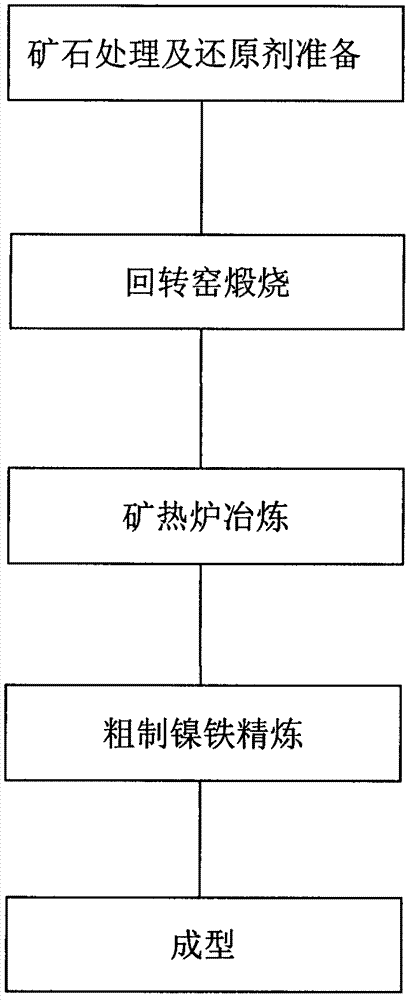

Nickel steel bean production method

A production method and technology of nickel steel, applied in the furnace type, furnace, rotary drum furnace, etc., can solve the problems of inability to alloy process, single weight, inconvenient use, etc., and achieve the effect of small size and light single weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

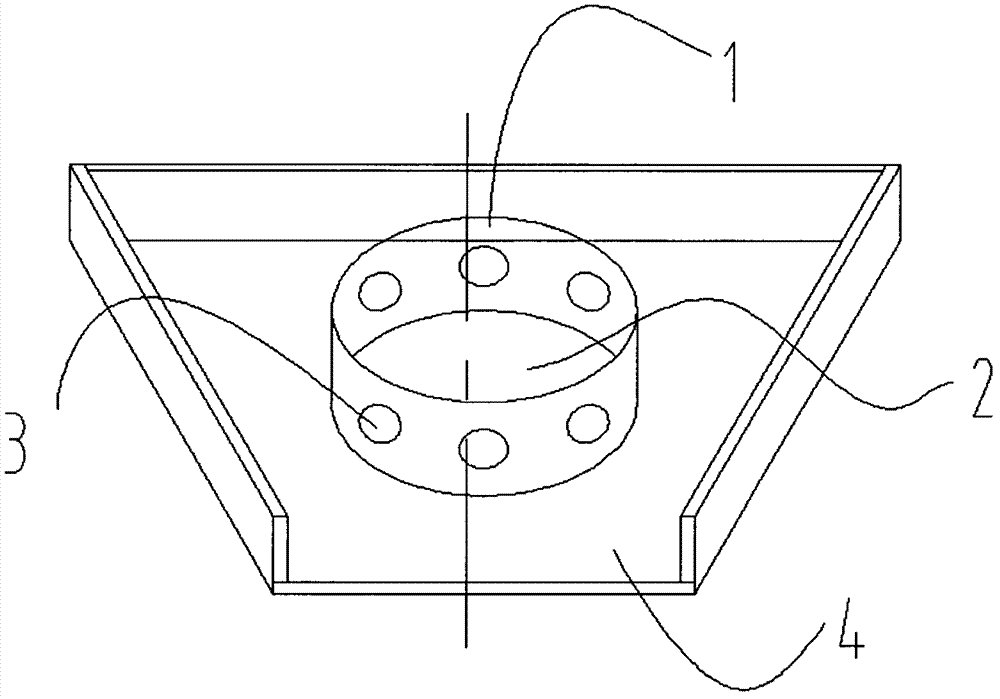

[0032] Embodiment 1: the production of round nickel steel beans

[0033] The laterite nickel ore is crushed, neutralized and mixed, mixed with reducing agent coke and sent to the rotary kiln. In the rotary kiln, the ore is roasted and dehydrated to reduce the weight by about 30%, and then the reducing agent CO and H2 are added to the nickel oxide and For partial iron reduction, a sealed discharge device is installed at the discharge end of the rotary kiln. At a temperature of 600-900 ° C, the nickel slag is sent to the feeding silo of the submerged arc furnace in a heat-insulated state, and then passed through The sealed tubular material distribution device is evenly distributed into the submerged arc furnace, and the rough nickel-iron and electric furnace slag are separated by electric arc smelting. The sulfur in the molten iron is reduced, the slag on the crude nickel-iron molten iron is removed, and mixed into the acidic converter, and the silicon is oxidized by oxygen blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com