A straight warp whole core aramid flame retardant conveyor belt

A conveyor belt and aramid fiber technology, which is applied in the field of high-strength fabric core structure flame-retardant conveyor belt, can solve the problems of large belt body, large energy consumption, poor bending performance, etc., and achieve improved strength utilization, short joint length, and belt The effect of high body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

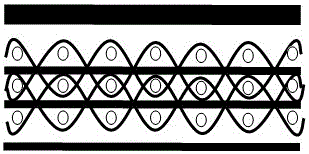

[0047] A straight-warp whole-core aramid flame-retardant conveyor belt of the present invention, the conveyor belt skeleton material is aramid fiber, adopts a straight warp and straight weft weaving structure, and is woven from main warp threads, weft threads and connecting warp threads, and the belt core has two layers Weft: the main warp is arranged in a straight line, and the weft is arranged in a straight line on the upper and lower surfaces of the warp and perpendicular to the main warp; the connecting warp is between the main warps, and the weft is bent up and down to weave the main warp and weft into one; the belt core is plasticized into a After the embryo is taken, the upper and lower sides are pasted with high wear-resistant and high-strength flame-retardant covering glue, and the conveyor belt is formed after vulcanization.

[0048] Aramid high-strength fiber, or aramid high-strength fiber and high-quality cotton yarn are used as the main warp thread to ensure the wa...

Embodiment 2

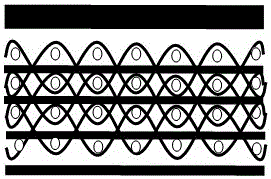

[0066] A straight-warp whole-core aramid flame-retardant conveyor belt of the present invention, the conveyor belt skeleton material is aramid fiber, adopts a straight warp and straight weft weaving structure, and is woven from main warp threads, weft threads and connecting warp threads, and the belt core has 3 layers Weft: the main warp is arranged in a straight line, and the weft is arranged in a straight line on the upper and lower surfaces of the warp and perpendicular to the main warp; the connecting warp is between the main warps, and the weft is bent up and down to weave the main warp and weft into one; the belt core is plasticized into a After the embryo is taken, the upper and lower sides are pasted with high wear-resistant and high-strength flame-retardant covering glue, and the conveyor belt is formed after vulcanization.

[0067] Aramid high-strength fiber, or aramid high-strength fiber and high-quality cotton yarn are used as the main warp thread to ensure the warp...

Embodiment 3

[0085]A straight-warp whole-core aramid flame-retardant conveyor belt of the present invention, the conveyor belt skeleton material is aramid fiber, adopts a straight warp and straight weft weaving structure, and is woven from main warp threads, weft threads and connecting warp threads, and the belt core has 5 layers Weft: the main warp is arranged in a straight line, and the weft is arranged in a straight line on the upper and lower surfaces of the warp and perpendicular to the main warp; the connecting warp is between the main warps, and the weft is bent up and down to weave the main warp and weft into one; the belt core is plasticized into a After the embryo is taken, the upper and lower sides are pasted with high wear-resistant and high-strength flame-retardant covering glue, and the conveyor belt is formed after vulcanization.

[0086] Aramid high-strength fiber, or aramid high-strength fiber and high-quality cotton yarn are used as the main warp thread to ensure the warp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com