Elastic abrasive disc and manufacturing process thereof

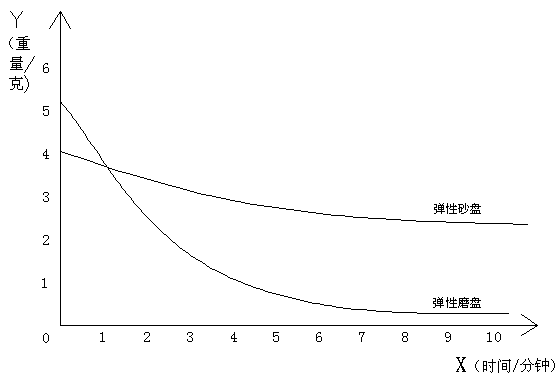

A sand disc and elastic technology, applied in the field of elastic sand disc and its production technology, can solve the problems of unsuitable edge and corner grinding, cumbersome production process, non-degradable and other problems, and achieves small change over time, simple production process, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

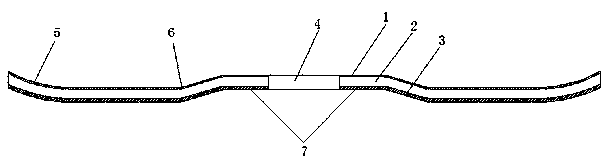

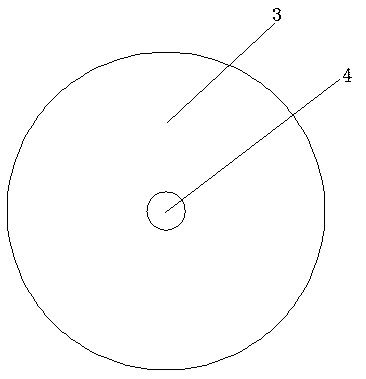

[0043] as attached figure 1 To attach image 3 Shown:

[0044] An elastic sand disc, which includes a label layer 1, a support layer 2 and a grinding layer 3, the support layer 2 is located between the label layer 1 and the grinding layer 3, and the three have the same shape, all in the shape of a ring, There is an installation hole 4 in the center, and the label layer, the support layer and the polishing layer are heated and solidified in the mold after pouring glue to form an integrated structure; the support layer 2 is plant jute, which is processed by dipping, drying, and cutting. Replacing traditional materials with degradable plant fibers has low cost and high specific strength. At the same time, it has a certain toughness, and the vibration is small during the grinding construction, so it will not hurt the workpiece.

[0045] Label layer 1 is label paper.

[0046] Grinding layer 3 is emery cloth.

[0047] The label layer, the support layer and the grinding layer ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com