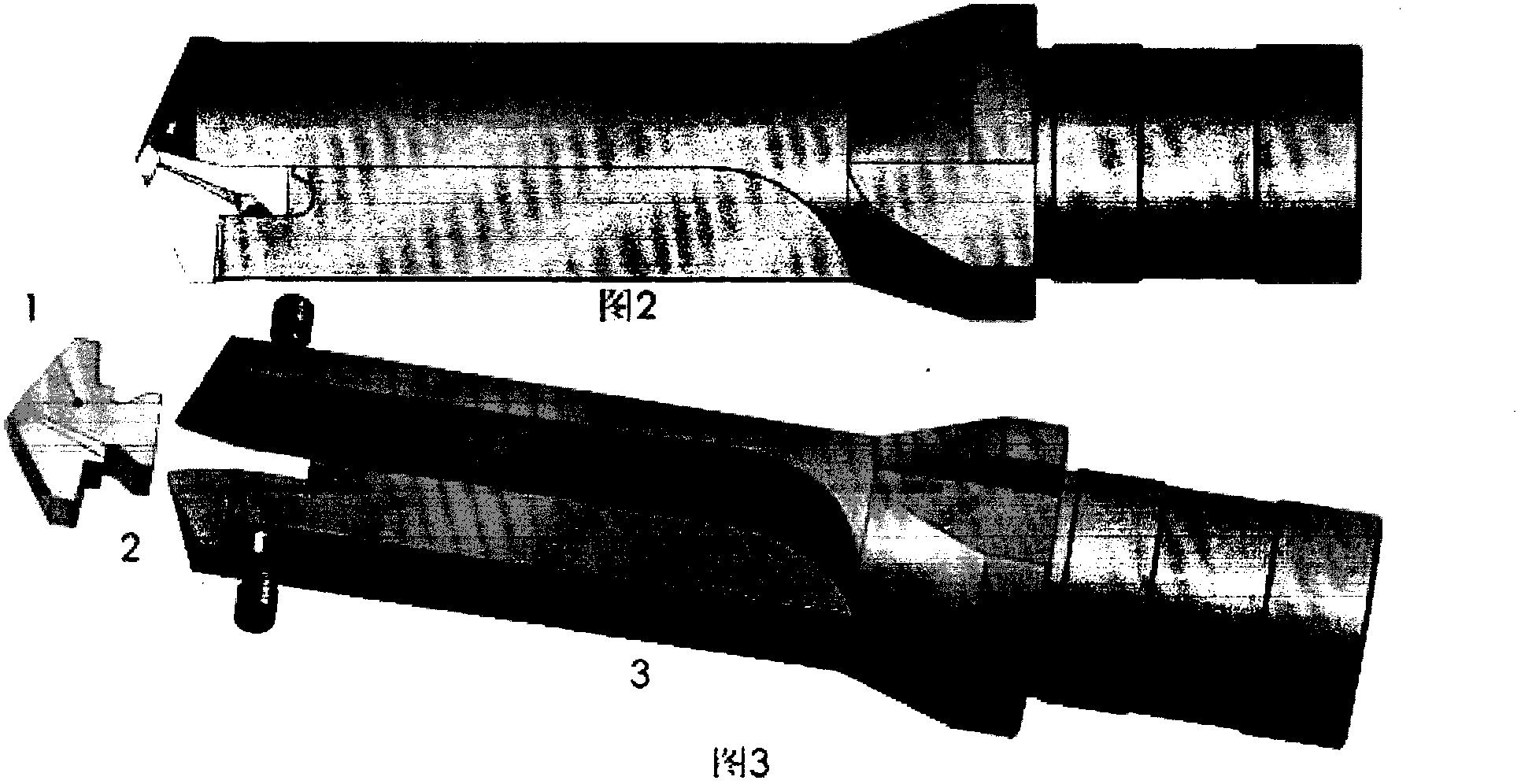

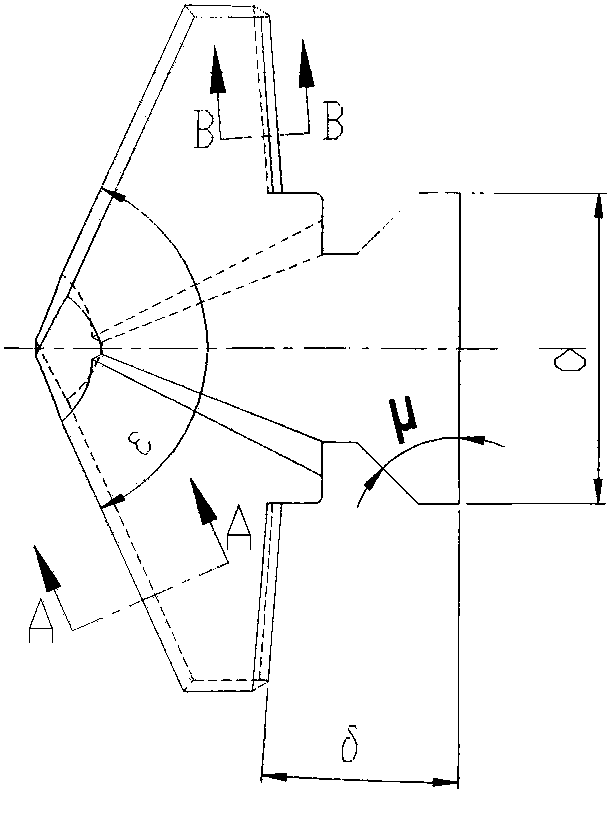

[0029] Such as image 3 As shown, the composition of the present invention includes a blade 1, a top wire 2, and a cutter body 3. The front portion of the blade 1 is in the same shape as the two wings of the aircraft, and the rear portion is in the same shape as the two empennages of the aircraft. Such as figure 1 , Figure 5 , Figure 8 , Figure 9 As shown, the rear surfaces 7 of the two wings are designed as inclined planes, and the two inclined planes are rotationally symmetrical to the axis, and the angle γ between them and the main plane is 78° to 85°, which is 81° in this example. In addition, the distance between the inclined planes and the blade back The included angle δ value is 0°~5°, in this case it is 4°; Figure 4 , Figure 9 As shown, the rear part of the blade is axially symmetrical and parallel with two sides 9, and the width dimension d of the side is 1 / 2 to 1 / 3 of the diameter D of the blade; Figure 4 As shown, the front portion of the blade tail is ...

no. 2 example

[0033] Such as Figure 16 , Figure 17 As shown, the shape, structure and clamping method of the insert remain the same as above, but the cutter body adopts a spiral groove structure, so that the drill bit is suitable for both shallow hole processing and deep hole processing.

no. 3 example

[0035] Such as Figure 18 , Figure 19As shown, the shape and structure of the rear part of the blade and the clamping method remain the same as above, but the edge of the blade adopts the impact drill bit shape, and the cutter body adopts a spiral groove structure, so that the drill bit can be used for building materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com